Henny Penny 500, 600 Installation Manual

Model 500/561/600

SECTION 2. MAINTENANCE

2-1. INTRODUCTION

2-2. MAINTENANCE

HINTS

This section provides procedures for the checkout and

replacement of the various parts used within the fryer.

Before replacing any parts, refer to Section 1, Troubleshooting.

It will aid you in determining the cause of the malfunction.

1. You may use two test instruments to check the electric

components.

• A continuity light

• An ohmmeter

2. When the manual refers to the circuit being closed,

the continuity light will be illuminated or the

ohmmeter should read zero unless otherwise noted.

3. When the manual refers to the circuit being open,

the continuity light will not illuminate or the

ohmmeter will read 1 (one).

A continuity tester cannot be used to check coils or motors.

103 2-1

Model 500/561/600

2-3. PREVENTIVE

MAINTENANCE

SCHEDULE

2-4. REMOVING THE

CONTROL PANEL

To ensure a long life of the fryers and their components, regular

maintenance should be performed. Refer to the chart below.

Frequency Action

Daily (3-4 loads) Filter shortening

Daily Clean deadweight valve cap,

weight, and orifi ce

30 Days Lubricate spindle threads and ball seat

90 Days Reverse lid gasket

90 Days Check limit stop adjustment

90 Days Check and tighten element spreader bars

Once a year Remove and clean safety relief valve

To replace parts inside the fryer you will often need to remove

the control panel. The following steps provide the correct

procedure:

Removal

1. Place the main power switch to the OFF position.

(This switch is labeled POWER/OFF/PUMP.)

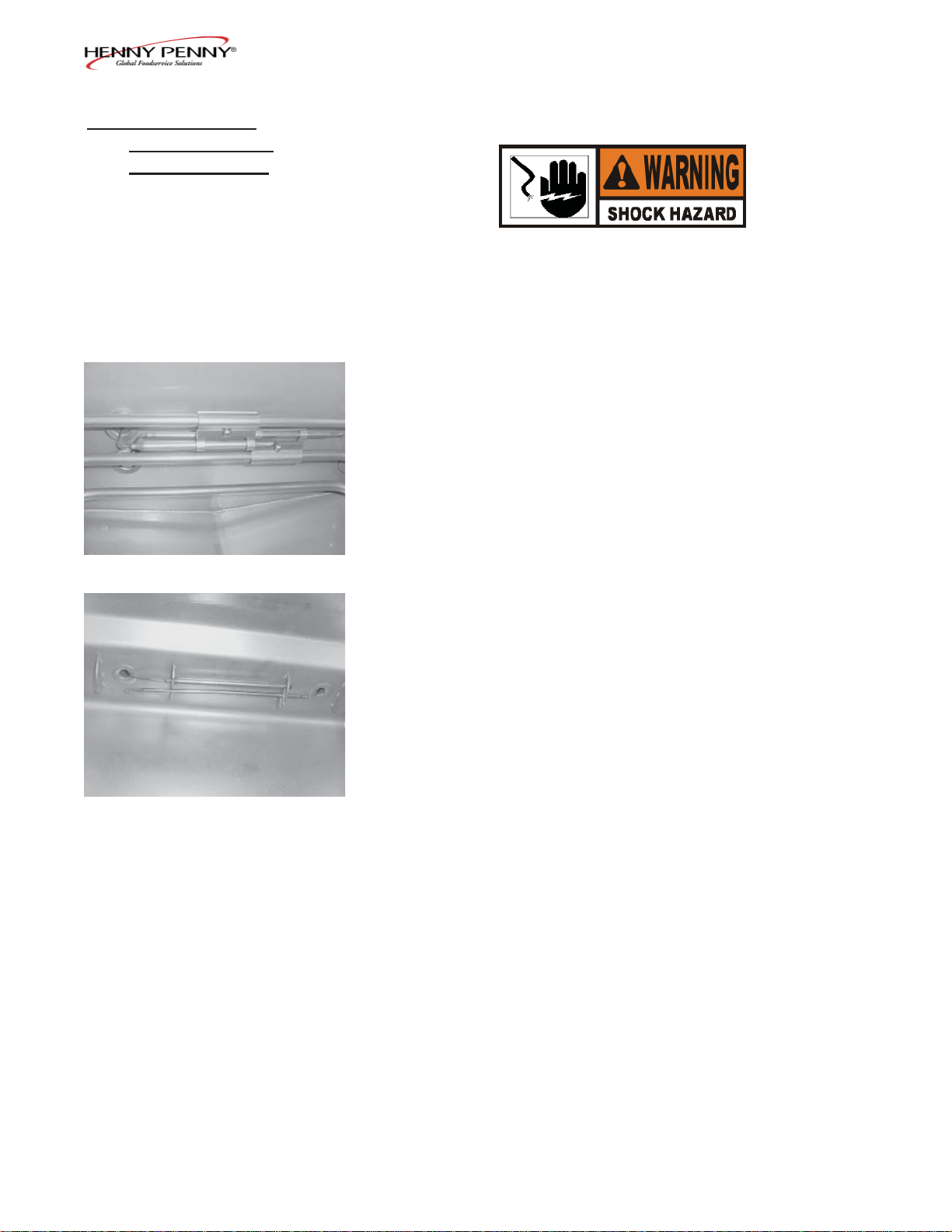

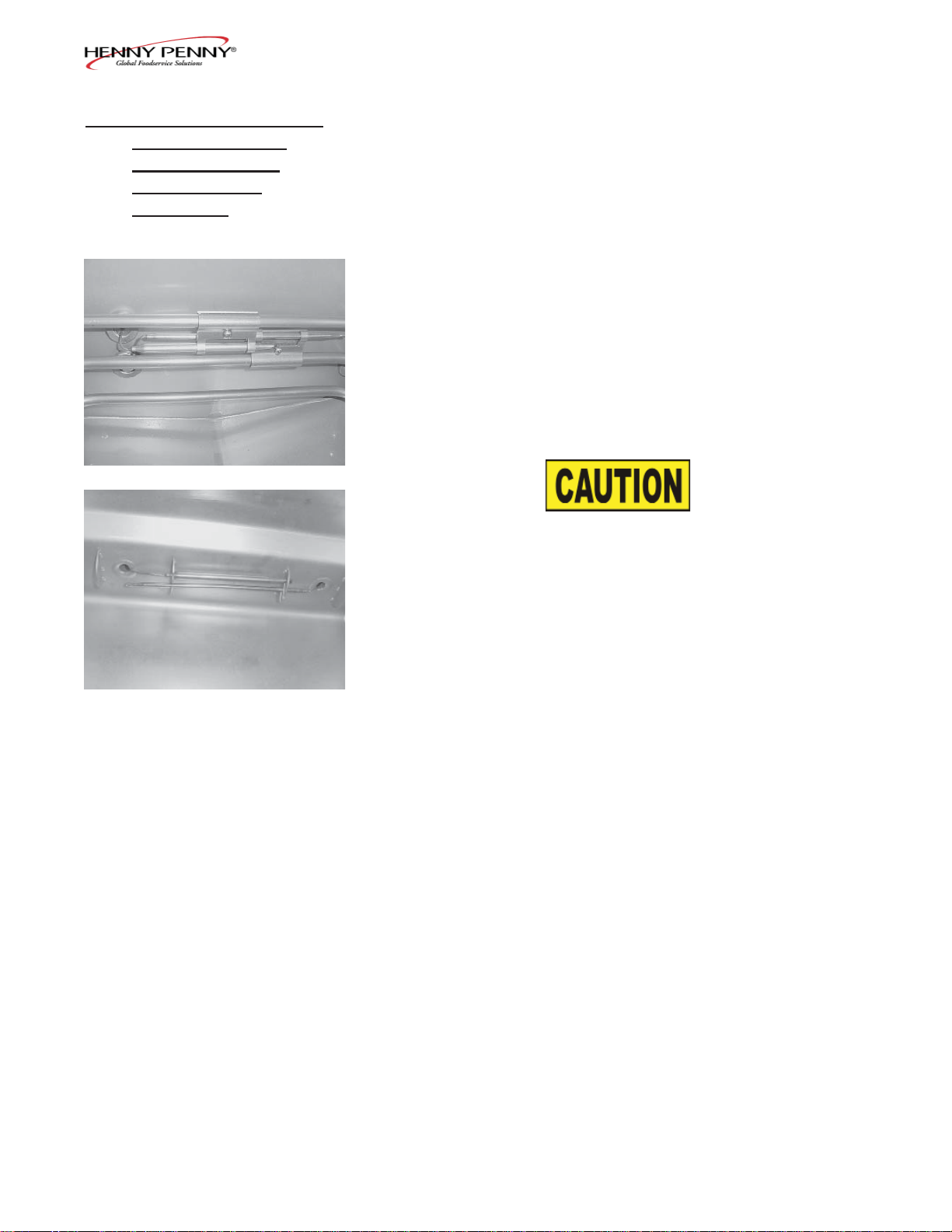

Step 3

Step 4

To avoid electrical shock or property damage, move the

power switch to OFF and disconnect main circuit

breaker, or unplug cord at wall receptacle.

