Henny Penny CFE-415 Service Manual

CFE 415/427 Technical Manual

,

Safety

The instructions in this manual have been prepared to aid you in learning the proper

procedures for your equipment. Where information is of particular importance or is safety

related, the words NOTICE, CAUTION, or WARNING are used. The definitions of safety

related words are described in the following table:.

SAFETY ALERT SYMBOL is used with DANGER,

WARNING, or CAUTION which indicates a personal injury type hazard.

NOTICE is used to highlight especially important

information.

CAUTION used without the safety alert symbol indicates a potentially hazardous situation which, if

not avoided, may result in property damage.

CAUTION indicates a potentially hazardous situation which, if not avoided, may result in minor or

moderate injury.

Preface

iii

WARNING indicates a potentially hazardous situation which, if not avoided, could result in death or

serious injury.

DANGER indicates an imminently hazardous situation which, if not avoided, will result in death or

serious injury.

Preface

iv

Chapter 1

System Overview

1.1 Controls and Indicators

The controls and indicators for the CFE 415.427 fryer are described in this section. The

controls and indicators

System Overview

1

System Overview

2

Figure 1-0 CFE 415/427 Controls and Indicators

Table 1-0 Controls and Indicators

Item Name Function

1 Heat On LED Lights when the control calls for heat, the oil should start heat-

ing when this LED is lit.

2 Wait LED Flashes when the oil temperature is not at the proper tempera-

ture for dropping product into the vat.

3 Ready LED Lights when the oil temperature is 5°F below setpoint to 15°F

above setpoint, signaling product can now be cooked.

4 Info button - Press to display current fryer information and status.

- When pressed in the program mode it shows previous settings.

- When pressed along with the program button accesses the information mode which has historic operator and fryer performance information.

Item Name Function

5 Filter/Up and Down

buttons

6 Program button - Press to access program mode.

7 This button

8 Menu Card Shows the name of the food product selected.

9 Product Select button -Press to select food products to be cooked

10 Digital Display Shows all the functions of the cook cycle, program mode, diag-

Used to access the Filter Menu; also used for ▲ or ▼ buttons.

- When pressed in program mode it is used to advance to the

next setting.

- When pressed along with the info button it will access the information mode which has historic operator and fryer performance information.

-Answers display prompts

-Button 4 accesses diagnostics

-Button 5 activates the clean-out mode

-Button 6 toggles between English and Spanish

nostic mode and alarms.

System Overview

3

System Overview

4

Chapter 2

Software

Software

5

Software

6

Chapter 3

Maintenance

Maintenance

7

Maintenance

8

Chapter 4

Removal/Installation

Procedures

This section contains removal/installation procedures for the CFE 415/427 fryer.

Removal/Installation Procedures

9

4.1 Removal Procedures

Removal procedure goes here XXX

Removal/Installation Procedures

10

4.1.1 Removal of the AIF Board

Removal procedure goes here XXX

Removal/Installation Procedures

11

4.1.2 Removal of the Control Board

Removal procedure goes here XXX

Removal/Installation Procedures

12

4.1.3 Removal of the Front Panels

This section contains the procedures to remove the front panels.

