Henny Penny CFE-410 Service Manual

TECHNICAL

MANUAL

OPEN FRYERM (Electric)

MODEL

CFE-410

CFE-420

REGISTER WARRANTY ONLINE AT WWW.HENNYPENNY.COM

REGISTER WARRANTY ONLINE AT WWW.HENNYPENNY.COM

TABLE OF CONTENTS

Section Page

Section 1. TROUBLESHOOTING

1-1. Introduction ........................................................................................1-1

1-2. Safety .................................................................................................1-1

1-3. Troubleshooting .................................................................................1-2

1-4. Warnings and Error Messages ............................................................1-5

Wiring Diagrams ................................................................................1-8

Section 2. INFORMATION MODE ..............................................................................2-1

Section 3. MAINTENANCE .........................................................................................3-1

3-1. Introduction ........................................................................................3-1

3-2. Maintenance Hints .............................................................................3-1

3-3. Complete Control Panel Replacement ...............................................3-1

3-4. Quick Filter ........................................................................................3-2

3-5. Daily Filtering ....................................................................................3-4

3-6. Filter Menu .........................................................................................3-6

3-7. Check/Replace Filter Drain Pan O-Rings ..........................................3-7

3-8. Power Switch .....................................................................................3-8

3-9. AIF Transformer ................................................................................3-8

3-10. Control Board Transformer ................................................................ 3-9

3-11. Circuit Breakers .................................................................................3-9

3-12. AIF Board (single well) .....................................................................3-10

3-12 AIF Board (double well) ....................................................................3-11

3-13 High Limit Module ............................................................................3-12

Section 4. PARTS INFORMATION ..............................................................................4-1

4-1. Introduction ........................................................................................4-1

4-2. Genuine Parts .....................................................................................4-1

4-3. When Ordering Parts ..........................................................................4-1

4-4. Prices ..................................................................................................4-1

4-5. Delivery ..............................................................................................4-1

4-6. Warranty .............................................................................................4-1

4-7. Recommended Spare Parts for Distributors .......................................4-1

..............................................................................1-1

iSept. 2016

SECTION 1. TROUBLESHOOTING

1-1. INTRODUCTION

1-2. SAFETY

This section provides troubleshooting information in the

form of an easy to read table.

If a problem occurs during the rst operation of a new fryer,

recheck the Installation Section of the Operator’s Manual.

Before troubleshooting, always recheck the Operation

Section of the Operator’s Manual.

Where information is of particular importance or is safety

related, the words DANGER, WARNING, CAUTION, or

NOTE are used. Their usage is described on the next page:

SAFETY ALERT SYMBOL is used with DANGER,

WARNING or CAUTION which indicates a personal

injury type hazard.

NOTICE is used to highlight especially important

information.

CAUTION used without the safety alert symbol indicates a potentially hazardous situation which, if not

avoided, may result in property damage.

CAUTION used with the safety alert symbol indicates

a potentially hazardous situation which, if not avoided, could result in minor or moderate injury.

WARNING indicates a potentially hazardous situation which, if not avoided, could result in death or

serious injury.

DANGER INDICATES AN IMMINENTLY HAZARDOUS SITUATION WHICH, IF NOT AVOIDED, WILL RESULT IN DEATH OR SERIOUS

INJURY.

1-1Jan. 2013

1-3. TROUBLESHOOTING

Problem Cause Correction

With the switch in the POWER

position, Fryer is completely

inoperative

Shortening will not heat but

lights are on

To isolate a malfunction, proceed as follows:

1. Clearly dene the problem, or symptom and when it

occurs.

2. Locate the problem in the troubleshooting table.

3. Review all possible causes, then one at a time, work

through the list of corrections until the problem is solved.

If maintenance procedures are not followed correctly, injuries and/or property damage could result.

• Open circuit • Check to see if unit is plugged

in

• Check breaker or fuse at supply

box

• Check POWER switch per

Power Switch Section; replace

if defective

• Check voltage at wall

receptacle

• Check cord and plug

• Faulty contactor (elec.

model)

• Faulty temperature probe

• Faulty high limit

• Faulty drain switch

• Check contactor per Heating

Contactors Section

• Check temperature probe

per T emperature Probe

Replacement Section; “E-6”

• Check high limit per the

appropriate High Temperature

Limit Control Section; “E-10”

• Check drain switch per Drain

Microswitch Section; “E-15”

1-2March 2013

1-3. TROUBLESHOOTING

(CONTINUED)