2. Remove the two screws from the bottom of the

control panel.

3. Carefully slide the control panel upward until it lifts off

the metal hangers.

4. With the fryer door closed, place the lower edge of the

control panel in the slot between the door and the frame

of the fryer.

Installation

1. To install the control panel, hook it on the metal hangers

that hold the top of the panel in place.

2. Install the two screws in the bottom of the panel.

3. Reconnect power to the fryer.

2-2 103

Model 500/561/600

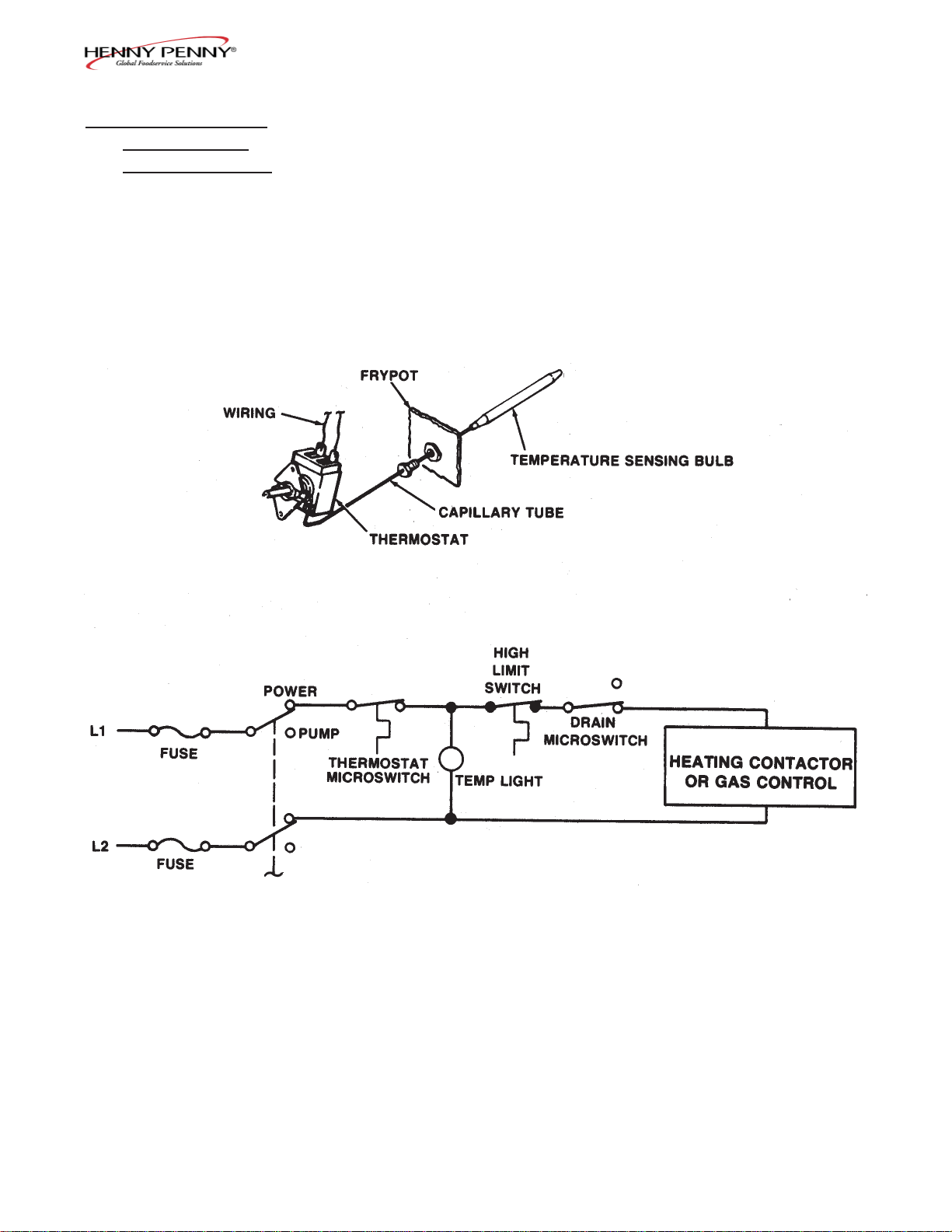

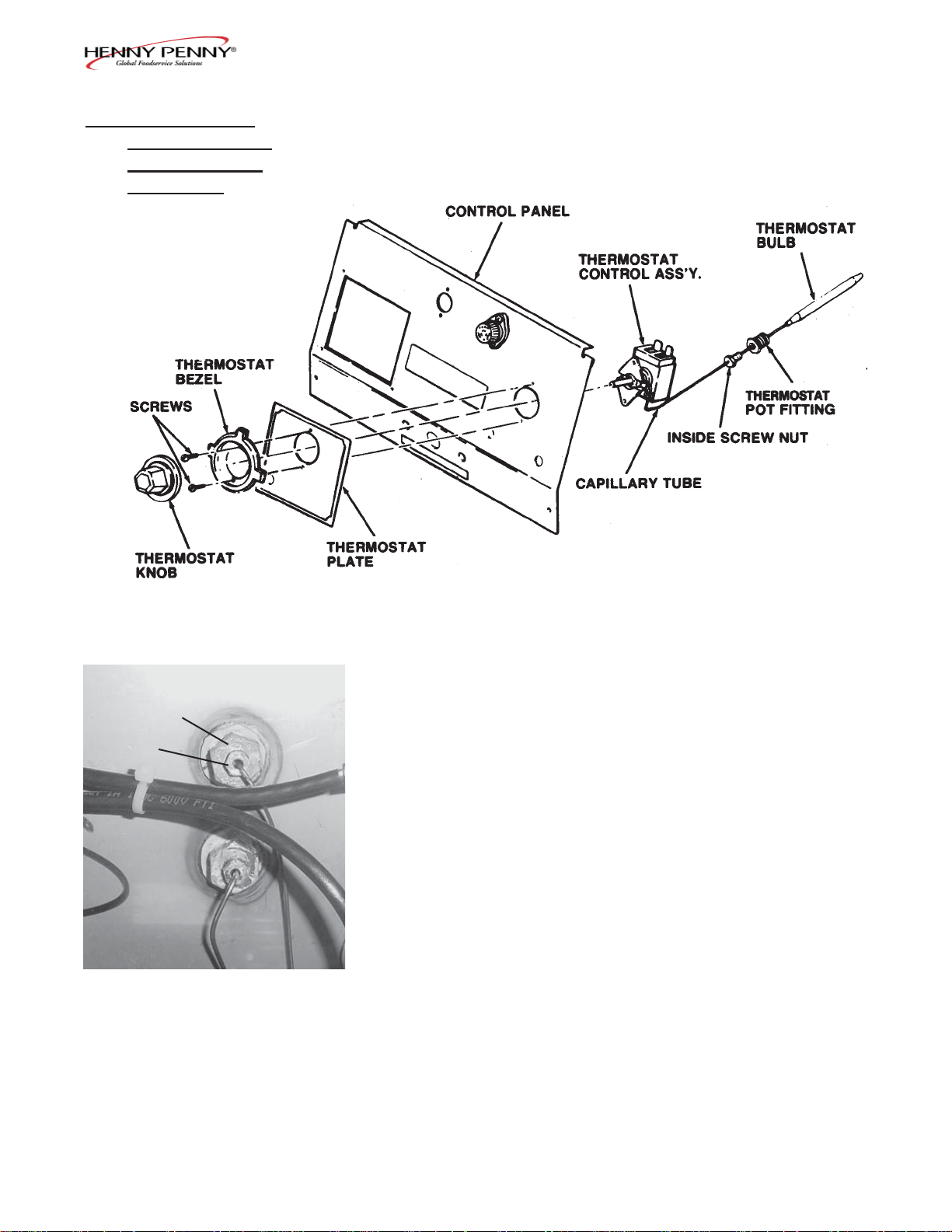

2-5. TEMPERATURE

REGULATION

(SINGLE STAGE)

Description

The cooking temperature is controlled by the front panel

thermostat and monitored by its sensing bulb mounted

just inside the frypot. Various thermostats are available,

but all work on the same principle.

