Page 1

Model 291

SECTION 1. TROUBLESHOOTING

1-1. INTRODUCTION This section provides troubleshooting information in the form

of an easy to read table.

If a problem occurs during the first operation of a new fryer,

recheck the installation per the Installation Section of this

manual.

Before troubleshooting, always recheck the operation procedures per Section 3 of this manual.

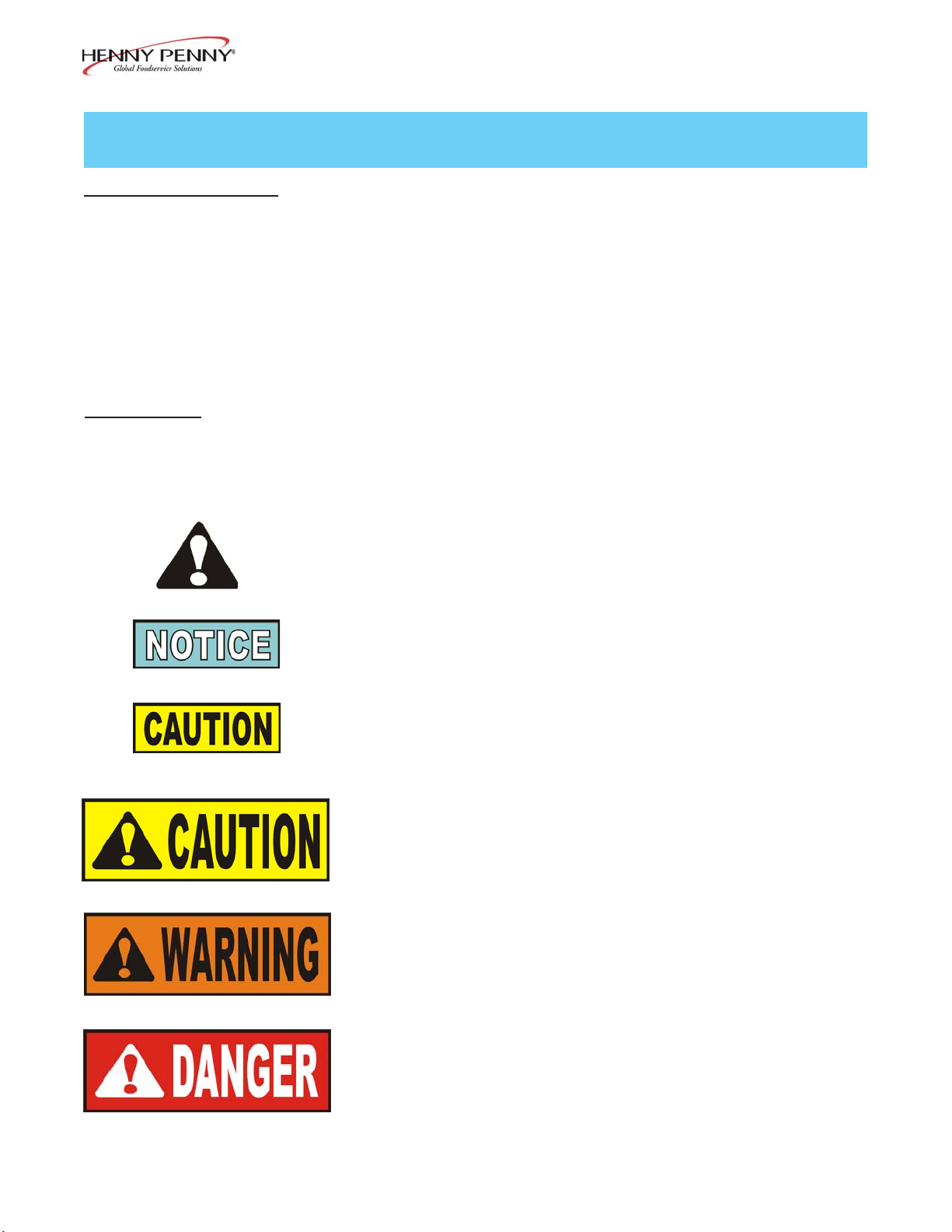

1-2. SAFETY

Where information is of particular importance or safety related,

the words DANGER, WARNING , CAUTION, and NOTICE are

used. Their usage is described below .

SAFETY ALER T SYMBOL is used with DANGER,

W ARNING, or CAUTION which indicates a personal injury

type hazard.

