Henny Penny 10, 20, 40 User Manual

59

Installation

Refer to the following pages for important information regarding the

installation of LCS and LCG ClimaPlus Combis. It is recommended

that installation be accomplished by a certified and properly trained

technician.

NOTE: When installing a ClimaPlus combi, humidity calibration must

be performed. This process takes approximately 45-60 minutes. (page 62)

Site, leveling

1) Check for any transport damages. Should there be any signs of transport

damage immediately inform your dealer/freight forwarder.

2) Check installation site. Check entrance clearance.

Minimum entrance space needed without pallet:

Model 6 & 10: 351⁄2 in. (902 mm)

Model 1020: 495⁄8 in. (1262 mm)

Model 20: 397⁄8 in. (1012 mm)

Model 40: 521⁄2 in. (1332 mm)

■ Floor at installation site must be level.

■ Cold water line in place. (page 63)

■ 2 in. (50 mm) drain connection installed.

■ Max. drain height for floor units: 4 in. (100mm)

■ Electrical power supply/protective measures installed and sized correctly.

(page 60-61)

3) Remove all cartons, packing materials, documents etc. from the interior cabinet.

4) Remove grid shelves/trolley from cabinet.

5) Take unit off the pallet.

■ Moving unit without pallet: Sizes 6, 10, 1020 (Fig. 1)

■ Moving unit without pallet: Sizes 20, 40 (Fig. 2)

Minimum clearance sides and back:

2 in. (50 mm)

Service clearance, left side:

20 in. (500 mm)

Clearance for door opening:

Model 6 & 10: 20

1

⁄

2

in. (521 mm)

Model 1020: 29

1

⁄

2

in. (749 mm)

Model 20: 28

3

⁄4 in.(730 mm)

Model 40: 30

3

⁄

4

in. (781 mm)

Fig. 1

Fig. 2

60

Unit weights:

LCS 6: 270 lbs. (123 kg) LCG 6 335 lbs. (152 kg)

LCS 10 334 lbs. (152kg) LCG 10 384 lbs. (174 kg)

LCS 1020 484 lbs.(220 kg) LCG 1020 584 lbs. (265 kg)

LCS 20 686 lbs. (312 kg) LCG 20 798 lbs. (362 kg

LCS 40 972 lbs. (442 kg) LCG 40 888 lbs. (403 kg)

