Page 1

Model 500/561/600

SECTION 3. OPERATING INSTRUCTIONS

3-1. OPERA TING COMPONENTS C1000 Controls - Reference Figure 3-1.

Fig. Item Description Function

No. No.

3-1 1 Digital Display Shows the shortening temperature, the timer countdown in

the Cook Cycle, and the selections in the Program Mode; the

temperature of the shortening can be shown by pressing

once, or twice to view set-point temperature;

if shortening temperature exceeds 425°F (218°C), the display

reads “E-5, FRYER TOO HOT”

3-1 2 This LED lights when the shortening temperature is within 5°

of the setpoint temperature, signaling the operator that the

shortening temperature is now at the proper temperature for

dropping product into the frypot

3-1 3 The timer buttons are used to start and stop Cook Cycles

3-1 4 The idle buttons are used to start an Idle Mode which reduces

the temperature of the shortening during non-use periods; press

and hold to exit the Idle Mode

3-1 5 The program button is used to access the Program Modes;

also, once in the Program Mode, it is used to advance to the

next parameter

3-1 6 & 7 Used to adjust the value of the currently displayed setting

in the Program Mode and to change set-point temperature of the

shortening

608 3-1

Page 2

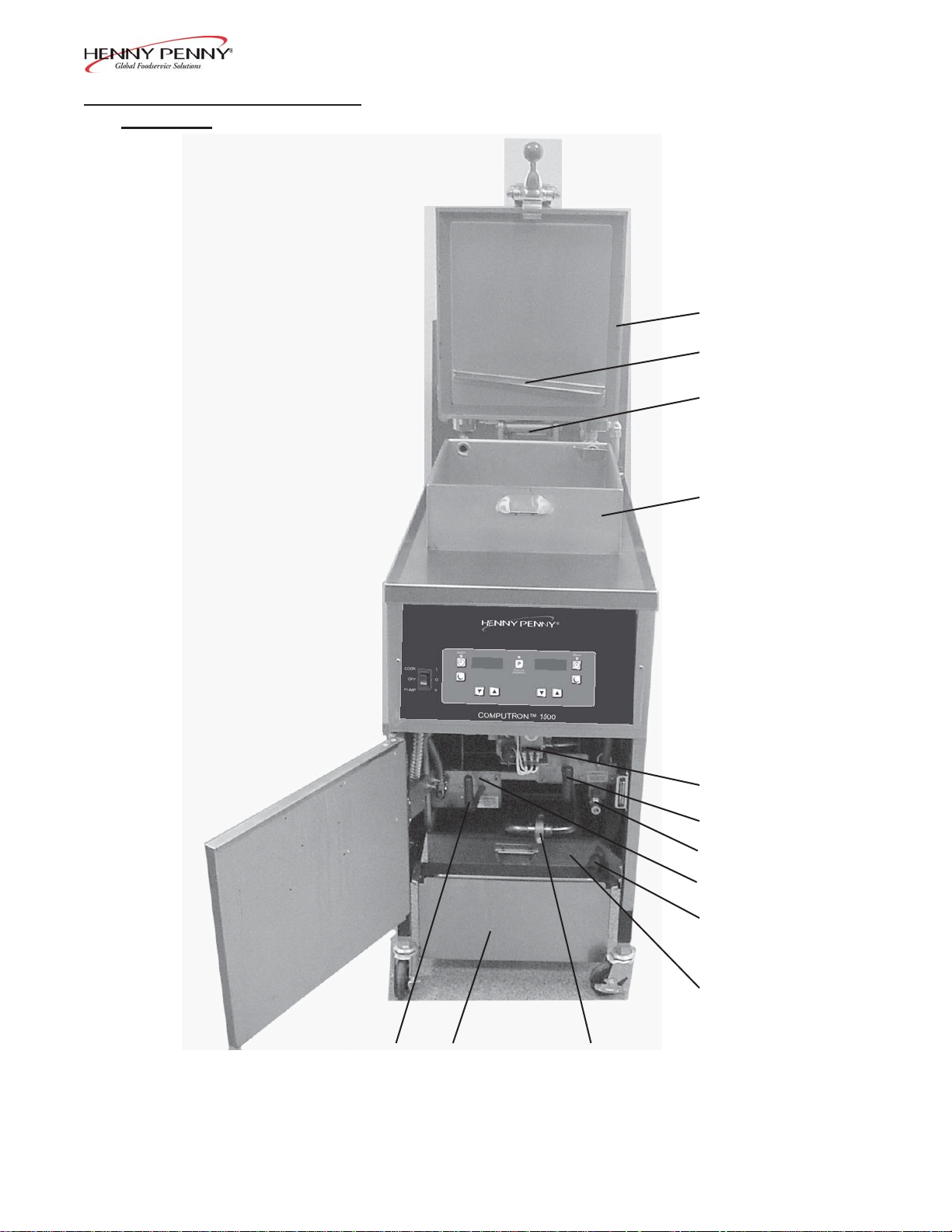

3-1. OPERA TING COMPONENTS

(Continued)

Model 500/561/600

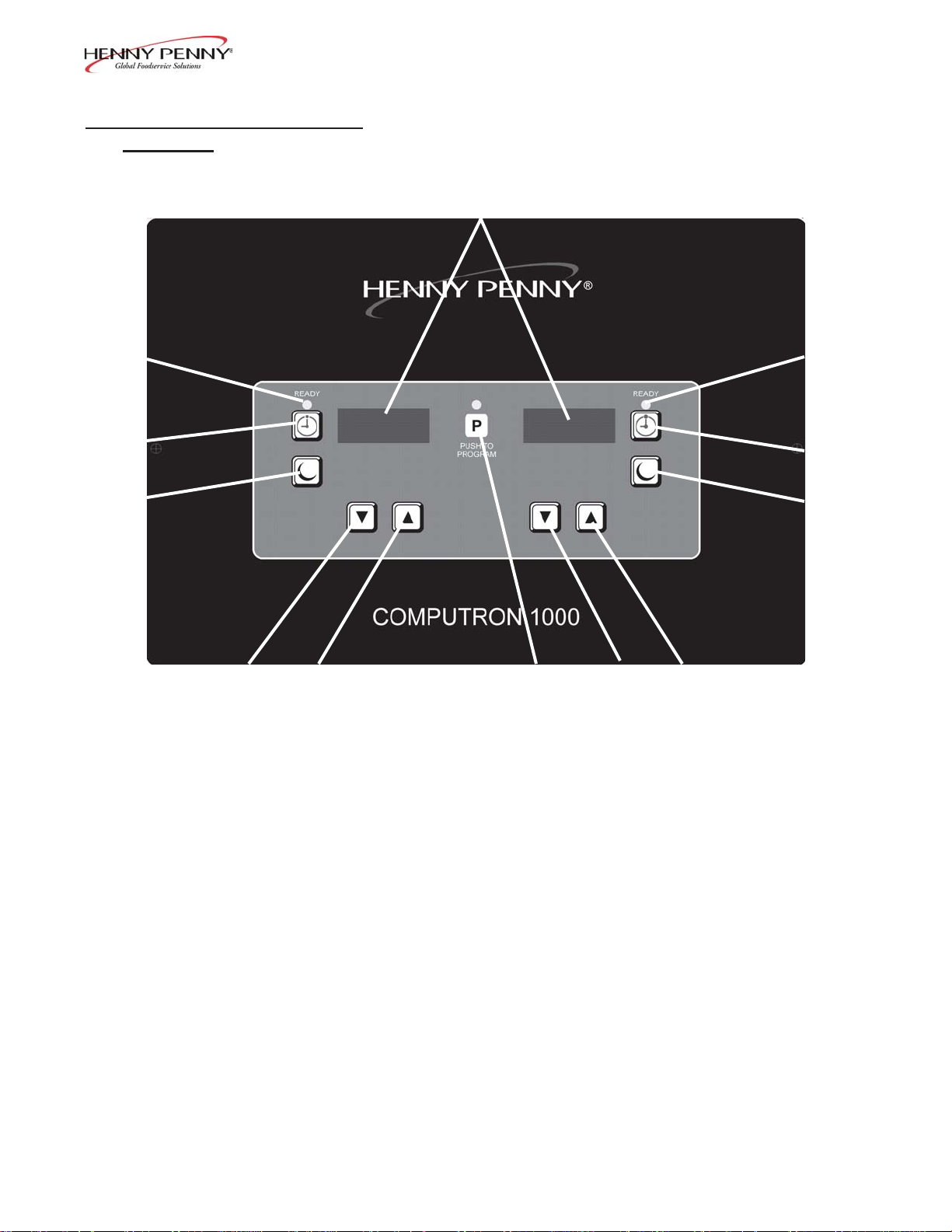

1

2

2

3

3

4

6

7

Figure 3-1

589

4

3-2 608

Page 3

Model 500/561/600

3-1. OPERA TING COMPONENTS

(Continued)

Fig. Item Description Function

No. No.

