Page 1

Page 2

Henny Penny Model BCC/BCR-140, BCC/BCR-175, BFR/BCR-350

Henny Penny Blast Chiller/Freezer

BFR/BCR-350

BCC/BCR-175

BCC/BCR-140

Page 3

Henny Penny Model BCC/BCR-140, BCC/BCR-175, BFR/BCR-350

LIMITED WARRANTY FOR HENNY PENNY APPLIANCES

Subject to the following conditions, Henny Penny Corporation makes the following limited warranties to the

original purchaser only for Henny Penny appliances and replacement parts:

NEW EQUIPMENT: Any part of a new appliance, except lamps and fuses, which proves to be defective

in material or workmanship within two (2) years from date of original installation, will be repaired or replaced

without charge F.O.B. factory, Eaton, Ohio, or F.O.B. authorized distributor. To validate this warranty, the

registration card for the appliance must be mailed to Henny Penny within ten (10) days after installation.

REPLACEMENT PARTS: Any appliance replacement part, except lamps and fuses, which proves to be

defective in material or workmanship within ninety (90) days from date of original installation will be repaired

or replaced without charge F.O.B. factory, Eaton, Ohio, or F.O.B. authorized distributor.

The warranty for new equipment and replacement parts covers only the repair or replacement of the defective

part and does not include any labor charges for the removal and installation of any parts, travel or other expenses

incidental to the repair or replacement of a part.

EXTENDED FRYPOT WARRANTY: Henny Penny will replace any frypot that fails due to manufacturing or

workmanship issues for a period of up to seven (7) years from date of manufacture. This warranty shall not cover

any frypot that fails due to any misuse or abuse, such as heating of the frypot without shortening.

0 TO 3 YEARS: During this time, any frypot that fails due to manufacturing or workmanship issues will be replaced at no charge for parts, labor, or freight. Henny Penny will either install a new

frypot at no cost or provide a new or reconditioned replacement fryer at no cost.

3 TO 7 YEARS: During this time, any frypot that fails due to manufacturing or workmanship issues will be replaced at no charge for the frypot only. Any freight charges and labor costs to install

the new frypot as well as the cost of any other parts replaced, such as insulation, thermal sensors,

high limits, fittings, and hardware, will be the responsibility of the owner.

Any claim must be represented to either Henny Penny or the distributor from whom the appliance was purchased. No allowance will be granted for repairs made by anyone else without Henny Penny’s written consent. If

damage occurs during shipping, notify the sender at once so that a claim may be filed.

THE ABOVE LIMITED WARRANTY SETS FORTH THE SOLE REMEDY AGAINST HENNY PENNY

FOR ANY BREACH OF WARRANTY OR OTHER TERM. BUYER AGREES THAT NO OTHER REMEDY

(INCLUDING CLAIMS FOR ANY INCIDENTAL OR CONSQUENTIAL DAMAGES) SHALL BE AVAILABLE.

The above limited warranty does not apply (a) to damage resulting from accident, alteration, misuse, or abuse;

(b) if the equipment’s serial number is removed or defaced; or (c) for lamps and fuses. THE ABOVE LIMITED

WARRANTY IS EXPRESSLY IN LIEU OF ALL OTHER WARRANTIES, EXPRESS OR IMPLIED, INCLUDING MERCHANTABILITY AND FITNESS, AND ALL OTHER WARRANTIES ARE EXCLUDED. HENNY

PENNY NEITHER ASSUMES NOR AUTHORIZES ANY PERSON TO ASSUME FOR IT ANY OTHER OBLIGATION OR LIABILITY.

FM01-781

Page 4

Henny Penny Model BCC/BCR-140, BCC/BCR-175, BFR/BCR-350

TABLE OF CONTENTS

Section Page

Section 1. INTRODUCTION ................................................................................................................... 1-1

1-1. Henny Penny Blast Chiller ........................................................................................... 1-1

1-2. Features ....................................................................................................................... 1-1

1-3. Proper Care ................................................................................................................. 1-1

1-4. Assistance .................................................................................................................... 1-1

1-5. Safety ........................................................................................................................... 1-2

Section 2. INSTALLATION ...................................................................................................................... 2-1

2-1. Introduction .................................................................................................................. 2-1

2-2. Unpacking .................................................................................................................... 2-1

2-3. Electrical ...................................................................................................................... 2-2

2-4. Location ....................................................................................................................... 2-3

2-5. Refrigerant Information ............................................................................................... 2-4

Section 3. OPERATION............................................................................................................................ 3-1

3-1. Introduction .................................................................................................................. 3-1

3-2. Operating Controls ....................................................................................................... 3-1

3-3. Basic Operation ........................................................................................................... 3-4

3-4. De-Icing ....................................................................................................................... 3-7

3-5. Cleaning ....................................................................................................................... 3-8

3-6. Seasonal or Prolonged Shutdown ................................................................................. 3-9

3-7. Programming ................................................................................................................ 3-10

Section 4. TROUBLESHOOTING ........................................................................................................... 4-1

4-1. Introduction .................................................................................................................. 4-1

4-2. Troubleshooting ............................................................................................................ 4-1

Section 5. WIRING DIAGRAMS AND PARTS INFORMATION ........................................................ 5-1

Wiring Diagram - BCC-140/175 .................................................................................. 5-1

Wiring Diagram - BCR-140/175 .................................................................................. 5-2

Wiring Diagram - BCR-350 ......................................................................................... 5-3

Parts List ...................................................................................................................... 5-4

100 i

Page 5

Henny Penny Model BCC/BCR-140, BCC/BCR-175, BFR/BCR-350

SECTION 1. INTRODUCTION

1-1. BLAST CHILLER/ The Henny Penny Blast Chiller are designed to carry out fast

refrigeration of food products. The units are electronically controlled for easy use and for consistent operation. The

BCC/BCR-140, will chill up to 140 lbs (65 kg) of product, the

BCC/BCR-175 will chill up to 175 lbs (80 kg), and the BCR-350

will chill up to 350 lbs (160 kg) of product. The BFR-350 chills

and freezes up to 350 lbs. (160 kg) of product.

1-2. FEATURES • Interior and Exterior made of 304 Stainless Steel

• Electronic Controls with Self Diagnostics

• Manual De-icing of the Interior by Electrical Heater

• Multi-Sensored Frigiprobe food probe

• Easily Maintained

• The BCC-140 and BCC-175 have water cooled

condensing units

• The BCR-140, BCR-175, and BCR-350 are shipped

without condensing units

• HACCP Printer capabilities

• The BCC/BCR-140 and 175 can use the combi, MOR-20

• The BFR and BCR-350 can use the combi, MOR-40

1-3. PROPER CARE As in any unit of food service equipment, the Blast Chiller does

require care and maintenance. Suggestions for the proper care and

maintenance are contained in this manual.

The conscientious use of the recommended procedures,

coupled with regular maintenance, will result in few repairs to

the equipment. When such repairs are required, they may be

accomplished by following the repair steps contained in this

manual.

1-4. ASSISTANCE Should you require outside assistance, just call your local

independent distributor maintained by Henny Penny Corporation.

In addition, feel free to contact our corporate headquarters in

Eaton, Ohio. Dial 800-417-8405 toll free, or 937-417-8405.

201 1-1

Page 6

Henny Penny Model BCC/BCR-140, BCC/BCR-175, BFR/BCR-350

1-5. SAFETY The Henny Penny Blast Chiller has may safety features incorpo-

rated. However, the only way to ensure a safe operation is to fully

understand the proper installation, operation, and maintenance

procedures. The instructions in this manual have been prepared to

aid you in learning the proper procedures. Where information is of

particular importance or safety related, the words WARNING,

CAUTION, and NOTE are used. Their usage is described below.

The word WARNING is used to alert you to a procedure,

that if not performed properly, might cause personal injury,

such as burns and/or loss of sight, and damage to the unit.

The word CAUTION is used to alert you to a procedure

that, if not performed properly, may damage the unit, or

product.

NOTE

The word NOTE is used to highlight especially important

information.

1-2 100

Page 7

Henny Penny Model BCC/BCR-140, BCC/BCR-175, BFR/BCR-350

SECTION 2. INSTALLATION

2-1. INTRODUCTION This section provides the installation for the Henny Penny

Blast Chiller.

NOTE

Installation of this unit should be performed only by a

qualified service technician.

Do not puncture the skin of the Blast Chiller with drills or

screws, as component damage or electrical shock could

result. Also, if the unit is shipped with a compressor, Do Not

lay the unit on its side. If the unit has been on its side, the unit

must be in an upright position for at least an hour before

power is applied to the unit. Check all components for signs

of being loose or damaged, and make sure the system has

refrigerant. Failure to follow these instructions may cause

damage to the components.

