Henny Penny ClassicCombi Installation Manual

ClassicCombi

Operating instructions

ClassicCombi

™

Global Foodservice Solutions

Open out the front cover to see the

controls.

306175----ABAE6- / 12.10.2009 / TAG-MaBr

SizeType no. (gas)Type no. (electric)Version

615GCC61XXXXECC61XXXXClassicCombi

620GCC62XXXXECC62XXXXClassicCombi

115GCC11XXXXECC11XXXXClassicCombi

120GCC12XXXXECC12XXXXClassicCombi

215GCC21XXXXECC21XXXXClassicCombi

220GCC22XXXXECC22XXXXClassicCombi

*FM05-060-A* en-US

Operating instructions

ClassicCombi

Controls

™

Classic

ClassicCombi

1

™

13

12

11

10

2

3

4

5

9

8

6

7

3

4

isteaming”

eration”

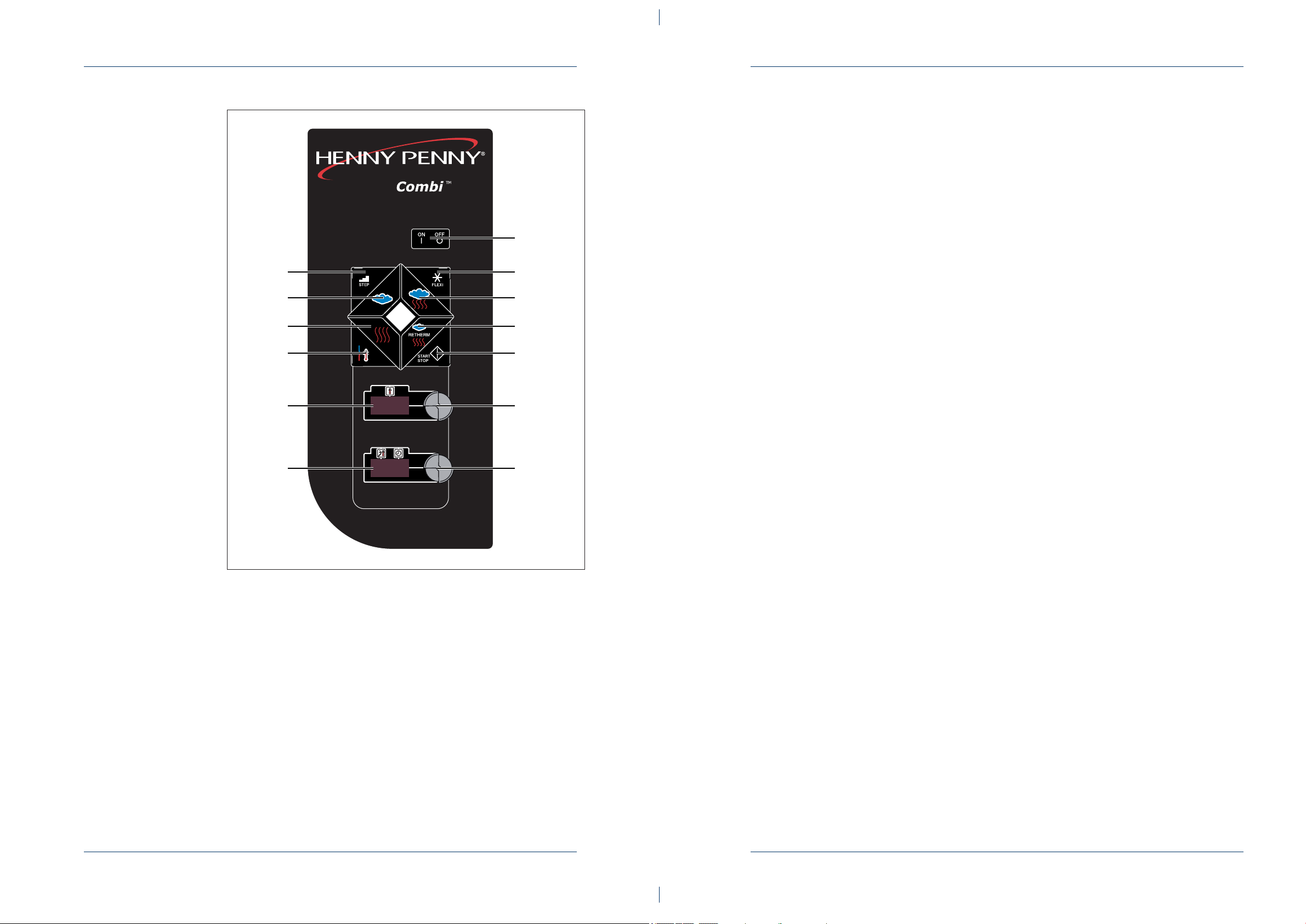

Set button7

Display8Button “On/Off”1

Display9Button “FLEXI”2

Button “Preheat”10Cooking mode button “Comb-

Cooking mode button “Convec-

11Cooking mode button “Regen-

tion”

Cooking mode button “Steam-

12Button “Start/Stop”5

ing”

Button “Step”13Set button6

Operating instructionsOperating instructions

ClassicCombi

™

Contents

6Introduction ........................................................1

6Intended use ...................................................................1.1

6About this operating manual .........................................1.2

7Warnings .........................................................................1.3

7Warranty and liability .....................................................1.4

8Signs and symbols .........................................................1.5

9Safety information ..............................................2

13Construction and function ................................3

13Description of the unit ...................................................3.1

16Description of the controls ............................................3.2

17Operating modes ............................................................3.3

4.1

Opening and closing cooking chamber door (tabletop

units) ................................................................................

17Step mode .......................................................................3.4

17Manual cooking ..............................................................3.5

17Steaming ..................................................................................3.5.1

19Combisteaming ........................................................................3.5.2

19Convection ...............................................................................3.5.3

20Regeneration ............................................................................3.5.4

22Advanced cooking functions ........................................3.6

22Manual steaming ......................................................................3.6.1

22Preset start time .......................................................................3.6.2

22Preheat ....................................................................................3.6.3

23Crisping control (optional) ........................................................3.6.4

23Core temperature measurement ...................................3.7

23HACCP log ......................................................................3.8

25WaveClean automatic cleaning system (optional) ......3.9

26Operation ............................................................4

26

4.2

Global Foodservice Solutions

Opening and closing cooking chamber door (floor

standing units) ................................................................