3-3 8 Frypot Holds the cooking shortening and an adequate cold zone for

collection of cracklings

3-3 9 Lid Spring Assists in raising the lid, and then holding it open (it is covered with

a shield)

3-3 10 Condensation Drain This channels the moisture, that collects on the lid liner when the

Channel lid is opened, into the drain line and prevents the moisture droplets

from falling into the shortening

3-3 11 Lid Gasket Provides the pressure seal for the frypot chamber

3-2 12 Lid Latch A spring loaded latch that provides a positive latch to hold the lid

closed; this latch, along with the spindle assembly and lid gasket,

provides a pressure sealed frypot chamber

3-2 13 Spindle Assembly An assembly that is tightened after the lid is latched, and applies

pressure to the top of the lid; the lid gasket then applies pressure

against the frypot rim; after building one pound of internal pressure,

the lid liner pushes a locking pin up into the locking collar, preventing the spindle from being turned while the frypot is pressurized

3-2 14 Lid Limit Stop A threaded adjustable collar used to obtain the proper

tightness between the lid gasket and the frypot rim; done by

controlling the number of clockwise rotations of the spindle

3-2 15 Deadweight This deadweight style, pressure relief valve maintains a constant

Assembly level of steam pressure within the frypot; excess steam is vented

through the exhaust stack

Failure to clean the deadweight assembly daily could

result in the fryer building too much pressure. Severe

injuries and burns could result.

608 3-3

Page 4

Model 500/561/600

3-1. OPERA TING COMPONENTS

(Continued)

Fig. Item Description Function

No. No.

3-2 16 Safety Relief V alve This is an ASME approved spring loaded valve, set at 14.5 psi; if

the deadweight assembly is clogged, this safety valve releases

excess pressure, keeping the frypot chamber at 14.5 psi

(999 mbar); if this occurs, turn the main power switch to OFF to

release all pressure from the frypot

If safety relief valve activates, turn main power switch

to the OFF position. To avoid serious burns and

injuries, have fryer serviced before next use.

3-2 17 Safety Relief V alve Ring

DO NOT PULL THIS RING. SEVERE BURNS FROM

THE STEAM WILL RESUL T .

3-2 18 Pressure Gauge Indicates the pressure inside the frypot

3-5

3-2 19 Solenoid V alve An electromechanical device that causes pressure to be held in the

frypot; the solenoid valve closes at the beginning of the Cook Cycle

and is opened automatically by the controls at the end of the Cook

Cycle; if this valve becomes dirty or the teflon seat nicked, pressure

will not build up and it must be repaired

3-3 20 Drain Valve (Only the A two-way ball valve that is normally close; turn the handle to drain

Handle is Shown) the shortening from the frypot, into the filter drain pan

DO NOT OPEN THE DRAIN V AL VE WHILE FRYPOT

IS UNDER PRESSURE. HOT SHORTENING WILL

EXHAUST AND SEVERE BURNS WILL RESUL T .

3-3 21 Drain Interlock Switch A microswitch that provides protection for the frypot in the event an

operator inadvertently drains the shortening from the frypot while

the main power switch is on; the switch automatically shuts off the

heat when the drain valve is opened

3-4 608

Page 5

Model 500/561/600

3-1. OPERA TING COMPONENTS

(Continued)

Fig. Item Description Function

No. No.

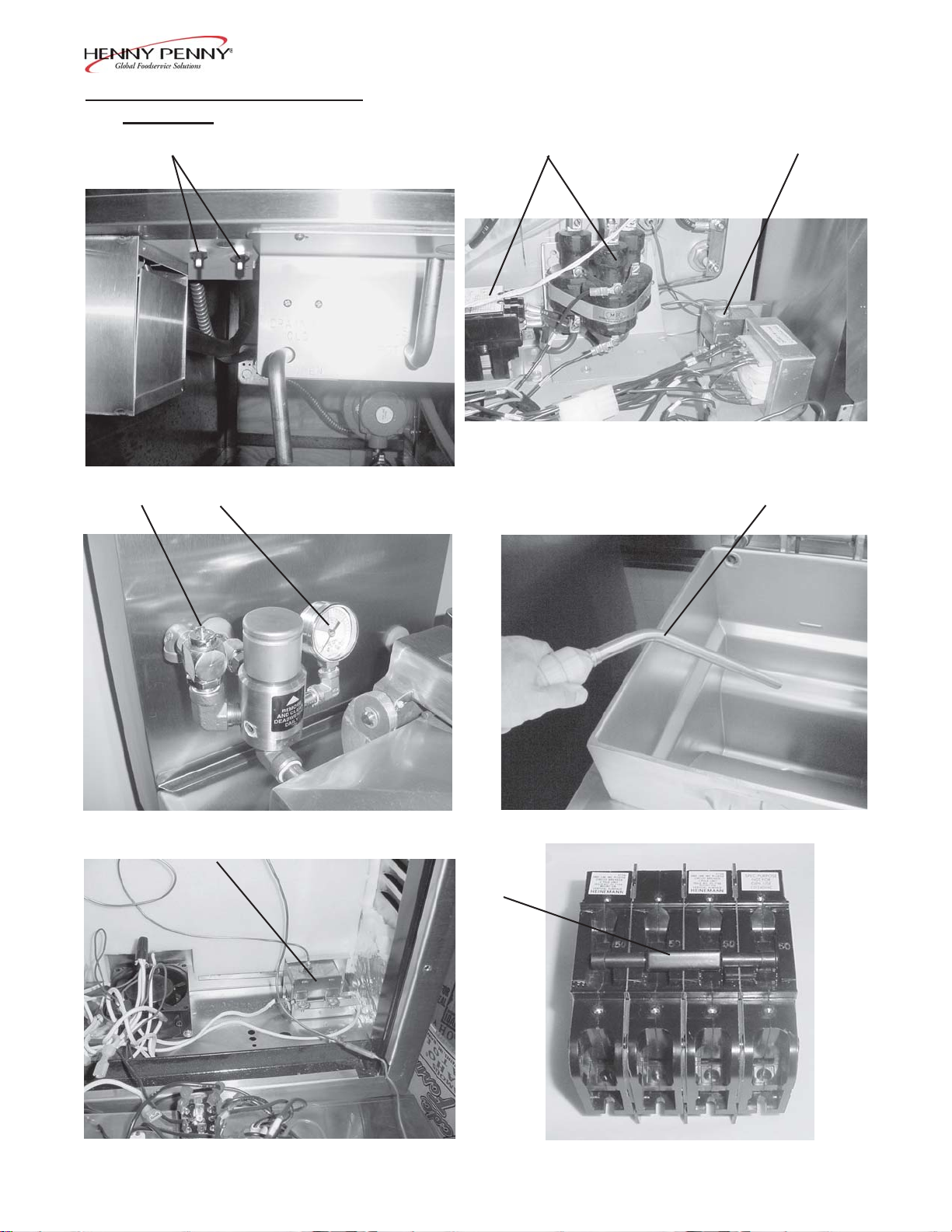

3-3 22 Filter Drain Pan The removable pan that houses the filter and catches the shortening

when it is drained from the frypot; it is also used to remove and

discard old shortening

When moving filter drain pan containing hot shortening,

use extreme care to avoid burns from hot surfaces or

splashing.

3-3 23 Filter Union Connects the filter to the filter pump, and allows easy removal of the

filter and drain pan

3-3 24 Filter V alve When the power switch is in the PUMP position, this two-way

valve directs filtered shortening from the drain pan, back into the

frypot

3-3 25 Condensation Drain A hose used to route the condensation collected within the steam

Line exhaust system, to the condensation pan

3-3 26 Condensation Drain The collection point for the condensation, formed within the steam

Pan exhaust system; remove and empty periodically

3-3 27 Rinse Hose (Optional) A hand-held hose used to rinse food particles from the frypot

3-8 into the filter pan; attaches to a quick disconnect fitting

3-3 28 Gas Control Valve (Gas Controls the gas flow to the burner

Models Only)

3-6

3-7

3-4 30 Breakers-Push Button Protective devices which break the circuit when the current

29 High Temperature Limit A control that senses the temperature of the shortening; if the

temperature of the shortening exceeds the safe operating limit, this

control opens and shuts off the heat to the frypot; when the

temperature of the shortening drops to a safe operation limit, the

control must be manually reset by pressing the red reset button,

located under the control panel, behind the door

Gas Electric

Reset (Electric Models exceeds the rated value

Only)

3-7 31 Contactors (Electric Relays that route power to the heating elements; one relay is in

Models Only) series with the high limit, the other one is in series with the controls;

the standard unit uses 2 electromechanical contactors, while the

computer controlled units have one electromechanical and one

mercury contactor

3-9 32 Circuit Breaker (Single Opens the electrical circuit, and removes power to elements

608 3-5

Phase Only)

Page 6

3-1. OPERA TING COMPONENTS

(Continued)

16

Model 500/561/600

13

19

15

18

14

12

ELECTRIC MODEL

Figure 3-2. Operating Controls

3-6 608

Page 7

3-1. OPERA TING COMPONENTS

(Continued)

Model 500/561/600

11

10

9

8

28

24

27

21

25

22

20

26

23

GAS MODEL

Figure 3-3. Operating Controls

608 3-7

Page 8

3-1. OPERA TING COMPONENTS

(Continued)

Model 500/561/600

17

30

18

Figure 3-4.

