Henny Penny 500 User Manual

Model 500/600

SECTION 3. OPERATING INSTRUCTIONS

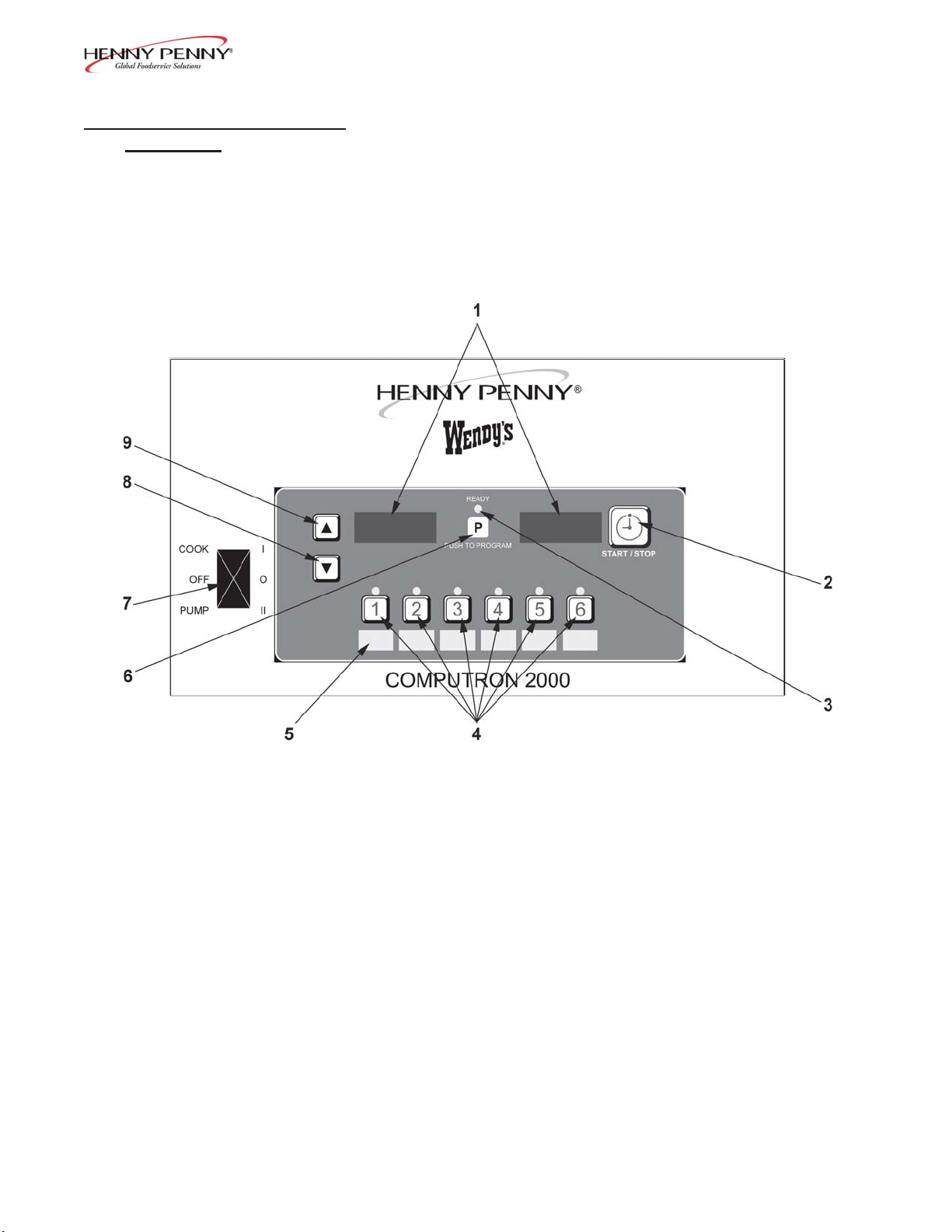

3-1. OPERA TING CONTROLS Refer to Figure 1.

Fig. Item Description Function

No. No.

