Page 1

Henny Penny

CFA Pressure Fryer

Electric Model 500

Gas Model 600

TECHNICAL MANUAL

Page 2

Page 3

Model 500/600

This manual should be retained in a convenient location for future reference.

A wiring diagram for this appliance is located on the rear shroud cover of the control panel.

Post in a prominent location, instructions to be followed if user smells gas. This information

should be obtained by consulting the local gas supplier.

The Model 600 Fryer is equipped with a continuous pilot. But Fryer cannot be operated with out electric power. Fryer will automatically return to normal operation when power is restored.

Do not obstruct the fl ow of combustion and ventilation air. Adequate clearance must be left all

around appliance for suffi cient air to the combustion chamber.

To avoid a fi re, keep appliance area free and clear from combustibles.

Improper installation, adjustment, alteration, service or maintenance can cause property

damage, injury or death. Read the installation, operating and maintenance

instructions thoroughly before installing or servicing this equipment.

DO NOT STORE OR USE GASOLINE OR OTHER FLAMMABLE VAPORS

AND LIQUIDS IN THE VICINITY OF THIS OR ANY OTHER APPLIANCE. FIRE OR

EXPLOSION COULD RESULT.

FM06-003

Revised 7-28-10

710

Page 4

Model 500/600

TABLE OF CONTENTS

Section Page

Section 1. TROUBLESHOOTING ............................................................................................... 1-1

1-1. Introduction ........................................................................................................ 1-1

1-2. Safety .................................................................................................................. 1-1

1-3. Troubleshooting .................................................................................................. 1-2

1-4. Warnings and Error Messages ............................................................................ 1-13

1-5. Diagnostic Mode Details .................................................................................... 1-16

1-6. Information Mode Details .................................................................................. 1-32

Section 2. MAINTENANCE ......................................................................................................... 2-1

2-1. Introduction ........................................................................................................ 2-1

2-2. Maintenance Hints .............................................................................................. 2-1

2-3. Preventive Maintenance Schedule ...................................................................... 2-2

2-4. Removing the Control Panel ............................................................................... 2-2

2-5. Transformer Replacement .................................................................................. 2-3

2-6. Temperature Probe Replacement ........................................................................ 2-4

2-7. High Temperature Limit Control (Electric and Gas Models) ............................. 2-6

2-8. Heating Elements (Electric Models) ................................................................... 2-9

2-9. Heating Contactors (Electric Models) ................................................................ 2-12

2-10. Gas Burner Assembly (Gas Models) .................................................................. 2-15

2-11. Thermocouple (Gas Models) .............................................................................. 2-18

2-12. Gas Control Valve ............................................................................................... 2-20

2-13. Electrical Components ........................................................................................ 2-23

2-14. Pressure Regulation/Exhaust .............................................................................. 2-27

2-15. Filtering System .................................................................................................. 2-47

2-16. Gas Conversion ................................................................................................... 2-52

Wiring Diagrams ................................................................................................ 2-53

Section 3. PARTS INFORMATION .............................................................................................. 3-1

3-1. Introduction ........................................................................................................ 3-1

3-2. Genuine Parts ...................................................................................................... 3-1

3-3. Model Variations ................................................................................................. 3-1

3-4. How to Find Parts ............................................................................................... 3-1

3-5. Subassemblies ..................................................................................................... 3-2

3-6. How to Order Parts ............................................................................................. 3-2

3-7. Prices .................................................................................................................. 3-3

3-8. Delivery .............................................................................................................. 3-3

3-9. Warranty ............................................................................................................. 3-3

3-10. Recommended Spare Parts for Distributors ....................................................... 3-3

3-11. Index of Parts List Illustrations .......................................................................... 3-4

i 206

Page 5

Model 500/600

SECTION 1. TROUBLESHOOTING

1-1. INTRODUCTION

This section provides troubleshooting information in the form of

an easy to read table.

If a problem occurs during the fi rst operation of a new fryer, re-

check the installation per Section 2 of the Operator’s Manual.

Before troubleshooting, always recheck the operating procedure

per Section 3 of the Operator’s Manual.

1-2. SAFETY

The Henny Penny Pressure Fryer has many safety features incor porated. However, the only way to ensure a safe operation is to

fully understand e proper installation, operation, and maintenance

procedures. The instructions in this manual have been prepared to

aid you in learning the proper procedures. Where information is

of particuloar importance or safety related, the words DANGER,

WARNING, CAUTION, and NOTICE are used. Their usage is

described below.

SAFETY ALERT SYMBOL is used with DANGER,

WARNING, or CAUTION which indicates a personal

injury type hazard.

NOTICE is used to highlight especially important

information.

CAUTION used without the safety alert symbol indicates

a potentially hazardous situation which, if not avoided,

may result in property damage.

CAUTION indicates a potentially hazardous situation

which, if not avoided, may result in minor or moderate

injury.

WARNING indicates a potentially hazardous situation

which, if not avoided, could result in death or serious

injury.

DANGER INDICATES AN IMMINENTLY

HAZARDOUS SITUATION WHICH, IF NOT

AVOIDED, WILL RESULT IN DEATH OR

SERIOUS INJURY.

305 1-1

Page 6

Model 500/600

1-3. TROUBLESHOOTING

To isolate a malfunction, proceed as follows:

1. Clearly defi ne the problem (or symptom) and when it occurs.

2. Locate the problem in the troubleshooting table.

3. Review all possible causes. Then, one-at-a-time work

through the list of corrections until the problem is solved.

Refer to the maintenance procedures in Section 2 of

this manual to safely and properly make the checkout

and repair needed. If maintenance procedures are not

followed correctly, injuries and/or property damage

could result.

1-2 305

Page 7

Model 500/600

Problem Cause Correction

COOKING SECTION

Product Color Not Correct:

A. Too Dark (some batches) • Temperature programmed too hot • See Diagnostic Mode D 10;

if temperature settings have

been changed, have the controls

reintialized

in advance

• Done alarm ignored for more • If the fryer hasn’t been used

than 20 seconds since the problem batch, see

Information Mode 4 H;

for more information on

this problem, see Information

Modes 5 U, 6 U, 7 R, or 8 R

• Wrong product button pressed • Be sure to press the correct

product button; if the fryer

hasn’t been used since the

problem batch, see Information

Mode 4 B to see what product

button was pressed

B. Too Dark (all batches)

calibration to adjust color of product

bration; see Checking Tempera ture Probe Calibration Section;

if less than 15 degrees off, have

probe calibrated; if more than

15 degrees off, replace probe

• Breading product too far • Bread product just before frying

• Temperature probe out of • See Diagnostic Mode D 1

• Check temperature probe cali-

burnt taste, change peanut oil

• See Diagnostic Mode D 2;

Change peanut oil if controls

indicate it should be changed

• Peanut oil too old • If peanut oil is smoking or has

• Peanut oil too dark • Filter peanut oil

• Change peanut oil

• Faulty probe “E6” • If probe can’t be recalibrated,

have probe replaced

305 1-3

Page 8

Model 500/600

Problem Cause Correction

COOKING SECTION (Continued)

C. Too Light (all batches) • Temperature probe out of • See Diagnostic Mode D 1

calibration to adjust color of product

• Check temperature probe cali-

bration; see Checking Tempera ture Probe Calibration Section;

if less than 15 degrees off, have

probe calibrated; if more than

15 degrees off, replace probe

• Slow fryer heat-up/recovery • See Diagnostic Mode D 4

for present day’s performance;

or see Information Modes 5, 6,

7, 8, and 9 for more information

on this problem

• Low voltage; see Diagnostic

Mode D 3 for present day’s

voltage performance; see

Information Modes 4, 5, 6, 7, 8,

9, and 15 for more information

on this problem

• Low gas pressure; have gas

pressure checked going to

burners, on gas fryers

• Oil usage wasn’t set for new • See Diagnostic Mode D 2 for

peanut oil the age of the oil; see section

3-7 for setting the age of the oil

D. Too Light (some batches) •Temperature programmed too low • See Diagnostic Mode D 10;

if temperature settings have

been changed, without authori zation, have the controls

reintialized

• Product placed in peanut oil • If fryer hasn’t been used since

before proper temperature the problem batch, see Informa tion Mode 4 C; for more

information on this see Informa tion Modes 5 S, 6 S, 7 P, or 8 P

• Wrong product button pushed • If fryer hasn’t been used since

problem batch, see Information

Mode 4 B to see what product

was selected

1-4 305

Page 9

Model 500/600

Problem Cause Correction

COOKING SECTION (Continued)

D. Too Light (some batches) • Cook Cycle aborted before alarm • See Diagnostic Mode D 7

(Continued) and “DONE” fl ashes to see how many times

the Cook Cycle was stopped

before the end of the cycle

peanut oil see Diagnostic Mode D 5

to see if the controls sensed any

frozen or overloaded batches

Dryness of Product

• Cover product with plastic

wrap, reducing evaporation

• Over-cooking the product • Done alarm ignored for more

than 20 seconds; if the fryer

hasn’t been used since the

problem batch, see Information

Mode 4 H; for more informa tion on this problem, see Infor mation Modes 5 U, 6 U, 7R, or

8 R

• Time of Cook Cycle set too long • See Diagnostic Mode D 10;

if time settings have been

changed, have the controls

reintialized

• Frozen product placed in • Use fresh or thawed product;

• Moisture loss prior to cooking • Use fresh product

problem batch, see Information

Mode 4 B to see what product

was selected

• Low operating pressure • Check pressure gauge reading

Check for pressure leaks

Burned Taste • Burned peanut oil fl avor • Replace peanut oil

• Peanut oil needs fi ltering • Filter peanut oil more often

• Frypot not properly cleaned • Drain and clean frypot

305 1-5

• Wrong product button pushed • If fryer hasn’t been used since

Page 10

Model 500/600

Problem Cause Correction

COOKING SECTION (Continued)

Product not done • Cook Cycle aborted before alarm, • See Diagnostic Mode D 7

and “DONE” fl ashes to see how many times

the Cook Cycle was stopped

before the end of the cycle

• Frozen product placed in • Use fresh or thawed product;

peanut oil see Diagnostic Mode D 5

to see if the controls sensed

frozen or overloaded batches.

