Henny Penny 561 Operation Manual

Model 500/561/600

SECTION 3. OPERATING INSTRUCTIONS

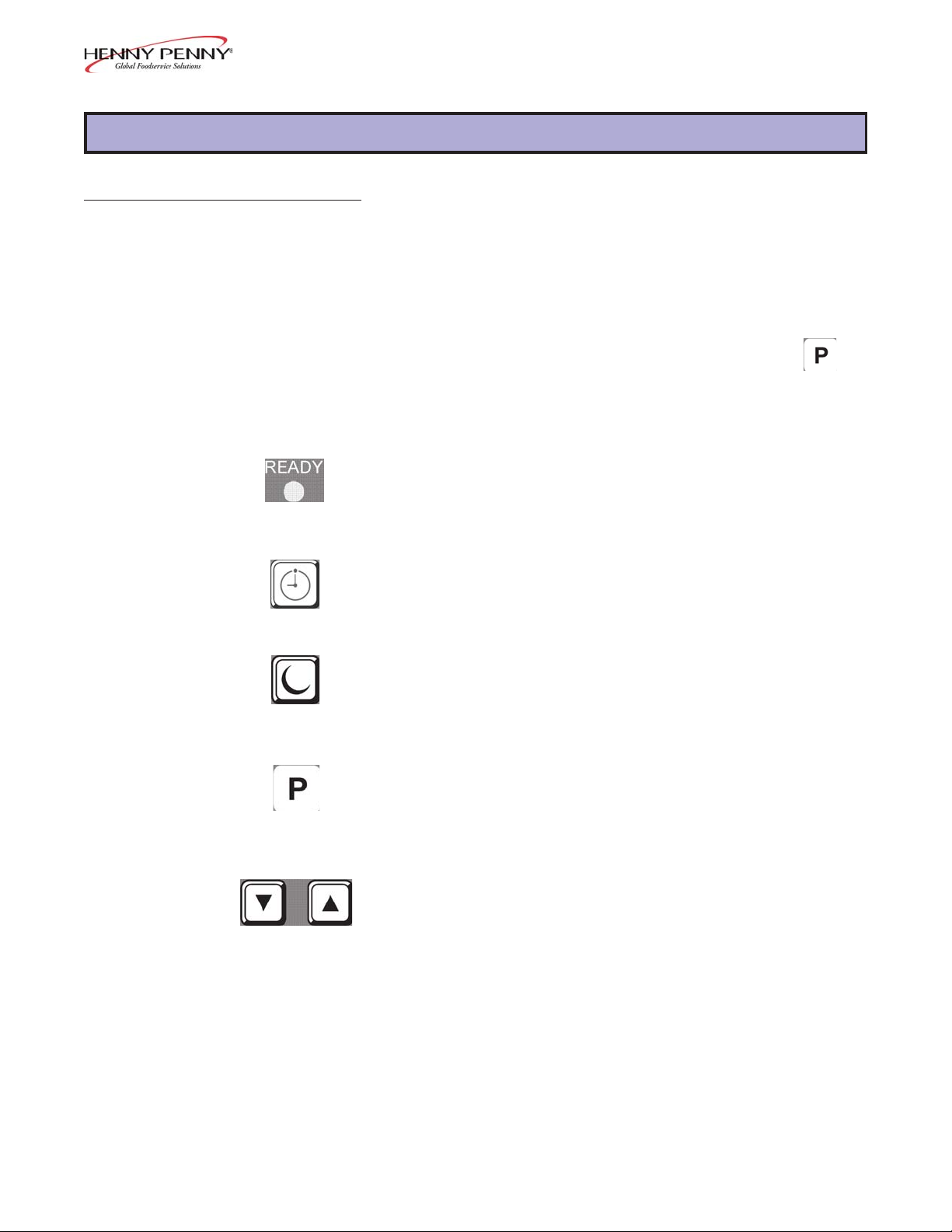

3-1. OPERATING COMPONENTS C1000 Controls - Reference Figure 3-1.

Fig. Item Description Function

No. No.