1 1 Digital Display Shows all the functions of the Cook Cycle, program modes,

diagnostic modes, and alarms

1 2 Used to start and stop Cook Cycles

1 3 Lights when the shortening temperature is 5° F (3° C) below

to 15° F (9° C) above the cooking temperature, signaling the

operator that the shortening temperature IS at the proper

temperature for cooking product

1 4 Product Select Used to select the product for cooking and the LED above

Buttons the selected product is lit; to start Cook Cycles with them; see

section 2, Special Program Mode item SP-10

1 5 Menu Card The name of the food product associated with each product

W ind ow selection button; the menu card strip is located behind the decal

1 6 Press to access program modes; once in the program mode, it

is used to advance to the next setting;

1 7 COOK/PUMP Switch A 3-way switch with a center OFF position; turn the switch

to the COOK position to operate the fryer; turn the switch to

the PUMP position to operate the filter pump; certain conditions

must be met before operating the filter pump; these conditions are

covered later in the Filtering section of the fryer manual

1 8 & 9 Used to adjust the value of the currently displayed setting in

the Program modes

1207 3-1

3-1. OPERA TING CONTROLS

(Continued)

Model 500/600

Figure 1 Control Panel

3-2 1207

Model 500/600

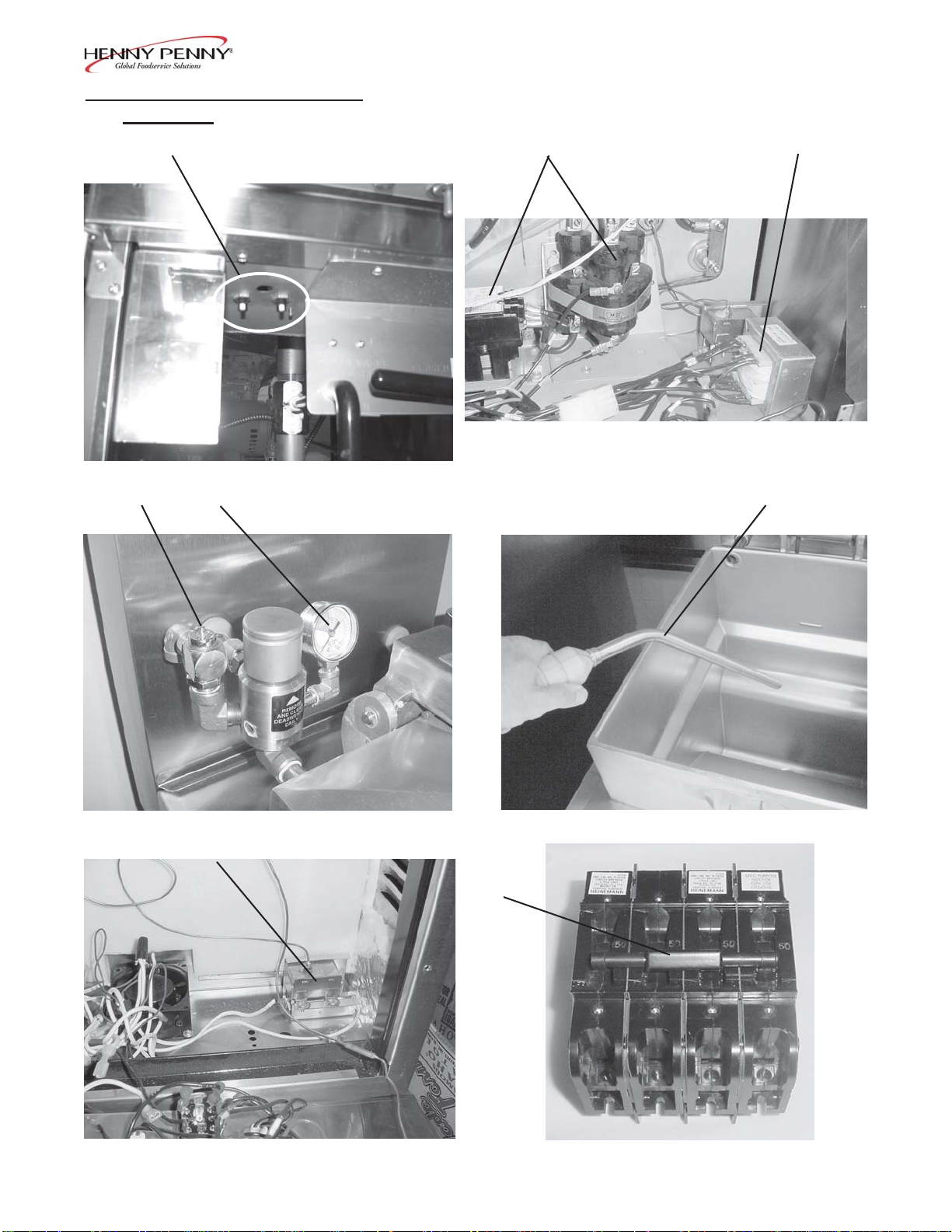

3-2. OPERA TING COMPONENTS

The images at the end of this section, identify all the operator

controls and the major components of the pressure fryer.

Fig. Item Description Function

No. No.

2 1 Lid Latch A spring loaded latch that provides a positive latch to hold the lid

closed; this latch, along with the spindle assembly and lid gasket,

provides a pressure sealed frypot chamber

2 2 Lid Limit Stop A threaded adjustable collar used to obtain the proper

tightness between the lid gasket and the frypot rim; done by

controlling the number of clockwise rotations of the spindle

2 3 Solenoid V alve An electromechanical device that causes pressure to be held in the

frypot; the solenoid valve closes at the beginning of the Cook Cycle

and is opened automatically by the controls at the end of the Cook

Cycle; if this valve becomes dirty or the teflon seat nicked, pressure

won’t build and must be repaired

2 4 Spindle An assembly that is tightened after the lid is latched, and applies