2-2. UNPACKING The Henny Penny Blast Chiller has been tested, inspected, and

expertly packed to insure arrival at its destination in the best pos

sible condition. The cabinet rests on a wooden skid and is then

packed inside a wooden box with sufficient padding to withstand

normal shipping treatment.

NOTE

Any shipping damage should be noted in the presence of

the delivery agent and signed prior to his or her departure.

To remove the Henny Penny Blast Chiller from the box, you

should:

1. Carefully cut banding straps.

2. Remove box from around unit.

3. Lift the unit off the skid.

The BCC/BCR-140 and BCC/BCR-175 weighs between

400 (181 kg) and 550 lbs (249 kg), and the BFR and

BCR-350 weigh approximately 770 lbs (350 kg). Take care

when lifting units to prevent personnal injury.

201 2-1

Page 8

Henny Penny Model BCC/BCR-140, BCC/BCR-175, BFR/BCR-350

2-2. UNPACKING 4. Open door and remove packing from the inside of the unit.

(Continued)

5. Peel off any protective covering from the exterior of the

cabinet.

6. Your Blast Chiller is now ready for operation.

If the blast chiller has been laid on its side, the unit must be

sitting upright for at least an hour before applying power to

the unit. Check all components for signs of being loose or

damaged, and make sure the system has refrigerant. Failure

to follow these instructions may causedamage to the

components. Failure to follow these instructions could cause

damage to the compressor.

NOTE

Be certain to save any literature that is packed inside the

cabinet, or separate boxes.

2-3. ELECTRICAL BCC-140 • 200 V, 50-60 Hz, 3 phase

• 208-240 V, 60 Hz, 3 phase

• 230 V, 50 Hz., 1 phase

BCC-175 • 200 V, 50-60 Hz, 3 phase

• 208-240 V, 60 Hz, 3 phase

• 400 V, 50 Hz., 3N phase

BCR-140 and 175 • 208-240 V, 60 Hz, single phase

• 230 V, 50 Hz, single phase

• 200 V, 50-60 Hz., single phase

BFR and BCR-350 • 200 V, 50-60 Hz, 3 phase

• 208-240 V, 60 Hz, 3 phase

• 400 V, 50 Hz., 3N phase

The data plate, located inside of the unit, will specify the correct

electrical supply. The unit requires a grounded receptacle with a

separate electrical line protected by a fuse or circuit breaker of the

proper rating.

The cabinet must be adequately and safely grounded

according to local electrical codes to prevent the possibility of electrical shock.

2-2 201

Page 9

Henny Penny Model BCC/BCR-140, BCC/BCR-175, BFR/BCR-350

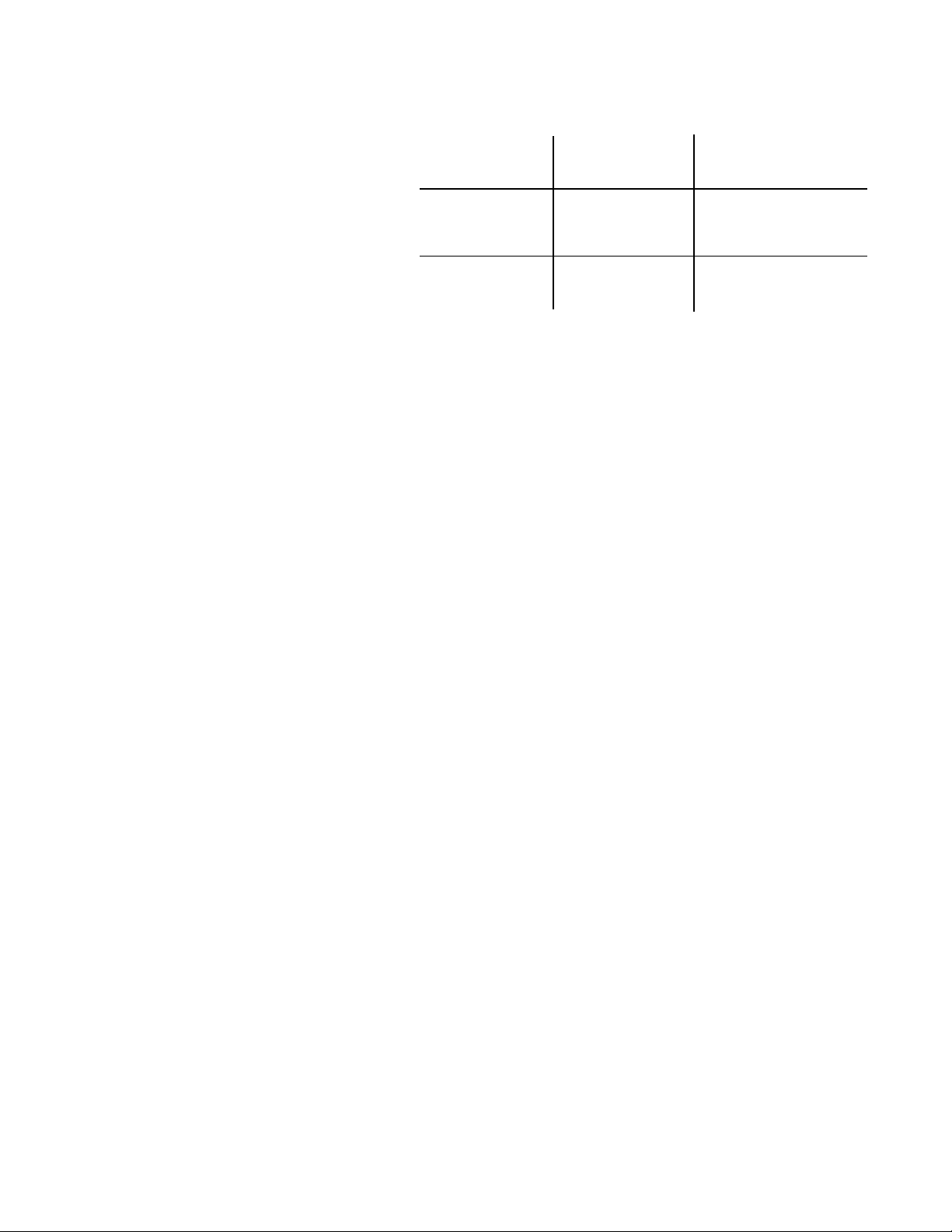

2-3. ELECTRICAL Refer to the table below for electrical ratings for both models.

(Continued) Model No. Volts Watts Amps Freq. Phase

BCC-140 200 4700 18 50/60 3

208-240 4700 18 60 3

230 4700 20 50 1

BCC-175 200 5800 20 50/60 3

208-240 5800 20 60 3

400 5800 9 50 3N

BCR-140 208-240 2400 12 60 1

230 2400 10 50 1

200 2400 12 50-60 1

BCR-175 200 2400 12 50/60 1

208-240 2400 12 60 1

230 2400 12 50 1

BFR & 200 4100 15 50/60 3

BCR-350 208-240 4100 15 60 3

400 4100 10 50 3N

2-4. LOCATION The Blast Chillers should be placed in an area where the doors can

be opened, for loading and unloading, without interruption. For

proper operation, the cabinet must be level.

For maximum efficiency, if the air temperature of the premises

is more than 100° F (38° C), the room should have adequate

ventilation, taking into account for the heat emitted by the unit.

Clearances should be as follows:

BCC/BCR-140 Top ........... 16 in. (400 mm) for air circulation

Left Side ... 4 in. (100 mm) for air circulation

Right Side . 8 in. (200 mm) for air circulation

Back ......... 4 in (100 mm) for air circulation

Front ........ 26 3/8 in (668 mm) for door swing

BCC/BCR-175 Top ........... 16 in. (400 mm) for air circulation

Sides ........ 3 in. (70 mm) for air circulation

Front ........ 33 3/8 in. (847 mm) for door swing

BFR & Top........... 16 in. (400 mm) for air circulation

BCR-350 Sides ........ 3 in. (70 mm) for air circulation

Pass Thru- Front and Back ... 38 1/8 in (970 mm) for door swing

Solid Back-Front ................... 38 1/8 in. (970 mm) for door swing

Back ................... 4 in. (100 mm) for air circulation

201 2-3

Page 10

Henny Penny Model BCC/BCR-140, BCC/BCR-175, BFR/BCR-350

2-5. REFRIGERANT

INFORMATION Design Pressure

Refrigerant Type Amount of Refrig. High Low

BCC-140 R404A 6 lbs. (2.7 kg) 406 psig 102psig

(28 bar) (7 bar)

BCC-175 R404A 5.5 lbs. (2.4 kg) 406 psig 102 psig

(28 bar) (7 bar)

2-6. REFRIGERATION BCC/BCR-140

CAPACITIES -4o F (-20o C) at 6,800 BTU/hr (2.0 kw)

32o F (0o C) at 16,000 BTU/hr (4.7 kw)

BCC/BCR-175

-4o F (-20o C) at 11,300 BTU/hr (3.3 kw)

32o F (0o C) at 38,800 BTU/hr (9.0 kw)

BCR-350

-4o F (-20o C) at 25,000 BTU/hr (7.3 kw)

32o F (0o C) at 58,000 BTU/hr (17.0 kw)

BFR-350

-4o F (-20o C) at 81,900 BTU/hr (24.0 kw)

-40o F (-40o C) at 35,500 BTU/hr (10.4 kw)

2-4 201

Page 11

Henny Penny Model BCC/BCR-140, BCC/BCR-175, BFR/BCR-350

SECTION 3. OPERATION

3-1. INTRODUCTION This section provides operating procedures for the Blast Chiller.