3-1 1 Digital Display Shows the shortening temperature, the timer countdown in

the Cook Cycle, and the selections in the Program Mode; the

temperature of the shortening can be shown by pressing

once, or twice to view set-point temperature;

if shortening temperature exceeds 425°F (218°C), the display

reads “E-5, FRYER TOO HOT”

3-1 2 This LED lights when the shortening temperature is within 5°

of the setpoint temperature, signaling the operator that the

shortening temperature is now at the proper temperature for

dropping product into the frypot

3-1 3 The timer buttons are used to start and stop Cook Cycles

3-1 4 The idle buttons are used to start an Idle Mode which reduces

the temperature of the shortening during non-use periods; press

and hold to exit the Idle Mode

3-1 5 The program button is used to access the Program Modes;

also, once in the Program Mode, it is used to advance to the

next parameter

3-1 6 & 7 Used to adjust the value of the currently displayed setting

in the Program Mode and to change set-point temperature of the

shortening

608 3-1

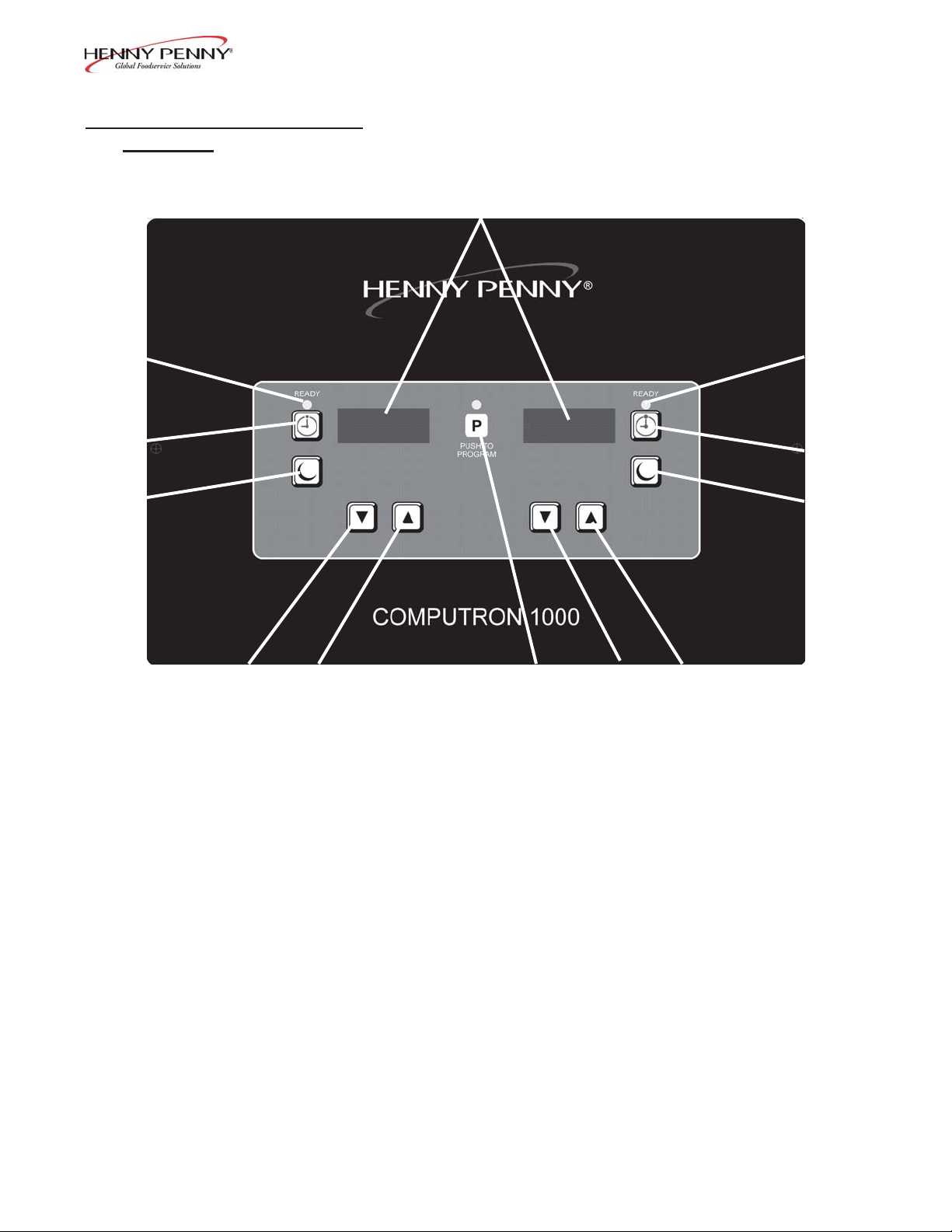

3-1. OPERATING COMPONENTS

(Continued)

Model 500/561/600

1

2

2

3

3

4

6

7

Figure 3-1

589

4

3-2 608

Model 500/561/600

3-1. OPERATING COMPONENTS

(Continued)

Fig. Item Description Function

No. No.