Removal/Installation Procedures

13

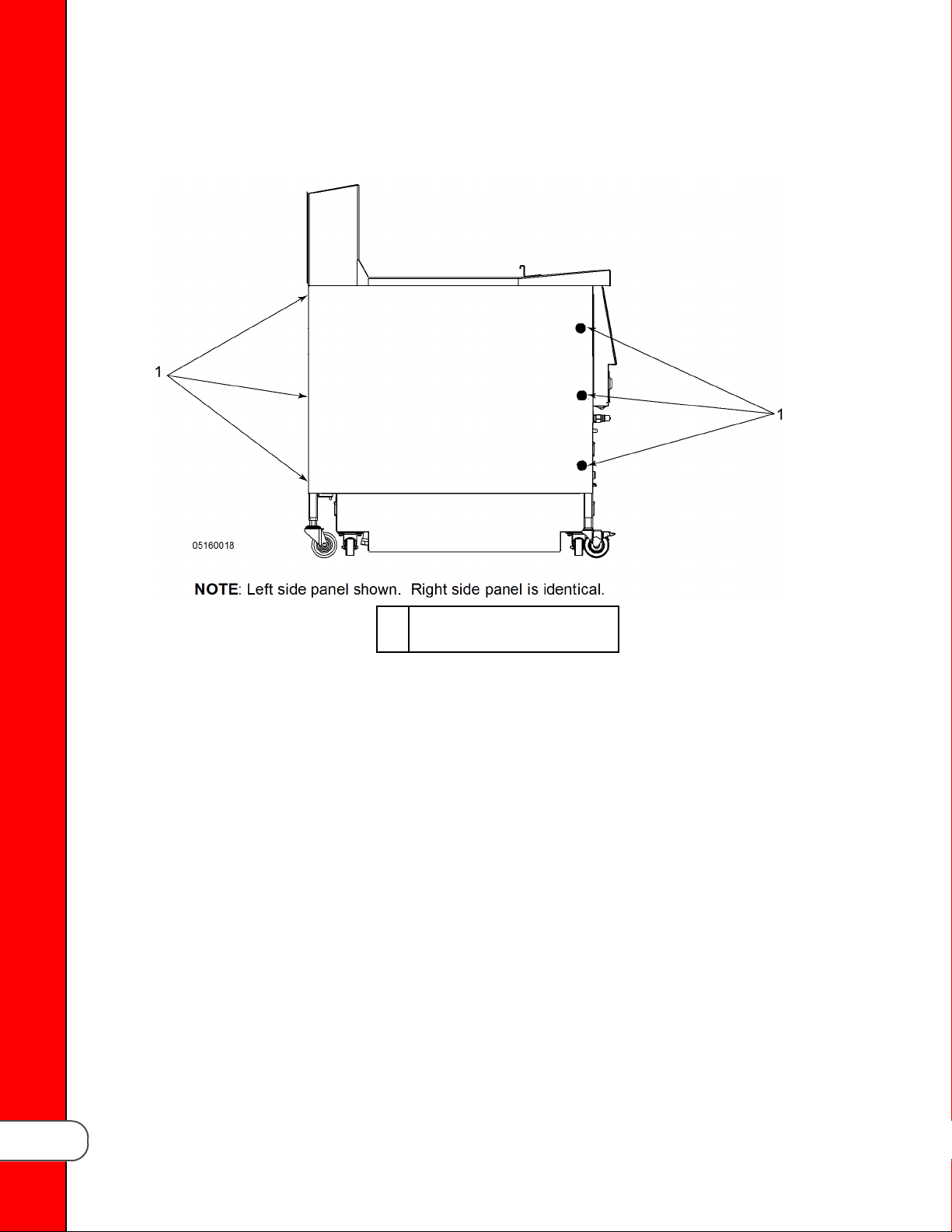

4.1.4 Removal of the Side Panels

This section contains the procedures to remove the side panels.

Removal/Installation Procedures

Screws (6 total)

1

Figure 4-1 Side Panel Removal

14

4.2 Installation Procedures

4.2.1 Installation of the Heating Element Assembly

This section contains the removal procedure for the Burner Assembly. The burner assembly

contains two burners which are joined together by hardware. There is an upper burner and

lower burner. The heating elements are identical and can be used interchangeably. Both

heating elements must be removed in order to access the defective burner.

1) Place both heating elements on the work area.