Problem Cause Correction

Heating of shorting too slow

Shorting overheating

Foaming or boiling over of

shortening

• Low or improper voltage

(elec. unit)

• Weak or Burnt out elements

(elect. unit)

• Wire(s) loose

• Burnt or charred wire con-

nection

• Faulty contactor

• Temperature probe needs

calibration

• Bad control board

• Watch in shortening

• Improper or bad shortening

• Improper ltering

• Improper rinsing after

cleaning fryer

• Use a meter and check the

receptacle voltage against the

data plate

• Check heating elements per

Heating Element Section

• Tighten

• Replace wire and clean

Connectors

• Check contactor per Heating

Contactors Section

• Calibrate temperature probe if

± 10° off, replace temperature

probe

• Replace control board if heat

indicator stays on past ready

temperature

• At end of cook cycle, drain

shortening and clean

• Use recommended shortening

• Refer to the Filtering the

Shortening Section in

Operator’s Manual

• Clean and rinse the frypot; then

dry thoroughly

1-3Jan. 2013

1-3. TROUBLESHOOTING

(CONTINUED)

Problem Cause Correction

Shortening will not drain from

frypot

• Drain valve clogged with

crumbs

• Drain valve will not open

by pulling handle

• Open valve, force cleaning

brush through drain

• Replace Drain valve

Filter motor runs but pumps

shortening slowly

Filter switch on but motor does

not run

Motor hums but will not pump

• Pump clogged

• Filter line connection loose

• Solidied shortening in

lines

• Defective switch

• Defective motor

• Motor thermal protector

tripped

• Clogged lines or pump • Remove and clean pump and

• Remove pump cover and

clean

• Tighten all lter line

connections

• Clear all lter lines of

solidied shortening

• Check/replace switch per

Filter Switch Section

• Check/replace motor

• Reset thermal switch on lter

motor

lines

• Replace pump seals, rotor and

rollers

1-4Jan. 2013

1-4. W ARNINGS AND ERROR

MESSAGES

Display Cause Correction

“W-1”

“LOW

VOLTAGE”

“W-2”

“SLOW

HEAT-UP”

“W-3”

“WAS NOT

READY”

“W-4”

“SLOW

COOKING”

“W-5”

“SLOW

COOKING”

“W-6”

“SLOW

COOKING”

“W-7”

LOW AMPS”

“W-9”

“DISCARD

PRODUCT”

“OIL TOO HOT”

In coming supply voltage too low Having voltage at plug and receptacle

Faulty components or connections Have elements, connections, and con-

Product loaded into frypot before

READY light

Too much product in frypot Do not overll frypot

Product loaded into frypot before

READY lights

Faulty components or connections Have elements, connections, and con-

Faulty components or connections Have elements, connections, and con-

Product overcooked. (may appear

after a “SLOW COOKING”

warning)

Didn’t allow shortening to drop to

current product’s setpoint

temperature

The controls monitor procedure problems and system failures

with warnings and error codes. The display shows the

warning or error code, and an alarm sounds.

Pressing cancels most warnings and pressing any

control button stops most error code alarms. But there are

some exceptions (see below). The display shows the error

until the situation is corrected.

WARNINGS

checked

tactors checked

Wait unit shortening is at proper temperature before loading product

Wait unit shortening is at proper temperature before loading product

tactors checked

tactors checked

Discard product immediately

Cancel button stops this

warning; once the shortening drops to

setpoint temperature, the alarm automatically stops.

1-5March 2013

1- 4 . WARNINGS AND

ERROR MESSAGES

(CONTINUED)

DISPLAY CAUSE CORRECTION

“E-1” Low oil in frypot Check oil level in JIB (oil reservoir)

Control board overheating Turn switch to OFF position, then turn switch

“E-4”

“CPU TOO HOT”

back to ON; if display shows “E-4”, the control

board is getting too hot; check the louvers on each

side of the unit for obstructions

“E-5”

“FRYER TOO

HOT”

“E-6A”

“FRYER TEMP

SENSOR”

“E-6B”

“FRYER TEMP

SENSOR”

“E-10”

“HIGH LIMIT

TRIPPED”