3-3 8 Frypot Holds the cooking shortening and an adequate cold zone for

collection of cracklings

3- 3 9 Lid Spring Assists in raising the lid, and then holding it open (it is covered with

a shield)

3-3 10 Condensation Drain This channels the moisture, that collects on the lid liner when the

Channel lid is opened, into the drain line and prevents the moisture droplets

from falling into the shortening

3-3 11 Lid Gasket Provides the pressure seal for the frypot chamber

3-2 12 Lid Latch A spring loaded latch that provides a positive latch to hold the lid

closed; this latch, along with the spindle assembly and lid gasket,

provides a pressure sealed frypot chamber

3- 2 13 Spindle Assembly An assembly that is tightened after the lid is latched, and applies

pressure to the top of the lid; the lid gasket then applies pressure

against the frypot rim; after building one pound of internal pressure,

the lid liner pushes a locking pin up into the locking collar, preventing the spindle from being turned while the frypot is pressurized

3-2 14 Lid Limit Stop A threaded adjustable collar used to obtain the proper

tightness between the lid gasket and the frypot rim; done by

controlling the number of clockwise rotations of the spindle

3-2 15 Deadweight This deadweight style, pressure relief valve maintains a constant

Assembly level of steam pressure within the frypot; excess steam is vented

through the exhaust stack

Failure to clean the deadweight assembly daily could

result in the fryer building too much pressure. Severe

injuries and burns could result.

608 3-3

Model 500/561/600

3-1. OPERATING COMPONENTS

(Continued)

Fig. Item Description Function

No. No.

3- 2 16 Safety Relief Valve This is an ASME approved spring loaded valve, set at 14.5 psi; if

the deadweight assembly is clogged, this safety valve releases

excess pressure, keeping the frypot chamber at 14.5 psi

(999 mbar); if this occurs, turn the main power switch to OFF to

release all pressure from the frypot

If safety relief valve activates, turn main power switch

to the OFF position. To avoid serious burns and

injuries, have fryer serviced before next use.

3-2 17 Safety Relief Valve Ring

DO NOT PULL THIS RING. SEVERE BURNS FROM

THE STEAM WILL RESULT.

3-2 18 Pressure Gauge Indicates the pressure inside the frypot

3-5

3- 2 19 Solenoid Valve An electromechanical device that causes pressure to be held in the

frypot; the solenoid valve closes at the beginning of the Cook Cycle

and is opened automatically by the controls at the end of the Cook

Cycle; if this valve becomes dirty or the teflon seat nicked, pressure

will not build up and it must be repaired

3-3 20 Drain Valve (Only the A two-way ball valve that is normally close; turn the handle to drain

Handle is Shown) the shortening from the frypot, into the filter drain pan

DO NOT OPEN THE DRAIN VALVE WHILE FRYPOT

IS UNDER PRESSURE. HOT SHORTENING WILL

EXHAUST AND SEVERE BURNS WILL RESULT.

3-3 21 Drain Interlock Switch A microswitch that provides protection for the frypot in the event an

operator inadvertently drains the shortening from the frypot while

the main power switch is on; the switch automatically shuts off the

heat when the drain valve is opened

3-4 608

Model 500/561/600

3-1. OPERATING COMPONENTS

(Continued)

Fig. Item Description Function

No. No.

3-3 22 Filter Drain Pan The removable pan that houses the filter and catches the shortening

when it is drained from the frypot; it is also used to remove and

discard old shortening

When moving filter drain pan containing hot shortening,

use extreme care to avoid burns from hot surfaces or

splashing.

3-3 23 Filter Union Connects the filter to the filter pump, and allows easy removal of the

filter and drain pan

3-3 24 Filter Valve When the power switch is in the PUMP position, this two-way

valve directs filtered shortening from the drain pan, back into the

frypot

3-3 25 Condensation Drain A hose used to route the condensation collected within the steam

Line exhaust system, to the condensation pan

3-3 26 Condensation Drain The collection point for the condensation, formed within the steam

Pan exhaust system; remove and empty periodically

3-3 27 Rinse Hose (Optional) A hand-held hose used to rinse food particles from the frypot

3-8 into the filter pan; attaches to a quick disconnect fitting

3-3 28 Gas Control Valve (Gas Controls the gas flow to the burner

Models Only)

3-6

3-7

3-4 30 Breakers-Push Button Protective devices which break the circuit when the current

29 High Temperature Limit A control that senses the temperature of the shortening; if the

temperature of the shortening exceeds the safe operating limit, this

control opens and shuts off the heat to the frypot; when the

temperature of the shortening drops to a safe operation limit, the

control must be manually reset by pressing the red reset button,

located under the control panel, behind the door

Gas Electric

Reset (Electric Models exceeds the rated value

Only)

3-7 31 Contactors (Electric Relays that route power to the heating elements; one relay is in

