Henny Penny Chick-fil-A Controls Installation Manual

Henny Penny Chick-fil-A Controls

Henny Penny Chick-fil-A Controls

Chick-fil-A Controls

TABLE OF CONTENTS

Section Page

Section 1. INTRODUCTION ...........................................................................................1-1

1-1 Introduction...........................................................................................1-1

1-2 Assistance .............................................................................................1-1

1-3 Safety ...................................................................................................1-2

.............................................................................................................

Section 2. OPERA TION ...................................................................................................2-1

2-1 Operating Controls ................................................................................2-1

2-2 Clock Set..............................................................................................2-3

2-3 Diagnostic Mode and Special Functions .................................................2-5

2-4 W arnings and Error Messages ...............................................................2-8

2-5 Basic Operations ...................................................................................2-11

2-6 Clean-Out Mode...................................................................................2-16

2-7 Manually Setting New or Used Peanut Oil .............................................2-17

2-8 Checking T emperature Probe Calibration ...............................................2-17

Section 3. TROUBLESHOOTING ...................................................................................3-1

3-1 Introduction...........................................................................................3-1

3-2 Troubleshooting .....................................................................................3-1

3-3 Diagnostic Mode Details ........................................................................3-10

3-4 Information Mode Details ......................................................................3-26

W arranty

FM01-908-A

602 i

Henny Penny Chick-fil-A Controls

SECTION 1. INTRODUCTION

1-1. INTRODUCTION

The Chick-fil-A controls for the Henny Penny models 500 (electric)

and 600 (gas) have many features to allow the Operator to produce

consistent, quality products. The controls monitor not only cooking

times and temperatures, but also peanut oil condition, product

weights, product temperatures, and many other operational variables. The controls may vary the actual peanut oil temperature and

cook times, based on changes of the operational variables.

The controls also have very extensive self-diagnostic functions

which alert the Operator to both component and procedure

problems.

Some unique features of the fryer are listed below:

• Diagnostic Function-provides summary of fryer and

Operator performance. See section 2-4.

• Alarms and Error Messages-provide immediate feedback for

Operator error or fryer malfunction. See section 2-5.

• Status Mode-allows the Operator to view basic fryer informa-

tion and status. See section 2-4.

• Information Mode-gathers and stores historic information on

the fryer and Operator performance, and can be viewed by the

Operator. See section 2-4.

• Oil Filter Enforcement-prevents the Operator from exceeding

approved number of cook cycles before filtering the peanut oil.

See section 2-4.

• Manual Program Mode-Operator can set time and tempera-

ture for nonstandard products. See section 2-4.

• Easy toggle between English and Spanish operation. See

section 2-4.

• Clean-Out Mode-a preprogrammed function for cleaning the

frypot. See section 2-14.

1-2. ASSISTANCE

Should you require outside assistance, just call Henny Penny

Corporation at 1-800-417-8405, or 937-456-8405.

