Henny penny 580 KFC User Manual

Global Foochervice Solutions

1

Henny Penny

Pressure Fryer __

* .

l

odel 580 KFC . . .

.

Henny Penny Model 580

HENNY PENNY 8 HEAD PRESSURE FRYER

Model 580 Electric Fryer

SPECIFICATIONS

Height 60" (155 cm)

Width 24" (61 cm)

Depth 41" (104 cm)

Floor Space Approximately 7 sq. ft. (.65 sq. m.)

Pot Capacity 8 Head of chicken (22 lbs.)(9.9 Kg.)

100 lbs. shortening (45.4 Kg.)

Electrical 120/208 VAC, 3 Phase, 50/60 Hz, 47.2 Amp, 17 KW

120/240 VAC, 3 Phase, 50/60 Hz, 40.9 Amp, 17 KW

200 VAC, 3 Phase, (Delta) 50/60 Hz, 49.1 Amp, 17 KW

240 VAC, 3 Phase, (Delta) 50 Hz, 40.9 Amp, 17 KW

380 VAC, 3 Phase, 50 Hz, 25.8 Amp, 17 KW

415 VAC, 3 Phase, 50 Hz, 23.7 Amp, 17 KW

Heating Two 8,500 Watt Electric Immersion Elements

Pressure 12 PSI operating pressure (827 mbar)

14.5 PSI safety relief pressure (999 mbar)

Shipping Weight Approximately 600 lbs. (226.8 Kg.)

NOTE

A data plate, located on the right side panel, gives the information of the type of fryer,

serial number, warranty date, and other information pertaining to fryer. Also, the serial

number is stamped on the outside of the cookpot. See figure below.

FM01-305

Revised 04-13-07

Henny Penny

LIMITED WARRANTY FOR HENNY PENNY APPLIANCES

Subject to the following conditions, Henny Penny Corporation makes the following limited warranties to the

original purchaser only for Henny Penny appliances and replacement parts:

NEW EQUIPMENT:

defective in material or workmanship within two (2) years from date of original installation, will be

repaired or replaced without charge F.O.B. factory, Eaton, Ohio, or F.O.B. authorized distributor. To

validate this warranty, the registration card for the appliance must be mailed to Henny Penny within ten

(10) days after installation.

REPLACEMENT PARTS:

be defective in material or workmanship within ninety (90) days from date of original installation will be

repaired or replaced without charge F.O.B. factory, Eaton, Ohio, or F.O.B. authorized distributor.

The warranty for new equipment and replacement parts covers only the repair or replacement of the defective

part and does not include any labor charges for the removal and installation of any parts, travel or other expenses

incidental to the repair or replacement of a part.

EXTENDED FRYPOT WARRANTY:

workmanship issues for a period of up to seven (7) years from date of manufacture. This warranty shall not cover

any frypot that fails due to any misuse or abuse, such as heating of the frypot without shortening.

0 TO 3 YEARS:

issues will be replaced at no charge for parts, labor, or freight. Henny Penny will either install a

new frypot at no cost or provide a new or reconditioned replacement fryer at no cost.

3 TO 7 YEARS:

issues will be replaced at no charge for the frypot only. Any freight charges and labor costs to

install the new frypot as well as the cost of any other parts replaced, such as insulation, thermal

sensors, high limits, fittings, and hardware, will be the responsibility of the owner.

Any part of a new appliance, except lamps and fuses, which proves to be

Any appliance replacement part, except lamps and fuses, which proves to

Henny Penny will replace any frypot that fails due to manufacturing or

During this time, any frypot that fails due to manufacturing or workmanship

During this time, any frypot that fails due to manufacturing or workmanship

Any claim must be represented to either Henny Penny or the distributor from whom the appliance was

purchased. No allowance will be granted for repairs made by anyone else without Henny Penny’s written

consent. If damage occurs during shipping, notify the sender at once so that a claim may be filed.

THE ABOVE LIMITED WARRANTY SETS FORTH THE SOLE REMEDY AGAINST HENNY PENNY

FOR ANY BREACH OF WARRANTY OR OTHER TERM. BUYER AGREES THAT NO OTHER REMEDY

(INCLUDING CLAIMS FOR ANY INCIDENTAL OR CONSQUENTIAL DAMAGES) SHALL BE

AVAILABLE.

The above limited warranty does not apply (a) to damage resulting from accident, alteration, misuse, or

abuse; (b) if the equipment’s serial number is removed or defaced; or (c) for lamps and fuses. THE ABOVE

LIMITED WARRANTY IS EXPRESSLY IN LIEU OF ALL OTHER WARRANTIES, EXPRESS OR

IMPLIED, INCLUDING MERCHANTABILITY AND FITNESS, AND ALL OTHER WARRANTIES ARE

EXCLUDED. HENNY PENNY NEITHER ASSUMES NOR AUTHORIZES ANY PERSON TO ASSUME

FOR IT ANY OTHER OBLIGATION OR LIABILITY.

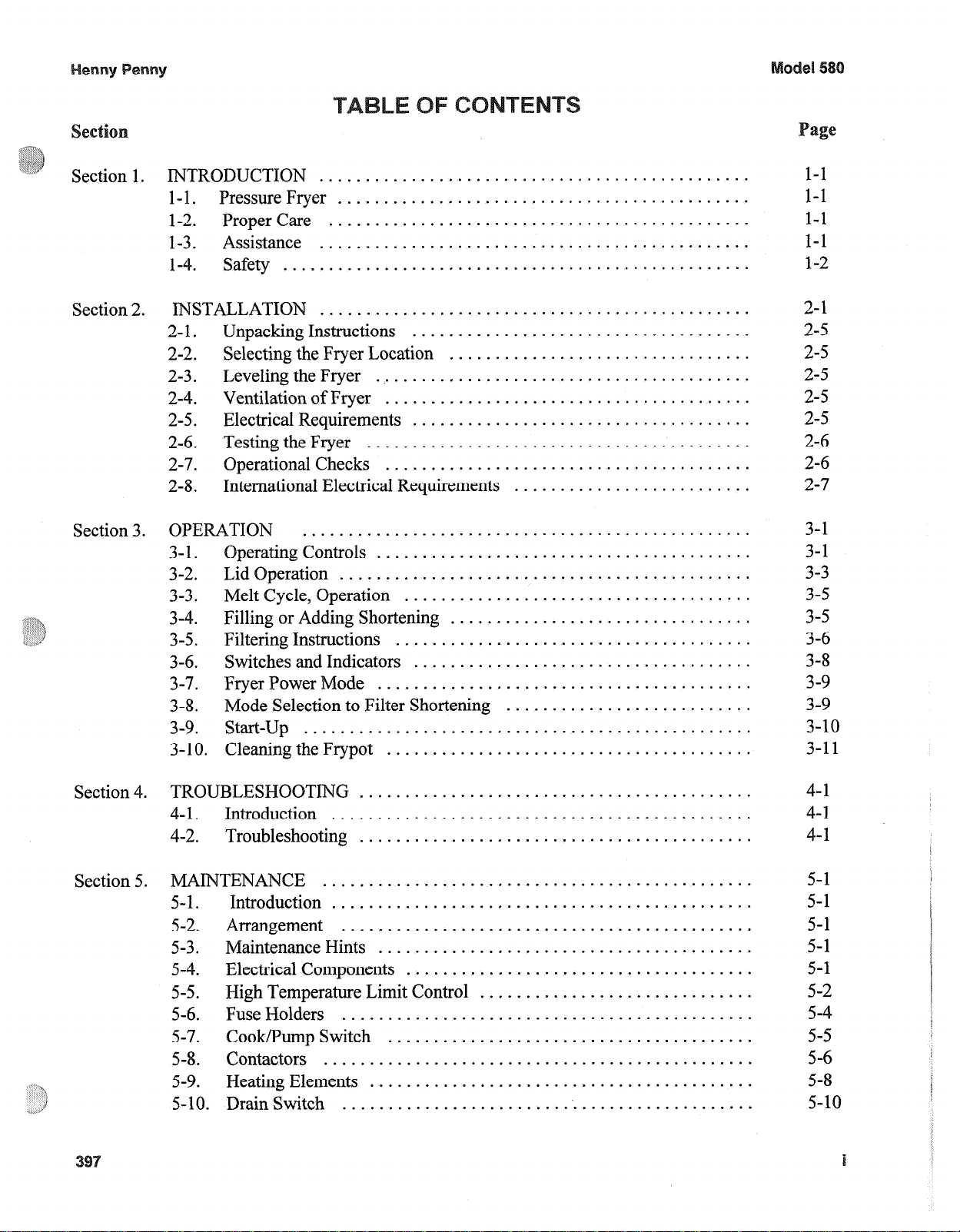

Section 1.

