Henny Penny AHC-993 User Manual

Henny Penny

Humidied Holding Cabinets

With Automatic Water Fill

Model AHC-993

Model AHC-990

TECHNICAL MANUAL

Model AHC-990/993

TABLE OF CONTENTS

Section Page

Section 1. TROUBLESHOOTING

1-1. Introduction ................................................................................................................. 1-1

1-1. Safety ........................................................................................................................... 1-1

1-3. Troubleshooting ........................................................................................................... 1-1

1-4. Error Codes and Warnings ........................................................................................... 1-5

1-5. Info Mode .................................................................................................................... 1-8

Section 2. LEVEL 2 PROGRAMMING

2-1. Introduction ................................................................................................................. 2-1

2-2. Tech Mode ................................................................................................................... 2-1

2-3. Stats Mode ................................................................................................................... 2-5

2-4. Data Logging and Manufacturing Mode ..................................................................... 2-8

Section 3. MAINTENANCE

3-1. Introduction ................................................................................................................. 3-1

3-2. Maintenance Hints ....................................................................................................... 3-1

3-3. Humidity Sensor Calibration and Replacement .......................................................... 3-1

3-4. Power Switch Replacement ......................................................................................... 3-4

3-5. Air Temperature Probe Replacement .......................................................................... 3-5

3-6. Transformer Replacement ........................................................................................... 3-7

3-7. Relay Replacement ...................................................................................................... 3-8

3-8. Module Top Removal .................................................................................................. 3-9

3-9. Cooling Fan Replacement ........................................................................................... 3-10

3-10. High Limit - Air Heater Replacement ......................................................................... 3-10

3-11. Blower Motor Replacement ........................................................................................ 3-11

3-12. Air Heater Replacement .............................................................................................. 3-12

3-13. Speaker Replacement .................................................................................................. 3-12

3-14. Complete Panel or PC Board Replacement ................................................................. 3-13

3-15. Float Switch Replacement ........................................................................................... 3-14

3-16. High Limit - Water Heater Replacement ..................................................................... 3-15

3-17. Water Pan Heater Replacement ................................................................................... 3-16

3-18. Solenoid Valve and Water Strainer Replacement ........................................................ 3-19

3-19. Door Gasket Replacement ........................................................................................... 3-20

3-20. Vent Motor Replacement ............................................................................................. 3-20

3-21. Vent Motor Microswitch Replacement ........................................................................ 3-21

3-22. HC-993 Flip Door Replacement .................................................................................. 3-22

Wiring Diagrams ......................................................................................................... 3-24

Section 4. PARTS INFORMATION

4-1. Introduction ................................................................................................................. 4-1

4-2. Genuine Parts............................................................................................................... 4-1

4-3. When Ordering Parts ................................................................................................... 4-1

4-4. Prices ........................................................................................................................... 4-1

4-5. Delivery ....................................................................................................................... 4-1

4-6. Warranty ...................................................................................................................... 4-1

4-7. Recommended Spare Parts for Distributors ................................................................ 4-1

Parts List ...................................................................................................................... 4-2

Revised 4/16/2015 RS

FM06-045

i

Model AHC-990/993

SECTION 1. TROUBLESHOOTING

1-1. INTRODUCTION

1-2. SAFETY

This section provides troubleshooting information in the form

of an easy to read table.

If a problem occurs during the rst operation of a cabinet,

recheck the installation per the Installation Section of the Operator’s Manual

Before troubleshooting, always recheck the operation proce-

dures in the Operator’s Manual.

Where information is of particular importance or is safety

related, the words NOTICE, CAUTION, or WARNING are

used. Their usage is described below.

SAFETY ALERT SYMBOL is used with DANGER,

WARNING, or CAUTION which indicates a personal injury

type hazard.

NOTICE is used to highlight especially important information.

CAUTION used without the safety alert symbol indicates a potentially hazardous situation which, if not avoided, may result

in property damage.

1-3. TROUBLESHOOTING

CAUTION used with the safety alert symbol indicates a potentially hazardous situation which, if not avoided, may result

in minor or moderate injury.

WARNING indicates a potentially hazardous situation

which, if not avoided, could result in death or serious

injury.

To isolate a malfunction, proceed as follows:

1. Clearly dene the problem or symptom and when it occurs.

2. Locate the problem in the troubleshooting table.

3. Review all possible causes. Then, one at a time work

through the list of corrections until problem is solved.

If maintenance procedures are not followed correctly,

injuries and/or property damage could result.