1-1 602

Henny Penny Chick-fil-A Controls

SECTION 2. OPERATION

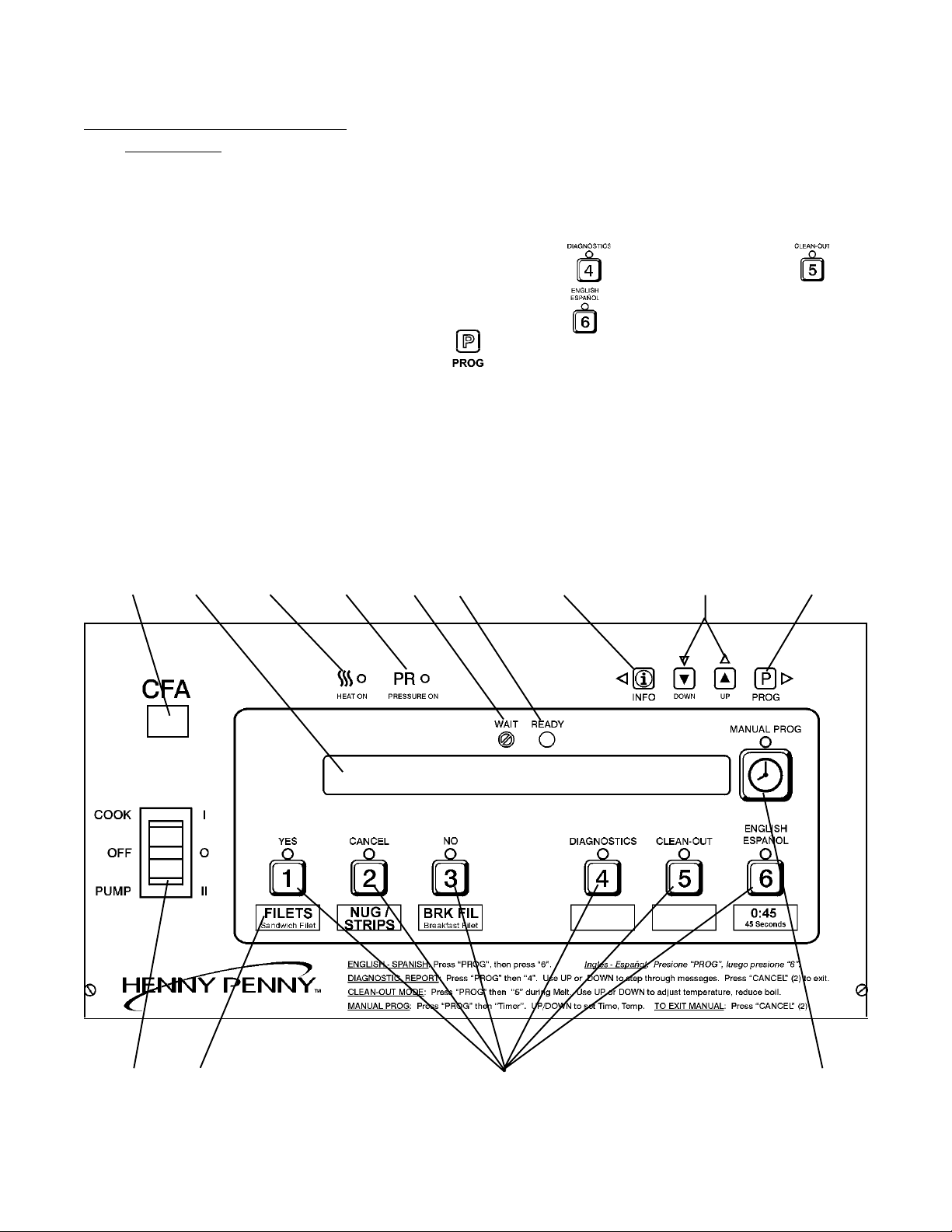

2-1. OPERATING CONTROLS Figure 2-2 shows the location of following computer control

items.

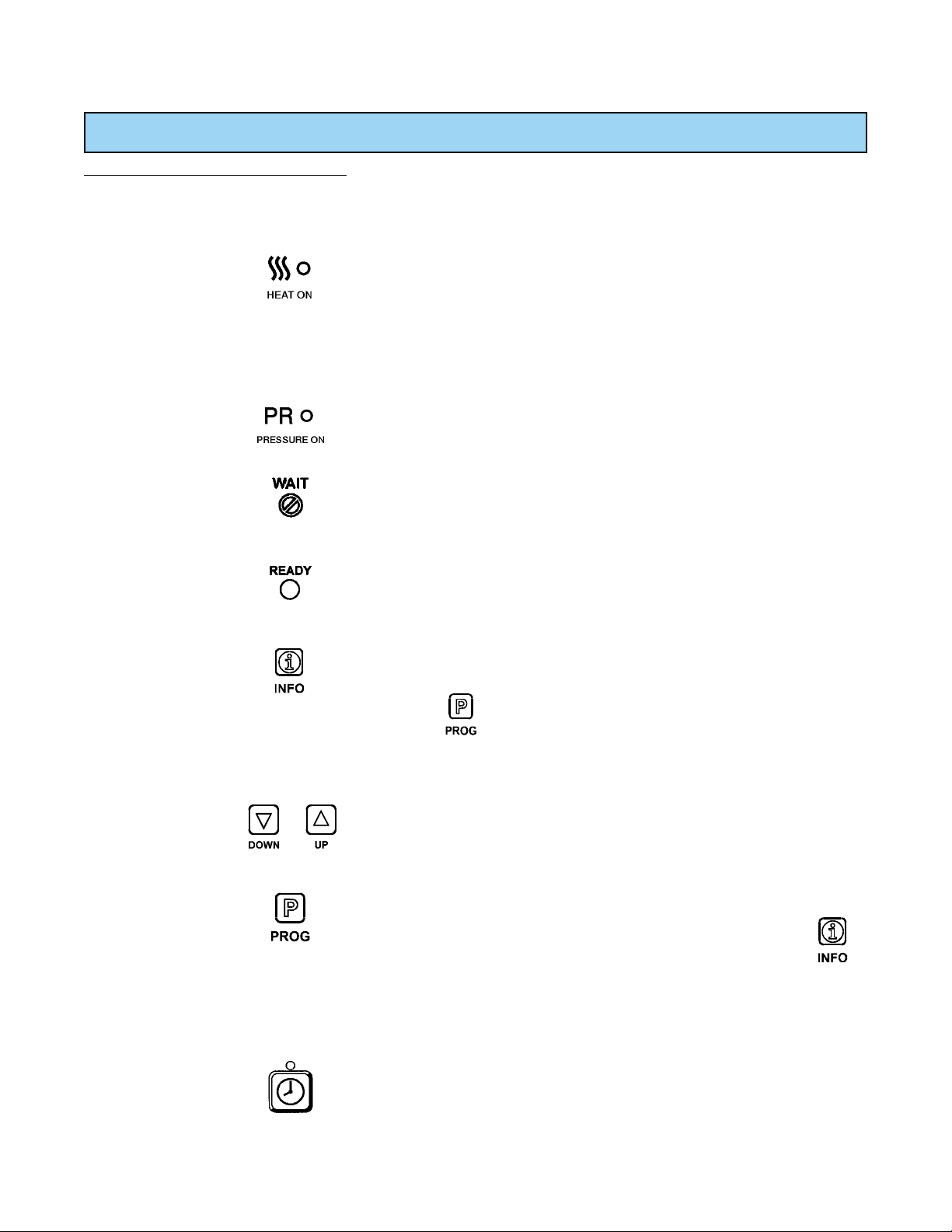

Figure Item Description Function

No. No.

2-2 1 Lights when the control calls for heat and the peanut oil should

start heating.

2-2 2 Digital Display Shows all the functions of the cooking cycle, Program Mode,

Diagnostic Mode and alarms.

