Henny Penny 580 User Manual

This section provides procedures for the checkout and replacement of the various parts used within the fryer. Before replacing any parts, refer to the Troubleshooting section. It will aid

you in determining the cause of the malfunction.

This section is arranged in groupings of the components that

work together within the fryer. The general groups are listed

below.

Removing the Control Panel

Probe

Electrical Components

Control Board

Pressure System

1. You may want to use a multimeter to check the electric

components.

2. When the manual refers to the circuit being closed, the

multimeter should read zero unless otherwise noted.

3. When the manual refers to the circuit being open, the

multimeter will read infinity.

4. The weights can be removed from the frame to easily

access the rear of cooker.

The following electrical components are described in this

section.

1. High Limit

2. Fuse Holders

3. Power/Pump Switch

4. Contactors

5. Heating Elements

6. Temperature Probe

7. Complete Control Panel Henny Penny

This high temperature control is a manual reset control which

senses the temperature of the shortening. If the shortening

temperature exceeds 420°F (215OC), this control switch will

open and shut off the heat to the cookpot. When the

temperature of the shortening drops to a safe operation limit,

the control must be manually reset. The reset button is located

above the filter knob in the front of the cooker. This will allow

heat to be supplied to the cookpot.

Before replacing a high temperature limit control, check to

see that its circuit is closed.

The shortening temperature must be below 380°F

(193°C) to accurately perform this check.

1. Remove electrical power supplied to the fryer.

Remove electrical power supplied to the fryer by

unplugging the unit, or by turning off the wall circuit

breaker or electrical shock could result.

2. Remove the control panel.

3. Remove the two electrical wires from the high

temperature limit control.

4. Manually reset the control, then check for continuity

between the two terminals after resetting the control. If

the circuit is open, replace the control, then continue with

this procedure. (If the circuit is closed, the high limit.is

not defective. Reconnect the two electrical wires.)

Remove electrical power supplied to the fryer by

unplugging the unit, or by turning off the wall circuit

breaker or electrical shock could result.

1. If the tube is broken or cracked, the control will open, shutting off electrical power. The control cannot be reset.

2. Drain shortening from the cookpot and discard. A

substance in the tube could contaminate the shortening.

3. Remove control panel.

4. Loosen small inside screw nut on capillary tube.

5. Remove capillary bulb from bulb holder inside the cookpot.

6. Straighten the capillary tube.

7. Remove larger outside nut that threads into pot wall.

8. Remove the two nuts securing the high limit bracket at

the front of the fryer, and remove bracket.

9. Remove the two screws that secure high limit to the high

limit bracket.

10. Remove defective control from control panel area.

Il. Insert new control and replace screws.

12. Uncoil capillary line, starting at capillary tube, and insert

through cookpot wall.

To avoid electrical shock or other injury, the capillary

line must run under and away from all electrical power

wires and terminals. The tube must NEVER be in such

a position where it could accidentally touch the electrical power terminals.

13. Carefully bend the capillary bulb holder on heating

elements.

14. Slip capillary bulb into bulb holder located on heating

elements. Pull excess capillary line from pot and tighten

nut into cookpot wall.

Be sure capillary bulb of high limit is positioned as not

to interfere with carrier or when cleaning the cookpot

wall, or damage to capillary tube could result.

With excess capillary line pulled out, tighten smaller nut.

15.

16. Replace front panel.

17. Refill with shortening.

There are two fuse holders on each model of the electric fryers.

There are no fuse holder assemblies for the gas models other

than that at the main power source.

Remove electrical power supplied to the fryer by

unplugging the unit, or turning off the wall circuit

breaker or electrical shock could result.

CONTROL PANEL FUSES 3 Phase Check from #54 to #55

and #68 to #69 on fuse assembly, or the fuse can be removed

to check for a closed circuit. If not, replace the fuse (HP#

EF02-007).