• Wrong product button pushed • If fryer hasn’t been used since

problem batch, see Information

Mode 4 B to see what product

was selected

• Temperature programmed too low • See Diagnostic Mode D 10;

or not programmed properly if temperature settings have

been changed, have the controls

reintialized

• Temperature probe out of • Check temperature probe cali calibration bration; see Checking Tempera ture Probe Calibration Section;

a. If less than 5° off, see

Diagnostic Mode D 1

b. If between 5 and 15 degrees

off, calibrate probe; if more

than 15° off, replace probe

• Slow fryer heat-up/recovery • See Diagnostic Mode D 4 for

present day’s performance; or

see Information Modes 5, 6, 7,

8, and 9 for more information

on this problem

• Low voltage; see Diagnostic

Mode D 3 for present day’s

voltage performance; see

Information Modes 4, 5, 6, 7, 8,

9, and 15 for more information

on this problem

• Low gas pressure; have gas

pressure checked going to

burners, on gas fryers

• Product too thick • Make sure chicken fi lets have

been fi leted

1-6 305

Page 11

Model 500/600

Problem Cause Correction

POWER SECTION

With COOK/PUMP Switch • Open circuit • Check to see if fryer is plugged

in COOK position, fryer is in

completely without power

fuse

cian check power supply and

COOK/PUMP switch

• Check wall circuit breaker or

• Have a qualifi ed service techni-

PRESSURE SECTION

Pressure will not • Exhaust line from solenoid • Turn unit off and allow fryer to

exhaust at end of valve to exhaust tank cool to release pressure from

cooking cycle. clogged frypot; have all pressure lines,

exhaust stacks, and exhaust

tank cleaned

cleaned

Operating pressure too high

cool to release pressure from

frypot; remove deadweight and

clean, per Cleaning the Dead-

weight Valve Section.

• Solenoid valve clogged • Have solenoid checked and

• Deadweight clogged • Turn unit off and allow fryer to

DO NOT OPERATE UNIT IF PRESSURE GAUGE SHOWS HIGH PRESSURE CONDITIONS.

SEVERE INJURIES AND BURNS WILL RESULT. IMMEDIATELY PLACE THE POWER/

PUMP SWITCH IN THE OFF POSITION, WHICH RELEASES THE PRESSURE BY ALLOW ING THE UNIT TO COOL. DO NOT RESUME USE OF UNIT UNTIL CAUSE OF HIGH

PRESSURE HAS BEEN FOUND AND CORRECTED.

305 1-7

• Exhaust line to stack clogged • Clean exhaust line to stack

Page 12

Model 500/600

Problem Cause Correction

PRESSURE SECTION (Continued)

Pressure does not • Not enough product in fryer • Place proper quantity of

build or product not fresh fresh product within frypot to

generate steam

removed from deadweight see Unpacking Section

• Metal shipping spacer not • Remove shipping spacer;

not closing cleaned

repaired

if pressure settings have been

changed, have the controls

reintialized

adjusted

• Lid open or not latched • Close and latch lid

• Solenoid valve leaking or • Have solenoid valve checked or

• Deadweight assembly leaking • Have deadweight assembly

• Pressure not programmed • See Diagnostic Mode D 10;

• Lid gasket leaking • Reverse gasket or lid needs

• Safety relief valve leaking. • Check and replace if necessary

FILTER SYSTEM SECTION

Filter motor runs • Pump clogged • Have pump cleaned

but pumps peanut oil

slowly • Filter line connection • Tighten all fi lter line

loose connections

• Solidifi ed peanut oil • Clear all fi lter lines of

solidifi ed peanut oil

Filter switch on, • Defective COOK/PUMP switch • Have switch checked

motor does not run

• Defective motor • Have motor checked

• Motor thermal protector tripped • Reset thermal protector

per Filter Pump Motor

Thermal Protector Section

1-8 305

Page 13

Model 500/600

Problem Cause Correction

FILTER SYSTEM SECTION (Continued)

Motor hums but • Clogged lines or pump • Have pump and lines

will not pump removed and cleaned

• Have pump seal, rotor

and rollers replaced

HEATING OF PEANUT OIL SECTION

Peanut oil will not heat • Blown fuse or tripped circuit • Reset breaker or replace fuse

breaker

• Faulty cord and plug • Check cord and plug

• Faulty PC board • Have control panel checked

• Faulty or tripped high • Reset high limit per Operat

limit “E10” ing Components Section; if

high limit doesn’t reset, have

it checked

• Drain valve open “E15” • Close drain valve

• Possible faulty probe “E6” • Have temperature probe

checked

• Possible faulty contactor • See Diagnostic Modes D 4;

(electric models) see if “CHECK COILS,

CONTACTORS AND

WIRING” shows on display

• Gas valve knob turned to the • Make sure the gas valve knob

OFF position (gas models) is turned to ON

• Faulty thermocouple on gas • Have thermocouple checked

control valve (gas models)

• Faulty COOK/PUMP switch • See Information Mode10

• Faulty drain switch “E15” and check to see if the

• Possible faulty gas control input code is present; if not,

have fryer checked by a

certifi ed service technician

• Pilot not lit (gas models)

• Light pilot per Gas Pilot Lighting

Procedure section in Operator’s

Manual

305 1-9

Page 14

Model 500/600

Problem Cause Correction

HEATING OF PEANUT OIL SECTION (Continued)

Peanut oil heating slowly • Low or improper amps • See Infomation Mode 16

for present amperage; or

see Information Modes 4, 5, 6,

7, 8, 9, for more information

on this problem; Diagnostic

Mode D 4 gives present day’s

heating performance

• Low or improper voltage • See Diagnostic Modes D 3 &

D 4 for present day’s voltage

and heating performance; or

see Information Modes 4, 5, 6,

7, 8, 9, and 15 for more infor mation on this problem

• Weak or burnt out • See Diagnostic Modes D 4;

elements (elec. model) see if “CHECK

COILS, CONTACTORS

• Burnt or charred connectors AND WIRING” shows on

display; if so, have fryer

• Faulty contactor (electric models) checked by a certifi ed service

technician

• Wire(s) loose • Have wires tightened

• Supply line too small - low • Increase supply line size;

gas volume (gas models) refer to installation

instructions

• Improper ventilation • Refer to installation

system (gas models) instructions

1-10 305

Page 15

Model 500/600

1-3. TROUBLESHOOTING (Continued)

PROBLEM CAUSE CORRECTION

PEANUT OIL DRAINING

Peanut oil will not

drain from frypot

(all models)

Gasket coming out

of lid liner

Lid spindle will not

turn or turns hard

with lid open

• Drain valve clogged with crumbs • Open valve - force cleaning

brush through drain opening

• Drain valve will not open by

turning handle

• Replace cotter pins in valve

coupling

LID SECTION

• Crumbs under gasket

• Remove gasket and clean per

Pressure Regulation/Exhaust section

• Clean top rim of frypot

• Replace worn or damaged

gasket per Pressure Regulation/Exhaust

section

• Spindle dry • Lubricate spindle per Pressure Regula tion/Exhaust section

• Worn acme nut • Replace acme nut per Pressure Regula tion/Exhaust section

305 1-11

Page 16

Model 500/600

1-3. TROUBLESHOOTING (Continued)

PROBLEM CAUSE CORRECTION

LID SECTION (Continued)

Lid will not unlatch

from closed position

• Lid gasket not seated properly

or idle nut not adjusted

• To check the problem, perform

the following procedures:

1. Remove pressure from frypot.

2. Turn main switch to off

position.

3. Drain shortening from frypot.

The next procedure must be

performed while holding the

lid closed until the lid latch is

free from the crossarm. Failure

to hold down the lid will result

in the lid springing back to a

full open position. Personal injury,

or damage to the hinge may result.

4. Remove Tru-Arc ring. Drive

latch pin out. Lid will open.

5. Raise lid slowly.

6. Reinstall latch.

7. Adjust limit stop, per Pressure

Regulation/Exhaust section.

8. Lid gasket should be properly

seated in lid liner.

1-12 305

Page 17

Model 500/600

1-4. WARNINGS AND

ERROR MESSAGES

The controls monitor procedure problems and system failures with warnings and error codes. The display shows the warning or error code, and

an alarm sounds.

Pressing cancels most warnings and pressing any control button

stops most Error Code alarms. But there are some exceptions (see below). The display shows the error until the situation is corrected.

WARNINGS

DISPLAY CAUSE CORRECTION

“W-1” “LOW Incoming supply voltage too low Have voltage at plug and receptacle checked

VOLTAGE”

“W-2” Faulty components or connections Have elements, connections, and contactors

“SLOW checked

HEAT-UP”

“W-3” Product loaded into frypot Wait until peanut oil is at proper temperature

“WAS NOT before lights before loading product

READY”

“W-4” Frozen or too much product Do not overfi

“SLOW in frypot into the frypot

COOKING”

“W-5” Product loaded into frypot Wait until peanut oil is at proper temperature

“SLOW before lights before loading product.

COOKING”

“W-6” Faulty components or connections Have elements, connections, and contactors

“SLOW checked

COOKING”

“W-7” Faulty components or connections Have elements, connections, and contactors

“LOW AMPS” checked

“W-9” Product overcooked (may Discard product immediately

“DISCARD appear after a “W-6”, “SLOW

PRODUCT” COOKING” warning)

“OIL TOO Didn’t allow peanut oil to drop CANCEL button will not stop this warning;

HOT” down to current product’s setpoint once the peanut oil temperature drops to set temperature point temperature, the alarm automatically stops

ll or place frozen product

“E-4” PC board too hot Check ventilation louvers on side of fryer for

“CPU TOO obstructions; if louvers are clear, have PC

HOT” board checked; check cooling fan if present.