2-2 3 Lights when the solenoid closes and pressure starts to build inside

frypot.

2-2 4 Flashes when the peanut oil temperature is NOT at the proper

temperature for dropping product into the frypot.

2-2 5 Lights when the peanut oil temperature is 5°F below setpoint to

15°F above the cooking temperature, signaling product can now

be be cooked.

2-2 6 Press to display current fryer information and status. If pressed in

the Program Mode, shows previous settings. Pressing this along

with accesses the Information Mode which has

historic information on the Operator and fryer performance.

2-2 7 Used to adjust the value of the currently displayed setting in the

Program Modes.

2-2 8 Press to access Program Mode. Once in the Program Mode, it is

used to advance to the next setting. If pressed along with it

accesses the Information Mode which has historic information on

the Operator and fryer performance. It also allows access to

the English-Spanish settings, diagnostics, Clean-Out Mode, and

Manual Mode, if pressed before the appropriate button.

2-2 9 Used to start and stop cooking cycles and to stop the timer at the

end of a holding cycle. It is also used to program a Manual

Program for nonstandard products.

602 2-1

Henny Penny Chick-fil-A Controls

2-1. OPERATING CONTROLS

(Continued)

2-2 10 Menu Card Shows name of food product selected. The menu card strip is

located behind the decal.

2-2 11 Product Select Press to select food products to be cooked, as well as, answering

display prompts. Also, accesses the diagnostics; , the

Clean-Out Mode; and toggles between English and Spanish

display.

(Press before entering any of the above modes.)

2-2 12 Cook/Pump Switch A 3-way switch with a center OFF position. Turn the switch to

COOK to operate the fryer. Turn the switch to PUMP to operate the filter pump. Certain conditions must be met before

operating the filter pump. These conditions are covered later in

this section.

2-2 13 Unit Identification The unit’s model number and the control’s hardware and software

Window version numbers appear here.

13 2 1 3 4 5 6 7 8

12 10 11 9

Control Decal

Figure 2-2

2-2 602

Henny Penny Chick-fil-A Controls

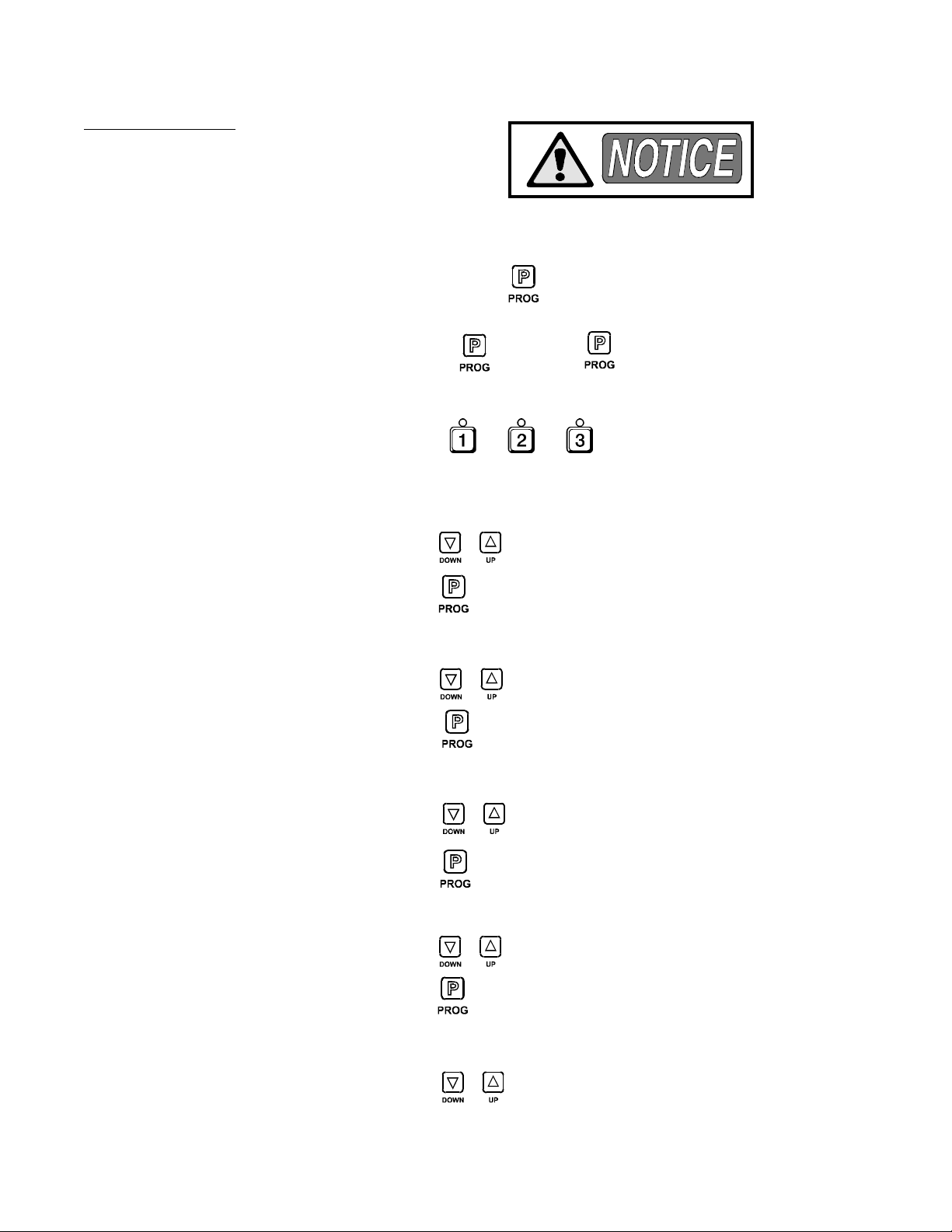

2-2. CLOCK SET

Upon initial start-up or PC board replacement, if “CLOCK SET”

automatically appears in the display, skip steps 1, 2 and 3.