26Opening the cooking chamber door .........................................4.1.1

26Closing the cooking chamber door ..........................................4.1.2

27

27Opening the cooking chamber door .........................................4.2.1

27Closing the cooking chamber door ..........................................4.2.2

28Filling and emptying the unit (tabletop unit) ................4.3

3Operating instructions

Contents

ClassicCombi

™

28Filling and emptying the unit (with loading trolley) ......................4.3.1

29Filling and emptying the unit (without loading trolley) .................4.3.2

30Filling and emptying the unit (floor standing units) ......4.4

30Switch on/switch off unit ..................................................4.5

30Switch on ....................................................................................4.5.1

30Switching off ...............................................................................4.5.2

31Basic functions .................................................................4.6

31Call up star t mode ......................................................................4.6.1

31Calling up the setup menu and changing parameters ................4.6.2

32Starting the cooking program ......................................................4.6.3

32End the prog ram .........................................................................4.6.4

33Changing the cooking program during operation ........................4.6.5

33Setting the cooking temperature .................................................4.6.6

33Setting the cooking time .............................................................4.6.7

34Setting the core temper ature ......................................................4.6.8

34Displaying actual values .............................................................4.6.9

34Measuring the core temperature .................................................4.6.10

35Printing the HACCP log ..............................................................4.6.11

4.7

Working with multi-step cooking programs

(step-mode) .......................................................................

36

36Entering a multi-step cooking program .......................................4.7.1

37Starting a multi-step cooking program ........................................4.7.2

38Manual cooking .................................................................4.8

38Starting the steaming process ....................................................4.8.1

38Start Combisteaming ..................................................................4.8.2

39Starting the convection cooking mode ........................................4.8.3

39Starting regeneration ..................................................................4.8.4

40Advanced cooking functions ...........................................4.9

40Manual steaming ........................................................................4.9.1

40Set preset star t time ...................................................................4.9.2

41Starting the preheating function ..................................................4.9.3

41Activating Crisping control (optional) ..........................................4.9.4

42Standard settings ..............................................................4.10

44Cleaning ................................................................5

44General cleaning ...............................................................5.1

44Cleaning the outside of the housing ...........................................5.1.1

44Cleaning the cooking chamber ...................................................5.1.2

44Cleaning the door seal ................................................................5.1.3

Operating instructions4

Global Foodservice Solutions

ClassicCombi

™

Contents

45Cleaning the cooking chamber door ........................................5.1.4

46Cleaning the steam outlet por t .................................................5.1.5

46Descaling .................................................................................5.1.6

47System-supported manual cleaning .............................5.2

47Preparing the cooking chamber ...............................................5.2.1

47Starting the cleaning program ..................................................5.2.2

48Spraying cleaning solution .......................................................5.2.3

48Let the cleaner work .................................................................5.2.4

48Cleaning ...................................................................................5.2.5

49Rinsing out ...............................................................................5.2.6

49Drying .......................................................................................5.2.7

49Automatic cleaning WaveClean (optional) ...................5.3

50Preparing the cooking chamber ...............................................5.3.1

50Select WaveClean level ............................................................5.3.2

51Using the WaveClean cartridge ................................................5.3.3

52Start WaveClean ......................................................................5.3.4

52Ending WaveClean ...................................................................5.3.5

53Cancelling WaveClean .............................................................5.3.6

53WaveClean faults .....................................................................5.3.7

54Removing the ventilation plate .....................................5.4

54Removing the ventilation plate (table top models) ...................5.4.1

55Removing the ventilation plate (floor standing units) ...............5.4.2

56Faults ...................................................................6

56Correcting faults .............................................................6.1

56Resetting the control electronics ..................................6.2

56Cause of errors and troubleshooting ...........................6.3

59Limited Warranty ................................................7

Global Foodservice Solutions

5Operating instructions

Introduction

1 Introduction

1.1 Intended use

Henny Penny combisteamers are solely intended to be used for

commercial purposes, especially in commercial kitchens.

The unit may only be used for cooking food and only with the correct

racks, containers, baking sheets, rack trolleys and slide-in units.

The unit may only be used with the purest quality drinking water for

producing steam; if necessary, in combination with a water preparation

system.

It is not permitted to use the unit for the following purposes, among others:

●

As a dishwasher

●

As a storage container

●

As a smoking oven

●

Drying towels, paper or dishes

●

Heating acids, brines or other chemicals

●

Heating closed containers (e.g. tinned food)

●

Heating inflammable liquids

●

Melting fats or salts

●

Heating rooms

●

Deep frying

●

Cleaning air filters

●

Operation without slide-in rails/trolley

ClassicCombi

™

1.2 About this operating manual

This operating manual is part of the equipment and contains information

required by the persons operating the unit to enable them to operate it

safely, for cleaning and looking after the unit and for handling faults.

●

The employees engaged to perform any tasks with the unit must have

read the operating manual, especially the section “Safety information”,

before beginning work.

●

Keep this operating manual stored safely during the life of the unit.

●

Make sure that this operating manual is constantly available for the

staff at the place where the unit is used.

●

Supply this operating manual to any subsequent owner or user of the

unit.

●

Include any supplements received from the manufacturer.

●

Supplement the instructions, including supervisory or notification

requirements, to take account of special operational circumstances

e.g. work organisation, workflows or deployed staff.

Operating instructions6

Global Foodservice Solutions

ClassicCombi

™

Introduction

Target group

1.3 Warnings

●

This operating manual is intended for employees who are

responsible for operating, cleaning and looking after the unit as

well as handling faults.

●

Repairs to the unit may only be carried out by specially trained

technical staff.

●

Adults may not use the unit without supervision if

-

they are unable to do so due to their physical, sensory or

mental capabilities,

-

they do not have the knowledge and experience required to

operate the unit safely and in the manner intended.

Warnings are indicated with a pictogram and a signal word.

The type and source of the risk as well as the consequences are

described together with instructions for avoiding the danger. The

meanings of the pictograms and signal words used are explained in

section “Signs and symbols” (see Chapter “Signs and symbols”,

Page 8).

1.4 Warranty and liability

The unit may not be modified or technically changed.

All guarantees or warranties cease to exist if technical changes are

made. Furthermore, the safety of the unit is no longer guaranteed.