205 1-13

Page 18

Model 500/600

1-4. WARNINGS AND

ERROR MESSAGES (Continued)

ERROR CODES

DISPLAY CAUSE CORRECTION

“E-5” Controls sensing 405°F Have heat components and temperature probe

“FRYER TOO or above checked

HOT”

“E-6” (A or B) Faulty temperature probe or Have temperature probe and connection

“FRYER TEMP connection checked

SENSOR

FAILED”

“E-10” Peanut oil temperature too hot, Reset high limit per Operating Components;

“HIGH LIMIT drain valve opened while heat was Section; check peanut oil temperature for

TRIPPED” on, or faulty high limit overheating; have heat components checked if

high limit continues to trip

“E-15” Drain is open or faulty microswitch Close drain; have drain microswitch checked

“DRAIN IS if error code persists

OPEN”

“E-25” Wrong or faulty elements or wiring Have electrical supply, wiring, and elements

“HEAT AMPS problem. checked

WERE TOO

HIGH”

(500 fryer only) Because of the seriousness of this error code,

turn the COOK/PUMP switch OFF and back

to COOK to cancel.

“E-26” Faulty contactors or PC board Have the contactors and PC board checked

“HEAT AMPS

ARE

LOCKED ON”

(500 fryer only) This error code could be displayed even with

fryer or shut off the wall circuit breaker to

disconnect electrical power to fryer.

the COOK/PUMP switch turned OFF. Unplug

“E-41” Memory scrambled; an individual Turn the COOK/PUMP switch OFF and back

“SYSTEM product program may be scrambled; to COOK; if error code persists, have the PC

DATA LOST” ex: “E-41 -2- DATA LOST”; this board checked or re-initialized

means product #2 program is

scrambled

“E-41” Memory scrambled; an individual Turn the COOK/PUMP switch OFF and back

“SYSTEM product program may be scrambled; to COOK; if error code persists, have the PC

DATA LOST” ex: “E-41 -2- DATA LOST”; this board checked or re-initialized

scrambled

1-14 205

means product #2 program is

Page 19

Model 500/600

1-4. WARNINGS AND

ERROR MESSAGES (Continued)

ERROR CODES

DISPLAY CAUSE CORRECTION

“E-41” Memory scrambled; an individual Turn the COOK/PUMP switch OFF and back

“SYSTEM product program may be scrambled; to COOK; if error code persists, have the PC

DATA LOST” ex: “E-41 -2- DATA LOST”; this board checked or re-initialized

means product #2 program is

scrambled

“E-46” Faulty eprom or PC board Turn the COOK/PUMP switch OFF and back

“DATA SAVE to COOK; if error code persists, have the PC

FAILED” board checked or re-initialized

“E-47” Failure of 12 volt DC supply Turn the COOK/PUMP switch OFF and back

“ANALOG on the I/O board to COOK; if the and DO NOT

SYSTEM

OR 12 VOLT light up when the 8888’s are displayed, have the

FAILED” I/O board replaced

Amp sensors plugged in backwards Have positions of amp sensors checked

Faulty PC board Have control panel replaced

“E-48” Failure of 12 volt DC supply Turn the COOK/PUMP switch OFF and back

INPUT on the I/O board to COOK; if the and DO NOT

SYSTEM

ERROR” light up when the 8888’s are displayed, have the

I/O board replaced

Faulty PC board Have control panel replaced

“E-70 A” Missing or broken wire in pins 1 and Have jumper wire between pins 1 and 2

“FAN VAC 2 of P11 connector, or faulty checked

JUMPER connector

MISSING”

Faulty I/O board Have I/O board checked and replaced if

necessary

“E-70 B” Faulty COOK/PUMP switch Have COOKPUMP switch checked, along

“PWR SW or switch wiring; faulty with its wiring; have I/O board checked

OR WIRES I/O board

FAILED”

“E-92” Blown 24 volt controller fuse, or Have the 14-pin cable connector checked or

“24 VOLT bad 14-pin cable connection have the fryer checked for a short to ground in

FUSE” components such as the drain switch, solenoid,

or high limit and wiring

Stuck or clogged solenoid valve Have solenoid checked and cleaned

205 1-15

Page 20

Model 500/600

1-5. DIAGNOSTIC MODE

DETAILS

The Chick-fi l-A fryer controllers provide diagnostic functions that

let an Operator review operating and performance data for the

fryer.

The information provided by Diagnostic Mode can be used to

monitor procedural errors, such as, not waiting for the READY

light before starting a Cook Cycle, canceling cycles early, etc.

In addition, Diagnostic Mode allows slight adjustment to product

color, reports the age and accumulated wear of the oil, and reports

information about the performance of the line voltage supply.

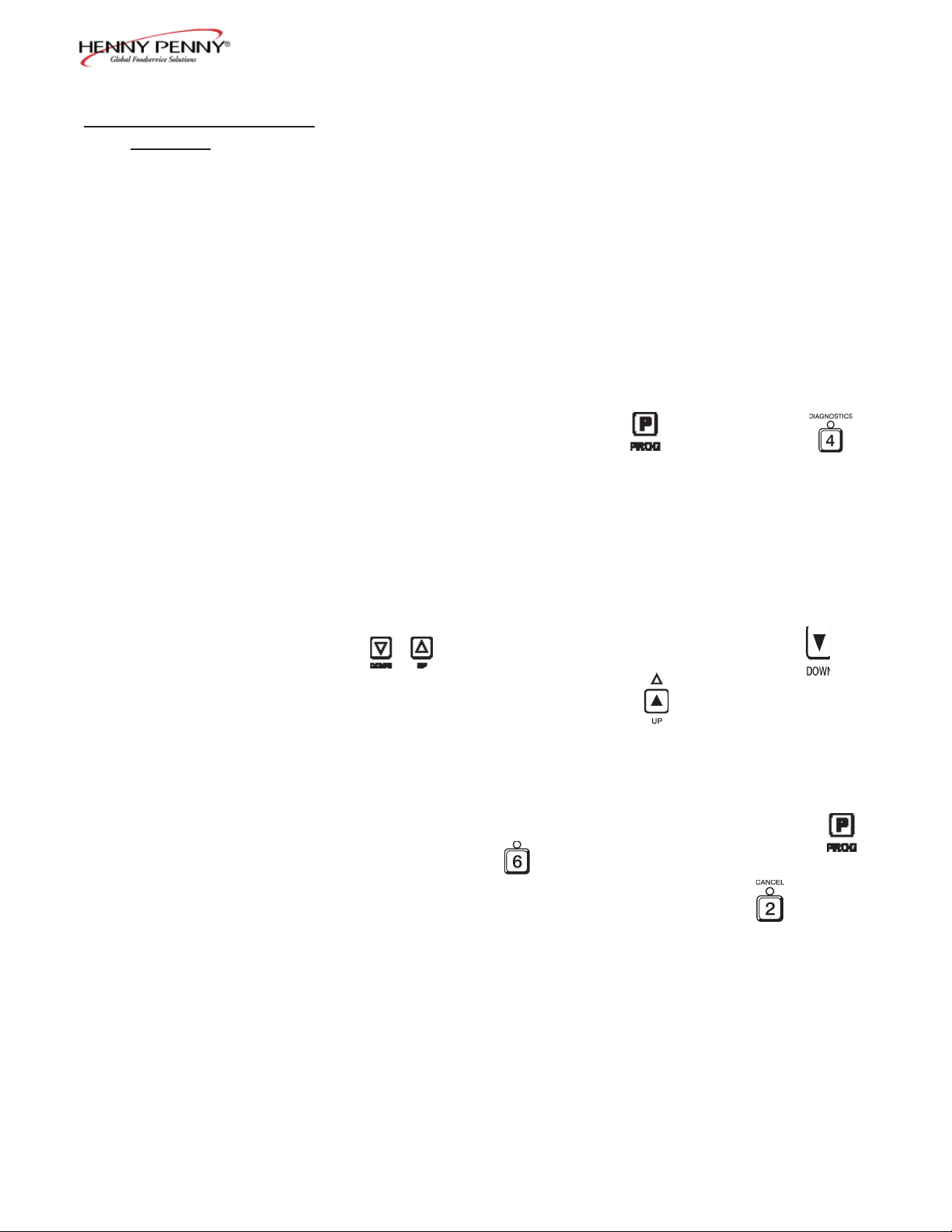

Accessing Diagnostic Mode

To activate Diagnostic Mode, press button, then press

button.

The controller displays the following message:

“ *DIAGNOSTIC* “

“ *REPORT* “

When this introduction message is fi nished, the controller displays

Diagnostic step D 1 (see below).

are used to step through the report items. Press to

step forward to the next item. Press to step backward

through the report items.

The report information is grouped into sections, D 1 through D 10.

Most sections have several related items.

To toggle between English and Spanish Display Mode, press

button then press .

To exit Diagnostic Report Mode at any point, press .

1-16 305

Page 21

Model 500/600

1-5. DIAGNOSTIC MODE

DETAILS (Continued)

D 1: Color Adjustment

This step lets the user make slight adjustments to the product color.

The fi rst step of this item asks “IS PRODUCT COLOR OK?”

If product color is okay and no change is desired press or

to move on to the next item, or press to exit Diagnostic Mode.

If a change is desired, press (i.e. color is not okay). The

controller shows “ADJUST DARKNESS”, then displays the

darkness control slider:

“ LT - - - - - + - - - - - DK”

A blinking asterisk (*) indicates the current position. and

are used to adjust the darkness setting.

To make the product darker, press to move the blinking “

* “ toward the DK (darker) side.

To make the product lighter, press to move the blinking “

* “ toward the LT (lighter) side.

When done adjusting, press to exit and return to normal

operating mode.

Any temperature adjustment activated by the color adjustment

feature will be refl ected in the normal setpoint display as part of

the offset from the basic product cook temperature. To view the

present regulating temperature, press twice.

In the example, “SETPT = 315°F + 6” the product cook

temperature is 315°F and has an additional offset of 6°F to

compensate for the age of the oil, how long the fryer sits idle, and

any color adjustments.

305 1-17

Page 22

Model 500/600

1-5. DIAGNOSTIC MODE

DETAILS (Continued)

D 2: Oil Wear Report

This section displays information about the age of the present

batch of peanut oil.

The fi rst step shows how many days of use this oil has:

“D2: THIS OIL IS “

“D2: 4 DAYS OLD “

The controller only counts days in which the fryer is in use.