Removal/Installation Procedures

15

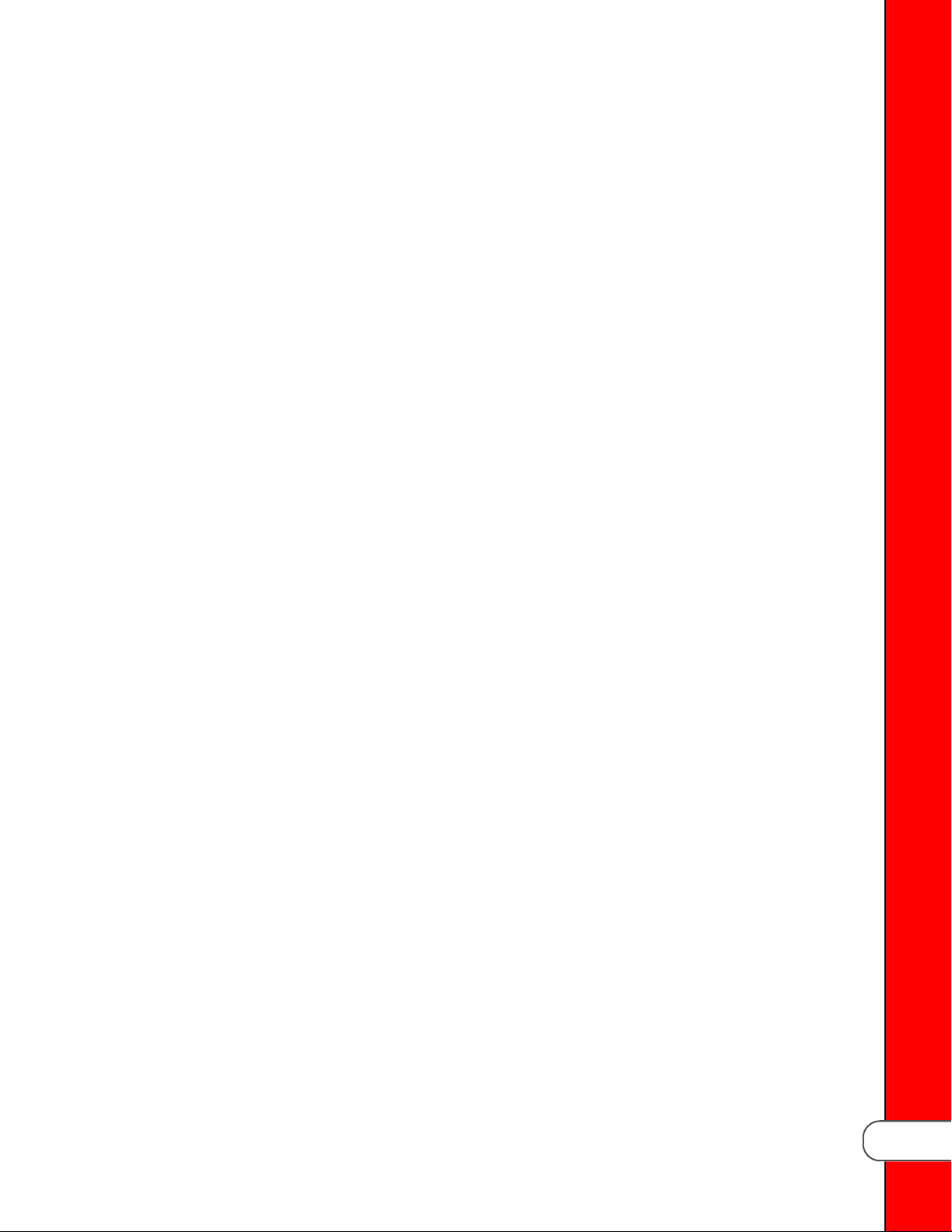

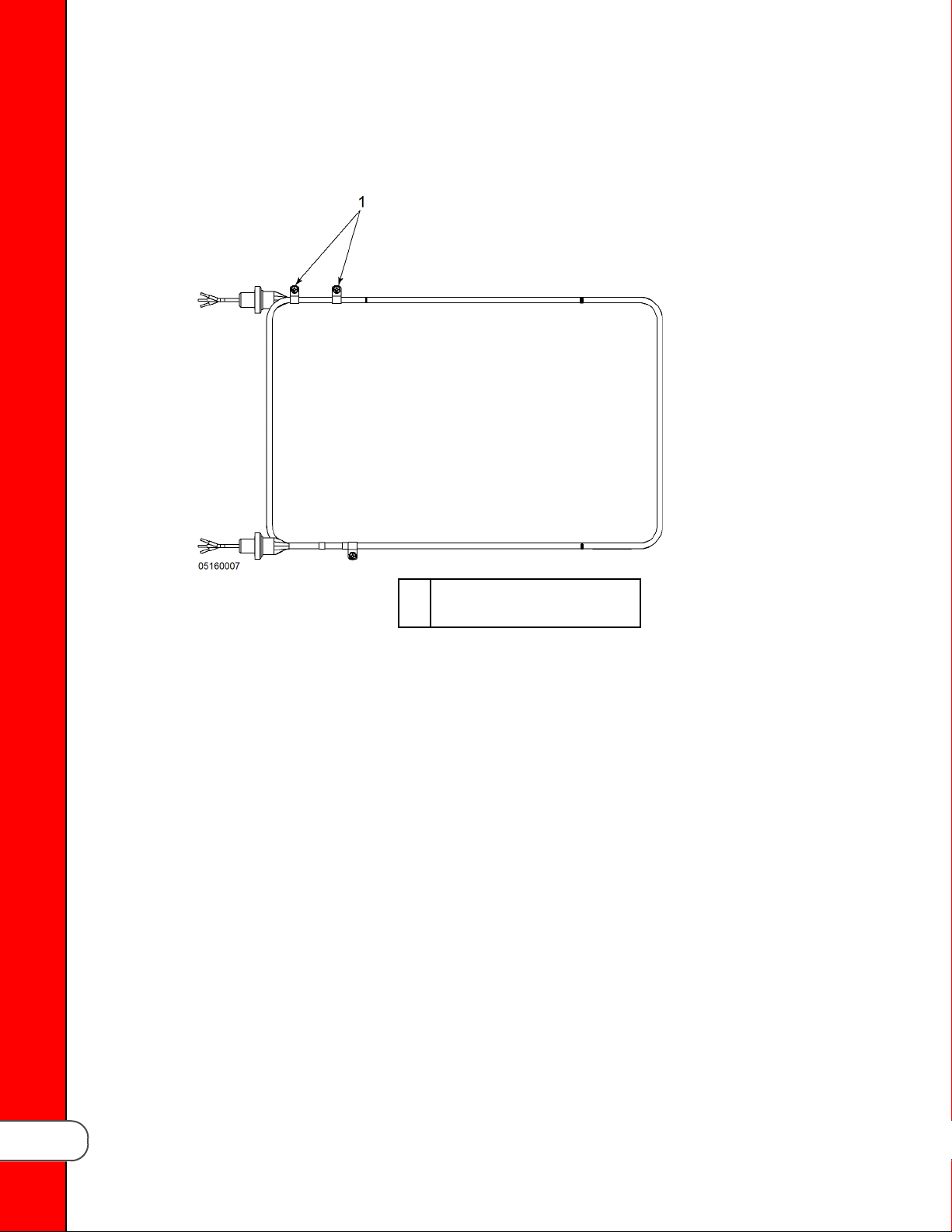

2) Draw the following marks on the upper heating element (see Figure 4-2 Marking the

Upper heating Element).

• Draw mark (1) on the left front side of the upper heating element five inches rear of

the connector flange.

• Draw a mark (2) on the left and right side of the upper heating element 3 1/8 inches

forward of the rear of the heating element.

• Draw a mark (3) on the right front side of the upper heating element 4 1/2 inches

rear of the connector flange.

• Draw a mark (4) on the right front side of the upper heating element 4 inches rear of

the connector flange.