Claims for warranty or liability for damages to persons or property are

excluded if they arise from one or more of the following causes:

●

Improper use of the unit

●

Incorrect installation, commissioning, operation or servicing of the

unit

●

Technical changes to the unit without the binding agreement of the

manufacturer

●

Use of spare parts or accessories not approved by Henny Penny

●

Faults resulting from the failure to comply with these operating

instructions

Global Foodservice Solutions

7Operating instructions

Introduction

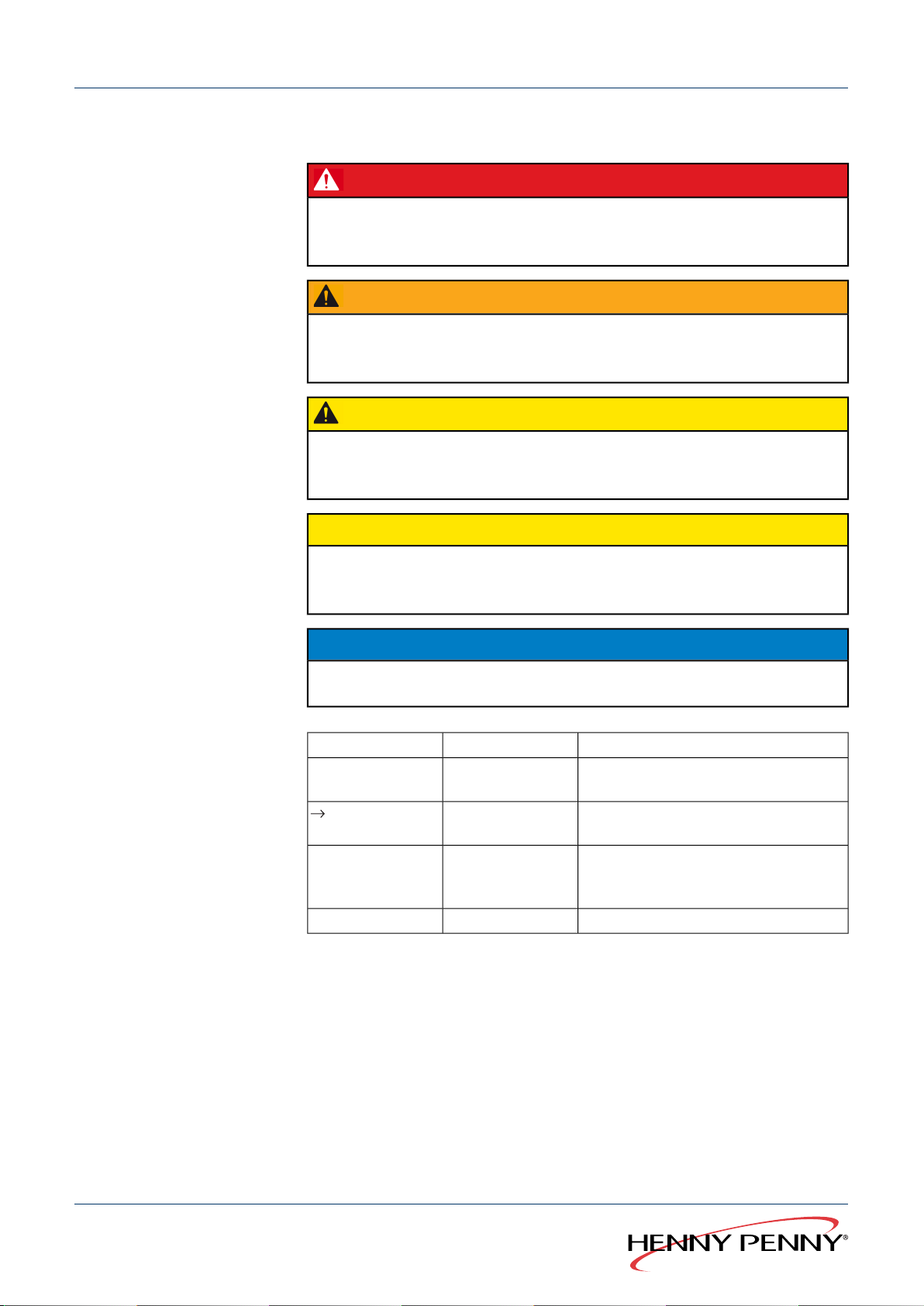

1.5 Signs and symbols

DANGER

Imminent danger

→

Non-compliance poses a threat of death or serious injury.

WARNING

Possible danger

→

Non-compliance may pose a threat of death or serious injury.

CAUTION

Dangerous situation

→

Non-compliance may result in slight injuries.

ClassicCombi

™

CAUTION

Dangerous situation

→

Non-compliance may result in equipment damage.

NOTICE

Provides helpful information regarding use.

ExplanationMeaningSymbol

These must be fulfilled before you can

follow the instructions.

An action is required here.Instruction, single

Instructions must be followed in the order given.

Emphasises the name of the controlControlOn/Off

1.

2.

RequirementsRequirements

step

Instruction, multiple

steps

Operating instructions8

Global Foodservice Solutions

ClassicCombi

2 Safety information

Electricity Risk of electric shock

™

Safety information

Henny Penny appliances comply with the relevant safety standards.

However, this does not exclude all possible dangers from arising, e.g.

due to improper use.

Therefore, when installing and operating the unit, the operating

personnel must be familiar with and observe local regulations, including

BGR 111 “Working in catering kitchens”.

The following safety measures must also be observed:

WARNING

Possible danger

→

Non-compliance may pose a threat of death or serious injury.

●

The cover of the housing may only be opened by specially trained

technical staff.

●

Repairs to the unit and to the mains power supply may only be

carried out by specially trained technical staff.

●

Disconnect the unit from the power supply before opening the cover

of the housing.

●

Do not operate the unit when the housing cover is open.

Gas Risk of explosion due to escaping gas

●

If you smell gas:

-

Shut off the gas supply.

-

Ensure the area is adequately ventilated.

-

Do not activate any switches or use any electrical devices.

-

Do not use any open flames.

-

Notify the gas supply company and/or fire department. Use a

telephone that is outside the installation site.

●

In the event of fire

-

Shut off the gas supply.

-

Put out the fire with a fire extinguisher (class F or ABC powder)

or fire blanket, never with water.

Soiled and greasy films Risk of fire due to soiled and greasy films

●

Clean the unit after each use.

●

Observe the instructions regarding cleaning.

Global Foodservice Solutions

9Operating instructions

Safety information

ClassicCombi

™

Hot surfaces, steam and

liquids

Risk of burns due to hot surfaces

●

Wear insulated protective gloves during operation.