Sections 1, 2, and 3 should be read, and all instructions should be

followed before operating the cabinet.

This section contains an explanation of all controls and components and information on operating procedures and daily

maintenance.

If the blast chillers (that have compressors shipped with them)

have been laid on its side, the unit must be sitting upright for at

least an hour before applying power to the unit. Check all

components for signs of being loose or damaged, and make

sure the system has refrigerant. Failure to follow these

instructions may cause damage to the components. Failure to

follow these instructions could cause damage to the compres

sor.

3-2. OPERATING CONTROLS Pages 3-1 to 3-4 identifies and describes the function of all the

operating controls.

Fig. Item Description Function

No. No.

3-1 1 On/Off Button The On/Off button, when pressed, is a button on the

control panel that starts a chilling cycle. It also must be

pressed before any changes to the controls can be made,

and to start and stop the De-ice cycle.

3-1 2 Digital Display The Digital Display shows the temperatures, the time

(in a timing cycle), and the information in the technical

mode.

3-1 3 Up and Down The Up and Down Arrows are used when changing

Arrows times or settings.

3- 1 4 Alarm Button The Alarm button is used to stop the optional alarm buzzer

and to enter the technical mode.

3-1 5 Temp Button The Temp button is used to select either the chilling

mode.

3-1 6 De-ice Button The De-ice button is used to remove ice that may have

formed on the evaporator during a chilling cycle.

3-1 100

Page 12

Henny Penny Model BCC/BCR-140, BCC/BCR-175, BFR/BCR-350

3-2. OPERATING CONTROLS

(Continued)

Fig. Item Description Function

No. No.

3-1 7 Select Button The Select button is used to choose between a timing

cycle or a cycle using the food probe.

3-1 8 Fan LED The Fan LED is a green light which illuminates when

the fan is running.

3-1 9 Compressor LED The Compressor LED is a green light which illuminates

when the compressor is running.

3-1 10 End-of-Cycle LED The End-of-Cycle LED is a green light which illumi-

nates at the end of a timing cycle, or food probe cycle.

3-1 11 Alarm LED The Alarm LED is a red light which illuminates when

the unit senses a fault in the system. (Ex: AL 1, AL 2,

etc.).

3-1 12 Chill LED The Chill LED is a green light which illuminates when

the chilling mode is selected.

3-1 13 Freeze LED The Freeze LED is a green light which illuminates

(Only applicable when the freezing mode is selected.

on BFR units)

3-1 14 De-ice LED The De-ice LED is a green light which illuminates

when the de-ice button is pressed.

3-1 15 Timer LED The Timer LED is a green light which illuminates when

the timing cycle is selected.

3-1 16 Frigiprobe LED The Frigiprobe LED is a green light which illuminates

when the food probe mode is selected.

201 3-2

Page 13

Henny Penny Model BCC/BCR-140, BCC/BCR-175, BFR/BCR-350

3-3 100

Page 14

Henny Penny Model BCC/BCR-140, BCC/BCR-175, BFR/BCR-350

3-3. BASIC OPERATION The Henny Penny Blast Chillers can chill food products with a

core temperature of 149ºF (65ºC), down to 40ºF (4ºC) within 4

hours (room ambiant temperature may impact time it takes

to reach the desired temperature). But, for the above statements

to be accurate, the following conditions must be met:

a. The food product must not be thicker than 1¾ to 2 inches

(40 to 50 mm.)

b. Meats should be placed directly onto the racks, but prod-

ucts in pans should be covered if possible. The steam from

the product can form ice on the evaporator, which will

increase the chilling or freezing time.

c. A minimum clearance of 1 inch (25 mm) between pans.

d. The best dishes or pans to use are stainless steel or alumi-

num. Do not use polycarbonate (plastic) pans. The polycarbonate acts as an insulator around the food product and

makes it hard to chill.

e. Do not exceed the product weight capacity specified by the

particular model of blast chiller. The BCC/BCR-140 has a 140

lbs.(65 kg) capacity, the BCC/BCR-175 has a 175 lb. (80 kg)

capacity, and the BCR-350 has a 350 lb. (160 kg.) capacity.

Start-up

1. Load all the product at one time, so the door does not need

to be opened while in operation.

2. If using the food probe, place probe into product that is

located on the left side, middle of the unit.

3. Press the ON/OFF button to turn unit on. The fan and

compressor LEDs should come on after 25 seconds.

4. Press the Temp button to select the chilling mode. (Chill mode

or freeze mode can be selected on BFR units).

NOTE

The chilling LEDs, and the timing or food probe LEDs, will stay

on with the power switch turned to the OFF position.

201 3-4

Page 15

Henny Penny Model BCC/BCR-140, BCC/BCR-175, BFR/BCR-350

3-3. BASIC OPERATION 5. Press the Select button to choose the food probe mode or

(Continued)

the timing mode. With the Frigiprobe mode selected, the

digital display will alternately show the core temperature of

the product, and the elapsed time of the cycle. If the timing

mode is selected, the digital display will alternately show

the air temperature and the time (hours and minutes) remaining in the cycle.

NOTE

The buzzer will sound 1 minute after the food probe mode is

selected, unless the temperature is above 140ºF(60ºC). Then

the buzzer will sound when 140ºF (60ºC) is reached.

6. Set the time in the timing cycle, if necessary, using the Up

and Down buttons. The time is affected by the thickness of

the food product, weight, food loading temperature, and

food’s packaging. The buzzer will sound 1 minute into the

timing cycle.

NOTE

Avoid opening the door once the cycle has started. This

will lengthen the time it takes to reach the desired temperature.

7. At the end of the cycle (40ºF (4ºC) in the food probe mode)

the buzzer will sound and the unit will automatically start

the hold cycle. The buzzer will sound for 30 seconds, or

press the Alarm button to stop it. In the hold cycle, the

product will be held at 37ºF (3ºC) in the chilling mode.

8. The product can remain in the unit for up to 12 hours, or

can be removed from the unit and placed in a cold storage

case.

3-5 300

Page 16

Henny Penny Model BCC/BCR-140, BCC/BCR-175, BFR/BCR-350

3-3. BASIC OPERATION A temperature conversion chart is provided for your

(Continued) convenience:

200 3-6

Page 17

Henny Penny Model BCC/BCR-140, BCC/BCR-175, BFR/BCR-350

3-4. DE-ICING Henny Penny recommends to perform the de-icing process after

every 3 cycles, and at the end of each day. This will eliminate any

ice that may have formed around the evaporator during the chilling

cycle. Failure the follow this procedure will increase the time it

takes to cool the product and may lead to unsafe product.

1. Remove all product from the unit.

2. Close the door.

3. Press the ON/OFF button to turn the unit on.

4. Press the De-ice button. The digital display will now show

“d. 01”. The compressor will not come on, but the evaporator fan will come on and pull warm air across the evaporator,

created by the de-icing elements.

5. Allow the de-ice cycle to run for a minimum of 10 minutes

and a maximum of 25 minutes. The unit will automatically

turn off when the evaporator has been de-iced, and reached

a temperature of 77ºF (25ºC).

NOTE

If the above procedures does not remove all the ice from

the evaporator, the length of time, and the temperature at

which the de-ice cycle turns the unit off, can be adjusted.

See the Programming section.

3-7 100

Page 18

Henny Penny Model BCC/BCR-140, BCC/BCR-175, BFR/BCR-350

3-5. CLEANING Daily:

1. Remove all electrical power supplied to the unit by turning off

the wall circuit breaker.

2. Remove all product from the unit.

3. Remove the racks and pans from the unit and clean with

soap and water at a sink.

4. Clean all surfaces with a soft cloth, soap and water. DO

NOT USE ABRASIVE CLEANSERS.

DO NOT use abrasives, such a steel wool, or abrasive

cleaners, such as, chlorine, bromine, iodine, or ammonia

chemicals to clean the unit. These will deteriorate the

stainless steel and greatly reduce the life of the unit.