31

29

Figure 3-7.

27

Figure 3-5.

29

Figure 3-8.

32

Figure 3-6.

3-8 608

Figure 3-9.

Page 9

3-2. FILLING OR

ADDING SHOR TENING

Model 500/561/600

Before the actual cooking operation and adding shortening to

the frypot, be sure frypot, filter screen assembly , and drain pan

are cleaned. Filter screen assembly and drain pan should be

cleaned with soap and hot water and thoroughly dried before

reassembling. At this time, the frypot should also be cleaned.

Refer to Cleaning the Frypot Section.

The shortening level must always be at the frypot level

indicator on the rear of the frypot (see photo on next

page). Failure to follow these instructions could r esult in a

fire and/or damage to the fryer.

When using solid shortening, it is recommended to melt

the shortening on an outside heating source before placing it in the frypots. The elements on electric fryers, or the

frypot surface on gas fryers, must be completely

submerged. Fire or damage to the frypot could result.

1. It is recommended that a high quality frying shortening be used

in the fryer. Some low grade shortenings have a high moisture

content and will cause foaming and boiling over.

T o avoid severe burns when pouring hot shortening into

frypot, wear gloves and take care to avoid splashing.

2. The electric model 500 requires 48 lbs. (21.8 kg) of liquid

shortening, and the model 561 requires 65 lbs. (29.5 kg). The

gas model requires 43 lbs. (19.5 kg). Model 500 fryers have

2 level indicator lines inscribed on the rear wall of the frypot,

whereas the models 561 & 600 have only 1 level indicator.

The level indicator lines show the proper shortening levels.

3. Cold shortening should be filled to 1/2-inch (12.7 mm) below

a single level indicator line, and frypots with 2 level indicator

lines, cold shortening should be even with the lower level

indicator line. The shortening expands when heated and

should be at the level indicator line when the shortening is hot,

or the top level indicator line on model 500s.

608 3-9

Page 10

3-3. CARE OF THE

SHORTENING

Model 500/561/600

FOLLOW THE INSTRUCTIONS BELOW TO A V OID

SHORTENING OVERFLOWING THE FR YPOT ,

WHICH COULD RESUL T IN SERIOUS BURNS,

PERSONAL INJUR Y , FIRE, AND/OR PROPERTY

DAMAGE.

1. T o protect, and get the maximum life out of the shortening,

press to lower the temperature to 250° F (135° C) when

the fryer is not in immediate use. Deteriorated shortening

smokes badly , even at lower temperatures.

2. Frying breaded food products requires frequent filtering to keep

the shortening clean. The shortening should be filtered after

every 3 to 6 Cook cycles. For the best quality product,

Do not

exceed 6 Cook Cycles without filtering. Refer to Filtering of

Shortening Section.

3. Maintain the shortening at the proper cooking level. Add fresh

shortening as needed.

4. Do not overload the baskets with product (12 lbs. (5.4 kg.) for

model 600 fryers; 14 lbs (6.4 kg.) for model 500 fryers and

18 lbs. (8.2 kg.) for the model 561) or place product with

extreme moisture content into baskets.

WITH PROLONGED USE, THE FLASHPOINT OF

SHORTENING IS REDUCED. DISCARD THE

SHORTENING IF IT SHOWS SIGNS OF EXCESSIVE

SMOKING OR FOAMING, OR SERIOUS BURNS,

PERSONAL INJUR Y , FIRE, AND/OR PROPERTY

DAMAGE COULD RESUL T .

3-10 608

Page 11

Model 500/561/600

3-4. PRODUCT COOKING

GUIDELINES

The following table provides the suggested frying times and temperatures

for single-stage cooking, using the Henny Penny Pressure Fryer combined with our special blends of PHT Fryer Breading Mixes.

All the suggested time and temperature settings are for a 10

pound (4.5 kg) load.

Product (size per piece) T emperature Time(Min.)

Chicken 315ºF (157ºC) 10-11

(2-1/4 lbs (1 kg), 8 or 9 pieces)

Fish 315ºF (157ºC) 3.5

(4 ozs (.11 kg))

Shrimp 315ºF (157ºC) 2

T rout 315ºF (157ºC) 5

(10 to 16 ozs (.28-.45 kg))

Pork Chops 315ºF (157ºC) 5

(4 to 5 ozs,(.11-.14 kg),

1

/2 to 3/4 ins (12.7-19 mm) thick)

Ribs 275°F) (135ºC) 14

(2-1/2 lb (1.13 kg) rack)

Cubed Steak 315ºF (157ºC) 5

(6 to 10 ozs,(.17-.28 kg),

1/4 to 1 in (6.4-25.4 mm) thick)

V eal Cutlet 315ºF (157ºC) 4

(4 ozs (.11 kg))

Potatoes 315ºF (157ºC) 8

(10 lbs (4.5 kg), cut in wedges)

608 3-11

Page 12

Model 500/561/600

3-5. CHICKEN FRYING

PROCEDURES

The following is a description of the operating procedures for fryers

with the Computron 1000 controls.

1. Check to see that all control switches are off and the drain and

filter valves are in the closed position.

2. Remove the basket from the frypot and leave lid open.

3. Make sure frypot is filled with shortening to the proper level.

Refer to filling and Adding

4. Make sure electrical power is connected to fryer. Gas units,

make sure gas lines are connected to fryer and gas valve is

turned on - See

DOWN PROCEDURE Section

5. Display shows “OFF” until power switch is turned to the ON

position. Display now shows the cook time and the unit automatically goes into the Melt Cycle until the shortening temperature reaches 230°F (110°C). The control then automatically exits

the Melt Cycle.

GAS PILOT & BURNER LIGHTING AND SHUT

Shortening Section.

.

The PFG-600 series pressure fryer has several safety devices

which shuts-down the gas supply when they are activated. The

above procedures should be followed to restart the open fryer

and if the shut down is repeated, a qualified technician should be

notified.

The Melt Cycle may be bypassed, if desired, by pressing and

holding for 3 seconds.

Do not bypass the Melt Cycle unless enough shortening has

melted to completely cover the curved surface of the gas

frypots and elements on electric fryers. If Melt Cycle is

bypassed before all gas frypot or elements are covered,

excessive smoking of the shortening, or a fire will result.

5. Once out of the Melt Cycle, the shortening is heated until

lights and the cook time is displayed.

6. Using the basket handle, thoroughly stir shortening to stabilize the

temperature throughout the frypot.

Step 6

3-12 608

7. Once the shortening temperature has stabilized at the setpoint

temperature, lower the basket into the frypot.