Oil overheating Turn switch to OFF position, then turn switch

back to ON; if display shows “E-5”, the heating

circuits and temperature probe should be checked

Temperature probe open Turn switch to OFF position, then turn switch

back to ON;if display shows “E-6A”, the

temperature probe should be checked

Temperature probe shorted Turn switch to OFF position, then turn switch

back to ON; if display shows “E-6B”, the

temperaturechecked

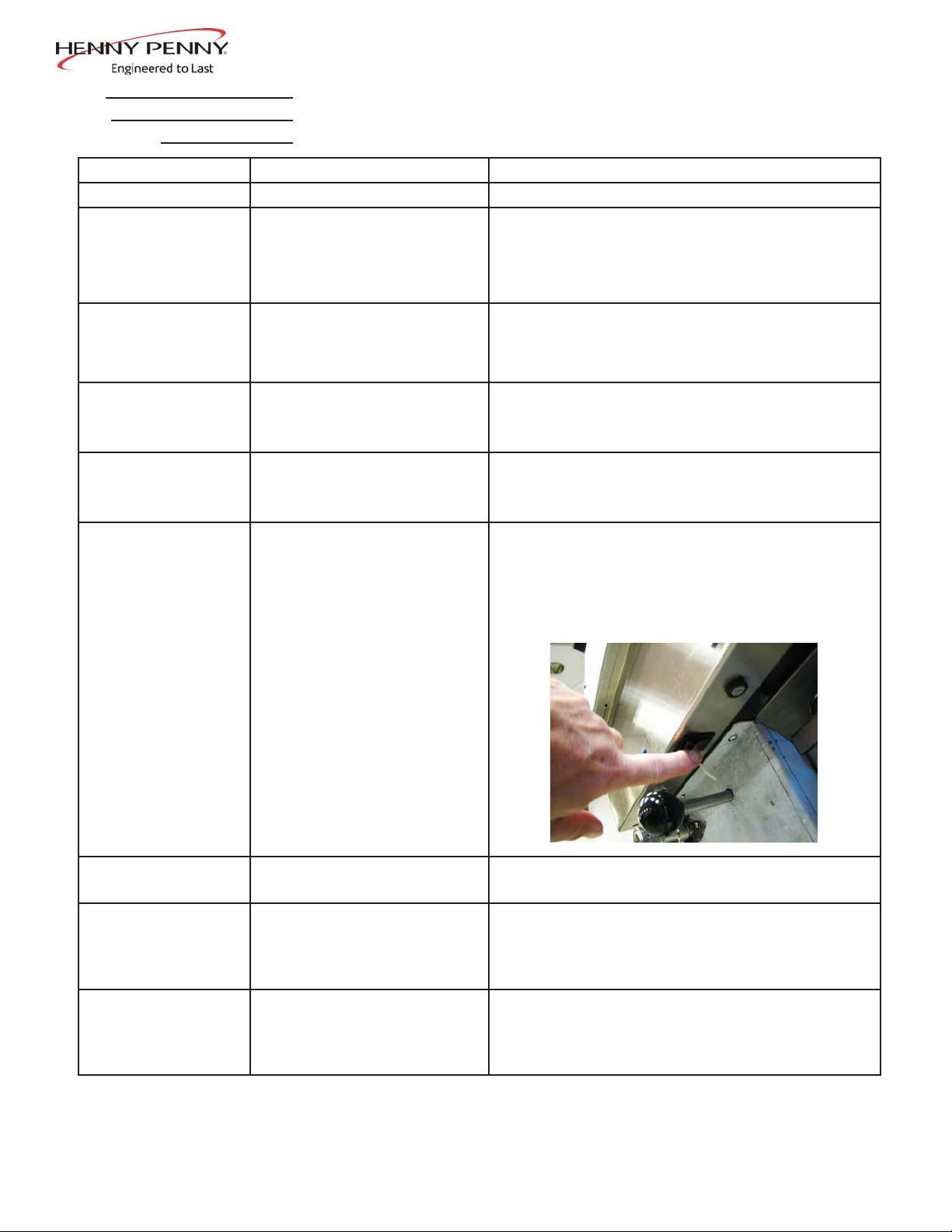

High limit Allow heating elements to cool (15-20 minutes) and

reset high limit by pressing down and releasing raised

side of the switch for the vat that is not operating;

switches are located just to the right of the drain knob;

if high limit does not reset, high limit must be replaced

“E-15”

“DRAIN IS OPEN”

“E-18”

“LEVEL SENSOR

FAILED’

“E-19”

“PROTECTION

SENSOR FAILED”

Drain switch Make sure drain knob is completely pushed-in; if

E-15 persists, have drain switch checked

Level sensor open Turn switch to OFF position and then back to ON;

if display still indicates a failed sensor, have the

connections checked on the control board; have sensor

checked & replaced if necessory

Frypot protection sensor open Turn switch to OFF position and then back to ON;

if display still indicates a failed sensor, have the

connections checked on the control board; have sensor

checked & replaced if necessory

1-6Jan. 2013

1- 4 . WARNINGS AND

ERROR MESSAGES

(CONTINUED)

