Henny Penny 592, 590 User Manual

SECTION 2. MAINTENANCE

Model 590/592

2-1. INTRODUCTION

2-2. MAINTENANCE HINTS

This section provides checkout and replacement procedures,

for various parts of the fryer. Before replacing any parts, refer

to the Troubleshooting Section to aid you in fi nding the cause

of the malfunction.

1. A multimeter will help you to check electric components.

2. When the manual refers to the circuit being closed, the

multimeter should read zero unless otherwise noted.

3. When the manual refers to circuit being open, multimeter

should read infi nity.

Do not move fryer with hot shortening in the frypot or

fi lter pan. Severe burns can result from splashing hot

shortening.

4. Remove weights from frame to easily access rear of fryer.

2-3. PREVENTIVE

MAINTENANCE

To ensure a long life of fryers and their components, regular

maintenance should be performed. Refer to the chart below.

Procedure Frequency

Filtering of shortening See KFC’s Standards Library

Changing of shortening See KFC’s Standards Library

Changing the fi lter envelope See KFC’s Standards Library

Cleaning deadweight assy. Daily-See Deadweight Valve

Section

Cleaning the frypot See KFC’s Standards Library

Reversing lid gasket Each 90 Days-see Reversing

Lid Gasket Section

Lubricate rear lid rollers Annually-See Lubricating Lid

Rollers Section

Cleaning safety relief valve Annually-See Removal/Cleaning

of Safety Relief Valve Section

307 2-1

Model 590/592

2-4. HIGH TEMPERATURE

LIMIT CONTROL

This high temperature control is a safety, manual reset control,

which senses the temperature of the shortening. If the shortening temperature exceeds 425°F (218°C), this switch opens

and shuts off the heat to the frypot. When the temperature of

the shortening drops to a safe operation limit, manually reset

by pressing the red reset button. The red reset button is located

under the control panel, in the front of the fryer, to the right of

the drain. Once reset, the frypot starts heating.

Checkout

Before replacing a high temperature limit control, check to see

that its circuit is closed.

The shortening temperature must be below 380°F (193°C)

to accurately perform this check.

1. Remove electrical power supplied to the fryer.

To avoid electrical shock or property damage, move the

power switch to OFF and disconnect main circuit

breaker, or unplug cord at wall receptacle.

2. Remove the control panel.

3. Remove the inner heat shield.

4. Remove two nuts securing the high limit bracket to unit,

and pull the bracket from the unit.

5. Remove two screws securing the high limit to the bracket,

and remove the high limit from the bracket.

6. Remove the two electrical wires from the high temperature

limit control.

7. Manually reset control, then check for continuity between

the two terminals after resetting the control. If circuit is

open, replace control, then continue with this procedure. (If

the circuit is closed, high limit is not defective. Reconnect

the two electrical wires.)

2-2 1103

Model 590/592

2-4. HIGH TEMPERATURE

LIMIT CONTROL

(Continued)

To avoid electrical shock of property damage, move the

power switch to OFF and disconnect main circuit

breaker, or unplug cord at wall receptacle.

Replacement

1. If the tube is broken or cracked, the control will open,

shutting off electrical power. The control cannot be reset.

2. Drain shortening from the frypot and discard. A substance

in the tube could contaminate the shortening.

