Henny Penny BCF-110 User Manual

PROJECT QUANTITY ITEM NO

BCF-110 Blast Chiller/Freezer

General Information

Henny Penny’s BCF-110 blast

chiller/freezer cools up to 110 lbs. (50

kg) of hot food from 140°F (60°C) to

40°F (5°C) in less than 4 hours for

later storage, serving or

rethermalization. Units are also

capable of blast freezing 55 lbs. (25

kg) from 140°F (65oC) to 0°F (-18°C)

in 4 1/2 hours.

Foods rapidly chilled spend less

time in the “danger zone” between

160-40°F (71-3°C), assuring food

safety with minimal energy

consumption.

Foods also store longer, taste

better when reheated and have

colors, flavors and textures preserved

longer since very little moisture is lost

through evaporation.

The BCF-110 features 14 pairs of

Compact blast chiller/freezer Model BCF110 with adjustable racking, 110 lbs (50

kg) max capacity.

removable, adjustable shelf runners

that accept standard steam table

pans and grids. Additional runners

are available. Fans are positioned on

the rear wall to accommodate side-

MODEL BCF-110

wall racking.

Unit includes stainless steel

temperature probe with 4 sensors that

enable the core temperatures of

different types of food products to be

measured accurately. Unit

automatically stops freezing/chilling

cycle when desired core temperature

level is reached.

Unit can also be operated in Timer

mode that ends the chilling cycle after

a desired time period and then

maintains temperature automatically.

The BCF-110 is cooled by a built-in

2.5-hp air-cooled condensing unit.

Models are available with right or

left-hinged doors. Compact size

requires minimal floor space.

Standard Features

• Stainless steel cabinet with

polyurethane foam injected

insulation.

• 14 pairs of removable, adjustable

shelf runners accept full-size steam

table pans and grids.

• Touch-pad controls feature simple

icons and a large digital display.

• Temperature displays can be set in

°F or °C.

• The unit’s operations can be

controlled either by a timer or by

the multi-point Frigiprobe that

• Self-contained evaporation, no

drain or attachments needed.

• De-icing mode rapidly removes

excess ice or water Self-diagnostic

system identifies and displays

service requirements.

• Designed with coved corners,

round door gasket and removable

shelf runners and supports for easy

cleaning.

• R404A refrigerant, CFC free.

• Adjustable leveling legs.

automatically controls food chilling.

• Automatic holding mode at end of

chilling cycle.