DISPLAY CAUSE CORRECTION

“E-25”

“HEA T AMPS TOO

HIGH”

“E-26”

“HEA T AMPS ARE

LOCKED ON”

“E-27”

“AMPS TOO LOW”

“E-28”

“AMP SENSORS

NOT DETECTED”

Wrong or faulty elements or

wiring problem

Faulty contactors or PCB Have the contactors and PC board checked

• Wrong SP-12 “Nominal

Amps Rdg” setting

• Defective contactor

• Wrong wattage or wrong

voltage heating element(s)

installed

• Fryer voltage excessively

low

The AMP sensors are not

detected by the control.

Have electrical supply, wiring, and elements checked

Because of the seriousness of this error code, turn the

POWER switch off and back on to cancel

This error code could be displayed even with the

POWER switch turned off. Unplug fryer or shut-off

the wall circuit breaker to disconnect electrical power

to fryer.

• The Min and Max amps limits are set as

percentages below and above the programmed

“Nominal Amps Reading” (Special Program

parameter SP-12). The Nominal, Min, and Max

amps limits can be viewed in Info Mode. (See the

E-25 error above for details.)

• Replace contacter

• Replace heating element

• Call electrician

1. Check that amp sensors are securely plugged into

the rear of the control board. If error still occurs,

proceed to step 2.

2. Check to see if the ohm value of each sensor is

within +/- 10% of 34 Ohms. If ohm value is not

within this range, proceed to step 3. If ohm value

is within range, proceed to step 4.

3. Replace amp sensors

4. Replace control board

1-7Sept. 2016

1- 4 . WARNINGS AND

ERROR MESSAGES

(CONTINUED)

DISPLAY CAUSE CORRECTION

“E-29”

“SHUNT BREAKER

HAS TRIPPED”

“E-41”

“PROGRAMMED

SETTINGS LOST”

• Amp draw detected on the

amp sensor input when there

is no call for heat (heat light

off).

• Control activates the shunt

trip circuit with 24V AC on

wires SH1 and SH2

• Breaker trips and will

require a manual reset.

(disconnect power – Drop

control – reset breaker)

• E-29 Error on Display

• Voltage spikes or dropouts

• Failure of backup capacitor

on CPU board

• Check the heat contactor for sticking and replace if

defective

• See instructions for resetting the breaker

• If an E-29 occurs, check amp sensors and replace

if out of range

• If still E-29, replace control

1. Turn off fryer, wait 15 seconds, turn on fryer. If

error still occurs, proceed to step 2.

2. Replace control

“E-46”

“EPROM MEMORY

WRITE ERROR”

“E-47”

“A-to-D FAILURE”

“E-48”

“INPUT SYSTEM

ERROR”

“E-60”

“AIF COMM

FAILED”

“E-75”

“HEAT RELAY

NEAR END OF

LIFE”

• Faulty EPROM on CPU

board

• Other faults or

contamination on CPU

board

• 12-volt supply failed on I/O

board

• Analog 5v supply bad

• A-to-D chip bad

• Defective component on the

control board

• AIF board has failed

• The wiring from the control

to the AIF board has become

disconnected

• In a two well unit the left vat

power is off

The secondary contactor has

reached the 90% of life mark.

Replace the control board.

Replace the control board.

Replace the control board

Press power button to turn vat off, wait 15 seconds,

and turn back on again. If “E-60” persists:

• Have connector between the PCB’s checked

• Replace AIF PCB or control PCB board if

necessary

Replace the contactor and reset the counter in Tech

Mode step T -23.

1-8Sept. 2016

SECTION 2. INFORMATION MODE

This historic information can be recorded and used for

operational and technical help and allows you to view the

following:

• 11. INPUT INFO

• 1. E-LOG

• 2. P-LOG

• 3. HEAT UPS

• 4. LEFT COOK DATA

• 5. RIGHT COOK DATA

• 6. TODAY’S DATA

• 7. PREV DAY - SUN

• 8. 7-DAY TOTALS

• 9. OIL DATA

• 10. PREV OIL DATA

Not all Information Mode functions are discussed in this

section. To ensure proper operation of fryer, please consult

Henny Penny Corp. before changing any of these settings.

For more information on these functions, contact Technical

Support at 1-800-417- 8405, or 1-937-456-8405.