INTRODUCTION

l-l.

l-2.

l-3.

l-4.

PressureFryer

Proper Care

Assistance

Safety ...................................................

...............................................

.............................................

..............................................

...............................................

l-l

l-l

l-l

l-l

l-2

Section 2.

Section 3.

INSTALLATION

2-l.

2-2.

2-3.

2-4.

2-5.

2-6.

2-7.

2-8.

Unpacking Instructions

Selecting the Fryer Location

LevelingtheFryer

Ventilation of Fryer

Electrical Requirements

Testing the Fryer

OperationalChecks

International Electrical Requirements

OPERATION

...............................................

.................................................

3-l. Operating Controls

3-2.

3-3.

3-4.

3-5.

3-6.

3-7.

3-8.

3-9.

3-l 0.

LidOperation

Melt Cycle, Operation

Filling or Adding Shortening

Filtering Instructions

Switches and Indicators

Fryer Power Mode

Mode Selection to Filter Shortening

start-up

Cleaning the Frypot

.............................................

.................................................

.....................................

.................................

.........................................

........................................

.....................................

..........................................

........................................

..........................

.........................................

......................................

.................................

.......................................

.....................................

.........................................

...........................

........................................

2-l

2-5

2-5

2-5

2-5

2-5

2-6

2-6

2-7

3-l

3-l

3-3

3-5

3-5

3-6

3-8

3-9

3-9

3-10

3-l 1

Section 4.

Section 5.

TROUBLESHOOTJNG

4-l.

4-2.

Introduction

Troubleshooting

MAINTENANCE

5-l.

5-2.

5-3.

5-4.

5-5.

5-6.

5-7.

5-s.

5-9.

5-10.

Introduction

Arrangement

Maintenance Hints

Electrical Components

High Temperature Limit Control

FuseHolders

Cook/PumpSwitch

Contactors

Heating Elements

Drain Switch

..............................................

...............................................

..............................................

.............................................

.............................................

...............................................

..............................................

...........................................

...........................................

.........................................

......................................

..............................

........................................

..........................................

4-l

4-1

4-l

5-l

5-l

5-l

5-l

5-l

5-2

5-4

5-5

5-6

5-8

5-10

Henny Penny Model 580

TABLE OF CONTENTS

Section Page

5-11. Temperature Probe...................................................................................... 5-10

5-12. Complete Control Panel.............................................................................. 5-12

5-13. Pressure Regulation .................................................................................... 5-12

5-14. Preventive Maintenance.............................................................................. 5-13

5-15. Reversing the Lid Gasket............................................................................ 5-13

5-16. Lid Counterweight ...................................................................................... 5-14

5-17. Pressure Pads .............................................................................................. 5-16

5-18. Lid Adjustment ........................................................................................... 5-16

5-19. Adjusting the Magnet Plate (SN: GG015JJ and below) ............................ 5-18

5-20. Solenoid Valve Replacement ...................................................................... 5-18

5-21. Operating Control Valve............................................................................. 5-20

5-22. Removal & Cleaning of Safety Valve ........................................................ 5-21

5-23. Pressure Gauge............................................................................................ 5-22

5-24. Drain Valve................................................................................................. 5-23

5-25. Nylatron Strips ............................................................................................ 5-24

Section 6. PROGRAMMING ................................................................................................ 6-1

6-1. Basic Programming Sequence .................................................................... 6-1

6-2. Cook Cycle.................................................................................................. 6-1

6-3. Error Codes ................................................................................................. 6-2

6-4. Special Programming Modes...................................................................... 6-2

6-5. One Step KFC Parameters .......................................................................... 6-3

6-6. Test Procedures........................................................................................... 6-3

6-7. Special Functions........................................................................................ 6-4

Parts Section................................................................................................ 6-5

Wiring Diagrams......................................................................................... 6-20

SMS Programming (If Applicable)............................................................. 6-34

ii 302

ode!

The Henny Penny Pressure Fryer is a basic unit of food

processing equipment. It has found wide

application in institutional and commercial food

service operations.

A combination of Pressure, Heat, and Time is

automatically controlled to produce the optimum in a

tasty, appealing product.

Pressure is basic to this method of food preparation.

The pressure is developed from the natural moisture

of the food. The patented lid traps this moisture and

uses it as steam. Because the steam builds rapidly,

the greater part of the natural juices are retained

within the food. An operation valve vents excess

steam from the pot and maintains constant live

steam pressure.

Heat generated is another important factor of the

pressure fryer. Energy savings is realized due to the

unit’s short frying time, low temperature, and heat

retention of the stainless steel cookpot.

Time is important because the shorter time involved

in frying foods results in additional economies for

the user. Foods are table ready in less time than it

would take to fry them in a conventional open-type

fryer.

As in any unit of food service equipment, the Henny

Penny Pressure fryer does require care and

maintenance. Requirements for the maintenance

and cleaning are contained in this manual and must

become a regular part of the operation o. the unit at

all times.

Should you require outside assistance, just call

l-800-417-8417, or 937-417-8417.

The Henny Penny Pressure Fryer has many safety features

incorporated. However, the only way to ensure a safe operation

is to fully understand the proper installation, operation, and

maintenance procedures. The instructions in this manual have

been prepared to aid you in learning the proper procedures.

Where information is of particular importance or safety

related, the words DANGER, WARNING, CAUTION, and

NOTE are used. Their usage is described below.

The word DANGER indicates an imminent hazard

which will result in highly serious injury such as second

or third degree burns, loss of sight, and other permanent injuries.

The word WARNING is used to alert you to a

procedure, that if not performed properly, might cause

personal injury, such as burns and/or loss of sight, and

damage to the fryer.

The word CAUTION is used to alert you to a procedure

that, if not performed properly, may damage the fryer,

or product.

The word NOTE is used to highlight especially important information.

