Henny Penny 500, 600 General Manual

Henny Penny Model 500/600

Henny Penny Model 500/600

This manual should be retained in a convenient location for future reference.

A wiring diagram for this appliance is located on the inside of the pressure fryer, on the right side panel.

Post in a prominent location instructions to be followed in event user smells gas. This

information shall be obtained by consulting the local gas supplier.

FOR YOUR SAFETY

DO NOT STORE OR USE GASOLINE OR OTHER FLAMMABLE VAPORS

AND LIQUIDS IN THE VICINITY OF THIS OR ANY OTHER APPLIANCE.

Keep appliance area free and clear from combustibles.

Do not obstruct the flow of combustion and ventilation air. Adequate clearance must be left all

around appliance for sufficient air to the combustion chamber.

The Model 600 Fryer is equipped with a continuous pilot. But fryer cannot be operated without electric power. Fryer will automatically return to normal operation when power is restored.

WARNING: Improper installation, adjustment, alteration, service or maintenance can

cause property damage, injury or death. Read the installation, operating and maintenance

instructions thoroughly before installing or servicing this equipment.

FM05-004

8-02

Henny Penny Model 500/600

TABLE OF CONTENTS

Section Page

Section 1. INTRODUCTION ........................................................................................... 1-1

1-1 Introduction ........................................................................................... 1-1

1-2 Proper Care .......................................................................................... 1-1

1-3 Assistance ............................................................................................. 1-1

1-4 Safety ................................................................................................... 1-2

Section 2. INSTALLATION ............................................................................................. 2-1

2-1 Unpacking Instructions ..........................................................................2-1

2-2 Selecting the Fryer Location .................................................................. 2-2

2-3 Leveling the Fryer ..................................................................................2-3

2-4 Ventilation of Fryer ................................................................................ 2-3

2-5 Gas Supply ........................................................................................... 2-5

2-6 Gas Piping ............................................................................................. 2-5

2-7 Gas Leak Test .......................................................................................2-6

2-8 Gas Pressure Regulator Settings............................................................. 2-8

2-9 Gas Pilot Lighting Procedures ................................................................ 2-8

2-10 Electrical Requirements (Gas Fryer) ....................................................... 2-9

2-11 Electrical Requirements (Electric Fryer) .................................................. 2-9

2-12 Testing the Fryer ....................................................................................2-10

Section 3. OPERATION ................................................................................................... 3-1

3-1 Operating Components.......................................................................... 3-1

3-2 Operating Controls ................................................................................3-4

3-3 Clock Set.............................................................................................. 3-6

3-4 Diagnostic Mode and Special Functions ................................................. 3-8

3-5 Warnings and Error Messages ............................................................... 3-11

3-6 Filling or Adding Peanut Oil ................................................................... 3-14

3-7 Basic Operation ....................................................................................3-15

3-8 Care of Peanut Oil................................................................................. 3-18

3-9 Filtering Instructions............................................................................... 3-19

3-10 Filter Pump Problem Prevention .............................................................3-21

3-11 Filter Pump Motor Thermal Protector .................................................... 3-22

3-12 Changing the Filter Envelope ..................................................................3-22

3-13 Cleaning the Frypot ............................................................................... 3-24

3-14 Manually Setting New or Used Peanut Oil Function ............................... 3-27

i 502

Henny Penny Model 500/600

TABLE OF CONTENTS

Section Page

Section 4. PREVENTIVE MAINTENANCE

4-1 Preventive Maintenance Schedule .......................................................... 4-1

4-2 Cleaning the Dead Weight Valve ............................................................ 4-2

4-3 Lubricate Lid Spindle and Ball Seat ....................................................... 4-2

4-4 Removal and Cleaning of Safety Relief Valve .......................................... 4-3

4-5 Reversing Lid Gasket ............................................................................ 4-4

4-6 Checking Temperature Probe Calibration ............................................... 4-4

Section 5. TROUBLESHOOTING

5-1 Introduction ........................................................................................... 5-1

5-2 Troubleshooting ..................................................................................... 5-1

5-3 Diagnostic Mode Details ........................................................................5-10

5-4 Information Mode Details ...................................................................... 5-26

GLOSSARY ..................................................................................................... G-1

Fryer Specs Page

Warranty

802 ii

Henny Penny Model 500/600

SECTION 1. INTRODUCTION

1-1. INTRODUCTION

The Henny Penny Pressure Fryer uses a combination of Pressure,

Heat, and Time to produce a quality product. The advantage of this

type fryer is the pressure allows the product to be cooked with less

heat and less time than the conventional open-type fryers.

The Chick-fil-A controls for the Henny Penny models 500 (electric)

and 600 (gas) have many features to allow the Operator to produce

consistent, quality products. The controls monitor not only cooking

times and temperatures, but also peanut oil condition, product

weights, product temperatures, and many other operational variables. The controls may vary the actual peanut oil temperature and

cook times, based on changes of the operational variables.

The controls also have very extensive self-diagnostic functions

which alert the Operator to both component and procedure

problems.

Some unique features of the fryer are listed below:

• Diagnostic Function-provides summary of fryer and

Operator performance. See section 3-4.

• Alarms and Error Messages-provide immediate feedback for

Operator error or fryer malfunction. See section 3-5.

• Status Mode-allows the Operator to view basic fryer informa-

tion and status. See section 3-4.

• Information Mode-gathers and stores historic information on

the fryer and Operator performance, and can be viewed by the

Operator. See section 3-4.

• Oil Filter Enforcement-prevents the Operator from exceeding

approved number of cook cycles before filtering the peanut oil.

See section 3-4.

• Manual Program Mode-Operator can set time and tempera-

ture for nonstandard products. See section 3-4.

• Easy toggle between English and Spanish operation. See

section 3-4.

• Clean-Out Mode-a preprogrammed function for cleaning the

frypot. See section 3-13.

1-2. PROPER CARE

As in any unit of food service equipment, the Henny Penny

Pressure Fryer does require care and maintenance. Requirements

for the maintenance and cleaning are contained in this manual and

must become a regular part of the operation of the Unit at all times.

1-3. ASSISTANCE

Should you require outside assistance, just call Henny Penny

Corporation at 1-800-417-8405, or 937-456-8405.

502 1-1

Henny Penny Model 500/600

1-4. SAFETY

The Henny Penny Pressure Fryer has many safety features incorporated. However, the only way to ensure a safe operation is to fully

understand the proper installation, operation, and maintenance

procedures, which are contained in this manual.