• 12. OUTPUT INFO

• 13. POT TMP

• 14. LVL TMP

• 15. PRO TMP

• 16. SSR TMP

• 17. CPU TMP

• 18. ANALOG INFO

• 19. AC VOL TS

• 20. AMPS INFO

2-1. INFORMATION MODE

DETAILS

1. E-LOG (error code log)

Press and buttons at the same time and “*INFO

MODE*” shows in the display, followed by “1. E-LOG”.

Press and to exit Information Mode at any time.

Press and “A. (date & time) *NOW* show in displays.

This is the present date and time.

Press and if an error was recorded, “B. (date, time, and

error code information)” shows in display. This is the latest

error code that the controls recorded. Sometimes the characters

“L:” and “R:” appear in front of the error code on the display

which refers to the left or right vat of a split vat.

Press and the next latest error code information is seen.

Up to 10 error codes (B to K) can be stored in the E-LOG

section.

Press to continue to P-Log.

2-1Jan. 2013

2-1. INFORMATION MODE

DETAILS (Continued)

2. P-LOG (power-up log)

Press and “2A. (date & time) *NOW* shows in

display. This is the present date and time.

Press and the latest power-up is shown, “2B. (date,

time,) PWR-UP”.

Press and the next latest power-up date is shown. Up

to 10 power-ups (2B to 2K) can be stored in P-LOG section.

Press to continue onto the heat-up log.

3. HEAT-UP’S

Press and “3A. (date & time) *NOW* shows in

display. This is the present date and time.

Press and the latest heat-up is shown, along with the

heat-up rate, ex: “3B. MAY-22, 8:37A 1.25”. The heat rate

is the maximum rate (degrees/second) the controller recorded

during the shown time frame.

Press and the next latest heat-up is shown. Up to 10

heat-ups (3B to 3K) can be stored in the Heat-Up Log.

Press to continue onto the COOK DATA.