●

Always open the door of the cooking chamber wide enough and let

it lock in place.

●

Allow surfaces to cool before cleaning.

●

Do not touch the interior of the unit or the inside of the cooking

chamber door immediately after use.

Risk of burns due to hot steam

●

Only open the door of the cooking chamber slightly at first to allow

the steam to escape. Then open the door fully.

●

Do not look into the steam outlet ports.

●

Do not hold your hand over the steam outlet ports.

Risk of burns due to hot liquids

●

Keep the door of the cooking chamber closed during the cleaning

program.

●

Do not insert containers with liquids to be cooked above eye-level.

●

When transporting food items, use a heat-resistant container with

handles and sealable lid.

●

Secure loading/rack trolleys against tipping over.

Rotating fan Risk of crushing fingers

●

Do not operate the unit without the ventilation plate.

Damaged windows Risk of injury due to glass splinters

●

Do not operate the unit if the windows are damaged.

●

Do not operate the unit if the cooking chamber lighting is defective.

●

Dispose of foods spoiled by glass splinters.

Cleaning Risk of burns caused by cleaning agents

●

Wear protective gloves and glasses when using caustic cleaning

agents.

●

Observe the information provided by the manufacturer of the cleaning

agent.

●

Store WaveClean and rinsing agent cartridges out of the reach of

children.

●

Observe the instructions for the storage of WaveClean and rinsing

agent cartridges.

Operating instructions10

Global Foodservice Solutions

ClassicCombi

™

CAUTION

Dangerous situation

→

Non-compliance may result in equipment damage.

Safety information

Core temperature

Do not overheat the core temperature sensor

measurement

●

Do not heat the core temperature sensor with a lighter or similar

object.

Incorrect handling Equipment damage due to incorrect handling

●

To avoid damaging the electronics, do not operate the unit if the

controls are damaged.

●

To avoid moisture penetrating the unit, do not operate if the door

seals are damaged.

Cleaning Equipment damage due to incorrect cleaning

●

Do not cool the cooking chamber abruptly after use (e.g. with a

hand-held rinsing head).

●

Do not clean the unit with a high-pressure cleaner.

●

Do not clean the surfaces with abrasive cleaners, scouring pads

or chemically aggressive cleaners.

●

Observe the reaction times for cleaning agents.

●

Clean the unit regularly.

●

Keep the cooking chamber free of scale.

●

For “WaveClean” automatic cleaning, only use the two-in-one

original cartridges.

●

Remove all GN containers and accessories from the cooking

chamber before cleaning.

Improper use Damage to equipment due to improper use

●

Do not operate the unit at continually high temperatures.

●

Do not operate the unit at temperatures below 4 °C (39.2 °F).

●

Remove the core temperature sensor before removing the food

item.

●

Replace the core temperature sensor back in its holder after use.

NOTICE

Provides helpful information regarding use.

Handling foodstuffs Provisions governing foodstuffs

Global Foodservice Solutions

11Operating instructions

Safety information

ClassicCombi

●

For the function “Preset start time”, observe the provisions regarding

foodstuffs.