5. Clean around the electronic controls and the door seal with

a soft, damp cloth.

DO NOT use large quantities of water, or a spray hose to

clean the unit. Damage to the components could result.

6. Reconnect the electrical power to the unit and unit is now

ready for operation.

Monthly: BCC-140 Only

At least once a month the air condenser needs to be cleaned of

dust or obstructions for the unit to run effeciently and to reduce

energy use of the unit.

1. Remove all electrical power supplied to the unit by unplugging the power cord from the wall, or by turning off the

wall circuit breaker.

2. Using a flathead screwdriver, remove the screws from the

front panel of the unit. Pull panel down and press in on the

side of the panel to release the tabs, and remove the panel

from the unit.

300 3-8

Page 19

Henny Penny Model BCC/BCR-140, BCC/BCR-175, BFR/BCR-350

3-5. CLEANING (Continued) 3. Use a vacuum cleaner, or soft brush to remove the dust, or

other obstructions from the condenser.

4. Finish cleaning with compressed air if possible.

DO NOT use a wire brush to clean the condenser, or

damage to the condenser could result.

5. Replace the front panel, and reconnect the electrical supply,

and unit is now ready for use.

3-6. SEASONAL OR 1. Remove all electrical power supplied to the unit by turning off

PROLONGED SHUTDOWN

the wall circuit breaker.

2. Make sure the inside of the unit is clean and completely

dry.

3. Leave the door slightly ajar to prevent smells from developing inside the unit.

3-9 201

Page 20

Henny Penny Model BCC/BCR-140, BCC/BCR-175, BFR/BCR-350

3-7. PROGRAMMING Information about the operation settings can be accessed by

pressing the Alarm button. These settings can also be changed

while in the different steps. The following information can be

accessed:

NOTE

After pressing the Alarm button, a delay will occur before

the desired number will appear in the display, and the

number in the left column will show for 2 seconds. You then

only have 12 seconds to change the setting.

00 1. Not Available at this time.

01 2. Not Available at this time.

02 3. Internal air temperature. Press the Alarm button three

times and the digital display will show the air temperature

during a food probe cycle.

03 4. Evaporator temperature. Press the Alarm button 4 times

and the digital display will show the evaporator temperature during the de-icing cycle.

04 5. Type of program setting indicated by the jumper

link located on the control board. Press the Alarm

button 5 times and the digital display will show a number

between 5 and 9, which indicates the position of the jumper

on the control board. The control panel area does not have

to be accessed to obtain the information.(See chart at left).

Henny Penny controls should show a “6” in the display.

05 6. Temperature of the holding cycle, after the chilling. Press

the Alarm button 6 times and the digital display will show the air

temperature. This is the temperatures the unit will stay at during

the hold cycle.

300 3-10

Page 21

Henny Penny Model BCC/BCR-140, BCC/BCR-175, BFR/BCR-350

3-7. PROGRAMMING The holding temperature can be changed at this time by

(Continued) using the Up and Down buttons. Factory setting for air

temperature is 37ºF (3ºC). The minimum temperature

setting is 32ºF (0ºC), and the maximum temperature is

50ºF (10ºC).

06 7. Maximum duration of de-icing cycle (minutes). Press

the Alarm button 7 times and the digital display will show

the time duration of the de-icing cycle. The factory setting is 25

minutes, but this can be changed to a maximum setting of 60, or

a minimum of 25, by using the Up and Down buttons.

07 8. Evaporator temperature for the end of de-icing cycle.

Press the Alarm button 8 times and the digital display will

show the evaporator temperature at which the controls will

automatically turn off the de-icing cycle. The factory

setting is 77ºF (25ºC), but this can be changed to a maximum setting of 59ºF (15ºC), or the minimum of 50ºF

(10ºC), by using the Up and Down buttons.

08 9. Temperature differential before high air temperature

alarm. Press the Alarm button 9 times and the digital display

will show the number of degrees, above the holding temperature, at which an alarm will sound, indicating the hold temperature is too high.

The factory air temperature setting is 27ºF (15ºC), but can

be changed to a maximum setting of 54ºF (30ºC), or a

minimum temperature of 7ºF (4ºC) by pressing the Up or

Down buttons.

09 10. Temperature differential before low air temperature

alarm. Press the Alarm button 10 times and the digital

display will show the number of degrees, below the holding

temperature, at which an alarm will sound, indicating the

hold temperature is too low.

The factory air temperature setting is 27ºF (15°C), but can

be changed to a maximum setting of 54ºF (30°C), or a minimum of 18ºF (10°C) by pressing the Up and Down buttons.

3-11 300

Page 22

Henny Penny Model BCC/BCR-140, BCC/BCR-175, BFR/BCR-350

3-7. PROGRAMMING 11. The duration of time the temperatures, (in 9 and 10

(Continued) above), must remain at before the alarms will sound.

Press the Alarm button 11 times and the digital display will

10 show the time at which the high and low temperatures (no.

9 and 10 above) must remain at, before the alarm will

sound.

The factory setting is 20 minutes, but can be changed to a

maximum setting of 60 minutes, or a minimum of 10 minutes

by pressing the Up and Down buttons.

This means, that the temperature must remain at a too high,

or too low temperature for 20 minutes before an alarm will

sound.

11 12. International Only. A Frigiprobe sensor temperature

which can turn off the compressor, in a chilling cycle,

to prevent freezing of the product. Press the Alarm

button 12 times and the digital display will show the temperature, at which a sensor in the Frigiprobe will turn off the

compressor during a Frigiprobe mode. This will prevent the

outer surfaces of the product from freezing, however the

cooling time will be greatly increased.

The factory setting is 39ºF (4ºC), but can be changed to a

maximum setting of 122ºF (50ºC), or a minimum of 32ºF

(0ºC) by pressing the Up and Down buttons.

NOTE

Do not change this setting lower than the setting used in parameter 22, (next page).

NOTE

This function will only activate when the factory setting is

changed to above 40ºF (4ºC). England must have a setting

of 3ºC (37ºF).

12 13. Re-initialize the controls to factory settings. Press the

Alarm button 13 times and the digital display will show

“dEF”, at which time the Up button is pressed and the unit

will shut down. Re-initialization is now complete.

NOTE

After re-initialization, the controls will default back to factory

settings. The temperature will be in Celsius and the values in

steps 12, 16, and 18, of this section, will need to checked to be

accurate for the country in which the unit is installed.

300 3-12

Page 23

Henny Penny Model BCC/BCR-140, BCC/BCR-175, BFR/BCR-350

3-7. PROGRAMMING 14. Blast chilling, low side air temperature limit, when using

(Continued)

the Frigiprobe, in step 12 of this section. Press the Alarm

button 14 times and the low side air temperature, at which

20 the compressor cycles on and off, will show in the display.

This temperature is used in preventing the product from

freezing, while in the chilling mode, which is described in

step 12.

The factory setting is -4ºF (-20ºC), but can be changed to a

maximum setting of 32ºF (0ºC), and a minimum setting of

-31ºF (-35ºC), by using the Up and Down buttons.

21 15. Blast chilling, high side air temperature limit, when using

the Frigiprobe, in step 12 of this section. Press the Alarm

button 15 times and the high side air temperature, at which

the compressor cycles on and off, will show in the display.

This temperature is used in preventing the product from

freezing, while in the chilling mode, which is described in

step 12.

The factory setting is 32ºF (0ºC), but can be changed to a

maximum setting of 50ºF (10ºC), and a minimum setting of

23ºF (-5ºC), by using the Up and Down buttons.

22 16. Frigiprobe, end of cycle temperature setting. Press the

Alarm button 16 times, and the temperature at which ends

the food probe cycle and starts the hold cycle, will show in

the display.

The factory setting is 39ºF (4ºC), but can be changed to a

maximum setting of 50ºF (10ºC), and a minimum setting of

32ºF (0ºC), by using the Up and Down buttons.

NOTE

The maximum settings for U.S.A. is 39ºF (4ºC), and for

England is 37ºF (3ºC).

3-13 300

Page 24

Henny Penny Model BCC/BCR-140, BCC/BCR-175, BFR/BCR-350

3-7. PROGRAMMING 17. Frigiprobe temperature for when the buzzer sounds at

(Continued) the start of a cycle. Press the Alarm button 17 times, and

the temperature that the buzzer will sound when the product

23 has reached the “danger zone” temperature, and must be

cooled to a “safe” temperature within the recommended

time, will be shown in the display.

The factory setting is 140ºF (60ºC), but can be changed to a

maximum setting of 176ºF (80ºC), and a minimum setting of

122ºF (50ºC), by using the Up and Down buttons.

NOTE

The settings for the U.S.A. must be 140ºF (60ºC) and for

England, 158ºF (70ºC).

