Henny Penny 500, 561, 600 Service Manual

as

ANUFACTURED BY HENNY PENNY CORPORATION, EATON, OHIO 45320

Call 800/417-8417 toll-free in the U.S. except Ohio dial 800/762-2964 0 TbVX Number 810-450-2181

FMOl-186

Revised 9-00

Henny Penny

LIMITED WARRANTY FOR HENNY PENNY APPLIANCES

Subject to the following conditions, Henny Penny Corporation makes the following limited warranties to the

original purchaser only for Henny Penny appliances and replacement parts:

NEW EQUIPMENT:

defective in material or workmanship within two (2) years from date of original installation, will be

repaired or replaced without charge F.O.B. factory, Eaton, Ohio, or F.O.B. authorized distributor. To

validate this warranty, the registration card for the appliance must be mailed to Henny Penny within ten

(10) days after installation.

REPLACEMENT PARTS:

be defective in material or workmanship within ninety (90) days from date of original installation will be

repaired or replaced without charge F.O.B. factory, Eaton, Ohio, or F.O.B. authorized distributor.

The warranty for new equipment and replacement parts covers only the repair or replacement of the defective

part and does not include any labor charges for the removal and installation of any parts, travel or other expenses

incidental to the repair or replacement of a part.

EXTENDED FRYPOT WARRANTY:

workmanship issues for a period of up to seven (7) years from date of manufacture. This warranty shall not cover

any frypot that fails due to any misuse or abuse, such as heating of the frypot without shortening.

0 TO 3 YEARS:

issues will be replaced at no charge for parts, labor, or freight. Henny Penny will either install a

new frypot at no cost or provide a new or reconditioned replacement fryer at no cost.

3 TO 7 YEARS:

issues will be replaced at no charge for the frypot only. Any freight charges and labor costs to

install the new frypot as well as the cost of any other parts replaced, such as insulation, thermal

sensors, high limits, fittings, and hardware, will be the responsibility of the owner.

Any part of a new appliance, except lamps and fuses, which proves to be

Any appliance replacement part, except lamps and fuses, which proves to

Henny Penny will replace any frypot that fails due to manufacturing or

During this time, any frypot that fails due to manufacturing or workmanship

During this time, any frypot that fails due to manufacturing or workmanship

Any claim must be represented to either Henny Penny or the distributor from whom the appliance was

purchased. No allowance will be granted for repairs made by anyone else without Henny Penny’s written

consent. If damage occurs during shipping, notify the sender at once so that a claim may be filed.

THE ABOVE LIMITED WARRANTY SETS FORTH THE SOLE REMEDY AGAINST HENNY PENNY

FOR ANY BREACH OF WARRANTY OR OTHER TERM. BUYER AGREES THAT NO OTHER REMEDY

(INCLUDING CLAIMS FOR ANY INCIDENTAL OR CONSQUENTIAL DAMAGES) SHALL BE

AVAILABLE.

The above limited warranty does not apply (a) to damage resulting from accident, alteration, misuse, or

abuse; (b) if the equipment’s serial number is removed or defaced; or (c) for lamps and fuses. THE ABOVE

LIMITED WARRANTY IS EXPRESSLY IN LIEU OF ALL OTHER WARRANTIES, EXPRESS OR

IMPLIED, INCLUDING MERCHANTABILITY AND FITNESS, AND ALL OTHER WARRANTIES ARE

EXCLUDED. HENNY PENNY NEITHER ASSUMES NOR AUTHORIZES ANY PERSON TO ASSUME

FOR IT ANY OTHER OBLIGATION OR LIABILITY.

This manual should be retained in a convenient location for future reference.

A wiring diagram for this appliance is located on the rear shroud cover of the control panel.

Post in a prominent location, instructions to be followed in event user smells gas. This

information shall be obtainedby consulting the local gas supplier.

R USE GASOLINE OR OTHE LE VAPORS

TY OFTHIS ORANY OTHERAPPL

Keep appliance area free and clear from combustibles.

Do not obstruct the flow of combustion and ventilation air. Adequate clearance must be left all

around appliance for suffkient air to the combustion chamber.

The Model 600 Fryer is equipped with a continuous pilot. But Fryer can not be operated with

out electric power. Fryer will automatically return to normal operation when power is restored.

ante can

maintenance

re i~stal~ng or se~ci~g this e

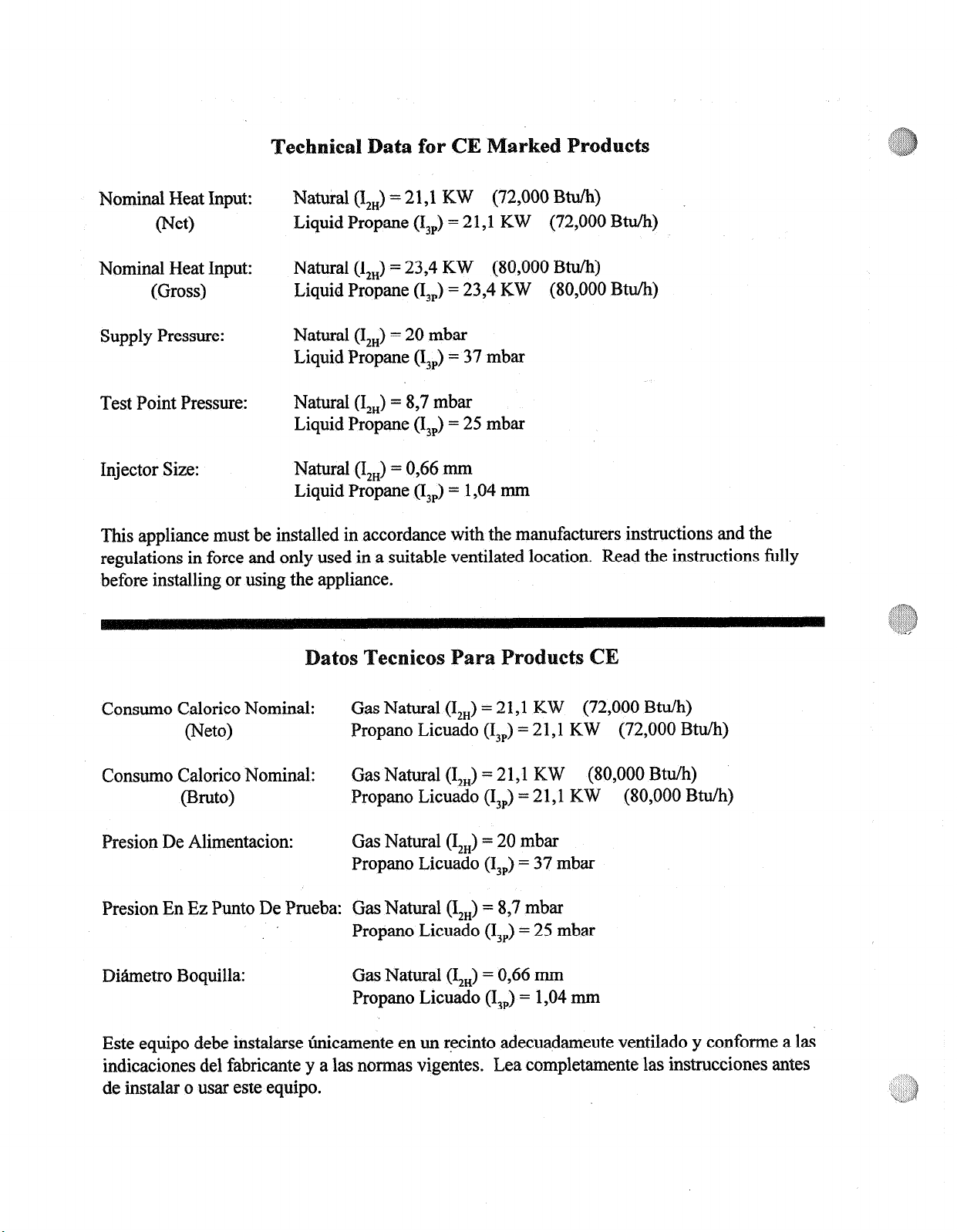

Nominal Heat Input:

(Net)

Natural (I,,) = 2 1,l KW

Liquid Propane (I& = 2 1,l KW

(72,000 Btu/h)

(72,000 Btu/h)

Nominal Heat Input:

(Gross)

Supply Pressure:

Test Point Pressure:

Injector Size:

This appliance must be installed in accordance with the manufacturers instructions and the

regulations in force and only used in a suitable ventilated location. Read the instructions fully

before installing or using the appliance.

Natural (I& = 23,4 KW

Liquid Propane (I,,) = 23,4 KW

Natural (I& = 20 mbar

Liquid Propane (I,,) = 37 mbar

Natural (I,,) = 8,7 mbar

Liquid Propane (I,,) = 25 mbar

Natural (I,,) = 0,66 mm

Liquid Propane (I,,) = 1,04 mm

(80,000 Btu/h)

(80,000 Btwh)

atos ~e~nicQs

Consumo Caloric0 Nominal:

(Net4

Gas Natural (I& = 21 ,l KW

Propano Licuado (IJ = 21,l KW

(72,000 Btu/h)

(72,000 Btu/h)

Consumo Caloric0 Nominal:

(Bruto)

Presion De Alimentacion:

Presion En Ez Punto De Prueba:

Diiunetro Boquilla:

Este equip0 debe instalarse kkxmente en un recinto adecuadameute ventilado y conforme a las

indicaciones de1 fabricante y a las normas vigentes.

de instalar o usar este equipo.