Feb. 2011

1-1

Model AHC-990/993

1-3. TROUBLESHOOTING (continued)

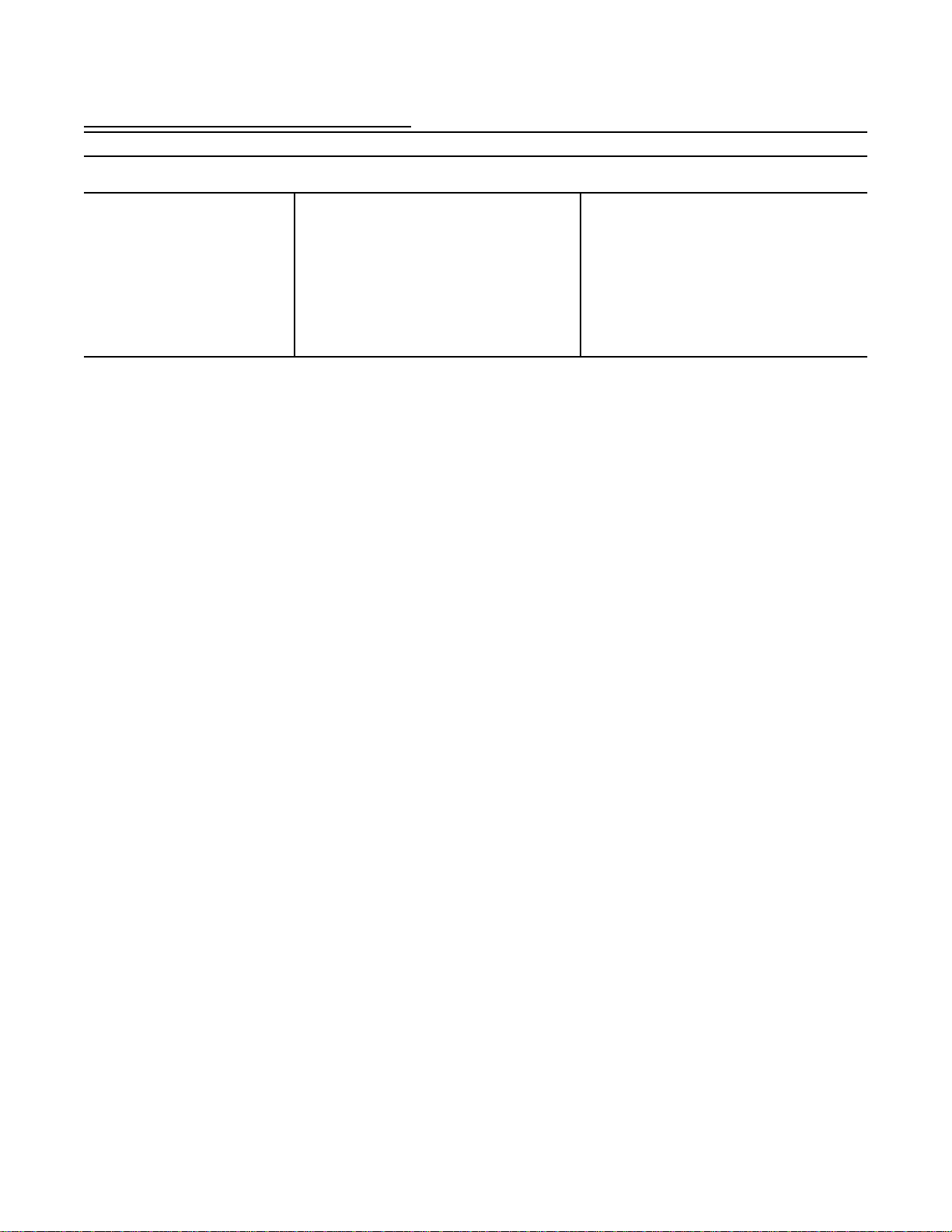

Problem Cause Correction

OPERATION

A. Product not • Doors left open • Keep doors closed except

holding temperature to load and serve product

• Product held too long • Hold product only for

recommended times

• Control temperature set too low • Increase air temperature

setpoint (SP-3) in Special

Program Mode

• Bad air heater • Check heaters and replace if bad

See Tech Mode items 10 and 16

• Blower not working • Check blower and replace if bad

See Tech Mode item 18

• Bad air heater, or blower relays • Replace relay

See Tech Mode items 10 and 16

• Bad high limit • Check high limit and replace if

bad

• Low or improper voltage • Compare receptacle voltage to

data plate voltage

• Door gasket torn or worn • Replace bad door gaskets

• Air probe faulty, open (“E-6A”), • Ohm out the probe and replace

or shorted (“E-6B”) if necessary

B. Cabinet steaming • Humidity setpoint too high • Decrease humidity setpoint

or product soggy (SP-4) in Special Program Mode

• Water heater probe faulty, open • Ohm out the probe and replace

(“E-12A”), or closed (“E-12B”) if necessary

• Bad humidity sensor (“E-17”) • Replace humidity sensor

• Relay stuck closed • Replace relay

• Vent stuck closed (“E-80”) • Bad vent motor - replace