Models Only) series with the high limit, the other one is in series with the controls;

the standard unit uses 2 electromechanical contactors, while the

computer controlled units have one electromechanical and one

mercury contactor

3-9 32 Circuit Breaker (Single Opens the electrical circuit, and removes power to elements

608 3-5

Phase Only)

3-1. OPERATING COMPONENTS

(Continued)

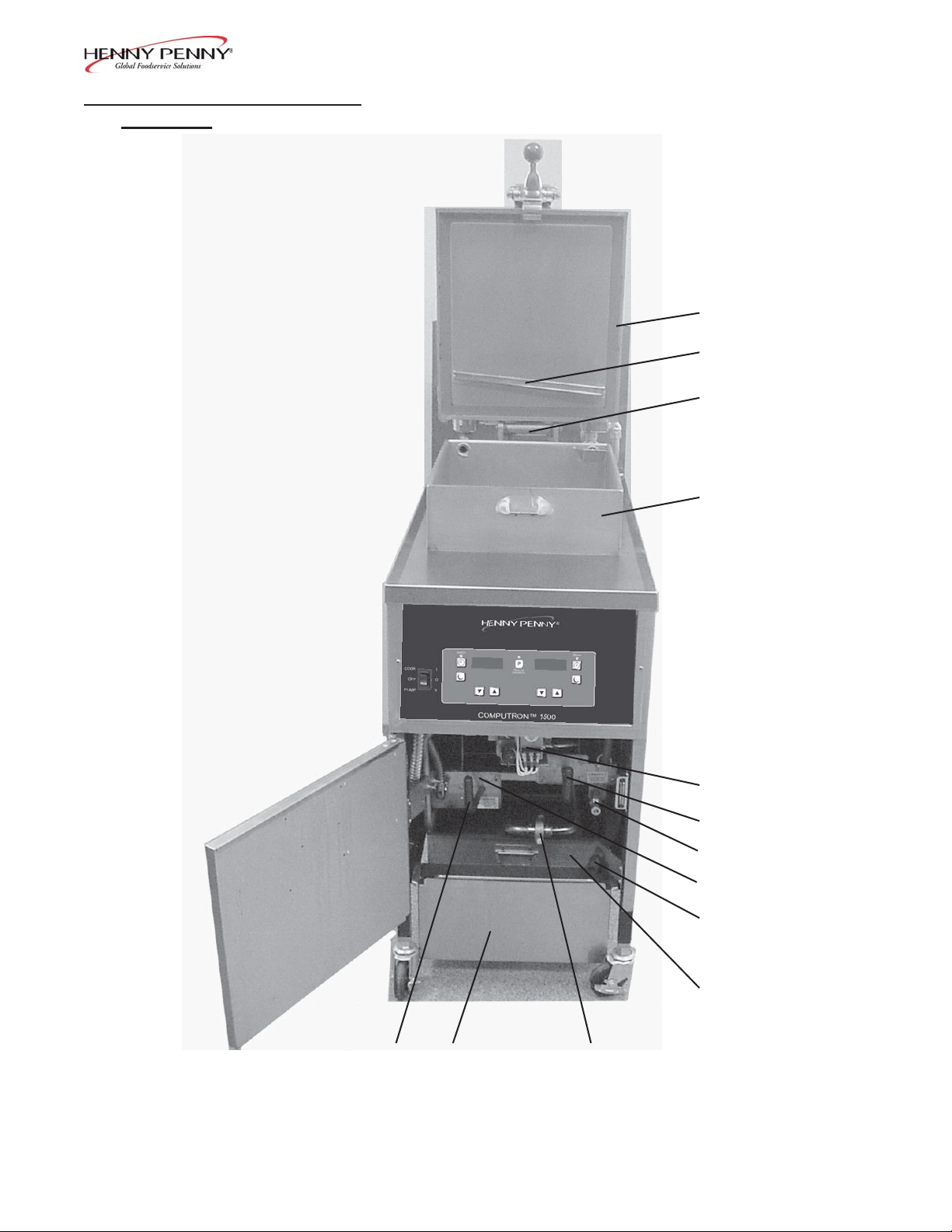

16

Model 500/561/600

13

19

15

18

14

12

ELECTRIC MODEL

Figure 3-2. Operating Controls

3-6 608

3-1. OPERATING COMPONENTS

(Continued)