Press to move on to the second step. This step shows the age

of the peanut oil by percentage of its expected lifetime.

The peanut oil’s present, accumulated wear is compared to the

wear setting at which the controller will prompt for the oil to be

changed.

“D2: THIS OIL IS “

“D2: 16% USED “

This information can be used as the oil nears the end of its life (i.e.

95%), to plan ahead for when a clean-out will be required.

Press to move on to the next section.

1-18 305

Page 23

Model 500/600

1-5. DIAGNOSTIC MODE

DETAILS (Continued)

D 3: Line Voltage Performance Report

This section displays information about how good the line voltage

supply has been for the present day and for the present batch of oil.

The controller continually monitors the line voltage supplied to the

fryer (when the fryer is on). If the line voltage drops below [90%]

of its nominal value, the controller signals a “LOW VOLTAGE”

alarm.

This alarm sounds at the end of each Cook Cycle for which

low voltage has been detected. While not cooking, the low voltage

alarm can sound as frequently as every 30 minutes.

“[ ]” around a value, such as [90%], means this value

is programmable and might change with later software

versions.

Voltage Report for Today

If no low voltage warnings have been detected for the present day,

the controller shows, “D3: VOLTAGE OK, D3: TODAY “

If one or more low voltage warnings have been detected for the

present day, the following sequence example could be displayed:

“D3: YOU HAD 3”

“D3: LOW VOLTAGE”

“D3: WARNINGS”

“D3: TODAY”

(Press )

“D3: MIN VOLTAGE”

“D3: TODAY = 83%”

(Press )

“D3: MAX VOLTAGE”

“D3: TODAY = 101%”

(Press )

305 1-19

Page 24

Model 500/600

1-5. DIAGNOSTIC MODE

DETAILS (Continued)

“D3: ARE OTHER”

“D3: FRYERS”

“D3: HAVING THIS”

“D3: PROBLEM”

“D3: TODAY?”

Press or .

If is pressed (other fryers are having this problem):

“D3: FACILITY”

“D3: OR UTILITY”

“D3: PROBLEM”

If is pressed (other fryers are not having this problem):

“D3: CHECK CORD,”

“D3: WIRING,”

“D3: AND

BREAKER”

In either case, press to move on to the next step.

Voltage Report for Present Batch of Peanut Oil

This report for the present batch of oil does not include data from

the today. It includes data for all days on the present batch of oil

before today.

For example, if low voltage warnings started appearing today but

had not been displayed before, the previous item might report “3

LOW VOLTAGE WARNINGS TODAY” while this step reports

“VOLTAGE OK SINCE LAST OIL CHANGE”.

If no low voltage warnings have been detected before today for the

present batch of oil, the controller shows:

“D3: VOLTAGE OK”

“D3: SINCE LAST”

“D3: OIL CHANGE”

1-20 305

Page 25

Model 500/600

1-5. DIAGNOSTIC MODE

DETAILS (Continued)

If one or more low voltage warnings have been detected before

today, the following sequence is displayed:

“D3: BEFORE TODAY”

“D3: 27 LOW VOLT”

“D3: WARNINGS”

“D3: ON THIS OIL”

(Press )

“D3: MIN VOLTAGE”

“D3: BEFORE TODAY”

“D3: = 85%”

(Press )

“D3: MAX VOLTAGE”

“D3: BEFORE TODAY”

“D3: = 105%”

Press to advance to the next section.

D 4: Heating Capacity Report

This section reports the present status of the heating system.

The controller examines a history of heat-up data and determines

whether or not the heating system is operating normally. The heat

capacity is said to be bad only if the most recent heat-up failed to

meet the expected heat-up rate and three of the last four heat-ups

also failed to achieve the expected rate. That is, a single slow heatup will not trigger a slow heat warning. The slow heat warning is

activated only after repeated low-rate heat-ups is observed.

The controller can’t assess the integrity of the heating system if

the fryer has been experiencing voltage problems. Low heat rates

observed in this situation might be due to voltage problems rather

than heater problems.

305 1-21

Page 26

Model 500/600

1-5. DIAGNOSTIC MODE

DETAILS (Continued)

If the fryer has witnessed two or more low voltage warnings today,

the following report is displayed:

“D4: CAN’T TEST”

“D4: HEA

T CAPACITY”

“D4: DUE TO”

“D4: VOLTAGE”

“D4: PROBLEMS”

Otherwise, if the assessed heat capacity rating is presently “good”

and there has been at most one heat-up today that failed to achieve

the expected rate, the following report is displayed:

“D4: HEATING”

“D4: CAPACITY”

“D4: IS FINE”

Otherwise, if the heat capacity is presently assessed as “bad”,

or presently assessed as “good” but two or more heat-ups today

have not reached the expected heat-up rate, the following report

sequence is generated:

“D4: YOU HAD 75%”

“D4: SLOW HEATS”

“D4: TODAY”

(Press )

“D4: HAVE 20%”

“D4: SLOW HEATS”

“D4: THIS OIL”

(Press )

“D4: HAD 0%”

“D4: SLOW HEATS”

“D4: LAST OIL”

(Press )

If the heat capacity is assessed as bad (low heat-up rate on last

heat-up, and on three of the last four heat-ups), then the heating

coils are suspect and the following message is displayed:

“D4: CHECK COILS,”

“D4: CONTACTORS,”

“D4: AND WIRING”

1-22 305

Page 27

Model 500/600

1-5. DIAGNOSTIC MODE

DETAILS (Continued)

Otherwise, the heating coils are presumed to be good and the

following messages appear:

“D4: HEATER COILS “

“D4: APPEAR OK “

(Press )

“D4: CHECK “

“D4: CONTACTORS, “

“D4: CONNECTIONS, “

“D4: AND WIRING “

D 5: Cook Times (Slow Cooks) Report

This section summarizes the slow cooking status for each product.

Actual cook times for Cook Cycles can vary from the programmed

cook time setting, due to the load compensation feature. Load

Compensation slows the cook timer down when the actual peanut

oil temperature is below a reference value, and speeds up the

cook timer countdown when peanut oil temperature is above the

reference.

When the peanut oil temperature is lower than expected during a

Cook Cycle, the overall cook time will be longer than normal. If

the actual cook time stretches beyond a programmed limit, the

controller counts a “SLOW COOK” event and sounds an alarm at

the end of the Cook Cycle.

If low voltage or low amps are detected during the Cook Cycle, the

warning message indicates “LOW VOLTAGE” or “LOW AMPS”,

but the cycle will still count as a “slow cook”. If the voltage and

amps have been fi ne during the Cook Cycle but the cycle was

started before the Ready light came on, then the warning message

indicates “SLOW COOK — WAIT FOR READY LIGHT”.

Otherwise, the slow cooking problem will be attributed to a “bad

batch” of product: cooking too much in one load, or cooking

product that is too cold (i.e. frozen product on a pressure fryer

when the product should be fresh).

If none of the products has more than 5% slow Cook Cycles today,

the following report is made:

“D5: COOK TIMES”

“D5: LOOK OK”

“D5: TODAY”

305 1-23

Page 28

Model 500/600

1-5. DIAGNOSTIC MODE

DETAILS (Continued)

Otherwise, if one or more cook products have generated a slow

cook warning more than 5% of the time, but four or more low

voltage or slow heat-up warnings (any combination) have been

generated today, then the report is as follows:

“D5: SOME SLOW”

“D5: COOKS

TODAY”

“D5: MAYBE DUE TO”

“D5: VOLTAGE OR”

“D5: COIL PROBLEMS”

Such a report is saying the slow cooking may be the result of low

voltage (which signifi cantly reduces heat capacity) or the result

of other problems with the heating system. In this case, the slow

cook problems might not have anything to do with user error.

Otherwise, the slow cooking is generally attributed to user error:

cooking too much product in one load, cooking frozen product (in

the pressure fryer) when it should be fresh, or cooking before the

Ready light illuminates, etc.

An individual “XXXXX IS COOKING SLOWLY TODAY” report

item is generated for each product that has had more than 5% slow

cook warnings today. This report item is triggered based solely

on the number of slow cooks for that product, whether those slow

cooks are due to voltage or heating problems, or due to cooking

before ready, cooking too much, or cooking frozen product.

“D5: “FILET” ( Product Name )

“D5: COOKING SLOW”

“D5: TODAY”

(Press )

If any of the slow cooks for this product are suspected as being

due user error, a second, “bad batch” report is generated for the

product.

“D5: “NUG-STRP” ( Product Name )

“D5: COOKING SLOW”

“D5: TODAY”

(Press )

1-24 305

Page 29

Model 500/600

1-5. DIAGNOSTIC MODE

DETAILS (Continued)

“D5: POSSIBLE”

“D5: OVERSIZED”

“D5: OR FROZEN”

“D5: BATCH OF”

“D5: “NUG-STRP” “ ( Product Name )

“D5: DETECTED”

“D5: 3

TIMES”

“D5: TODAY”

(Press )

“D5: POSSIBLE”

“D5: OVERSIZED”

“D5: BATCH OF”

“D5: “FRIES”

“D5: DETECTED”

“D5: 5 TIMES”

“D5: TODAY”

D 6: “Cooked Before Ready” Report

This section shows how many Cook Cycles were started before the

READY light was on. This is strictly a user error.

If the fryer was in the ready range when the user begins to load

product, but is out of the ready range by the time the Cook Cycle is

started, the control will not give you an alarm.

If the fryer wasn’t ready before loading, an alarm sounds and

“WAS NOT READY” warning is generated. The number of times

this has happened today is indicated by the following report item:

“D6: COOKED”

“D6: BEFORE READY”

“D6: 11 TIMES”

“D6: TODAY”

(Press )

305 1-25

Page 30

Model 500/600

1-5. DIAGNOSTIC MODE

DETAILS (Continued)

The number of “WAS NOT READY” warnings for this batch

of peanut oil is also reported. Note that this value does not yet

include the not ready warnings generated today.