• Bad vent motor relay - replace See Tech Mode item 18

• Check alignment and condition

of mechanical vent parts

• Vent acorn nuts too tight, loosen

if necessary

Feb. 2011

1-2

Model AHC-990/993

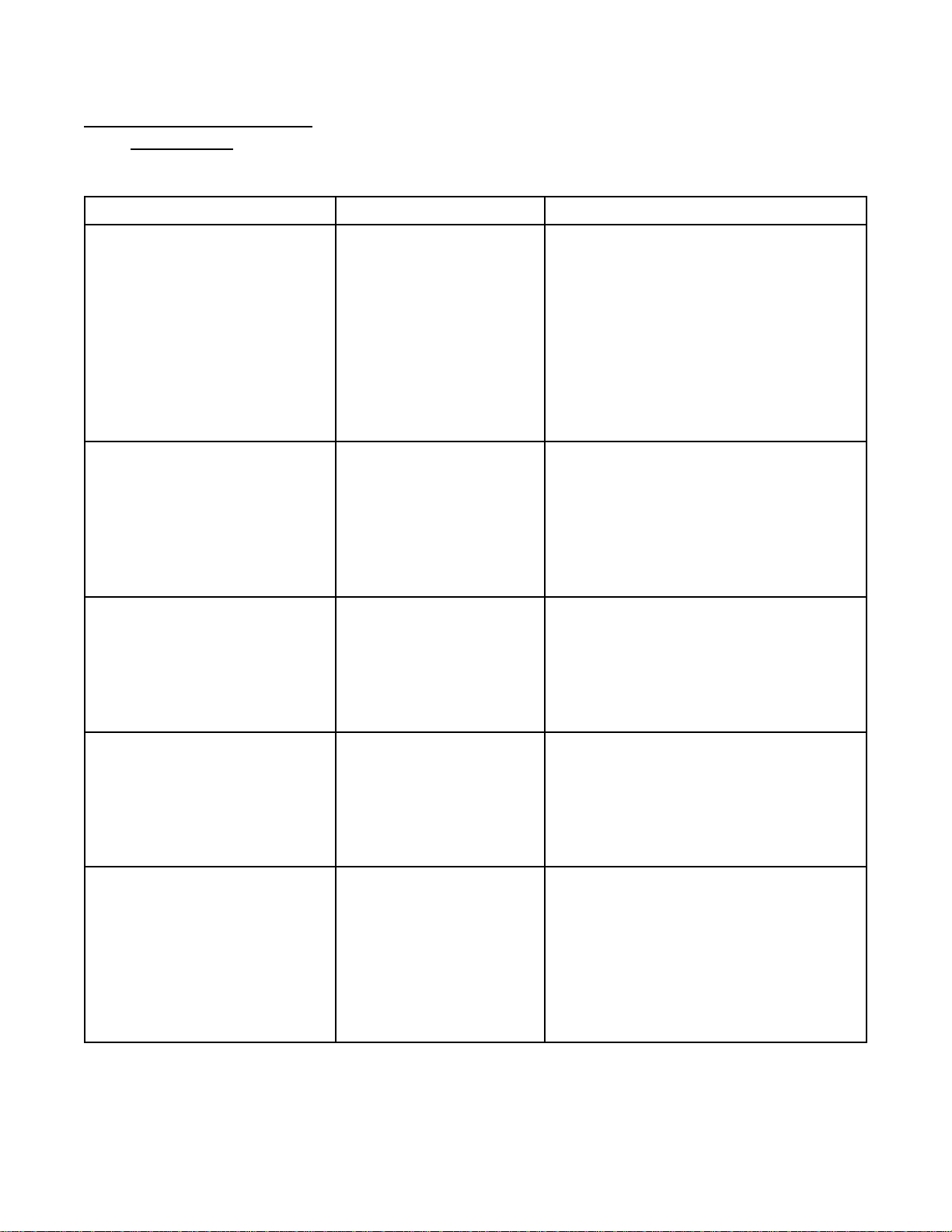

1-3. TROUBLESHOOTING (continued)

Problem Cause Correction

OPERATION (Continued)

C. Product dry • Bad oat switch • Replace oat switch

• Bad water heater high limit • Replace high limit

• Bad water heater • Check heater and replace if bad;

see Tech Mode item 18

• Humidity setpoint too low • Increase humidity setpoint

(SP-4) in Special Program Mode

• No water in pan • Turn water supply on

• Adjust ow control valve

• Check solenoid valve and relay

• Vent stuck open (“E-80”) • Bad vent motor - replace; see

Tech Mode item 18

• Bad vent motor relay - replace

• Check alignment and condition

of mechanical vent parts

HEATING SYSTEM

A. Unit not heating • Bad control board • Replace control board

• Bad high limit • Check high limit; replace if bad

• Bad air heater or blower relays • Replace relay

• Bad air heater • Check heaters and replace if bad;

see Tech Mode item 18

• Faulty wiring • Check for loose connections or

broken wires

B. Unit not reaching set • Blower not working. • Check Blower and replace if bad;

temperature see Tech Mode item 18

• Bad air heater • Check heaters and replace if bad;