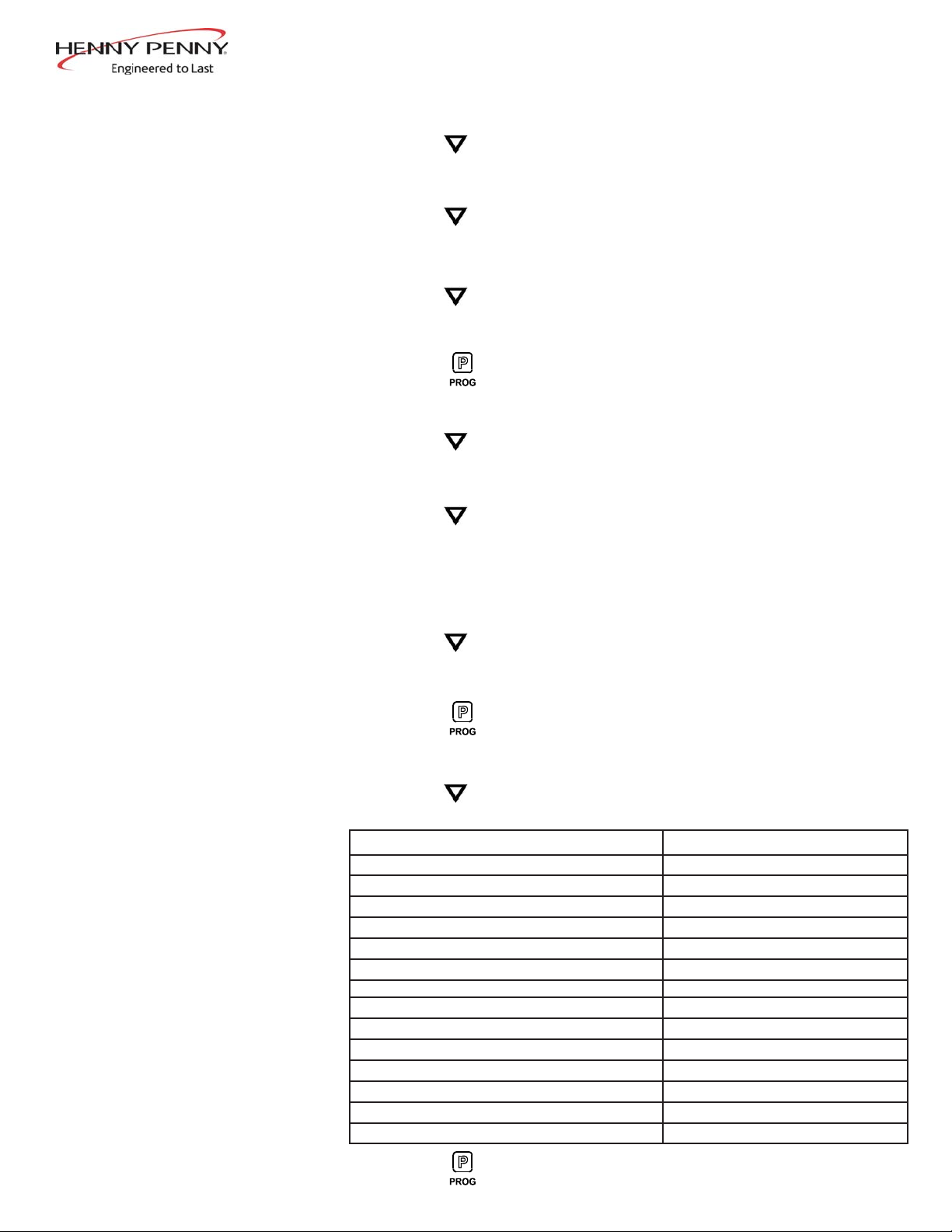

4. LEFT COOK DATA

Press to step through the following data:

FUNCTION DISPLAY EXAMPLE

Time of last Cook Cycle started 4A. STARTED 10.25A

Product (last product cooked) 4B. PRODUCT -1Ready? (fryer ready before start?) 4C. READY? YES

Drop detect status 4D. DETECT X NO

Drop adjust (real time seconds) 4E. DROP ADJ T-14

Cook time adj (clock adjust) 4F. CK TM ADJ -13

Actual elapsed cook time (seconds) 4G. ACT TIME 2:23

Stopped: Time remaining, or secs past done 4H. STOP DONE+1

“Slow cook” for this cycle? 4I. SLOW? NO

Overloaded? (Bad batch) 4J. OVRLD? NO

Avg Temp during Cook Cycle 4K. AVG TMP 343°F

Max voltage during Cook Cycle 4L. MAX VOLT 99%

Min voltage during Cook Cycle 4M. MIN VOLT 97%

Max amps during Cook Cycle 4N. MAX AMPS 33

Min amps during Cook Cycle 4O. MIN AMPS 33

Press to continue onto the RIGHT COOK DATA.

2-2Jan. 2013

2-1. INFORMATION MODE

DETAILS (Continued)