3. Remove control panel.

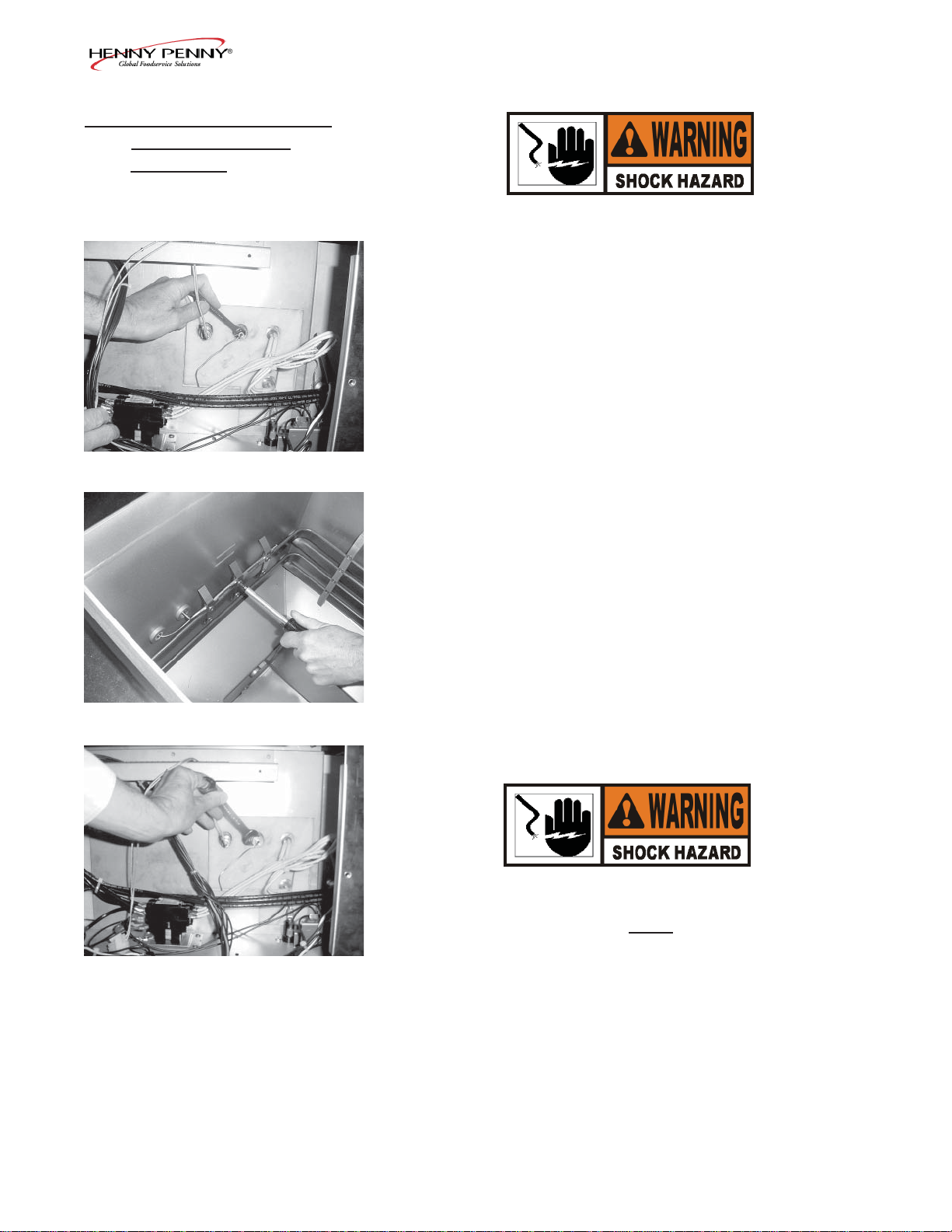

4. Loosen small inside screw nut on capillary tube.

5. Remove capillary bulb from bulb holder inside the frypot.

6. Straighten the capillary tube.

7. Remove larger outside nut that threads into pot wall, and

remove defective control from control panel area.

8. Insert new control and replace screws.

9. Uncoil capillary line, starting at capillary tube, and insert

through frypot wall.

To avoid electrical shock or other injury, run capillary

line under and away from all electrical power wires and

terminals. The tube must never be in such a position

where it could accidentally touch the electrical power

terminals.

10. Carefully bend the capillary tube as shown in photo and

place into bulb brackets.

1103 2-3

Model 590/592

2-4. HIGH TEMPERATURE

LIMIT CONTROL

(Continued)

2-5. FUSE HOLDERS

11. Pull excess capillary line from pot and tighten nut into

frypot wall.

Be sure capillary bulb of high limit is positioned so it does

not interfere with carrier or get damaged when cleaning

frypot.

12. With excess capillary line pulled out, tighten smaller nut.

13. Replace inner and front panels.

14. Refi ll with shortening.

There are two fuse holders on each model of the electric fryers.