Page 13

3-5. CHICKEN FRYING

PROCEDURES (Continued)

Model 500/561/600

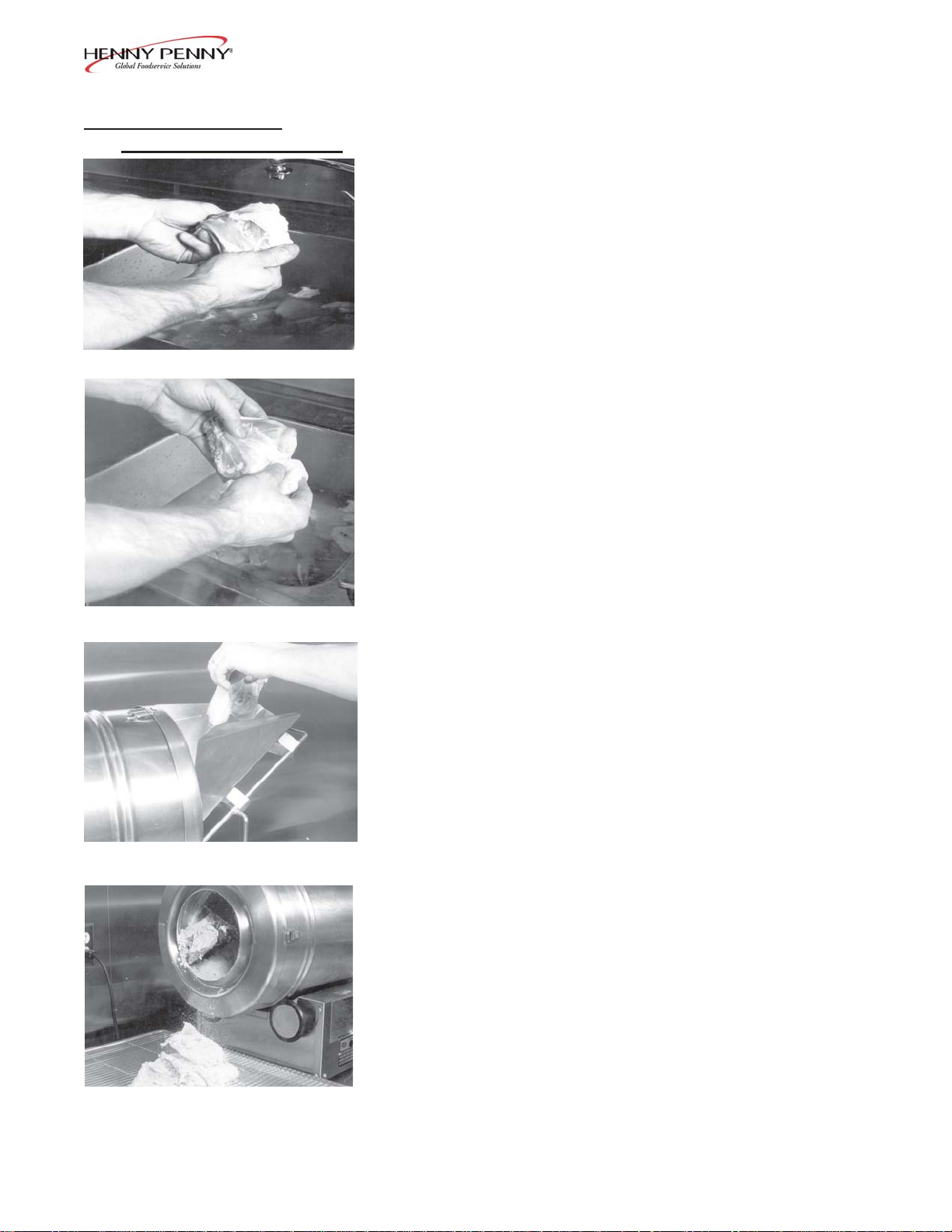

8. T ake the chicken parts, either 4 or 5 cut-up chickens, from the

cooler and place in a scullery sink. W ash the chicken and, at this

point, break the thigh from the joint of the backbone.

Step 8

9. Remove any excess fat from the thigh.

10. Remove the chicken from the water and drain slightly , but allow

the parts to remain moist.

Step 9

Step 11

11. If a breading machine is used, fill the breading drum with

approximately 8 to 10 pounds of PHT Breading Mix. Feed the

moist but drained pieces into the chute at one end of the breader .

12. Allow the breaded pieces to fall onto a tray as they come out of

the breader drum.

Step 12

608 3-13

Page 14

Model 500/561/600

3-5. CHICKEN FRYING

PROCEDURES (Continued)

Step 13

13. If a breading machine is not used, the food should be placed in

the dry mix and hand tumbled so that each piece of food is

completely covered.

14. Knock off any excess breading and place the breaded product

on a tray for cooler storage. Place a damp cloth over the

breaded food to retain moisture. The breaded food should be

held for a minimum of 30 minutes before frying so that it can

absorb spices from the breading and so that breading can

better adhere to the product.

15. Determine the time and temperature settings according to the

type of product to be fried.

16. Set the controls to the desired temperature and time. See C1000

Programming Instructions Section.

Before placing the product into the basket, make certain that

the shortening is at the correct frying temperature for the type

of product. Also check that is on.

Step 17

17. Place the food into the submerged basket by first putting in the

largest pieces (thighs and drumsticks). This gives the large

and more difficult pieces time to fry a few extra seconds in

the shortening. Leave the lid open.

Use care to prevent splashing hot shortening. Severe

burns can result.

Do not overload, or place product with extreme moisture

content into the basket.

The maximum load size is 12 lbs.

(5.4 kg.) for model 600 fryers; 14 lbs (6.4 kg.) for model

500 fryers and 18 lbs. (8.2 kg.) for the model 561. Failure

to follow these directions can result in shortening overflowing the frypot. Serious burns, fire, or damage to the unit

could result.

18. Lift the basket slightly out of the shortening and shake it,

causing the pieces to separate. Return the basket to the shortening. Doing this will prevent white spots on the finished

product.

3-14 608

Page 15

Model 500/561/600

3-5. CHICKEN FRYING

PROCEDURES (Continued)

19. Remove the basket handle and close the lid quickly .

Latch the lid with the lid latch.

20. Tighten the lid spindle clockwise to properly secure and seal the

lid. Align the red knob on the spindle with the red knob on the

lid latch.

LID MUST BE LA TCHED PROPERL Y OR PRESSURIZED SHORTENING AND STEAM MAY ESCAPE

FRYPOT . SEVERE BURNS WILL RESUL T .

Step 19

21. Press .

22. Within a few minutes, the pressure gauge should increase to the

OPERA TING ZONE. If it does not recheck the procedures

and then refer to the Troubleshooting Section.

Step 20

During operation, perform the following checks:

• Make sure the pressure gauge indicator needle reads in the

Operating Zone. A full load must be placed in frypot upon

using new shortening, or not enough steam will be generated

to obtain full cooking pressure.

- if pressure does not build, check T roubleshooting Section

or call your local Henny Penny service agent if need be

• Check the drain and filter valve for leaks

23. At the end of the Cook Cycle (the timer reaches zero), the fryer

automatically depressurizes, the timer buzzer sounds, and the

display flashes “DONE”. Press button to turn off alarm.

DO NOT LIFT HANDLE OR FORCE LID LA TCH

OPEN BEFORE PRESSURE GAUGE READS “0”

PSI. ESCAPING STEAM AND SHORTENING

WILL RESULT IN SEVERE BURNS.

608 3-15

Page 16

Model 500/561/600

3-5. CHICKEN FRYING

PROCEDURES (Continued)

24. After the pressure drops to zero, turn the spindle

counterclockwise approximately one turn.

Do not spin or flip the spindle cross arm when opening the

lid. Damage to the acme nut inside the cross bar could

result.

25. Raise the lid promptly to allow most of the condensation on the

lid to drain down and out through the drain channel and not

back into the shortening.

To avoid damage to the hinge, do not let the lid slam up

against its backstop.

26. Insert the handle into the basket. Lift the basket and hang it on

the side of the frypot to drain. Allow the product to drain

approximately 15 seconds before dumping it onto a tray .

Step 26

27. Place the product into a warming cabinet immediately .

28. Before frying the next load, wait until is on, indicating

the shortening has reheated.

IF THE SHORTENING TEMPERA TURE EXCEEDS

420°F (216°C), IMMEDIA TELY SHUT OFF THE

POWER AT THE MAIN CIRCUIT BREAKER AND

HAVE THE FRYER REP AIRED. IF SHOR TENING

TEMPERA TURE EXCEEDS ITS FLASHPOINT , FIRE

WILL OCCUR, RESULTING IN SEVERE BURNS

AND/OR PROPERTY DAMAG

E.

3-16 608

Page 17

Model 500/561/600

3-6. C1000 PROGRAMMNG

INSTRUCTIONS

3-7. C1000 SPECIAL

PROGRAMMNG

Timer Programming

1. Anytime the cook time is displayed, press under the appropri-

ate display to change the cook time.

Set-Point Temperature Programming

1. Press once to view the actual shortening temperature and

press again to view the set-point temperature.

2. While the set-point temperature is in the display , press

to change the set-point temperature.

If “LOCK” shows in display when pressing ,

the controls are locked and must be unlocked before changing

the time or set-point temperature. See C1000 Special

Programming Section.

Special Programming is used to set the items below:

Fahrenheit or Celsius

Initialize System

Lock or Unlock Controls

Fryer Type – Open or Pressure

Heat Source – Electric; Gas w/electronic ignition

Vat Type - Full or Split

Oil T ype - Solid or Liquid

1. T o enter Special Programming, turn off power switch

(either side). Press and hold and turn the power

switch back on.

2. “SPEC” “PROG” followed by, “DEG” “°F” or “°C”.

Us e to choose “°F” or “°C”.