see Tech Mode item 18

• Bad air heater, or blower relays • Replace relay

• Doors left open • Keep doors closed except

to load and serve product

• Door gasket torn or worn • Replace bad door gaskets

Feb. 2011

1-3

Model AHC-990/993

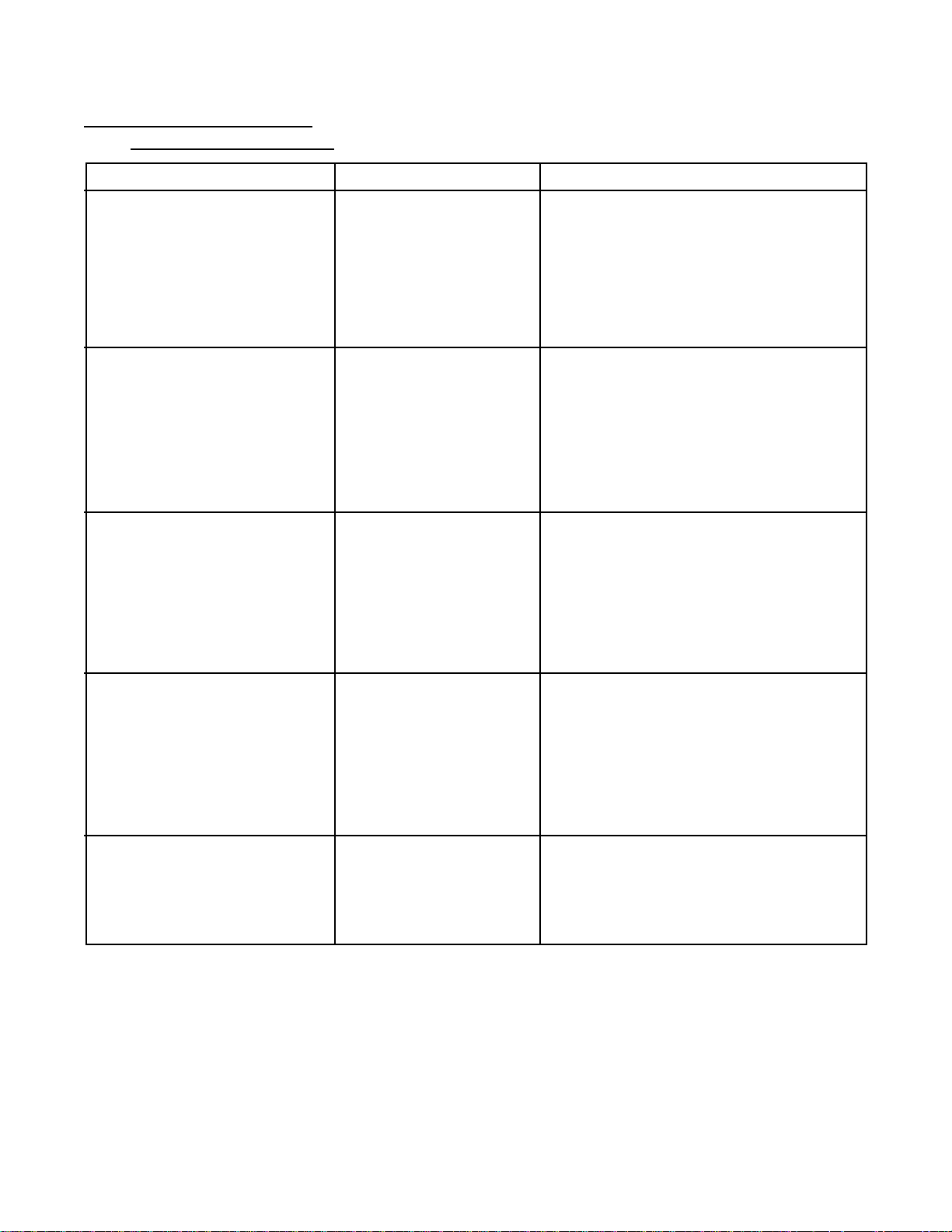

1-3. TROUBLESHOOTING (continued)

Problem Cause Correction

HEATING SYSTEM (Continued)

C. Unit Overheating • Blower not working • Check blower and replace if bad

(“E-5”) See Tech Mode item 18

• Bad control board • Replace control board

• Relay stuck closed • Replace relay

Feb. 2011

1-4

Model AHC-990/993

1-4. ERROR CODES AND The display shows the following error codes and warnings when a

WARNINGS fault is detected, along with an alarm sound. Both the heat and

humidity systems shut down, except when specied otherwise.