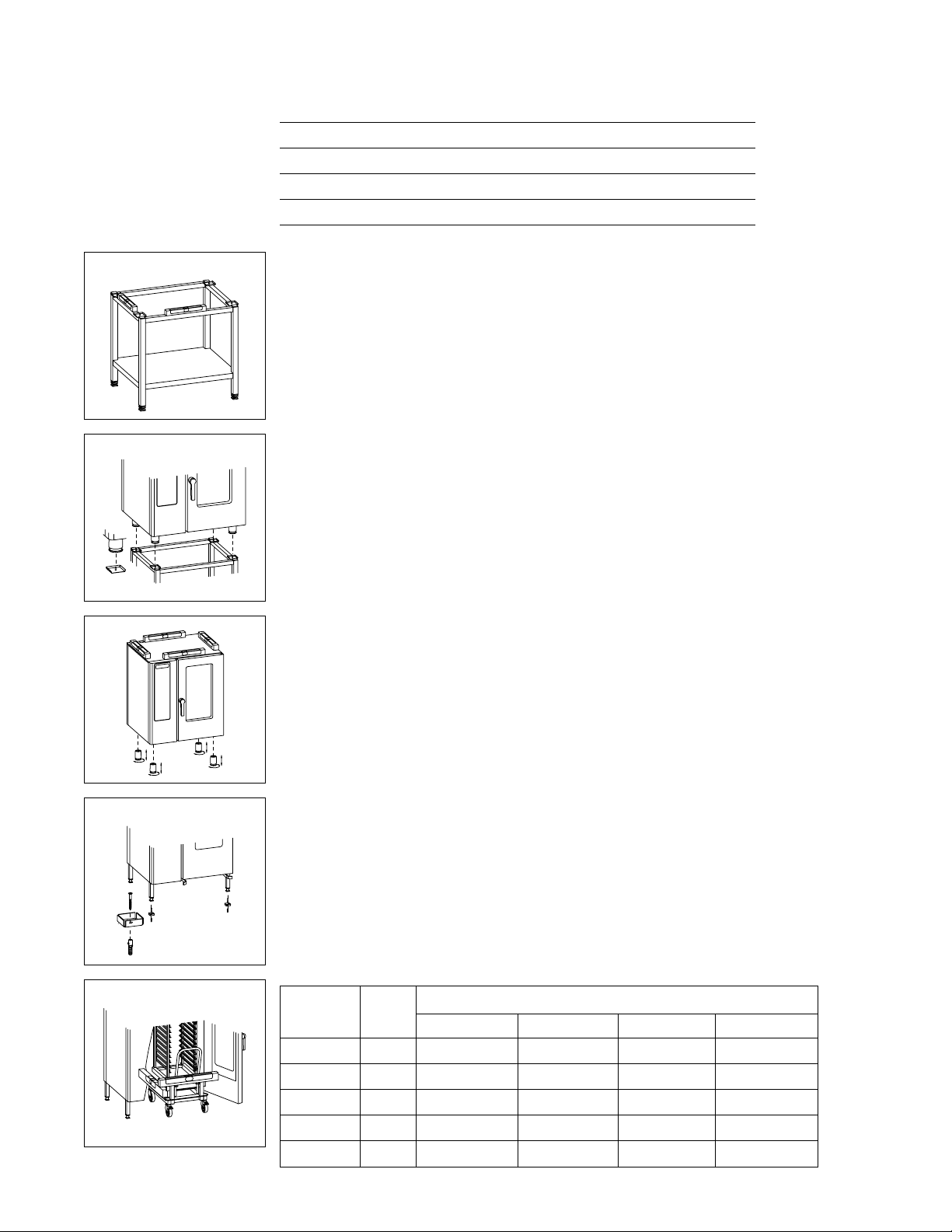

6) Installation models 6, 10, 1020

■ Place floor stand at the installation place and level by adjusting legs. (Fig. 3).

■ Minimum clearance required to neighboring equipment or walls. (page 59)

■ Place the unit on top of the stand. The unit’s legs must be centered on

the locating pins of the stand (Fig. 4).

■ Unit must be level (Fig. 5).

7) Installation models 20, 40

■ The unit must be secured against shifting on the floor by means of floor

fixtures (Fig. 6). If floor fixtures are glued to the floor (use polyurethane

glue or similar), remove all grease from the floor first.

■ Place the unit at its final location and level by adjusting legs. (Fig. 5).

■ Minimum clearance required to neighboring equipment or walls. (page 59)

■ The area of floor under the unit where Mobile Oven Racks will roll in

must be level or door will not seal. (Fig. 7).

Electrical

8) Electrical connection

■ Connect the unit only according to the information given on the data plate.

■ Observe all regulations of your local Electrical Code.

■ The appliance may only be connected by a licensed electrician.

■ Each appliance requires an independent fused power supply line.

■ Connection via GFI circuit breaker is advisable.

■ On-site installation: provide accessible all-pole disconnection device with

minimum of

1

⁄8 in. (3 mm) contact gap (not required for 120v gas units.)

■ Connect appliance to ground.

■ Special voltages on request. Circuit diagram is located behind the operator

panel.

Connected load for electric units:

INST ALLATION

continued

Model KW

Amps

208v 3Phase 240v 3 Phase 208v 1 Phase 240v 1 Phase

LCS-6 10 28 24 48 42

LCS-10 19 53 45.8

LCS-1020 31.5 87.5 75.9

LCS-20 38 105.6 91.5

LCS-40 63 175.1 151.8

Fig. 3

Fig. 4

Fig. 5

Fig. 6

Fig. 7

61

Choose conductor size according above tables and your local regulations.

IMPORTANT

Gas units are voltage specific. Supply voltage must match voltage rated on data plate.

■ Gas units are supplied with grounded power cord and plug.

■ Electric units are NOT supplied with power cord.