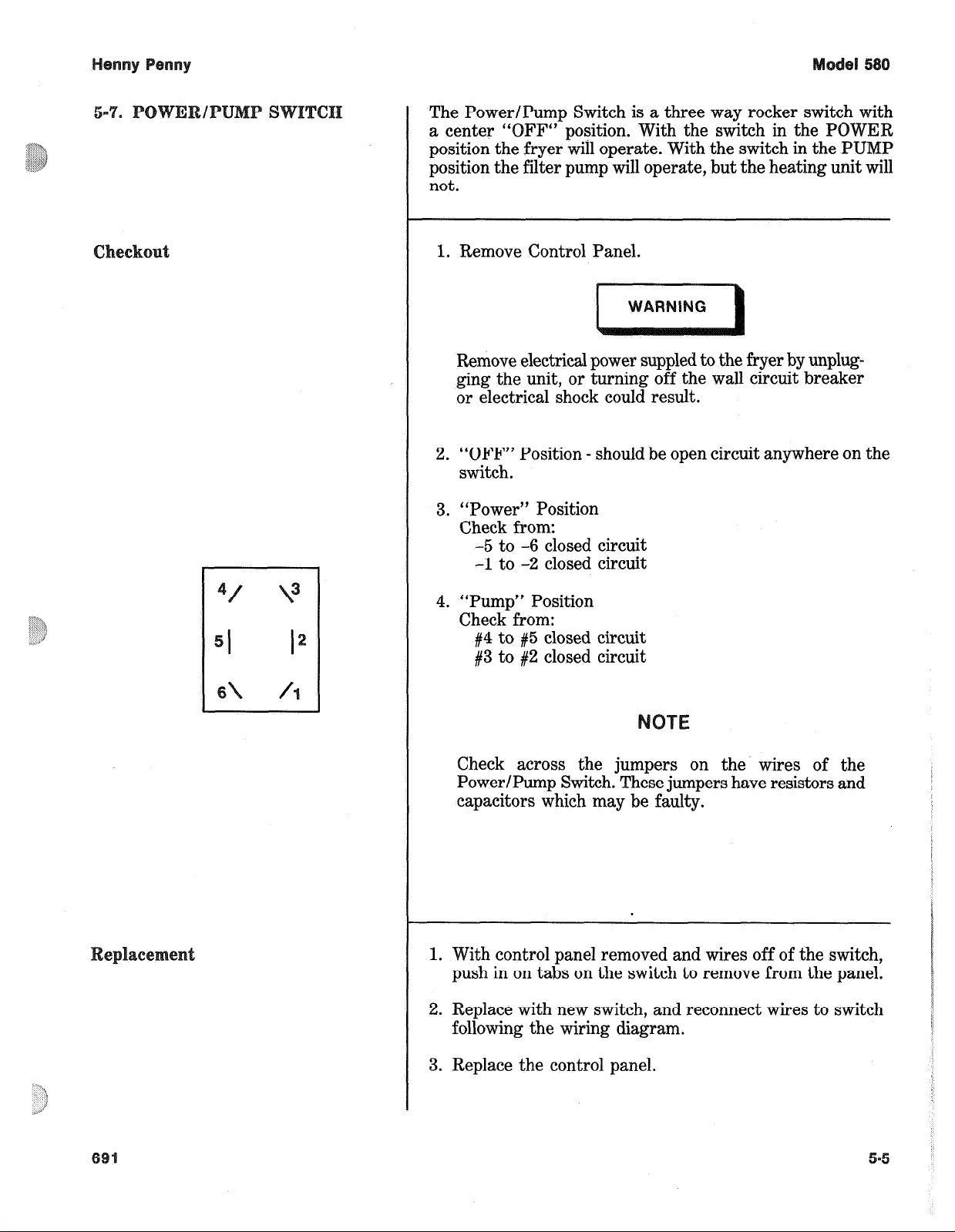

The Power/Pump Switch is a three way rocker switch with

a center “OFF“ position. With the switch in the POWER

position the fryer wiil operate. With the switch in the PUMP

position the filter pump will operate, but the heating unit will

not.

1. Remove Control Panel.

Remove electrical power suppled to the fryer by unplugging the unit, or turning off the wall circuit breaker

or electrical shock could result.