APPROVED APPROVED AS NOTED RESUBMIT

AUTHORIZED SIGNATURE DATE

© 2006 Henny Penny Corporation, Eaton, OH 45320 USA Revised 12/04/07

Options, accessories

Door hinge

Right OR

Left

Henny Penny Corporation

PO Box 60 Eaton OH 45320 USA

+1 937 456.8400 800 417.8417

+1 937 456.8434 Fax 800 417.8434 Fax

www.hennypenny.com

PROJECT ITEM NO

•

BCF-110 Blast Chiller/Freezer

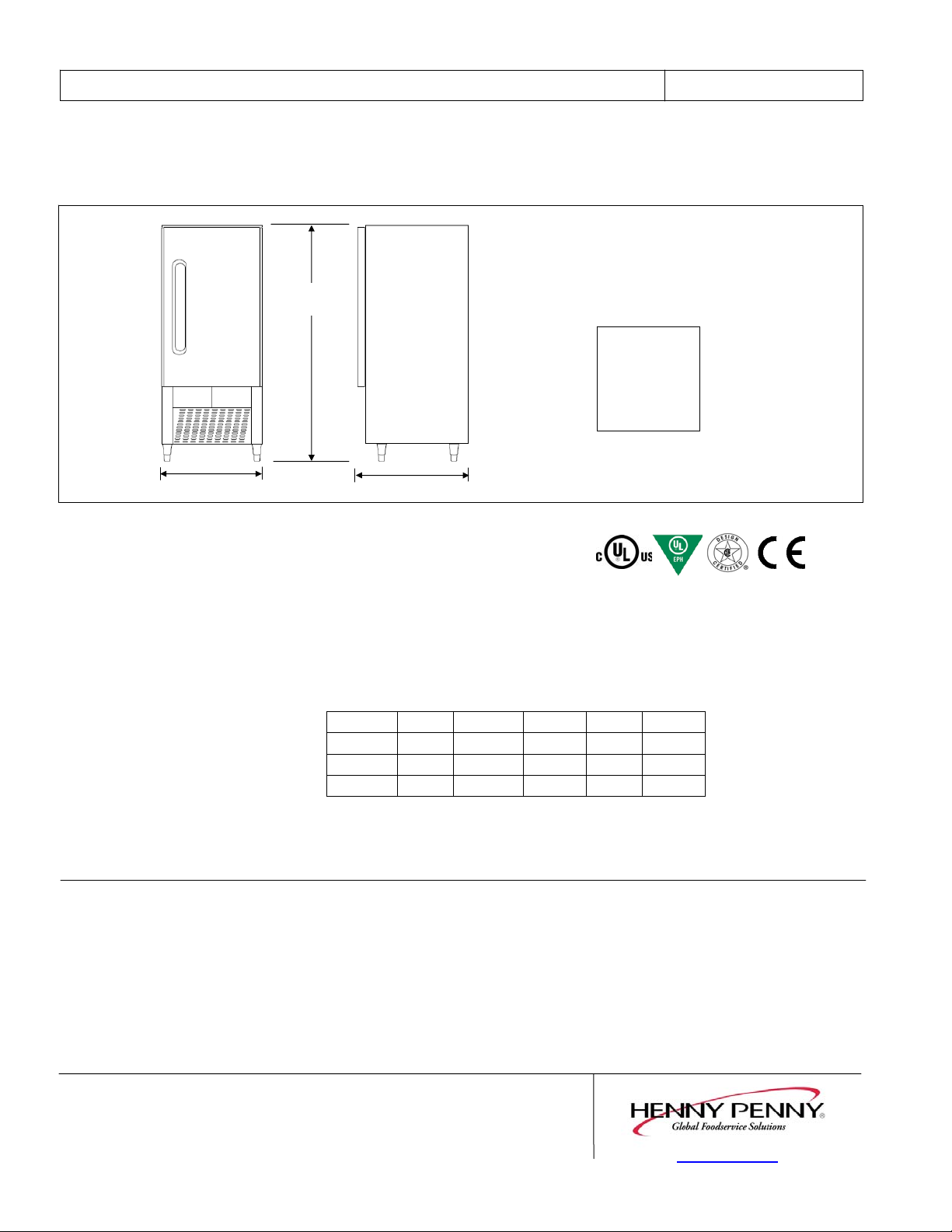

Dimensions

Height: 71 ¾ in. (1822 mm)

Width: 29 1/8 in. (740 mm)

Depth: 31 ½ in. (800 mm)

Required clearances

Top: 16 in. (400 mm)

Sides: 4 in. (100 mm) air flow

Back: 4 in. (100 mm)

Front: 30 in. (762 mm) door open

Crated dimensions

Length: 35 in. (889 mm)

Depth: 34 ¼ in. (870 mm)

Height: 82 ½ in. (2095 mm)

Volume: 57 cu. ft. (1.60 m³)

Capacity

Maximum product capacity: 110 lbs. (50 kg)

chills 140-40°F (60-5°C) in less than 4 hours.

Freezes 55 lbs. (25 kg) 140-0°F (604 ½ hours.

Accepts full-size steam table pans and grids.

Adustable shelving: locations for 27 runners

on 1 3/8 in. (35 mm) centers. 14 runner pairs

shipped with unit.

29 1/8 in. (740 mm)

71 ¾ in.

(1822 mm)

-

18°C) in

31 1/2 in. (800 mm)

Net weight N/A

Crated weight 508 lbs. (231 kg)

Water connections

No water connection. 1 in. (25 mm) drain.

Required cooling capacity

N/A

Condensing unit

Air-cooled, 2.5 hp

Refrigerant type: R404A

Electrical

Volts Phase Cycle/Hz Watts Amps Wire

200 3 50/60 3800 17.0 3+G

208-240 3 60 4600 17.0 3+G

400 3 50 3100 9.0 3NG

MODEL

PLAN

FRONT

Laboratory certifications

BCF-110

Utilities connections

A Electrical

B Refrigerant in

C Drain

Bidding Specifications

• Provide Henny Penny Model BCF-110 Blast

Chiller/Freezer capable of cooling full loads

in less than 4 hours and freezing half loads

in 4 ½ hours.

• Cabinet and door inside and outside is

stainless steel with 1/8 thick injected

plyurethane foam insualtion in full

compliance with NSF standards in force.

• Units will use R404A refrigerant and have

built-in 2.5-hp air-cooled condensing units.

• Units shall have condensing unit hooding

Continuing product improvement may subject specifications to change without notice.

© 2006 Henny Penny Corporation, Eaton, OH 45320 USA Revised 12/04/07

for direct outside installation, liquid tank with

safety valve,

and HP/LP safety cut-out.

• Units will have LED digital controls located

on front panel.

• Unit will operate either by timer or a multipoint food core probe that automatically

controls cycle

• (1) Frigiprobe temperature probe for probecontrolled cooling shipped with unit.

condensing pressure control

Units will automatically trigger holding mode at

the end of chilling cycles

• Units will have a de-icing feature that prevent

ice from forming on evaporators

www.hennypenny.com

Loading...

Loading...