Display Cause Panel Board Correction

“E-4 CPU TOO HOT” • Control board too hot;

unit overheating or

louvers clogged

“E-5 AIR TEMP TOO HOT” • Faulty relay, PC board,

or air probe

“E-54A CPU TEMP SENSOR • Faulty PC board

OPEN”

• Turn switch to OFF position, then back

to ON; if display still shows “E-4”, PC

board is getting too hot; clean louvers

and check cooling fan; if cooling fan is

not working, have it replaced; once

panel cools down, the controls should

return to normal; if “E-4” persists, have

the PC board replaced

• Turn switch to OFF position, then back

to ON; if display shows “E-5”, heating

circuits and temperature probe should

be checked; once the unit cools down,

the controls should return to normal; if

“E-5” persists, have PC board replaced

• Turn switch to OFF position, then back

to ON; if display shows “E-54A”, the

control should be re-initialized (see Pro gramming Section); if the error code

persists, have PC board replaced

“E-54B CPU TEMP SENSOR • Faulty PC board

SHORTED”

“E-6A AIR TEMP SENSOR • Faulty air probe

FAILED OPEN”

• Turn switch to OFF position, then back

to ON; if display shows “E-54B”, the

control should be re-initialized (see Pro gramming Section); if the error code

persists, have PC board replaced

• Turn switch to OFF position, then back

to ON; if the display shows “E-6”, the

temperature probe should be checked;

once the temperature probe is repaired,

or replaced, the controls should return

to normal; if “E-6” persists, have the PC

board replaced

Feb. 2011

1-5

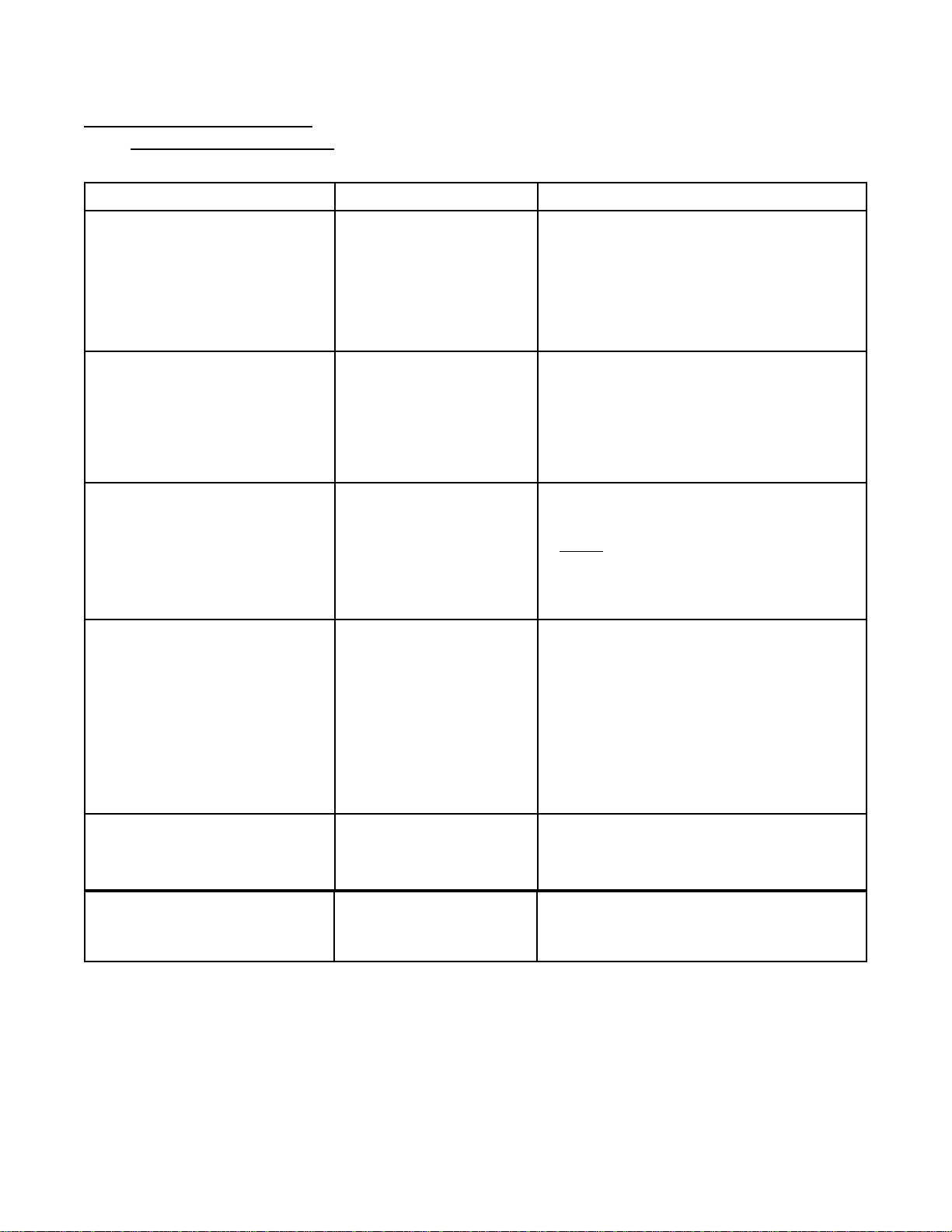

Model AHC-990/993

1-4. ERROR CODES AND

WARNINGS (Continued)

Display Cause Panel Board Correction

“E-6B AIR TEMP SENSOR • Faulty air temperature

FAILED SHORTED” probe

“E-12A WATER HEATER • Faulty water

SENSOR FAILED heater probe

OPEN”

“E-12B WATER HEATER • Faulty water

SENSOR FAILED heater probe

CLOSED”

