Henny Penny 500, 600 Installation Manual

SECTION 2. INST ALLA TION

Model 500/600

2-1. INTRODUCTION

2-2. UNP ACKING

INSTRUCTIONS

This section provides the installation instructions for the Henny Penny

pressure fryer.

Installation of this unit should be performed only

by a qualified service technician.

Do not puncture the fryer with any objects such

as drillsor screws as electrical shock or component damage could result.

1. Cut the bands from around the carton.

Any shipping damage should be noted in the

presence of the delivery agent and signed prior

to their departure.

2. Lift the main carton off the fryer.

3. Remove the inside packing from the fryer.

4. Open fryer lid and remove the basket plus all the accessories.

5. Open front door and remove the condensation drain pan.

6. Unscrew the filter union and remove the filter drain pan.

710 2-1

Model 500/600

2-2. UNP ACKING

INSTRUCTIONS

(Continued)

7. Close the front door .

T ake care when moving the fryer to prevent personal

injury . The fryer weighs approximately 300 lb (136 kg).

8. Tilt the fryer to one side so one side of the fryer frame is raised up

off of the skid.

9. While one person holds the unit, another person hits the vertical

wooden supports with a hammer pushing them under the fryer.

10. Return the fryer to fully upright.

11. Open front door, remove two vertical supports and a horizontal

support and close the front door.

12. Unlock all 4 casters.

13. Lift fryer up so casters are above the skid, move the fryer off the

skid, and set the fryer on the floor.