30 18. Selecting Fahrenheit or Celsius. Press the Alarm button

18 times and ºF or ºC will show in the display. Use the Up

and Down buttons to toggle from ºF to ºC, or vice versa.

100 3-14

Page 25

Henny Penny Model BCC/BCR-140, BCC/BCR-175, BFR/BCR-350

SECTION 4. TROUBLESHOOTING

4-1. INTRODUCTIONThis section provides troubleshooting information in the form

of an easy to read table.

If a problem occurs during the first operation of a new cabinet,

recheck the installation per section 2 of this manual.

Before troubleshooting always recheck the operating procedure

per section 3 of this manual.

4-2. TROUBLESHOOTING To isolate a malfunction proceed as follows:

1. Clearly define the problem (or symptom) and when it

occurs.

2. Locate the problem in the troubleshooting table.

3. Review all possible causes, then one-at-a-time work

through the list of corrections until the problem is solved.

WARNINGS In the event of a system failure, the digital display will show an

alarm message. These messages are coded; “AL 1”, “AL-2”,

“AL-3”, “AL-5”, and “AL-6”. When an alarm occurs, the red

alarm LED will illuminate and a buzzer (optional) will sound .

Press the Alarm button to stop the buzzer.

NOTE

The unit can operate on Auto Back-up if an alarm sounds

for a faulty probe. Must select the timing mode, and enter a

time.

Display Cause Correction

AL-1 Faulty air temperaure Replace the probe. Unit can operate on Auto

probe Back-up until a new probe is installed.

AL-2 Faulty evaporator probe Replace the probe. The de-icing cycle can operate at

50% of the setting in step 7 of the Programming section.

AL-3 Faulty Food Probe Replace the probe. The food probe mode will not

operate, but the unit will operate in the timing mode.

4-1 300

Page 26

Henny Penny Model BCC/BCR-140, BCC/BCR-175, BFR/BCR-350

4-2. TROUBLESHOOTING

(Continued)

ALARMS

Display Cause Correction

AL-5 Temperature too low

in the hold mode. Faulty control board - replace control board.

Faulty contactor - replace contactor.

AL-6 Temperature too high in

the hold mode. Faulty control board - Replace board.

Door opened too much - Make sure door stays

closed as much as possible.

Problem Cause Correction

The evaporator is iced-up Faulty De-icing Heater Replace De-icing Heater

after a de-icing cycle.

Evaporator temperature at end Increase the setting of step 8

of de-icing cycle too low. in Section 3.

Maximum time of de-icing cycle Increase the setting of step 7

too short. in Section 3.

Too much water on evaporator The unit has been shut down without Start a de-icing cycle.

fins. a de-icing cycle.

Slow to decrease Compressor not working properly Check compressor and rein temperature (decline in place if neccessary.

performance)

Evaporator fan not working properly Check the fan and replace if

neccessary.

Temperature of room too high. Ventilate the room.

Not enough clearance around unit. Change the location of the

unit. (See section 2-4)

300 4-2

Page 27

Henny Penny Model BCC/BCR-140, BCC/BCR-175, BFR/BCR-350

4-2. TROUBLESHOOTING

(Continued)

Problem Cause Correction

Slow to decrease Condenser obstructed by dirt. Clean the Condenser.

in temperature (decline in

performance) Evaporator iced up. Perform a de-icing cycle.

Refrigerating problem Check refrigeration circuit and

components.

Display temperature does In Frigiprobe mode, the display Normal

not match the actual inlet air shows the product temperature.

temperature. (No alarm)

In timer mode, or hold mode, Ohm out the probe and check

the probe may be showing the the reading with the table on

wrong temperature. page 4-5. Change the probe if

it is out of tolerance.

Green compressor indicator Compressor and condenser fan

light on and the compressor do not work:

not working, or working - Faulty contactor Check contactor and change if

sometimes. neccessary.

- Faulty control board relay-no Replace control board.

voltage across terminals 10-11.

Compressor works, but condenser

fan does not:

- Faulty condenser fan Replace fan.

Compressor and condenser fan

work together:

- Faulty protection component Check items and replace if

for the compressor (overload neccessary.

protector, potential relay, start

and run capacitor)

- Faulty overload protector of Check fan and replace if

condenser fan. necessary.

4-3 100

Page 28

Henny Penny Model BCC/BCR-140, BCC/BCR-175, BFR/BCR-350

4-2. TROUBLESHOOTING

(Continued)

Problem Cause Correction

Green compressor indicator Voltage across terminals 10-11

light off and compressor of control board:

is working. - Control board relay bad Replace control board.

No voltage across terminals 10-11

of control board:

- Faulty contactor.Replace contactor.

Green fan indicator light Voltage across terminals 8-9 of

on and fan(s) not working. control board.

- Fan or capacitor bad Replace fan or its capacitor.

- Fan thermo-switch tripped. Allow the fan motor to cool to

see if the fan comes back on.

If the fan does not come back

on, or it keeps tripping, replace the fan.

No voltage across terminals 8-9

of control board:

- Faulty control board relay. Replace control board.

All indicator lights off and Check electrical supply. Plug unit into receptacle, or

On/Off switch will not reset wall circuit breaker.

operate.

Fuse of control board blown. Change the fuse.

No voltage from the control Change the control board.

board transformer.

Connector between the control Check the connection.

board and display board not

connected properly.

Bad wire in the connector between Replace the connector.

the control board and display

board.

100 4-4

Page 29

Henny Penny Model BCC/BCR-140, BCC/BCR-175, BFR/BCR-350

4-5 100

Page 30

Henny Penny Model BCC/BCR-140, BCC/BCR-175, BFR/BCR-350

201 5-1

Page 31

Henny Penny Model BCC/BCR-140, BCC/BCR-175, BFR/BCR-350

5-2 201

Page 32

Henny Penny Model BCC/BCR-140, BCC/BCR-175, BFR/BCR-350

201 5-3

Page 33

Henny Penny Model BCC/BCR-140, BCC/BCR-175, BFR/BCR-350

Quantity BFR/

Item BCC BCR BCC BCR BCR

No. Part No. Description 140 140 175 175 350

19504.0205 Control PC Board11111

2 9503.3692 Display PC Board 11111

3 9503.3700 Auxiliary Display Board 11111

49503.3759Connecting Cable11111

5 9503.7719 Communication Board 11111

6 9503.8436 Printer 11111

7 9503.8428 Printer Connecting Cable 11111

8 9503.3726 Buzzer - 240V - UL 11111

9 9500.7936 Drier 1 - 1 - -

10 9503.6232 De-icing Heater - UL - 500W 33336

11 9500.7209 Air Probe 11111

12 9500.7209 Evaporator Probe 11111

13 9502.6563 Run Capacitor - 4 mF 333314 9560.0334 Evaporator Fan 33334

15 9505.3963 Evaporator Fan Grid - UL 33334

16 9502.0400 Frigiprobe 11111

17 9503.3643 Fuse Holder 11111

18 9503.3650 Fuse - 10A 11111

19 9503.0185 Varistor V320LA20A 11111

20 9503.3601 Control Panel Decal 111120 9503.6224 Control Panel Decal - BCR-350 ----1

21 9503.0920 Contactor - UL/CSA - 3P 23A/AC3 - - 1 - 1

21 9503.0912 Contactor - UL/CSA - 3P 12A/AC3 1 ---22 9503.3304 Condenser Fan Motor-25W, 230V, 60 Hz - - 1 - 22 9502.1846 Condenser Fan Motor-120W, 230V, 60 Hz 1 ---23 9501.8644 Water Condenser - 115V - - 1 - 24 9503.7784 Condenser - UL 1 ---25 9503.3312 Fan Blade for Condenser - BCC-175 - - 1 - 26 9503.6190 Compressor - BCC-175 - - 1 - 26 9502.1762 Compressor - BCC-140 1 ---27 9502.8668 Evaporator - BCC/BCR-175 - - 1 1 27 9501.6283 Evaporator - BCC/BCR-140 1 1 - - 27 9502.8676 Evaporator - BCR-350 ----1

28 9503.6174 Thermal Overload Relay - BCC-175 - - 1 - 28 9503.6158 Thermal Overload Relay - BCC-140 1 ---29 9503.6257 F. Frame Heater-BCC-175; BCR-175/350 - - 2 2 2

29 9503.7735 Front Frame Heater-75W-BCC/BCR-140 1 1 - - 30 9502.5995 Expansion Valve-BCC-175; BCR-175/350 - - 1 1 2

30 9502.6951 Expansion Valve - BCC/BCR-140 1 1 - - 30 9502.5383 Expansion Valve - BFR-350 ----2