1202 2-3

Model 500/561/600

2-5. TEMPERATURE

REGULATION

(SINGLE STAGE)

(Continued)

Internal Operation

Drain Microswitch

High Limit Temperature Control

The thermostat bulb is connected to the thermostat by a thin

capillary tube. When the temperature rises, the fl uid inside the

bulb expands (as in a thermometer) and pushes fl uid through the

tube into the control panel thermostat. When the frypot temperature is lower than the thermostat setting, the TEMP light is illuminated and frypot is being heated. When the temperature setting

is reached, a switch inside the thermostat opens the circuit to the

heat source and turns off the TEMP light. When the frypot starts

to cool, the switch closes the circuit to the heat source.

This interlock provides protection for the frypot in the event an

operator inadvertently drains the shortening with the switch in the

power position. The heat will automatically shut off when the

drain valve is opened.

The high limit temperature provides the safety feature of interrupting the heat if the temperature ever exceeds the safe operating

limits. On electric models it must be manually reset when the

frypot cools. Refer to High Temperature Limit Control section for

maintenance of the high limit temperature control.

2-4 103

Model 500/561/600

2-6. CALIBRATING

THE STANDARD

SINGLE STAGE

THERMOSTAT

Henny Penny does not recommend that a fi eld calibration be

performed on the thermostats mentioned above. The reasons for

this are as follows:

• The thermostat is calibrated in a controlled environment from

the factory. The thermostat manufacturers do not recommend

any adjustments to the thermostat in the fi eld, as this will affect

the factory calibration.

• The difference between a hand-held thermometer and an

installed thermostat can be quite large due to shortening

temperature variation.

• The adjustment of a thermostat is not precise, since the dial

reads only in 25 degrees F increments. The accuracy of a

thermostat needs to be less than 5 degrees F.

If a thermostat is not reading accurately and suspected to be

faulty, Henny Penny suggests that the thermostat be replaced.

If you have any questions, please do not hesitate to call the

Technical Services Department.

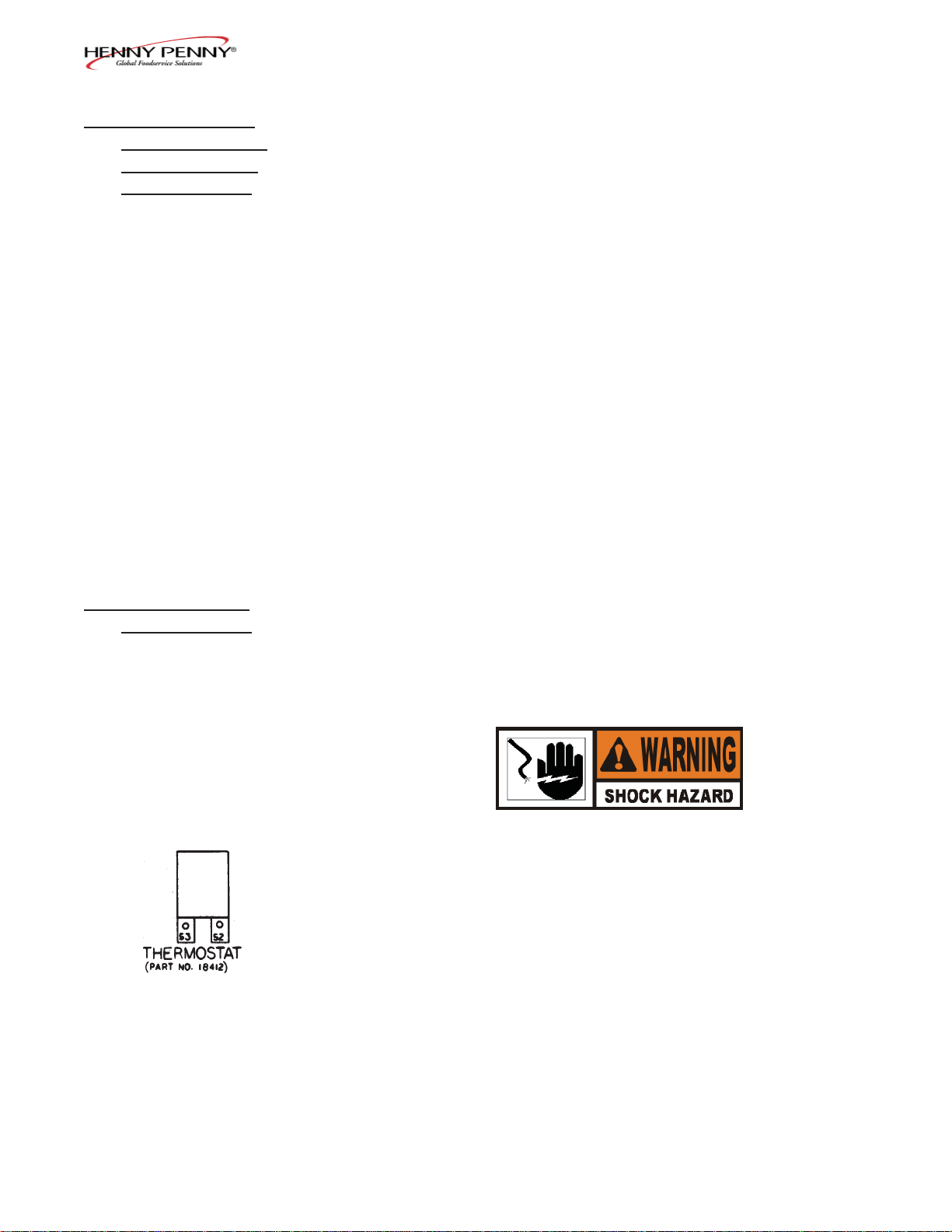

2-7. TESTING THE

THERMOSTAT

Procedure

If the thermostat fails to work properly, perform the following

checks before replacing the thermostat:

1. Remove electrical power supplied to the fryer.

To avoid electrical shock or property damage, move the

power switch to OFF and disconnect main circuit

breaker, or unplug cord at wall receptacle.

2. Remove the control panel.

3. With an ohmmeter or continuity light, check for continuity

as follows.

4. On a standard (single temperature) thermostat, check

between terminals 52 and 53. Move the temperature knob

from OFF to maximum.

• At OFF, the circuit should be open.

• At maximum, the circuit should be closed.

504 2-5

Model 500/561/600

2-8. THERMOSTAT

REPLACEMENT

(ALL MODELS)

ELECTRIC

GAS

1. Remove electrical power supplied to the fryer.

To avoid electrical shock or property damage, move the

power switch to OFF and disconnect main circuit

breaker, or unplug cord at wall receptacle.

2. Drain the shortening from the frypot.

3. Remove the thermostat sensing bulb from the bulb

holder inside the frypot.

4. Place your thumb at the bend in the capillary tube,

where it comes into the frypot, and straighten the

bulb. The bulb should be extending out into the

frypot.

Step 3

5. Remove the two screws which secure the control panel

to the frame of the fryer.

6. Lift the panel up and off the metal fl anges.

2-6 1202

Model 500/561/600

2-8. THERMOSTAT

REPLACEMENT

(ALL MODELS)

(Continued)

LARGE SCREW

NUT

SMALL SCREW

NUT

7. With the door of the fryer closed, put the bottom edge

of the control panel in the slot between the door and

the frame of the fryer.

8. Locate the thermostat on the back of the panel.

9. Remove the thermostat knob on the front of the control

panel.

10. Remove the two screws which secure the thermostat to

the back of the panel. Remove the thermostat bezel.

11. Remove the small inside screw nut which holds the

capillary line.

12. Remove the large screw nut.

13. Label the wire connections to the thermostat for correct

identifi cation when the new thermostat is installed.