Where information is of particular importance or safety related,

the words DANGER, WARNING, CAUTION, and NOTICE are

used. Their usage is described below.

The word NOTICE is used to highlight especially important

information.

The word CAUTION is used to alert you to a procedure

that, if not performed properly, may damage the fryer.

The word WARNING is used to alert you to a procedure

that, if not performed properly, might cause personal

injury.

THE WORD DANGER INDICATES AN IMMINENT

HAZARD WHICH WILL RESULT IN HIGHLY SERIOUS INJURY SUCH AS SECOND OR THIRD DEGREE BURNS.

1-2 502

Henny Penny Model 500/600

SECTION 2. INSTALLATION

2-1. UNPACKING

INSTRUCTIONS

Installation of this unit should be performed only by a qualified

service technician.

1. Cut and remove the band from the bottom of carton.

2. Lift the main carton off the fryer.

3. Open lid and remove the basket, plus all the accessories.

4. Lay fryer on its side, resting it on supports.

HEAVY OBJECT

The fryer weighs approximately 300 lb (136 kg). Extreme

care should be taken when moving the fryer to prevent

personal injury.

5. Remove the four leg bolts from the wooden shipping base, and

discard the wooden base.

6. Thread the four casters (previously removed from the frypot)

into the legs of the fryer.

7. Place fryer in upright position.

502 2-1

Henny Penny Model 500/600

2-1. UNPACKING

INSTRUCTIONS

(Continued)

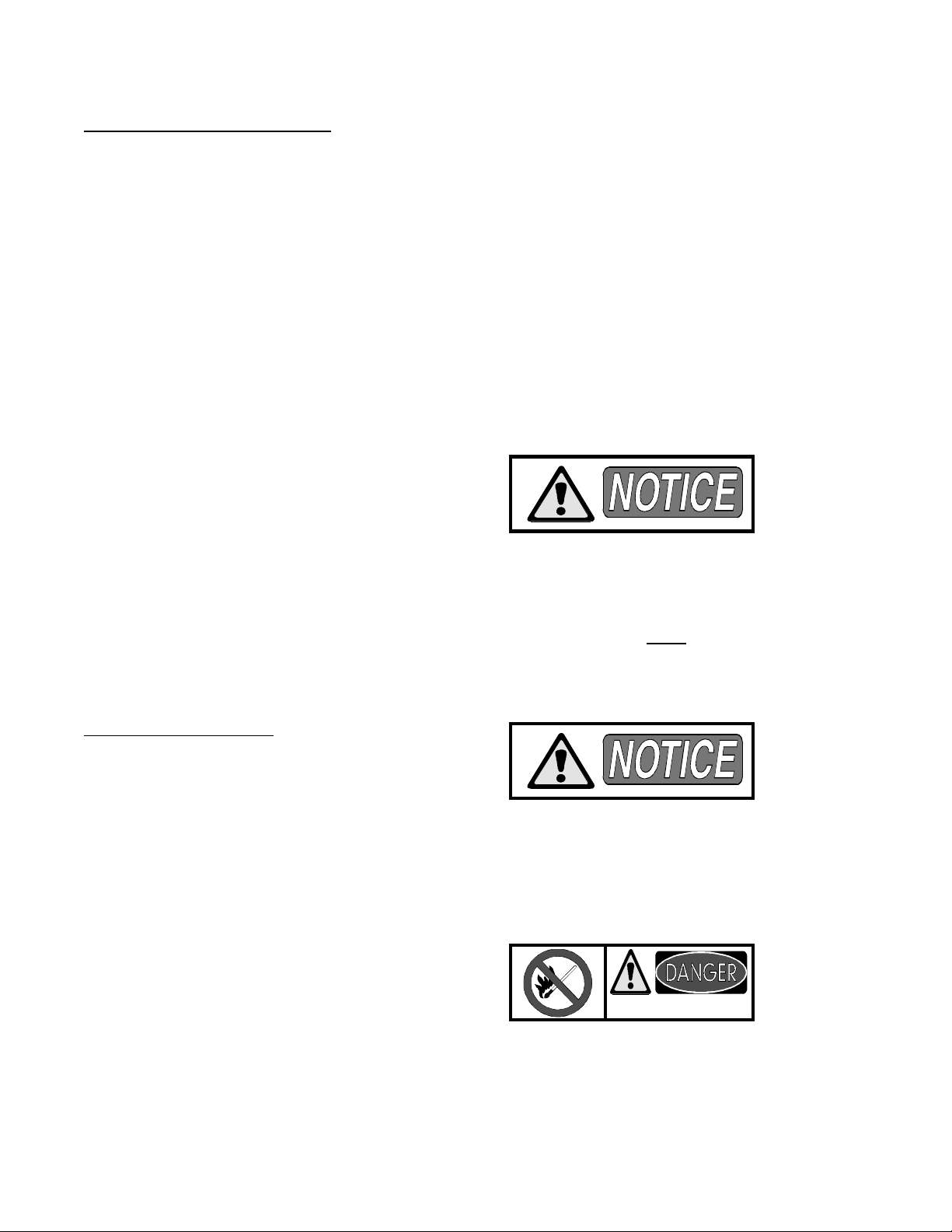

ORIFICE

8. Unscrew the dead weight cap. Figure 2-1.

A metal shipping support is placed inside the dead weight

valvehousing to protect the orifice and weight during shipment. This support must be removed prior to installation or

the unit will not build pressure.

9. Remove the round weight. Figure 2-1.

10. Remove and discard the shipping support. Figure 2-1.

11. Clean the orifice with a dry cloth.

12. Replace the weight and cap.

Figure 2-1

2-2. SELECTING THE

FRYER LOCATION

13. Remove the protective paper from the fryer exterior and clean

with a cloth, soap and water.

The proper location of the fryer is very important for operation,

speed, and convenience. Choose a location which provides easy

loading and unloading without interfering with the final assembly of

food orders. Operators have found that frying from raw to finish, and

holding the product in warmers, provides fast continuous service.

Landing or dumping tables should be provided next to, at least, one

side of the fryer. Keep in mind the best efficiency will be obtained by

a straight line operation, i.e., raw in one side and finished out the other

side. Order assembly can be moved away with only a slight loss of

efficiency.

The gas fryer is designed for installation on combustible floors

and adjacent to combustible walls. Fryer must be installed

with minimum clearance from all combustible and noncombustible materials, 6 inches from side and 6 inches from back.