2. “OFF” Position - should be open circuit anywhere on the

switch.

3. “Power” Position

Check from:

-5 to -6 closed circuit

-1 to -2 closed circuit

4. “Pump” Position

Check from:

#4 to #5 closed circuit

#3 to #2 closed circuit

Check across the jumpers on the wires of the

Power/Pump Switch. These jumpers have resistors and

capacitors which may be faulty.

1. With control panel removed and wires off of the switch,

push in on tabs on the switch to remove from the panel.

2. Replace with new switch, and reconnect wires to switch

following the wiring diagram.

3. Replace the control panel.

Primary

The electric fryer requires two switching contactors:

a primary

contactor and a heat contactor. The primary contactor

energizes (contacts close) any time the Power/Pump Switch

is in the “Power” position and the temperature of the pot is

below 420°F (215OC). The hi limit will cut the power at the

primary contactor if temperatures in the cookpot exceed 420° F

(215O 6). The primary contactor supplies power to one side of

the heat contactors.

The heat contactor is controlled by the computer controller.

en the controller calls for heat, the heat contactor applies

power to one side of the heating elements. When the heat

contactor and the primary contactor are energized (contacts

closed), the electric heating elements heat the shortening.

Heat

1. Remove electrical power supplied to the fryer.

Remove electrical power supplied to the fryer by

unplugging the unit, or turning off the wall circuit

breaker or electrical shock could result.

2. Remove the control panel.

3. Perform a check on both contactors as follows:

E?SL

L3 - L3

L2 - L2

Ll - Ll

Its

Open Circuit

Open Circuit

Open Circuit

4. Check across the coil terminals:

Standard Contactor - 415 ohms

Mercury Contactor - 1500 ohms

The following checks, are performed with the wall

circuit breaker on, and the Power/Pump Switch in the

ower” position. Extreme caution should be taken.

ake connections before applying power, take reading,

and remove power by unplugging the power cord, or

by turning off the wall circuit breaker, before removing meter leads or electrical shock could result.

ith power re-applied and in a heat-up mode, check the

5.

power going to both contactor coils. This is to be sure

power is going to the contactors.

If no voltage is found going into the coils, the

and drain switch for the primary contactor.

Section.) For the heat contactor, check wi

If either contactor is defective it must be replaced as follows:

Remove electrical power supplied to the fryer by

unplugging power cord or turning off the wall circuit

breaker, or electrical shock could result.

emove only those wires directly connected to the

contactor being replaced. Label the wires.

2. Remove the two mounting screws on the base plate and

remove standard contactor (primary). Proceed to step 5.

3. Remove the two nuts securing the mercury contactor

bracket to the base plate and remove bracket.

4. move the two screws securing the mercury contactor

the bracket and remove contactor.

5. Install new contactor in reverse order of previous steps.

nstall control panel.