Removal/Installation Procedures

16

5 inches from connector flange

1

3.125 inches from rear of heat-

2

ing element

Figure 4-2 Marking the Upper heating Element

4.5 inches from connector

3

flange

4 inches from connector flange

4

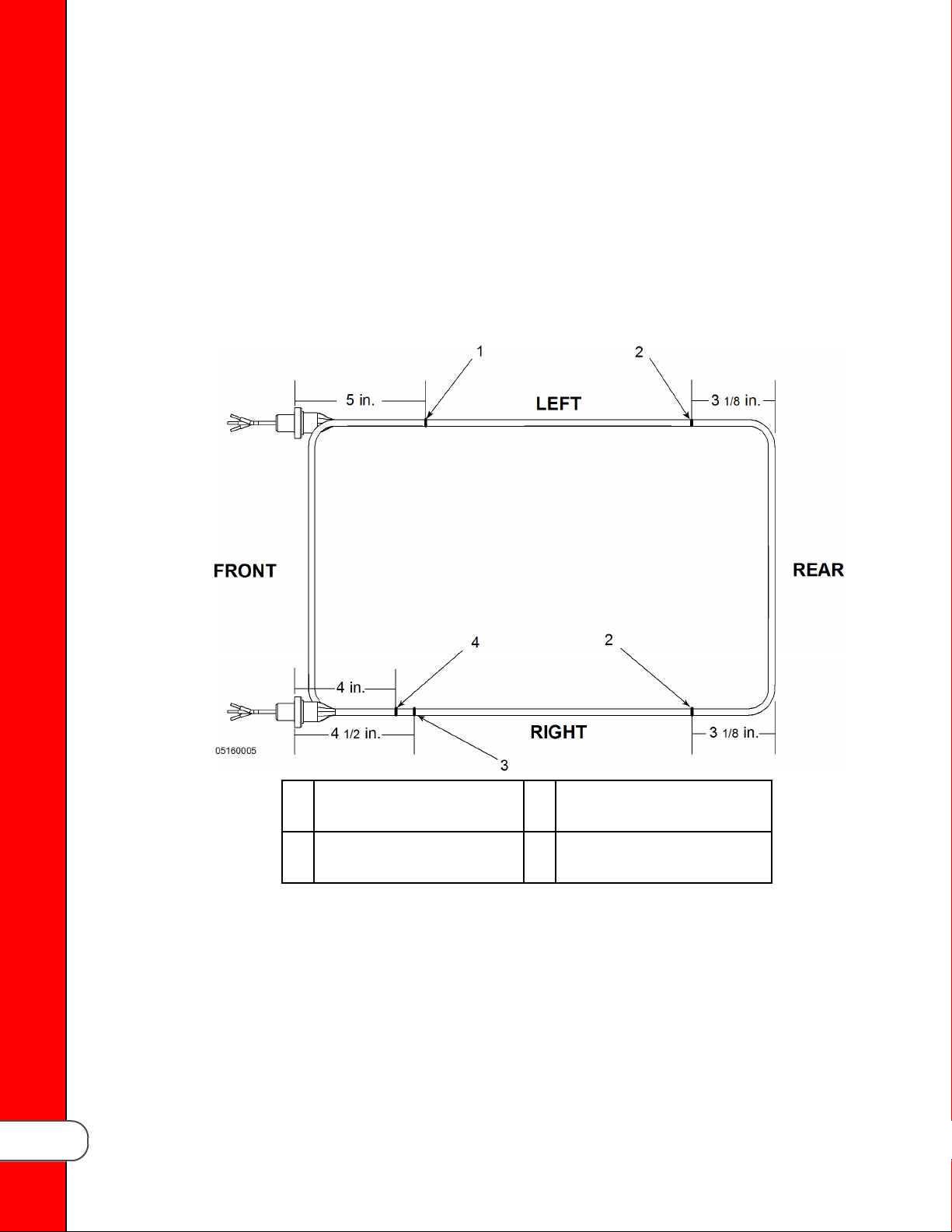

3) Position one high limit clip (2) on the top front right side of both heating elements

(see Figure 4-3 High Limit Clip and Clamp Install).

4) Position one high limit clamp (1) rear of the high limit clip (2) on the top front right

side of both heating elements.