2-2 502

Henny Penny Model 500/600

2-2. SELECTING THE

FRYER LOCATION

(Continued)

2-3. LEVELING THE FRYER

The fryer should be installed in such a way as to prevent tipping or

movement causing splashing of hot peanut oil. This may be accomplished by the location of the fryer, or by restraining ties.

The area under the gas and electric fryers is not to be used

as storage. The filter pan sits under the fryer. Supplies

stored under the unit would be ruined and could be a fire

hazard.

For proper operation, the fryer should be level from side to side

and front to back. Place a level on the flat areas around the frypot

collar, then adjust the leveling bolts or casters until the unit is level.

2-4. VENTILATION OF

FRYER

The fryer must be located with provision for venting into adequate

exhaust hood or ventilation system. This is essential to permit efficient

removal of the flue gases and frying odors. Take special precautions

in designing an exhaust canopy to avoid interference with the operation of the fryer. Make certain the exhaust hood is designed high

enough to allow for proper opening of the fryer lid. We recommend

you consult a local ventilation or heating company to help in designing

an adequate system.

Ventilation must conform to local, state, and national codes.

Consult your local fire department or building authorities.

When installing the gas fryer do not attach an extension to

the gas flue exhaust stack. This may impair proper operation of the burner, causing malfunctions and possible

negative back draft.

702 2-3

Henny Penny Model 500/600

2-4. VENTILATION 0F

FRYER

(Continued)

2-4 502

Henny Penny Model 500/600

2-5. GAS SUPPLY

2-6. GAS PIPING

The gas fryer is factory available for either natural or propane gas.

Check the data plate behind the front door of the fryer to determine

the proper gas supply requirements.

DO NOT ATTEMPT TO USE ANY GAS OTHER THAN

THAT SPECIFIED ON THE DATA PLATE. INCORRECT GAS SUPPLY COULD RESULT IN A FIRE OR

EXPLOSION RESULTING IN SEVERE INJURIES AND/

OR PROPERTY DAMAGE.

Please refer below for the recommended hookup of the fryer to main

gas line supply.

To avoid possible serious personal injury:

• Installation must conform with American National Standard

Z223.1 - (the latest edition) National Fuel Gas Code and the

local municipal building codes. In Canada, installation must be

in accordance with Standard CGA Bl49-& 2, Installation Codes

Gas Burning Appliances and local codes.

• The fryer and its individual shut-off valve must be disconnected

from the gas supply piping system during any pressure testing of

that system at test pressures in excess of 1/2 PSIG (3.45 KPA).

• The fryer must be isolated from the gas supply piping system by

closing its individual manual shut-off valve during any pressure

testing of the gas supply piping system at test pressures equal to

or less than 1/2 PSIG (3.45 KPA).

• A standard 3/4 inch, black steel pipe and malleable fittings

should be used for gas service connections.

• Do not use cast iron fittings.

• Although 3/4 inch size pipe is recommended, piping should be

of adequate size and installed to provide a supply of gas sufficient

to meet the maximum demand without undue loss of pressure

between the meter and the fryer. The pressure loss in the piping

system should not exceed 0.3 inch water column.

502 2-5

Henny Penny Model 500/600

2-6. GAS PIPING (Continued)

Provisions should be made for moving the fryer for cleaning and

servicing. This may be accomplished by:

1. Installing a manual gas shut off valve and disconnect union, or

2. Installing a heavy duty design (minimum 3/4 inch) A.G.A. certified

connector which complies with standard connectors for moveable gas appliances. ANSI Z21.69 (the latest edition) or

CAN l, 6. l0M88. Also, a quick disconnect coupling which

complies with the Standard for Quick Disconnect Devices for

use with Gas Fuel, ANSI 21.41 (the latest edition) or CAN 1,

6.9M79. Also, adequate means must be provided to limit the

movement of the fryer without depending on the connector and

any quick-disconnect device or its associated piping to limit the

fryer movement.

3. See the illustration on the following page for the proper connections of the flexible gas line and cable restraint.

The cable restraint limits the distance the fryer can be

pulled from the wall. For cleaning and servicing the fryer,

unsnap the cable from the unit, and disconnect the flexible

gas line. This allows better access to all sides of the fryer.

The gas line and cable restraint must be reconnected once the

cleaning or servicing is complete.

2-7. GAS LEAK TEST

Prior to turning the gas supply on, be sure the gas valve knob

on the gas valve is turned to the OFF position. After the

piping and fittings have been installed, check for gas leaks.

Turn the gas on and brush all connections with a soap solution. Bubbles show escaping gas and that the piping

connection must be redone.

NO OPEN FLAME

NEVER USE A LIGHTED MATCH OR OPEN FLAME

TO TEST FOR GAS LEAKS. ESCAPING GAS COULD

CAUSE AN EXPLOSION, RESULTING IN SEVERE

INJURY AND/OR PROPERTY DAMAGE.

2-6 502

Henny Penny Model 500/600

502 2-7

Henny Penny Model 500/600

2-8. GAS PRESSURE

REGULATOR SETTINGS

2-9. GAS PILOT LIGHTING

PROCEDURES

The gas pressure regulator on the automatic gas valve is factory set as

follows:

Natural: 3.5 inches water column

Propane: 10.0 inches water column

1. The gas valve knob has a dual function:

• Complete control of gas to the pilot and main burner.

• When in the PILOT position, it is the reset mechanism for the

automatic pilot.

2. Partially press and turn the gas valve knob to the OFF position.

3. Wait at least 5 minutes to allow any gas to escape that may

have accumulated in the burner compartment.

4. Turn the Cook/Pump switch to OFF.

5. Turn the gas valve knob to the PILOT position.

6. Press and hold the gas valve knob while lighting the pilot. Allow

the pilot to burn about 30 seconds before releasing the knob.

If the pilot does not stay lit, repeat steps 5 and 6, allowing a

longer period of time before releasing the gas valve knob.

7. Turn the gas valve knob to the ON position.

8. Turn the Cook/Pump switch to COOK.

8. With the lid open, select a product on control panel, and listen for

the gas burner ignition (no longer than 10 seconds) and then turn

Cook/Pump switch OFF.

Do not leave unit on, without peanut oil, for more than 10

seconds or damage to the frypot could result.

9. Clean the frypot per the instructions in section 3-13.

10. Fill the frypot with peanut oil to the proper level.

11. The fryer is now ready for operation.

2-8 502

Henny Penny Model 500/600

2-10. ELECTRICAL

REQUIREMENTS

(GAS FRYER)

The gas fryer requires 120 single phase, 60 Hertz, 10 or 5 amp, 2 wire

+ ground service. The gas fryer is factory equipped with a grounded

cord and plug for your protection against shock and should be plugged

into a 3 prong grounded receptacle. A wiring diagram is located behind

the front door.