• Turn switch to OFF position, then back to

ON; if the display shows “E-6”, the

temperature probe should be checked;

once the temperature probe is repaired, or

replaced, the controls should return to

normal; if “E-6”persists, have PC board

replaced

• Turn switch to OFF position, then back to

ON; if the display shows “E-12A”, the

water heater should be checked and

repaired or replaced (the water heater

probe is built into the water heater); the

controls should return to normal; if

“E-12A” persists, have PC board replaced

• Turn switch to OFF position, then back to

ON; if the display shows “E-12B”, the

water heater should be checked and

repaired or replaced (the water heater

probe is built into the water heater); the

controls should return to normal; if

“E-12B” persists, have PC board replaced

“E-17 HUMIDITY SENSOR • Faulty humidity sensor

FAILED”

“E-41 SYSTEM DATA LOST”

A humidity error only shuts down the humidity system. If a humidity error occurs, and you want to use

the cabinet without humidity, turn the humidity off by following the directions for SP-4, Humidity Set-

point, in Special Programming Section of this manual. Once the setpoint is off, the alarm stops, but the

error code shows in display. (Includes “E-12A”, “E-12B”, and “E-17”).

• Memory scrambled

• Turn switch to OFF position, then back to

ON; if the display shows “E-17”, the

humidity sensor should be checked;

once the humidity sensor is repaired, or

replaced, the controls should return to

normal; if “E-17” persists, have PC board

replaced

• Turn switch to OFF position, then back

to ON; if the display shows “E-41”, the

control should be re-initialized (see Pro-

gramming Section); if “E-41”persists,

have PC board replaced

Feb. 2011

1-6

Model AHC-990/993

1-4. ERROR CODES AND

WARNINGS (Continued)

Display Cause Panel Board Correction

“E-46 DATA SAVE FAILED” • Memory scrambled

“E-80 VENT STUCK OR • V ent on rear of module

BAD SWITCH” stuck or faulty vent

activation switch

“WATER LEVEL LOW, • Water pan low on

PLEASE ADD WATER” water or empty

(Appears only if ll option is

set to Manual)

“WATER PAN NOT FILLING, • Water supply turned

CHECK WATER SUPPLY” off

(Appears only if ll option is

set to Auto) • Water ow reduced

• Fill solenoid relay bad

• Turn switch to OFF position, then back

to ON; if the display shows “E-46”, the

control should be re-initialized (see Pro gramming Section); if “E-46”persists,

have PC board replaced

• Check vent on rear of module for

obstructions, or have vent activation

switch replaced

• Vent acorn nuts too tight; loosen if

necessary

• Fill water pan, in bottom of unit, to the

maximum water ll mark; this warning

won’t shut down the heat or humidity

• Turn water supply on

• Adjust ow control valve

• Check solenoid relay

• Fill solenoid bad

“CALL SERVICE, WATER • Faulty relay or heater

• Check solenoid valve

• Check heater relay and heater

HEATER FAILURE”

“PURGE” Unit is purging humidity No correcting action needed. If message

continues, contact the Henny Penny Tech-

nical Support Line at 1-800-417-8405

March 2014

1-7

Model AHC-990/993

1-5. INFO MODE

This mode records historic information on the holding cabinet

and operator performance, which could help in troubleshooting

a problem.

This mode records historic information on the unit and operator

performance. Press and at the same time and

“*INFO MODE*” shows on display. Press or to

access the steps and press to view the statistics within

each step.

Information Mode is intended for technical use, but the opera-

tor can view the following information:

1. Error Log - last 10 errors and time they occurred

2. Power Up Log - time of last 10 power-ups

3. Outputs/Inputs - shows the state of unit’s inputs and

outputs

a. OUT V_S_F_W_A_ (vent motor, ll solenoid valve, fan,

water heater, air heater, relay order from left to right)

b. AMPS V_S_F_W_A_

c. NC/GD V_S_F_W_A_ (no connect/ground detection on

outputs to relays)

d. All outputs and inputs V_S_F_W_A_ P_ (power switch

input) E_(exhaust vent switch input) F_ (oat switch

input)

4. Vent - open or closed

5. CPU temperature

6. Cabinet air temperature

7. Water heater temperature

8. Food probe temperature

9. Humidity counts value

10. Humidity value

11. Water heater conditions

12. Analog inputs

Feb. 2011

1. E-LOG (error code log)

Press and “A. (time) *NOW*” shows in display.

This is the present date and time.

Press and if a error was recorded, “B. (date, time, and

error code information)” shows in display. This is the latest

error code that the controls recorded.

Press and the next latest error code information can

be seen. Up to 10 error codes (B to K) can be stored in the

E-LOG section.

1-8

1-5. INFO MODE (Continued)

Model AHC-990/993

Press to continue to P-LOG.

2. P-LOG (power-up log)

Press and “A. (time) *NOW*” shows in display.

This is the present date and time.

Press and the latest power-up is shown, “B. (date, time,)

PWR-UP”.