“D6: BEFORE TODAY,”

“D6: COOKED”

“D6: BEFORE READY”

“D6: 8

TIMES”

“D6: ON THIS OIL”

(Press )

Finally, the controller identifi es how many times the not ready

warning was generated for the previous batch of peanut oil:

“D6: LAST OIL,”

“D6: COOKED”

“D6: BEFORE READY”

“D6: 24 TIMES”

D 7: “Stopped Too Soon” Report

This section shows how many Cook Cycles were stopped early by

the user, before the cook timer had counted down to 0:00 and the

“*DONE*” indication was given. This is strictly a user error.

Cycles that are canceled after cooking for less than 30 seconds are

not counted here. For example, if a cycle is accidentally started,

and the Cook Cycle is canceled after just a few seconds, this cycle

will not be counted as a Stopped Too Soon Cycle.

Also, some allowance is given for stopping a cycle a little early.

The user can cancel the cycle up to 10 seconds early without

penalty.

Otherwise, however, any cycle that was stopped with more than 10

seconds remaining (0:10) on the cook clock with be counted as a

Stopped Too Soon Cycle.

The fi rst item displays what percent of cycles today were stopped

with more than 0:10 remaining. All products are grouped into one

count.

“D7: 8% OF LOADS”

“D7: WERE STOPPED”

“D7: TOO SOON”

“D7: TODAY”

(Press )

1-26 305

Page 31

Model 500/600

1-5. DIAGNOSTIC MODE

DETAILS (Continued)

The number of Stopped Too Soon cycles for this batch of peanut

oil is reported next. Note that this value does not yet include the

Cook Cycles from today.

“D7: BEFORE TODAY “

“D7: 3% OF LOADS”

“D7: WERE

STOPPED”

“D7: TOO SOON”

“D7: ON THIS OIL”

(Press )

Finally, the controller identifi es percentage of Stopped Too Soon

Cycles for the previous batch of peanut oil:

“D7: LAST OIL”

“D7: 5% OF LOADS”

“D7: WERE STOPPED”

“D7: TOO SOON”

D 8: “Beeped *DONE* Too Long” Report

Diagnostic Report section 8 reveals how many Cook Cycles

beeped “*DONE*” for more than 20 seconds before the user

pressed the timer button to stop the cycle. This is strictly a user

error.

The controller cannot detect when the product is actually removed

from the fryer. It only identifi es how long the controller beeped

“*DONE*” before the user pressed to stop the alarm.

The fi rst item displays the percent of today’s Cook Cycles that

beeped “*DONE*” for more than 20 seconds before the user

pressed to stop it. All products are grouped into one count.

“D8: 10% OF LOADS”

“D8: BEEPED ‘DONE’”

“D8: TOO LONG”

“D8: TODAY”

(Press )

305 1-27

Page 32

Model 500/600

1-5. DIAGNOSTIC MODE

DETAILS (Continued)

The number of Beeped Done Too Long Cycles for this batch

of peanut oil is reported next. Note that this value does not yet

include the Cook Cycles from today.

“D8: BEFORE TODAY “

“D8: 7% OF LOADS”

“D8: BEEPED ‘DONE’”

“D8: T

OO LONG”

“D8: ON THIS OIL”

(Press the DOWN button...)

Finally, the controller identifi es percentage of Beeped Done Too

Long Cycles for the previous batch of peanut oil:

“D8: LAST OIL”

“D8: 6% OF LOADS”

“D8: BEEPED ‘DONE”

“D8: TOO LONG”

D 9: Irregular Loading Report

For most Cook Cycles, the controller determines when the product

was placed into the peanut oil. This report identifi es the percentage

of cycles for which this determination was not successful.

This drop detection detects most loads, but can fail for several

reasons. Anytime the detection routine fails to fi nd the true drop

point, the controller logs an irregular loading count.

Examples of failed drop detection might be: the Operator takes too

long to load the product to the time he presses the start button, or

the Operator cooks a very light product load, one or two fi lets, for

example.

In these instances, no drop point will be found and that Cook Cycle

counts as an Irregular Loading Cycle. Only products that have

more than 5% of loads with missed detection’s are reported.

1-28 305

Page 33

Model 500/600

1-5. DIAGNOSTIC MODE

DETAILS (Continued)

Loading Report for Today

If no products have a failed to detect rate of more than 5%, the

controller shows:

“D9: LOADING”

“D9: LOOKS OK”

“D9: TODAY”

Otherwise, for each product that has more than 5% of loads in

which the controller failed to detect the drop point, the following

message is displayed:

“D9: IRREGULAR”

“D9: LOADING”

“D9: FOR 8% OF”

“D9: “FILET” ( Product Name )

“D9: TODAY”

Loading Report for Present Batch of Peanut oil

The data for this batch of peanut oil does not yet include Cook

Cycles from today.

If no products have a failed to detect rate of more than 5%, the

controller shows:

“D9: LOADING “

“D9: LOOKS OK “

“D9: THIS OIL “

Otherwise, for each product that has more than 5% of loads in

which the controller failed to detect the drop point, the following

message is displayed:

“D9: FOR THIS OIL,”

“D9: IRREGULAR “

“D9: LOADING “

“D9: FOR 12% OF “

“D9: “NUG-STRP” “ ( Product Name )

305 1-29

Page 34

Model 500/600

1-5. DIAGNOSTIC MODE

DETAILS (Continued)

Loading Report for Previous Batch of Peanut oil

If no products have a failed to detect rate of more than 5%, the

controller shows:

“D9: LOADING”

“D9: LOOKED OK”

“D9: PREVIOUS OIL”

Otherwise, for each product that has more than 5% of loads in

which the controller failed to detect the drop point, the following

message is displayed:

“D9: PREVIOUS OIL,”

“D9: IRREGULAR”

“D9: LOADING”

“D9: FOR 6% OF”

“D9: “BRK-FIL” ( Product Name )

D 10: Non-Standard Program Items Report

The last section in the diagnostic report identifi es how many

programmable settings have been altered from their original,

factory default settings.

For each of the various program modes, the controller either

reports that all settings match original values or reports N items do

not match original values. This report makes it easy to see if any

cook parameters or other settings have been changed from CFA

settings.

Some programming items may have been changed from original

values under the direction of CFA corporate headquarters. In some

cases, a controller should have values that don’t match original

values. A report that “all items match original values” could

actually be an indication that something isn’t set right.

Keep in mind also that the number of such approved alterations

might be different for different versions of software.

If all product cook settings match the original, factory default

values, the controller displays the following message:

“10: ALL PROD’S”

“10: MATCH”

“10: ORIG. VALUES”

1-30 305

Page 35

Model 500/600

1-5. DIAGNOSTIC MODE

DETAILS (Continued)

If any of the product settings do not match original values, the

following message is displayed (with one or more of the product

numbers blinking):

“10: PROD’S 123456”

“10: DO NOT MATCH”

“10: ORIG. VALUES”

In this case, the blinking numbers indicate which products do

not match original settings. If the numbers 3 and 5 are the only

numbers blinking, then product #3 and product #5 each have

at least one setting changed from their factory preset values.

Products 1, 2, 4, and 6 are confi rmed to exactly match their original

settings.

The second item in D 10 identifi es how many items in CFA

Programming Mode have been changed from their original values.

These Chick-fi l-A settings mainly deal with special Chick-fi l-A

controller features like oil wear, heat-up monitoring, new oil

compensation, oil idle compensation, drop detection, amps and

voltage alarms, and Clean-out Mode.

If all items in CFA Prog Mode match their original, factory preset

values, the following report is made:

“10: ALL CFA ITEMS”

“10: MATCH”

“10: ORIG. VALUES”

If any of the items in CFA Prog Mode do not match their original

values, the following message is displayed (with the actual number

of changed items):

“10: 2 CFA ITEMS”

“10: DO NOT MATCH”

“10: ORIG. VALUES’

A similar report is made for Special Program Mode. Special

Program (SP) Mode settings deal with °F/°C display, speaker tone

and volume, Melt and Idle Modes, and how the product buttons

function (start cook or merely select product).

“10: ALL SP ITEMS” “10: 1 SP ITEMS “

“10: MATCH “ “10: DO NOT MATCH “

“10: ORIG. VALUES “ “10: ORIG. VALUES “

305 1-31

Page 36

Model 500/600

1-5. DIAGNOSTIC MODE

DETAILS (Continued)

1-6. INFORMATION MODE

DETAILS

The fi nal item in D 10 identifi es if any changes have been made to

the heat control settings. These settings affect the fryer’s heating

algorithms, and include the PC factors, rate-of-rise compensations,

and heat pulse cycle time, etc.

“10: ALL HC ITEMS” “10: 3 HC ITEMS”

“10: MA

TCH” “10: DO NOT MATCH”

“10: ORIG. VALUES” “10: ORIG. VALUES”

This historic information in this mode can be recorded and used for

operational and technical help.