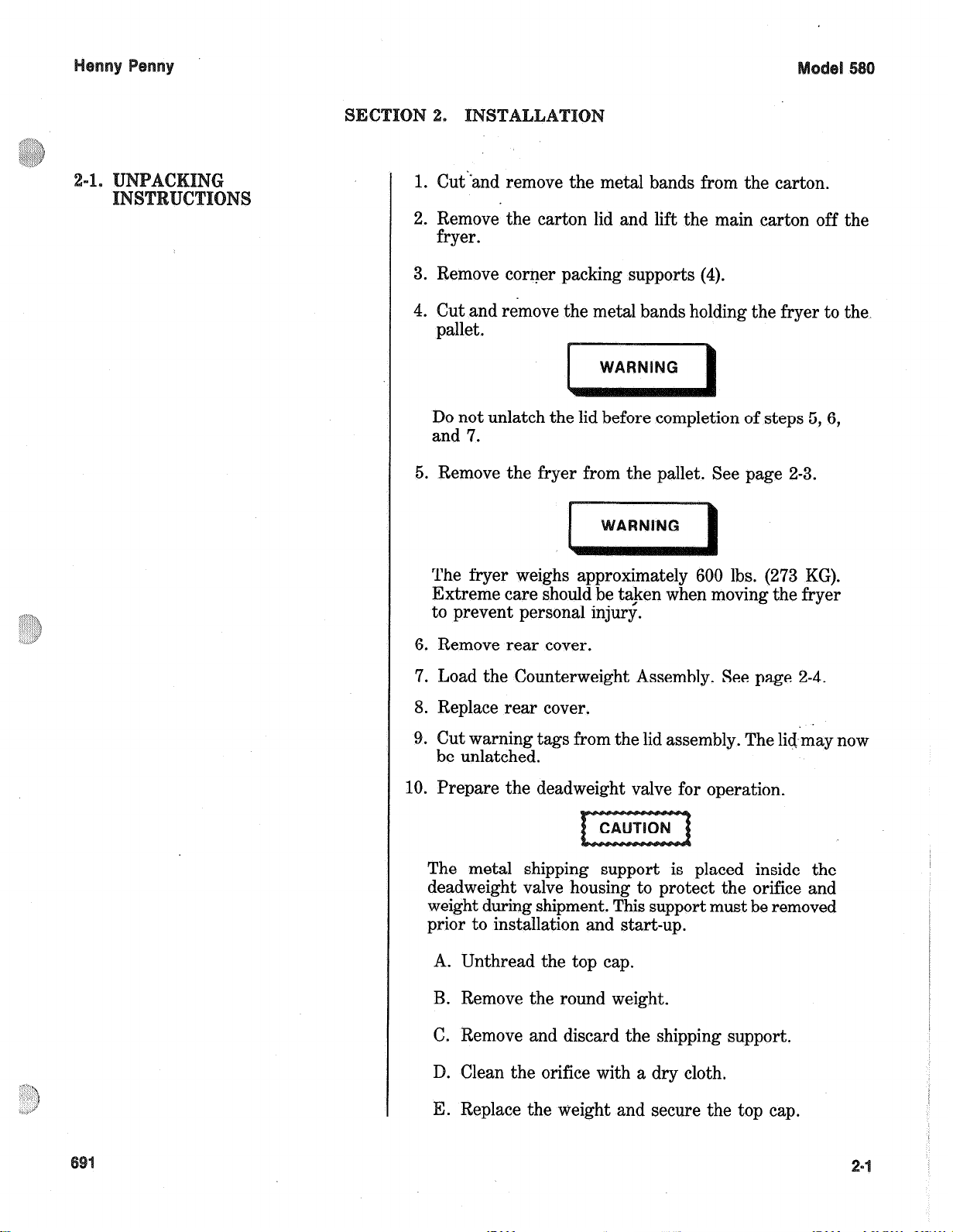

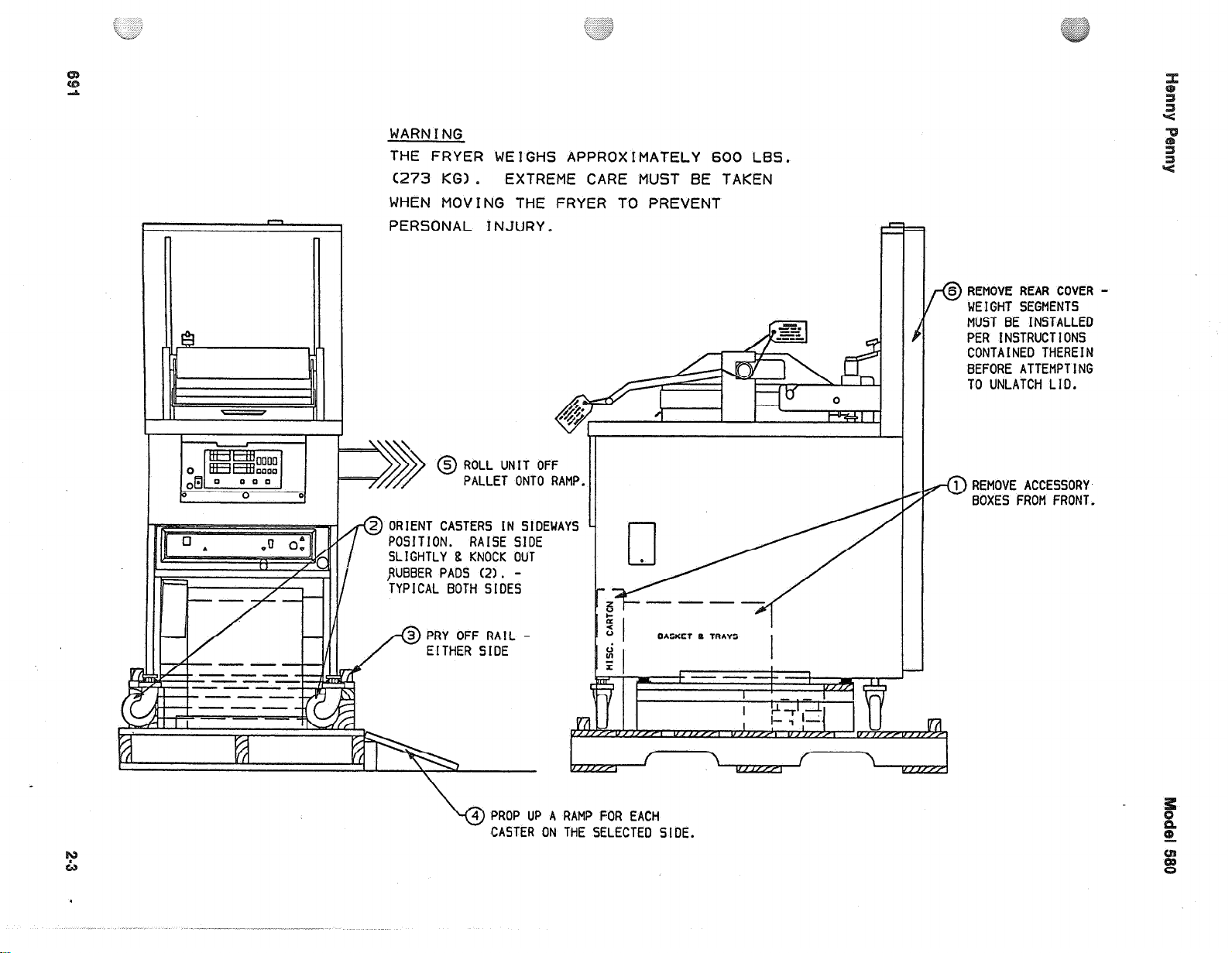

1. Cut‘&nd remove the metal bands from the carton.

2. Remove the carton lid and lift the main carton off the

fryer.

3. Remove corner packing supports (4).

4. Cut and remove the metal bands holding the fryer to the.

pallet.

Do not unlatch the lid before completion of steps 5, 6,

and 7.

5. Remove the fryer from the pallet. See page 2-3.

The fryer weighs approximately 600 lbs. (273 KG).

Extreme care should be taken when moving the fryer

to prevent personal injury.

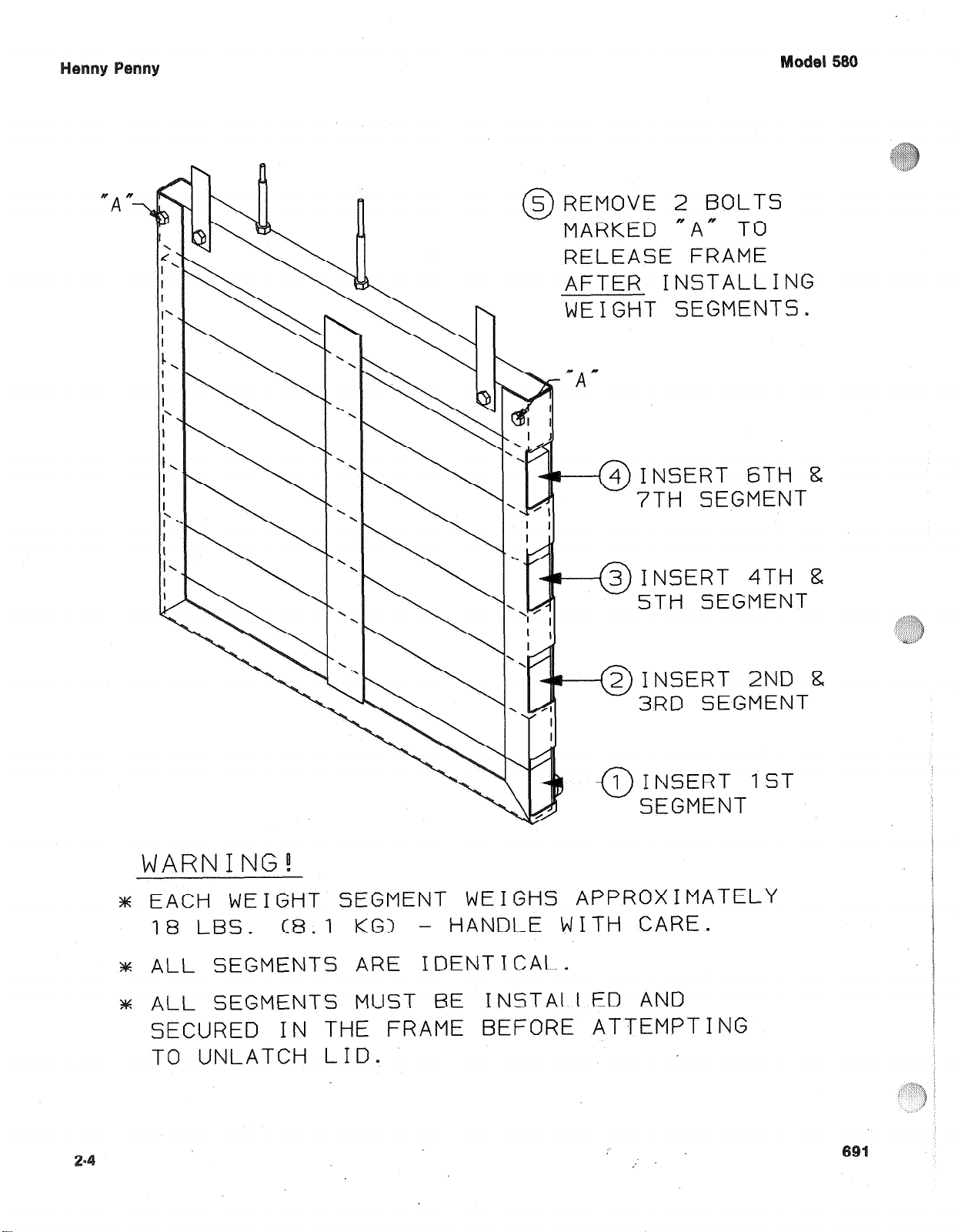

6. Remove rear cover.

7. Load the Counterweight Assembly. See page 2-4.

8. Replace rear cover.

9. Cut warning tags from the lid assembly. The lidmay now

be unlatched.