1. Press and hold for 5 seconds until “LEVEL 2” shows in

display.

2. Release , then press twice. “CLOCK SET” then

“ENTER CODE” shows in display.

3. Press . .

4. Display shows “CS-1” then “SET” then “MONTH”, with the

month flashing.

5. Press to change the month.

6. Press . Display shows “CS-2 then SET then DATE” with the

date flashing.

7. Press to change the date.

8. Press . Display shows “CS-3 then SET then YEAR” along

with the year flashing.

9. Press to change the year.

10. Press . Display shows “CS-4 then SET then HOUR” shows

with the hour and “AM” or “PM” flashing.

11. Press to change the hour and AM/PM setting.

12. Press . Display shows “CS-5, SET, MINUTE” with

the minutes flashing.

13. Press to change the minutes.

602 2-3

Henny Penny Chick-fil-A Controls

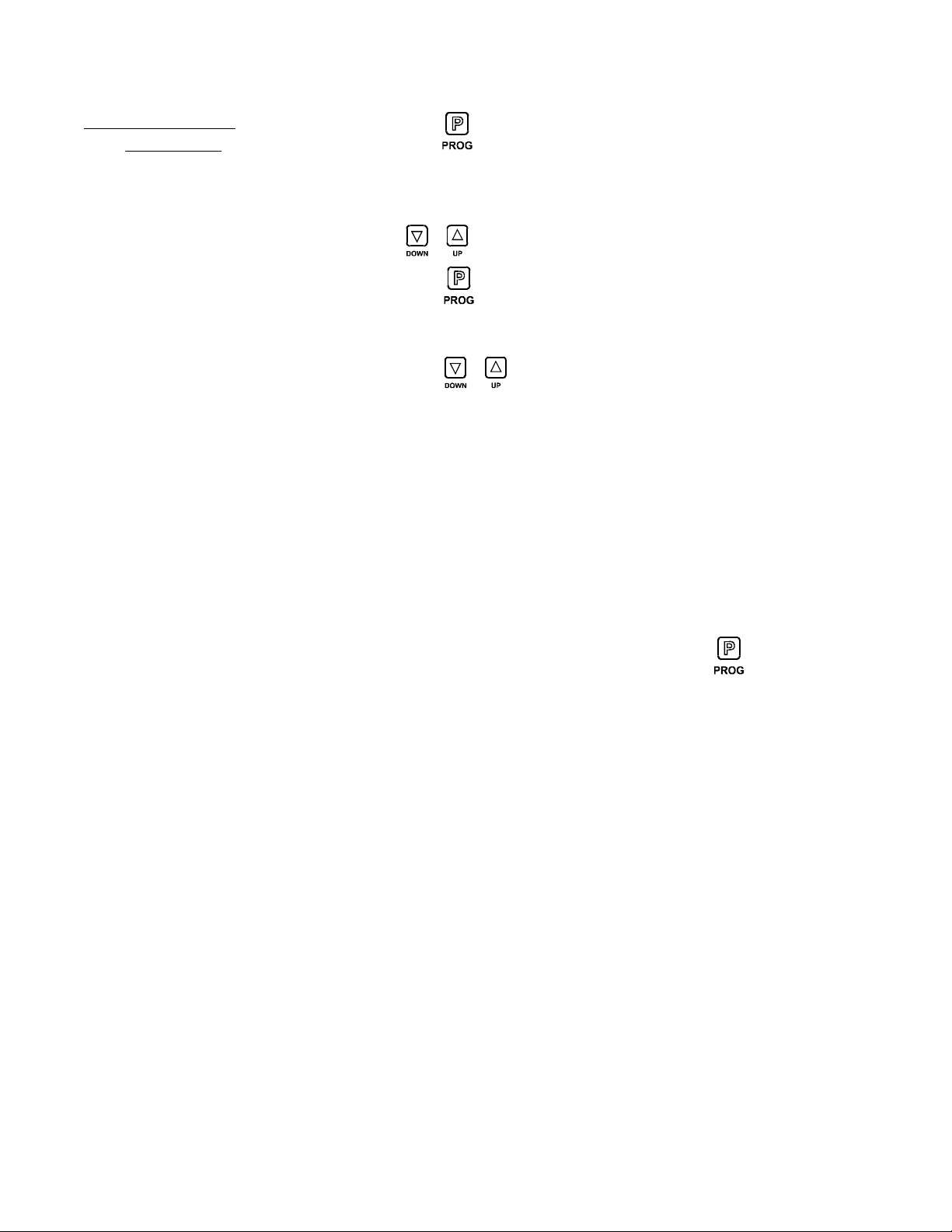

2-2. CLOCK SET

(Continued)

14. Press . Display shows “CS-6” then “CLOCK MODE”

along with “1.AM/PM”.