SHOCK HAZARD

DO NOT DISCONNECT THE GROUND PLUG. This fryer

MUST be adequately and safely grounded or electrical shock

could result. Refer to local electrical codes for correct

grounding procedures or, in absence of local codes, with the

National Electrical Code, ANSI/NFPA No. 70 (the current

edition). In Canada, all electrical connections are to be made

in accordance with CSA C22. 1, Canadian Electrical Code

Part 1, and/or local codes.

The Cook/Pump switch on this appliance does not disconnect

all line conductors. This appliance must be equipped with an

external circuit breaker which will disconnect all ungrounded

conductors.

2-11. ELECTRICAL

REQUIREMENTS

(ELECTRIC FRYER)

The electric fryer requires 208 or 240 volt, three phase, 50/60

Hertz service. The power cord may be already attached to the

fryer or provided at installation. Check the data plate behind the

front door to determine the correct power supply.

SHOCK HAZARD

This fryer MUST be adequately and safely grounded or

electrical shock could result. Refer to local electrical codes

for correct grounding procedures or, in absence of local

codes, with the National Electrical Code, ANSI/NFPA No. 70

(the current edition). In Canada, all electrical connections are

to be made in accordance with CSA C22.1, Canadian Electrical Code Part 1, and/or local codes.

The Cook/Pump switch on this appliance does not disconnect

all line conductors. This appliance must be equipped with an

external circuit breaker which will disconnect all ungrounded

conductors.

502 2-9

Henny Penny Model 500/600

2-11. ELECTRICAL

REQUIREMENTS

(ELECTRIC FRYER)

(Continued)

2-12. TESTING THE FRYER

A separate disconnect switch with proper capacity fuses or breakers

must be installed at a convenient location between the fryer and the

power source. It should be an insulated copper conductor rated for

o

600 volts and 90

C. For runs longer than 50 feet (15.24 m), use the

next larger wire size.

Supply Wiring and Fusing for Electric Fryer

Supply Min.

Wire Fuse

Volts Phase KW Amps Size Size

208 Single 13.50 65 2 90

208 Three 13.50 38 6 50

240 Single 13.50 61 3 70

240 Three 13.50 35 6 50

Each Henny Penny Pressure Fryer was completely checked and

tested prior to shipment. However, it is good practice to check the unit

again after installation.

2-10 502

Henny Penny Model 500/600

SECTION 3. OPERATION

3-1. OPERATING

COMPONENTS

Frypot

Lid Gasket

Dead Weight Valve

Safety Relief Valve

This reservoir holds the peanut oil, and is designed to hold

12 lb (5.4 kg) of product, with a “cold zone” for collection of crumbs.

Provides the pressure seal for the frypot chamber.

The dead weight style relief valve is used to maintain a constant level of

operating steam pressure within the frypot. Any excess steam pressure

is vented through the exhaust stack. Figure 3-1.

Remove and clean the dead weight cap, weight, and orifice,

once a day to prevent over pressurization inside the frypot

An ASME approved, spring loaded valve, set at 14.5 psi. In the event

the dead weight valve becomes clogged, this safety valve releases

excess pressure, keeping the frypot chamber at 14.5 psi. If the safety

valve releases pressure, turn the Cook/Pump switch OFF to release all

pressure from the frypot. Figure 3-1.

Safety Relief Valve Ring

THE RING IS NOT TO BE PULLED. Figure 3-1.

DO

NOT

PULL

STEAM

THIS RING, WHEN PULLED, ACTIVATES THE

RELIEF VALVE AND RELEASES HOT STEAM.

SEVERE BURNS FROM THE STEAM WILL RESULT.

Pressure Gauge

Saftey Relief

Valve Ring

Saftey Relief Valve

702 3-1

Indicates the pressure inside the frypot. Figure 3-1.

Pressure Gauge

Dead Weight Valve

Figure 3-1

Henny Penny Model 500/600

3-1. OPERATING

COMPONENTS

(Continued)

Solenoid Valve

An electromechanical device that allows pressure to be held in the

frypot. The solenoid valve closes at the beginning of the frying cycle

and automatically opens at the end of the frying cycle. If this valve

becomes dirty or the teflon seat nicked, pressure will not build, and the

valve must be repaired per the maintenance section.

Drain Valve

A two-way ball valve that is normally closed. Turn the handle to drain

the peanut oil from the frypot into the filter drain pan.

PRESSURIZED

Drain Interlock Switch

Condensation Drain Pan

Lid Latch

High Limit

Red Reset Button

DO NOT OPEN THE DRAIN VALVE WHILE FRYPOT IS

UNDER PRESSURE. HOT PEANUT OIL EXHAUSTS

FROM THIS VALVE, AND SEVERE BURNS WILL

RESULT.

A microswitch, providing protection for the frypot in the event an

Operator inadvertently drains the peanut oil from the frypot while the

Cook/Pump switch is ON. The switch automatically shuts off the heat

when the drain valve is opened.

The collection point for the condensation, formed within the steam

exhaust system. Remove and empty periodically.

A mechanical catch on the front of the lid which engages a bracket

on the front of the frypot. This device holds the lid down during a cook

cycle.

This is a safety component that senses the temperature of the peanut oil.

If the temperature of the peanut oil exceeds 420°F (212°C), this control

opens and shuts off the heat to the frypot. When the temperature of the

peanut oil drops to a safe operation limit, the control must be manually

reset by pressing the red reset button.

To locate the high limit reset button, open the door to the drain pan.

Look up under the controls and to the right of the filter drain handle for

a red reset button. See Figure 3-2.

Figure 3-2

3-2 702

Henny Penny Model 500/600

3-1. OPERATING

COMPONENTS

(Continued)

Gas Control Valve

Controls the gas flow to the burner. The pilot is lit manually.

Spindle Assembly

When tightened after lid is latched, it puts pressure, from the lid gasket

to the frypot rim. After one pound of internal frypot pressure, the lid

liner pushes the locking pin into the locking collar, and prevents the

spindle assembly from being unscrewed while frypot is pressurized.

Lid Limit Stop

An adjustable collar to obtain the proper tightness between the lid

gasket and the frypot rim. This limits the number of clockwise rotations

of the spindle.