14. Disconnect the wires.

15. Remove the defective thermostat.

16. Install the new thermostat.

1202 2-7

Model 500/561/600

2-8. THERMOSTAT

REPLACEMENT

(ALL MODELS)

(Continued)

17. Connect the wires to the new thermostat.

Be careful not to cross the wires or thermostat will

not operate properly.

18. Uncoil the capillary tube.

19. Insert the bulb through the wall of the frypot.

To avoid electrical shock or other injury, the capillary

line must run under and away from all electrical power

wires. The tube must never be in contact with the

electrical power wires or terminals.

20. Install the thermostat pot fi tting into the wall of the frypot

and tighten.

21. Replace the thermostat sensing bulb into the mounting

bracket.

Do not bend the capillary tube where it connects

to the sensing bulb, or damage to capillary will

result.

22. ELECTRIC only: slip the bulb holder in place. With

bulb in place, tighten the clamp screw.

23. Pull the excess capillary tube from the inside of the frypot.

24. Insert and tighten the inside screw nut into the thermostat

pot fi tting.

25. Install the two screws on the front of the control panel

which secure the thermostat to the back of the panel.

Install the thermostat bezel.

26. Install the thermostat knob.

2-8 1202

Model 500/561/600

2-8. THERMOSTAT

REPLACEMENT

(ALL MODELS)

(Continued)

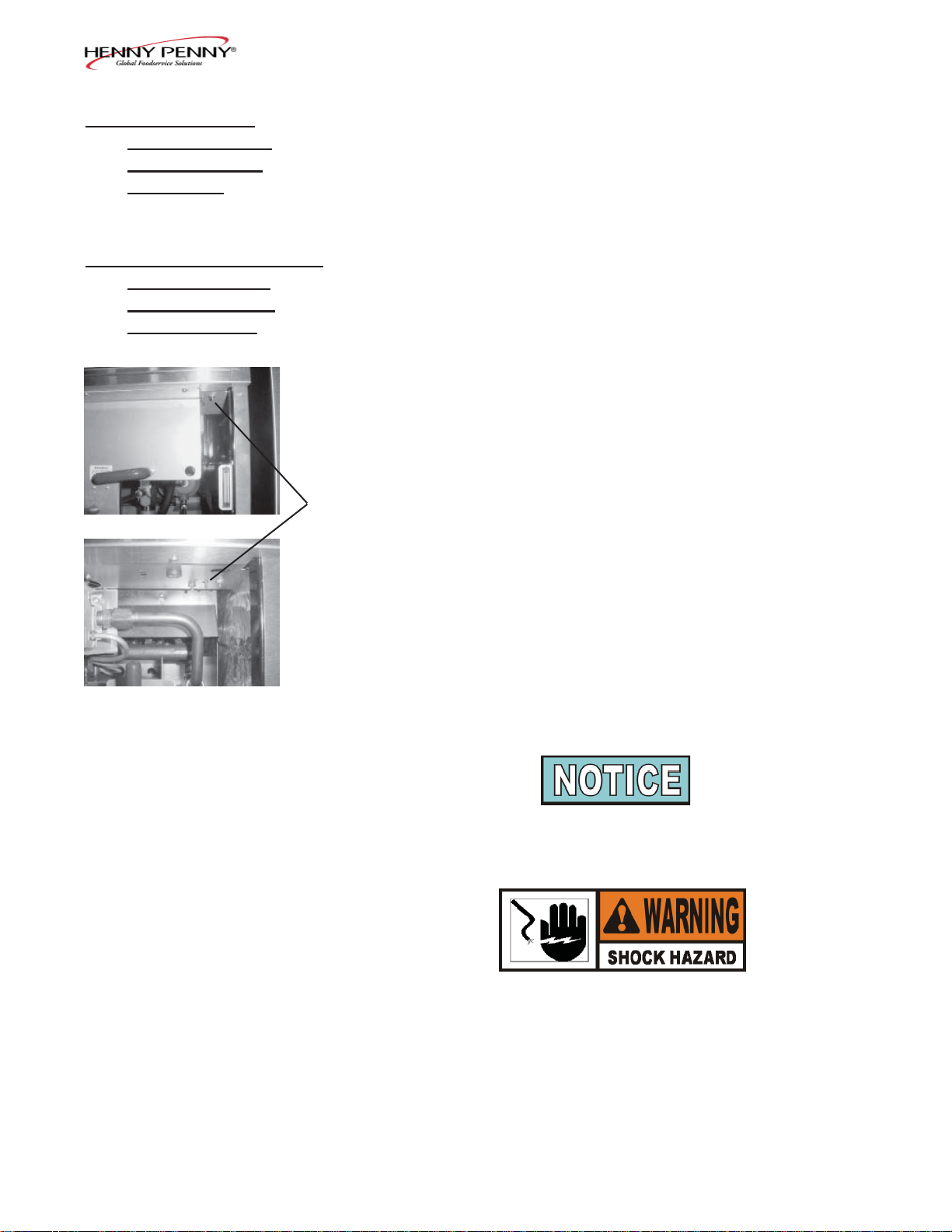

2-9. HIGH TEMPERATURE

LIMIT CONTROL

(ELECTRIC AND

GAS MODELS)

Electric

Gas

Red Reset

Button

27. Secure the control panel with the 4 screws.

28. Reconnect power to the fryer.

29. Calibrate the thermostat per paragraph 2-6.

Description

This high temperature control is a manual reset control which

senses the temperature of the shortening. If the shortening

temperature exceeds the safe operating limit, this control switch

will open and shut off the heat to the frypot. When the

temperature of the shortening drops to the safe operating limit,

the control must manually be reset.

To locate the high limit reset button, open the door to the drain

pan. Look up under the controls and to the right of the fi lter

handle for a red reset button. (On the left for single phase units.)

Checkout

Before replacing a high temperature limit control, check to

see that its circuit is closed.

The shortening temperature must be below 380º F to accurately perform this check.

1. Remove electrical power supplied to the fryer.

To avoid electrical shock or property damage, move the

power switch to OFF and disconnect main circuit

breaker, or unplug cord at wall receptacle.

2. Remove the control panel and insert it in the slot above the

door. Refer to paragraph 2-4.

103 2-9

Model 500/561/600

2-9. HIGH TEMPERATURE

LIMIT CONTROL

(ELECTRIC AND

GAS MODELS)

(Continued)

Step 3

Electric

3. Remove the two electrical wires from the high

temperature limit control.

4. Check for continuity between the two terminals after

resetting the control. If the circuit is open, replace the

control, then continue with this procedure. (If the circuit

is closed, the high limit is not defective. Reconnect the

two electrical wires.)

Replacement

To avoid electrical shock or property damage, move the

power switch to OFF and disconnect main circuit

breaker, or unplug cord at wall receptacle.

1. If the capillary tube is broken or cracked, the control will

open,shutting off electrical power. The control cannot be

reset.