15. “1.AM/PM” is 12 hour time, “2.24-HR” is 24 hour time. Press

to change.

16. Press . Display shows “CS-7” then “DAYLIGHT

SAVINGS ADJ” along with “2.US”.

17. Press to change to the following:

a. “1.OFF” = No automatic adjustments for Daylight Savings

Time.

b. “2.US” = Automatically applies United States Daylight Savings

Time adjustment. DST activated on the first Sunday in April.

DST de-activated on the last Sunday in October.

c. “3.EURO” = Automatically applies European (CE) Daylight

Saving Time adjustment. DST activated on the last Sunday in

March. DST de-activated on the last Sunday in October.

18. Clock Set is now complete. Press and hold to exit.

2-4 602

Henny Penny Chick-fil-A Controls

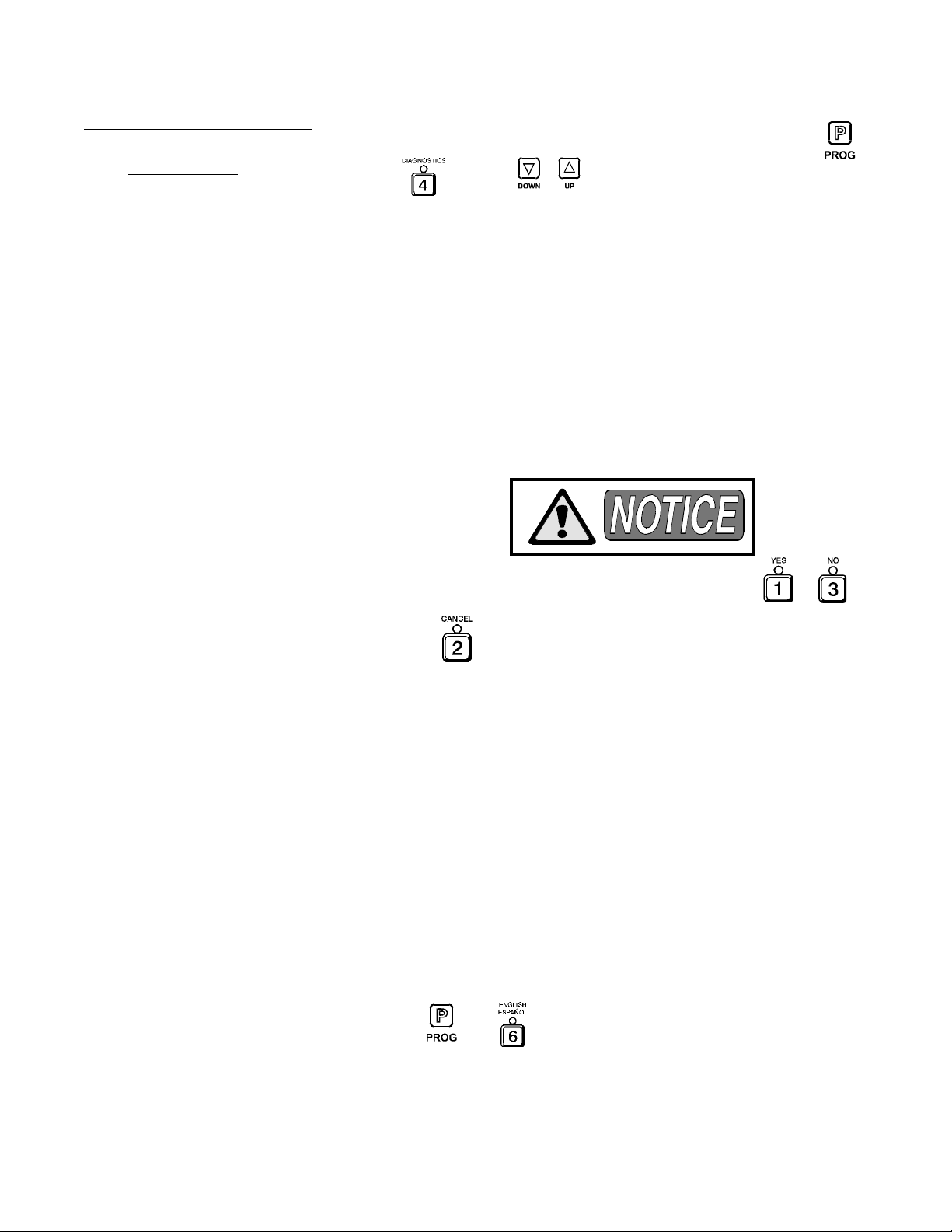

2-3. DIAGNOSTIC MODE

AND SPECIAL

FUNCTIONS

Diagnostic Mode

To view summaries of the fryer and Operator performance, press

then . Press to view the following functions:

D1 - Adjust product color for all products (not individually)

D2 - The age of the peanut oil and life remaining

D3 - Outlet voltage monitoring

D4 - Fryer’s heating performance

D5 - Slow or oversized product batches

D6 - Cook cycles started before temperature recovered

D7 - Cook cycles stopped more than 10 seconds before end of

cycle

D8 - Cook cycles not ended within 20 seconds after expired time

D9 - Number of times loading product took too long

D10 - Programmed variables changed by Operator

On several of the screens you may have to press or to

respond to questions asked.

Press at any time to exit and return to normal operation.

See section 5-3 for more details of the Diagnostic Mode.