Model 500/561/600

11

10

9

8

28

24

27

21

25

22

20

26

23

GAS MODEL

Figure 3-3. Operating Controls

608 3-7

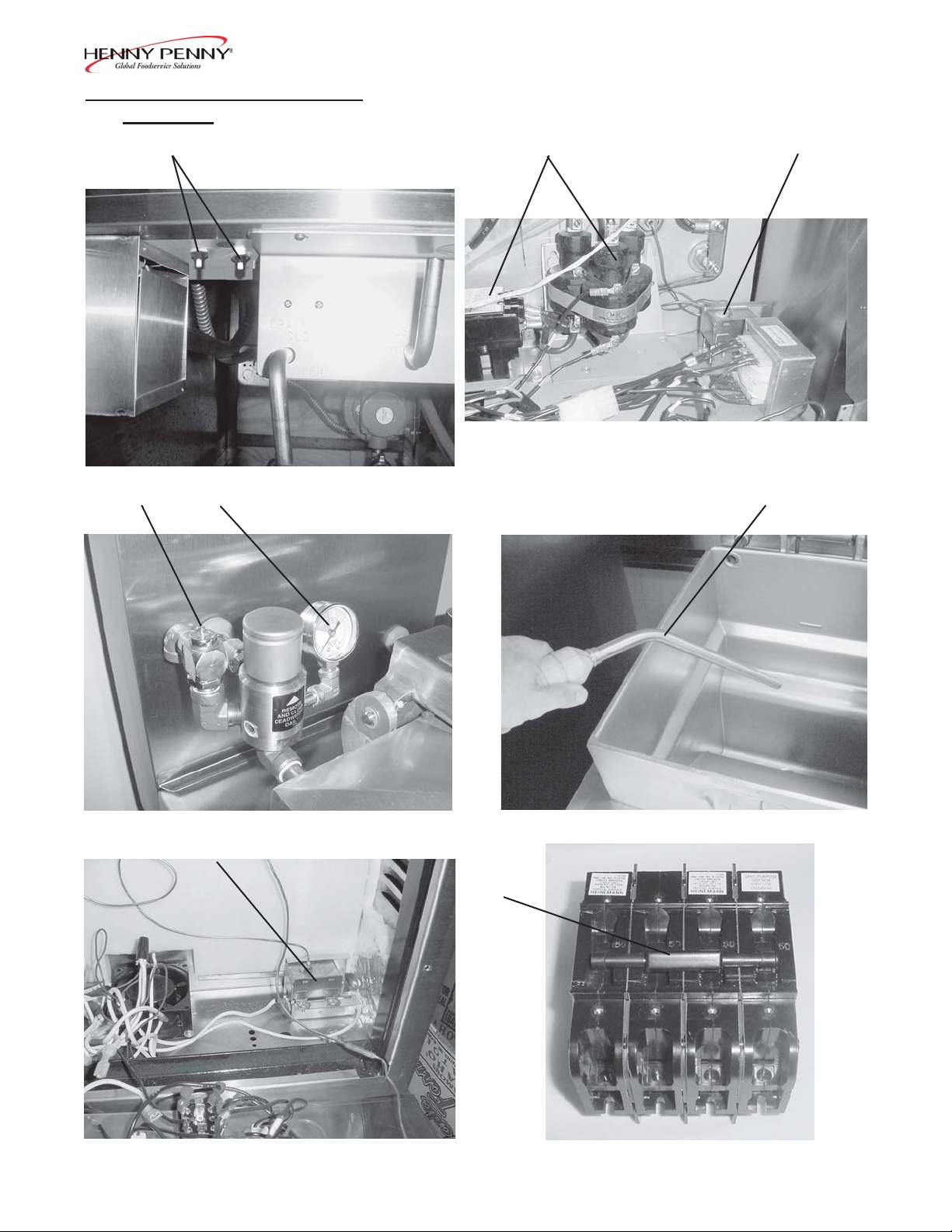

3-1. OPERATING COMPONENTS

(Continued)

Model 500/561/600

17

30

18

Figure 3-4.

31

29

Figure 3-7.

27

Figure 3-5.

29

Figure 3-8.

32

Figure 3-6.

3-8 608

Figure 3-9.

3-2. FILLING OR

ADDING SHORTENING

Model 500/561/600

Before the actual cooking operation and adding shortening to

the frypot, be sure frypot, filter screen assembly, and drain pan

are cleaned. Filter screen assembly and drain pan should be

cleaned with soap and hot water and thoroughly dried before

reassembling. At this time, the frypot should also be cleaned.

Refer to Cleaning the Frypot Section.

The shortening level must always be at the frypot level

indicator on the rear of the frypot (see photo on next

page). Failure to follow these instructions could result in a

fire and/or damage to the fryer.

When using solid shortening, it is recommended to melt

the shortening on an outside heating source before placing it in the frypots. The elements on electric fryers, or the

frypot surface on gas fryers, must be completely

submerged. Fire or damage to the frypot could result.