Gas Natural (I,,) = 21,l KW

Propano Licuado (I,,) = 21,l KW

Gas Natural (I& = 20 mbar

Propano Licuado (IJ = 37 mbar

Gas Natural (I,,) = 8,7 mbar

Propano Licuado (IJ = 25 mbar

Gas Natural (I,,) = 0,66 mm

Propano Licuado (I,,) = 1,04 mm

Lea completamente las instrucciones antes

(80,000 Btu/h)

(80,000 Btu/h)

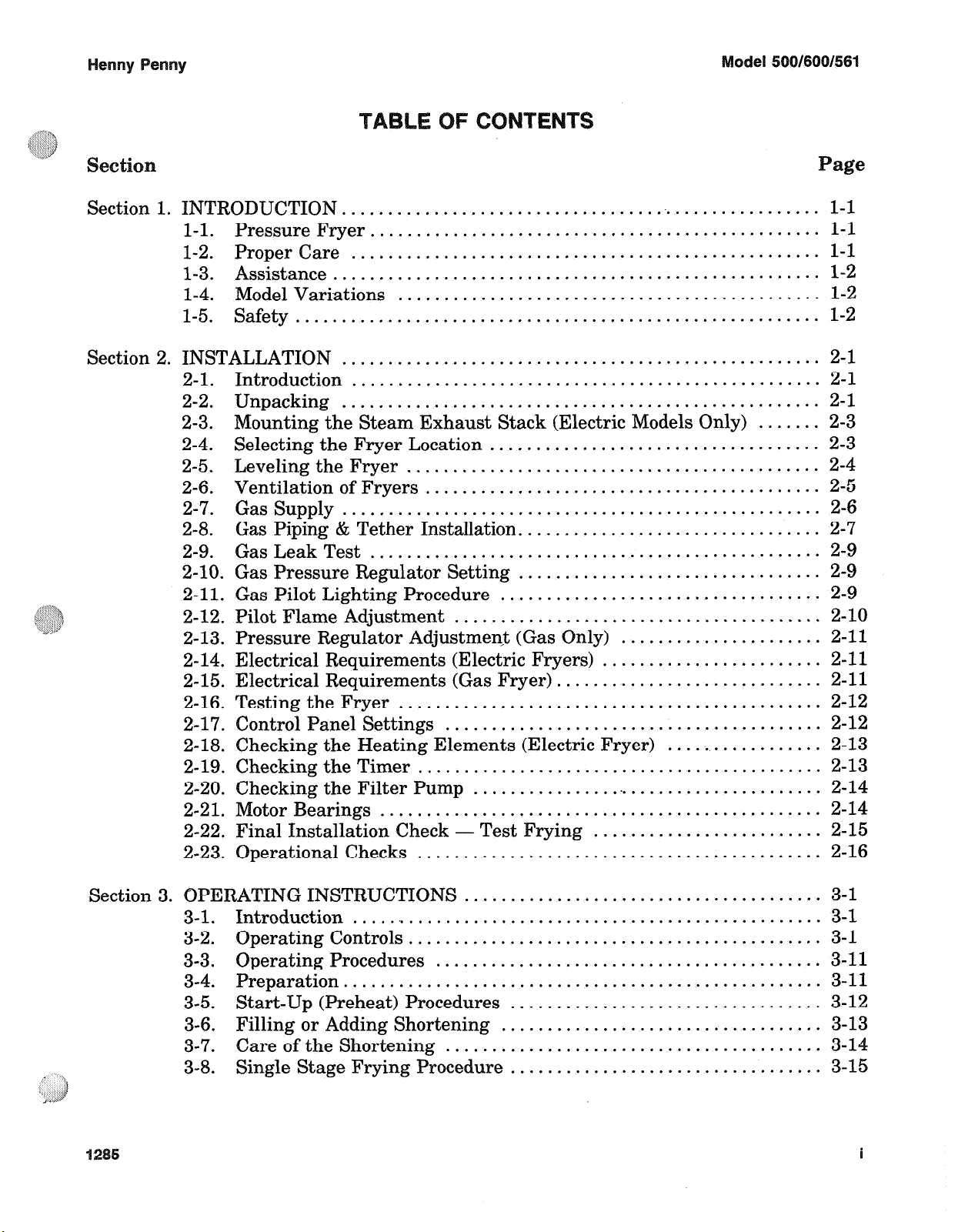

Section 1. INTRQDUCTI~N.

l-l. PressureFryer

l-2.

Proper Care

1-3. Assistance

l-4.

1-5. Safety

Model Variations

.........................................................

....................................................

.................................................

...................................................

.....................................................

..............................................

l-l

l-l

l-l

l-2

l-2

l-2

Section 2. INSTALLATION

2-l.

2-2.

2-3.

2-4.

2-5.

2-6.

2-7.

2-8.

2-9.

Introduction

Unpacking

Mounting the Steam Exhaust Stack (Electric Models Only)

Selecting the Fryer Location

Leveling the Fryer

Ventilation of Fryers

GasSupply..

Gas Piping & Tether Installation.

Gas Leak Test

2-10. Gas Pressure Regulator Setting

2-11. Gas Pilot Lighting Procedure

2-12. Pilot Flame Adjustment

2-13. Pressure Regulator Adjustment (Gas Only)

2-14. Electrical Requirements (Electric Fryers)

2-15. Electrical Requirements (Gas Fryer)

2-16. Testingthe Fryer

2-17. Control Panel Settings

2-18. Checking the Heating Elements (Electric Fryer)

2-19.

CheckingtheTimer

2-20. Checking the Filter Pump

earings

2-22. Final Installation Check - Test Frying

2-23. Operational Checks

....................................................

...................................................

....................................................

....................................

.............................................

...........................................

..................................................

................................

.................................................

.................................

...................................

........................................

........................

.............................

..............................................

.........................................

............................................

.......................................

................................................

.........................

............................................

......................

.................

.......

2-l

2-l

2-l

2-3

2-3

2-4

2-5

2-6

2-7

2-9

2-9

2-9

2-10

2-11

2-11

2-l 1

2-12

2-12

2-13

2-13

2-14

2-14

2-15

2-16

Section 3. OPERATING INSTRUCTIONS

3-l.

3-2.

3-3.

3-4.

3-5.

3-6.

3-7.

3-8.

Introduction

Operating Controls

OperatingProcedures

Preparation

Start-Up (Preheat) Procedures

Filling or Adding Shortening

Care of the Shortening

Single Stage Frying Procedure

...................................................

.............................................

..........................................

....................................................

.........................................

.......................................

..................................

...................................

..................................

3-l

3-l

3-l

3-11

3-11

3-12

3-13

3-14

3-15

e&ion 3.

3-9.

3-10.

3-11.

3-12.

3-13.

3-14.

3-15.

3-16.

3-17.

3-18.

3-19.

3-20.

3-21.

3-22.

3-23.

3-24.

3-25.

3-26.

3-27.

3-28.

3-29.

3-30.

3-31.

3-32.

3-33.

3-34.

3-35.

3-36.

(Continued)

cedure (Using’s Standard Fryer)

aintenance

ied

Chops/Veal Cutlets.

Pork Chops

ters ....................................................

....................................................

ock Lobster Tail.

tatoes ...................................................

Corn on the Cob

Cauliflower

................................................

....................................

...................................... 3-26

Prevention

lope

lter

....................................

alve

....................................

....................................

................................... 3-39

Chicken .......................................

....................................

....................................

......................................

....................................

....................................

..........................................

............................................ 3-42

..............................

................................

................................. 3-33

................................ 3-37

perating Valve). .................. 3-38

...............................

................................. 3-40

ignon ...........................

.......... 3-20

tage Thermostat ...... 3-24

3-25

3-29

3-30

3-34

3-38

3-39

3-39

3-40

3-40

3-40

3-40

3-41

3-41

3-41

3-41

3-41

3-42

3-42

3-42

OOTING

4-1. Introduction

4-2.

Section 5. AINTENANCE

5-2. rangement

5-3.

5-4. aintenance Schedule

5-5.

5-6.

5-7. egulation (Two Stage) (Optional) .................

5-8. Calibrating the Standard Single Stage Thermostat. ..............

Troubleshooting

Introduction

1.

aintenance

............................................

............................................... 4-l

............................................ 4-l

.................................................

............................................... 5-l

............................................... 5-l

.........

Hints..

ontrol Panel.

egulation (Single Stage)

..............................

.............................

.................................

........................

.