Filter Drain Pan

The removable pan that houses the filter and catches the peanut oil

when it is drained from the frypot. It is also used to remove and discard

old peanut oil.

Filter Union

Filter Valve

Contactors (Electric Models)

WHEN HOT PEANUT OIL IS IN THIS PAN, USE

EXTREME CARE TO AVOID BURNS.

Connects the filter to the filter pump, and allows easy removal of the

filter and drain pan.

When the Cook/Pump switch is in the PUMP position, this two-way

valve directs filtered peanut oil from the drain pan, back into the frypot.

Relays that route power to the heating elements. One relay is in

series with the high limit, the other one is in series with the controls.

502 3-3

Henny Penny Model 500/600

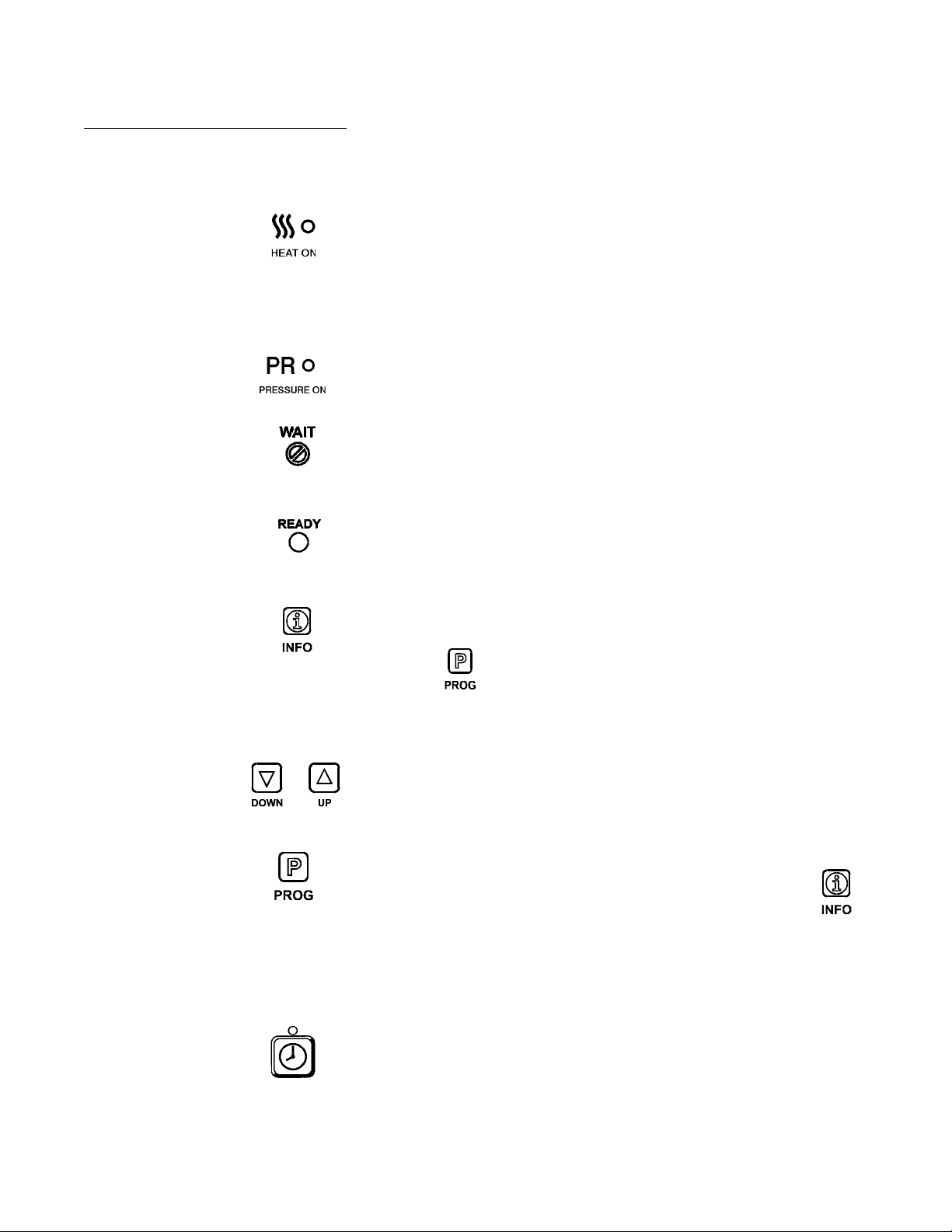

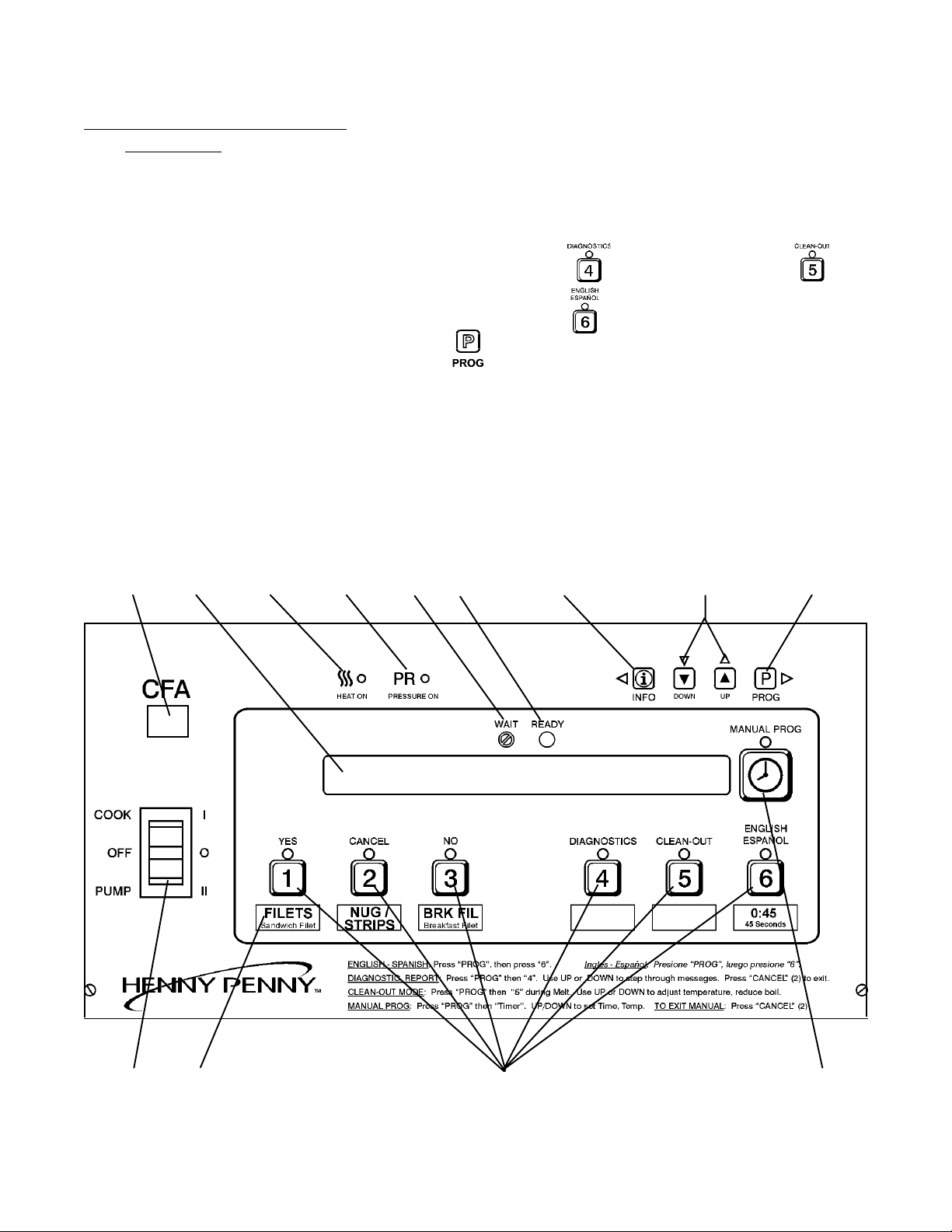

3-2. OPERATING CONTROLS Figure 3-2 shows the location of following computer control

items.

Figure Item Description Function

No. No.

3-3 1 Lights when the control calls for heat and the peanut oil should

start heating.

3-3 2 Digital Display Shows all the functions of the cooking cycle, Program Mode,

Diagnostic Mode and alarms.

3-3 3 Lights when the solenoid closes and pressure starts to build inside

frypot.

3-3 4 Flashes when the peanut oil temperature is NOT at the proper

temperature for dropping product into the frypot.

3-3 5 Lights when the peanut oil temperature is 5°F below setpoint to

15°F above the cooking temperature, signaling product can now

be be cooked.

3-3 6 Press to display current fryer information and status. If pressed in

the Program Mode, shows previous settings. Pressing this along

with accesses the Information Mode which has

historic information on the Operator and fryer performance.