1. It is recommended that a high quality frying shortening be used

in the fryer. Some low grade shortenings have a high moisture

content and will cause foaming and boiling over.

To avoid severe burns when pouring hot shortening into

frypot, wear gloves and take care to avoid splashing.

2. The electric model 500 requires 48 lbs. (21.8 kg) of liquid

shortening, and the model 561 requires 65 lbs. (29.5 kg). The

gas model requires 43 lbs. (19.5 kg). Model 500 fryers have

2 level indicator lines inscribed on the rear wall of the frypot,

whereas the models 561 & 600 have only 1 level indicator.

The level indicator lines show the proper shortening levels.

3. Cold shortening should be filled to 1/2-inch (12.7 mm) below

a single level indicator line, and frypots with 2 level indicator

lines, cold shortening should be even with the lower level

indicator line. The shortening expands when heated and

should be at the level indicator line when the shortening is hot,

or the top level indicator line on model 500s.

608 3-9

3-3. CARE OF THE

SHORTENING

Model 500/561/600

FOLLOW THE INSTRUCTIONS BELOW TO AVOID

SHORTENING OVERFLOWING THE FRYPOT,

WHICH COULD RESULT IN SERIOUS BURNS,

PERSONAL INJURY, FIRE, AND/OR PROPERTY

DAMAGE.

1. To protect, and get the maximum life out of the shortening,

press to lower the temperature to 250° F (135° C) when

the fryer is not in immediate use. Deteriorated shortening

smokes badly, even at lower temperatures.

2. Frying breaded food products requires frequent filtering to keep

the shortening clean. The shortening should be filtered after

every 3 to 6 Cook cycles. For the best quality product, Do not

exceed 6 Cook Cycles without filtering. Refer to Filtering of

Shortening Section.

3. Maintain the shortening at the proper cooking level. Add fresh

shortening as needed.

4. Do not overload the baskets with product (12 lbs. (5.4 kg.) for

model 600 fryers; 14 lbs (6.4 kg.) for model 500 fryers and

18 lbs. (8.2 kg.) for the model 561) or place product with

extreme moisture content into baskets.

WITH PROLONGED USE, THE FLASHPOINT OF

SHORTENING IS REDUCED. DISCARD THE

SHORTENING IF IT SHOWS SIGNS OF EXCESSIVE

SMOKING OR FOAMING, OR SERIOUS BURNS,

PERSONAL INJURY, FIRE, AND/OR PROPERTY

DAMAGE COULD RESULT.

3-10 608

Model 500/561/600

3-4. PRODUCT COOKING

GUIDELINES

The following table provides the suggested frying times and temperatures

for single-stage cooking, using the Henny Penny Pressure Fryer combined with our special blends of PHT Fryer Breading Mixes.

All the suggested time and temperature settings are for a 10

pound (4.5 kg) load.

Product (size per piece) Temperature Time(Min.)

Chicken 315ºF (157ºC) 10-11

(2-1/4 lbs (1 kg), 8 or 9 pieces)

Fish 315ºF (157ºC) 3.5

(4 ozs (.11 kg))

Shrimp 315ºF (157ºC) 2

Trout 315ºF (157ºC) 5

(10 to 16 ozs (.28-.45 kg))

Pork Chops 315ºF (157ºC) 5

(4 to 5 ozs,(.11-.14 kg),

1

/2 to 3/4 ins (12.7-19 mm) thick)

Ribs 275°F) (135ºC) 14

(2-1/2 lb (1.13 kg) rack)

Cubed Steak 315ºF (157ºC) 5

(6 to 10 ozs,(.17-.28 kg),

1/4 to 1 in (6.4-25.4 mm) thick)

Veal Cutlet 315ºF (157ºC) 4

(4 ozs (.11 kg))

Potatoes 315ºF (157ºC) 8

(10 lbs (4.5 kg), cut in wedges)

608 3-11

Model 500/561/600

3-5. CHICKEN FRYING

PROCEDURES

The following is a description of the operating procedures for fryers

with the Computron 1000 controls.

1. Check to see that all control switches are off and the drain and

filter valves are in the closed position.

2. Remove the basket from the frypot and leave lid open.

3. Make sure frypot is filled with shortening to the proper level.

Refer to filling and Adding Shortening Section.

4. Make sure electrical power is connected to fryer. Gas units,

make sure gas lines are connected to fryer and gas valve is

turned on - See GAS PILOT & BURNER LIGHTING AND SHUT

DOWN PROCEDURE Section.

5. Display shows “OFF” until power switch is turned to the ON

position. Display now shows the cook time and the unit automatically goes into the Melt Cycle until the shortening temperature reaches 230°F (110°C). The control then automatically exits

the Melt Cycle.