Assembly pressure to the top of the lid; the lid gasket then applies pressure

against the frypot rim; after building one pound of internal pressure,

the lid liner pushes a locking pin up into the locking collar, preventing the spindle from being turned while the frypot is pressurized

2 5 Safety Relief

V alve Ring

DO NOT PULL THIS RING. SEVERE BURNS FROM

THE STEAM WILL RESUL T .

2 6 Safety Relief This is an ASME approved spring loaded valve, set at 14.5 psi;

V alve if the deadweight assembly is clogged, this safety valve releases

excess pressure, keeping the frypot chamber at 14.5 psi

(999 mbar) if this occurs, turn the main power switch to OFF to

release all pressure from the frypot

If safety relief valve activates, turn main power switch to

the OFF position. T o avoid serious burns and injuries,

have fryer serviced before next use.

1207 3-3

Model 500/600

3-2. OPERA TING COMPONENTS

(Continued)

Fig. Item Description Function

No. No.

2 7 Deadweight This deadweight style, pressure relief valve maintains a constant

Assembly level of steam pressure within the frypot; excess steam is vented

through the exhaust stack

Failure to clean the deadweight assembly daily could

result in the fryer building too much pressure. Severe

injuries and burns could result.

2 8 Pressure Gauge Indicates the pressure inside the frypot

3 9 Frypot Holds the cooking shortening and an adequate cold zone for

collection of cracklings

3 10 Lid Spring Assists in raising the lid, and then holding it open (shield covered)

3 11 Condensation This channels the moisture, that collects on the lid liner when the

Drain Channel lid is opened, into the drain line and prevents the moisture

droplets from falling into the shortening

3 12 Lid Gasket Provides the pressure seal for the frypot chamber

3 13 Drain V alve A two-way ball valve that is normally close; turn the handle to drain

(Only the Handle is Shown) the shortening from the frypot, into the filter drain pan

3 14 Condensation The collection point for the condensation, formed within the steam

Drain Pan exhaust system; remove and empty periodically

3 15 Filter Union Connects the filter to the filter pump, and allows easy removal of the

filter and drain pan

3-4 1207

Model 500/600

3-2. OPERA TING COMPONENTS

(Continued)

Fig. Item Description Function

No. No.