™

Operating instructions12

Global Foodservice Solutions

ClassicCombi

3 Construction and

3.1 Description of the unit

™

Construction and function

function

10

9

8

7

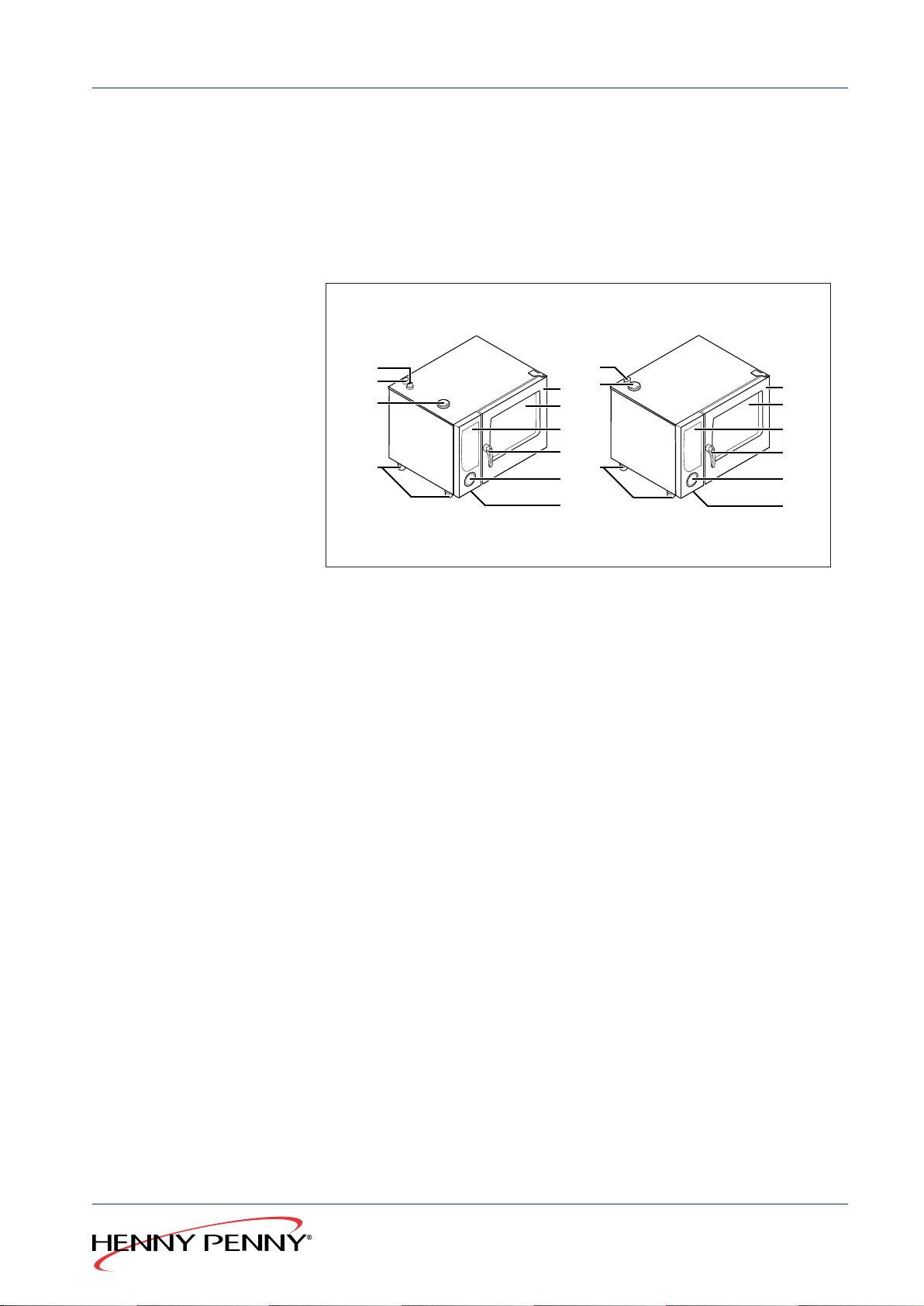

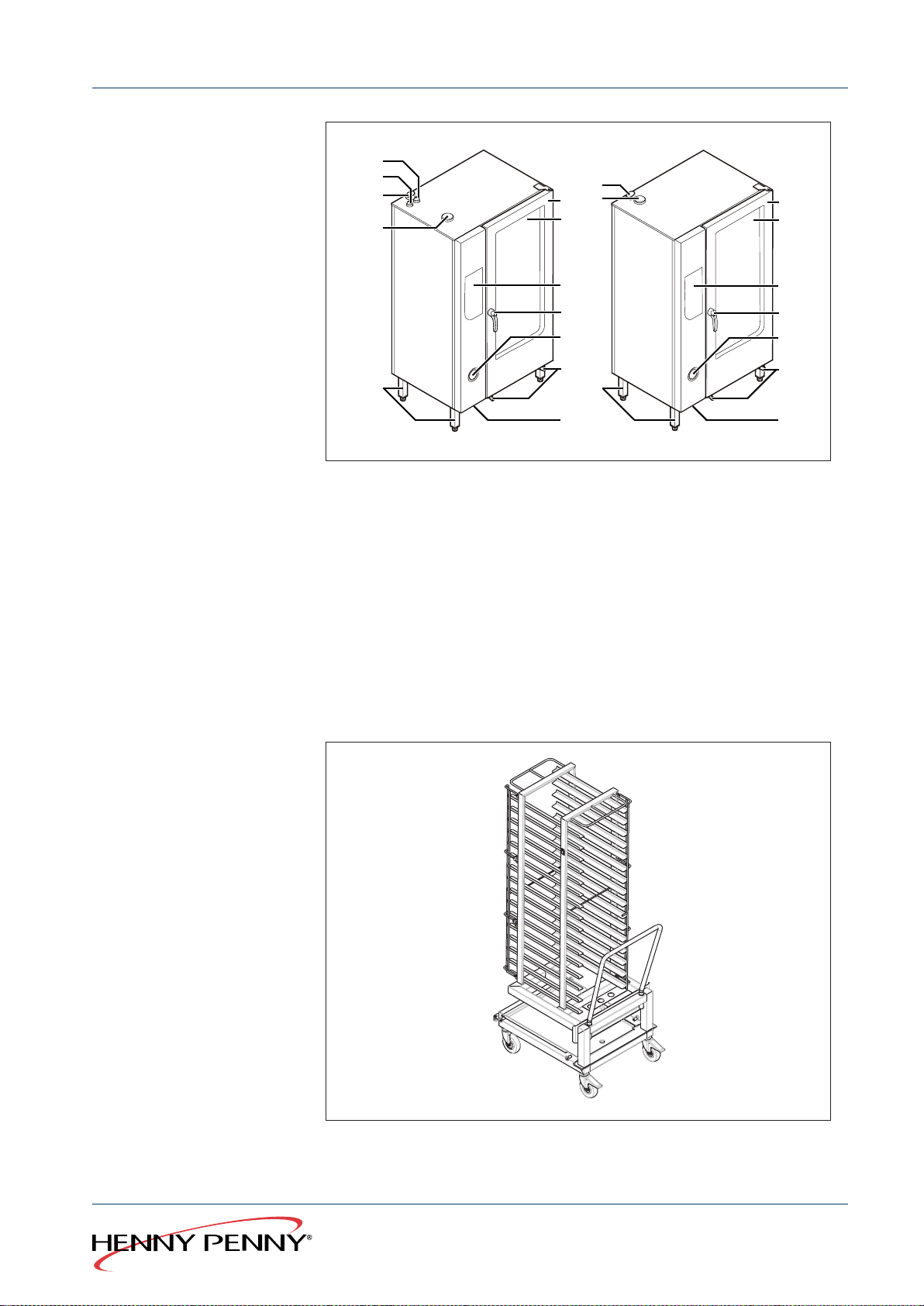

Figure 1: Sizes 615 and 620, left: gas, right: electric

5

tional)

9

8

1

2

3

4

7

5

6

Data interface (concealed)6Cooking chamber door1

Height-adjustable feet7Insulated window2

Air intake port for the cooking

8Controls3

chamber

Steam outlet port9Door handle4

Flue outlet10Hand-held rinsing head (op-

1

2

3

4

5

6

Global Foodservice Solutions

13Operating instructions

Construction and function

ClassicCombi

™

10

9

8

7

Figure 2: Sizes 115 and 120, left: gas, right: electric

9

8

1

2

3

4

5

7

6

Data interface (concealed)6Cooking chamber door1

Height-adjustable feet7Insulated window2

Air intake port for the cooking

8Controls3

chamber

Steam outlet port9Door handle4

5

Flue outlet10Hand-held rinsing head (option-

al)