Press and the next latest power-up date is shown. Up to

10 power-ups (B to K) can be stored in the P-LOG section.

Press to continue onto the Outputs/Inputs.

3. OUTPUTS/INPUTS

This mode displays the status of components and inputs. If

the input or output signal is detected, an identifying letter is

displayed (see below). If the signal is not detected, “_” is

displayed. Press to view the following:

a. “3. OUT V_S_F_W_A_” shows in the display. If the

output is on, “*” shows beside the output letter. Ex: “V*”.

If the control senses a problem with the output, “*” ashes.

b. “AMPS V_S_F_W_A_” shows in the display. A

checkmark (“

√” ) beside the letter indicates normal amps.

A ashing “X” beside the letter means a problem exists.

c. “NC/GD V_S_F_W_A_” shows in the display. This

monitors a possible problem with the relays on the output

PC board. A checkmark (“√” ) beside the letter indicates

means everything on the output PC board is good. A

ashing “X” beside the letter means a problem exists.

d. V_S_F_W_A_P_E_F_ shows in the display. If the output

or input signal is detected, “*” shows beside the letter. Ex:

“V*”. If the control senses a problem with the output, “*”

ashes.

Press to continue to VENT.

4. VENT

This indicates whether the vent is open or closed.

Feb. 2011

Press to continue to CPU TMP.

1-9

1-5. INFO MODE (Continued) 5. CPU TMP

This step shows the present PC board temperature.

Press to continue to the Cabinet Air TMP.

6. CABINET AIR TMP

This step shows the present air temperature inside the cabinet.

Press to continue to the Water Heater TMP.

7. WATER HEATER TMP

This step shows the present water heater temperature.

Press to continue to Food TMP.

8. FOOD TMP

This step shows the present food probe temperature, if used.

Model AHC-990/993

Press to continue to Humidity Counts Value.

9. HUMIDITY COUNTS VALUE

Factory use only!

Press to continue to the Humidity Value.

10. HUMIDITY VALUE

This step shows the present humidity level inside the cabinet.

Press to continue to the Water Heater Condition.

11. WATER HEATER CONDITION

This step shows water heater condition as GOOD or BAD.

Press to continue to the Analog Inputs.

12. ANALOG INPUTS

This step displays the present status of any channel of the

controller’s a to d converter. This feature may be useful to a

technician troubleshooting a problem with the controller.

Feb. 2011

The displayed value can be toggled between volts and bits by

pressing . If the displayed value has a decimal point, it is

voltage (0 to 5 VDC). If no decimal point is shown, value is

a-to-d bits (0 - 4095).

Press and to exit.

1-10

Model AHC-990/993

SECTION 2. LEVEL 2 PROGRAMMING

2-1. INTRODUCTION

2-2. TECH MODE

The Tech Mode and Stats Mode in the Level 2 Programming,

have information that could help in troubleshooting a problem

with the unit.

Press and hold until “L-2 LEVEL 2”, followed by,

“CLOCK SET”, shows in display.

Press 3 times and “TECH”, followed by, “ENTER

CODE” shows in display.

Enter code, to access

the following items: (Use hidden buttons, see Section 3-3)

T-1 Software

T-2 Cabinet version

T-3 Push button test

T-4 All on display test

T-5 Segments test

T-6 Digits test

T-7 Decimal points test

T-8 LED test

T-9 Factory Use

T-10 Air temperature - user calibration/offset/highest value

T-11 Factory Use

T-12 Water heater temperature - user calibration/offset/highest

value

T-13 Humidity - circuit calibration

T-14 Humidity sensor – calibration/offset; specic value sent

with each humidity sensor

T-15 Humidity- user calibration/offset/highest value

T-16 CPU° - control temperature - highest value

T-17 Factory Use

T-18 Outputs/Inputs; on outputs steps use the four hidden

buttons [1-4] to toggle on outputs; [1] - vent motor,

[2] - auto ll solenoid valve, [3] - circulation fan,

[4] - water heater, [5] - air heater

T-19 Total init – initialization of programming areas and

statistics

Feb. 2011

moves you forward through the above selections and

moves you backwards through the selections.

2-1

Model AHC-990/993

2-2. TECH MODE (Continued)

T-1: Software

This section shows “PN/ID/SRL”

Press and hold the button. The Henny Penny EPROM

part number is displayed.

Press and hold the button. The customer ID (i.e. KFC) is

displayed.

Press and hold the button. The software revision level is

displayed.

T-2: Cabinet Version

This section shows the model number, e.i. AHC-993.

T3: Push Button Test

Press any button on the control and a digital display feedback

conrms the button is working.

T4: All On Display Test

Press any of the product buttons and every LED on the 16 digit

display lights.

T5: Segments Test

Repeatedly pressing any product button lights one segments in

every one of the 16 digit displays.

T6: Digits Test

Repeatedly pressing any product button lights all segments in

one of the 16 digital displays. (Scrolls though all 16.)

T7: Decimal Points Test

Repeatedly pressing any product button lights a decimal point

(DP) in one of the 16 digital displays. (Scrolls though all 16.)