High Limit Clamp with 6-32

1

screw

High Limit Clip

2

Figure 4-3 High Limit Clip and Clamp Install

Removal/Installation Procedures

17

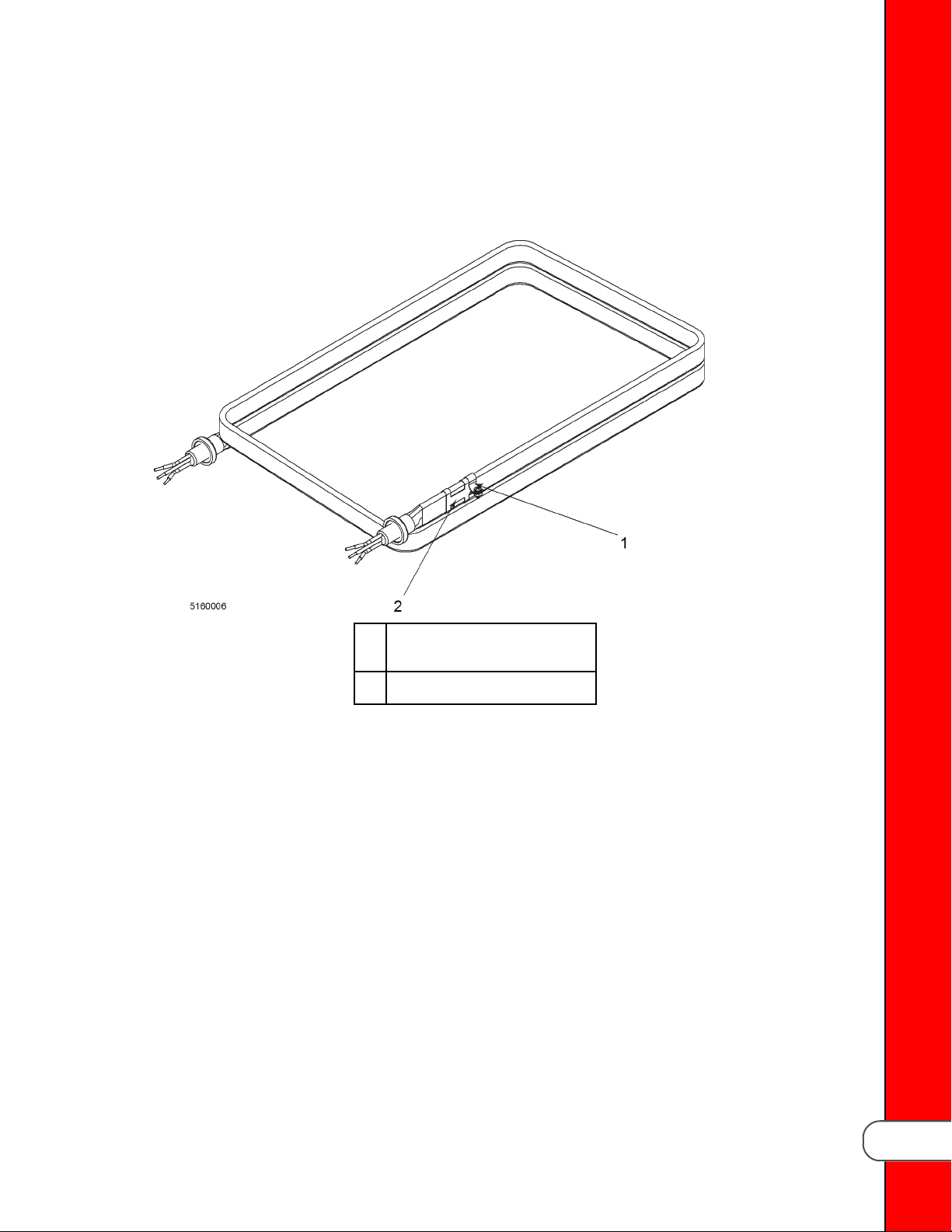

5) Position two high limit clamps (1) on the top front left of the upper heating (see

Figure 4-4 Upper Heating Element Clamp Install).