31 9500.8850 Nozzle-Exp.Valve-BCC-175; BCR-175/350 - - 1 1 2

31 9500.8843 Nozzle-Expansion Valve - BCC/BCR-140 1 1 - - -

5-4 603

Page 34

Henny Penny Model BCC/BCR-140, BCC/BCR-175, BFR/BCR-350

Quantity BFR/

Item Part BCC BCR BCC BCR BCR

No. No. Description 140 140 175 175 350

31 9500.8967 Nozzle-Expansion Valve BFR-350 ----2

32 9500.7993 Water Pressure Valve - BCC-175 - - 1 - 33 9503.6182 High Pressure Switch - BCC-140 1 ---34 9502.5045 Liquid Receiver - BCC-140 1 ---34 9550.4585 Door - BCC/BCR-175/350 - - 1 1 1

34 9550.6630 Door - BCC/BCR-140 1 1 - - 35 9543.0831 Front Panel for Printer - BCC/BCR-175 - - 1 1 35 9542.5989 Front Panel for Printer - BCC/BCR-140 1 1 - - 36 9541.6053 Vert. Evap. Deflector-BCC/BCR-175 - - 1 1 36 9541.7671 Vert. Evap. Deflector-BCR-350 ----1

37 9505.3674 Door Seal - BCC/BCR-175/350 - - 1 1 1

37 9505.4466 Door Seal - BCC/BCR-140 1 1 - - 38 9501.9998 Floor Door Seal - BCC/BCR-175 - - 1 1 39 9541.8919 Left and Right Side Panels - BCC/BCR-175 - - 2 2 40 9542.5963 LH Panel-BCC-140; LH & RH-BCR-140 1 2 - - 41 9542.7225 Right Side Panel - BCC-140 1 ---42 9543.0419 Top Cover with Condensing Unit-BCC-140 1 ---42 9543.0518 Top Cover w/o Condensing Unit-BCR-140 - 1 - - 42 9543.0427 Top Cover with Condensing Unit-BCC-175 - - 1 - 42 9543.0542 Top Cover w/o Cond.Unit-BCR-175/350 - - - 1 1

43 9502.8601 Door Latch - BCC/BCR-175; BCR-350 - - 1 1 1

43 9501.4551 Door Latch with Strike - BCC/BCR-140 1 1 - - 44 9502.8619 Door Strike - BCC/BCR-175; BCR-350 - - 1 1 1

45 9502.8585 Door Hinge - BCC/BCR-175; BCR-350 - - 2 2 1

45 9501.4601 Door Hinge - BCC/BCR-140 1 1 - - 46 9502.8593 Hinge Shim - BCC/BCR-175; BCR-350 - - 2 2 1

47 9503.6240 High Limit Safety Thermostat 11112

48 9503.4583 Valve Body - BCR-140/175/350 - 1 - 1 1

40 9503.4591 Coil - BCR-140/175/350 - 1 - 1 1

201 5-5

Page 35

Page 36

For Sales or Service Please Contact

The Nearest Henny Penny Distributor

1. General Services

100 Hicks Ave.

Medford, MA 02155

(800) 233-1033

2. Art Cole Associates

Golden Street

Industrial Park

Meriden, CT 06450

(203) 237-7177

3. Globe-Monte Metro, Inc.

47-02 Metropolitan Avenue

Ridgewood, NY 11385

(718) 786-5760

4. Guertin Dist. Inc.

5 Technology Drive

East Syracuse, NY 13057-9713

(315) 437-4928

(800) 468-6336

5. Kreiser Distributing Co.

13800 Lincoln Highway

N. Huntington, PA 16652

(724) 863-3360

6. AFS Equipment Company

9130-X Red Branch Road

Columbia, MD 21045

(410) 964-3770

(800) 969-3770

7. HP Sales & Service Co.

200 Rittenhouse Circle, 4-East

Bristol, PA 19007

(215) 785-3250

NJ Watts (800) 477-4379

8. Astro Food Equipment

7901 Old Rockside Rd.)

Independence, OH 44131

(216) 619-8821

(800) 367-4237

9. Carlisle Food Systems, Inc.

11020 Lakeridge Pkwy.

Ashland, VA 23005

(804) 550-2169

10. Price-Davis, Inc.

Route 1, Highway 27

Iron Station, NC 28080

(509) 928-8815

(704) 732-2236

(800) 456-1014

11. Big A Distributors, Inc.

P.O. Box 1283

Forest Park, GA 30051

(404) 366-6510

(800) 222-0298

12. W.H. Reynolds

Distributors, Inc.

4817 Westshore Blvd.

Tampa, FL 33609

(813) 873-2402

Miami-(954) 845-0841

Jacksonville-(904) 781-9054

FL Watts (800) 282-2733

13. Ber-Vel Distributing Co. Inc.

P.O. Box 9943

Birmingham, AL 35220

(205) 681-1855

14 . Barnett Supply

2089 York Ave.

Memphis, TN 38104

(901) 278-0440

Nashville, TN

(615) 242-6451

Scotsman Supply

516 5th Ave., South

Nashville, TN 37203

(615) 242-6451

15. St. Clair Supply Company

231 East Main Street

Eaton, OH 45320

(937) 456-5500

(800) 762-2968

16. Dine Equipment Co.

3110 Preston Hwy.

P.O. Box 34038 zip 40232

Louisville, KY 40213

(502) 637-3232

FAX (502) 637-5177

17. United Marketing Assoc.

11877 Belden Court

Livonia, MI 48150

(734) 261-5380

18 . T&H Distributors

1235 Parkview

Green Bay, WI 54304

(920) 339-9838

19. Food Service Solutions, Inc.

1682 Barclay Blvd.

Buffalo Grove, IL 60089

(847) 459-8040

(847) 459-7942

20. MEC

2511 Cassens Dr.

Fenton, MO 63026-2547

(636) 343-0664

(800) 397-1515

21. Delta Supply Co., Inc.

3315 W. Roosevelt Rd.

Little Rock, AR 72204

(501) 664-4326

22. Dixie Supply

490 Julianne St.

Bldg. A-2

Jackson, MS 39201

(601) 354-3025

23. Beaullieu Refrigeration Inc.

200 North Luke St.

Lafayette, LA 70506

(337) 235-9755

24. S.L.E. Corporation

1110 Avenue H East

Arlington, TX 76011

(817) 640-7999

25. Brooks Industries

4420 S.W. 29th St.

Oklahoma City, OK 73119

(405) 685-7200

26 . B & D Dist.

19915 W. 161st St.

Suite D

Olathe, KS 66062

(913) 768-8588

FAX 913-768-8855

27 . PHT Systems

1801 Highway 8

Suite 120

New Brighton, MN 55112

(651) 639-0368

28. Mid-Nebraska Restaurant

Supply Co.

1415 S. Webb Road

Grand Island, NE 68802

(308) 384-5780

29. Robert G. Wood & Co.

2080 W. Cornell Ave.

Englewood, CO 80110

(303) 761-0500

(800) 358-3061

30. Open Territory

31 . CPE-USALCO

1310 West Drivers Way

Tempe, AZ 85284

(480) 496-6995

32. National Equipment Corp.

242 West-3680 South

Salt Lake City, UT 84115

(800) 266-5824

(800) 955-9202

33. The Nicewonger Co.

19219 West Valley Hwy

Suite M103

Kent, WA 98032

(800) 426-5972

(425) 656-0907 FAX

34. Tri-State Market Supply

11115 E. Montgomery, Suite A

Spokane, WA 99206

(509) 928-8815

(877) 828-4268

36. Western Pacific

Distributors, Inc.

19422 Cabot Boulevard

Haywood, CA 94545

(510) 732-0100

37. Don Walters Company

2121 S. Susan Street

Suite A

Santa Ana, CA 92704

(714) 979-5863

38 . Troyer Foods, Inc.

17141 State Route 4

Goshen, IN 46526

(219) 533-0302

39. Tri-City HP, Inc.

527 West Fourth St.

Davenport, IA 52801

(319) 322-5382

40. Certified Commercial Service &

Equipment (CCSE)

6031-A Industrial Heights Drive

Knoxville, TN 37909

(865)-546-8778

41 . Gower Distributors, Inc.

P.O. Box 4804

Box 216K Rt. -4

Victoria, TX 77903

(361) 573-9777

42 . Top-Line Distributors

1501 College Ave.

Houston, TX 77585

(713) 946-6008

43. DSL Inc., Canada

14520 128th Ave.