2-2 710

Model 500/600

2-2. UNP ACKING

INSTRUCTIONS

ORIFICE

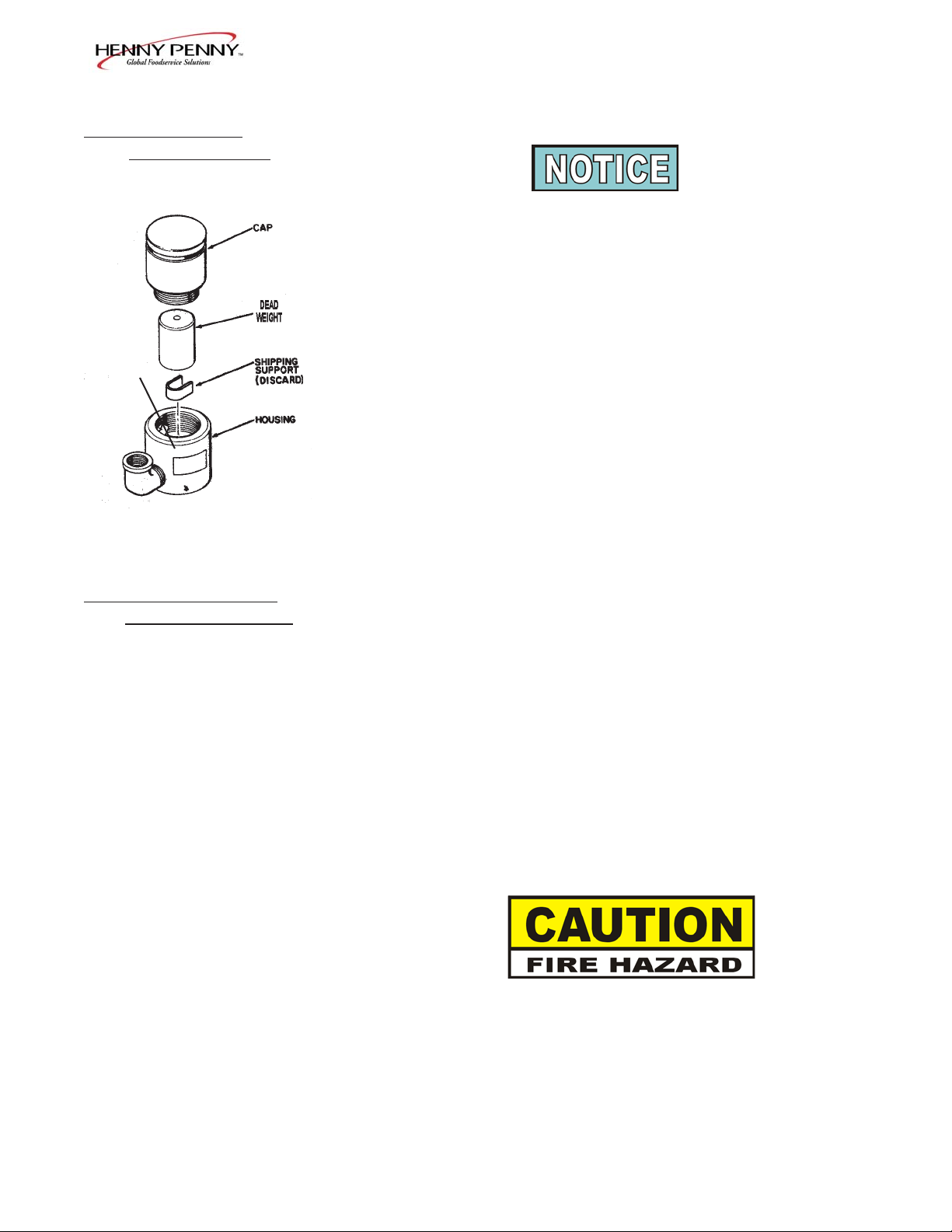

Figure 2-1

14. Prepare deadweight valve assembly for operation.

A metal shipping support is installed inside the deadweight valveassembly and must be removed prior to

installation and startup,or unit will NOT build pressure.

15. Unscrew the deadweight cap.

16. Remove the deadweight.

17. Remove and discard the shipping support.

18. Clean the deadweight orifice with a dry cloth.

19. Replace the deadweight and secure the deadweight cap.

20. Remove the protective paper from the fryer exterior and clean

with the surfaces with a cloth, soap and water.

2-3. SELECTING THE

FRYER LOCATION

The proper location of the fryer is very important for operation,

speed, and convenience. Choose a location which provides easy

loading and unloading without interfering with the final assembly of

food orders. Operators have found that frying from raw to finish, and

holding the product in warmers, provides fast continuous service.

Landing or dumping tables should be provided next to, at least, one

side of the fryer. Keep in mind the best ef ficiency will be obtained by

a straight line operation, i.e., raw in one side and finished out the other

side. Order assembly can be moved away with only a slight loss of

efficiency . T o properly service the fryer , 24 inches (60.96 cm) of

clearance is needed on all sides of the fryer. Access for servicing can

be attained by removing a side panel. Also, at least 6 inches (15.24

cm) around the base of the gas units is needed for proper air supply

to the combustion chamber.

To avoid a fire, install the fryer with minimum clearance

from all combustible and noncombustible materials, 6 inches

(15.24 cm) from side and 6 inches (15.24 cm) from back. If

installed properly, the gas fryer is designed for operation on

combustible floors and adjacent to combustible walls.

To avoid fire and ruined supplies, the area under the fryer

should not be used to store supplies.

710 2-3

2-3. SELECTING THE

FRYER LOCATION

(Continued)

Model 500/600

T o prevent sever e burns from splashing hot shortening,

position and install fryer to prevent tipping or movement.

Restraining ties may be used for stabilization.

2-4. LEVELING THE FRYER

2-5. VENTILATION OF

FRYER

For proper operation, the fryer should be level from side to side

and front to back. Place a level on the flat areas around the frypot

collar, then adjust the leveling bolts or casters until the unit is level.

FAILURE TO FOLLOW THESE LEVELING INSTRUCTIONS CAN RESUL T IN SHOR TENING OVERFLOW ING THE FR YPOT WHICH COULD CAUSE SERIOUS

BURNS, PERSONAL INJUR Y , FIRE, AND/OR PROPERTY DAMAGE.

The fryer must be located with provision for venting into adequate

exhaust hood or ventilation system. This is essential to permit efficient

removal of the flue gases and frying odors. T ake special precautions

in designing an exhaust canopy to avoid interference with the operation of the fryer. W e recommend you consult a local ventilation or

heating company to help in designing an adequate system.

V entilation must conform to local, state, and national codes.

Consult your local fire department or building authorities.

When installing the gas fryer do not attach an extension to

the gas flue exhaust stack. This may impair proper operation of the burner, causing malfunctions and possible negative backdraft.

2-4 803

Loading...

Loading...