3 16 Filter Drain Pan The removable pan that houses the filter and catches the shortening

when it is drained from the frypot; it is also used to remove and

discard old shortening

When moving filter drain pan containing hot shortening,

use extreme care to avoid burns from hot surfaces or

splashing.

3 17 Condensation A hose used to route the condensation collected within the

Drain Line steam exhaust system, to the condensation pan

3 18 Drain Interlock A microswitch that provides protection for the frypot in the event an

Switch operator inadvertently drains the shortening from the frypot while

the main power switch is on; the switch automatically shuts off the

heat when the drain valve is opened

DO NOT OPEN THE DRAIN V AL VE WHILE FRYPOT

IS UNDER PRESSURE. HOT SHORTENING WILL

EXHAUST AND SEVERE BURNS WILL RESUL T

3 19 Rinse Hose A hand-held hose used to rinse food particles from the frypot

(Optional) into the filter pan; attaches to a quick disconnect fitting

3 20 Filter V alve When the power switch is in the PUMP position, this two-way

valve directs filtered shortening from the drain pan, back into the

frypot

3 21 Gas Control Controls the gas flow to the burner

Valve

(GasModels Only)

1207 3-5

Model 500/600

3-2. OPERA TING COMPONENTS

(Continued)

Fig. Item Description Function

No. No.

4 22 Circuit Breakers A protective device which breaks the circuit when the current

(Electric Models Only) exceeds the rated value

5 23 Contactors Relays that route power to the heating elements; one relay is in

(Electric Models Only) series with the high limit, the other one is in series with the controls

5 24 Transformer Reduces the voltage down to accommodatethose components with

low voltage

8 25 High T emperature A control that senses the temperature of the shortening; if the

Limit temperature of the shortening exceeds the safe operating limit, this

control opens and shuts off the heat to the frypot; when the

temperature of the shortening drops to a safe operation limit, the

control must be manually reset by pressing the red reset button,

located under the control panel, behind the door

Gas Electric

9 26 Circuit Breaker Opens the electrical circuit, and removes power to elements

(Single Phase

Electrics Only)

3-6 1207

3-2. OPERA TING COMPONENTS

(Continued)

5

6

Model 500/600

4

3

7

8

2

1

ELECTRIC MODEL

Figure 2. Operating Controls

1207 3-7

3-2. OPERA TING COMPONENTS

(Continued)

Model 500/600

12

11

10

9

21

20

19

18

17

16

13

14

15

GAS MODEL

Figure 3. Operating Controls

3-8 1207

3-2. OPERA TING COMPONENTS

(Continued)