4-l

5-l

5-l

5-2

5-2

5-3

5-5

5-6

~~~~~~

: ,,,;;;a,*

we

Section 5.

AINTENANCE (Continued)

5-9.

5-10.

5-11.

5-12.

5-14.

5-15.

5-16.

5-17.

5-18.

5-19.

5-20.

5-21.

5-22.

5-23.

5-24.

5-25.

5-26.

5-27.

5-28.

Calibrating the Optional Two Stage Thermostat

Testing the Thermostat.

Thermostat Replacement (All Models).

High Temperature Limit Control (Electric Models).

Heating Elements (Electric

Heating Contactors (Electric Models)

Gas Burner Assembly

Thermocouple (Gas Models).

Gas Control Valve

Electrical Components.

Timing Control

.............................................

Pressure Regulation/Exhaust

Filtering System.

Gas Conversion.

...........................................

............................................

Electrical Conversions

Wiring Diagrams

Introduction

Genuine Parts.

...........................................

...............................................

.............................................

Index of Wiring Diagrams

.....................................

.........................

odels)

...........................

..........................

.......................................

..................................

................................

......................................

.................................

.......................................

...................................

.................

..............

.........

:

5-9

5-12

5-13

5-16

5-20

5-23

5-26

5-29

5-31

5-34

5-43

5-46

5-65

5-72

5-74

5-75

5-75

5-75

5-75

Section 6. PARTS INFORMATION

6-l.

6-2.

6-3.

6-4.

6-5.

6-6.

6-7.

6-8.

6-9.

6-10.

Introduction

Genuine Parts.

Model Variations

How to Find Parts.

Subassemblies

ow to Order Parts.

.....................................................

S

ery ...................................................

Warranty.................................~

Index of Parts List Illustrations

...............................................

.............................................

..............................................

enny Distributor List

..........................................

...........................................

.........................................

........................................

..............................

................

6-l

6-l

6-l

6-l

6-l

6-2

6-2

6-3

6-3

6-3

6-4

61

The Henny Penny Pressure Fryer is a basic unit of food

processing equipment. It has found wide application in

institutional and commercial food service operations.

A combination of Pressure, Heat, and Time is automatically controlled to produce the optimum in a tasty,

appealing product.

ressure

e

Pressure is basic to this method of food preparation.

This pressure is developed from the natural moisture of

the food. The patented lid traps this moisture and uses

it as steam. Because the steam builds rapidly, the

greater part of the natural juices are retained within

the food. An exclusive operating valve vents excess

steam from the pot and maintains constant low, live

steam pressure.

Heat generated is another important factor of the pressure fryer. The normal suggested frying operation is

between 315 and 325°F. This results in energy savings

and extends the frying life of the shortening. Energy

savings is realized due to the unit’s short frying time,

low temperature, and heat retention of the stainless

steel frypot.

Time is important because the shorter the time in-

volved in frying foods results in additional economies

for the user. Foods are table ready in less time than it

would take to fry them in a conventional open-type

fryer.

As in any unit of food service equipment, the Henny

Penny Pressure Fryer does require care and maintenance. Suggestions for this maintenance and cleaning

are contained in this manual and must become a regular part of the operation of the unit.

Henny Penny Model 500/600/561

1-2. PROPER CARE For your convenience, this manual consists of the following sections:

• Table of Contents

• Introduction

• Installation

• Operation

• Troubleshooting

• Maintenance

• Wiring Diagrams

• Illustrated Parts List

• Distributor List

The conscientious use of the recommended procedures, coupled