T8: LED’S Test

Repeatedly pressing any product button lights individual

LEDs. (Scrolls though all LEDs.)

T9: Air Temperature - Circuit Calibration

Factory use.

Feb. 2011

2-2

Model AHC-990/993

2-2. TECH MODE (Continued)

T10: Air Temperature - Calibration/Offset/Highest

This is a user calibration to make sure the display shows the

actual air temperature.

Press and hold and use to set the display to

match the actual temperature. (+/-15

Press and hold to change the amount of the offset.(+/-15

Press and hold to view the highest air temperature recorded.

Press to reset highest temperature.

o

F)

o

F)

T11: Water Heater Temperature - Circuit Calibration

Factory use.

T12: Water Heater Temperature - Calibration/Offset/

Highest

This is a user calibration to make sure the display shows the

actual water heater temperature.

Press and hold and use to set the display to

match the actual temperature. (+/-15o F)

Press and hold to change the amount of the offset.

Press and hold to view the highest air temperature recorded.

Press to reset highest temperature.

(+/-15o F)

T13: Humidity - Circuit Calibration

See Section 3-3 on Humidity Sensor Calibration and

Replacement.

T14: Humidity Sensor - Calibration/Offset

This is a specic value that is sent with the humidity sensor,

when necessary. Otherwise, this value should be 0.

Feb. 2011

2-3

Model AHC-990/993

2-2. TECH MODE (Continued)

T15: Humidity - Calibration/Offset/Highest

This is a user calibration to make sure the display shows the

actual humidity inside the cabinet.

Press and hold and use to set the display to

match the actual humidity. (0 to 100%)

Press and hold to change the amount of the offset.

-99)

Press and hold to view the highest humidity recorded.

Press to reset highest humidity.

(-0 to

T16: CPUo - Control Temperature - Highest Value

Press to show the highest temperature to which the control

board was exposed.

T17: View ADC Channel

Factory use.

T18: Outputs/Inputs

The following components can be tested:

toggles the vent motor off and on.

toggles the ll solenoid valve off and on.

toggles the cooling fan off and on.

toggles the water heater off and on.

toggles the air heaters off and on.

T19: Total Initialization

This completely resets any accumulated information and

changed settings in the controls. Contact Henny Penny before

completing this step.

Feb. 2011

2-4

Model AHC-990/993

2-3. STATS MODE

Press and hold until “L-2 LEVEL 2”, followed by,

“CLOCK SET”, shows in display.

Press 4 times and “STATS”, followed by, “ENTER

CODE” shows in display.

Enter code, to access

the following items: (Use hidden buttons, see Section 3-3.)

ST-1 Power live hours

ST-2 Power ‘on’ hours

ST-3 Power-ups count

ST-4 Errors count

ST-5 Air heat ‘on’ hours

ST-6 Water heater ‘on’ hours

ST-7 Circulation fan ‘on’ hours

ST-8 Water solenoid on hours

ST-9 Solenoid cycle count

ST-10 Longest solenoid on time; max.=5 minutes

ST-11 Vent motor

ST-12 Highest air temperature

ST-13 Highest water heater temperature

ST-14 Factory Use

ST-15 Highest humidity value

ST-16 Highest CPU temperature

ST-17 Water heater (too hot) cycle count

ST-18 Sys ram – fade count

ST-19 Hold ram – fade count

ST-20 Stat ram – fade count

ST-21 Ram data error count

ST-22 Data total loss count

ST-23 User init’s count

ST-24 Auto init’s count

ST-25 Error log

ST-26 Power-up log

ST-27 Factory Use

ST-28 Reset all stats

Feb. 2011

moves you forward through the above selections and

moves you backwards through the selections.

2-5

2-3. STATS MODE (Continued) ST-1: Power Live Hours

This section shows the number of hours the control has been

on.

ST-2: Power On Hours

This section shows the number of hours the control has been

on.

ST-3: Power Ups Count

This section shows the number of times the control has been

turned on.

ST-4: Errors Count

This section shows the total number of all errors (displayed on

control) that have occurred with the unit.

ST-5: Air Heat On Hours

This section shows the number of hours the air heaters have

been on.

Model AHC-990/993

ST-6: Water Heater On Hours

This section shows the number of hours the water heater has

been on.

ST-7: Circulation Fan On Hours

This section shows the number of hours the cooling fan has

been on.

ST-8: Water Solenoid On Hours

Shows the number of hours the solenoid has been on.

ST-9: Solenoid Cycle Count

Shows the number of times the solenoid has been turned on.

ST-10: Longest Solenoid ‘On’ time. Maximum 5 minutes.

Shows the longest the solenoid has been on at any one time, to

a maximum of 5 minutes.

ST-11: Vent Motor On Hours

This section shows the number of hours the vent motor has

been on.

Feb. 2011

ST -12: Highest Air Temperatur e

This section shows highest air temperature sensed by the temperature probe.

2-6

Loading...

Loading...