NOTICE is used to highlight especially important information.

CAUTION used without the safety alert symbol indicates

a potentially hazardous situation which, if not avoided,

may result in property damage.

CAUTION indicates a potentially hazardous situation

which, if not avoided, may result in minor or moderate

injury.

W ARNING indicates a potentially hazardous situation

which, if not avoided, could result in death or serious

injury.

DANGER INDICA TES AN IMMINENTL Y

HAZARDOUS SITUA TION WHICH, IF NOT

AVOIDED, WILL RESUL T IN DEA TH OR SERIOUS

INJURY.

1-1 904

Page 2

1-3. TROUBLESHOOTING T o isolate a malfunction, proceed as follows:

1. Clearly define the problem (or symptom) and when it

occurs.

2. Locate the problem in the Troubleshooting table.

3. Review all possible causes. Then, one-at-a-time work

through the list of corrections until the problem is solved.

4. Refer to the maintenance procedures in the Maintenance

Section to safely and properly make the checkout and repair needed.

If maintenance procedures are not followed corr ectly,

injuries and/or property damage could result.

Model 291

904 1-2

Page 3

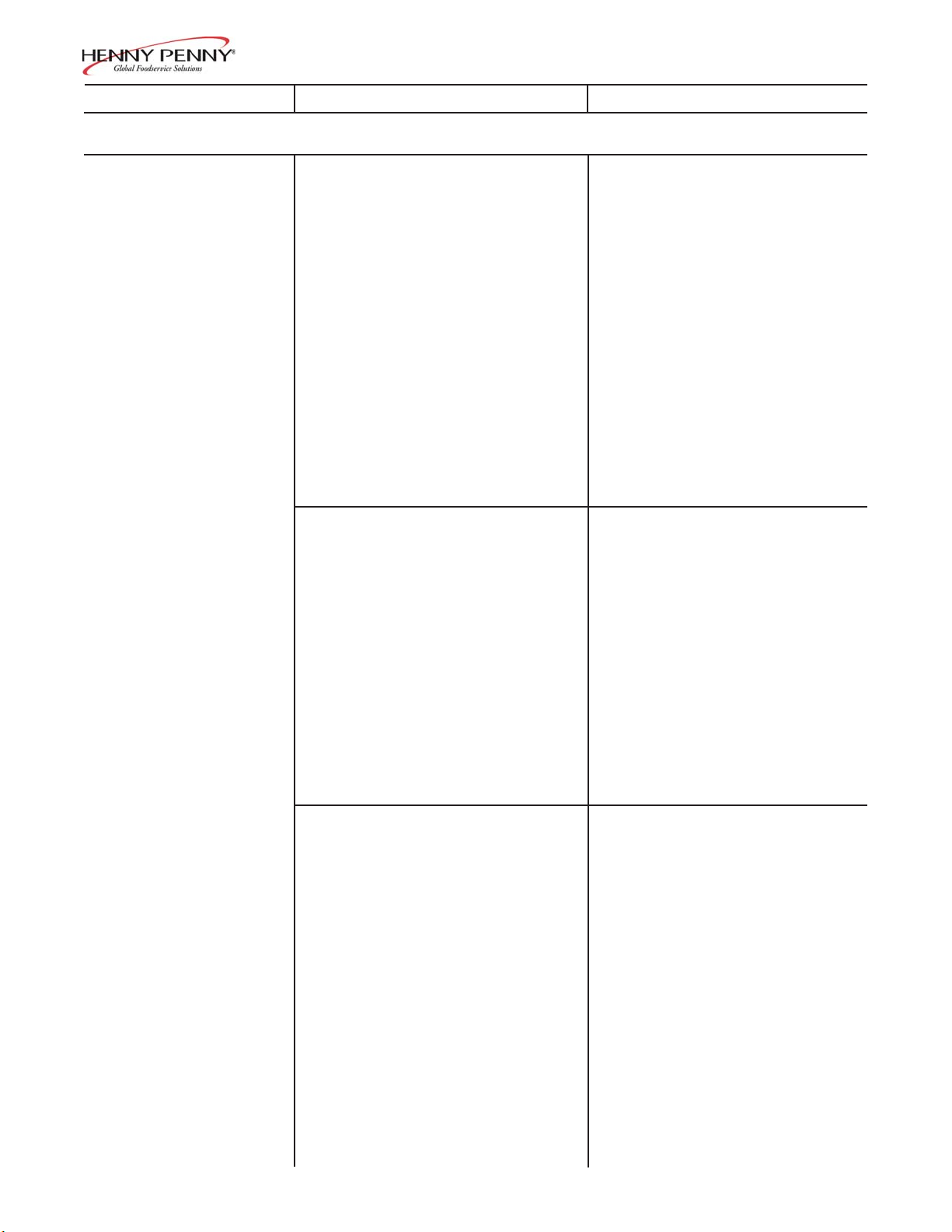

Problem Cause Correction

COOKING SECTION

Product color not correct:

A. Too dark

• Temperature too high • Check temperature setting

in the program mode; see

Programming Section in

Operator’s Manual

• Faulty temperature probe • Remove and replace tempera-

ture probe

• Shortening too old • Change shortening

• Shortening too dark • Filter shortening

• Change shortening

• Breading product too far • Bread product closer to

in advance actual frying period

Model 291

B. T oo light

C. Product

greasy

• Temperature too low • Check temperature setting

• Remove and replace tempera-

ture probe

• Fryer incorrect preheat • Allow proper preheat time

• Slow fryer heat-up/recovery • Faulty element

• Wrong cook button • Be sure to select the correct

pushed. product to be cooked

• Shortening old • Replace shortening

• Temperature too low • Check temperature setting

• Temperature not recovered

when product was dropped

in frypot

• Faulty temperature probe • Remove and replace defective

temperature probe

• Frypot overloaded • Reduce cooking load

• Product not removed from • Remove product from

frypot immediately after frypot immediately after

end of cycle end of cycle

1-3 904

Page 4

Model 291

Problem Cause Correction

COOKING SECTION (Continued)

D. Spotted • Improper separation of the • Load product into racks

product product properly

• Breading not uniform on • Sift breading regularly

the product • Separate product during

breading

• Burned breading particles • Filter the shortening more

on product frequently

• Product sticking together • Separate product prior to

pressure cooking

E. Dryness of • Moisture loss prior to • Use fresh products

product cooking

Product flavor

(taste):

A. Salty taste

B. Burned taste

• Overcooking the product • Reduce cooking time

• Reduce cooking

temperature

• Wrong cook button pushed • Be sure to select the

correct product to be cooked

• Breading mixture is too salty • Sift breading after each use

• Incorrect breading mixture

• Discard old breading

• Incorrect choice of • Use breading designed for

breading the desired product

• Burned shortening favor • Replace shortening

• Frypot not properly cleaned • Drain and clean frypot

C. Bland taste

• Raw product not fresh • Use fresh raw product

• Breading mixture incorrect • Use breading designed for

for product (spice content desired product

too low)

• Cooking temperature too • Check temperature

high (spice flavors lost)

904 1-4

Page 5

Model 291

Problem Cause Correction

COOKING SECTION (Continued)

D. Rancid taste • Shortening too old • Replace shortening, and

follow recommended care

and use of shortening

• Infrequent filtering • Replace shortening and

follow recommended care

and use of shortening

• Non-compatible products • Replace shortening

cooked within the same

• Use compatible products,

shortening. - and follow

recommended care and use of

shortening

• Raw product not fresh • Use fresh product

General:

• Incorrect meat cut • Use correct meat cutting

A. Meat procedures

separation

from bone

• Overcooking • Check cooking time

• Product not fresh • Use fresh product

B. Bone color

not proper (black bone)

• Using frozen product • Use fresh product

• Improper processing of • Use proper processing

product (black bone) procedure for product

• Product not thoroughly • Check cooking time

cooked (red bone)