with regular maintenance, should minimize the need for repairs to

the equipment. When such repairs are required, they may be

accomplished by following the repair steps contained in this manual.

1-3. ASSISTANCE Should you require outside assistance, just call your local indepen-

dent distributor. (Refer to distributor list in rear of this manual.)

In addition, feel free to contact our corporate headquarters in

Eaton, Ohio. Dial 1-800-417-8405 toll free, or 937-456-8405.

1-4. MODEL VARIATIONS This manual covers both gas and electric models, as well as, various

options and major accessories. Where information pertains to only

one model, it is so noted.

1-5. SAFETY The Henny Penny Pressure Fryer has may safety features

incorporated. However, the only way to ensure a safe operation

is to fully understand the proper installation, operation, and

maintenance procedures, which are contained in this manual.

1-2 1000

odel 5QOl600~561

words NOTE, CAUTION, or WARNING are used. Their

usage is described below:

The word DANGER indicates an imminent hazard

which will result in highly serious injury such as

second or third degree burns.

The word WARNING is used to alert you to a

procedure, that if not performed properly, might

cause personal injury.

The word CAUTION is used to alert you to a

procedure that, if not performed properly, may

damage the fryer.

The word NOTE is used to highlight especially

important information.

el

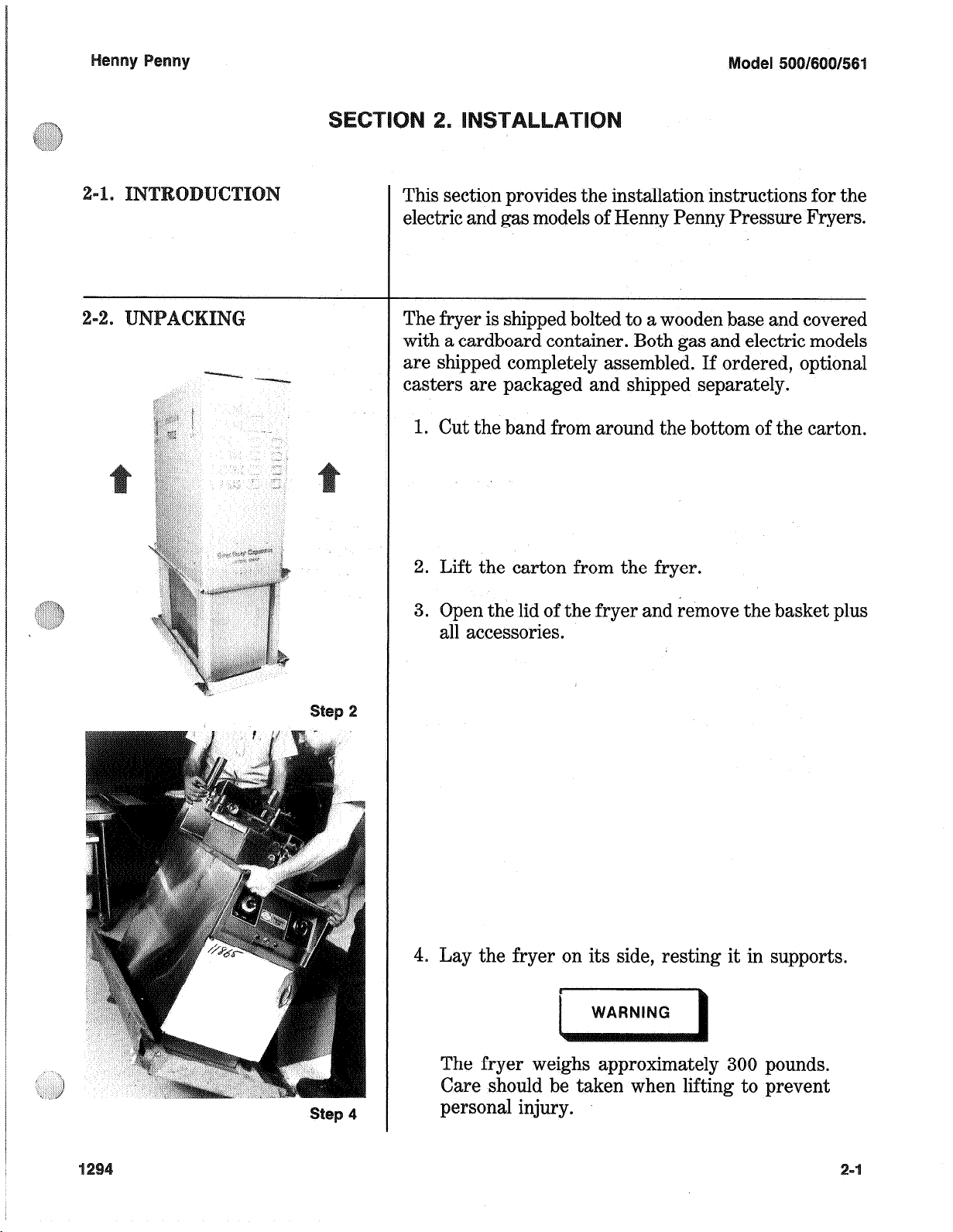

This section provides the installation instructions for the

electric and gas models of Henny Penny Pressure Fryers.

The fryer is shipped bolted to a wooden base and covered

with a cardboard container. Both gas and electric models

are shipped completely assembled. If ordered, optional

casters are packaged and shipped separately.

1. Cut the band from around the bottom of the carton.

2. Lift the carton from the fryer.

3. Open the lid of the fryer and remove the basket plus

all accessories.

4. Lay the fryer on its side, resting it in supports.

The fryer weighs approximately 300 pounds.

Care should be taken when lifting to prevent

personal injury.

Y

Step 8

61

5. Remove the four leg bolts from the wooden shipping base.

Remove and discard the wooden base.

6. Thread the shipping bolts back into the legs to provide leveling

adjustment feet. If ordered, install casters into the legs, with the

locking casters in front.

7. Place fryer in an upright position.

The fryer weighs approximately 300 pounds (136 kg). Use

care when lifting to prevent personal injury.

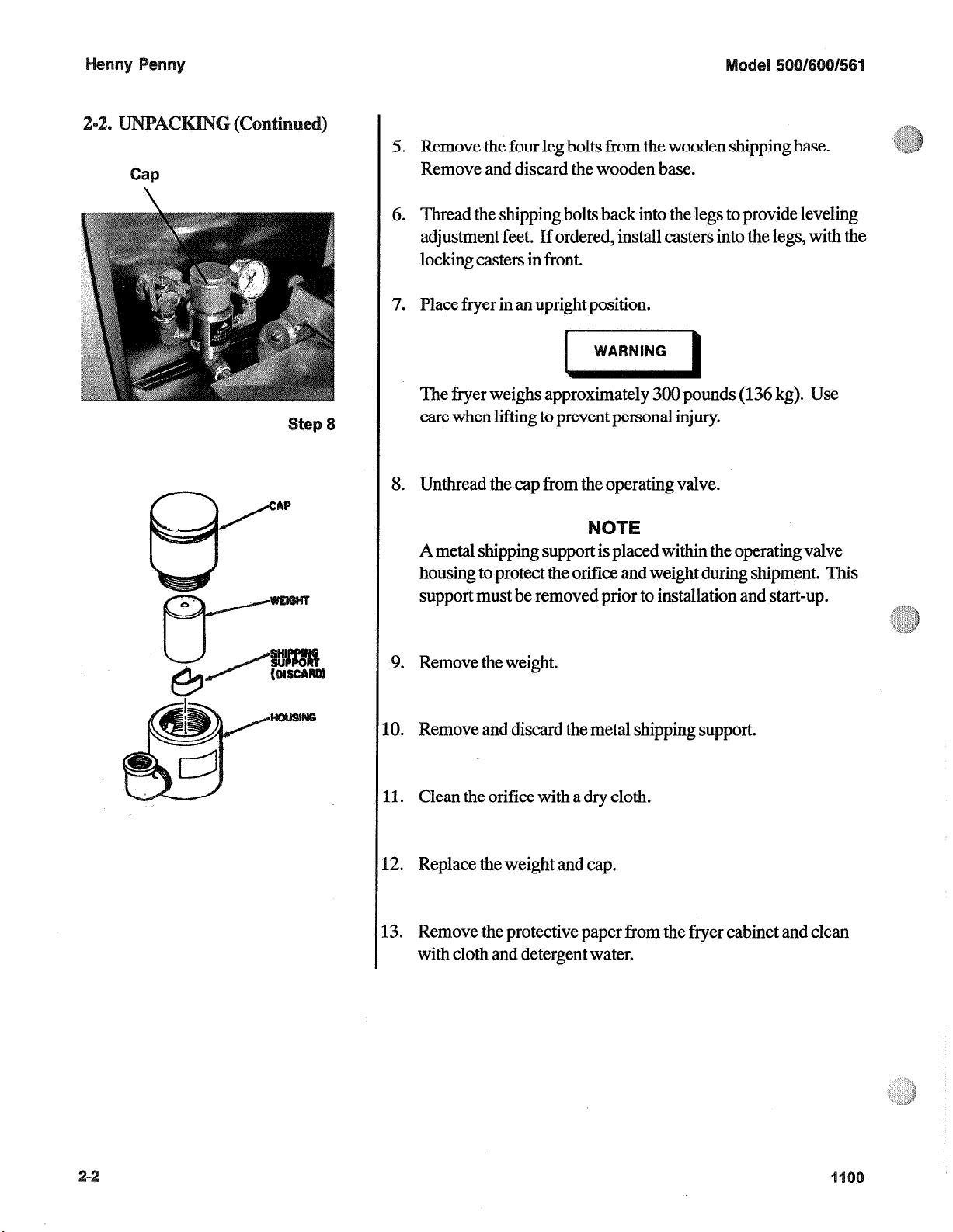

8. Unthread the cap from the operating valve.

,.$“r>

&,$

‘:Q&

NOTE

A metal shipping support is placed within the operating valve

housing to protect the orifice and weight during shipment. This

support must be removed prior to installation and start-up.

9. Remove the weight.

10. Remove and discard the metal shipping support.

11. Clean the orifice with a dry cloth.

12. Replace the weight and cap.

13. Remove the protective paper from the fryer cabinet and clean

with cloth and detergent water.

odel

5OOl6OOl56~

The proper location of the fryer is very important for operation,

speed, and convenience. Choose a location which will provide

easy loading and unloading without interfering with the final assembly of food orders.

Operators have found that frying from raw to

finish, and holding the product in warmers, provides fast continuous

service. Landing or dumping tables should be provided next to, at

least, one side of the fryer.

Keep in mind the best efficiency will be

obtained by a straight line operation, i.e. raw in one side and

finished out the other side.

Order assembly can be moved away

with only a slight loss of efficiency.

The fryer should be installed in such a way as to prevent tipping or

movement causing splashing of hot liquid shortening.

This may be

accomplished by the location of the fryer, or by restraining ties.

ode150

O/561

.

E PLE

ET-U

TC

The gas Model 600 Fryer is design certified by A.G.A. and

CGA. for installation on combustible floors and adjacent to

combustible walls.

Fryer must be installed with minimum