Peanut Oil Life Function

Based on the number of cook cycles of specific products and the

amount of time the fryer idles, the controls tell the Operator when to

change the peanut oil.

“CHANGE OIL SOON” shows on the display when the controls

determine it’s time to change peanut oil. Unless the peanut oil is smoking or has a burnt flavor, the peanut oil does not need to be changed

before this message shows on the display. After cleaning the frypot,

using the Clean-Out Mode (section 3-14), this function resets.

Language Selection

Pressing then allows the Operator to choose to have the

information on the display in English or Spanish.

602 2-5

Henny Penny Chick-fil-A Controls

2-3. DIAGNOSTIC MODE

AND SPECIAL

FUNCTIONS

(Continued)

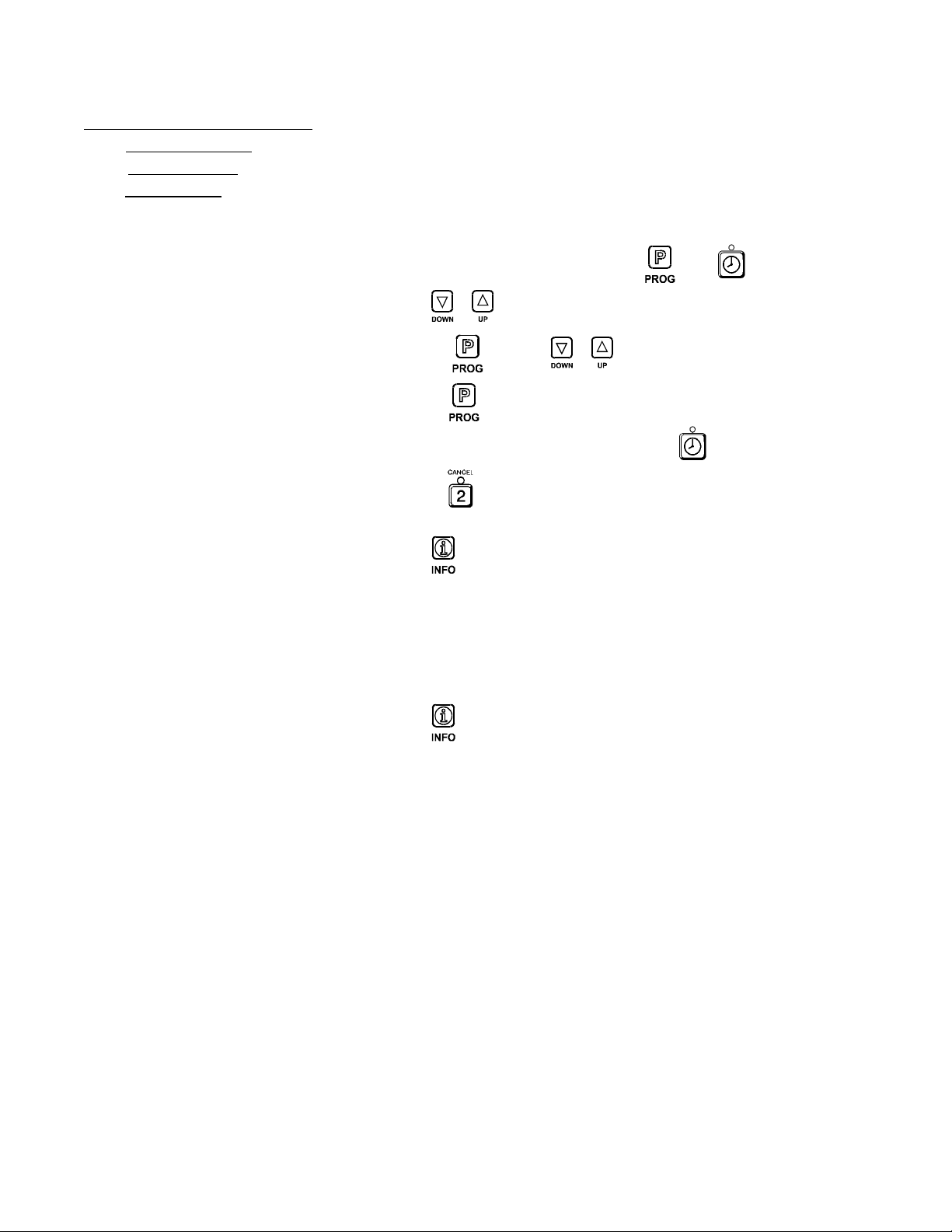

Manual Mode

This allows the Operator to quickly program a time and temperature for

nonstandard products that are not on the menu card. This is to be a

temporary setting and disables most of the advanced features of the

controls. To enter Manual Mode:

1. Once out of the Melt cycle, press then .

2. Use to set cook time.

3. Press and use to set temperature.

4. Press t o start Manual Mode. Display shows “MANUAL”

and you start a cook cycle by pressing .

5. Press to exit Manual Mode.

Status Mode

Pressing during idle time, allows Operator to view:

a. The temperature of the peanut oil

b. The temperature setpoint and any offset

c. The average peanut oil temperature during last cook cycle

d. The rate of temperature rise or fall

e. Date and Time

Pressing during a cook cycle allows the Operator to view:

a. The temperature of peanut oil, plus the degrees and rate the Load

Compensation has affected the cook cycle (slows down or speeds

up the timer)

b. The cooking step, the time left in cook cycle, setpoint temperature

and whether pressure is on

c. The average peanut oil temperature in cook cycle so far

d. The rate of temperature rise or fall

e. Date and Time

After 5 seconds, the control exits the Status Mode and the pressure

fryer returns to normal operation.