To check or change fuse, unscrew black fuse holder cap.

To avoid electrical shock or property damage, move the

power switch to OFF and disconnect main circuit

breaker, or unplug cord at wall receptacle.

Checking Procedure for Fuse Holders

CONTROL PANEL FUSES 3 Phase

Remove the control panel and pull the wires from the fuse

holder terminals. Using a multimeter or continuity light, check

across the terminals. The circuit should be closed. If not, replace the fuse (HP# EF02-007) or fuse holder (HP# EF02-006).

2-4 1103

Model 590/592

2-6. POWER/PUMP SWITCH

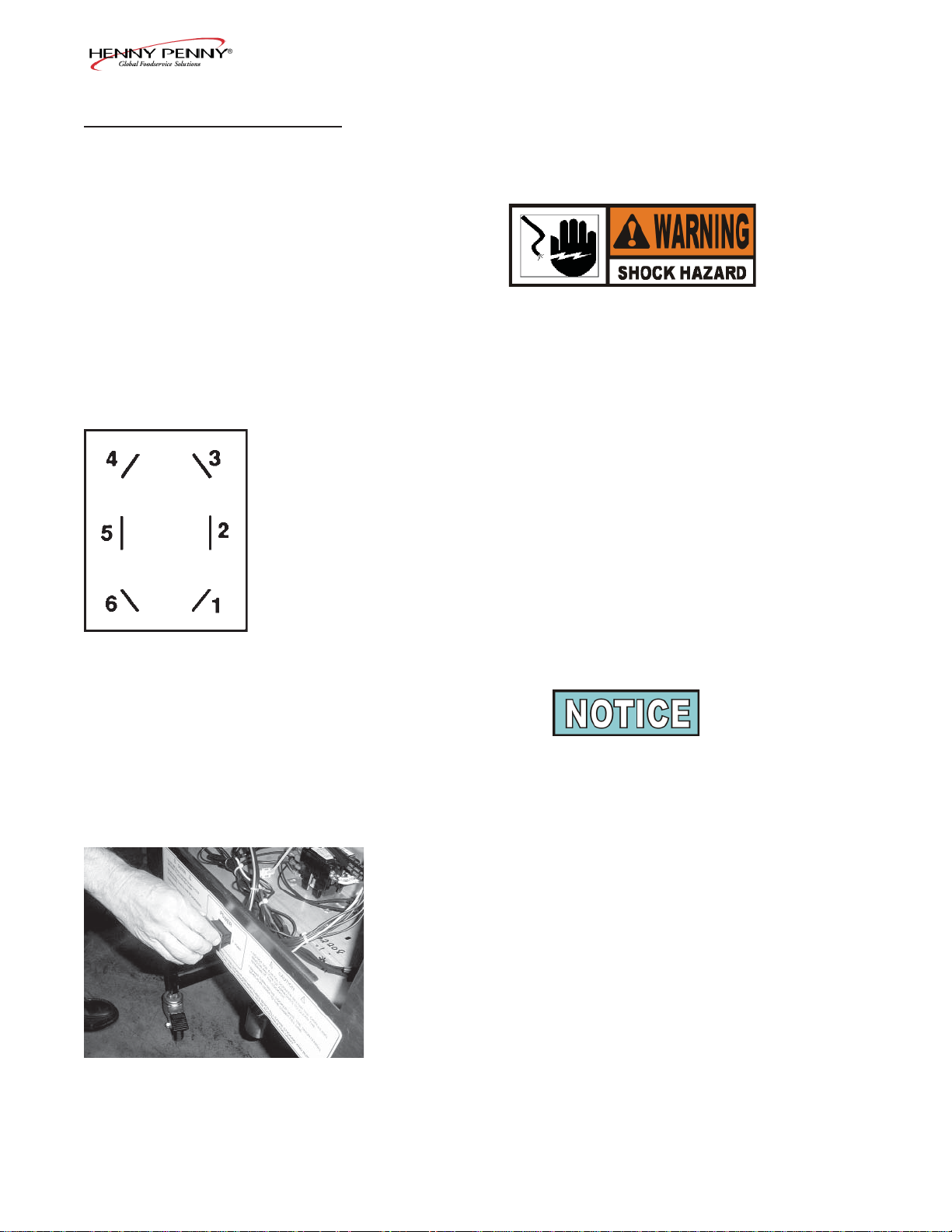

The POWER/PUMP switch is a three way rocker switch with a

center OFF position. With switch in the POWER position, the

fryer operates. With switch in PUMP position, the fi lter pump

operates, but the unit will not heat.