clearance from all combustible and noncombustible materials,

6 inches f?om side and 6 inches from

and front to back.

Sing a level placed on the flat areas around the

back.

fiypot collar, adjust the leveling bolts or casters until the unit is level.

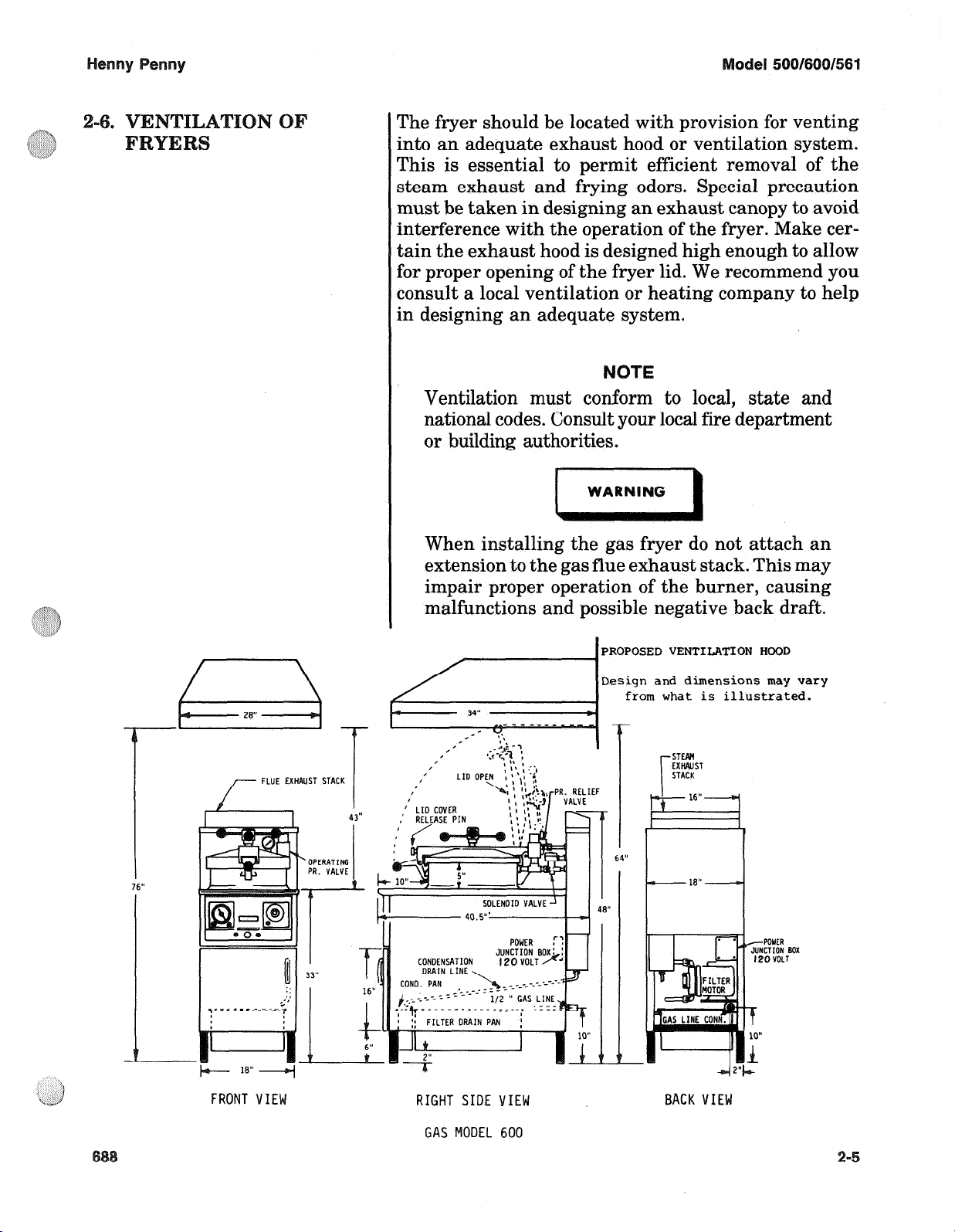

The fryer should be located with provision for venting

into an adequate exhaust hood or ventilation system.

This is essential to permit efficient removal of the

steam exhaust and frying odors. Special precaution

must be taken in designing an exhaust canopy to avoid

interference with the operation of the fryer. Make certain the exhaust hood is designed high enough to allow

for proper opening of the fryer lid. We recommend you

consult a local ventilation or heating company to help

in designing an adequate system.

Ventilation must conform to local, state and

national codes. Consult your local fire department

or building authorities.

When installing the gas fryer do not attach an

extension to the gas flue exhaust stack. This may

impair proper operation of the burner, causing

malfunctions and possible negative back draft.

'OPERATING

CONDENSATION

PROPOSED VENTILATION HOOD

Design and dimensions may vary

from

what

is illustrated.

STEM

EXHPlJST

STACK

P

FRONT VIEW

RIGHT SIDE VIEW

GAS MODEL 600

BACK VIEW

POWER

JUNCTION

+ BOX

___

::

FlLTER ORAIN PAN

iliP

~‘ 0

f.2 Bcl’

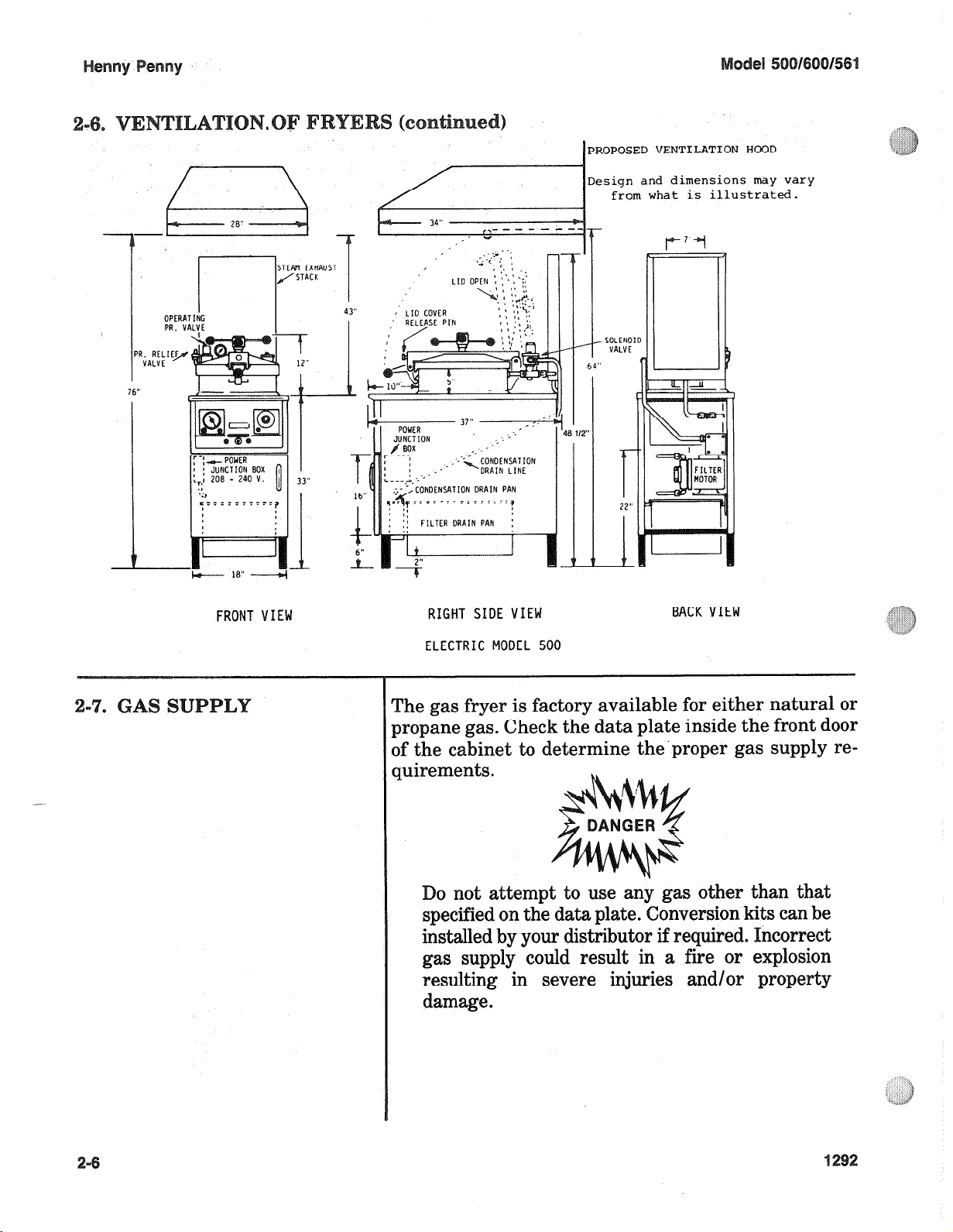

PROPOSED VENTILATION HOOD

Design and dimensions may vary

from what is illustrated.

SOLENOI[

VALVE

--t-

:

'y&p"

FRONT VIEW

RIGHT SIDE VIEW

ELECTRIC MODEL 500

BACK VIEW

I’he gas fryer is factory available for either natural or

propane gas. Check the data plate inside the front door

If the cabinet to determine the proper gas supply reluirements.

0 not attempt to gas other than that

specified on the data plate. Conversion kits can be

installed by your distributor if required. Incorrect

gas supply could result in a fire or explosion

resulting in severe injuries and/or property

damage.

Henny Penny Model 500/600/561

2-8. GAS PIPING Please refer to the illustration below for the recommended hookup

of the fryer to the main gas line supply.

To avoid possible serious personal injury:

• Installation must conform with American National Standard Z223.1-Latest Edition National Fuel Gas Code and

the local municipal building codes. In Canada, installation

must be in accordance with Standard CGA Bl49-1&2, Installation Codes Gas Burning Appliances and local codes.

In Australia, installation must conform to Australian requirements.

• The fryer and its individual shutoff valve must be disconnected from the gas supply piping system during any pressure testing of that system at test pressures in excess of 1/2

PSIG (3.45 KPA).

• The fryer must be isolated from the gas supply piping system by closing its individual manual shutoff valve during

any pressure testing of the gas supply piping system at test

pressures equal to or less than 1/2 PSIG. (3.45 KPA)

• A standard 1/2 inch, black steel pipe and malleable fittings

should be used for gas service connections.

• Do not use cast iron fittings.

• Although 1/2 inch size pipe is recommended, piping should

be of adequate size and installed to provide a supply of gas

sufficient to meet the maximum demand without undue loss

of pressure between the meter and the fryer. The pressure

loss in the piping system should not exceed 0.3 inch water

column.

Provisions should be made for moving the fryer for cleaning and

servicing. This may be accomplished by:

1. Installing a manual gas shut off valve and a disconnect

union, or

2. Installing a heavy duty (design A.G.A. certified connector

which complies with the Standard for Connectors for Moveable Gas Appliances, ANSI Z21.6, or CAN/CGA 6.16 with

a quick disconnect coupling (Henny Penny Part No. 19921,

which complies with ANSI standard Z21.41, or CAN 1-

6.9. Also adequate means must be provided to limit the

movement of the fryer without depending on the connector

and quick-disconnect device or its associated piping to limit

the fryer movement.

3. See The illustration on page 2-8 for the proper connections of the flexible gas line and cable restraint.