10. Prepare the deadweight valve for operation.

The metal shipping support is placed inside the

deadweight valve housing to protect the orifice and

weight during shipment. This support must be removed

prior to installation and start-up.

A. Unthread the top cap.

B. Remove the round weight.

C. Remove and discard the shipping support.

D. Clean the orifice with a dry cloth.

E. Replace the weight and secure the top cap.

11. Open lid and remove packing and racks from inside of

cookpot.

12. Remove the protective paper from the fryer cabinet. It

is necessary to clean exterior surface with a damp cloth.

WARN I NG

THE FRYER WEIGHS APPROXIMATELY 600 LBS.

CL273

WHEN MOVING THE FRYER TO PREVENT

PERSONAL INJURY.

KG) . EXTREME CARE MUST BE TAKEN

6 REMOVE REAR COVER -

0

WEIGHT SEGMENTS

MUST BE INSTALLED

PER INSTRUCTIONS

CONTAINED THEREIN

BEFORE ATTEMPTING

TO UNLATCH LID.

PALLET ONTO RAMP.

ORIENT CASTERS

SLIGHTLY 8 KNOCK OUT

,RUBEJER PADS (2). -

TYPICAL BOTH SIDE5

IN SIDEWAYS

PROP UP A RAMP FOR EACH

CASTER ON THE SELECTED SIDE.

1 REMOVE ACCESSORY

-0

BOXES FROM FRONT.

), “-

E 2 BOLTS

MARKED “A” TO

RELEASE FRAME

AFTER INSTALLING

WEIGHT

INSERT 6TH ti

7TH SEGMENT

INSERT 4TH !Z

STH SEGMENT

INSERT 2ND 5%

3RD SEGMENT

SEGMENTS.

INSERT IST

SEGMENT

WARNING!

x EACH WEIGHT SEGMENT

18 LBS.

m ALL SEGMENTS ARE IDENTICAL.

33~ ALL SEGMENTS MUST BE INSTALLED AND

SECURED

TO UNLATCH LID.

(8.1 KG> - HANDLE WITH CARE.

IN

THE FRAME BEFORE ATTEMPTING

WEIGHS

APPROXIMATELY

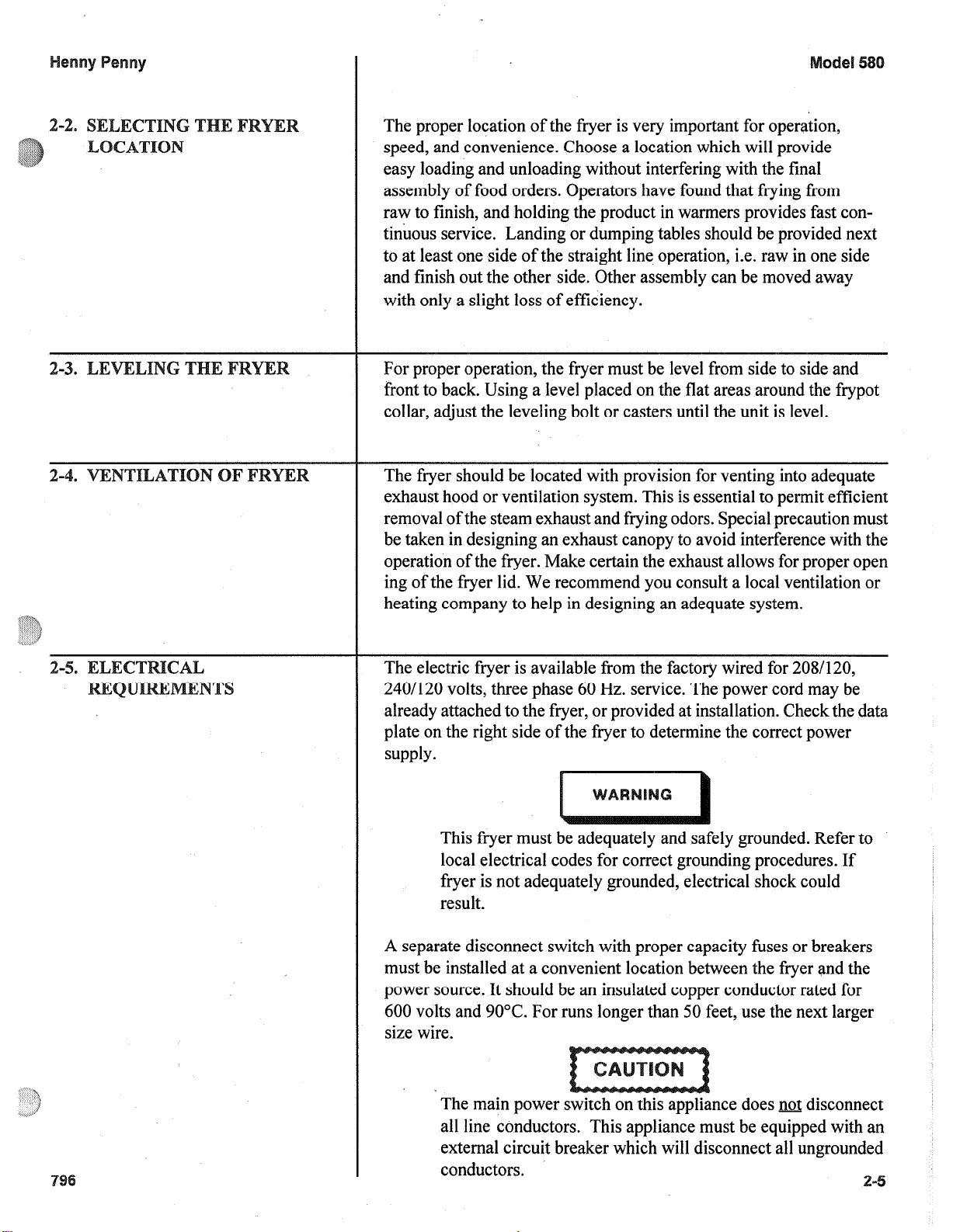

The proper location of the fryer is very important for operation,

speed, and convenience. Choose a location which will provide

easy loading and unloading without interfering with the final

assembly of food orders. Operators have found that frying from

raw to finish, and holding the product in warmers provides fast continuous service. Landing or dumping tables should be provided next

to at least one side of the straight line operation, i.e. raw in one side

and finish out the other side. Other assembly can be moved away

with only a slight loss of efficiency.

For proper operation, the fryer must be level from side to side and

front to back. Using a level placed on the flat areas around the frypot

collar, adjust the leveling bolt or casters until the unit is level.

The fryer should be located with provision for venting into adequate

exhaust hood or ventilation system. This is essential to permit efficient

removal of the steam exhaust and frying odors. Special precaution must

be taken in designing an exhaust canopy to avoid interference with the

operation of the fryer. Make certain the exhaust allows for proper open

ing of the fryer lid. We recommend you consult a local ventilation or

heating company to help in designing an adequate system.

The electric fryer is available from the factory wired for 208/120,

240/120 volts, three phase 60 Hz. service. The power cord may be

already attached to the fryer, or provided at installation. Check the data

plate on the right side of the fryer to determine the correct power

supply.

This fryer must

local electrical codes for correct grounding procedures. If

fryer is not adequately grounded, electrical shock could

result.

A separate disconnect switch with proper capacity fuses or breakers

must be installed at a convenient location between the fryer and the

power source. It should be an insulated copper conductor rated for

600 volts and 90°C. For runs longer than 50 feet, use the next larger

size wire.