Edmonton, Alberta

Canada T5L3H6

(403) 452-7580

(Alberta, British Columbia,

Manitoba, Saskatchewan,

Yukon, & N.W. Territories)

44. Taylor Freezers, Inc.

52 Armthorpe Rd.

Brampton, Ontario

Canada L6T5M4

(905) 790-2211

(Ontario, Montreal, and

Maritime Provinces)

45. Bazinet Taylor Ltee.

4750 Rue Bourg

Ville St. Laurent

Quebec, Canada H5T 1J2

(514) 735-3627

(Quebec only)

If Further Assistance Is Needed Please Contact: Henny Penny Corporation

1219 U. S. Route 35 West

Eaton, Ohio 45320

1-800-417-8417

Fax 1-800-417-8402

Revised 4-01

Page 37

Page 38

Henny Penny International Distributor Network

U.S. Headquarters

Henny Penny Corporation

1219 U.S. Route 35 West

Eaton, OH 45320 USA

Telephone: 937-456-8417

Fax: 937-456-1860

Representative Office

1 . Henny Penny Corporation

Representative Office

Parc dEntreprises de

IEsplanade

2bis Rue Paul Henri Speak

Saint Thibault des Vignes

77462 Lagny sur Mame Cedex,

France

Telephone: 33 (1) 60075600

Fax: 33 (1) 60071489

U.S. Export Centers

2. Feco International Company

20 North San Mateo Drive,

Suite 9

San Mateo, CA 94401 USA

Telephone: 415-348-3499

Fax: 415-348-3575

3. Caribbean Islands & Central

America (excluding Puerto Rico)

Total Equipment Suppliers

9550 NW 41

Miami, FL 33178

Telephone: 305-718-9550

Fax: 305-718-9505

Algeria

4. SOMAB

Y1 Rue Mahmoud Boudjatit

(Oasis) Ager, Algeria

Tel: 213-21-23-3051/3052

Fax: 213-21-23-3161

Argentina

5. Oditec S.A.

Augstin Alvarez 2128

1602 Florida

Buenos Aires, Argentina

Telephone: (541) 796-0820

Fax: (541) 796-2009

6. Australia

J.L. Lennard Pty. Ltd.

937-941 Victoria Rd.

West Ryde NSW 2114

Sydney, Australia

Telephone: 617-3272-4744

Fax: 617-3272-4799

Bahrain

7. Mohammed Jalal Catering

Old Palace Road

P.O. Box 1335

Manama, State of Bahrain

Telephone: 973-53-45-39

Fax: 973 53-14-78

Bangladesh

8. Puffin International Ltd.

3691B Elephant Rd.

Swarankika Plaza

4th Floor-Dhaka 1205

Dhaka, Bangladesh

Telephone: 8802-863117

Fax: 880-2-867563

Belgium

9. Engelen-Heere N.V.

Industrialpark Terbekehof

Fotografielaan 14

B-2610 Antwerpen (Wilrijk)

Telephone: 323-825-5577

Fax: 323-825-3702

st

St.

Brazil

10. Pesin Equipment Food Service

R. Olavo Bilac 188/198

Sao Caetano Do Sul - SP

Brazil

Telephone:55-11-7690-1470

Fax: 55-11-7690-1466

Bulgaria

11. E.C.E. - CAIX

23A Rue Oborichte

Sofia 1604, Bulgaria

Telephone: 19-359-2-946-1479

Fax: 19-359-2-946-1669

Chile

12. IMAHE

Manuel Montt 1154 Providencia

Santiago, Chile

Tel: 562-341-4953/5707

Fax: 562-274-8567

China

13. Bonny Foodservice Products

Flat C, 8/F, Yeung Yiu Chung

Industrial Bldg., No. 20

Wang Hoi Rd.

Kowloon Bay, Kowloon Hong Kong

Telephone: 852-796-5616

Fax: 852-799-8490

Colombia

14. Industrial Taylor Ltda.

Transversal 93, Numero 64-24

Apartado Aereo 95075

Bogota D.E., Colombia

Telephone: 57 (1) 4340016

Fax: 571-223-2642

Crotia

15. New Rok

Opatija M. Tita 15

51410 Opatija, Crotia

Telephohe: 385-51-701-251

Fax: 385-51-701-251

Cyprus

16. AMF Chistofides Ltd.

104A Prodromos Str.

P.O. Box 25100

Nicosia, Cyprus

Telephone: 357-2-454-380

Fax: 357-2-454-088

Czech Republic

17. Citus

Argentinska 20

CZ 4170 00 Pragues 7

CZECH REPUBLIC

Telephone: 420-2-667-10-561

Fax: 420-2-667-10-557

Denmark

18. Inter-Gastro A.S.

Midtager 18

2605 Brondby

Denmark DK2605

Telephone: 45-43292000

Fax: 45-43292001

Ecuador

19. Equindeca Cia. Ltda.

Hotel El Conquistador

Gran Colombia 6-65

Cuenca, Ecuador

Telephone: 593-7-831788

Fax: 593-7-843221

Egypt

20. Con Trade Centre

3A Ramsis Street

Maaroof Building #83 & #62

Cairo, Egypt

Telephone: 20 (2) 770642/762551

Fax: 20 (2) 756258

Estonia

21. Sisustaja As

Tihniku 5

11625 Tallinn, Estonia

Telephone: 372-6502300

Fax: 372-6502301

Finland

22. Monilaite Oy

P.O. Box 27

Salpakuja 6

SF-01200 Vantaa, Finland

Telephone: 358-9-877-0100

Fax: 358-9-877-01099

France

23. Diffusion International de

Materiel (DIM)

Parc dactivite Clemenceau

Chemin du Chateau dEau

B.P. 4009

59704 Marcq-En-Baroeuil

Cedex, France

Telephone: (33) 20890000

Fax: (33) 20727355

Germany

24. Sesjak KG

Wullener Feld 9a

D-58454 Witten

Germany

Telephone: 49-2302-697077

Fax: 49-2302-698451

Ghana

25. DRT Ghana

E6619 Ablade Road

Kanda Estate

P.O. Box C2074

Accra-Cantonments, Ghana

Telephone: 233-2123-3949

Fax: 233-2123-1380

Greece

26. Domestica S.A.

65 Stournara Str.

Athens 10432, Greece

Telephone: 30-15-24-30-14/15

Fax: 30-15-22-91-58

Guam

27. Pacific Technical Service, Inc.

New Commercial Building

#979 Rt. 16, Suite B-3

Barrigada, Guam 96913

Telephone: 6710632-5000

Fax: 671-632-3333

Holland

28. Englelen-Heere B.V.

Straatveg 85, Postbus 35020

3005 DA Rotterdam, Holland

Telephone: 311-042-23077

Fax: 311-042-23435

Hong Kong

29. Bonny Foodservice Products

Flat C, 8/F, Yeung Yiu Chung

Industrial Building #20

Wang Hoi Road

Kowloon Bay, Kowloon,

Hong Kong

Telephone: 852-796-5616

Fax: 852-799-8490

Hungary

30. Hotex Service

H-2094 Nagykovacsi

Kossith Lajos u. 1.

Hungary

Telephone: 36-263-56653/89463

Fax: 36-26389463

Iceland

31. A. Karlsson H. F.

Brautarholti 28

105 Reykjavik, PO Box 167

Iceland

Telephone: 354-560-0900

Fax: 354-560-0901

India

32.

AISHWARYA

Trust Complex, 10 OVG Rd

Basavanagudi

Bangalore 560004, India

Telephone: 91-80-667-7576

Fax: 91-80-667-7576

Intl. Refrigeration Corp

7 Netaji Subhash Marg

Darya Ganj

New Delhi 110002, India

Telephone: 91-11-3275651

Fax: 91-11-6221827

Indonesia

33. P.T. Gema

JL. Raya Bloulevard Raya

Block IOA 2 No. 27

Kelapa Gading Permai

Jakarta 14240, Indonesia

Telephone: 62-21-4532077

62-21-4508910

Fax: 62-21-4532586/4530777

Ireland

34. Martin Food Equipment Ltd.

Gaskin Business Park

Coes Road

Dundalk, Louth County

Ireland

Telephone: 353-42-30366

Fax: 353-42-30370

Italy

35. Allegra SRL

Corso Matteotti, 5 - 10121

Torino, Italy

Telephone: 39-011-540264

Fax: 39-011-533779

Japan

36. Toei Kogyo Co. Ltd.

4F, Nissay Nishi-Gotanda

Building 24-5

Nishi-Gatanda 7-Chome

Shinagawa-ku, Tokyo 141-0031

Japan

Telephone: 813-3779-1081

Fax: 813-3779-1638

Jordan

37. Awar Trading Est

PO Box 962227

Amman 11196, Jordan

Telephone: 962-6-55-19-610

Fax: 962-6-55-19-605

Korea

38. Ohjin Corporation

3rd Floor, Hee Jung Building

1635-0 Seocho-dong

Seocho-ku

C.P.O. Box 3252

Seoul 137-070, Korea

Telephone: 82-2-5850441

Fax: 82-2-5874197

Kuwait

39. Mabrook Hotel Supplies Co.

PO Box 43832 Hawalli

32053 Kuwait

Telephone: 965-481-8242

965-483-01648

Fax: 965-483-4314

Revised 5/01

Page 39

Lebanon

40. Pro Kitchen

Cahlfoun Building

Kaslik - Main Road

PO Box 1066 Jounieh

Lebanon

Telephone: 961-9-635-077

Fax: 961-9-635-059

Lithuania

41. Master Group Baltic Master

Dariaus Ir Girena 175

2038 Vilnius, Lithuania

Telephone: 3702-306-528/529

Fax: 3702-306-533

Malaysia

42. SCC Corp. Sdn. Bhd.

19-21 Jalan Hujan

Taman Overseas Union

58200 Kuala Lumpur,

Malaysia

Telephone: 60-3-77828384

Fax: 60-3-77818561

Malta

43. C & H Bartoli Ltd.

232 The Strand

Gzira Gzros, Malta

Telephone: 356-342-584

Fax: 356-342-569

Mauritius Island

44. (Mauritius, Reunion Island,

Seychelles)

Hassam Moussa Rawat

10 Bourbon Street

P.O. Box 492

Port Louis, Mauritius Island

Telephone: 160 (230) 2080024

Fax: 160-230-2080147

Mexico

45.