Peanut oil Filter Enforcement

Prevents the Operator from exceeding the set number of cook cycles

before filtering the peanut oil. The number in the center of the display

shows how many cook cycles remain before the Filter Lockout occurs.

For example, “5X” means the Operator can run 5 more cook cycles

before filtering. This function cannot be bypassed and greatly increases

the life of the peanut oil.

2-6 602

Henny Penny Chick-fil-A Controls

2-3. DIAGNOSTIC MODE

AND SPECIAL

FUNCTIONS

(Continued)

Information Mode

This mode gathers and stores historic information on the fryer and

Operator performance. Press and at the same time and

“*INFO MODE*” shows on display. Press or to access the

steps and press to view the statistics within each step.

Information Mode is intended for technical use, but the Operator can

view the following information:

1. E-LOG - last 10 errors and time they occurred

2. P-LOG - time of last 10 power-ups

3. HEAT-UPS - time of day and maximum heating rate (°/second) for

the last 10 heat-ups

4. COOK DATA - information on the last cook cycle

5. TODAY’S DATA - data since the start of day (not including the

last cook cycle)

6. PREV-DAY-SUN - creates a log of the last 7 days, using the

information in TODAY’S DATA.

7. 7-DAY TOTALS -totals the information from the last 7 days

8. OIL DATA - information on the current peanut oil, not including

today’s cooking information

9. PREV OIL DATA - information on last batch of peanut oil

10. INP - provides test of fryer inputs

11. OUTP - shows the state of heater and pressure

12. POT TMP - temperature of peanut oil

13. CPU TMP - temperature of PC board

14. ANALOG - status of controller’s a-to-d converter

15. AC VOLTS - status of the line voltage to fryer

16. AMPS (Electric models only) - the present amp readings to

heaters.

See section 5-4 for more details of the Information Mode.

602 2-7

Henny Penny Chick-fil-A Controls

2-4. WARNINGS AND

ERROR MESSAGES

The controls monitor procedure problems and system failures with

warnings and error codes. The display shows the warning or error

code, and an alarm sounds.

Pressing cancels most warnings, and pressing any control button

stops most Error Code alarms. But there are some exceptions (see

below). The display shows the error until the situation is corrected.

WARNINGS

DISPLAY CAUSE CORRECTION

“W-1” Incoming supply voltage too low. Have voltage at plug and receptacle checked.

“LOW

VOLTAGE”

“W-2” Faulty components or connections. Have elements, connections, and contactors

“SLOW checked.

HEAT-UP”

“W-3” Product loaded into frypot Wait until peanut oil is at proper temperature

“WAS NOT before lights. before loading product.

READY”

“W-4” Frozen or too much product Do not overfill or place frozen product

“SLOW in frypot. into the frypot.

COOKING”

“W-5” Product loaded into frypot Wait until peanut oil is at proper temperature

“SLOW before lights. before loading product.

COOKING”

“W-6” Faulty components or connections. Have elements, connections, and contactors

“SLOW checked.

COOKING”

“W-7” Faulty components or connections. Have elements, connections, and contactors

LOW AMPS checked.

“W-9” Product overcooked. (May Discard product immediately.

“DISCARD appear after a Slow Cooking

PRODUCT” warning.)

“OIL TOO Didn’t allow peanut oil to drop Cancel button will not stop this warning. Once

HOT” down to current product’s setpoint the peanut oil temperature drops to setpoint

temperature. temperature, the alarm automatically stops.

2-8 602

Henny Penny Chick-fil-A Controls

2-4. WARNINGS AND

ERROR MESSAGES

(Continued)

ERROR CODES

DISPLAY CAUSE CORRECTION

“E-4” PC board too hot. Check ventilation louvers on side of fryer for

“CPU TOO obstructions. If louvers are clear, have PC

HOT” board checked. Check cooling fan if present.

“E-5” Controls sensing 405°F Have heat components and temperature probe

“FRYER TOO or above. checked.

HOT”

“E-6” (A or B) Faulty temperature probe or Have temperature probe and connection

“FRYER connection. checked.

TEMP

SENSOR

FAILED”

“E-10” Peanut oil temperature too hot, Reset high limit. Check peanut oil temperature

“HIGH LIMIT drain valve opened while heat was for overheating. Have heat components

TRIPPED” on, or faulty high limit. checked if high limit continues to trip.

“E-15” Drain is open or faulty microswitch. Close drain. Have drain microswitch checked

“DRAIN IS if error code persists.

OPEN”

(500 fryer only)

“E-25” Wrong or faulty elements or wiring Have electrical supply, wiring, and elements

“HEAT AMPS problem. checked.

WERE TOO

HIGH

Because of the seriousness of this error code,

turn the Cook/Pump switch OFF and back

to COOK to cancel.

602 2-9

Henny Penny Chick-fil-A Controls

2-4. WARNINGS AND

ERROR MESSAGES

(Continued)

ERROR CODES

DISPLAY CAUSE CORRECTION

(500 fryer only)

“E-26” Faulty contactors or PC board. Have the contactors and PC board checked.

“HEAT AMPS

ARE

LOCKED ON”

This error code could be displayed even with

the Cook/Pump switch turned OFF. Unplug

fryer or shut off the wall circuit breaker to

disconnect electrical power to fryer.