299 2-7

MINIMUMS PlJLLof equip

ment away from wall

permissible for accessi-

iimh’,o Quick Disconnect

AVOID SHARP BENDS AND KINKS when

pulling equipment away from wall. (Maximum pull will kink ends, even if installed

properly, and reduce Connector life.)

-8.

Please refer to the illustration below

when installing cable restraint on all

moveable gas fryers.

DISCONNECT

MAXIMUM PULL

MINIMUM PULL

FOR ACCESSIBILITY ONLY

Couplings and hose

should be installed in the

same plane as shown at

left. DO NOT OFFSET

COUPLINGS-this causes

torsional twisting and

undue strain causing

premature failure.

This is the correct way to

tical traverse. Note the

Allowing a sharp bend, as

coupling.

install metal hose for ver-

single, natural loop.

shown at right, strains and

twists the metal hose to a

point of early failure at the

QUICK

DISCON-

NECT DEVICE

while extended at

l-bolt is to be secured to the building

using acceptable building construc-

tion practices.

Secure l-bolt to a building stud. DO

NOT attach to dry wall only. Also,

locate the l-bolt at the same height as

the gas service. Preferred installation

is approximately six inches to either

side of service. Cable restraint must

be at least six inches shorter than

flexible gas line.

‘x

__. .._.. , ,,’

Maintain the minimum or

larger bending diameter

between the couplings for

longest life.

Closing in the diameter at

the couplings, as shown

at right, creates double

bends causing work

fatigue failure of the

fittings..

In all installations where

“self-draining” is not

necessary, connect metal

hose in a vertical loop.

DO NOTCONNECT

METAL HOSE HORIZONTALLY . . . unless

“self-draining” is necessary, then use support on

;c);er plane as shown at

.’

Utilize elbows when necessary to

avoid sharp kinks or excessive bending. For ease of movement, install

with a “lazy” loop. Gas appliance

must be disconnected prior lo maximum movement.

inimom movement is permissible for hose

disconnection).

Prior to turning the gas supply on, be sure the

gas dial cock on the fryer gas valve is in the OFF

position.

After the piping and fittings have been installed, check

for gas leaks. A simple checking method is to turn on

the gas and brush all connections with $ soap solution.

If bubbles occur, it indicates escaping gas. In this event,

the piping connection must be redone.

Never use a lighted match

for gas leaks. Escaping gas could cause an explo-

sion resulting in severe personal injury and/or

property damage.

The gas pressure regulator-on the automatic gas valve

is factory set as follows:

Natural: 3.5 inches water column

Propane:

The following steps provide the pilot lighting procedure:

1. The gas cock dial has a dual function.

I

a. Complete control of gas to the pilot and main

burner.

b. When in the pilot position, it is the reset mecha-

nism for the automatic pilot.

10.0 inches water column

or open flame to test

2. Partially depress and turn the control gas cock dial

to the OFF position.

3. Wait a sufficient length of time to allow any gas

which may have accumulated in the burner com-

partment to escape (at least 5 minutes).

4. Turn the main power switch and the thermostat

knob to the

5. Turn the gas cock dial to the

position.

position.

6.

epress and hold gas cock dial while lighting the

pilot. Allow the pilot to burn approximately 30

seconds before releasing the gas cock dial. The pilot

should remain lighted.

Ifthe pilot does not remain lighted, repeat steps 2

and 3, allowing a longer period of time before

releasing the gas cock dial.

7. Turn the gas cock dial to the ON position.

8. With the lid open, turn the thermostat to a setting

of 200°F.

9. Listen for the gas burner ignition.

It will be an audible sound due to the gas igniting

at the gas jets within the burner.

o not leave the

seconds; damage to the frypot may result.

10. The frypot should be cleaned per the instructions in

section 3.

11. The frypot must be filled to the proper level with

shortening. Refer to paragraph 3-6.

12. The fryer is now ready for operation.

13. Turn the thermostat dial to the desired temperature.

he pilot flame is preset at the factory. If adjustment is