The main power nce does not disconnect

all line conductors. This appliance must be equipped with an

external circuit breaker which will disconnect all ungrounded

conductors.

ly grounded. Refer to

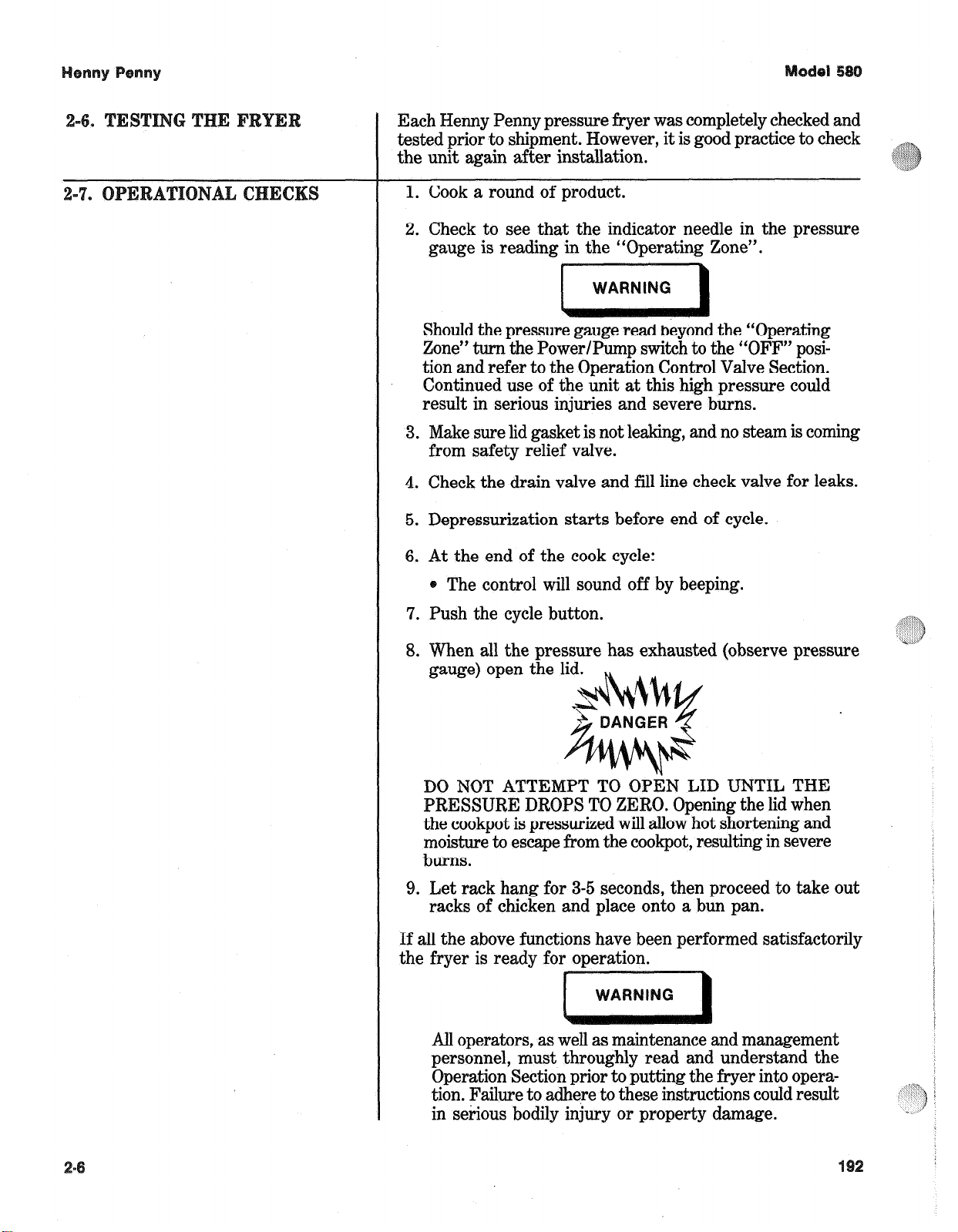

Each Nenny Penny pressure fryer was completely checked and

tested prior to shipment. However, it is good practice to check

the unit again after installation.

1. Cook a round of product.

2. Check to see that the indicator needle in the pressure

gauge is reading in the “Operating Zone”.

Should the pressure gauge read beyond the “Operating

Zone” turn the Power/Pump switch to the “OFF” position and refer to the Operation Control Valve Section.

Continued use of the unit at this high pressure could

result in serious injuries and severe burns.

3. Make sure lid gasket is not leaking, and no steam is coming

from safety relief valve.

4. Check the drain valve and fill line check valve for leaks.

5. Depressurization starts before end of cycle.

6. At the end of the cook cycle:

e The control will sound off by beeping.

7. Push the cycle button.

8. When all the pressure has exhausted (observe pressure

gauge) open the li

DO NOT ATTEMPT TO OPEN LID UNTIL THE

RESSURE DROPS TO ZERO. Opening the lid when

the cookpot is pressurized will allow hot shortening and

moisture to escape from the cookpot, resulting in severe

burns.

9. Let rack hang for 3-5 seconds, then proceed to take out

racks of chicken and place onto a bun pan.

If all the above functions have been performed satisfactorily

the fryer is ready for operation.

All operators, as well as maintenance and management

personnel, must throughly read and understand the

Operation Section prior to putting the fryer into operation. Failure to adhere to these instructions could result

in serious bodily injury or property damage.

Units being used outside the United States may not be shipped

with the power cord attached to the unit because of the

different wiring codes. The fryers are available from the

factory wired for 208,240,380 and 415 volts, 3 phase, 50 Hertz

service. A terminal block is mounted inside the fryer for the

cable wiring. A decal on the inside of the right side panel will

help in the wiring of the unit.

To install the power cord, follow these procedures:

1. Remove the side panel from the right side of the unit.

2. Remove the front panel, behind the filter knob and quick

disconnect.

3. Thread the cable through the strain relief on the junction

box.

4. Attach the wires to the terminal block according to the

wiring diagram on the side panel.

5. Pull the slack out of the cable and tighten the screws on

the strain relief.

6. Pull the slack out of the cable and secure it with the clamp

on the back of the cookpot.

Be sure the cable doesn’t sag, or it could interfere with

the use of the portable filter.

7. Pull the slack out of the cable and secure it with the clamp

on the frame, at the rear, right leg of fryer.

Be sure enough slack is out of the cable so it doesn’t

extend out past the portable filter stop bracket at the

bottom of the fryer frame. The cable could interfere

with the portable filter, not allowing it to be pushed

all the way in. This could cause hot shortening to spill

onto the floor.

8. Wiring the fryer is now complete.

FAILURE TO FOLLOW THESE INSTRUCTIONS CAN RESULT IN SHORTENING

OVERFLOWING THE COOKPOT, WHICH COULD CAUSE SERIOUS BURNS,

PERSONAL INJURY, FIRE AND/OR PROPERTY DAMAGE.

@

THE SHORTENING MAY

START UP PROCEDURE.

.

e

FILTER THE SHORTENING AT LEAST TWICE A DAY.

a

FILTER ONLY WHEN “COOL” IS DISPLAYED.

e

BRUSH ALL CRACKLINGS FROM COOKPOT SURFACES AND THE COLD

ZONE DURING THE FILTERING PROCESS.

b

MAKE SURE THE COOKER IS LEVEL.

BE CERTAIN THE SHORTENING IS NEVER ABOVE THE UPPER COOKPOT

“FILL” LINE.

0

USE RECOMMENDED PRODUCT LOAD SIZE IN BASKET.

FOR ADDITIONAL INFORMATION ON THESE INSTRUCTIONS REFER TO THE

HENNY PENNY SERVICE M L AND THE KFC CONFIDENTIAL

OPERATIONS MANUAL (,(C

NG THE MORNING

GE

Henny Penny Model 580

SECTION 3. OPERATION

3-1. OPERATING CONTROLS

1 Power/Pump Switch The Power/Pump Switch is a three way switch with center

"OFF" position. Move the switch to the position marked

"POWER" to operate the fryer. Move the switch to the

position marked "PUMP" to operate the optional portable

filter pump. These conditions are covered later in this section.

2 Frypot This reservoir holds the cooking shortening.

3 Cooking Rack This stainless steel rack consists of five shelves which

contain the food product during and after frying.

4 Lid Gasket The lid gasket provides the pressure seal for the frypot

chamber.

5 Deadweight Valve The dead weight style operating pressure relief valve is used

to maintain a constant level of steam pressure within the

frypot. Any excess steam pressure is vented through the

exhaust stack.

6 Safety Relief Valve The safety relief valve is an ASME approved spring loaded

valve set at 14.5 psi. In the event the operation valve

becomes obstructed, this safety valve will release excess

pressure, keeping the frypot chamber at 14.5 psi. If this

occurs, turn the Power/Pump switch to the "OFF" position to

release all pressure from the frypot.