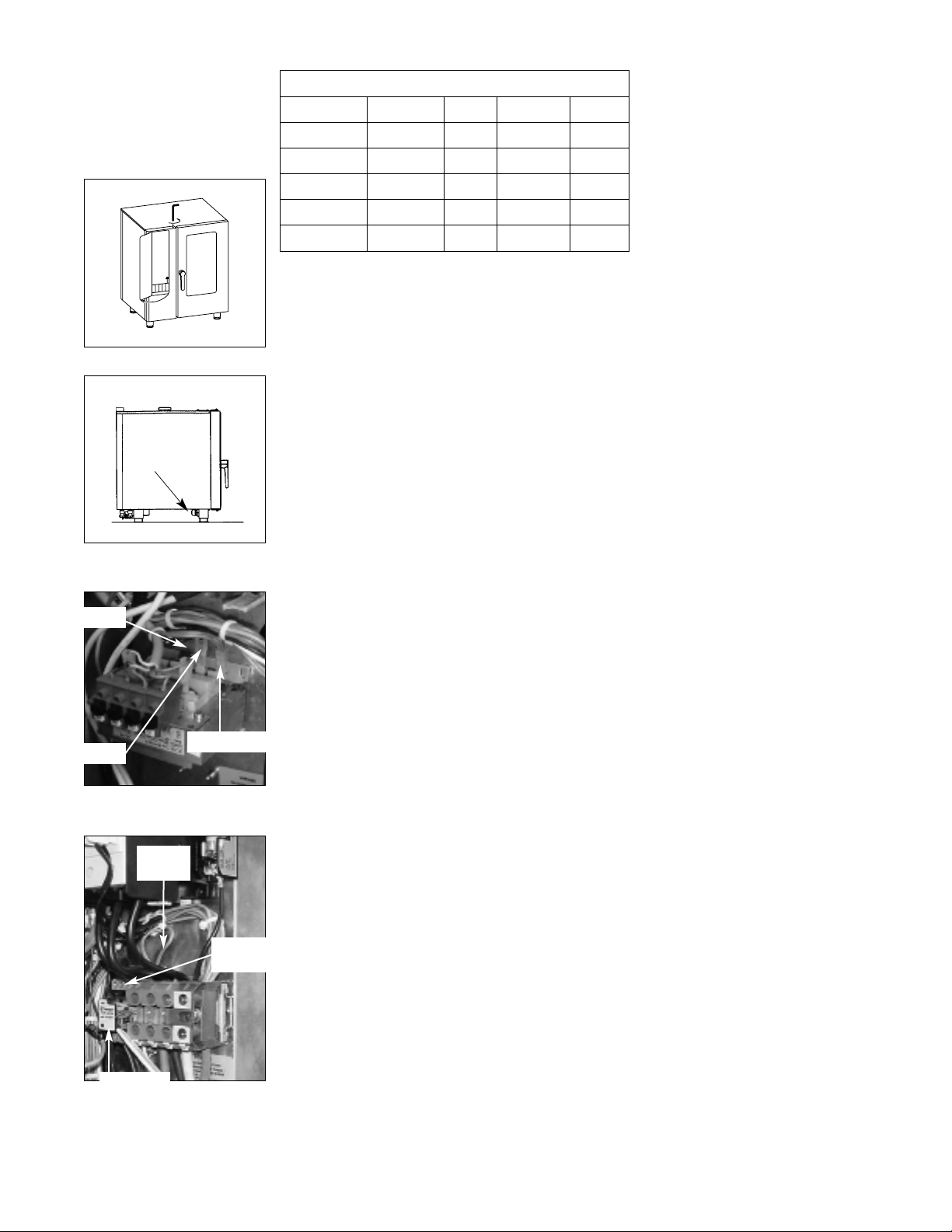

To connect power supply for electric units, models 6, 10:

■ Open the operator panel. (Fig. 8)

■ Insert power cord through cable inlet under left side of unit to desired

length and secure the cable connection tight. (Fig. 9)

■ The circuit diagram is located behind the control panel.

To connect power supply for electric units, models 1020, 20, 40:

■ Access power connection terminals by removing left side panel.

■ Insert power supply cable through cable inlet under left side of unit to desired

length and secure the cable connection tight. (Fig. 9)

■ Connect supply wires as follows:

Gray terminals: L1, L2, L3, phase sequence

does not need to be observed

Blue terminal: Neutral (if applicable)

Yellow/Green terminal: Ground

IMPORTANT

In some areas Henny Penny Electric Combis are shipped set up for 240 volts, but

can be converted to 208 volt operation. If conversion is necessary the unit must be

reset and calibrated.

Convert from 240 volt to 208 volt operation

■ Disconnect unit from power supply source.

■ Open service door (Fig. 8) by loosening fastener at top of the unit over the

control panel using a 5 mm Allen wrench. A rubber grommet must first be

removed to access the bolt.

■ Move transformer primary lead from the 240v tap to the 208v tap (Fig. 10).

■ Open left side panel and locate relay K3.1 (Fig. 11).

■ Remove the jumper wire from the appropriate terminal positions. The

terminals on K3.1 relay socket are numbered. Use the chart below to

determine from which terminals to disconnect jumpers.

INST ALLATION

Electrical requirements of gas units:

Model Voltage Phase Cycle/Hz KW

LCG-6 120 1 60 1

LCG-10 120 1 60 1

LCG-1020 208/240 1 60 1.5

LCG-20 208/240 1 60 1.6

LCG-40 208/240 3 60 3.5

Fig. 8

Fig. 10

Fig. 9

240 volt tap

208 volt tap

Common tap

Fig. 11

Jumper

wire

Terminal

location

K3.1 relay

Cable

Inlet

N

L

L

L

3

2

1

Loading...

Loading...