Central Mexico Metro Mexico City

Cavimex S.A. de C.V.

Revillagigedo No. 61 Col Centro

Mexico, D.F. 06070

Mexico

Telephone: 525-521-4200

Fax: 525-510-2791

Pacific

Micro Herros De Occidente,

S.A. de C.V.

Av. Juan Palamar y Arias

#83 Col. Jardines Vallarta

Zapopan, Jalisco, Mexico

C.P.45020

Telephone: 52-3-629-54-05

Fax: 52-3-673-29-43

Southeast

Equipo Para El Mercado

S.A. de C.V

Calle 55 No. 501-B por 60 y 62

Merida, Yucatan,

Mexico C.P. 97000

Telephone: 52-99-236500

Fax: 52-99-286649

Morocco

46. Electra

Boulevard AHL Loghlam

BP 25698

Sidi Bernoussi - Ain-Sebaa

Casablanca Morocco

Telephone: 212-22-753-531

Fax: 212-22-753-554

New Zealand

47. Taylor Equipment Limited

4 Ponuz Place

Mt. Wellington

Auckland, New Zealand

Telephone: 64 (9) 5733377

Fax: 64 (9) 5730841

Norway

48. Grillfagmannen A.S.

Ostensjoveien 44

N-0667 Oslo 6, Norway

Telephone: 47 (2) 651410

Fax: 47 (2) 720017

Oman

49. Mohsin Haider Darwish LLC

P.O. Box 880

Ruwi, Code 112

SULTANATE OF OMAN

Telephone: 968-703411

Fax: (968) 789927

Pakistan

50. The Equipment Company

Ground Floor, Dadabhoy Centre

Sharea Faisai, Karachi 75530

Pakistan

Telephone: 922-1-778-1778/2778

Fax: 922-1-587-0456/778-2777

Peru

51. Importadora Tecnica

Comercial C.R. Ltda.

Jr. Marcos de Aramburu #595

Lima 17, Peru

Telephone: 51-1-226-2124

Fax: 51-1-275-2689

Philippines

52. HKR Equipment Corp.

2nd Floor, THC Bldg.

2176 Primo Rivera St.

La Paz, Makati City, Philippines

Telephone: 632-899-4511

Fax: 632-899-4541

Poland

53. I. F. E.

Rydygiera 12

01 793 Warsaw, Poland

Telephone: 48-3912-3373

42-22-663-4820/4069

Fax: 48-3912-3373

Portugal

54. Restaurotel

AV Da Republica

83 C 1050

243 Lisboa

Portugal

Telephone: 351 7967116/7/8/9

FAX: 351 7933982

Puerto Rico

55. Progressive Sales and Service

PO Box 10876

Caparra Heights Station

San Juan, Puerto Rico 009220876

Telephone: 787-782-7474

Fax: 787-793-6479

Qatar

56. Tristar Group

C.R. No. 6778

P.O. Box 4746

Doha, Qatar

Telephone: 974-4664433

Fax: 974-4365365

Romania

57. Delta Technologies Romani S.A.

Sector 6, 20 Constructorilor Blvd.

Bloc 20 A, sc. B 7th Floor

Apt. 64

Bucharest, D599 Romania

Telephone: 401-220-4261

Fax: 401-220-3990

US Address:

115 Main St.

Mishawaka, In. 46544

Telephone: 219-256-3783

Fax: 219-256-7130

Saudi Arabia

58. Commercial Center

Development & Economy

P.O. Box 1210

Jeddah 21431, Saudi Arabia

Telephone: 966 (2) 629-1857

Fax: 966 (2) 629-1860

Senegal

59. Breading Systems Co.

C/ Ripoche,14

35007 Las Palmas

Spain

Telephone: 34-9-28-22-43-86

Fax: 34-9-28-27-56-90

Singapore

Simplex Pte. Ltd.

60.

Block 1, Lorong 8

Toa Payoh Industrial Park 01-1383

Singapore 319053

Telephone: 65-251-6241

Fax: 65-253-8814

Shopfit (S) Pte. Ltd.

Blk 623 Aljunied Industrial Complex

Unit 02-09

Singapore 389835

Telephone: 65-7410911

Fax: 65-7438911

South Africa

61. Foodserv CC

PO Box 55269

Northlands 2116,

Republic of South Africa

Telephone: 27 (11) 616-5183,

Fax: 27 (11) 616-8287

Spain

62. Adisa

Tuset, 8-10

08006 Barcelona, Spain

Telephone: 34-93-415-0018

Fax: 34-93-218-1782

Sri Lanka

63. Sperrys Commercial Equipment

1014 Parliament Road

Etul Kotte

Kotte/Colombo, Sri Lanka

Telephone:941-873-0561

Fax: 941-863-8361

Suriname

64. Tessco N.V.

Oude Charlesburgweg #47

Paramaribo Suriname

Telephone: 597-473366/477388

Fax: 597-473366

Sweden

65. Eurospice AB

Box 5050

Hejargatan 6

632 29 Eskilstuna, Sweden

Telephone: 46 (16) 125600

Fax: 46 (16) 131390

Switzerland

66. Stuppen Fast Food GmbH

Oberneuhofstrasse 8

CH-6340 Baar, Switzerland

Telephone: 41-41-761-5052

Fax: 41-41 761-7210

Syria

67. Lahham Trading & Contracting

Hamra Str. Omyad Building

P.O. Box 2960

Damascus Syria

Telephone: 963-11-331-2251

Fax: 963-11-331-2252

Taiwan

68. Feco Corporation

420, 11 F Keelung Rd.

Sec. 1 Postal Code 110

Taipei, Taiwan

Republic of China

Telephone:886-2-2758-2288

Fax: 886 (2) 2758-2297

Thailand

69. Fieco Company Ltd.

43/524-526 Amarinnivej 1

Anusaovari Laksi

Phaholoyothin Road

Bangkok 10220

Thailand

Telephone: 66-2-521-3824/3878

Fax: 66-2-552-0833

Tunisia

70. Semci

16, Rue Aziz Taj

1101 Tunis RP, Tunisia

Telephone: 216 -133-1501

Fax: 216-133-0698

Turkey

71. Klimatek

Inonu Caddesi, Opera Palas 73/5

80090 Gumussuyu

Istanbul, Turkey

Telephone: 90-212-245-1812

90-212-293-7892

Fax: 90-212-293-3903

United Arab Emirates

72. Habtoor International

P.O. Box 55332

Dubai, United Arab Emirates

Telephone: 971-4-272-1212

Fax: 971-4-272-2255

United Kingdom

73. Servequip Products Ltd.

214 Purley Way

GB-Croyden CRO 4XG, England

Telephone: 44-208-6868855

Fax: 44-208-6817509

Uruguay

74. Tecnoland S.A.

Dr. José Scorsería 2740

CP 11300 Montevideo, Uruguay

Telephone: 598-2-7105900

Fax: 598-2-7105900

Venezuela

75. Prefer, C.A.

Avenida Presidente Medina

Edificio Prefer, Local No. 44

Entre Calles Chile y Progreso

urb. Los Acacias

Caracas 1040, Venezuela

Telephone: 58-212-633-6933/2801

Fax: 58-212-632-6711

Vietnam

76. Cao Sinh Pte

Block 1, Lorong 8

Toa Payoh Industrial

Estate #01-1383

Singapore 319053

Telephone: 65-2516241

Fax: 84-2538814

Yemen

77. Mukiriani Sanaa

PO Box 8150 Sanaa

Yem e n

Telephone: 967-1-230-675

Fax: 967-1-230-929

Revised 4/01

Loading...

Loading...