3. Press and “INIT” shows in the display.

Press and hold and display shows “In-3”,

“In-2”, “In-1” followed by “Init Sys” “DONE DONE”. The

controls now are reset to factory parameters, the time set to

0:00 and temperature 190°F or 88°C.

4. Press and “LOCK” or “UNLOCK” shows in the displays. Use to choose “LOCK” or “UNLOCK.

5. Press an d “FRYR” shows in left display and the right

display should show “PRES”. Use to change from

“OPEN” to “PRES” if needed.

1209 3-17

Page 18

Model 500/561/600

3-7. C1000 SPECIAL

PROGRAMMNG

(Continued)

6. Press and “HEA T” shows in the display . Use

to change the heat source: “ELEC” for electric models; “GAS”

for units with standing pilot; SSI for units with solid state

ignition.

7. Press and “V AT” and “FULL” should show in the

displays if controls are set to “PRES” in step 5.

8. Press and “MEL T” and “Solid” or “LIQD” shows in the

displays.

shortening, or “LIQD”, if using liquid shortening.

Use to choose “Solid”, if using solid

9. Press and hold to exit Special Programming at any time.

3-18 1209

Page 19

Model 500/561/600

3-8. REGULAR MAINTENANCE

SCHEDULE

Procedure Frequency

Filter pump motor protector- As required

manual reset

Filtering of shortening Every 3 to 6 frying cycles

Cleaning the Optional Crumb pan As required

Filter pump problem prevention As required

Changing of shortening As required

Changing the filter envelope As required

Changing the charcoal filter As required

Cleaning the frypot Before changing the shortening

Cleaning the deadweight valve Daily

Night closing procedures Daily

Check optional rinse hose W eekly

for deterioration

Reversing the lid gasket Quarterly

As in all food service equipment, the Henny Penny pressure fryer does

require care and proper maintenance. The table below provides a

summary of scheduled maintenance.

Lid lubrication Quarterly

Limit stop adjustment Quarterly

Check tightness of spreader bars Quarterly

Clean safety relief valve Annually

3-9. FIL TER PUMP

MOTOR

PROTECTORMANUAL RESET

The filter pump motor is equipped with a manual reset button,

located on the rear of the motor, in case the motor overheats. W ait

about 5 minutes before attempting to reset this protective device to

allow motor to cool. The filter motor is on the rear of the fryer . It

takes some effort to push the reset, and a screwdriver can be used to

help reset the button.

Electric fryers with serial numbers of HB013JB & below , and gas

fryers with serial numbers of GA085JB & below , can push the reset

button, by removing the access panel on the left side panel of the unit.

To prevent burns caused by splashing shortening, turn

the unit’s main power switch to the OFF position before

resetting the filter pump motor’ s manual r eset protection

device.

708 3-19

Page 20

Model 500/561/600

3-10. FIL TERING OF

SHORTENING

Step 2

Frying breaded food requires frequent filtering. T aste the cold shortening every day for flavor. W atch the shortening for foaming during frying

cycles. Discard the shortening as soon as it shows signs of foaming.

Clean the frypot as follows each time the shortening is changed or

filtered:

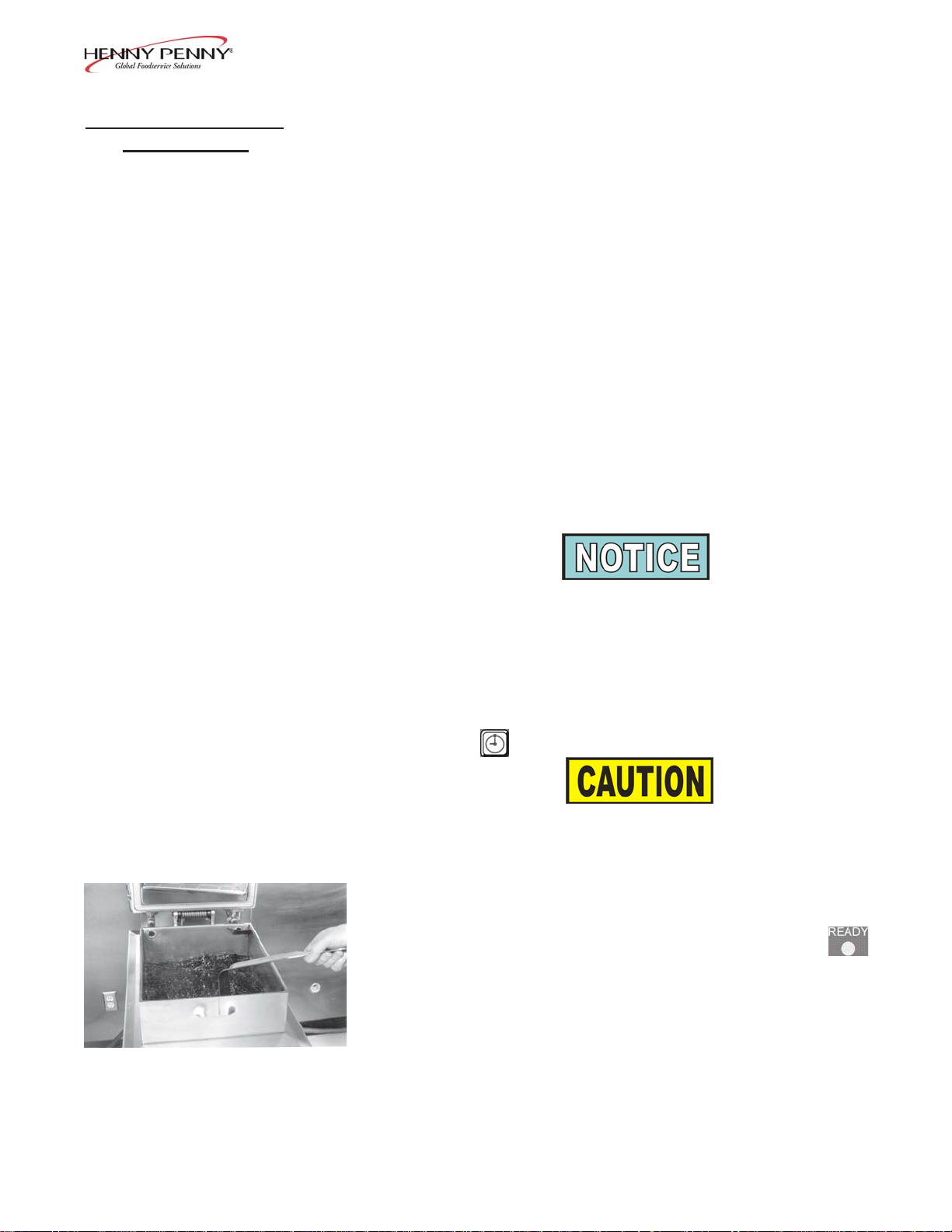

1. Turn the main power switch to the OFF position. Remove and

clean the fry basket in soap and water. Rinse thoroughly .

The best results are obtained when the shortening is

filtered at the normal frying temperature.

2. Use a metal spatula to scrape any build-up from the sides of

the frypot. Do not scrape heating element on electric units,

or the curved portion of the gas frypot.

Scraping the electric fryer elements, or the curved portion

of the gas frypot, produces scratches in these surfaces

causing breading to stick and burn.

Step 4

Do not bang the pot scraper, or other cleaning utensil, on

the frypot rim. Damage to the frypot rim could result and

the lid may not seal properly during a cook cycle.

The filter drain pan must be as far back under fryer as

it will go, and the cover in place. Be sure the hole in the

cover lines up with the drain before opening the drain.

Failure to follow these instructions causes splashing of

shortening and could result in personal injury .

Surfaces of fryer and basket will be hot. Use care when

filtering to avoid getting burned.

3. Open the drain valve very slowly , half a turn at first and then

slowly to the full open position. This will prevent excessive

splashing of the hot shortening as it drains into the filter drain pan.

4. As the shortening drains from the frypot, use fryer brushes

(Henny Penny part number 12105 includes both brushes) to

clean the side of the frypot and the heating elements (if electric

unit). If the drain fills with breading, use the white brush to push

the breading into the filter pan.

3-20 708

Page 21

Model 500/561/600

3-10. FIL TERING OF

SHORTENING

(Continued)

5. When all of the shortening has drained, scrape or brush the sides

and the bottom of the frypot.

6. Rinse the frypot as follows:

a. Close the drain valve.

b. Open the filter valve.

c. Lower lid and hold closed.

d. Move the main power switch to the PUMP position. Carefully

open the lid to see if the shortening is returning properly . Fill

frypot 1/3 full, then turn off pump.