To avoid electrical shock or property damage, move the

power switch to OFF and disconnect main circuit

breaker, or unplug cord at wall receptacle.

Checkout

1. Remove control panel.

2. Label and remove wires from the switch.

3. OFF position-should be open circuit anywhere on switch.

4. Power position. Check from: #5 to #6 closed circuit

#l to #2 closed circuit

5. Pump position. Check from: #4 to #5 closed circuit

#3 to #2 closed circuit

Check across the jumpers on the wires of POWER/PUMP

switch. These jumpers have resistors and capacitors which

may be faulty.

Replacement

1. With control panel removed, and wires off of the switch,

push in on tabs on the switch to remove from the panel.

2. Replace with new switch, and reconnect wires to switch

following the wiring diagram.

3. Replace the control panel.

1103 2-5

Model 590/592

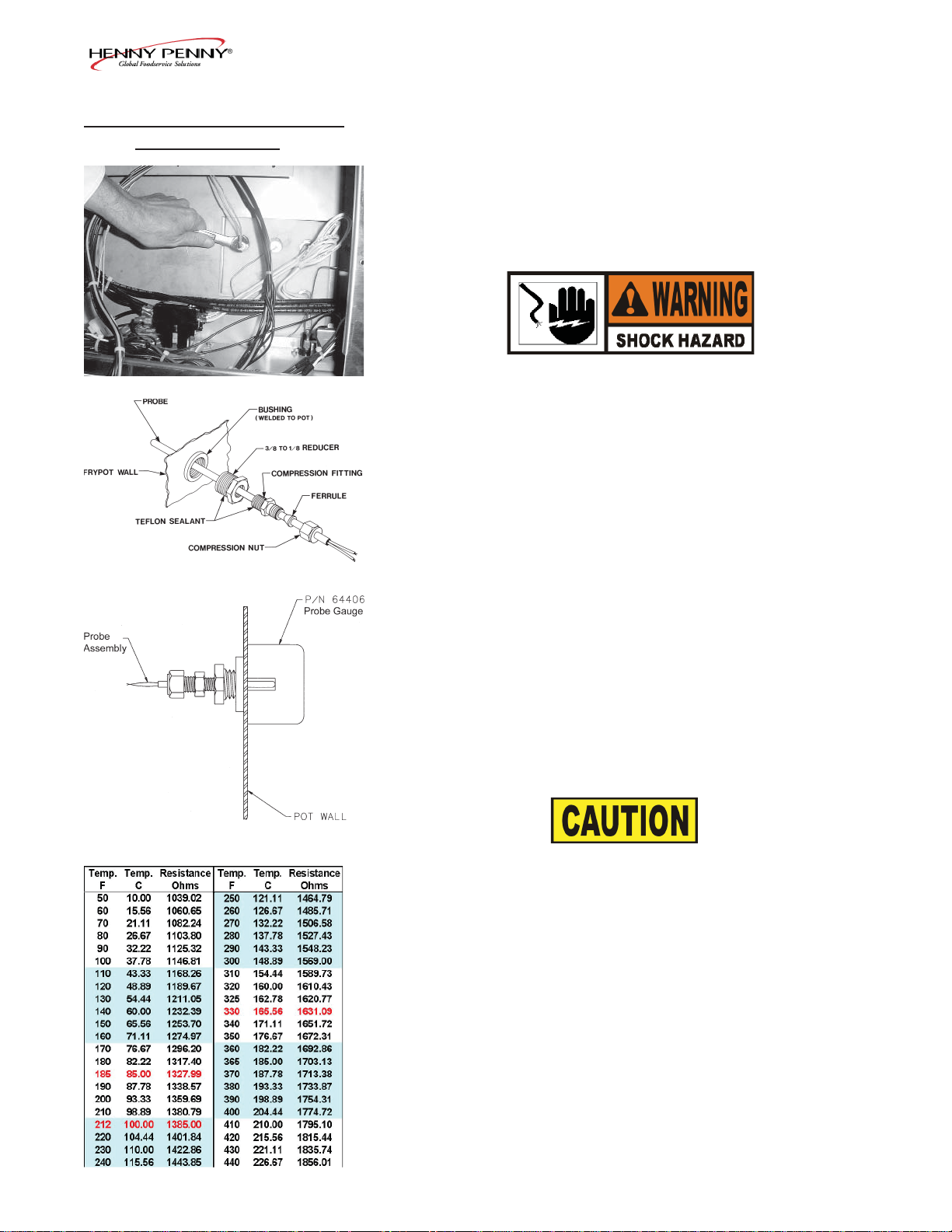

2-7. TEMPERATURE PROBE

REPLACEMENT

The temperature probe relays actual shortening temperature to

the control. If it becomes disabled, “E06” will show in the display. Also, if temperature is out of calibration more than 10°F,

or 10°C, the temperature probe should be replaced. An Ohm

check can be performed also. See chart at end of this section.

1. Remove electrical power supplied to the fryer.

To avoid electrical shock or property damage, move the

power switch to OFF and disconnect main circuit

breaker, or unplug cord at wall receptacle.