1

2

3

4

5

6

Operating instructions14

Global Foodservice Solutions

ClassicCombi

™

12

11

10

Construction and function

10

1

9

9

2

1

2

3

4

5

6

8

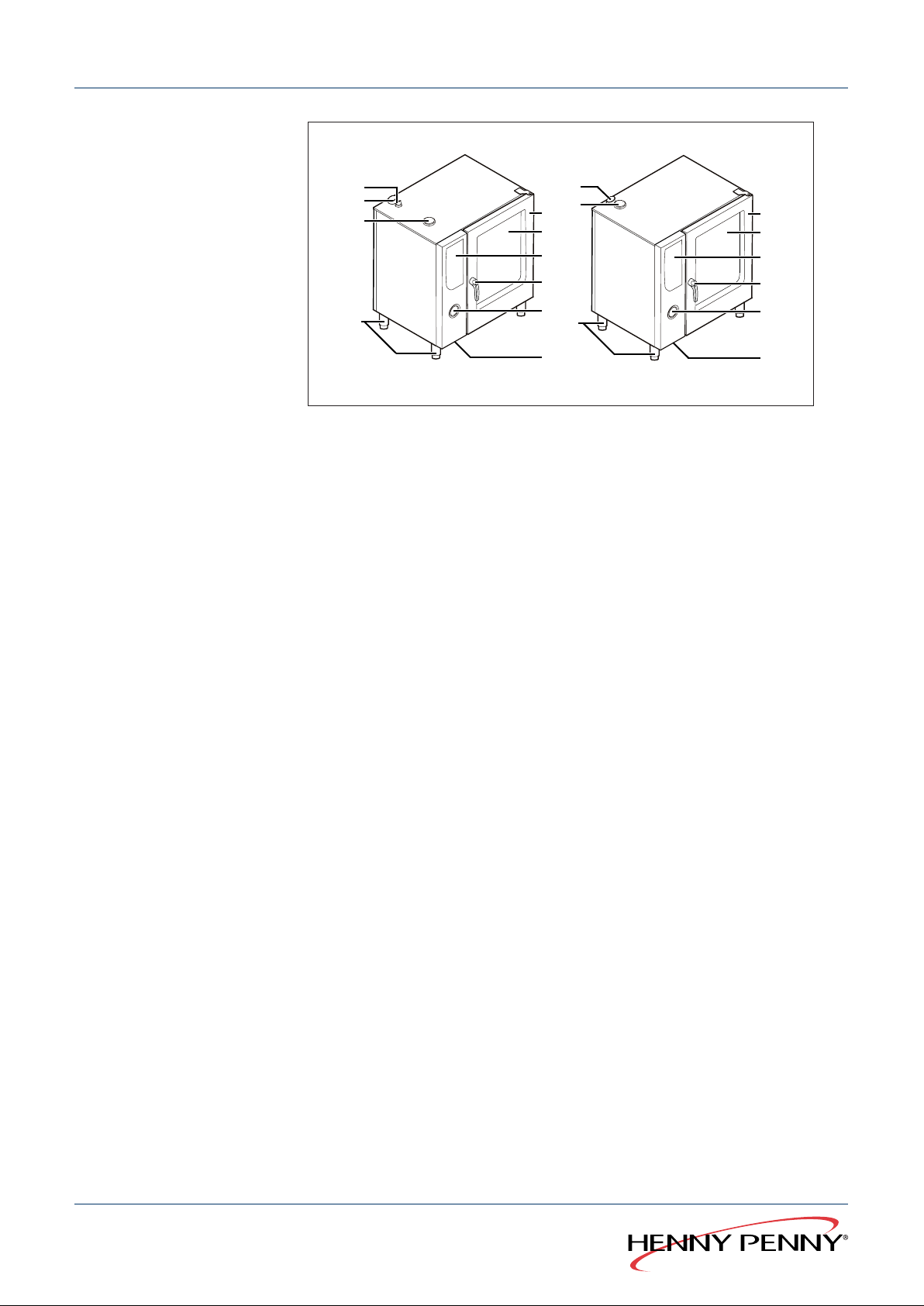

Figure 3: Sizes 215 and 220, left: gas, right: electric

8

7

Data interface (concealed)7Cooking chamber door1

Height-adjustable feet8Insulated window2

Air intake port for the cooking

9Controls3

chamber

Steam outlet port10Door handle4

5

Flue outlet (lower burner)11Hand-held rinsing head (op-

tional)