Model 500/600

22

Figure 4. Operating Controls

5

8

23

Figure 5. Operating Controls

24

19

Figure 6. Operating Controls Figure 7. Operating Controls

25

26

Figure 8. Operating Controls Figure 9. Operating Controls

1207 3-9

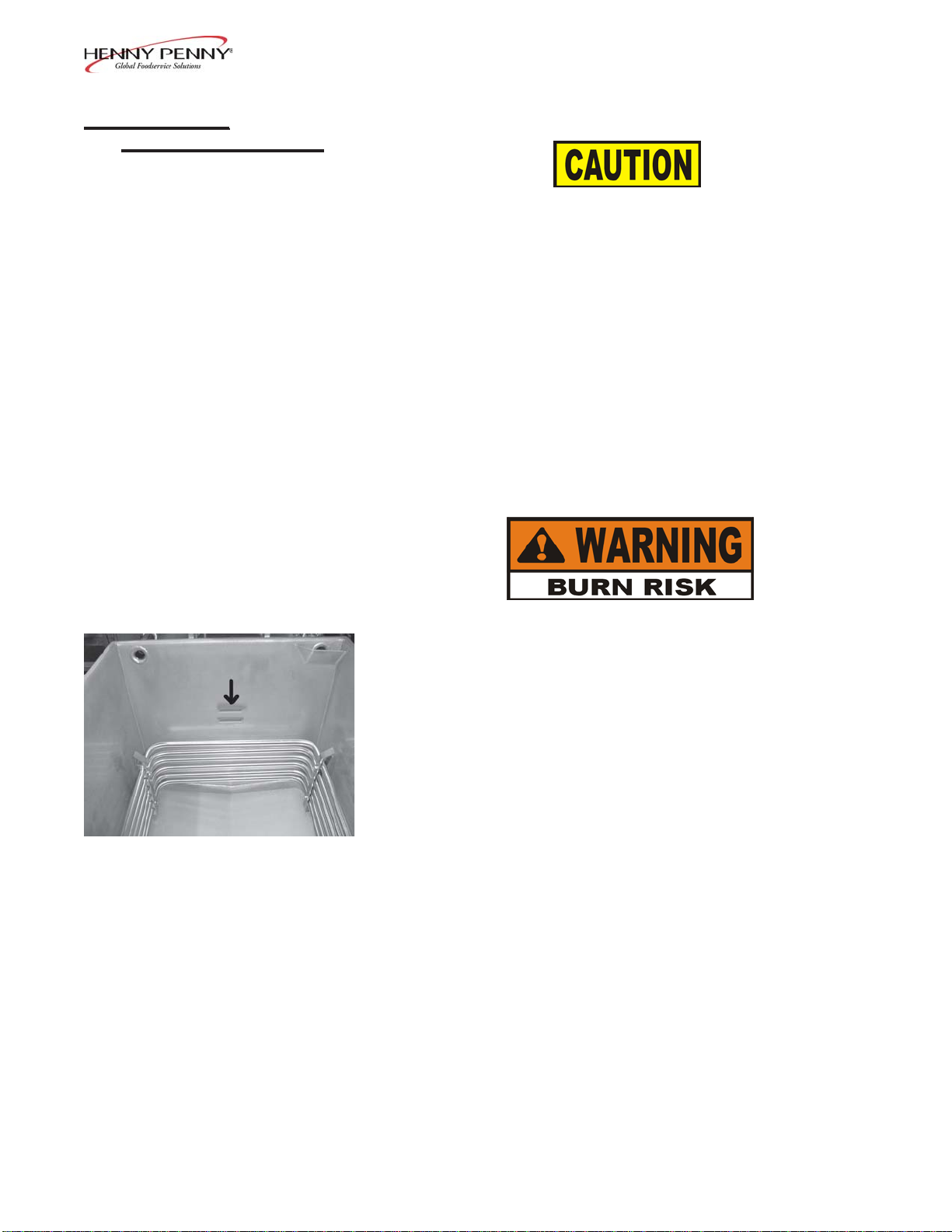

3-3. FILLING OR

ADDING SHOR TENING

Model 500/600

The shortening level must always be at the frypot level

indicator on the rear of the frypot (see photo on next

page). Failure to follow these instructions could r esult in a

fire and/or damage to the fryer.

When using solid shortening, it is recommended to melt

the shortening on an outside heating source before placing it in the frypots. The elements on electric fryers, or the

frypot surface on gas fryers, must be completely

submerged. Fire or damage to the frypot could result.

1. It is recommended that a high quality frying shortening be used in

the fryer. Some low grade shortenings have a high moisture

content and will cause foaming and boiling over.

T o avoid severe burns when pouring hot shortening into

frypot, wear gloves and take care to avoid splashing.

2. The electric model 500 requires 48 lbs. (21.8 kg) of liquid

shortening, and the gas model requires 43 lbs. (19.5 kg). Model

500 fryers have 2 level indicator lines inscribed on the rear wall of

the frypot, whereas the model 600 has only 1 level indicator. The

level indicator lines show the proper shortening levels.

3. Cold shortening should be filled to 1/2-inch (12.7 mm) below

a single level indicator line, and frypots with 2 level indicator lines,

cold shortening should be even with the lower level indicator line.

The shortening expands when heated and should be at the level

indicator line when the shortening is hot, or the top level indicator

line on model 500s.

3-10 1207

Loading...

Loading...