The PFG-600 series pressure fryer has several safety devices

which shuts-down the gas supply when they are activated. The

above procedures should be followed to restart the open fryer

and if the shut down is repeated, a qualified technician should be

notified.

The Melt Cycle may be bypassed, if desired, by pressing and

holding for 3 seconds.

Do not bypass the Melt Cycle unless enough shortening has

melted to completely cover the curved surface of the gas

frypots and elements on electric fryers. If Melt Cycle is

bypassed before all gas frypot or elements are covered,

excessive smoking of the shortening, or a fire will result.

5. Once out of the Melt Cycle, the shortening is heated until

lights and the cook time is displayed.

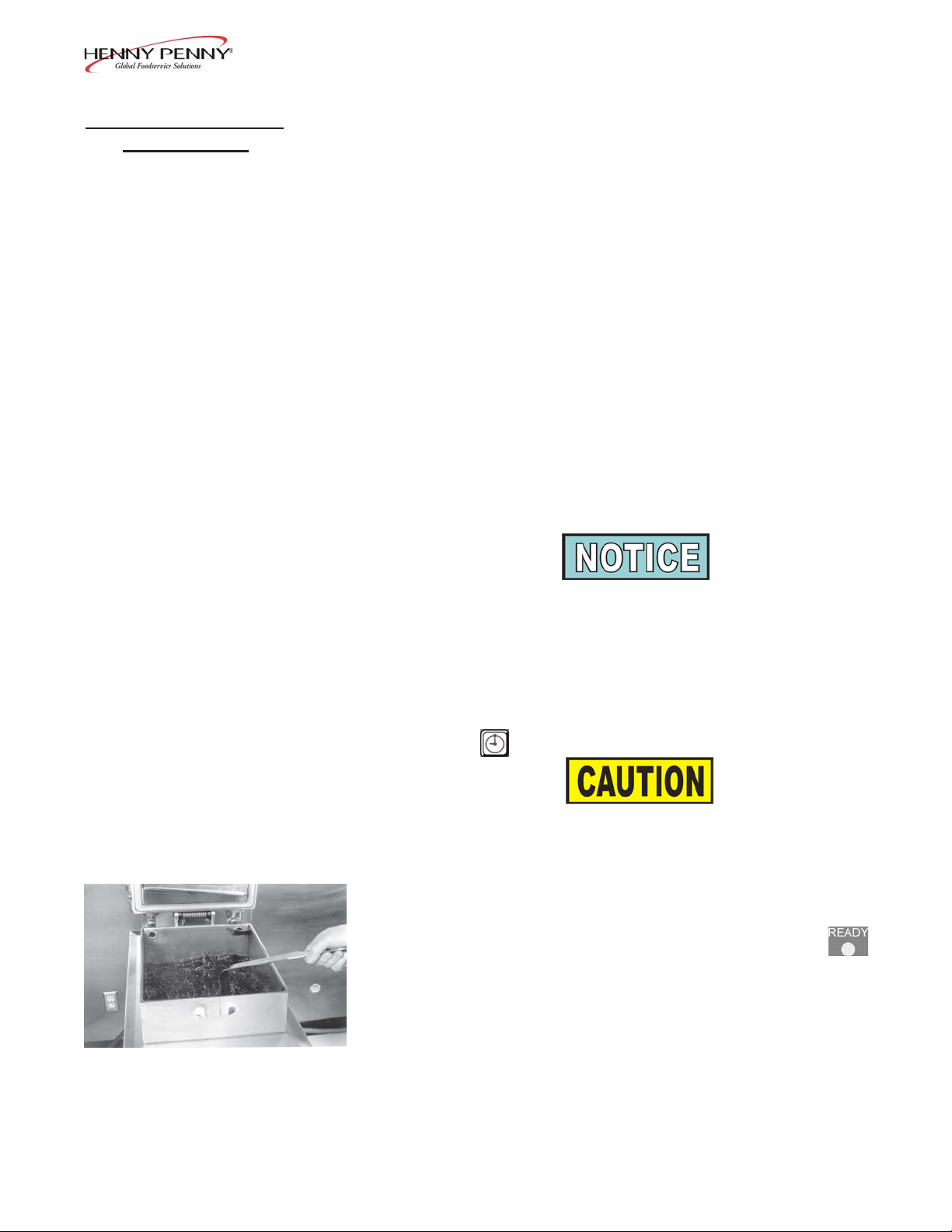

6. Using the basket handle, thoroughly stir shortening to stabilize the

temperature throughout the frypot.