F AILURE TO HOLD THE LID CLOSED SO THA T

THE FIRST SURGE OF THE RETURNING SHOR T ENING WILL NOT SPLASH OUT OF THE FR YPOT ,

WILL RESULT IN SEVERE BURNS.

Step 6e

Step 7a

IF THERE ARE AIR BUBBLES COMING UP IN THE

SHORTENING, IT’S POSSIBLE THA T THE FIL TER

CONNECTION A T THE UNION ON THE FILTER

TUBE IS NOT TIGHTENED PROPERL Y. IF SO,

TURN OFF THE PUMP AND USE PROTECTIVE

CLOTH OR GLOVE WHEN TIGHTENING THE

UNION. THIS UNION WILL BE HOT AND SEVERE

BURNS COULD RESUL T .

e. W ash down and scrub the sides of the frypot. Use “L” brush to

clean the heating elements.

f. After the sides and bottom are cleaned, open the

drain valve.

7. If an optional filter rinse hose is available on your fryer, the

following cleaning procedure may be used.

a. Attach the filter rinse hose with its quick disconnect fitting

to the male fitting inside the door next to the filter valve handle.

T o do this, slide back the spring ring on the female side of the

quick disconnect fitting and let it snap into place over the male

half of the fitting.

708 3-21

Page 22

Model 500/561/600

3-10. FIL TERING OF

SHORTENING

(Continued)

Step 7b

b. While holding the wooden handle, make sure the hose nozzle

is pointed down into the bottom of the frypot. Pull the lid

down over the nozzle, close the filter valve, and move the

main power switch to the PUMP position. Hold nozzle

carefully to avoid excessive splashing.

Use care to prevent burns caused by splashing of

hot shortening.

c. Rinse the frypot interior . Especially work on hard to clean areas,

like the frypot bottom. On electric models clean around heating

elements.

d. After suf ficient rinsing with shortening, close the drain valve.

e. Turn the main power switch to the OFF position.

Step 7c

Step 7f

ONL Y CONNECT AND DISCONNECT THE FIL TER

RINSE HOSE WHEN THE MAIN POWER SWITCH

IS IN THE OFF POSITION. ALSO, USE A DRY

CLOTH OR GLOVE TO AVOID BURNS. FAILURE

TO DO THIS COULD RESULT IN SEVERE BURNS

FROM HOT SHORTENING SPRA YING FROM THE

MALE FITTING .

f. Detach the hose. Raise the fitting end of hose high for a minute

to allow the remaining shortening in the hose to drain into the

frypot.

8. Pump all the shortening out of the filter pan and back into the

frypot. Close lid during first surge of pumping.

3-22 803

Page 23

Model 500/561/600

3-10. FIL TERING OF

SHORTENING

(Continued)

9. When the pump is pumping air only , the shortening in the frypot

will appear to be boiling. Close the filter valve first and then

move the main power switch from PUMP to OFF . This will

keep the filter pump and lines from filling up with shortening.

When bubbling occurs, immediately close the filter valve. This

prevents aeration of the shortening, therefore increasing

shortening life.

10. Check the level of the shortening if necessary , until it reaches the

level indicator line on the rear wall of the frypot, or the top level

indicator line on model 500s..

Step 9

11. After completing the filtering operation, empty and

replace the condensation drain pan.

Step 11

12. If frying is to be continued at this time, move the main power

switch back to the ON position, and allow time for reheating of

the shortening.

205 3-23

Page 24

Model 500/561/600

3-11. CLEANING THE

OPTIONAL CRUMB PAN

Electric Gas

Electric Gas

The crumb pan allows improved filtration process because finer, hard

to filter particles are now retained within the pan. Crumb accumulation

within the filter pan is reduced, and it is quicker to pump the shortening

back into the frypot. Also, cracklings can be taken out of the crumb

pan and used for gravy .

See crumb pan removal procedure below:

1. Drain shortening from frypot to access pan.

2. Insert provided handle at angle to get by support nubs on shaft.

Use protective cloth or gloves when removing the crumb

pan. The crumb pan and frypot surfaces may be hot and

burns could result.

3. T urn handle until notches in handle are below support nubs on

shaft.

Electric Gas

4. Lift crumb pan out of frypot.

Electric Gas

5. Clean frypot of all crumbs before reinstalling crumb pan and

returning shortening to frypot.

3-24 703

Page 25

Model 500/561/600

3-12. FIL TER PUMP

PROBLEM

PREVENTION

3-13. CHANGING THE

FILTER ENVELOPE

The following steps will help prevent filter pump problems:

1. Make certain the charcoal filter is installed with the smooth

side down and the arms on the frame are clamped down over

the protrusions on the outside of the frame.

2. The filter valve is to be closed at all times during frying.

3. Pump all the shortening from the filter lines by running the filter

pump motor until the shortening in the frypot appears to be

bubbling or boiling.

The filter envelope should be changed after 10-12 filterings or whenever it becomes clogged with crumbs. Proceed as follows:

1. Move the main power switch to the OFF position.

2. Remove and empty the condensation drain pan.

3. Disconnect the filter union and remove the drain pan from

under the frypot. If available, a drain pan may have casters

under it, allowing easy transport of filter pan and filter

assembly .

Step 3

Step 4

Filter Union

This union could be hot! Use protective cloth or glove,

or severe burns could result.

If the filter pan is moved while full of shortening, use

care to prevent splashing, or burns could result.

4. Lift the screen assembly from the drain pan.

5. W ipe the shortening and crumbs from the drain pan. Clean

the drain pan with soap and water, then thoroughly rinse with

hot water.

703 3-25

Page 26

3-13. CHANGING THE

FILTER ENVELOPE

(Continued)

Model 500/561/600

6. Unthread the suction standpipe from the screen assembly .

Step 7

7. Remove the crumb catcher and clean thoroughly with soap and

water. Rinse thoroughly with hot water .

Step 8

Step 9

8. Remove the filter clips and discard the filter envelope.

9. Clean the top and bottom filter screen with soap and water.

Rinse thoroughly with hot water .

Be sure that the filter screens, crumb catcher, filter clips,

and the suction standpipe are thoroughly dry before

assembly of filter envelope as water will dissolve the

filter paper.

10. Assemble the top filter screen to the bottom filter screen.

3-26 703

Page 27

3-13. CHANGING THE

FILTER ENVELOPE

(Continued)

Model 500/561/600

11. Slide the screens into a clean filter envelope.

12. Fold the corners in and then double fold the open end.

13. Clamp the envelope in place with the two filter retaining clips.

Step 12

14. Replace the crumb catcher screen on top of the filter paper .

Screw on the suction standpipe assembly .

15. Place complete filter screen assembly back into filter drain pan

and slide pan back into place beneath the fryer .

16. Connect the filter union by hand. Do not use a wrench to tighten.

17. Slide the condensation drain pan back into place. The fryer is

now ready to operate.

803 3-27

Page 28

Model 500/561/600

3-14. CHANGING THE

CHARCOAL FIL TER

Step 3

The charcoal filter should be changed every day or whenever it becomes clogged with crumbs. Proceed as follows:

1. Move the main power switch to the OFF position.

2. Remove and empty the condensation drain pan.

3. Disconnect the filter union and remove the filter drain pan from

beneath the frypot.

Use protective cloth or glove when disconnecting the

filter union and removing the charcoal filter assembly , or

severeburns could result.

If the filter pan is moved while full of shortening, use

care to prevent splashing, or severe burns could result.

4. An optional filter pan dolly can be used to safely transport filter

pan filled with hot shortening.

Step 7

Step 7

5. Discard shortening, or pump shortening back into frypot.

6. W earing protective gloves or using a cloth, remove the charcoal

filter assembly from drain pan.

7. Set charcoal filter assembly on a counter or table and turn the 4

clips securing the charcoal pad frame, and pull frame from

assembly .

3-28 205

Page 29

3-14. CHANGING THE

CHARCOAL FIL TER

(Continued)

Model 500/561/600

8. Remove and discard old filter pad. Clean and dry pan, frame,

and grid thoroughly .

9. Place grid, frame and new charcoal filter pad in assembly with

smooth side facing the grid and secure with clips.

3-15. CLEANING

THE FRYPOT

Step 9

10. Slide the drain pan back into place under the fryer and connect

the filter union by hand. Do not use a wrench to tighten.

11. Slide the condensation drain pan back into place. The fryer is

now ready to operate.

After the initial installation of the fryer, as well as before every change

of shortening, the frypot should be thoroughly cleaned as follows:

1. Turn the main power switch to OFF , and unplug unit from the

wall receptacle.

Moving either the frypot, or filter pan, while containing hot

shortening is not recommended. Hot shortening can splash

out. Severe burns could result.