“E-41” Memory scrambled. An individual Turn the Cook/Pump switch OFF and back to

“SYSTEM product program may be scrambled. COOK. If error code persists, have the PC

DATA LOST” Ex: “E-41 -2- DATA LOST”. This board checked or re-initialized.

means product #2 program is

scrambled.

“E-46” Faulty eprom or PC board. Turn the Cook/Pump switch OFF and back to

“DATA SAVE COOK. If error code persists, have the PC

FAILED” board checked or re-initialized.

“E-70” Faulty Cook/Pump switch Have Cook/Pump switch checked, along with

“PWR SW or switch wiring. Faulty its wiring. Have I/O board checked.

OR WIRES I/O board.

FAILED”

“E-92” Blown 24 volt controller fuse, or Have the 14-pin cable connector checked or

“24 VOLT bad 14-pin cable connection. have the fryer checked for a short to ground in

FUSE” components such as the drain switch, solenoid,

or high limit.

Stuck or clogged solenoid valve. Have solenoid checked and cleaned.

2-10 602

Henny Penny Chick-fil-A Controls

2-5. BASIC OPERATION

The following procedures should be followed on the initial start-up of

the fryer, and each time the fryer is brought back into operation from a

cold or shut down condition. These are basic, general instructions.

1. Check to see that the Cook/Pump switch is turned OFF.

2. Make sure the drain valve and filter valve are closed.

3. Remove the fry basket from the frypot and leave lid up.

4. Make sure the peanut oil is filled to the proper level in the frypot;

1/4 to1/2 inch (6.4-12.7 mm) below level indicator line.

5. Connect power to the fryer.

6. On gas models, light the pilot light.

7. Turn the Cook/Pump switch to COOK. Upon initial start-up

“CLOCK SET” shows in display. Set the clock to your time,

following prompts on the display, or see section 3-3 for help. Then

display asks if the peanut oil is NEW or OLD. The controls automatically adjust the peanut oil temperature to the age of the peanut oil. Use to set the number of days of old peanut oil.

8. Unit automatically goes into the melt cycle, until the peanut oil

temperature reaches 230°F (110°C). Then the controls go into

the heat cycle and heats the peanut oil to preset temperature.

Once melted peanut oil reaches the proper level in the frypot,

the melt cycle can be bypassed by pressing and holding one of

the Product buttons.

Do not bypass the melt cycle unless enough melted peanut

oil completely covers the elements in electric fryers or the

curved frypot surface in gas fryers. Excessive smoking or

fire could result.

9. Stir the peanut oil as it is heating up from a “cold” start. Be sure to

stir down into the bottom of the frypot.

602 2-11

Henny Penny Chick-fil-A Controls

2-5. BASIC OPERATION

(Continued)

10. Once out of the melt cycle, flashes until 5° before setpoint

temperature ( plus any offset temperature). Then lights

and the selected product shows on the display.

The heat cycles on and off about 4 degrees before the

setpoint temperature to help prevent overshooting the

setpoint temperature (proportional control).

11. If the peanut oil was not filtered the night before at shutdown,

filter the peanut oil now. Refer to section 3-9.

12. Follow the steps in Chick-fil-A’s training materials to load the

product.

Before loading product, make certain is lit, indicating

that the peanut oil is at the correct cooking temperature

for the type of product being cooked. The actual temperature

may vary 20 degrees or more depending peanut oil age,

product weights, product temperature, and other operational

variables.

Do not overload, or place product with extreme moisture

content into the basket. 12-14 lb (5.44-6.35 kgs.) is the

maximum amount of product. Failure to follow these instructions can result in peanut oil overflowing the frypot, causing

burns or damage to the fryer.

13. Close the lid quickly, latching the lid.

Do not press until lid is closed, or the lid will try to lock as

it is being tightened down.

14. Tighten the lid spindle clockwise, sealing the lid. Align the red

knob on the spindle with the red knob on the latch.

2-12 602

Henny Penny Chick-fil-A Controls

2-5. BASIC OPERATION

(Continued)

PRESSURIZED

LATCH THE LID PROPERLY AND ALIGN THE RED

BALLS OR SEVERE BURNS WILL RESULT.

15. Press the desired Product button to start a cook cycle. The

display counts down the cooking time.

To check the peanut oil temperature press . To stop a

cook cycle, press .

The cook times may vary, compensating for peanut oil age,

product weights, product temperature, and other operational

variables.

16. Within a few minutes, the pressure gauge should increase to the

OPERATING ZONE. If not, recheck the Installation and Operation procedures.

17. Near the end of the cook cycle, the fryer automatically depressurizes. Then at the end of the cook cycle, an alarm sounds, and the

display flashes “DONE”. Press to stop the alarm.

DEPRESSURIZE

CHECK THE PRESSURE GAUGE READING. DO NOT

ATTEMPT TO OPEN THE LID UNTIL THE PRESSURE

DROPS TO ZERO. OPENING THE LID WHEN THE

FRYPOT IS PRESSURIZED ALLOWS HOT PEANUT OIL

AND MOISTURE TO ESCAPE FROM THE FRYPOT,

RESULTING IN SEVERE BURNS.

18. After pressure drops to zero, turn the spindle counterclockwise.

Do not flip or spin the spindle cross arm when opening

because it could damage the acme nut inside the cross bar.

602 2-13

Loading...

Loading...