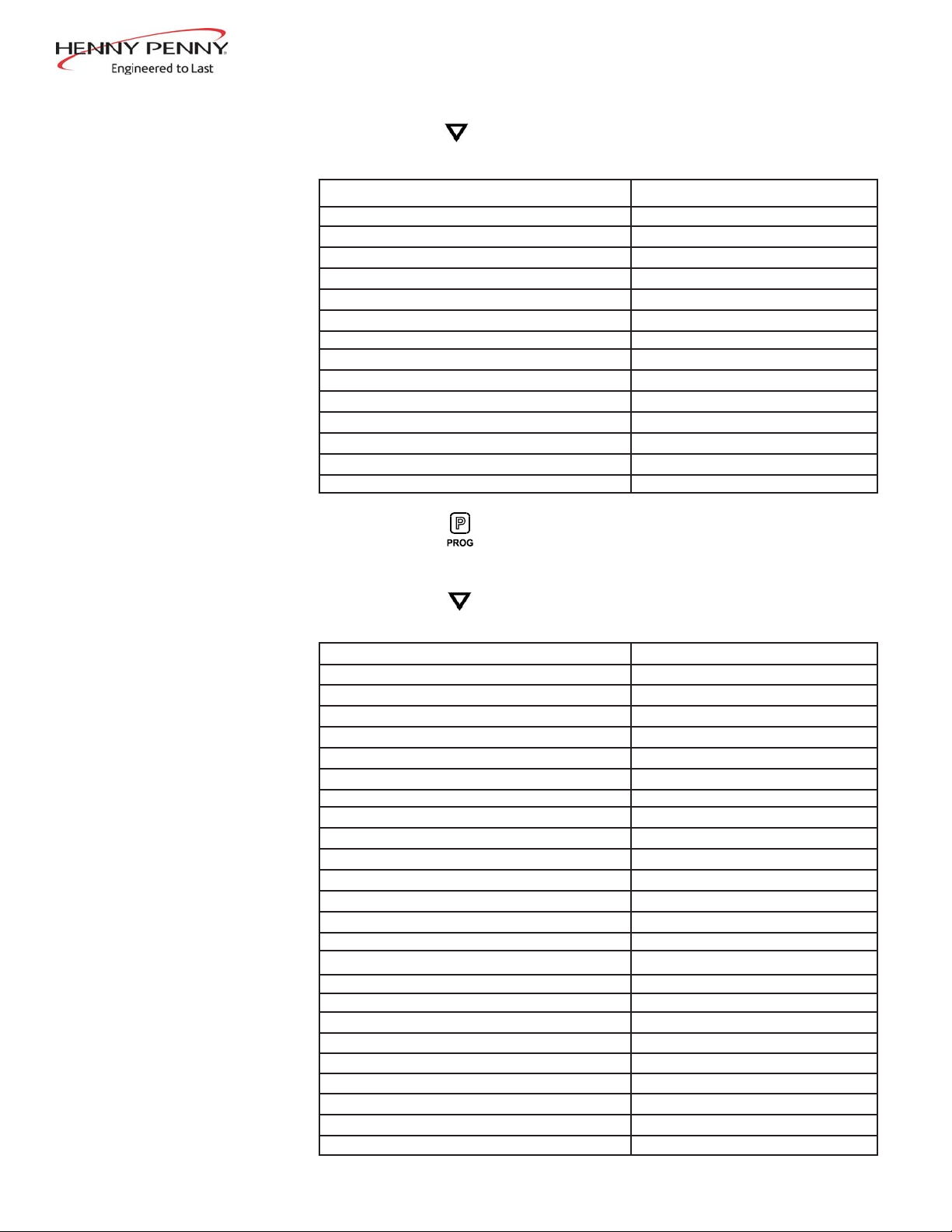

5. RIGHT COOK DATA

Press button to start viewing the cook data.

FUNCTION DISPLAY EXAMPLE

Time of last Cook Cycle started 5A. STARTED 10.25A

Product (last product cooked) 5B. PRODUCT -1Ready? (fryer ready before start?) 5C. READY? YES

Drop detect status 5D. DETECT X NO

Drop adjust (real time seconds) 5E. DROP ADJ T-10

Cook time adj (clock adjust) 5F. CK TM ADJ -13

Actual elapsed cook time (seconds) 5G. ACT TIME 2:23

Stopped: Time remaining, or secs past done 5H. STOP DONE+1

“Slow cook” for this cycle? 5I. SLOW? NO

Overloaded? (Bad batch) 5J. OVRLD? NO

Avg Temp during Cook Cycle 5K. AVG TMP 343°F

Max voltage during Cook Cycle 5L. MAX VOLT 99%

Min voltage during Cook Cycle 5M. MIN VOLT 97%

Max amps during Cook Cycle 5N. MAX AMPS 33

Min amps during Cook Cycle 5O. MIN AMPS 33

Press to continue onto the TODAYS DATA.

6. TODAY’S DATA (automatically resets each day)

Press to step through the following data:

FUNCTION DISPLAY EXAMPLE

Today’s Date 6A. DATE APR-12

Time of day last heat-up was completed 6B.LAST HEAT 9:45A

Peak heat-up rate(°F/Sec)for last heat-up 6C. LAST RATE 0.82

Was last heat-up acceptable? 6D. LAST OK? YES

Heat Cap. status (based on last 4 ht-ups) 6E.HEAT CAP GOOD

Number of monitored heat-ups today 6F. HEAT-UPS 2

Number of slow heat-ups 6G. SLOW HT’S 0

Max time to heat 270°F to 310°F today 6H. MAX HT TM 1:17

Lowest “peak rate” for today’s heat-ups 6I. MIN RATE 0.82

Maximum voltage today (when fryer on) 6J. MAX VOLT 99%

Minimum voltage today (when fryer on) 6K. MIN VOLT 95%

No.of “low voltage” warnings generated 6L. LO VOLT’S 0

Maximum amp draw today 6M. MAX AMPS 35

Minimum amp draw today 6N. MIN AMPS 33

Number of “low amps” warnings today 6O. LO AMP’S 0

Non-cooking time (hh:mm) fryer was on 6P. IDLE HRS 1:23

Oil Wear accumulated so far today 6Q. OIL WEAR 3

Total number of Cook Cycles today 6R. TOT CK’S 11

Number of cycles started before Ready 6S. NOT RDY’S 2

No. cycles quit early, 0:11 or more rem. 6T. QUIT 11+ 0

No. cycles beeped *DONE *21 sec or more 6U. DONE 21+ 1

Individual product cook counts 6V. Px CK CT 2

Individual product “not detected” counts 6W. Px NO DET 0

Individual product “slow cook” counts 6X. Px SLO CT 0

Ind. product “frozen or overloaded” 6Y. Px FRZ/OV 0

(During steps 6V through 6Y, press the product buttons (or Manual Prog) to see data on

individual product items)