Step 6

3-12 608

7. Once the shortening temperature has stabilized at the setpoint

temperature, lower the basket into the frypot.

3-5. CHICKEN FRYING

PROCEDURES (Continued)

Model 500/561/600

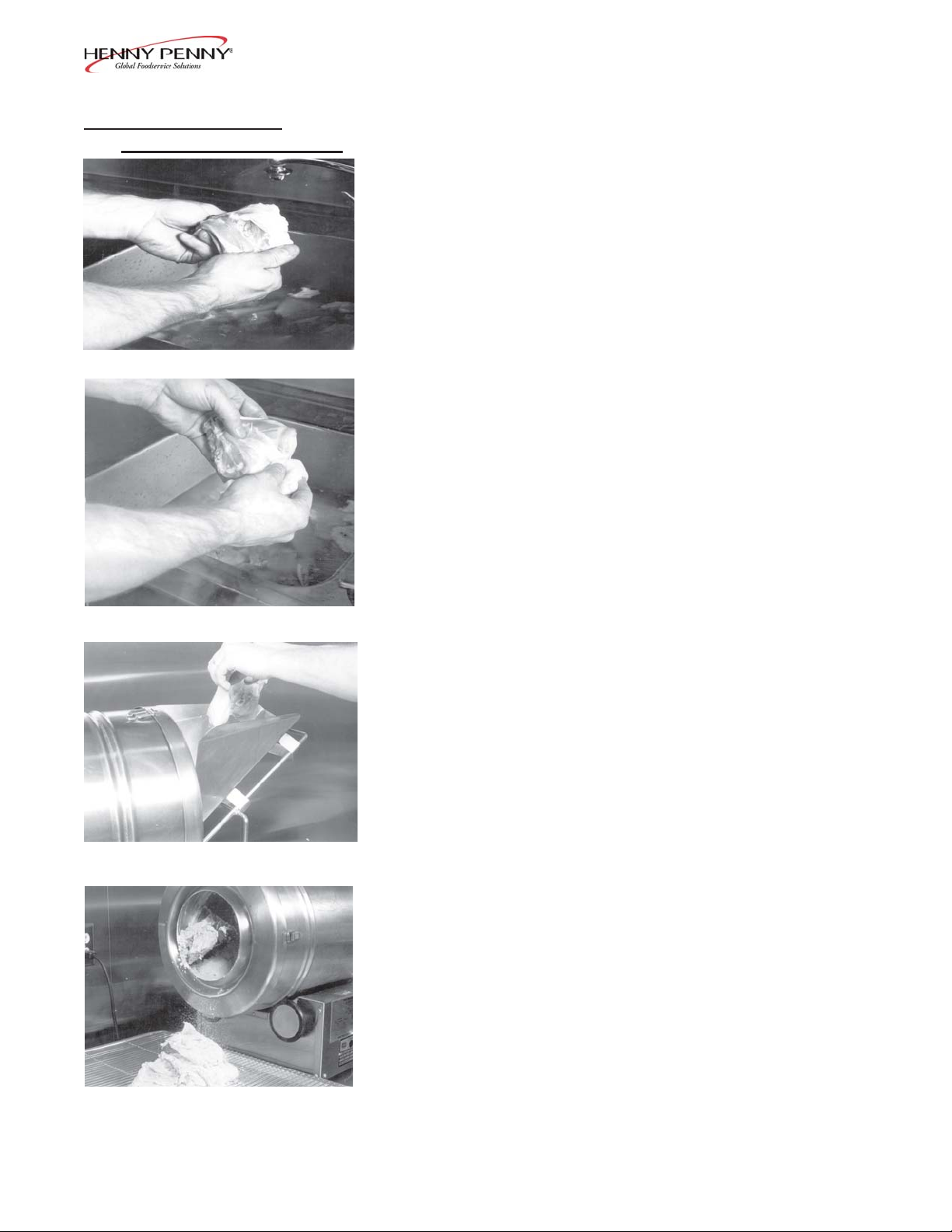

8. Take the chicken parts, either 4 or 5 cut-up chickens, from the

cooler and place in a scullery sink. Wash the chicken and, at this

point, break the thigh from the joint of the backbone.

Step 8

9. Remove any excess fat from the thigh.

10. Remove the chicken from the water and drain slightly, but allow

the parts to remain moist.

Step 9

Step 11

11. If a breading machine is used, fill the breading drum with

approximately 8 to 10 pounds of PHT Breading Mix. Feed the

moist but drained pieces into the chute at one end of the breader.

12. Allow the breaded pieces to fall onto a tray as they come out of

the breader drum.

Step 12

608 3-13

Loading...

Loading...