High Limit Clamp with 6-32

1

screw

Figure 4-4 Upper Heating Element Clamp Install

Removal/Installation Procedures

18

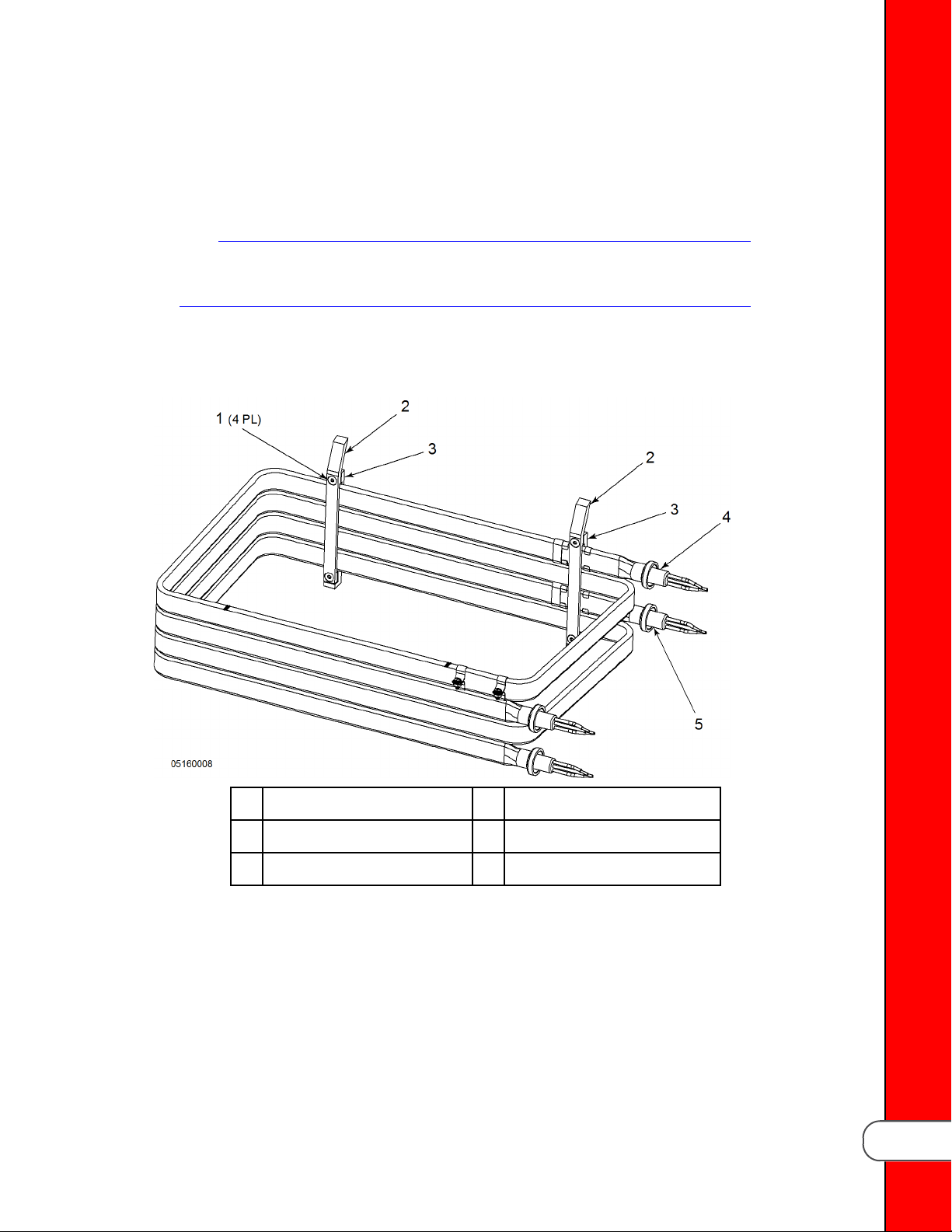

6) Place upper heating element (4) on top of the lower heating element (5) (see Figure 4-

5 Spreader Bar Installation, Right Side).

7) Position angled spreader (2) and straight spreader (3) over the high limit clips on the

front right side of the heating elements.

8) Position angled spreader (2) and straight spreader (3) on the rear right side mark on

the heating element.

Note

Do not tighten the allen screws all the way. The screws will be permanently

tightened when the heating element assembly is placed in the vat.

9) Insert four allen screws (1) into the right side spreader bars (2) and (3) to keep them

together.