econnect power to fryer and test the fryer for proper

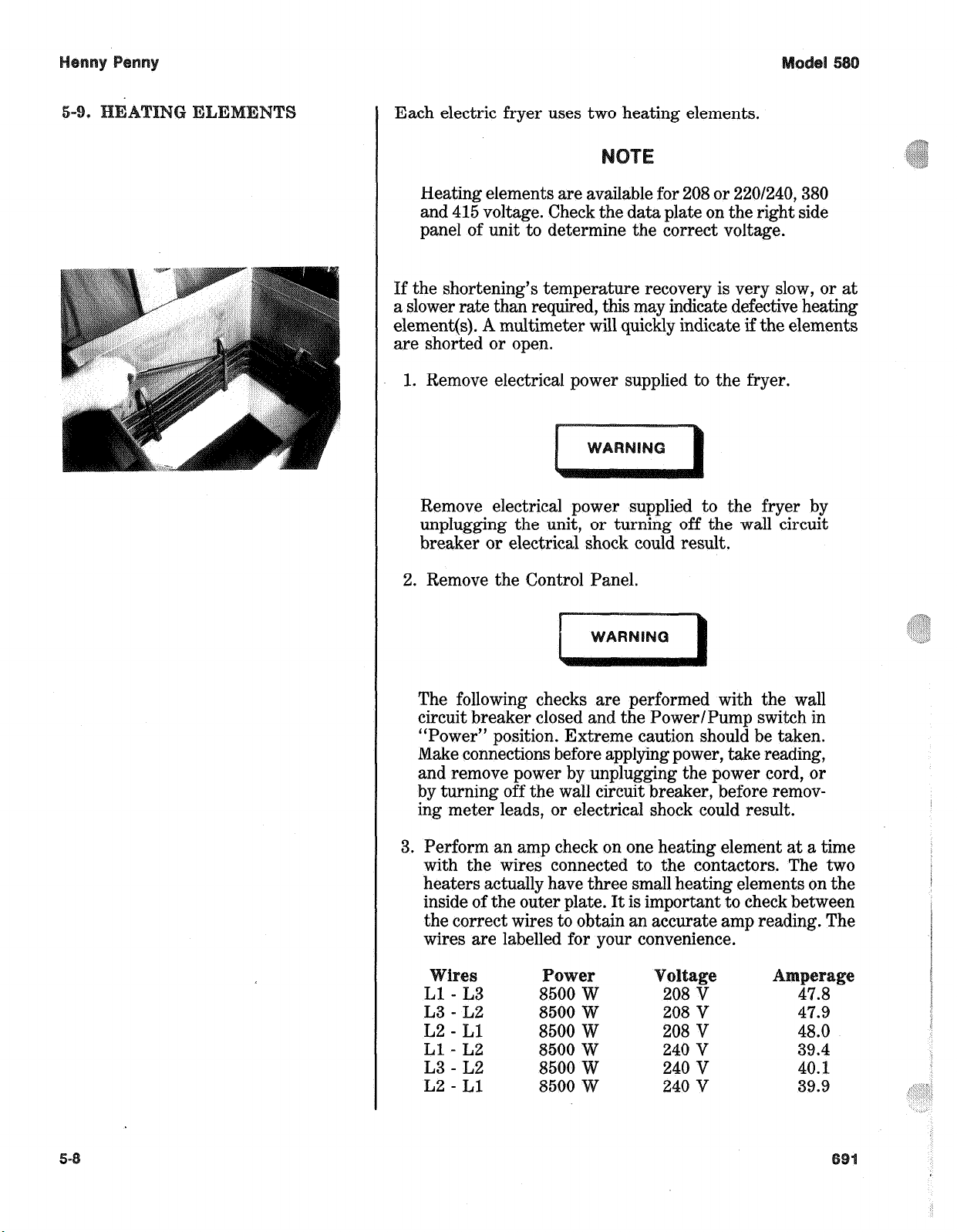

Each electric fryer uses two heating elements.

Heating elements are available for 208 or 220/240,380

and 415 voltage. Check the data plate on the right side

panel of unit to determine the correct voltage.

If the shortening’s temperature recovery is very slow, or at

a slower rate than required, this may indicate defective heating

element(s). A multimeter will quickly indicate if the elements

are shorted or open.

1. Remove electrical power supplied to the fryer.

Remove electrical power supplied to the fryer by

unplugging the unit, or turning off the wall circuit

breaker or electrical shock could result.

2. Remove the Control Panel.

The following checks are performed with the wall

circuit breaker closed and the Power/Pump switch in

“Power” position. Extreme caution should be taken.

Make connections before applying power, take reading,

and remove power by unplugging the power cord, or

by turning off the wall circuit breaker, before removing meter leads, or electrical shock could result.

3. Perform an amp check on one heating element at a time

with the wires connected to the contactors. The two

heaters actually have three small heating elements on the

inside of the outer plate. It is important to check between

the correct wires to obtain an accurate amp reading. The

wires are labelled for your convenience.

ower

47.3

47.9

48.0

39.4

40.1

39.9

L3 - L2

L2 - Ll

Ll - L2

L3 - L2

L2 - Ll

8500 w

8500 w

8500 w

8500 w

8500 w

8500 w

203 v

208 v

208 V

240 V

240 V

240 V

Loading...

Loading...