7 Safety Relief Valve THE RING IS NOT TO BE PULLED.

Ring

Severe burns from the steam will result.

8 Pressure Gauge The pressure gauge indicates the pressure inside the cookpot.

402 3-1

Henny Penny Model 580

9 Solenoid Valve The solenoid valve is an electro-mechanical device that

causes pressure to be held in the frypot.

The solenoid valve closes at the beginning of the frying cycle

and is opened automatically at the end of the frying cycle. If

this valve should become dirty or the teflon seat nicked,

pressure will not build up and it must be repaired per the

maintenance section.

10 Drain Valve The drain valve is a two-way ball valve. It is normally in the

closed position. Pull the knob out to drain the shortening

from the frypot into the filter drain pan.

DO NOT OPEN THE DRAIN VALVE WHILE

FRY POT IS UNDER PRESSURE. Hot shortening

will exhaust from this valve. Severe burns will result.

11 Drain Interlock The drain interlock switch is a microswitch that provides

Switch protection for the frypot in the event an operator

inadvertently drains the shortening from the frypot while the

main switch is in the POWER position. The switch is

designed to automatically shut off the heat when the drain

valve is opened.

12 Condensation The condensation drain pan is the collection point for the

Drain Pan condensation formed within the steam exhaust

system. It must be removed and emptied periodically.

3-2 402

Henny Penny Model 580

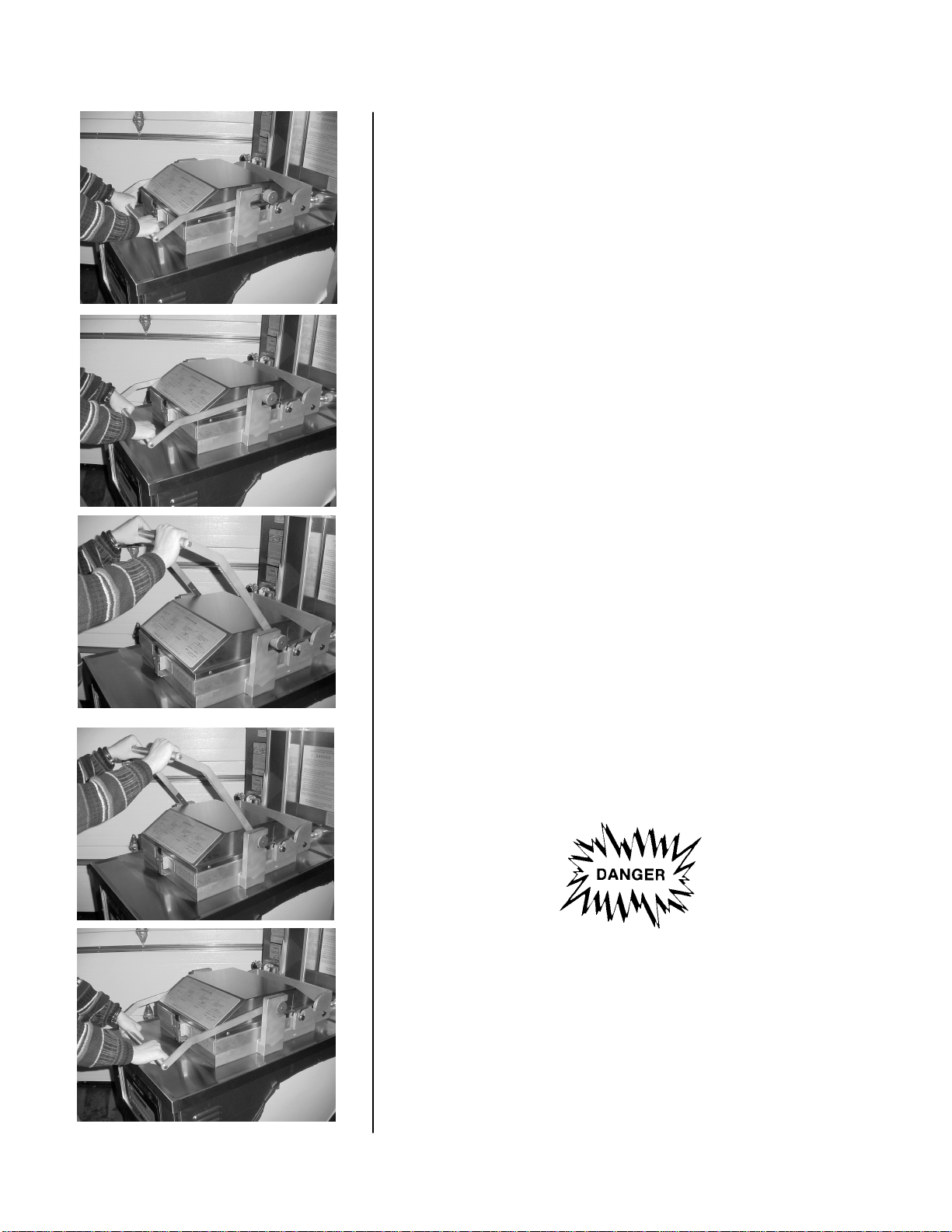

3-2. LID OPERATION

To close lid:

1. Lower the lid until lid latches into place.

1

2. Pull lid handle forward until it stops.

2 3. Lift up on the lid handle until it stops.

3

4

5

4. Bring lid handle out towards

you until it stops.

5. Push lid handle down, locking lid in place.

DO NOT ATTEMPT TO OPEN LID UNTIL THE

PRESSURE DROPS TO ZERO. Lid is locked when fryer

is under pressure. Do not attempt to force the lid latch or

open the lid while under pressure. Opening the lid when

the cookpot is pressurized will allow hot shortening and

moisture to escape from the cookpot, resulting in severe

burns.

501 3-3

Henny Penny Model 580

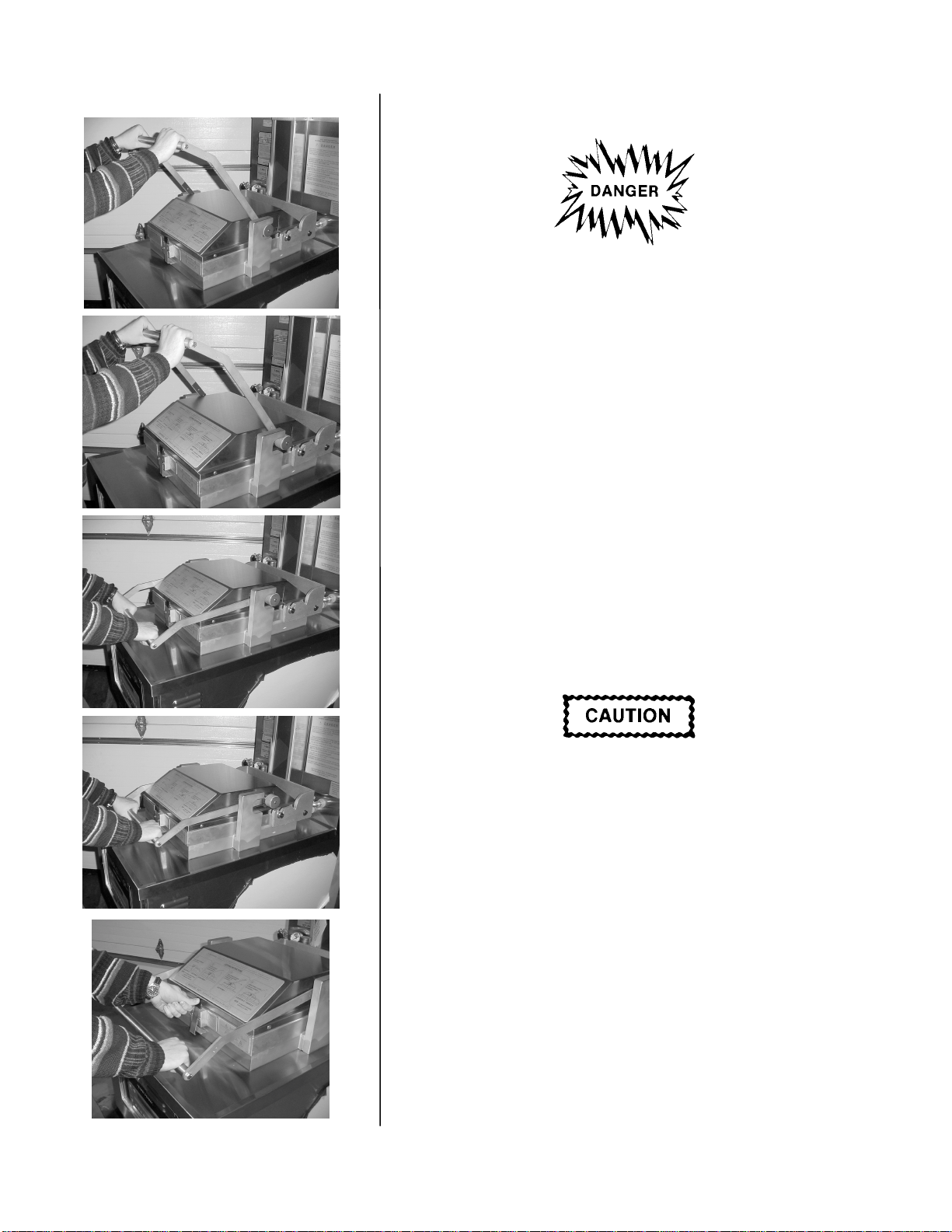

3-2. LID OPERATION (Continued) To open lid:

DO NOT ATTEMPT TO OPEN LID UNTIL THE

1 PRESSURE DROPS TO ZERO. Lid is locked when fryer

is under pressure. Do not attempt to force the lid latch or

open the lid while under pressure. Opening the lid when

the cookpot is pressurized will allow hot shortening and

moisture to escape from the cookpot, resulting in severe

burns.

1. Gently raise handle until it stops.

2

2. Push handle back until it stops.

3. Lower handle.

3

DO NOT raise the lid with the handle in the up position.

Lower the handle before attempting to raise the lid, or

damage to the lid could result.

4

4. Push handle back.

5. Unlatch the front lid latch and raise lid with handle.

5

3-4 501

If the shortening is below 185 “F (85 “6) with the Power/Pump

Switch in the “Power” position, the fryer will enter the melt

cycle. The shortening is heated slowly to prevent scorching

of the shortening. The display will read “LO” and the heat

will cycle, 10 seconds on, 30 seconds off, to ensure slow melting

of shortening. No other buttons on the control panel will

operate except the Power/Pump Switch.

Should you require outside assistance, just call

1-300-543-6243, or Ohio, l-800-762-2964.

1. It is recommended that a high quality frying shortening

be used in the pressure fryer. Some low grade shortenings have a high moisture content and will cause foaming

and boiling over.

2. If a solid shortening is used, it can be melted into a liquid

first, then poured into the cookpot. Attempting to melt

solid shortening in the cookpot may cause burning or

scorching of the fresh shortening.

GLOVES SHOULD BE WORN AND CARE MUST

E TAKEN WHEN POURING HOT SHORTENING.

Severe burns could result. Also, when adding fresh

shortening to existing shortening, care must be taken

to avoid splashing or severe burns could result.

3. The electric model requires 100 lbs. The pot has three level

indicator lines inscribed on the rear wall of the eookpot

which show when the heated shortening is at the proper

level.

4. Cold shortening should be filled to l/z inch below lower

indicator.

3-5

The Henny Penny Electric 8 Head Fryer must be cleaned and

the shortening must be cleaned and polished at least twice

daily; after lunch rush and at the end of the day.

Shortening should be filtered immediately following a

cook cycle when the shortening temperature is at or

below low heat; less than 270 “F. DO NOT DRAIN THE

SHORTENING IF IT IS AT DROP TEMPERATURE.

The high temperature can cause cracklings to burn on

the steel cookpot surfaces after the shortening has

drained.

Filter only when “COOL” is

displayed.

Failure to do

so can result in shortening overflowing the cookpot,

causing serious burns, personal injury, fire and/or

property damage.

If volume dictates, cleaning may be required more often. Part

of the process involves removing cracklings from the cold zone

of the cookpot. High volume cooking could cause the cold zone

to fill quicker with cracklings, and if so, cleaning would be

required. SURFACES OF FRYER AND COOK BASKET

WILL BE EXTREMELY HOT. USE CARE NOT TO GET

BURNED.

1. Turn power/pump switch OFF before draining shortening.

2. Roll filter unit under fryer and lock in place.

The filter unit must be as far back under fryer as it

will go, and latched into place. If not fully seated and

latched, the hole in the filter tank cover will not be

directly under the drain. This will cause splashing of

shortening and could result in severe burns.

3-6

Leave filter hose connected to the filter tank and plug the

filter power cord into fryer outlet.

3. Remove cooking basket and wipe bottom of lid. Tilt lid

out of the way to clean cookpot.

397

4. Lift up drain handle safety latch and pull handle out to

open drain valve. Use L-shaped brush to clean cracklings

from elements (electric fryer only) and from sides and

bottom of cookpot as shortening drains. Use straight brush

to push cracklings through drain opening in bottom of

cookpot if necessary.

Brush ALL cracklings from cookpot surfaces and the

cold zone during the filtering process. Failure to do so

can result in shortening overflowing the cookpot, which

could cause serious burns, personal injury, fire and/or

property damage.

5. Turn power/pump switch to PUMP to circulate shortening

in filter tank. Polish for 5 (five) minutes.

6. Scrape cracklings and crackling ring from cookpot and

discard. DO NOT let cracklings drain into filter tank. These

cracklings can cause a burned taste in gravy. Wipe all

surfaces with a clean damp towel. If water drops into cold

zone, dry with towel before pumping shortening back into

cookpot.

7. Turn power/pump switch of OFF, and connect filter hose

to cookpot fill line. Lower lid and use swing lock pin to

hold lid in lower position to keep shortening from splashing

out of cookpot. Turn power/pump switch to PUMP, and

close drain valve by pushing handle in all the way.

8. ‘When all shortening has been pumped into cookpot turn

power/pump switch OFF.

If the fryer has the FAST controls, see the FAST

operation manual.

66

The display will read

“LO” anytime the shortening

temperature is below 250°F. When the Power/Pump Switch

is placed in the “Power” position, the control will begin a melt

mode which cycles the heat on and off. This slowly melts/heats

the shortening until the temperature reaches 185°F (85°C).

This heat stays on until the “COOL” mode is reached, or until

reaching the temperature of the selected cooking cycle.

After cooking or filtering the shortening, the temperature will

automatically go into the “COOL” mode which keeps shortening at 250°F (121°C). This temperature extends the shortening life and minimizes the time needed to heat the shortening

for the next cook cycle. Press “Exit Cool” to leave the “Cool”

mode, then press product button for the cook cycle desired.

To manually place the controls in the “COQL” mode, start a cooking cycle, and then press the cycle button again. The display

should then show “COOL”. See Cycle Selection below.

Although the display will read “COOL” in the standby mode, the shortening is hot and could cause burns.

Select the cook cycle by pressing the button for the number

of heads, or product, to be cooked. Shortening will then heat to

“Drop” temperature.

Pressing the same’button again will begin the cook cycle. The

indicator will change from “Drop” to counting down the cook time

in minutes and seconds.

At the end of the cook cycle, press the same button again when

the indicator reads “Done” and the alarm sounds. The fryer will

reset to the “Cool” mode.

This is a four (4) digit LED type display which shows the

remaining cook time during cook cycles and also the shortening temperature on demand from the operator.

The heat light will illuminate whenever the control calls for

heat. When setpoint temperature has been reached the heat

light will go off.

The display will read “HI” if the shortening temperature is

40” above the setpoint.

The display will read “Drop” when the shortening has reached

the setpoint temperature (-I- 4” to -2O).

The display will read “Done” at the end of the cook cycle.

This button allows the operator to read the temperature of

the shortening while in a cook cycle. The display range is from

256°F (124°C) to 390°F (199°C).

With the Power Switch in the “Power” position, the mode is

selected depending on the temperature of the shortening.

1. If pot temperature is below the melt temperature of 185 “F

(85 “C) the fryer will enter the melt mode. Display will read

“LO”.

2. If the pot temperature is 185°F ($5 “6) or higher, the

control will regulate the programmed temperature of the

selected cycle.

3. The temperature will be regulated at 250 “F (121 “C), if the

“Exit Cool” button is pressed during heat up. The display

will read “COOL”.

Although the display will read “COOL” in the standby mode, the shortening is hot and could cause burns.

When the operator wishes to filter, move the Power Switch

to the “OFF” position and filter as usual (refer to filter instructions). The display should read “COOL” before filtering.

To avoid personal injuries or property damage be sure

shortening has been pumped back into the cookpot

before depressing the “EXIT COOL” switch. Unit will

enter heat mode:

397

3-9

The filter pump motor on the PF-180 is equipped with

a manual reset button in the event the motor’s thermal

protection actuates. This reset button is located on the

rear of the motor. A hinged door is placed on the motor

cover to easily access this reset button. Wait approximately 5 minutes before attempting to reset this

protective device. Also, some effort must be used when

resetting the button and a definite “click” will be heard

when it resets.