3-3 7 Used to adjust the value of the currently displayed setting in the

Program Mode.

3-3 8 Press to access Program Mode. Once in the Program Mode, it is

used to advance to the next setting. If pressed along with it

accesses the Information Mode which has historic information on

the Operator and fryer performance. It also allows access to

the English-Spanish settings, diagnostics, Clean-Out Mode, and

Manual Mode, if pressed before the appropriate button.

3-3 9 Used to stop cooking cycles and to stop the timer at the end of a

holding cycle. It is also used to program a Manual Program for

nonstandard products.

3-4 702

Henny Penny Model 500/600

3-2. OPERATING CONTROLS

(Continued)

3-3 10 Menu Card Shows name of food product selected. The menu card strip is

located behind the decal.

3-3 11 Product Select Press to select food products to be cooked, as well as, answering

Buttons display prompts. Also, accesses the diagnostics; , the

Clean-Out Mode; and toggles between English and Spanish

display.

(Press before entering any of the above modes.)

3-3 12 Cook/Pump Switch A 3-way switch with a center OFF position. Turn the switch to

COOK to operate the fryer. Turn the switch to PUMP to operate the filter pump. Certain conditions must be met before

operating the filter pump. These conditions are covered later in

this section.

3-3 13 Unit Identification The unit’s model number and the control’s hardware and software

Window version numbers appear here.

13 2 1 3 4 5 6 7 8

12 10 11 9

Control Decal

Figure 3-3

502 3-5

Henny Penny Model 500/600

3-3. CLOCK SET

Upon initial start-up or PC board replacement, if “CLOCK SET”

automatically appears in the display, skip steps 1, 2 and 3.