necessary, refer to paragraph 5-18.

on for more than 10

:,%,,I;4

The gas regulator is preset at the factory at 3.5 inch

water column for natural gas (10.0 inch for propane). If

adjustment is necessary, refer to paragraph 5-18.

The electric fryer is available from the factory wired for

208,220/240, or 440/480 volts, single or three phase, 60

Hertz service. The proper power service cable must be

ordered as an accessory or provided at installation.

Check the data plate on the inside of the fryer door to

determine the correct power supply.

This fryer must be adequately and safely

grounded. Refer to local electrical codes for correct grounding procedures. If fryer is not

adequately grounded, electrical shock could result *

A separate disconnect switch with proper capacity fuses

or breakers must be installed at a convenient location

between the fryer and the power source. (The field supply wiring to the fryer should be of the size indicated in

the data table.) It should be an insulated copper conductor rated for 600 volts and 90°C. For runs longer than 50

feet, use the next larger size wire.

Table

using for Electric Fryer

Min.

Fuse

70

90

40

50

70170

70180

40140

50150

20120

20120

V&s Phase KW

208

208

208

208

2201240

2201240

2201240

2201240

4401480

4401480

Single

Single

Three

Three

Single

Single

Three

Three

Three

Three

13.50

11.25

13.50

11.25

13.50

11.25

13.50

11.25

13.50

SUPPlY

Wire

Amps Size Size

54

65

31 8

38

51156 414

56161

30132

33135

13114

18116

4

2

6

413

818

616

12112

12112

el

The gas fryer requires 120 volt, single phase, 60

10 amp, 3 wire grounded service. The gas fryer

tory equipped wit

and plug.

DO NOT DISCONNECT THE GROUND PLUG.

This fryer MUST be adequately and safely

grounded or electrical shock could result. Refer to

local electrical codes for correct grounding

procedures or in absence of local codes, with The

National Electrical Code, ANSIlNFPA No. 70Latest Edition. Canadian models are supplied with

a terminal box, suitable for conduit connection.

In Canada, all electrical connections are to be

made in accordance with GSA C22.1, Canadian

Electrical Code Part 1, and/or local codes.

enny Penny pressure fryer was completely

checked and tested prior to shipment.

owever, it is

good practice to check the unit again after installation.

Any deviation from the following steps may result in damage to the fryer.

1. ove all switches and controls to the OFF position.

2. aise the lid.

emove all items including basket from the frypot.

4. Turn on the main power supply to the fryer using

the main circuit breaker.

5. ove the main power switch on the fryer control

panel to the POWE

The

indicator light will illuminate showing

power is present at the fryer.

el 5

1561

ny Y

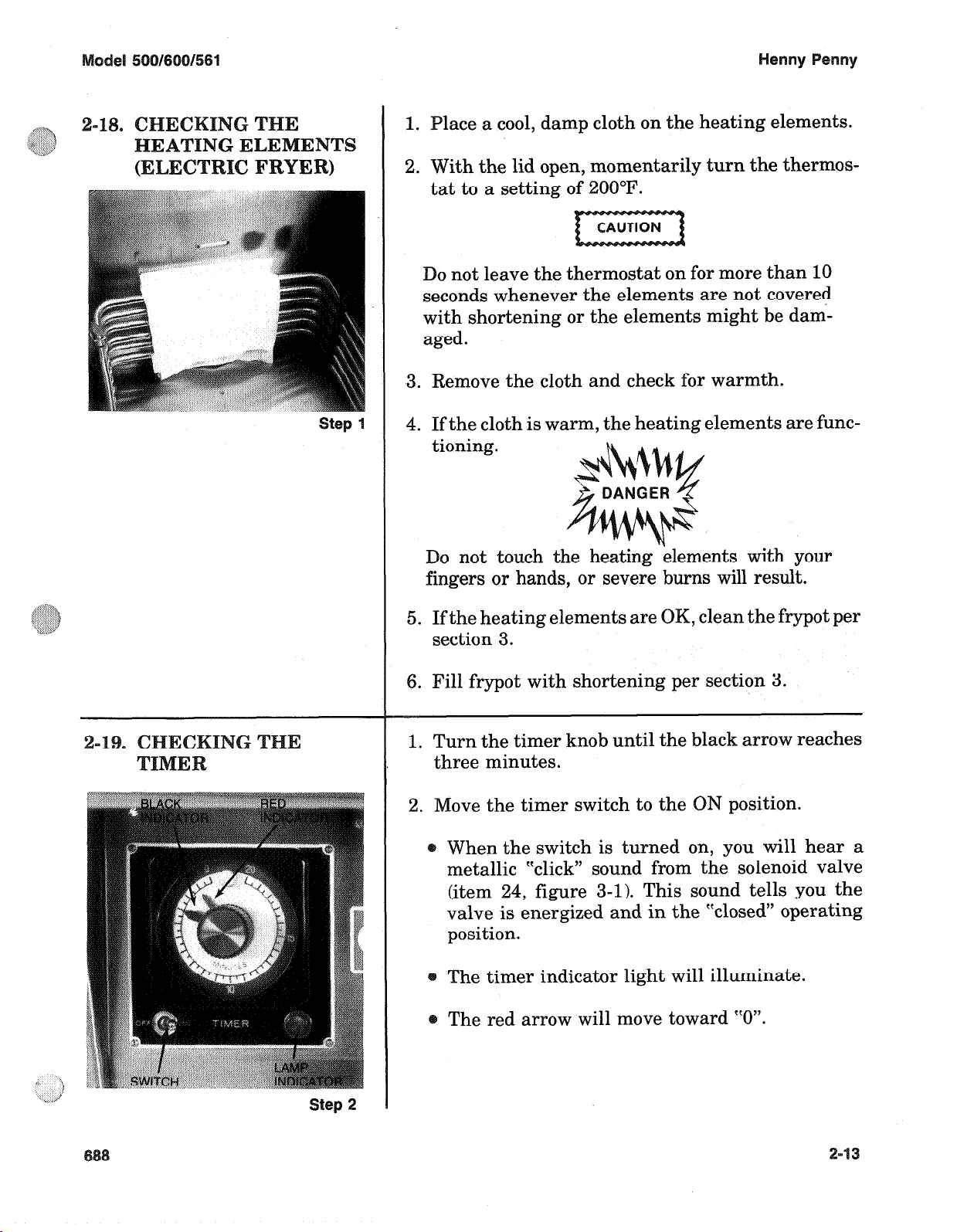

lace a cool, damp cloth on the heating elements.

1.

ith the lid open, momentarily turn the thermos-

2.

tat to a setting of 200°F.

o not leave the thermostat on for more than 10

seconds whenever the elements are not covered

with shortening or the elements might be damaged.

3. Remove the cloth and check for warmth.

tep 1

4. If the cloth is warm, the heating elements are functioning.

Do not touch the heating “elements

with your

fingers or hands, or severe burns will result,.

5. If the heating elements are OK, clean the frypot per

section 3.

6. Fill frypot with shortening per section 3.

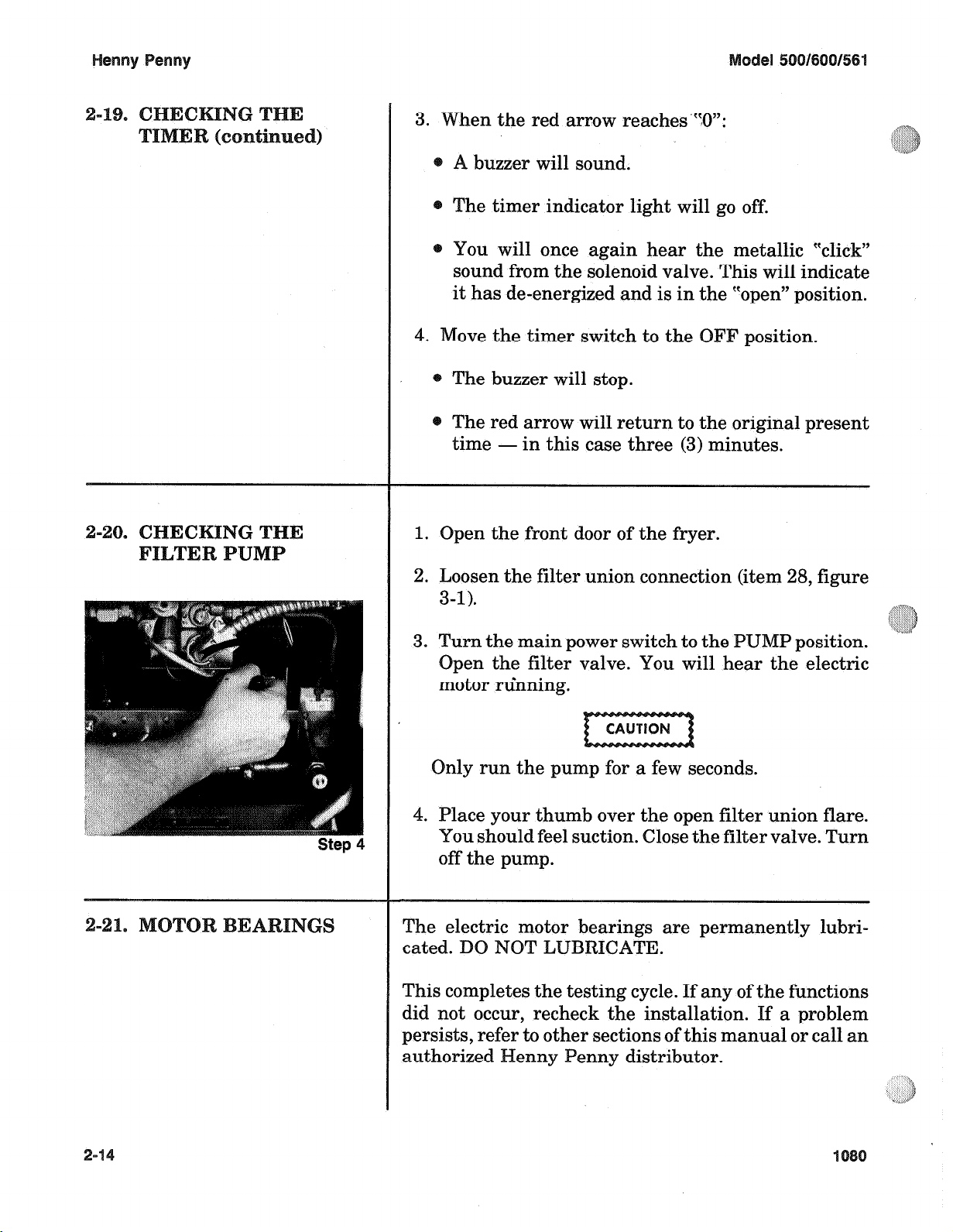

1. Turn the timer knob until the black arrow reaches

three minutes.

2. Move the timer switch to the ON position.

When the switch is turned on, you will hear a

metallic “click” sound from the solenoid valve

(item 24, figure 3-l). This sound tells you the

valve is energized and in the “closed” operating

position.

step 2

The timer indicator light will illuminate.

The red arrow will move toward “0”.

3. When the red arrow reaches”50”:

A buzzer will sound.

The timer indicator light will go off.

You will once again hear the metallic “click”

sound from the solenoid valve. This will indicate

it has de-energized and is in the “open” position.

4. Move the timer switch to the OFF position.