To prevent burns caused by splashing shortening, the

unit’s main power switch must be in the “OFF” position

before resetting the filter pump motor’s manual reset

protection device.

The pump motor and the combustion air motor are

permanently lubricated and need no maintenance.

Failure of brushing all cracklings from the cookpot and

cold zone and putting the controls in the “COOL” mode

before filtering can result in shortening overflowing

the cookpot. This could cause serious burns, personal

injury, fire and/or property damage.

The following procedures should be followed on the initial startup of the fryer each time the fryer is brought from a cold, or

shut down condition, back into operation;

1. Make sure the shortening is filled to the proper level in the

cookpot - l/2 inch below lower indicator.

Be certain the shortening is never above the upper

cookpot “fill” line. Failure to follow these instructions

can result in shortening overflowing the cookpot which

could cause serious burns, personal injury, fire and/or

property damage.

397

2. Turn Power/Pump Switch to the “Power” position, then

select the product to be cooked.

3. Stir the shortening as it’s heating up from a “cold” start.

Be sure to stir down into the cold zone.

Do not stir the shortening at any other time except at

initial “cold” start-up. Failure to follow these instructions can result in shortening overflowing the cookpot

which could cause serious burns, personal injury, fire

and/or property damage.

4. Slide cook basket into rails of lid and push the basket back

into the lid as far as it will go.

5. After the product has been loaded onto the basket, the lid

can be lowered, immersing the product into the shortening when the display indicates the shortening is at the

correct temperature.

After the initial installation of the fryer, as well as before every

change of shortening, the cookpot should be thoroughly cleaned

as follows:

1. Turn the main power switch to “OFF”

The filter drain pan must be in position under the drain

valve to prevent splashing or spilling of hot liquids.

Failure to do so will result in splashing and severe

burns.

2. If hot shortening is present in the cookpot, it must be

drained by slowly pulling the drain valve knob.

3. Close the drain valve and discard the shortening.

4. Lower the lid to the lid stop bracket and tilt lid back, so

that the lid won’t interfere with cleaning.

5. Refer to KFC’s COM on cleaning instructions.

NEVER PRESSURIZE FRYER TO CLEAN. Leave the lid open.

Water under pressure is super heated and will cause severe burns

if it comes in contact with skin.

Never heat the cleaning solution to the boiling point. If the clean-

ing solution in the cookpot starts to foam and boil over, immediately move the main power switch to OFF. DO NOT TRY TO

CONTAIN IT BY CLOSING THE FRYER LID, or severe burns

could result.

Do not use steel wool, other abrasive cleaners or

cleaners/sanitizers containing chlorine, bromine, iodine,

or ammonia chemicals, as these will deteriorate the

stainless steel material and shorten the life of the unit.

Make sure the inside of the cookpot. the drain valve opening,

and all parts that come in contact with the new shortening are

dry as possible. Refill the fryer with fresh shortening.

397 .

This section provides troubleshooting information in the form

of an easy to read table.

If a problem occurs during the first operation of a new fryer,

recheck the installation per the Installation Section of this

manual.

efore troubleshooting, always recheck the operation pro-

cedures per Section 3 of this manual.

To isolate a malfunction, proceed as follows:

1. Clearly define the problem (or symptom) and when it

occurs.

2. Locate the problem in the Troubleshooting table.

3. Review all possible causes. Then, one-at-a-time work

through the list of corrections until the problem is solved.

4. Refer to the maintenance procedures in the

Section to safely and properly make the checkout and

repair needed.

If maintenance procedures are not followed correctly,

injuries and/or property damage could result.

’

1

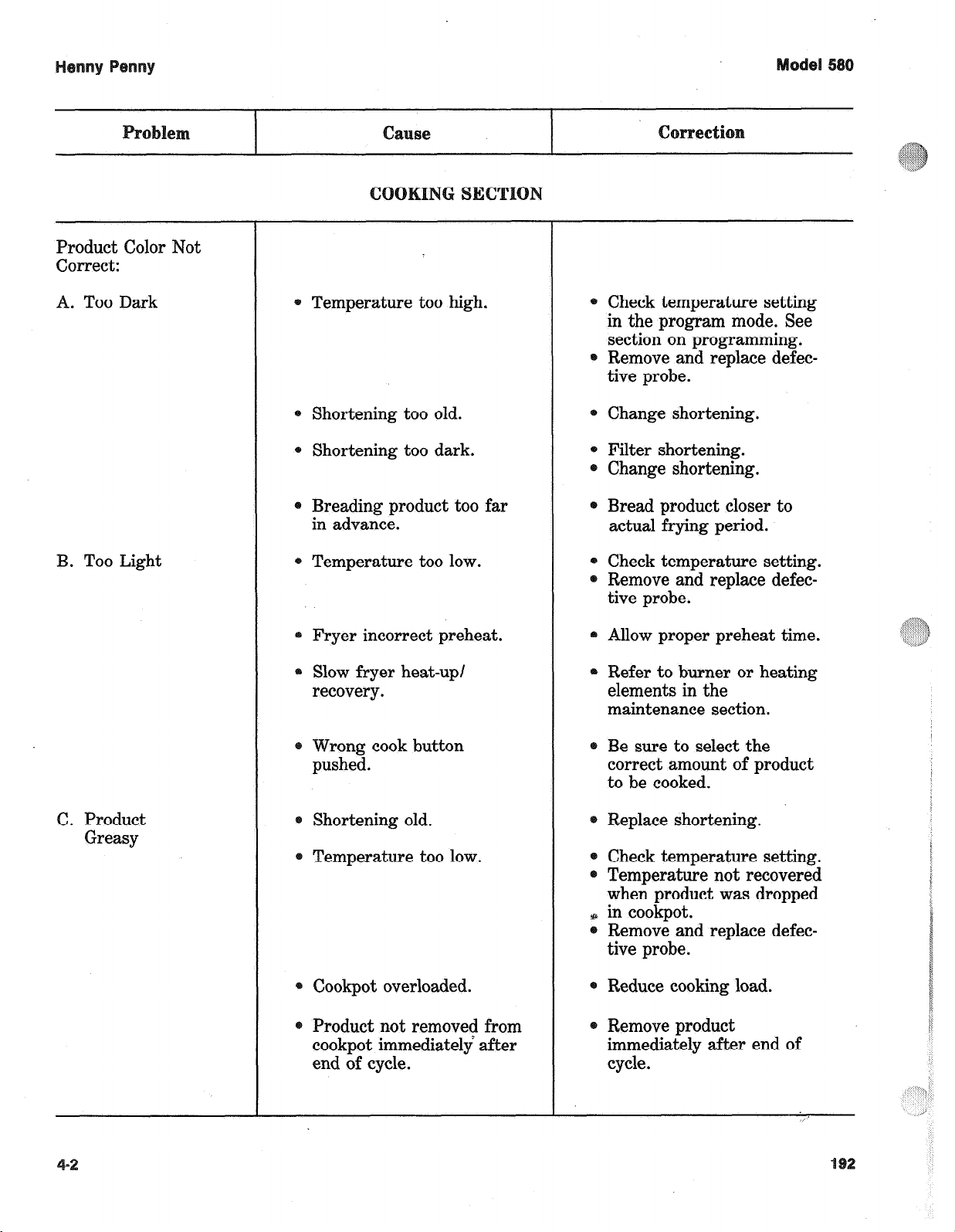

Product Color Not

Correct:

A. Too Dark

B. Too Light

Temperature too high.

@ Shortening too old.

0 Shortening too dark.

Breading product too far

in advance.

Temperature too low.

Fryer incorrect preheat.

Slow fryer heat-up/

recovery.

Wrong cook button

pushed.

Check temperature setting

in the program mode. See

section on programming.

Remove and replace defective probe.

Change shortening.

Filter shortening.

Change shortening.

@ Bread product closer to

actual frying period.

@ Check temperature setting.

Remove and replace defective probe.

@ Allow proper preheat time.

Refer to burner or heating

elements in the

maintenance section.

Be sure to select the

correct amount of product

to be cooked.

C. Product

Greasy

Shortening old.

Temperature too low.

Cookpot overloaded.

Product not removed from

eookpot immediately after

end of cycle.

eplaee shortening.

Check temperature setting.

Temperature not recovered

when product was dropped

e in cookpot.

@ Remove and replace defec-

tive probe.

* Reduce cooking load.

Remove product

immediately after end of

cycle.

Loading...

Loading...