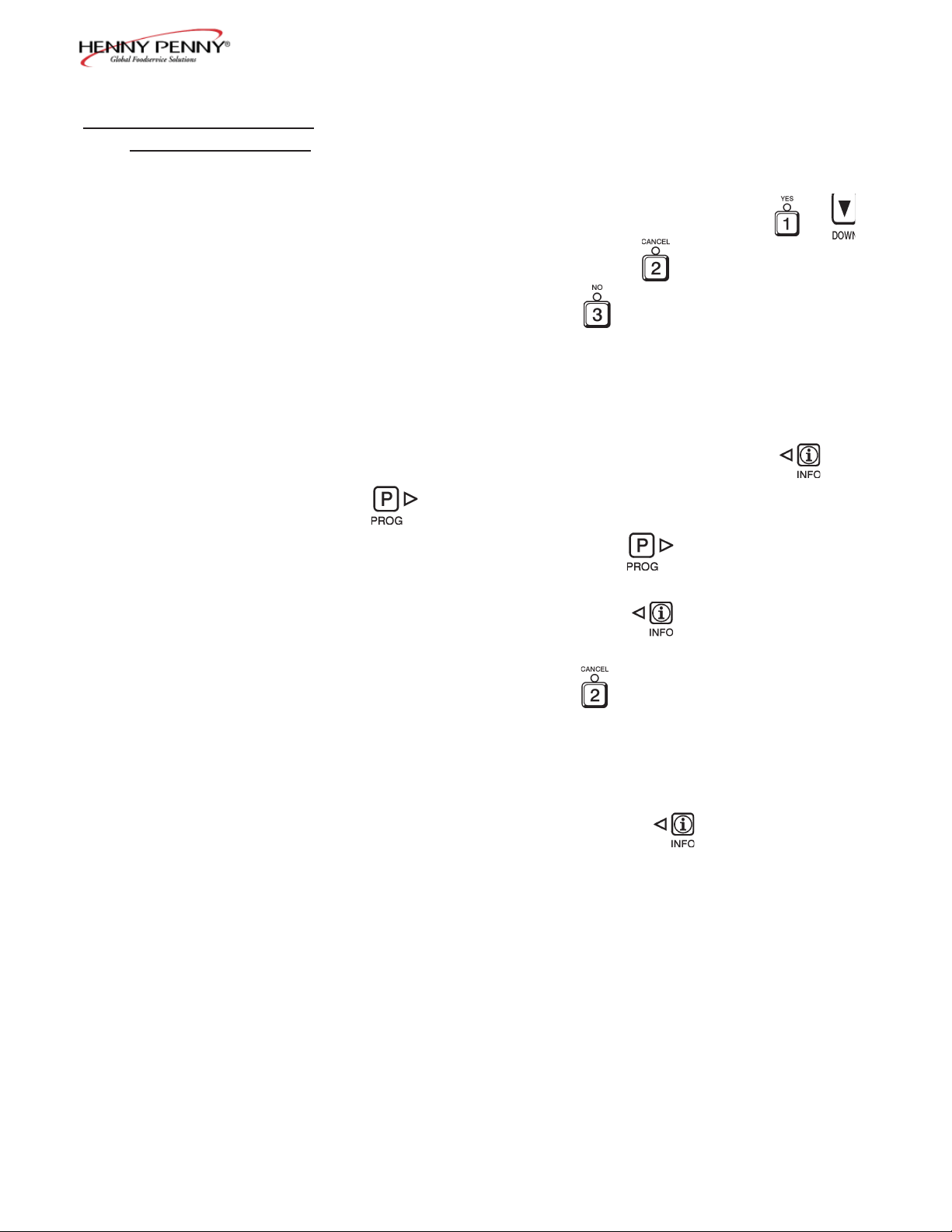

Press and at the same time and “*INFO MODE*”

shows in the display, followed by “1. E-LOG”.

Press and hold to exit Information Mode at any time,

or after 2 minutes, controls automatically exit back to normal

operation.

1. E-LOG (error code log)

Press and “1A. (date & time) *NOW* shows in display. This

is the present date and time.

Press and if a error was recorded, “1B. (date, time, and error

code infromation)” shows in display. This is the latest error code

that the controls recorded.

Press and the next latest error code information can be seen. Up

to 10 error codes (1B to 1K) can be stored in the E-LOG section.

Press to continue to P-LOG.

2. P-LOG (power-up log)

Press and “2A. (date & time) *NOW* shows in display. This

is the present date and time.

Press and latest power-up is shown, “2B. (date, time,) PWR-

UP”.

1-32 305

Page 37

Model 500/600

1-6. INFORMATION MODE

DETAILS

Press and the next latest power-up date is shown. Up

to 10 power-ups (2B to 2K) can be stored in the P-LOG section.

Press to continue onto the heat-up log.

3. HEAT-UP’S

Press and “3A. (date & time) *NOW* shows in display. This

is the present date and time.

Press and the latest heat-up is shown, along with heat-up rate,

ex: “3B. MAY-22, 8:37A 1.25”. The heat rate is the maximum

rate (degrees/second) the controller recorded during the shown

time frame.

Press and the next latest heat-up is shown. Up to 10 heat-ups

(3B to 3K) can be stored in the HEA

T-UP log.

Press to continue onto the COOK DATA.

4. COOK DATA

Press to step through the following data:

FUNCTION DISPLA

Y EXAMPLE

Time of day last Cook Cycle was started 4A. STARTED 10.25A

Product (last product cooked) 4B. PRODUCT -1-

Ready? (was fryer ready before start?) 4C. READY? YES

Drop detect status 4D. DETECT

/ T-14

\

Drop adjust (real time seconds) 4E. DROP ADJ T-14

Cook time adj (clock adjust) 4F. CK TM ADJ -13

Actual elapsed cook time (real seconds) 4G. ACT TIME 4:50

Stopped: time remaining, or secs past done 4H. STOP DONE+2

Slow cook for this cycle? 4I. SLOW? NO

Frozen or overload? (bad batch) 4J. FRZ/OVL? NO

Avg temp during Cook Cycle 4K. AVG TMP 317°F

Max voltage during Cook Cycle 4L. MAX VOLT 99%

Min voltage during Cook Cycle 4M. MIN VOLT 97%

Max amps during Cook Cycle 4N. MAX AMPS 35

Min amps during Cook Cycle 4O. MIN AMPS 34

Press to continue onto today’s data log.

305 1-33

Page 38

Model 500/600

1-6. INFORMATION MODE

DETAILS

5. TODAY’S DATA (automatically resets each day)

Press to step through the following data:

FUNCTION DISPLA

Today’s Date 5A. DATE APR-12

Time of day last heat-up was completed 5B. LAST HEAT 9:45A

Peak heat-up rate (°F/Sec) for last heat-up 5C. LAST RATE 0.82

Was last heat-up acceptable? 5D. LAST OK? YES

Heat cap. status (based on last 4 ht-ups) 5E. HEAT CAP GOOD

Number of monitored heat-ups today 5F. HEAT-UPS 2

Number of slow heat-ups 5G. SLOW HT’S 0

Max time to heat 270°F to 310°F today 5H. MAX HT TM 1:17

Lowest peak rate for today’s heat-ups 5I. MIN RATE 0.82

Maximum voltage today (when fryer on) 5J. MAX VOLT 99%

Minimum voltage today (when fryer on) 5K. MIN VOLT 95%

No. of “LOW VOLTAGE” warnings 5L. LO VOLT’S 0

Maximum amp draw today 5M. MAX AMPS 35

Minimum amp draw today 5N. MIN AMPS 33

Number of “Low Amps” warnings today 5O. LO AMP’S 0

Non-cooking time (hh:mm) while fryer was on 5P. IDLE HRS 1:23

Oil wear accumulated so far today 5Q. OIL WEAR 3

Total number of Cook Cycles today 5R. TOT CK’S 11

No. of cycles started before ready 5S. NOT RDY’S 2

No. cycles quit early (0:11 or more remaining) 5T. QUIT 11+ 0

No. cycles beeped *DONE* 21 sec or more 5U. DONE 21+ 1

Individual product cook counts 5V. Px CK CT 2

Individual product not detected counts 5W. Px NO DET 0

Individual product slow cook counts 5X. Px SLO CT 0

Individual product frozen or overloaded 5Y. Px FRZ/OV 0

Y EX:

During steps 5V through 5Y, press the product buttons (or

Manual Prog) to see data on individual product items.

Press to continue onto prev-day-sun log.

1-34 305

Page 39

Model 500/600

1-6. INFORMATION MODE

DETAILS

6. PREV DAY - SUN

Press to step through following data. During each step, press

to choose the day of the week, of the past 7 days.

FUNCTION DISPLA

Day this data was recorded for 6A. DATE APR-8

Time of day last heat-up was completed 6B. LAST HEAT 8:15P

Peak heat-up rate (°F/Sec) for last heat-up 6C. LAST RATE 0.88

Was that day’s last heat-up acceptable? 6D. LAST OK? YES

Heat cap. status (based on last 4 ht-ups) 6E. HEAT CAP GOOD

Number of monitored heat-ups that day 6F. HEAT-UPS 7

Number of slow heat-ups 6G. SLOW HT’S 0

Max time to heat 270°F to 310°F that day 6H. MAX HT TM 1:11

Lowest peak rate for that day’s heat-ups 6I. MIN RATE 0.67

Maximum voltage that day (when fryer on) 6J. MAX VOLT 102%

Minimum voltage that day (when fryer on) 6K. MIN VOLT 98%

No. of “LOW VOLTAGE” warnings 6L. LO VOLT’S 0

Maximum

Minimum

No. of “LOW AMPS” warnings that day 6O. LO AMP’S 0

Non-cooking time (hh:mm) while fryer was on 6P. IDLE HRS 7:09

Oil wear accumulated that day 6Q. OIL WEAR 39

Total number of Cook Cycles that day 6R. TOT CK’S 18

Number of cycles started before ready 6S. NOT RDY’S 2

No. cycles quit early (0:1

No. cycles beeped *DONE* 21 sec or more 6U. DONE 21+ 3

Individual product cook counts 6V. Px CK CT 12

Individual product not detected counts 6W. Px NO DET 1

Individual product slow cook counts 6X. Px SLO CT 0

Individual product frozen or overloaded 6Y. Px FRZ/OV 1

Amp Draw that day 6M. MAX AMPS 35

Amp Draw that day 6N. MIN AMPS 34

1 or more remaining) 6T. QUIT 11+ 1

Y EX:

During steps 6V through 6Y, press the product buttons (or

Manual Prog) to see data on individual product items.

Press to continue onto 7-day totals log.

305 1-35

Page 40

Model 500/600

1-6. INFORMATION MODE

DETAILS

7. 7-DAY TOTALS

Press to step through the following data:

FUNCTION DISPLA

Oldest day in the previous days history 7A. SINCE APR-5

Number of days with data included in totals 7B. DAYS CNT 6

Number of monitored heat-ups 7C. HEAT-UPS 30

Number of slow heat-ups 7D. SLOW HT’S 1

Max time to heat 270°F to 310°F 7E. MAX HT TM 3:25

Lowest peak rate of all heat-ups 7F. MIN RATE 0.47

Maximum voltage 7G. MAX VOLT 102%

Minimum voltage 7H. MIN VOLT 91%

No. of “LOW VOLTAGE” warnings 7I. LO VOLT’S 0

Maximum amp draw 7J. MAX AMPS 35

Minimum amp draw 7K. MIN AMPS 32

Number of “LOW AMPS” warnings 7L. LO AMP’S 0

Non-cooking time (hrs) while fryer was on 7M. IDLE HRS 43

T

otal oil wear accumulated 7N. TOT WEAR 278

T

otal number of Cook Cycles 7O. TOT CK’S 125

Number of cycles started before ready 7P. NOT RDY’S 7

No. cycles quit early (0:1

No. cycles beeped *DONE* 21 sec or more 7R. DONE 21+ 3

Individual product cook counts 7S. Px CK CT 77

Individual product not detected counts 7T. Px NO DET 3

Individual product slow cook counts 7U. Px SLO CT 0

Individual product frozen or overloaded 7V. Px FRZ/OV 1

1 or more remaining) 7Q. QUIT 11+ 1

Y EX:

During steps 7S through 7V, press the product buttons (or

Manual Prog) to see data on individual product items.