2. Drain shortening from the frypot.

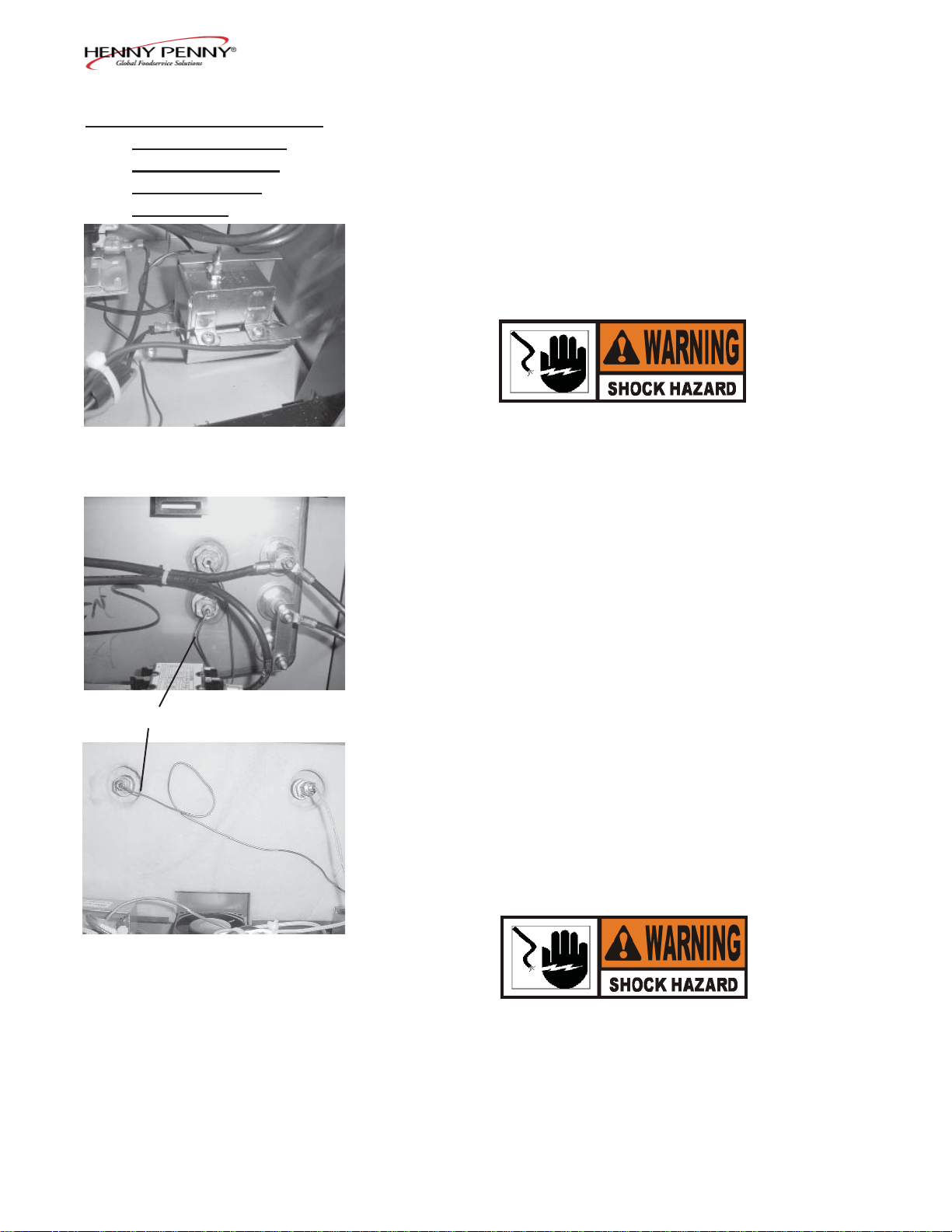

High Limit Capillary Tube

Gas

Step 1

3. Remove control panel.

4. Loosen small inside screw nut on capillary tube.

5. Remove capillary bulb from bulb holder inside the frypot.

6. Straighten the capillary tube.

7. Remove larger outside nut that threads into pot wall.

8. Remove the two screws that secure the high limit to

the high limit bracket.

9. Remove defective control from control panel area.

10. Insert new control and replace screws.

11. Uncoil capillary line, starting at capillary tube, and

insert through frypot wall.

To avoid electrical shock or other injury, the capillary

line must run under and away from all electrical power

wires. The tube must never be in contact with the

electrical power wires or terminals.

2-10 1202

Model 500/561/600

2-9. HIGH TEMPERATURE

LIMIT CONTROL

(ELECTRIC AND

GAS MODELS)

(Continued)

Electric

Gas

Step 13

12. Carefully bend the capillary bulb and tube toward bulb holder

on heating elements, and on electric units, toward the welded

clips on gas units.

13. Slip capillary bulb into bulb holder located on heating ele-

ments, on electric units, and snap the bulb in place in the

welded clips, on gas units. Pull excess capillary line from pot

and tighten nut into frypot wall.

Be sure capillary bulb of high limit is located behind

capillary bulb of thermostat. Both capillary bulbs

and bulb holders should be positioned as not to

interfere with basket or when cleaning the frypot

wall, or damage to capillary tube could result.

14. With excess capillary line pulled out, tighten smaller nut.

15. Replace front panel.

16. Refi ll with shortening.

1202 2-11

Model 500/561/600

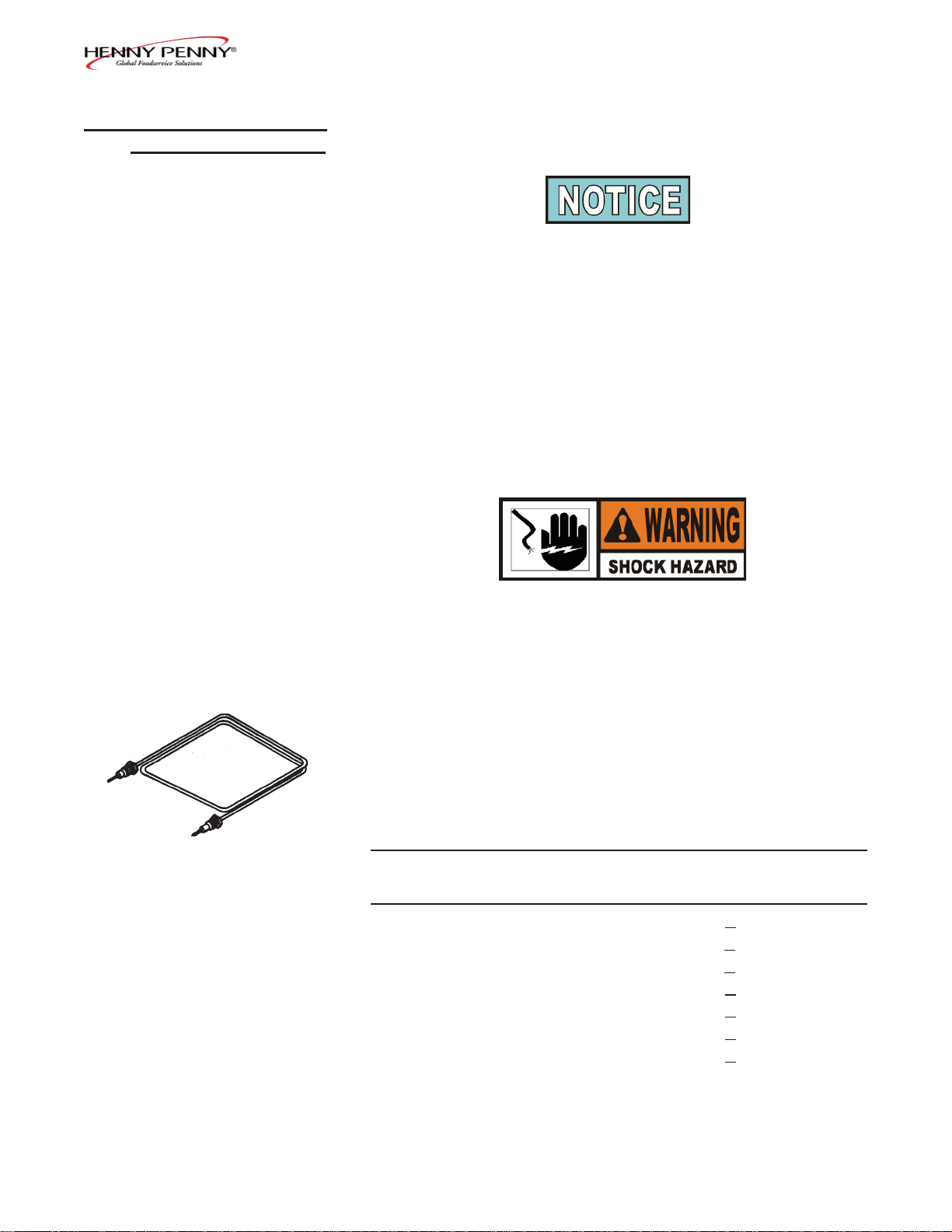

2-10. HEATING ELEMENTS

(ELECTRIC MODELS)

Description

Each electric fryer uses three heating element assemblies.

Heating elements are available for 208, 220/240, or 440/480

voltage. Check the data plate inside the door to determine the

correct voltage.

Maintenance Hint

If the shortening’s temperature recovery is very slow, or at a

slower rate than required, this may indicate defective heating

element(s). An ohmmeter will quickly indicate if the elements are

shorted or open.

Checkout

1. Remove electrical power supplied to the fryer.

To avoid electrical shock or property damage, move the

power switch to OFF and disconnect main circuit

breaker, or unplug cord at wall receptacle.

2. Remove the control panel and insert it in the slot

above the door. Refer to paragraph 2-4.

3. Perform an ohm check on one heating element at a

time, with wires disconnected from element. If the

resistance is not within tolerance, replace the element.