The filter drain pan must be as far back under the fryer as it

will go, and the cover in place. Be sure the hole in the cover

lines up with the drain before opening the drain. Failure to

follow these instructions causes splashing of shortening and

could result in personal injury .

703 3-29

Page 30

Model 500/561/600

3-15. CLEANING

THE FRYPOT

(Continued)

2. If hot shortening is present in the frypot, it must be drained by

slowly opening the drain valve handle one half turn. Leave for

a few minutes, then slowly open the valve to the full open

position.

3. Close the drain valve and discard the shortening in the filter pan.

Then install the filter drain pan under the fryer, leaving out the

filter screen assembly .

4. Fill the frypot to the level indicator with hot water. Add 4 to 6

ounces of fryer cleaner (Henny Penny part number 12101) to

the water and mix thoroughly . The fry basket can be placed

inside frypot for cleaning.

Always wear chemical splash goggles or face shield and

protective rubber gloves when cleaning the frypot as the

cleaning solution is highly alkaline. A void splashing or

other contact of the solution with your eyes or skin.

Severe burns and possible blindness can result. Care

fully read the instructions on the cleaner . If solution

comes in contact with your eyes, rinse thoroughly with

cool water and see a physician immediately .

5. Turn main power switch to the POWER position set controls to

195ºF (90.5° C).

DO NOT CLOSE LID WITH WA TER AND/OR

CLEANER IN FRYPOT . WA TER UNDER PRESSURE BECOMES SUPERHEA TED. WHEN LID IS

OPENED, ESCAPING WA TER AND STEAM WILL

RESUL T IN SEVERE BURNS.

Henny Penny has the following cleaners available:

Foaming Degreaser - Part no. 12226

PHT Liquid Cleaner - Part no. 12135

PHT Dry Powder Cleaner - Part no. 12101

See your local distributor for details.

3-30 708

Page 31

Model 500/561/600

3-15. CLEANING

THE FRYPOT

(Continued)

6. When comes on and solution temperature is at

195ºF (90.5° C), immediately move the main power switch to

OFF.

Watch the cleaning solution constantly to make sure it

does not boil over causing damage to controls.

If the cleaning solution in the frypot starts to foam and

boil over , immediately turn the power switch to OFF

and do not try to contain it by closing the fryer lid

or severe burns could result.

Pour a cup of hot cleaning solution (taken from the frypot) into

the condensation tower to keep it free and clean.

7. Let the cleaning solution stand for 15 to 20 minutes with the

unit off.

8. Using the fryer brush (Henny Penny part number 12105),

scrub the inside of the frypot, the lid liner, and around the

countertop of the fryer.

Do not use the cleaning solution on the lid or the lid hinge.

These parts are aluminum and will corr ode if the PHT

cleaner comes in contact with them.

Do not use steel wool, other abrasive cleaners, or cleaners/sanitizers containing chlorine, bromine, iodine, or

ammonia chemicals as these will deteriorate the stainless

steel material and shorten the life of the unit.

Do not use a water jet (pressure sprayer) to clean unit or

component damage could result.

9. After cleaning, open the drain valve and drain the cleaning solu-

tion from the frypot into the drain pan and discard.

10. Replace the empty drain pan, close the drain valve and refill

the frypot with plain hot water to proper level.

708 3-31

Page 32

Model 500/561/600

3-15. CLEANING

THE FRYPOT

(Continued)

3-16. CLEANING THE

DEADWEIGHT ASSEMBLY

11. Add approximately 8 ounces of distilled vinegar and bring the

solution to 195º F (90.5° C).

12. Using a clean brush, scrub the interior of the frypot and lid liner.

This will neutralize the alkaline left by the cleaning compound.

13. Drain the vinegar rinse water and discard.

14. Rinse down the frypot, using clean hot water.

15. Thoroughly dry the drain pan, and the frypot interior .

Make sure the inside of the frypot, the drain valve opening, and all

the parts that will come in contact with the new shortening are as

dry as possible.

16. Replace the clean filter assembly in the drain pan and install

under fryer.

17. Refill the fryer with fresh shortening.

At the end of each day , the deadweight assembly valve must be

cleaned as follows:

DO NOT A TTEMPT T O REMOVE DEADWEIGHT

CAP WHILE FRYER IS OPERA TING. SEVERE

BURNS OR OTHER INJURIES WILL RESUL T .

1. Turn the main power switch to the OFF position. Be sure all

pressure has been released and open the lid.

2. Unscrew the deadweight cap and remove the cap and dead

weight.

Deadweight cap may be hot. Use protective cloth or

glove, or burns could result.

Step 3

Failure to clean the deadweight assembly daily could

result in the fryer building too much pressure. Severe

injuries and burns could result.

3. Clean the exhaust tube with stainless steel brush (Henny Penny

part number 12147).

3-32 708

Page 33

3-16. CLEANING THE

DEADWEIGHT

ASSEMBLY (Continued)

Model 500/561/600

4. Clean the deadweight cap and weight in hot detergent water .

Make certain to thoroughly clean the inside of the valve cap and

the deadweight.

5. Clean the deadweight orifice and the inside of the deadweight

assembly body with a clean lint-free cloth.

6. Dry the deadweight and deadweight assembly cap.

7. Replace deadweight and deadweight assembly cap. Finger

tighten the cap.

3-17. NIGHT CLOSING

PROCEDURES

Step 6

At the end of each day or shift, perform the following procedures:

1. Filter the shortening per Filtering of Shortening Section.

2. Move the main power switch to the OFF positions.

3. Place the fryer basket in a sink for cleaning.

4. Clean the deadweight assembly per Cleaning the Deadweight

Assembly Section.

5. Dump the water from the condensation drain pan.

If disconnection of the cable restraint is necessary, be

sure to reconnect the restraint after the fryer has been

returned to its originally installed position.

708 3-33

Page 34

Model 500/561/600

3-18. OPERA TING INSTRUC-

TIONS FOR OPTIONAL

DIRECT-CONNECT

SHORTENING SYSTEM

Figure 1

1. Connect the female quick disconnect, that is attached to

the hose in the rear of the fryer, to the correct male quick

disconnect at the wall. Once attached, the hose can

remain connected unless the fryer is moved. Figure 1.

In order for the system to work properly, attach the hose

to the shortening return line only.

2. Open the drain valve and drop the shortening from the

desired frypot, into the drain pan.

Figure 2

3. Once all shortening is gone from frypot, turn the red

handle counterclockwise, into the down position and

hold. Figure 2.

4. While holding the handle down, turn the POWER/PUMP

switch to the PUMP position. Shortening is now pumped

from the drain pan.

5. Once all the shortening is out of the drain pan, turn the

POWER/PUMP switch to the OFF position.

6. T urn red handle back to original position.

7. Frypot is now ready for fresh shortening.

3-34 703

Page 35

Model 500/561/600

3-19. REVERSING THE

LID GASKET

Reversing the lid gasket helps to prevent early failure of lid gasket

and the loss of pressure during a cook cycle.

1. Back the 4 lid liner screws (2 on each side) out about 1/2 inch

(12.7 mm).

2. Using a thin blade screwdriver pry out the gasket at the corners,

and then pull gasket from lid.

Check the gasket for any tears or nicks. If the

gasket is damaged, it needs to be replaced.

3. Clean the gasket and gasket seat with hot water and cleaning

detergent. Rinse with clean hot water .

4. Install the gasket with the “good” side out and tighten the 4

screws.

Install the four corners of the lid gasket. Smooth

the gasket into place, working from the corners

towards the middle of each side.

1002 3-35

Page 36

Model 500/561/600

3-20. LID LUBRICA TION T o extend the life of lid components, lubricate the ball seat and

spindle, following the steps below .

1. Close and latch the lid, and turn the spindle counterclockwise

until it stops.

2. Press down on the front of the cross bar , pull out the release

pin, lift the latch, and raise the cross bar .

3. Using spindle lube (part no. 12124), lubricate the ball seat in

the center of the lid cover .

4. Turn spindle clockwise until it stops and then lubricate the

threads on the spindle using the spindle lube.

5. Turn the spindle counterclockwise until it stops, line up the lid

cover with the cross bar, pull the release pin out, and firmly

press the cross bar back into place.

6. The fryer is now ready for use.

3-36 703

Page 37

Model 500/561/600

3-21. LIMIT STOP

ADJUSTMENT

T o extend the life of the lid gasket and help prevent steam

leakage, check the limit stop adjustment quarterly , following the

steps below .

1. Close and latch lid, and turn spindle counterclockwise until

it stops.

2. Using a 3/16” Allen wrench, loosen the 2 set screws on the

outer collar of the limit stop.

3. Turn the inner collar clockwise until it stops.

Step 2

Insert a small screwdriver or Allen wrench in the hole in the

inner collar to assist you in turning the collar .