Flue outlet (upper burner)12Rails for rack trolley (optional)6

3

4

5

6

7

Global Foodservice Solutions

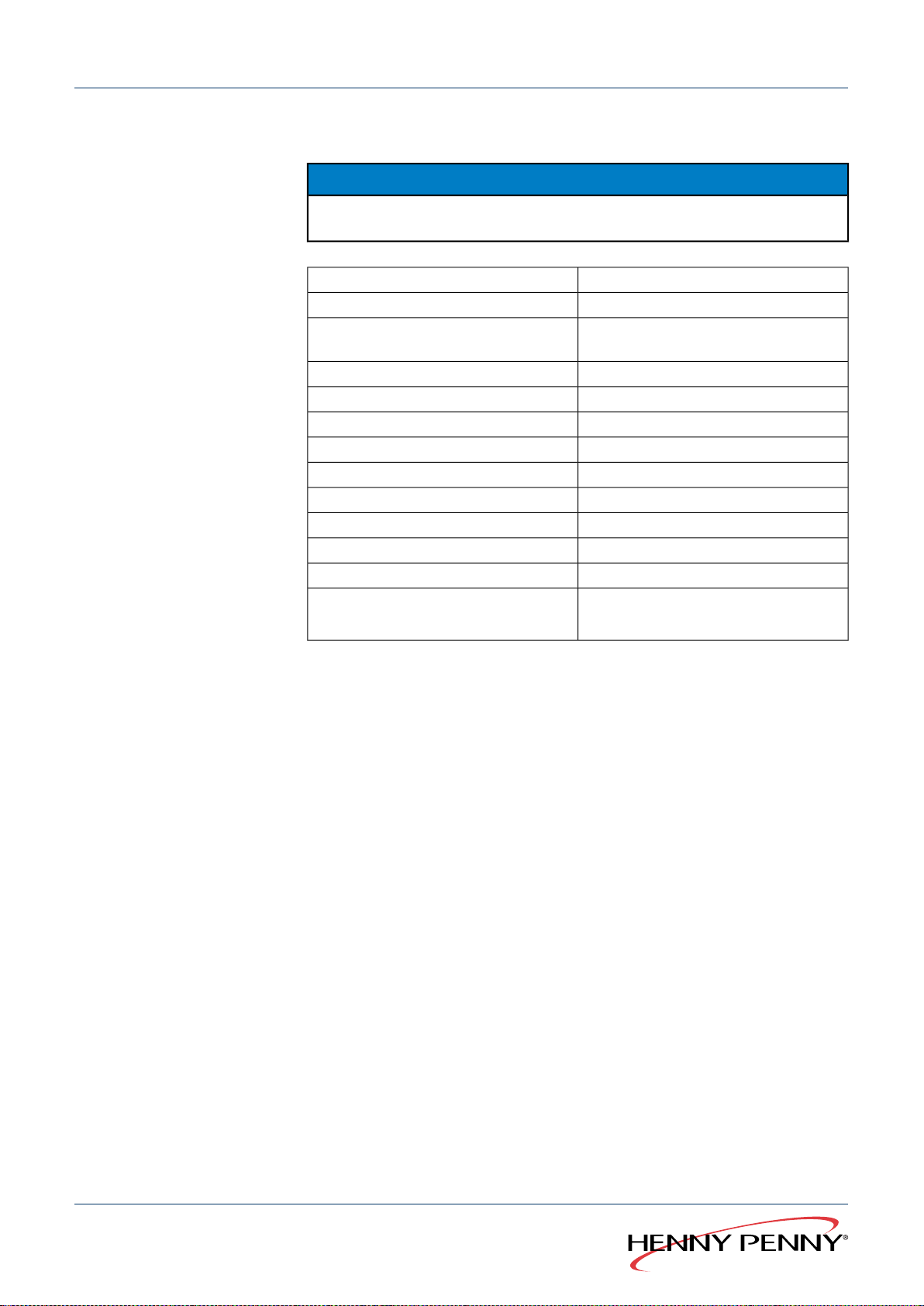

Figure 4: Rack trolley (for sizes 215 and 220)

15Operating instructions

Construction and function

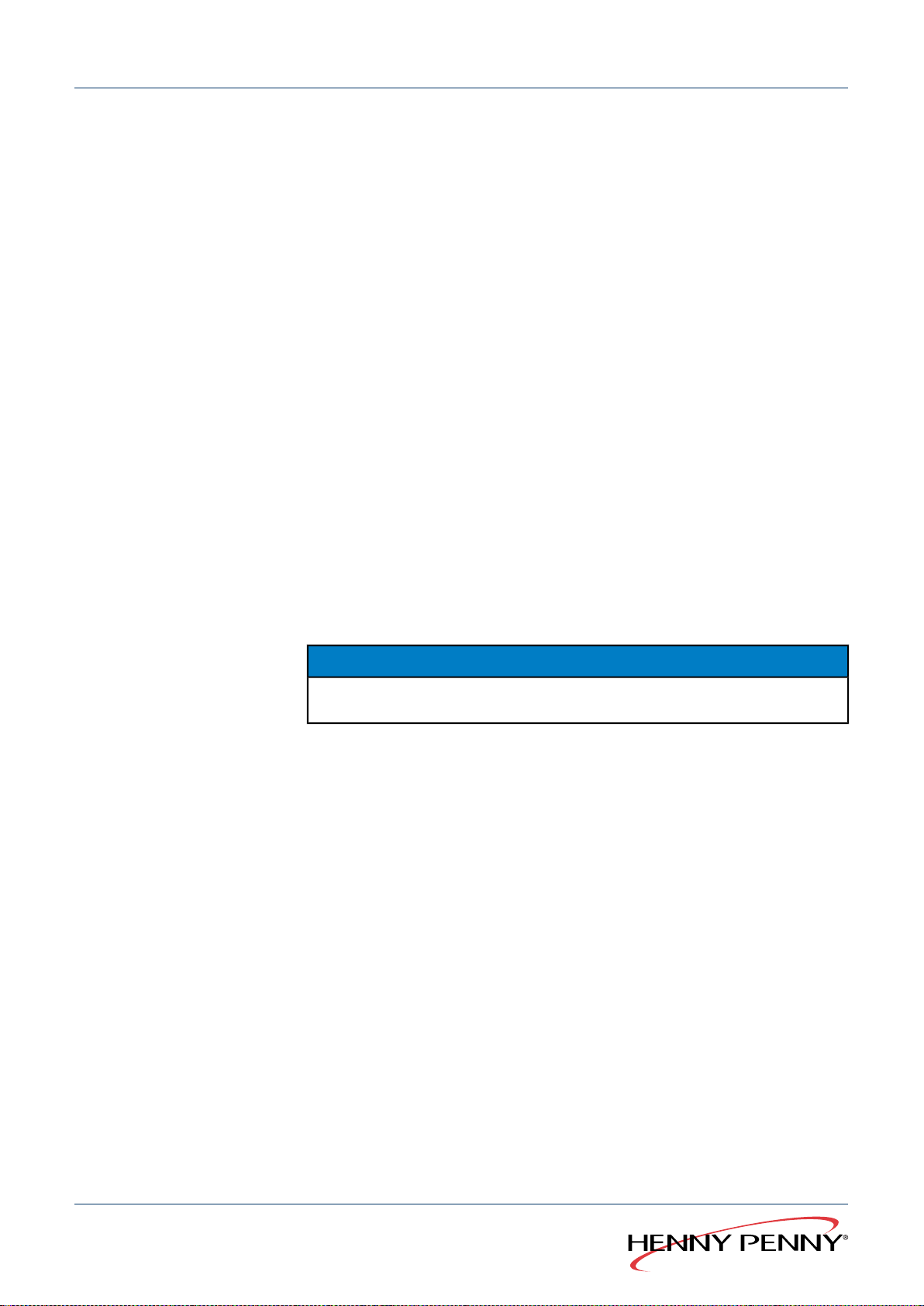

3.2 Description of the controls

NOTICE

Open out the cover page to see the controls.

Lower display

Set button

ClassicCombi

DescriptionControl

Cooking temperature displayUpper display

Display of cooking time and core temperature

Call up “Combisteaming” cooking modeCooking mode button “Combisteaming”

Call up “Regeneration” cooking modeCooking mode button “Regeneration”

Call up “Convection” cooking modeCooking mode button “Convection”

Call up “Steaming” cooking modeCooking mode button “Steaming”

Switch on/off“On/Off” button

Start/stop operation“Start/Stop” button

Call up the “Preheat” function“Preheat” button

Call up various functions“FLEXI” button

Call up step mode“Step” button

Navigation in menus

™

Selection of values

Operating instructions16

Global Foodservice Solutions

ClassicCombi

3.3 Operating modes

™

Construction and function

The unit has two operating modes:

●

Step mode

●

Manual cooking

You can use different cooking methods in both operating modes:

●

Steaming

●

Combisteaming

●

Convection

●

Regeneration

Advanced cooking functions such as:

●

Manual steaming

●

Preset start time

●

Preheat

●

Crisping control (optional)

can be used to adjust the cooking processes individually.

3.4 Step mode

Step mode is the operating mode for multi-step cooking programs.

Up to three program steps can be stored.

3.5 Manual cooking

3.5.1 Steaming

With the Steaming cooking mode, you can blanch, steam, steep, boil,

preserve and poach.