HEATER RESISTANCE IN

P/N POWER VOLTAGE OHMS (COLD)

18233-1 4500W 208VAC 9+1

18233-2 4500W 230VAC 11+1.5

18233-4 3750W 208VAC 11+1.5

18233-5 3750W 220VAC 12+2

18233-6 3750W 480VAC 60+5

18233-7 4500W 480VAC 50+4

18233-8 4500W 380VAC 32+3.5

2-12 103

Model 500/561/600

2-10. HEATING ELEMENTS

(ELECTRIC MODELS)

(Continued)

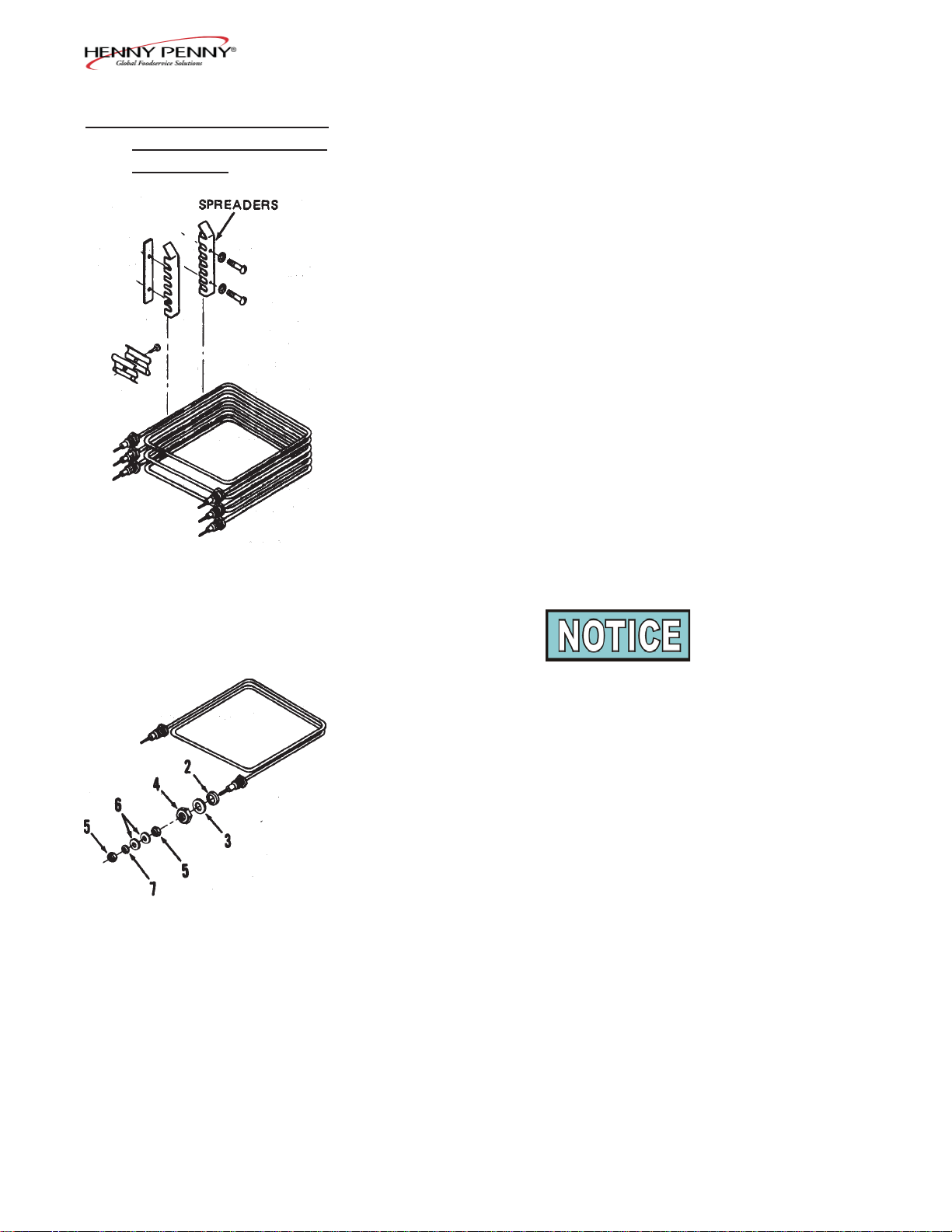

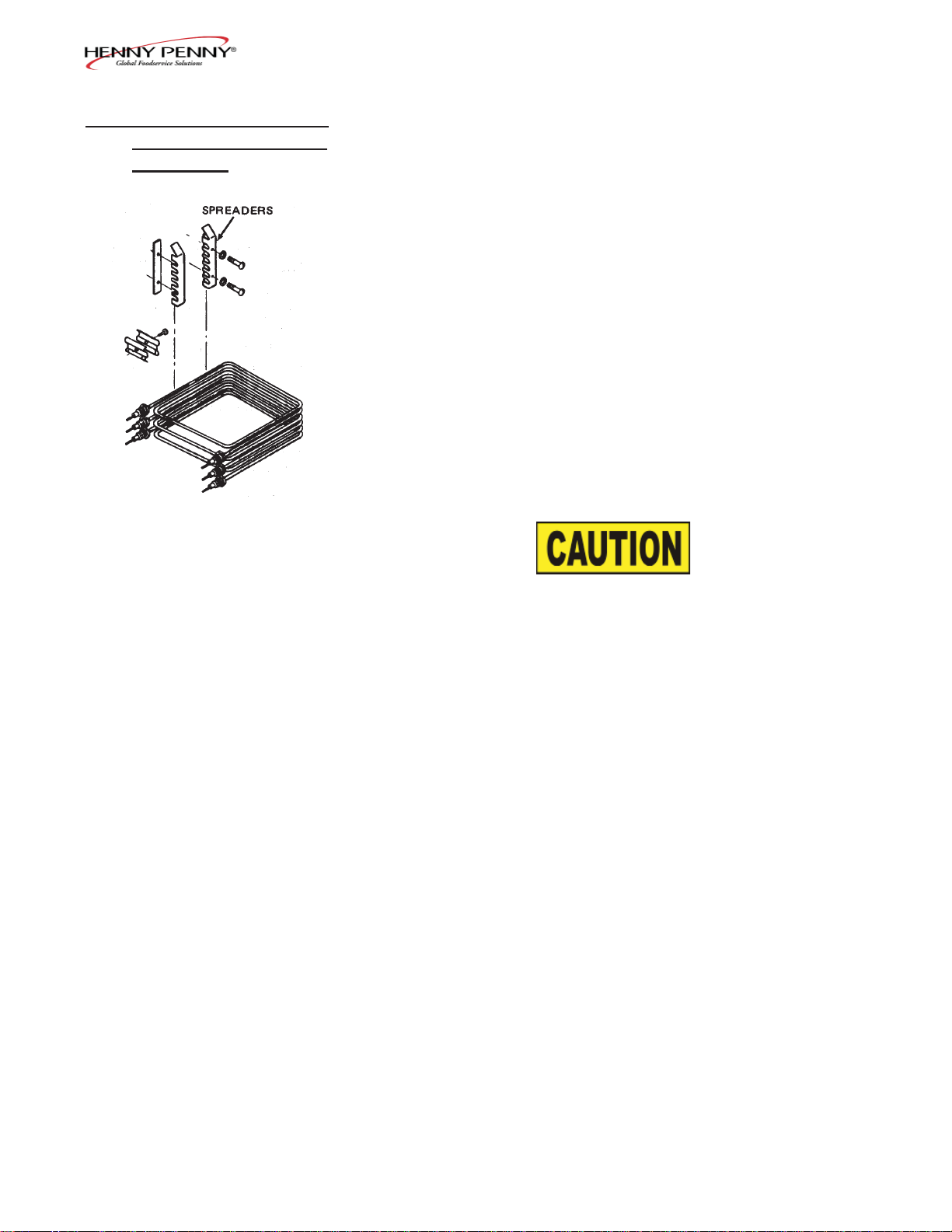

Replacement

1. Drain the shortening.

2. Remove the thermostat bulb holder from the heating

element inside the frypot.

3. Remove the heating element wires from the terminals by

removing nuts (5) and washers (6 and 7). Label each

so it can be replaced in the same position on the new

element.

4. Loosen the bolts on the four element spreaders.

5. Slide the element spreaders to the center of the heating

element.

6. Remove the brass nuts (4) and washers (3), which

secure the ends of the elements through the frypot wall.