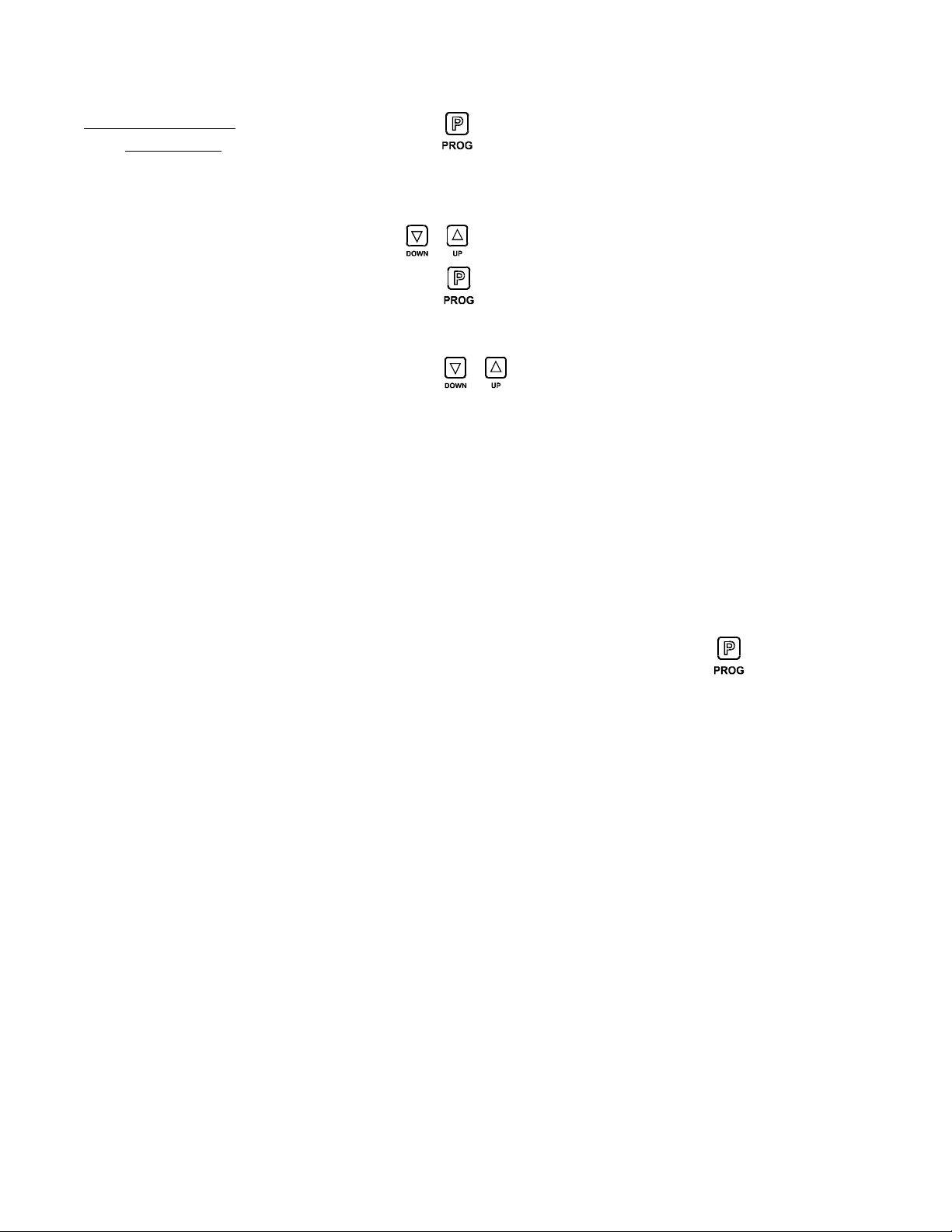

1. Press and hold for 5 seconds until “LEVEL 2” shows in

display.

2. Release , then press twice. “CLOCK SET” then

“ENTER CODE” shows in display.

3. Press . .

4. Display shows “CS-1” then “SET” then “MONTH”, with the

month flashing.

5. Press to change the month.

6. Press . Display shows “CS-2” then “SET” then “DATE”

with the date flashing.

7. Press to change the date.

8. Press . Display shows “CS-3” then “SET” then “YEAR”

along with the year flashing.

9. Press to change the year.

10. Press . Display shows “CS-4” then “SET” then “HOUR”

shows with the hour and “AM” or “PM” flashing.

11. Press to change the hour and AM/PM setting.

12. Press . Display shows “CS-5” then “SET” then “MINUTE”

with the minutes flashing.

13. Press to change the minutes.

3-6 702

Henny Penny Model 500/600

3-3. CLOCK SET

(Continued)

14. Press . Display shows “CS-6” then “CLOCK MODE”

along with “1.AM/PM”.

15. “1.AM/PM” is 12 hour time, “2.24-HR” is 24 hour time. Press

to change.

16. Press . Display shows “CS-7” then “DAYLIGHT

SAVINGS ADJ” along with “2.US”.

17. Press to change to the following:

a. “1.OFF” = No automatic adjustments for Daylight Savings

Time.

b. “2.US” = Automatically applies United States Daylight Savings

Time adjustment. DST activated on the first Sunday in April.

DST de-activated on the last Sunday in October.

c. “3.EURO” = Automatically applies European (CE) Daylight

Savings Time adjustment. DST activated on the last Sunday in

March. DST de-activated on the last Sunday in October.

18. Clock Set is now complete. Press and hold to exit.

702 3-7

Henny Penny Model 500/600

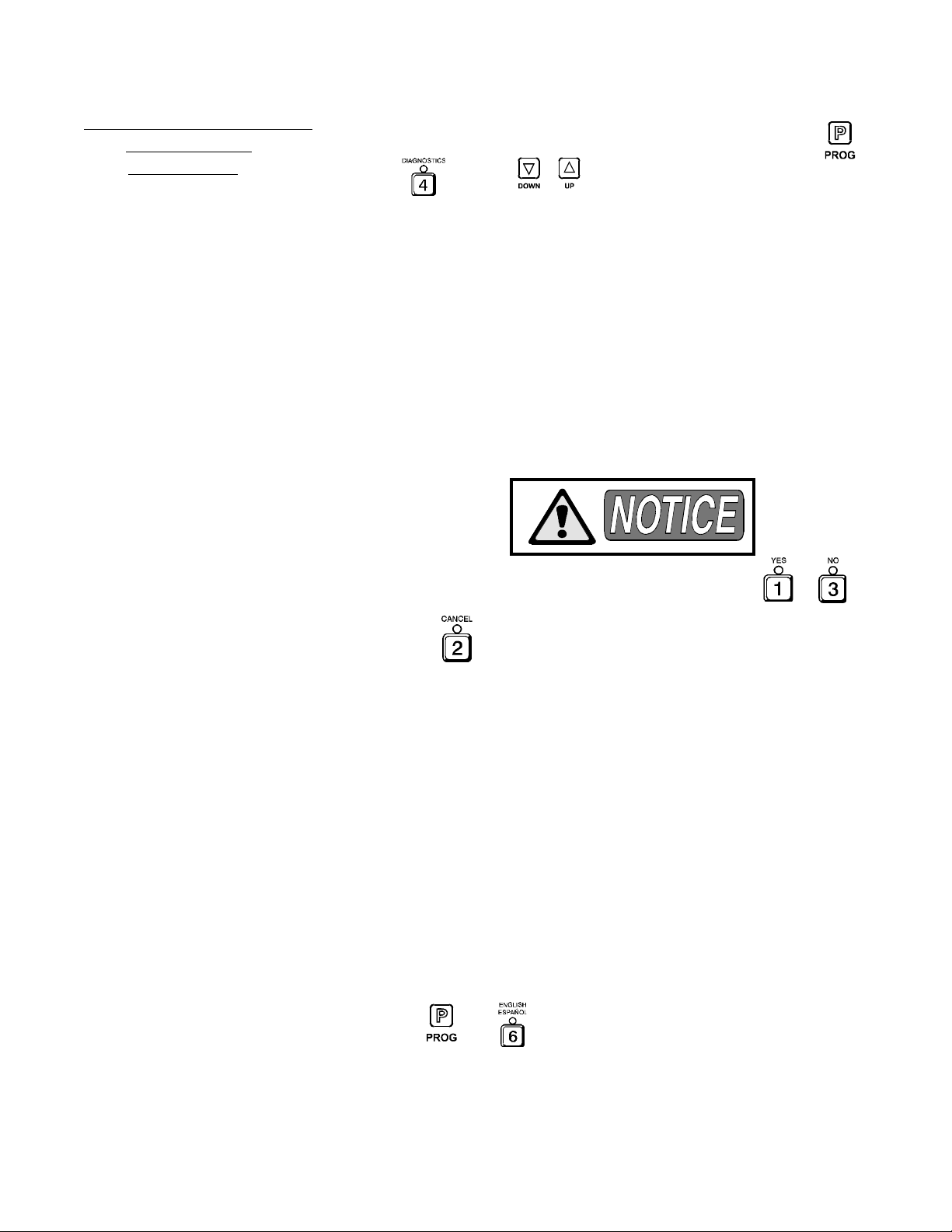

3-4. DIAGNOSTIC MODE

AND SPECIAL

FUNCTIONS

Diagnostic Mode

To view summaries of the fryer and Operator performance, press

then . Press to view the following functions:

D1 - Adjust product color for all products (not individually)

D2 - The age of the peanut oil and life remaining

D3 - Outlet voltage monitoring

D4 - Fryer’s heating performance

D5 - Slow or oversized product batches

D6 - Cook cycles started before temperature recovered

D7 - Cook cycles stopped more than 10 seconds before end of

cycle

D8 - Cook cycles not ended within 20 seconds after expired time

D9 - Number of times loading product took too long

D10 - Programmed variables changed by Operator

On several of the screens you may have to press or to

respond to questions asked.

Press at any time to exit and return to normal operation.

See section 5-3 for more details of the Diagnostic Mode.

Peanut Oil Life Function

Based on the number of cook cycles of specific products and the

amount of time the fryer idles, the controls tell the Operator when to

change the peanut oil.

“CHANGE OIL SOON” shows on the display when the controls

determine it’s time to change peanut oil. Unless the peanut oil is smoking or has a burnt flavor, the peanut oil does not need to be changed

before this message shows on the display. After cleaning the frypot,

using the Clean-Out Mode (section 3-14), this function resets.

Language Selection

Pressing then allows the Operator to choose to have the

information on the display in English or Spanish.

3-8 502

Henny Penny Model 500/600

3-4. DIAGNOSTIC MODE

AND SPECIAL

FUNCTIONS

(Continued)

Manual Mode

This allows the Operator to quickly program a time and temperature for

nonstandard products that are not on the menu card. This is to be a

temporary setting and disables most of the advanced features of the

controls. To enter Manual Mode:

1. Once out of the Melt cycle, press then .

2. Use to set cook time.

3. Press and use to set temperature.

4. Press to start Manual Mode. Display shows “MANUAL”

and you start a cook cycle by pressing .

5. Press to exit Manual Mode.

Status Mode

Pressing during idle time, allows Operator to view:

a. The temperature of the peanut oil

b. The temperature setpoint and any offset

c. The average peanut oil temperature during last cook cycle

d. The rate of temperature rise or fall

e. Date and Time

Pressing during a cook cycle allows the Operator to view:

a. The temperature of peanut oil, plus the degrees and rate the Load

Compensation has affected the cook cycle (slows down or speeds

up the timer)

b. The cooking step, the time left in cook cycle, setpoint temperature

and whether pressure is on

c. The average peanut oil temperature in cook cycle so far

d. The rate of temperature rise or fall

e. Date and Time

After 5 seconds, the control exits the Status Mode and the pressure

fryer returns to normal operation.

Peanut Oil Filter Enforcement

Prevents the Operator from exceeding the set number of cook cycles

before filtering the peanut oil. The number in the center of the display

shows how many cook cycles remain before the Filter Lockout occurs.

For example, “5X” means the Operator can run 5 more cook cycles

before filtering. This function cannot be bypassed and greatly increases

the life of the peanut oil.

502 3-9

Henny Penny Model 500/600

3-4. DIAGNOSTIC MODE

AND SPECIAL

FUNCTIONS

(Continued)

Information Mode

This mode gathers and stores historic information on the fryer and

Operator performance. Press and at the same time and

“*INFO MODE*” shows on display. Press or to access the

steps and press to view the statistics within each step.

Information Mode is intended for technical use, but the Operator can

view the following information:

1. E-LOG - last 10 errors and time they occurred

2. P-LOG - time of last 10 power-ups

3. HEAT-UPS - time of day and maximum heating rate (°/second) for

the last 10 heat-ups

4. COOK DATA - information on the last cook cycle

5. TODAY’S DATA - data since the start of day (not including the

last cook cycle)

6. PREV-DAY-SUN - creates a log of the last 7 days, using the

information in TODAY’S DATA.

7. 7-DAY TOTALS -totals the information from the last 7 days

8. OIL DATA - information on the current peanut oil, not including

today’s cooking information

9. PREV OIL DATA - information on last batch of peanut oil

10. INP - provides test of fryer inputs

11. OUTP - shows the state of heater and pressure

12. POT TMP - temperature of peanut oil

13. CPU TMP - temperature of PC board

14. ANALOG - status of controller’s a-to-d converter

15. AC VOLTS - status of the line voltage to fryer

16. AMPS (Electric models only) - the present amp readings to

heaters.

See section 5-4 for more details of the Information Mode.

3-10 502

Henny Penny Model 500/600

3-5. WARNINGS AND

ERROR MESSAGES

The controls monitor procedure problems and system failures with

warnings and error codes. The display shows the warning or error

code, and an alarm sounds.

Pressing cancels most warnings and pressing any control button

stops most Error Code alarms. But there are some exceptions (see

below). The display shows the error until the situation is corrected.

WARNINGS

DISPLAY CAUSE CORRECTION

“W-1” Incoming supply voltage too low. Have voltage at plug and receptacle checked.

“LOW

VOLTAGE”

“W-2” Faulty components or connections. Have elements, connections, and contactors

“SLOW checked.

HEAT-UP”

“W-3” Product loaded into frypot Wait until peanut oil is at proper temperature

“WAS NOT before lights. before loading product.

READY”

“W-4” Frozen or too much product Do not overfill or place frozen product

“SLOW in frypot. into the frypot.

COOKING”

“W-5” Product loaded into frypot Wait until peanut oil is at proper temperature

“SLOW before lights. before loading product.

COOKING”

“W-6” Faulty components or connections. Have elements, connections, and contactors

“SLOW checked.

COOKING”

“W-7” Faulty components or connections. Have elements, connections, and contactors

“LOW AMPS” checked.

“W-9” Product overcooked. (May Discard product immediately.

“DISCARD appear after a Slow Cooking

PRODUCT” warning.)

“OIL TOO Didn’t allow peanut oil to drop Cancel button will not stop this warning. Once

HOT” down to current product’s setpoint the peanut oil temperature drops to setpoint

temperature. temperature, the alarm automatically stops.

602 3-11

Loading...

Loading...