2-3Jan. 2013

2-1. INFORMATION MODE

DETAILS (Continued)

Day this data was recorded for 7A. DATE APR-8

Time of day last heat-up was completed 7B. LAST HEAT 8:15P

Peak heat-up rate (°F/Sec) - last heat-up 7C. LAST RATE 0.88

Was that day’s last heat-up acceptable? 7D. LAST OK? YES

Heat cap. status (based on last 4 ht-ups) 7E. HEAT CAP GOOD

Number of monitored heat-ups that day 7F. HEAT-UPS 7

Number of slow heat-ups 7G. SLOW HT’S 0

Max heat time 270°F to 310°F that day 7H. MAX HT TM 1:11

Lowest “peak rate” - that day’s heat-ups 7I. MIN RATE 0.67

Max voltage that day (when fryer on) 7J. MAX VOLT 102%

Min voltage that day (when fryer on) 7K. MIN VOLT 98%

No. of “low voltage” warnings generated 7L. LO VOLT’S 0

Maximum amp draw that day 7M. MAX AMPS 35

Minimum amp draw that day 7N. MIN AMPS 34

No. of “low amps” warnings that day 7O. LO AMP’S 0

Non-cooking time (hh:mm) fryer was on 7P. IDLE HRS 7:09

Oil wear accumulated that day 7Q. OIL WEAR 39

Total number of Cook Cycles that day 7R. TOT CK’S 18

Number of cycles started before ready 7S. NOT RDY’S 2

No. cycles quit early, (0:11 or more remaining) 7T. QUIT 11+ 1

No. cycles beeped *DONE* 21 sec or more 7U. DONE 21+ 3

Individual product cook counts 7V. Px CK CT 12

Individual product “not detected” counts 7W. Px NO DET 1

Individual product “slow cook” counts 7X. Px SLO CT 0

Individual product “frozen or overloaded” 7Y. Px FRZ/OV 1

Press to continue onto PREV-DAY-SUN log.

7. PREV DAY - SUN

Press to step through the following data. During each

step, press to choose the day of the week, of the past 7

days.

FUNCTION DISPLAY EXAMPLE

(During steps 7V through 7Y, press the product buttons (or Manual Prog) to see data on

individual product items.)

Press to continue onto 7-DAY TOTALS log.

2-4Jan. 2013

2-1. INFORMATION MODE

DETAILS (Continued)

Oldest day in the “previous days” history 8A. SINCE APR-5

Number of days with data included in totals 8B. DAYS CNT 6

Number of monitored heat-ups 8C. HEAT-UPS 30

Number of slow heat-ups 8D. SLOW HT’S 1

Max time to heat 270°F to 310°F 8E. MAX HT TM 3:25

Lowest “peak rate” of all heat-ups 8F. MIN RATE 0.47

Maximum voltage 8G. MAX VOLT 102%

Minimum voltage 8H. MIN VOLT 91%

No. of “low voltage” warnings generated 8I. LO VOLT’S 0

Maximum amp draw 8J. MAX AMPS 35

Minimum amp draw 8K. MIN AMPS 32

Number of “low amps” warnings 8L. LO AMP’S 0

Non-cooking time (hrs) while fryer was on 8M. IDLE HRS 43

Total oil wear accumulated 8N. TOT WEAR 278

Total number of Cook Cycles 8O. TOT CK’S 125

Number of cycles started before ready 8P. NOT RDY’S 7

No. cycles quit early, (0:11 or more remaining) 8Q. QUIT 11+ 1

No. cycles beeped *DONE* 21 sec or more 8R. DONE 21+ 3

Individual product cook counts 8S. Px CK CT 77

Individual product “not detected” counts 8T. Px NO DET 3

Individual product “slow cook” counts 8U. Px SLO CT 0

Individual product “frozen or overloaded” 8V. Px FRZ/OV 1

8. 7-DA Y TOTALS

Press to step through the following data:

FUNCTION DISPLAY EXAMPLE

(During steps 8S through 8V, press the product buttons (or Manual Prog) to see data on individual

product items.)

Press to continue onto OIL DATA log.

2-5Jan. 2013

Loading...

Loading...