(Reference Figure 3-16)

7. Remove the heating elements from the frypot as a group

by lifting the far end and sliding them up and out toward

the rear of the frypot.

Always install new rubber O-rings (2) when installing

heating elements.

8. Install new heating elements with new rubber O-rings (2)

mounted on terminal ends, and spreaders loosely

mounted in the center of the stacked elements.

9. Replace the heating elements, terminal end fi rst at

approximately 45º angle, slipping the terminal ends

through the front wall of the frypot.

1202 2-13

Model 500/561/600

2-10. HEATING ELEMENTS

(ELECTRIC MODELS)

(Continued)

10. Replace the brass nuts (4) and washers (3) on the

heating element terminals. Tighten the brass nuts to

30 foot lbs of torque.

11. Move the element spreaders from the center of the

element, into a position which will spread each element

apart evenly on all four sides, and tighten.

12. Replace the thermostat bulb holder on the top element,

and position the bulb between the top and second element

midway from side to side, and tighten screw which holds

the bulb in place.

13. Reconnect the wires to the appropriate terminal as

labeled when they were removed.

14. Replace the front control panel.

15. Connect the power cord to the wall receptacle or close

wall circuit breaker.

Heating elements should never be energized without

shortening in the frypot, or damage to elements could

result.

16. Check the heating elements as described in paragraph 2-17 of

Operator’s Manual.

17. Replace the shortening in the frypot.

2-14 1202

Model 500/561/600

2-11. HEATING

CONTACTORS

(ELECTRIC MODELS)

Description

Each electric fryer requires two switching contactors. One is the

primary contactor and the second in line is the heat contactor.

When open, the primary contactor allows no power to fl ow to the

heat contactor. When closed, the primary contactor completes

the timer circuit and the high limit (heat) circuit. It also supplies

power to the heat contactor which is controlled by the thermostat.

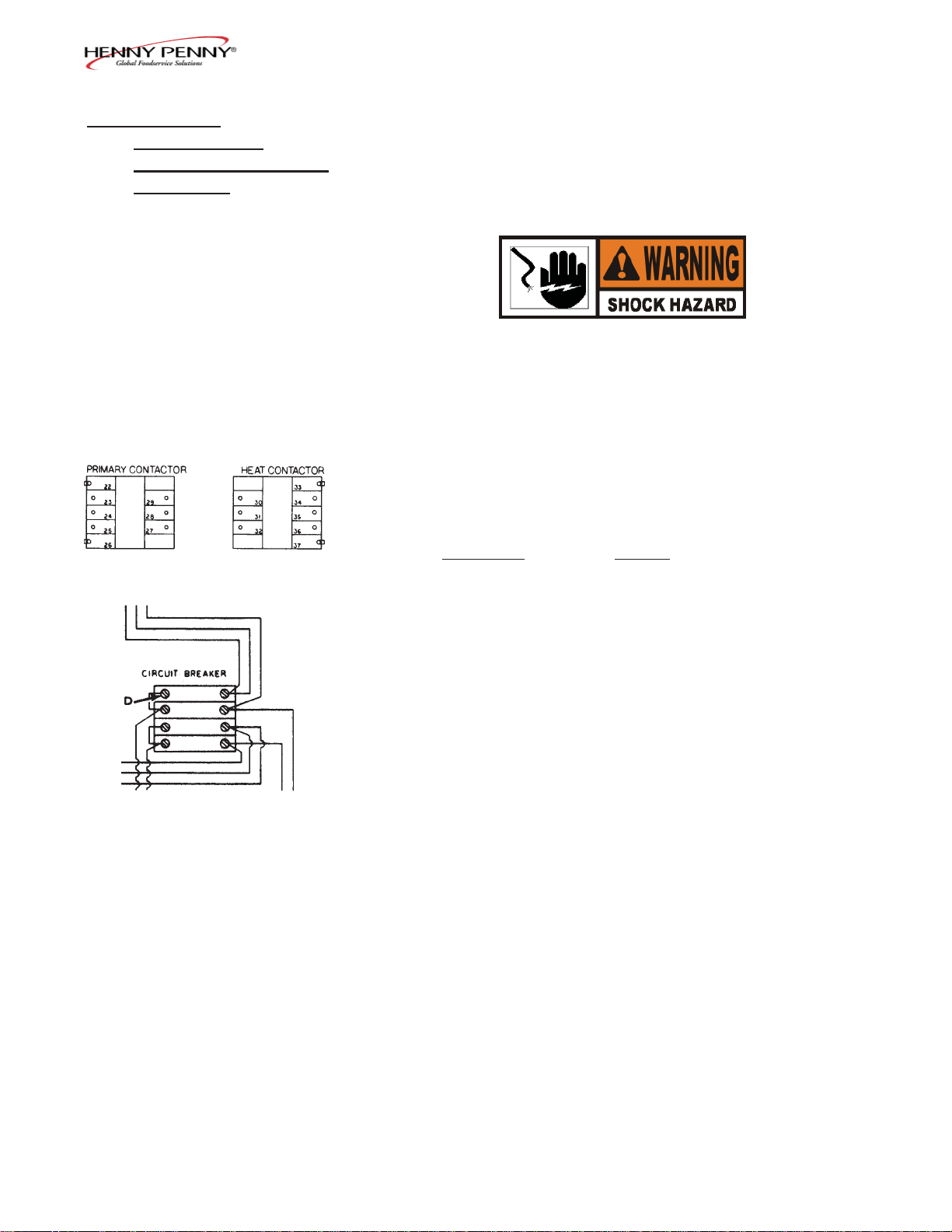

Checkout (power removed)

1. Remove electrical power supplied to the fryer.

To avoid electrical shock or property damage, move the

power switch to OFF and disconnect main circuit

breaker, or unplug cord at wall receptacle.

2. Remove the control panel and insert it in the slot above

the door. Refer to Removing the Control Panel section.

3. Perform a check on the contactor as follows:

Test Points Results

from 23 to 29 open circuit

from 24 to 28 open circuit

from 25 to 27 open circuit

from 30 to 34 open circuit

from 31 to 35 open circuit

from 32 to 36 open circuit

from 22 to 26 ohm reading 415

from 33 to 37 ohm reading 415

103 2-15

Model 500/561/600

2-11. HEATING

CONTACTORS

(ELECTRIC MODELS)

(Continued)