Press to continue onto oil data log.

1-36 305

Page 41

Model 500/600

1-6. INFORMATION MODE

DETAILS

8. OIL DATA (current batch; resets by Clean-Out Mode)

Press to step through the following data:

FUNCTION DISPLA

The day current batch of oil was started 8A. SINCE APR-1

Number of days with data included in totals 8B. DAYS CNT 10

Number of monitored heat-ups 8C. HEAT-UPS 75

Number of slow heat-ups 8D. SLOW HT’S 2

Max time to heat 270°F to 310°F 8E. MAX HT TM 3:25

Lowest peak rate of all heat-ups 8F. MIN RATE 0.43

Maximum voltage 8G. MAX VOLT 102%

Minimum voltage 8H. MIN VOLT 91%

No. of “LOW VOLTAGE” warnings 8I. LO VOLT’S 0

Maximum amp draw 8J. MAX AMPS 35

Minimum amp draw 8K. MIN AMPS 32

No. of “LOW AMPS” warnings 8L. LO AMP’S 0

Non-cooking time (hrs) while fryer was on 8M. IDLE HRS 43

Total oil wear accumulated 8N. TOT WEAR 278

Total number of Cook Cycles 8O. TOT CK’S 125

Number of cycles started before ready 8P. NOT RDY’S 7

No. cycles quit early (0:11 or more remaining) 8Q. QUIT 11+ 1

No. cycles beeped *DONE* 21 sec or more 8R. DONE 21+ 3

Individual product cook counts 8S. Px CK CT 77

Individual product not detected counts 8T. Px NO DET 3

Individual product slow cook counts 8U. Px SLO CT 0

Individual product frozen or overloaded 8V. Px FRZ/OV 1

Y EX:

During steps 8S through 8V, press the product buttons (or

Manual Prog) to see data on individual product items.

Press to continue onto prev oil data log.

305 1-37

Page 42

Model 500/600

1-6. INFORMATION MODE

DETAILS

9. PREV OIL DATA (moved here from Oil Data log; assumes new

peanut oil)

Press to step through the following data:

FUNCTION DISPLA

The day previous batch of oil was started 9A. BEGAN MAR-9

Number of days with data included in totals 9B. DAYS CNT 18

Number of monitored heat-ups 9C. HEAT-UPS 98

Number of slow heat-ups 9D. SLOW HT’S 0

Max time to heat 270°F to 310°F 9E. MAX HT TM 1:31

Lowest peak rate of all heat-ups 9F. MIN RATE 0.57

Maximum voltage 9G. MAX VOLT 101%

Minimum voltage 9H. MIN VOLT 96%

Number of “LOW VOLTAGE” warnings 9I. LO VOLT’S 0

Maximum amp draw 9J. MAX AMPS 35

Minimum amp draw 9K. MIN AMPS 33

Number of “LOW AMPS” warnings 9L. LO AMP’S 0

Non-cooking time (hours) while fryer was on 9M. IDLE HRS 62

Total oil wear accumulated 9N. TOT WEAR 1523

Total number of Cook Cycles 9O. TOT CK’S 653

Number of cycles started before ready 9P. NOT RDY’S 25

Num. cycles quit early with 0:11 or more rem 9Q. QUIT 11+ 3

Num. cycles beeped *DONE* 21 sec or more 9R. DONE 21+ 13

Individual product cook counts 9S. Px CK CT 466

Individual product not detected counts 9T. Px NO DET 31

Individual product slow cook counts 9U. Px SLO CT 0

Individual product frozen or overloaded 9V. Px FRZ/OV 5

Y EX:

During steps 9S through 9V, press the product buttons (or

Manual Prog) to see data on individual product items.

Press to continue onto INP A_VHDSF_M checks.

1-38 305

Page 43

Model 500/600

1-6. INFORMATION MODE

DETAILS

10. INP A_VHDSF_M

This mode displays the status of components and inputs. If the

input signal is detected, an identifying letter is displayed (see

below). If the signal is not detected, “_” is displayed.

W

ith the COOK/PUMP switch turned to COOK, and all inputs

detected, “H_ P_ A_VHDSF_M” shows in the display, for electric

fryers; “H_ P_ A_VHDSFP_” for gas fryers. See below for

defi nition of codes.

A = COOK/PUMP switch turned to COOK

B = COOK/PUMP switch in PUMP position

V = Volts - 24 VAC detected

H = High Limit - If “H” is present, the high limit is good; if “H”

is missing, the high limit is tripped (overheated) or faulty

D = Drain switch - If “D” is present, the drain handle is closed;

if “D” is missing, the drain is open or faulty

S = COOK/PUMP switch “on” interlock circuit: If “S” is present,

COOK/PUMP switch is in the COOK position; if “S” is

missing, power switch is either off, failed, or wired incorrectly

F = Fan

P = PV - Detects 24 V jumper to PV terminal - gas fryers only

M = MV - Detects 24 V jumper to MV terminal - electric fryers

only

Press to view specifi c status of each input. An underscore

(“_”) indicates the input is not presently detected. A checkmark

(“\/” ) indicates the signal is detecting a normal input. A blinking

(“X”) indicates the signal is presently detected, but is detected as a

half-wave (partially failed) input.

The V, H, D, S, F, P, and M signals below are wired in series.

The fi rst signal missing out of this sequence will generally

cause all signals to the right of it to be missing as well.

Press to continue onto OUTP H* P_ checks.

305 1-39

Page 44

Model 500/600

1-6. INFORMATION MODE

DETAILS

11. OUTP H* P_

This mode displays the status of components and outputs. If the

output signal is detected, an identifying letter is displayed (see

below), followed by an “*”. If the output is off, “_” is displayed.

H = Heat output

P

= Pressure output

If heat is on, “H*” shows in display. If heat is off, “H_” shows in

display. If controls senses a problem with the heat output, “H*”

shows in display, with the “*” fl ashing.

If pressure is on, “P*” shows in display. If pressure is off, “P_”

shows in display. If controls senses a problem with the pressure

output, “P*” shows in display, with the “*” fl ashing.

Press to view the “amps” status of each output.

“H\/” and “P\/” in the display means the amps are good. A fl ashing

“X” behind the H or P means a problem exists.

Press to view the no connect/ground (“NC/GD”) status of each

output. This monitors a possible problem with the relays on the

output PC board.

“H\/” and “P\/” in the display means everything on output PC board

is good. A fl ashing “X” behind H or P means a problem exists.

Press to view the outputs and inputs (see step 10) together.

Press to continue onto the POT TMP reading.

12. POT TMP

This step shows the present peanut oil temperature. The display

shows “12. POT TMP (temp.)”.

Press to continue onto the CPU TMP reading.

13. CPU TMP

This step shows the present PC board temperature.

Press to continue onto the

1-40 305

ANALOG reading.

Page 45

Model 500/600

1-6. INFORMATION MODE

DETAILS

14. ANALOG <1> 2344

This step displays the present status of any channel of the

controller’s a to d converter. This feature may be useful to a

technician troubleshooting a problem with the fryer or controller.

Displayed value can be toggled between volts and bits by pressing

. If the displayed value has a decimal point, it is voltage

(0 to 5 VDC). If no decimal point is shown, the value is a-to-d bits

(0 - 4095).

Press to continue onto AC volts reading.

15. AC VOLTS 98%

This item displays the present status of the line voltage supply to

the fryer

. The displayed value is averaged over a 10-second period, so brief dips or fl uctuations in the voltage might not show up

in this display.

The voltage is normally displayed as a “percent of nominal” value,

where 100% would indicate that voltage is right on the nominal

value (i.e. 208 volts for a 208v fryer). The display can be toggled

to an actual Voltage value by pressing .

Press to continue onto AMPS reading.

16. AMPS 33 33 33

For electric fryers, this display shows the present readings from the

fryer’s amps sensors, which monitor the electrical current supplied

to the heaters. (These sensors are not present on gas fryers.)

On pressure fryers, these values indicate the current through each

supply leg to the heaters. These values do not correspond directly

to the current through an individual heater coil.

The amps values should normally cycle on and off with the heat

light, and all three values should be about the same.

Press and hold to exit Information Mode at any

time, or after 2 minutes, controls automatically exit back

to normal operation.

305 1-41

Page 46

Model 500/600

Page 47

Model 500/600

SECTION 2. MAINTENANCE

2-1. INTRODUCTION

2-2. MAINTENANCE

HINTS

This section provides procedures for the checkout and

replacement of the various parts used within the fryer.

Before replacing any parts, refer to Section 1, Troubleshooting.

It will aid you in determining the cause of the malfunction.

1. You may use two test instruments to check the electric

components.

• A continuity light

• An ohmmeter

2. When the manual refers to the circuit being closed,

the continuity light will be illuminated or the

ohmmeter should read zero unless otherwise noted.

3. When the manual refers to the circuit being open,

the continuity light will not illuminate or the

ohmmeter will read 1 (one).

A continuity tester cannot be used to check coils or motors.

305 2-1

Page 48

Model 500/600

2-3. PREVENTIVE

MAINTENANCE

SCHEDULE

2-4. REMOVING THE

CONTROL PANEL

To ensure a long life of the fryers and their components, regular

maintenance should be performed. Refer to the chart below.