4. T urn spindle clockwise until it stops. The lid gasket is now

touching the frypot rim.

Step 3

5. From the front of the fryer , turn the spindle at least 3/4 of a

turn, but not over 1 turn. One of the spindle arms should be

lined up with the red ball of the latch, at this time.

6. Slightly turn the spindle past this position, so it should show in

about the 7 o’clock position.

The 7 o’clock position is only to allow slight additional turning

of the spindle to relieve any side pressure against the locking

pin. Side pressure holds the pin in the locked position, even

after all the pressure has released.

When adjustment is complete, if a black ball on the spindle is

lined up with the red ball on the latch, unscrew the black ball

and the red ball on the spindle and change places on the

spindle. The red ball on the spindle should now line up with

the red ball on the latch.

703 3-37

Page 38

Model 500/561/600

3-21. LIMIT STOP

ADJUSTMENT

(Continued)

3-22. CLEANING THE

SAFETY RELIEF

VALVE

7. Turn the inner collar counterclockwise until it stops against the

bottom hub of the spindle.

8. Tighten Allen screws.

If the lid cover fails to seal properly , steam escapes from

around the gasket during frying. Readjust the limit stop, this

time turning the spindle 1 full turn after the initial contact of the

lid gasket with the frypot rim (step 5).

DO NOT A TTEMPT TO REMOVE THE SAFETY

VALVE WHILE FRYER IS OPERA TING, OR SEVERE

BURNS OR OTHER INJURIES WILL RESUL T .

SAFETY V AL VE

DO NOT DISASSEMBLE OR MODIFY THIS

SAFETY RELIEF V AL VE. TAMPERING WITH THIS

VALVE COULD CAUSE SERIOUS INJURIES AND

WILL V OID AGENCY APPROV ALS AND APPLIANCE W ARRANTY .

1. Remove deadweight cap and deadweight.

2. Use a wrench to loosen the valve from the pipe elbow , turn

counterclockwise to remove.

3. Clean the inside of the pipe elbow with hot water .

Turn the safety relief valve towards the rear of the fryer when

reinstalling the relief valve.

4. Immerse the safety relief valve in a soapy water solution

for 24 hours. Use a 1 to 1 dilution rate. The valve cannot

be disassembled. It is factory preset to open at 14-1/2

pounds of pressure (999 mbar). If it does not open or close,

it must be replaced.

3-38 703

Page 39

Model 500/561/600

3-23. CHECK & TIGHTEN

ELEMENT SPREADER

BARS (Model 500 only)

T o extend the life of the temperature probe, high limit, and elements,

every 90 days check the tightness of the element spreader bar screws,

following the steps below:

Drain shortening and allow fryer to cool before proceeding with the following steps. Surfaces of the fryer will be

hot and burns could result.

1. Check that all spreader bars are in place (4 sets), and using a

5/16” socket or wrench, tighten all the element spreader

screws.

If the bolts or spreaders are missing or damaged, order

kit no. 14685 from your nearest Henny Penny distributor.

2. Pump shortening back into frypot and unit is now ready for

use.

205 3-39

Page 40

Model 500/561/600

3-24. SEASONAL

SHUTDOWN

3-25. CUT -UP

FRIED CHICKEN

1. Drain and clean the frypot per Cleaning the Frypot Section.

2. Turn the main circuit breaker OFF and unplug the electrical cord,

if possible.

3. On gas models turn the gas valve to OFF . Shut off the gas valve

on the main gas supply line.

4. Close the lid but do not tighten the spindle.

5. Remove and clean the condensation drain pan.

6. Clean the inside of the steam exhaust tank on gas

models.

1. Cut 2 1/2 to 2 3/4 pound (1.13-1.3 kg) net weight birds into 8 or

9 pieces. Nine pieces allows you to serve 3 three-piece dinners

from each bird.

2. W ash the chicken parts and drain thoroughly . Break the thigh

bone from the front of the backbone and remove excess fat

from the thigh.

3. Bread the pieces in advance (if using Henny Penny Fryer

Breading Mix) so that the breaded chicken will be held at

least 30 minutes before frying. Breading in advance will give

the breading an opportunity to permeate the meat and adhere

better to the product. The pieces can be breaded and held

refrigerated for as long as 24 hours before frying. This

procedure eliminates continuous breading and will save labor .

4. Frying temperature for best results is 320°F (160°C) for 10 to 11

minutes.

3-40 703

Page 41

Model 500/561/600

3-26. CHICKEN

QUARTERS

3-27. BARBECUED

CHICKEN

3-28. FRIED

PORK CHOPS/

VEAL CUTLETS

Follow the “Cut-up Fried Chicken” procedure above, allowing an

additional 2 to 3 minutes for frying. The portions are larger and will

need the additional frying time.

1. Whole halves (2 to 2-1/2 lbs. (.9-1.13 kg) less giblets): Prepare

the birds by washing and draining thoroughly .

2. Place them into the fryer whole or cut into halves.

3. The frying temperature is 310°F (154°C) for 12 minutes for

halves. The whole birds should be fried at 310°F (154°C) for

15 minutes.

4. After the frying has been completed, place the halves or whole

birds into a pan of warm barbecue sauce. For best results, allow

a minimum of 30 minutes in barbecue sauce before serving.

1. W ash and drain the chops thoroughly .

2. Bread the pork chops (4 oz. portion, 1/2-inch to 3/4-inch

(.11 kg, 12.7-19 mm) thick)with the Henny Penny Fryer Mix.

3. Fry at 315°F (157°C) for 5 minutes. If the chops are larger ,

allow an additional minute for each 2 ounce (.06 kg) increase per

portion.

3-29. BARBECUED

PORK CHOPS

1. Fry the chops (4 oz. (.11 kg) portion) for 5 minutes at 305°F

(152°C).

2. After frying has been completed, place the chops in warm

barbecue sauce.

3. The chops should remain in the barbecue sauce for

30 minutes prior to serving at 150°F (66°C) minimum.

3-30. BARBECUED RIBS 1. Prepare racks of ribs (racks of 2-1/2 pounds (1.13 kg) and

under) by trimming excessive fat.

2. Cut the ribs into proper portions for serving before preparing.

(Ribs lightly breaded with Henny Penny Fryer Mix before frying

gives additional flavor.)

703 3-41

Page 42

Model 500/561/600

3-30. BARBECUED RIBS

(Continued)

3-31. TOP SIRLOIN

STEAK AND

FILET MIGNON

3-32. FISH FILLETS

3. The ribs should be fried for 13 minutes at 275°F (135°C).

4. Ribs should then be brushed well on both sides with

barbecue sauce, or placed in a pan of warm sauce.

5. Hold ribs in a sauce at 150ºF (66°C), for 30 minutes so

flavor can permeate.

6. Racks of ribs that exceed 2-1/2 pounds (.9 kg) will need addi

tional time for frying. Use approximately 15 minutes for 3-pound

(1.4 kg) racks.

1. For steak (6 to 8 oz. (.17-.23 kg) portions, normal thickness)

that is to be served brown outside with pink inside, fry for 4

minutes at 315°F (157°C).

2. T o serve a steak with brown outside and no pink inside,

fry for 7 to 8 minutes at 315°F (157°C).

1. Clean, wash and drain. Use 4 oz. (.11 kg) size pieces.

2. Marinate or bread.

3. Fry for 3-1/2 minutes at 315°F (157°C).

3-33. FROG LEGS

1. Clean, wash, and drain.

2. Marinate or bread.

3. Fry for 7 minutes at 315°F (157°C).

3-34. OYSTERS

1. Clean, wash, and drain. Remove shell particles.

2. Bread.

3. Fry at 2 minutes at 315°F (157°C).

3-35. SHRIMP 1. Clean, wash, and drain.

2. Bread.

3. Fry for 3 minutes at 315°F (157°C).

3-42 703

Page 43

Model 500/561/600

3-36. ROCK

LOBSTER T AIL

3-37. POT A TOES

3-38. CORN ON THE COB

3-39. CAULIFLOWER

1. Clean, wash, and drain.

2. Fry for 6 minutes at 315°F (157°C).

1. Use U.S. No. 1 grade Idaho potatoes, unpeeled.

W ash and cut into 8 wedges. Drain and bread.

2. Fry for 8 minutes at 315°F (157°C). If smaller potatoes are

used, time may be reduced.

1. Clean, wash, and drain.

2. Fry for 4 minutes at 315°F (157°C).

1. Clean, wash, and drain.

2. Cut into 1 inch (25.4 mm) pieces.

3. Bread.

4. Fry for 2 minutes at 315°F (157°C).

703 3-43

Loading...

Loading...