There are three steaming methods:

●

Soft Steaming: 30 °C (86 °F) to 99 °C (210.2 °F)

●

Steaming: 100 °C (212 °F)

●

Express Steaming: 101 °C (213.8 °F) to 130 °C (266 °F)

Benefits

●

Fast production of dishes that are firm to the bite with a good colour

and an intensive natural flavour.

●

Vitamins and minerals are retained.

●

Flavours are not transferred. The food retains its taste and aroma;

mixed loads are possible.

●

Less seasoning, fats and salt needed.

Global Foodservice Solutions

Tips

●

Use perforated GN containers with a depth of 40–65 mm. These

allow for short cooking times and avoid the food underneath being

overcooked.

17Operating instructions

Construction and function

●

●

●

●

●

●

●

ClassicCombi

™

Break up lumps of ice when using frozen foodstuffs so that all the

food will be heated evenly.

Chill vegetables quickly after steaming, add butter and season.

Use stock for vegetable bundles. Steam the vegetables in perforated

GN containers and catch the stock in unperforated containers.

Steam long grain rice in unperforated containers.

Use 1½ parts of cold water or cold stock to 1 part of rice.

Steam hard wheat pasta in unperforated containers.

Use at least 5 parts of water for 1 part of pasta.

Steam large and small dumplings in perforated containers lined with

baking paper.

Uncover immediately after cooking.

If necessary, keep them warm in water thickened with starch.

Sprinkle potatoes with fine grained salt and mix immediately before

steaming.

Alternatively, place potatoes in salt water for 15 minutes.

Benefits

Tips

Soft steaming

Steaming at temperatures between 30 °C (86 °F) and 99 °C (210.2 °F)

is called Soft steaming.

You can use soft steaming to prepare dishes especially gently, to swell

grains or to cook ham or sausages.

NOTICE

Cooking time is longer than with steaming or express steaming.

●

Less weight loss with meat and sausages.

●

Burst skin or gut is avoided when scalding or heating sausages.

●

Optimal food quality with delicate dishes such as terrines, jellies,

flans, forcemeat dumplings, creme caramel or diet meals.

●

Good when using vacuum pouches with the sous vide process.

●

Egg white sets optimally thanks to the precise cooking temperature

and doesn't run out of the food.

●

Allow yeast doughs for bread, buns or pastries to rise at a temperature

of 32 °C (89.6 °F).

●

When preparing poached trout, pour vinegar or wine over the fish.

Express steaming

Steaming at temperatures between 101 °C (213.8 °F) and 130 °C (266 °F)

is called Express steaming.

Express steaming is suitable for foods that are not damaged easily such

as jacket potatoes, beetroot, swede, pulses and cabbage.

Operating instructions18

Global Foodservice Solutions

ClassicCombi

Benefits The cooking time is reduced by about 10% as compared to the

Tips

3.5.2 Combisteaming

Benefits

™

Construction and function

“Steaming” cooking mode.

●

Set the cooking temperature between 105 °C (221 °F) and 110 °C

(230 °F) for small loads.

●

If the unit is fully loaded, set the temperature between 110 °C

(230 °F) and 130 °C (266 °F).

The Combisteaming cooking mode is especially suitable for large

roasting joints, casseroles and baked foods.

●

Optimal cooking chamber climate: the food does not dry out.

●

Very fast cooking with minimum weight loss.

●

Flavours are not transferred. The food retains its taste and aroma;

mixed loads are possible.

●

Foods such as yeast-based doughs rise optimally when baking.

●

The steam closes the pores of large roasting joints immediately;

searing is not necessary.

Tips

●

Preheat unit for at least 10–15 minutes.

●

Reduce cooking temperature by 20–30 % compared to other

cooking methods.

●

Food starts to brown at a cooking temperature of 120 °C (248 °F)

and above.

The higher the set cooking temperature, the greater the food's

weight loss but the more intensive the level of browning.

●

Place roast joints on racks. The pores of the joint will be closed

from all sides, the joints do not have to be turned over.

●

Place a drip tray underneath the rack holding the joints for gravy

or drippings. Place bones, roast vegetables and seasonings in the

drip tray and pour water or stock over them.

3.5.3 Convection

The Convection cooking mode is especially suitable for products that

don't need any additional humidity.

●

Benefits

Large capacity.

●

Even cooking results thanks to auto-reverse fan.

●

Up to 95 % less fat required as with other cooking modes.

Global Foodservice Solutions

Tips

●

Preheat unit for at least 10–15 minutes.

19Operating instructions

Construction and function

●

●

3.5.4 Regeneration

With the Regenerate cooking mode, food can be regenerated in perfect

quality on plates, platters or in GN containers.

Benefits

●

●

●

●

ClassicCombi

™

Food starts to brown at a cooking chamber temperature of 120 °C

(248 °F) and above.

The higher the set cooking chamber temperature, the greater the

food's weight loss but the more intensive the level of browning.

To produce crumbed dishes, use convenience products that are

suitable for convection or crumbed products with browning fats.

Production and presentation of meals in quiet, slack periods: for

banquets, you can regenerate as many plates as you wish on demand.

No loss of quality due to keeping prepared meals warm.

Optimal cooking chamber climate: the food does not dry out.

No condensation or dry edges on the plates.

Tips

●

Preheat the unit, then fill it quickly. In this way, the prewarmed air

remains in the cooking chamber.

●

Large thick foods such as dumplings, roulades or casseroles need

more time to regenerate: slice up thicker items.

●

Individually arrange meal items evenly on the plate. Keep overlaps

to a minimum and avoid different heights when arranging.

●

Only add sauces to the plates after regeneration is completed.

●

Place fish and meat on a raised bed so that they will be regenerated

evenly and not stick to the plate.

●

Meat should be pre-cooked precisely to the minute if it is to be served

medium after regenerating.

●

Season vegetables, rice and pasta and add fat before regenerating.

●

Use thermo covers and multiple banquet trolleys if the meals are to

be transported over a long distance and for large banquets. Warm

the thermo covers before use.

Plates can only be kept warm for a maximum of 20 minutes.

Regenerate further batches during this time; in this way, you can

serve the meals to your guests at the same time.

●

To reduce cooking time, use portioned GN containers with lids for

regenerating foods that are already portioned.

●

Regeneration time and regeneration temperature are dependent on

the number of plates (see table “Plate capacities” and table

“Regeneration temperatures and times”).

Operating instructions20

Global Foodservice Solutions

Loading...

Loading...