Frequency Action

Daily (3-4 loads) Filter shortening

Daily Clean deadweight valve cap,

weight, and orifi ce

30 Days Lubricate spindle threads and ball seat

90 Days Reverse lid gasket

90 Days Check limit stop adjustment

90 Days Check and tighten element spreaders

Once a year Remove and clean safety relief valve

To replace parts inside the fryer you will often need to remove

the control panel. The following steps provide the correct

procedure:

Removal

1. Place the main power switch to the OFF position.

(This switch is labeled COOK/OFF/PUMP.)

Step 2

Step 3

To avoid electrical shock or property damage, move the

power switch to OFF and disconnect main circuit

breaker, or unplug cord at wall receptacle.

2. Remove the screws from the of the control panel.

3. With the fryer door partially closed, place the lower edge of

control panel in the slot between the door and the frame

of the fryer.

2-2 305

Page 49

Model 500/600

2-5. TRANSFORMER

REPLACEMENT

The transformer reduces the voltage down to accommodate

those components with low voltage.

1. Remove electrical power supplied to the unit.

To avoid electrical shock or property damage, move the

power switch to OFF and disconnect main circuit

breaker, or unplug cord at wall receptacle.

2. Remove the control panel. Refer to Section 2-4.

3. Disconnect the white box connector.

Step 3

Step 4

4. Remove the two screws securing transformer to the

unit and remove transformer.

5. Replace with new transformer in reverse order.

305 2-3

Page 50

Model 500/600

2-6. TEMPERATURE PROBE

REPLACEMENT

Step 4

The Temperature Probe relays the actual shortening temperatureto the

control. If it becomes disabled, “E-6” shows in thedisplay. Also, if the

temperature is out of calibration more than 10°F, or 10°C, the temperature probe should be replaced. An Ohm check can be performed also.

See chart at end of this section.

1. Remove electrical power supplied to the fryer.

To avoid electrical shock or property damage, move the

power switch to OFF and disconnect main circuit

breaker, or unplug cord at wall receptacle.

2. Drain the shortening from the frypot.

3. Remove the control panel. Refer to Section 2-4.

4. Using a 1/2” wrench, remove the nut on the compression fi tting.

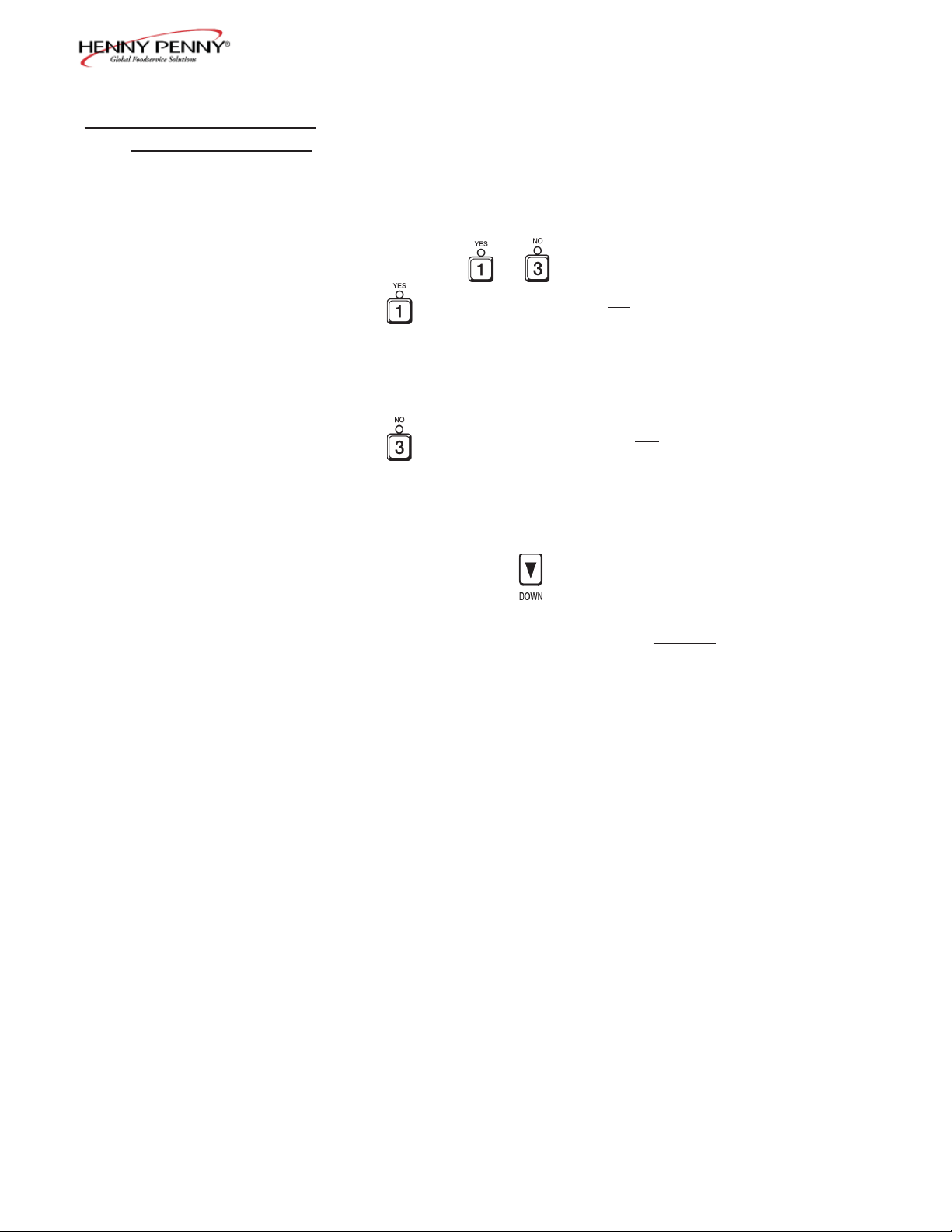

5. Remove the temperature probe from the frypot.

6. Follow the appropriate instructions below depending upon the type

of fryer, gas or electric.

ELECTRIC

2-4 906

Page 51

Model 500/600

2-6. TEMPERATURE PROBE

REPLACEMENT (Contin-

GAS

ued)

7. Tighten the compression nut hand tight and then a half turn

with wrench.

Excess force will damage temperature probe.

8. Connect new temperature probe to PC board and replace

control panel.

9. Replace shortening and turn power on and check out fryer.

906 2-5

Page 52

Model 500/600

2-7. HIGH TEMPERATURE

LIMIT CONTROL

(ELECTRIC AND

GAS MODELS)

Electric

Gas

Red Reset

Button

Description

This high temperature control is a manual reset control which

senses the temperature of the shortening. If the shortening

temperature exceeds the safe operating limit, this control switch

will open and shut off the heat to the frypot. When the

temperature of the shortening drops to the safe operating limit,

the control must manually be reset.

To locate the high limit reset button, open the door to the drain

pan. Look up under the controls and to the right of the fi lter

handle for a red reset button. (On the left for single phase units.)

Checkout

Before replacing a high temperature limit control, check to

see that its circuit is closed.

The shortening temperature must be below 380º F to accurately perform this check.

1. Remove electrical power supplied to the fryer.

To avoid electrical shock or property damage, move the

power switch to OFF and disconnect main circuit

breaker, or unplug cord at wall receptacle.

2. Remove the control panel. Refer to Section 2-4.

2-6 305

Page 53

Model 500/600

2-7. HIGH TEMPERATURE

LIMIT CONTROL

(ELECTRIC AND

GAS MODELS)

(Continued)

Electric

High Limit Capillary Tube

Step 3

Gas

3. Remove the two electrical wires from the high

temperature limit control.

4. Check for continuity between the two terminals after

resetting the control. If the circuit is open, replace the

control, then continue with this procedure. (If the circuit

is closed, high limit is not defective. Reconnect the two

electrical wires.)

Replacement

To avoid electrical shock or property damage, move the

power switch to OFF and disconnect main circuit

breaker, or unplug cord at wall receptacle.

1. If the capillary tube is broken or cracked, control will open,

shutting off electrical power. The control cannot be

reset.

2. Drain shortening from the frypot.

3. Remove control panel.

4. Loosen small inside screw nut on capillary tube.

5. Remove capillary bulb from bulb holders inside the frypot.

6. Straighten the capillary tube.

7. Remove larger outside nut that threads into pot wall.

8. Remove the two screws that secure the high limit to

the high limit bracket.

9. Remove defective control from control panel area.

10. Insert new 450 degree high limit (part no. 16738) and replace

screws.

11. Uncoil capillary line, starting at capillary tube, and

insert through frypot wall.

Step 1

To avoid electrical shock or other injury, the capillary

line must run under and away from all electrical power

wires. The tube must never be in contact with the

electrical power wires or terminals.

409 2-7

Page 54

Model 500/600

2-7. HIGH TEMPERATURE

LIMIT CONTROL

(ELECTRIC AND

GAS MODELS)

(Continued)

CENTER

Electric

Gas

Step 13

12. Carefully bend capillary bulb and tube toward bulb holders

on heating elements on electric units, and toward the welded

clips on gas units.

Hang 2 high limit bulb holders, for capillary bulb of the 450

degree high limit (part no. 16738) from the center of the top

element. See photo at left.

13. Slip capillary bulb into 2 bulb holders located on heating

elements, on electric units, and snap bulb in place in welded

clips, on gas units. Pull excess capillary line from pot and

tighten nut into frypot wall.

Be sure capillary bulb of high limit on electric units is not

located past the front of the elements. The capillary bulb

and bulb holders should be positioned as not to interfere with

basket or when cleaning the frypot wall, or damage to capillary tube could result.

14. With excess capillary line pulled out, tighten smaller nut.

15. Replace front panel.

16. Refi ll with shortening.

2-8 409

Page 55

Model 500/600

2-8. HEATING ELEMENTS

(ELECTRIC MODELS)

Description

Each electric fryer uses three heating element assemblies.

Heating elements are available for 208, 220/240, or 440/480

voltage. Check the data plate inside the door to determine the

correct voltage.

Maintenance Hint

If the shortening’s temperature recovery is very slow, or at a

slower rate than required, this may indicate defective heating

element(s). An ohmmeter will quickly indicate if the elements are

shorted or open.

Checkout

1. Remove electrical power supplied to the fryer.