Allen Screw, 10-32

1

Angled Spreader

2

Straight Spreader

3

Figure 4-5 Spreader Bar Installation, Right Side

Upper Heating Element

4

Lower Heating Element

5

Removal/Installation Procedures

19

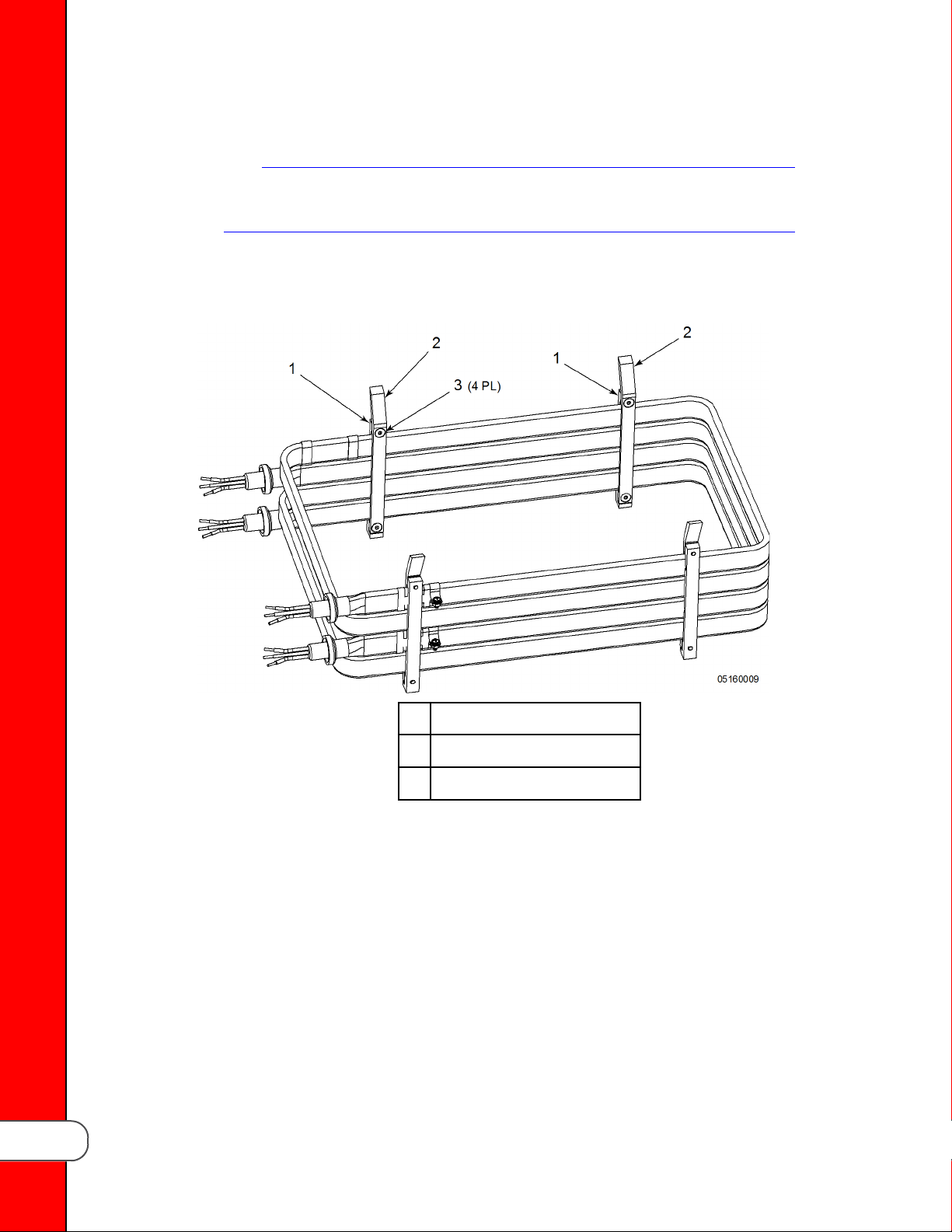

10) Position one angled spreader (2) and one straight spreader (1) on each mark on the left

side of the heating element assembly (see Figure 4-6 Spreader Bar Installation, Left

Side).

Note

Do not tighten the allen screws all the way. The screws will be permanently

tightened when the heating element assembly is placed in the vat.

11) Insert four allen screws (3) into the left side spreader bars (1) and (2) to keep them

together.

Removal/Installation Procedures

20

Allen Screw, 10-32

1

Angled Spreader

2

Straight Spreader

3

Figure 4-6 Spreader Bar Installation, Left Side

Loading...

Loading...