The buzzer will stop.

The red arrow will return to the original present

time - in this case three (3) minutes.

1. Open the front door of the fryer.

2. Loosen the filter union connection (item 28, figure

3-l).

urn the main power switch to the PUMP position.

Open the filter valve. You will hear the electric

motor running.

Only run the pump for a few seconds.

I

4. Place your thumb over the open filter union flare.

You should feel suction. Close the filter valve. Turn

off the pump.

The electric motor bearings are permanently lubri-

0 NOT LUBRICATE.

This completes the testing cycle. If any of the functions

did not occur, recheck the installation. If a problem

persists, refer to other sections of this manual or call an

enny Penny distributor.

enny

he final check to insure a proper installation involves

test frying. This gives the installer an opportunity to

observe the actual cooking operation of the pressure

fryer.

efore the actual cooking operation and adding

shortening to the fry-pot, be sure fry-pot, filter

screen assembly, and drain pan are cleaned. Filter

screen assembly and drain pan should be cleaned

with soap and hot water and thoroughly dried

before reassembling. At this time the fry-pot should

also be cleaned. &efer to paragraphs 3-15 & 3-16

in the “Operation”

section of this manual.

1. Set the thermostat knob at 320°F.

The temperature indicator light will go off when

the shortening is up to the temperature setting.

Step

1 2. Set the main timer to eight minutes.

3. Cut up 3 to 5 pounds of unpeeled potatoes into ‘/z to

% inch wedges.

4. Place the wedges in a pan of water.

5. Drain off the water and bread the wedges -bread-

ing is normally available at the store.

6. Thoroughly stir the shortening for even heating.

7. Place the standard fry basket into the frypot.

8. Carefully drop the breaded wedges into the hot

shortening.

Use care to prevent burns caused by splashing

shortening.

Do not place the potato wedges into the fry

basket, then into the shortening. To do so will

cause the breaded wedges to stick together.

Ste

.

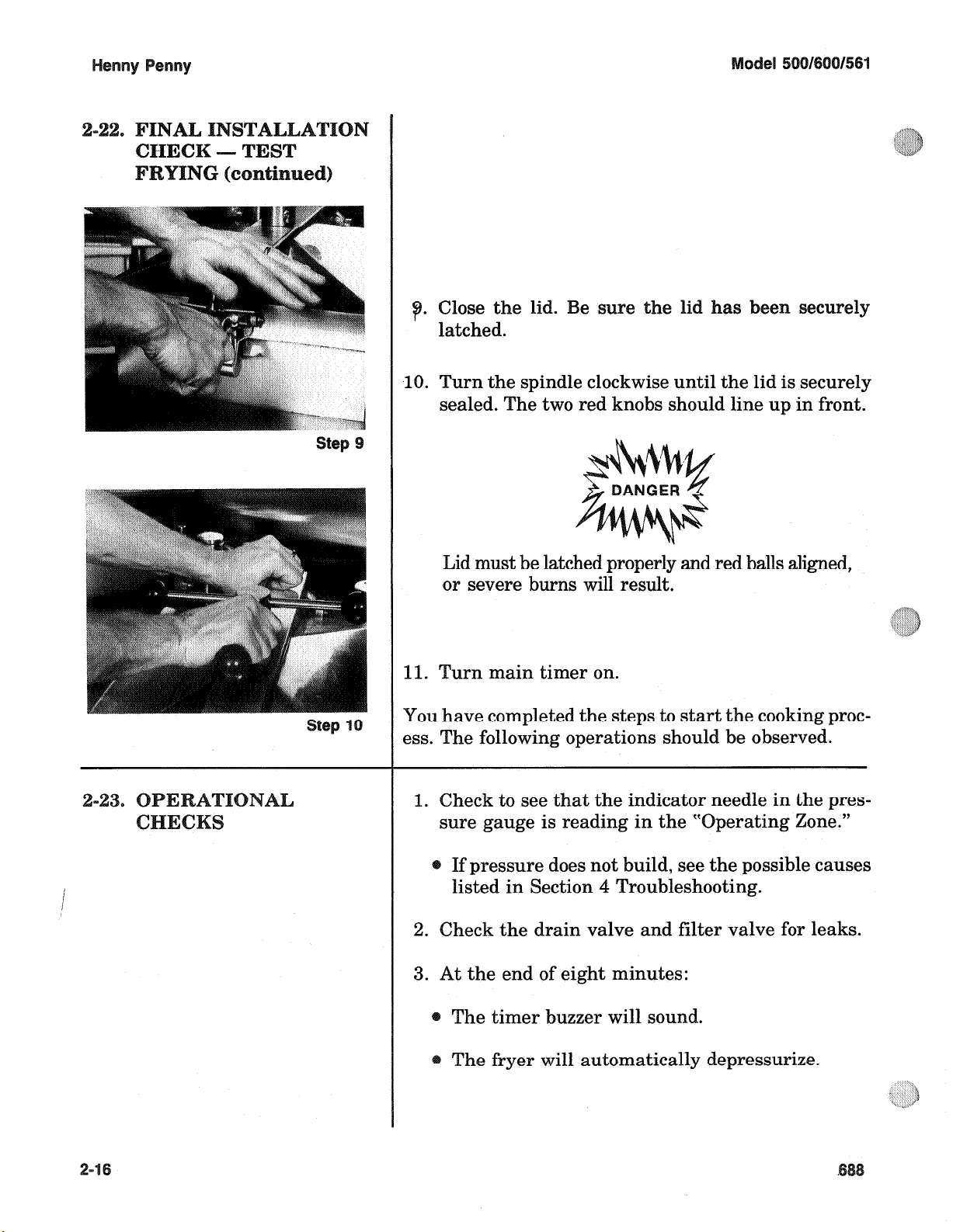

e sure the li

latched.

10. Turn the spindle clockwise until the lid is securely

sealed. The two red knobs should line up in front.

Lid must be latched properly and red balls aligned,

or severe burns will result.

urn main timer on.

You have completed the steps to start the cooking process. The following operations should be observed.

1. Check to see that the indicator needle in the pressure gauge is reading in the “Operating Zone.”

If pressure does not build, see the possible causes

listed in Section 4 Troubleshooting.

2. Check the drain valve and filter valve for leaks.

3. At the end of eight minutes:

The timer buzzer will sound.

The fryer will automatically depressurize.

en

Y

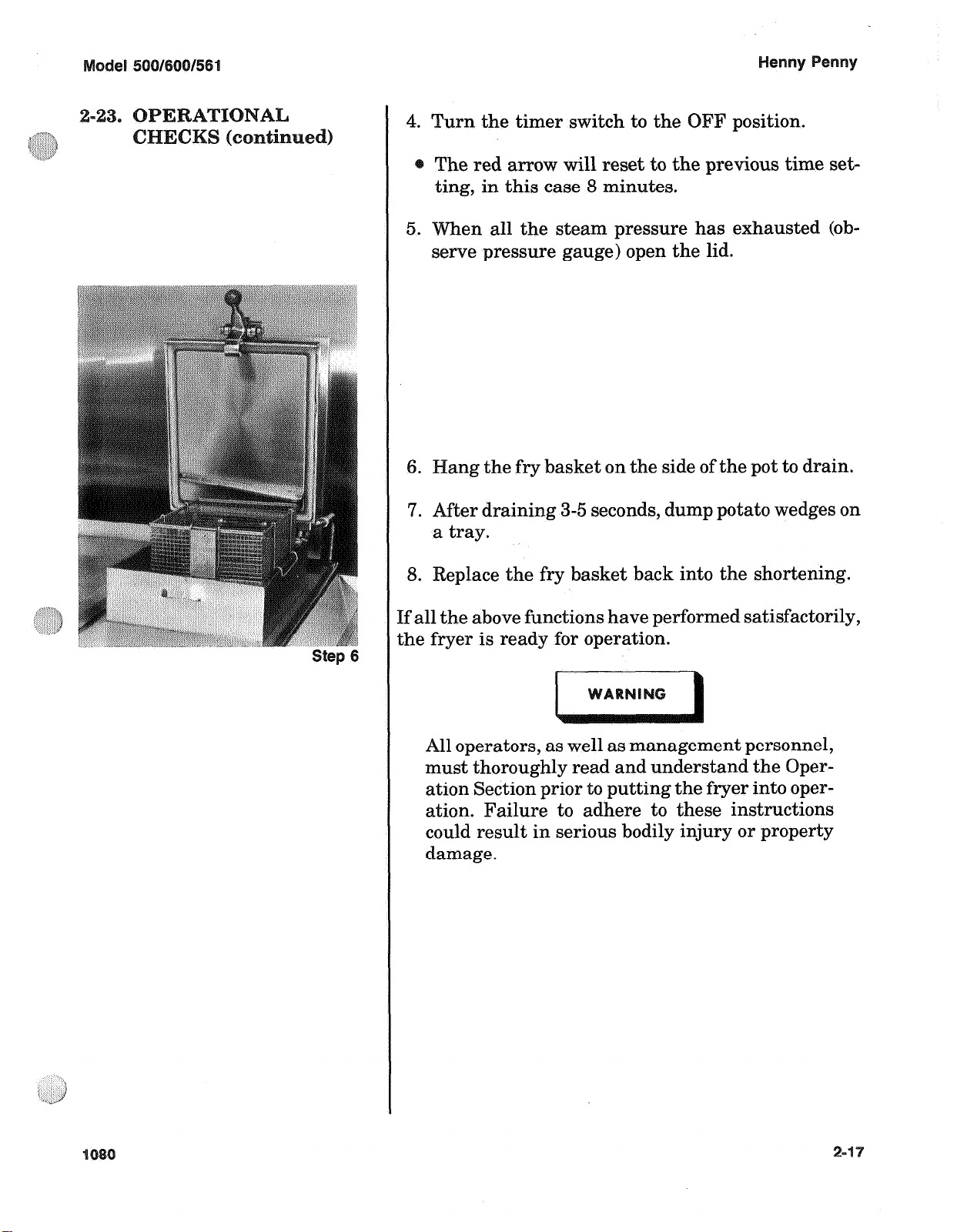

4. Turn the timer switch to the OFF position.

The red arrow will reset to the previous time setting, in this case 8 minutes.

5. When all the steam pressure has exhausted (observe pressure gauge) open the lid.

6.

ang the fry basket on the side of the pot to drain.

7. After draining 3-5 seconds, dump potato wedges on

a tray.

eplace the fry basket back into the shortening.

If all the above functions have performed satisfactorily,

the fryer is ready for operation.

All operators, as well as management personnel,

must thoroughly read and understand the Operation Section prior to putting the fryer into operation. Failure to adhere to these instructions

could result in serious bodily injury or property

damage.

This section provides the daily operating procedure for

1

your pressure fryer.

ead Section

and this section

before operating the fryer. Also, refer to Section 2 to be

sure the fryer has been properly installed and tested.

The arrangement of this section is:

An illustration and explanation of all operating

controls.

Step-by-step operating procedures.

aily maintenance procedures.

Food preparation recipes.

3-1

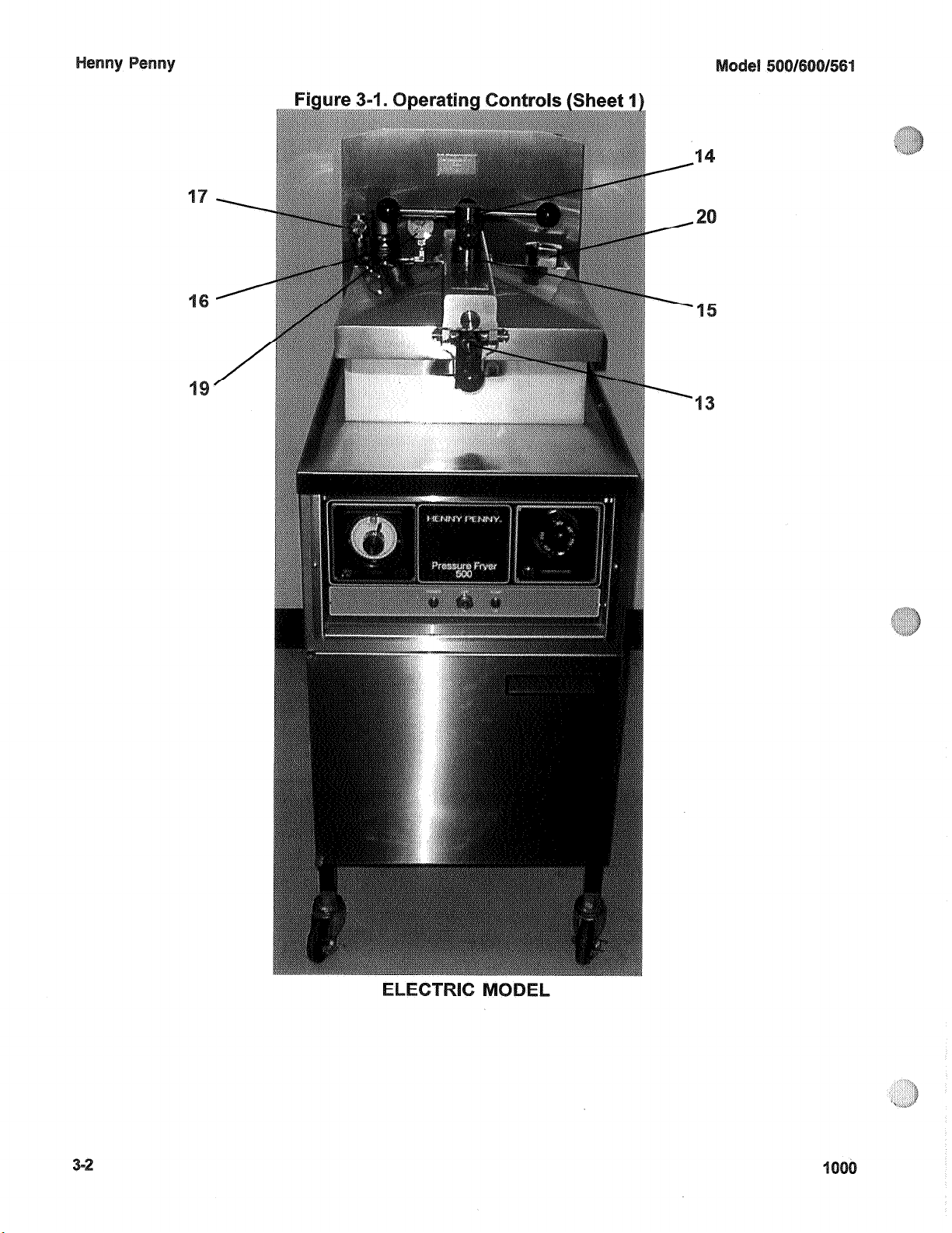

Figure

identifies and describes the function of all

the operator controls and the major components of the

pressure fryer.

Loading...

Loading...