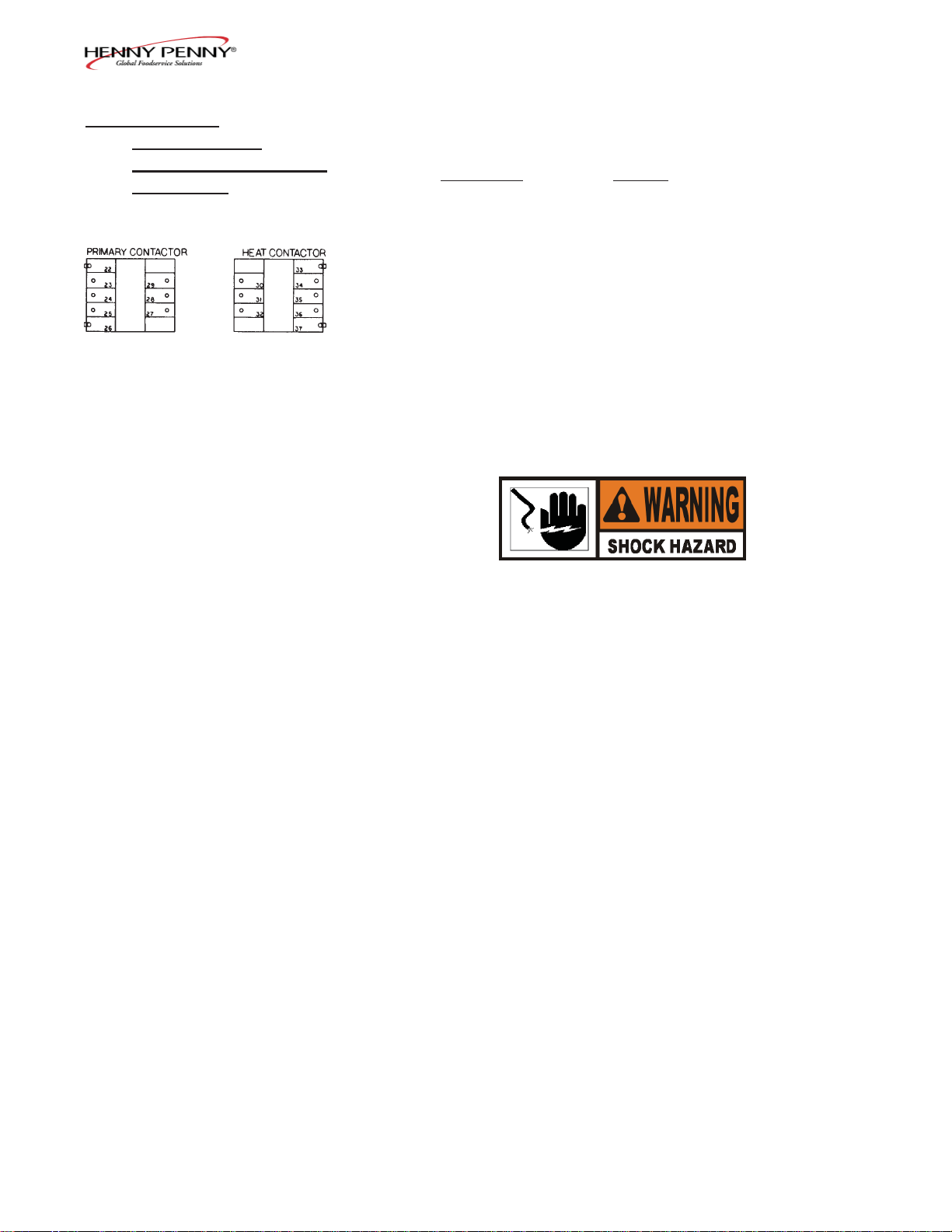

Checkout (power suppled)

To avoid electrical shock, make connections before applying power, take reading, and remove power before removing meter leads. The following checks are performed with

the wall circuit breaker closed and the main power switch

in the ON position.

1. With power re-applied, set the thermostat to its maximum

temperature.

2. On fryers using single phase power, check voltage as

follows:

Test Points Results

from pin D on The voltage

circuit breaker to: should read

terminal 34 the same at

terminal 35 each terminal.

terminal 36 It should

(If voltage is not correspond to

present, check out- the voltage

put of primary rating stated

contactor at on the data

terminals 27, 28, plate.

and 29.)

2-16 1202

Model 500/561/600

2-11. HEATING

CONTACTORS

(ELECTRIC MODELS)

(Continued)

3. On fryers using three-phase power, check voltage

as follows:

Test Points Results

Heat contactor The voltage

from terminal 34 to 35 should read

from terminal 35 to 36 the same at

from terminal 34 to 36 each terminal.

Primary contactor It should

from terminal 27 to 28 correspond to

from terminal 28 to 29 the voltage

from terminal 27 to 29 rating stated

on the data

plate.

Replacement

If either contactor is defective it must be replaced as follows:

To avoid electrical shock or property damage, move the

power switch to OFF and disconnect main circuit

breaker, or unplug cord at wall receptacle.

1. Remove only those wires directly connected to the

contactor being replaced. Label the wires.

2. Remove the two mounting screws on the base plate

and remove contactor.

3. Install the new contactor and tighten the two mounting

screws.

4. Connect the labeled wires to their respective positions.

5. Install the control panel per paragraph 2-4.

6. Reconnect power to the fryer and test the fryer for

proper operation.

1202 2-17

Model 500/561/600

2-12. GAS BURNER

ASSEMBLY

(GAS MODELS)

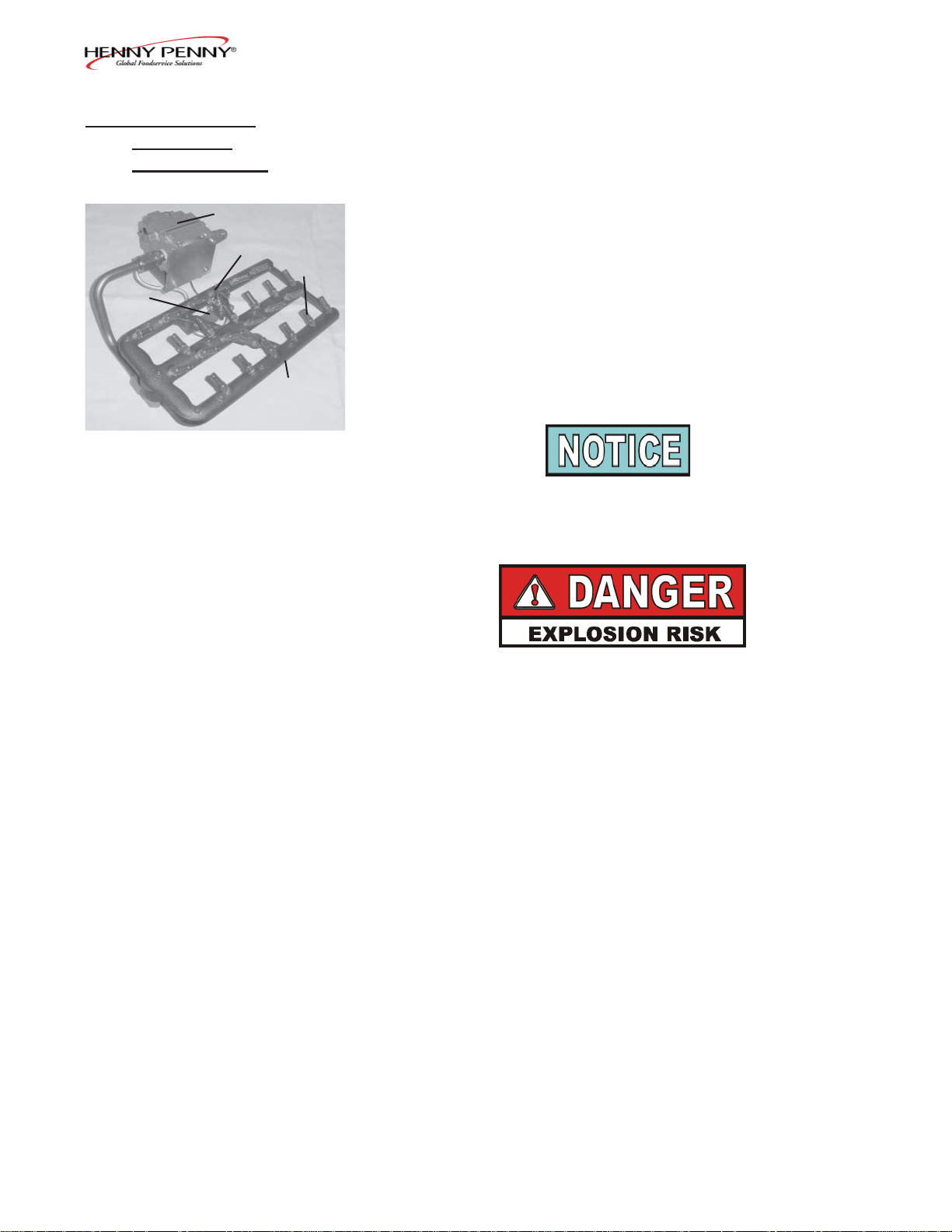

Description

The gas model fryer has a gas burner assembly consisting of a

burner casting, orifi ces, thermocouple, pilot holder, and main

gas control valve.

Safety Precautions

PILOT

HOLDER

MAIN GAS

CONTROL VALVE

THERMOCOUPLE

ORIFICE

BURNER

CASTING

If converting from natural gas to propane gas or from propane

gas to natural gas, conversion must be done by a qualifi ed

service technician.

TO AVOID PERSONAL INJURY OR PROPERTY

DAMAGE, BEFORE STARTING THIS PROCEDURE,

MOVE THE MAIN POWER SWITCH TO THE OFF

POSITION. DISCONNECT THE MAIN CIRCUIT

BREAKERS AT THE CIRCUIT BREAKER BOX OR

UNPLUG SERVICE CORD FROM WALL RECEPTACLE. TURN OFF THE MAIN GAS SUPPLY TO THE

FRYER AND DISCONNECT AND CAP THE MAIN

SUPPLY LINE TO FRYER, OR POSSIBLE EXPLOSION COULD RESULT.

1. Remove the control panel per paragraph 2-4.

2. Place the control panel back in upright position, in the

metal fl anges.

2-18 103

Loading...

Loading...