2. Drain the shortening from the frypot.

3. Remove the control panel.

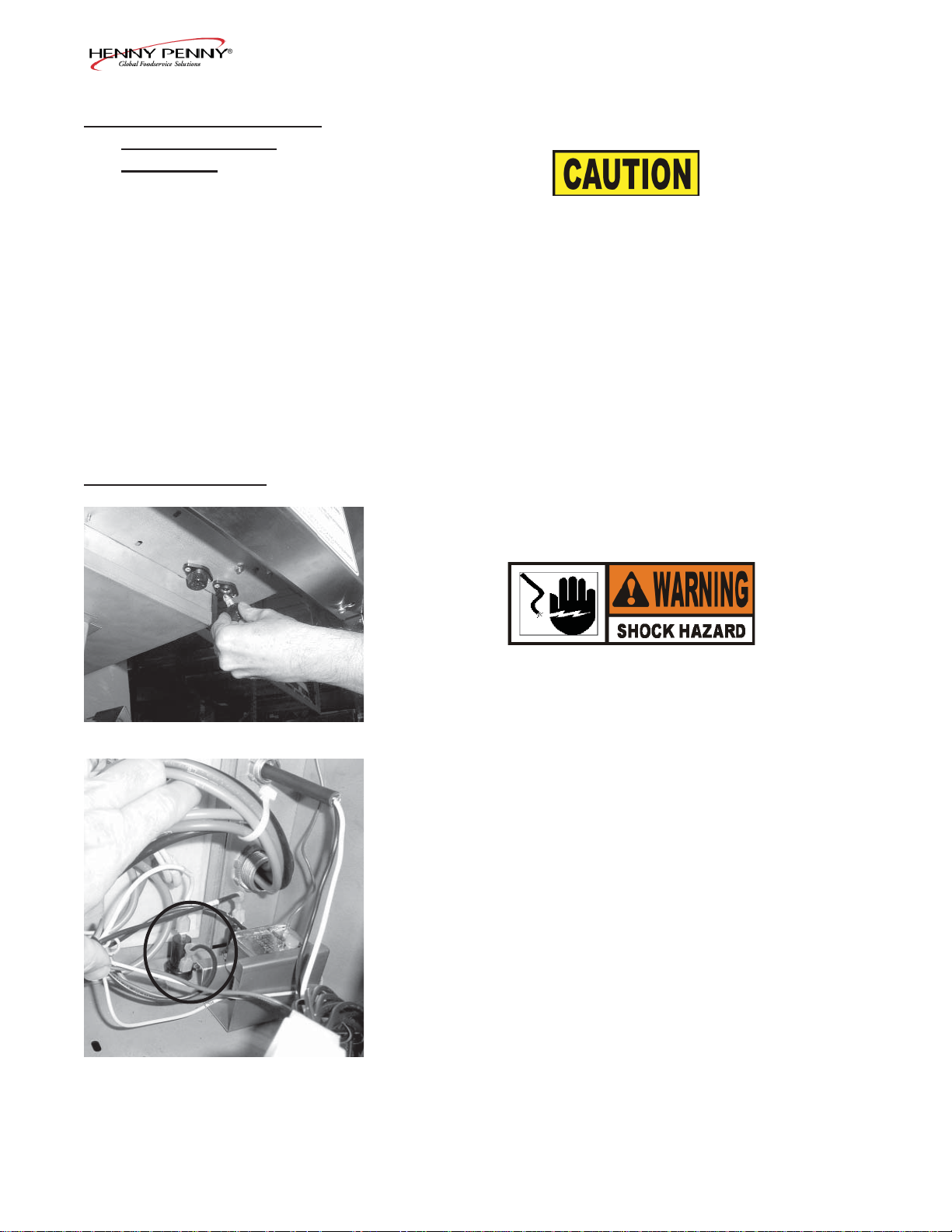

4. Using a 1/2” wrench, remove the nut on compression fi tting.

Figure 2-1

Figure 2-2

5. Remove the temperature probe from the frypot.

6. Place nut and new ferrule on new temperature probe and

insert temperature probe into compression fi tting until it

extends one-half (1/2) inch (1.3 cm) into frypot. Use temp-

erature probe gauge provided in temperature probe kit, to

ensure proper placement in frypot. See Figures 2-1 & 2-2.

7. Tighten hand tight and then a half turn with wrench.

Excess force will damage temperature probe.

8. Connect new temperature probe to PC board and replace

control panel.

9. Replace shortening.

10. Turn power on and check out fryer.

2-6 407

Model 590/592

2-8. COMPLETE CONTROL

PANEL-HENNY PENNY

2-9. PRESSURE REGULATION

Should the control panel become inoperative, follow these

instructions for replacing the board.

1. Remove electrical power supplied to the fryer.

To avoid electrical shock or property damage, move the

power switch to OFF and disconnect main circuit

breaker, or unplug cord at wall receptacle.

2. Remove the two screws securing he control panel and lift

panel up and out

3. Unplug the connectors going to the control board.

4. Install a new control panel.

The Henny Penny Fryer uses pressure as one of the components of the cooking process. Once the lid is sealed to the

frypot, and the solenoid valve closes, a deadweight valve maintains the correct pressure in the frypot.

The lid has minimal and limited maintenance and repair procedures, which are addressed in the following sections.

The following is a routine maintenance schedule for the Lid:

Every 90 days

• Clean and reverse the lid gasket

Yearly Inspection

• Check Lid Gasket for splits and tears-replace if necessary

• Check Pressure Pads for wear-rotate if necessary

• Check Cam Slide Guides-replace if worn or broken

• Check Lid Rollers-replace if cracked or damaged

1103 2-7

Model 590/592

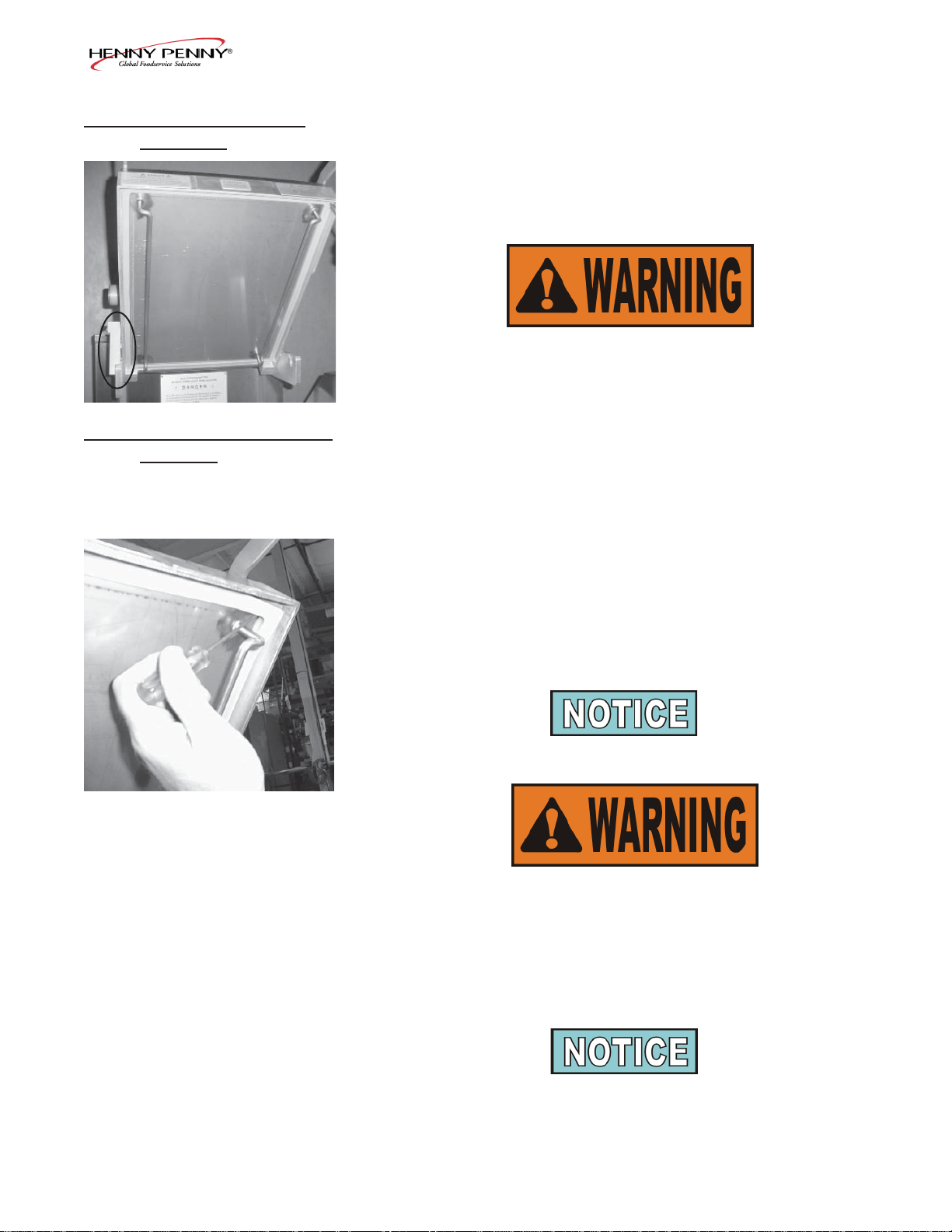

2-10. TILTING THE LID

UPRIGHT

2-11. REVERSING THE LID

GASKET

The Lid Assembly is easily tilted up for cleaning or servicing.

1. Raise the lid and remove racks and carrier.

2. Grasping the lid handle, lift the front of the lid up until it

stops in an upright position.

Be sure the metal arm on the left side of the lid is in the

vertical position holding lid upright, or severe injuries

could result. (See photo at left).

The gray rubber gasket surrounding the inside of the lid is designed to be reversed.

Because of heat expansion and the pressure used for cooking

process, gasket is constantly under extreme stress. Reversing

the lid gasket will help to assure that the fryer will not lose

pressure through leakage.

1. Put the lid in the upright position, as previously described.

2. Using a thin blade screwdriver, pry out the gasket at the

corners. Remove the gasket.

Check the gasket for any tears or nicks. If the gasket is

damaged it needs to be replaced.

Be sure the metal arm on the left side of the lid is in the

vertical position holding lid upright, or severe injuries

could result. (See photo in Tilting Lid Upright section)

3. Clean the gasket and gasket seat with hot water.

4. Rotate the gasket with the opposite side facing out.

Install the 4 corners of the lid gasket. Smooth gasket into

place, working from the corners towards the middle of each

side.

2-8 1103

Loading...

Loading...