C. Breading falls

off procedures procedure

• Incorrect breading • Use correct breading

• Check cooking temperature

• Product partially frozen • Thoroughly thaw the

product, before breading

D. Product

sticking prior to cooking fryinginstructions

together

• Product breaded too long • Refer to breading and

• Improper loading • Properly load product per

procedure loading procedures

• Wrong cook button pushed • Be sure to select the

correct product to be cooked

1-5 904

Page 6

Model 291

Problem Cause Correction

POWER SECTION

With switch in • Open circuit • Check to see that unit is

POWER position, plugged in

the fryer is completely inoperative at supply box

(NO POWER) • Check voltage at wall

• Check the breaker or fuse

receptacle

• Check MAIN POWER

switch; replace if defective

• Check cord and plug

• Check 15 amp fuses

HEA TING OF SHORTENING SECTION

Shortening will not heat

• Blown fuse or tripped • Reset breaker or replace fuse

circuit breaker at supply

box or control panel

• Blown fuse in PC board • Replace glass fuse in board

• Faulty POWER/PUMP switch. • Check POWER/PUMP switch

per maintenance section on

the POWER/PUMP switch

• Faulty cord and plug • Check cord and plug

• Check power at receptacle

• Faulty drain switch • Check drain switch per

maintenance section on

drain switches

• Faulty PC Board • Remove and replace control

panel

• Faulty high limit control switch • Check high limit control

switch per maintenance

section on the high limit

• Drain valve open • Close drain valve

• Possible faulty temperature probe • Replace temperature probe

• Faulty contactor • Check contactor per maintenance

section on contactors

904 1-6

Page 7

Model 291

Problem Cause Correction

HEA TING OF SHORTENING SECTION (Continued)

Heating of shortening • Low or improper voltage • Use a meter and check the

too slow receptacle against data plate

• W eak or burnt out element(s) • Check heating element(s) per

Heating Elements Section

• Points in contactor bad • Check contactor per Heating

Contactors Section

• Wire(s) loose • T ighten

• Burnt or charred wire • Replace wire and clean

connection connectors

Shortening • Programming wrong • Check temperature setting

overheating in the program mode

• Faulty PC board • Remove and replace control

panel

• Faulty temperature probe • Remove and replace temperature

probe

• Check contactor for not • Check faulty contactor per

opening Heating Contactors Section

1-7 904

Page 8

Model 291

Problem Cause Correction

SHORTENING FOAMING/DRAINING SECTION

Foaming or boiling • W ater in shortening • At end of a Cook Cycle,

over of shortening drain shortening and clean

frypot; add fresh shortening

• Condensation line stopped up • Remove and clean condensation

line

• Improper or bad • Use recommended

shortening shortening

• Improper filtering • Refer to the procedure

covering filtering the shortening

• Cold zone full of cracklings • Filter shortening

• Improper rinsing after • Clean and neutralize the

cleaning the fryer frypot; rinse with vinegar

to remove the alkaline, then

rinse with hot water and

dry frypot

Shortening will • Drain valve clogged with • Open valve - push cleaning

not drain from frypot crumbs rod through drain opening from

inside of frypot

Shortening leaking • Obstruction in drain • Remove obstruction

through drain valve

• Faulty drain valve • Replace drain valve

904 1-8

Page 9

Model 291

1-4. ERROR CODE TABLE In the event of a control system failure, the digital

display shows an error message. These messages

are coded: “E4”, “E5”, “E6”, “E10”, “E15”, “E41”,

“E46”, “E47”, “E48”, “E70B” and “E92”. An alarm

sounds when an error code is displayed, and to silence

this alarm, press any button.

DISPLAY CAUSE PANEL BOARD CORRECTION

“E-4” Control board Turn switch to OFF position, then turn switch back ON;

overheating if display shows “E-4”, the control board is getting too hot;

check the louvers on each side of the unit for obstructions;

check cooling fan, if present

“E-5” Shortening Turn switch to OFF position, then turn switch back to ON;

overheating if display shows “E-5”, the heating circuits and temperature

probe should be checked

“E-6 A” T emperature Turn switch to OFF position, then turn switch back to ON;

probe open if display shows “E-6”, have the temperature probe checked

“E-6 B” T emperature Turn switch to OFF position, then turn switch back to ON;

probe shorted if display shows “E-6” have the temperature probe checked

“E-10” High limit Reset the high limit by manually pushing up on the reset

button; if high limit does not reset, high limit must be replaced

“E-15” Drain switch Close drain, using the drain valve handle; if display still

failure shows “E-15”, have the drain microswitch checked

1-9 904

Page 10

Model 291

1-4. ERROR CODE TABLE

(Continued)

DISPLAY CAUSE PANEL BOARD CORRECTION

“E-41”, “E-46” Programming Turn switch to OFF , then back to ON, if display shows any

Failure of the error codes, try to reinitialize the control; if error code

persists, have the control board replaced

“E-47” Analog converter Turn switch to OFF, then back to ON, if “E-47” persists,

chip or 12 volt have the I/O board, or the PC board replaced; if speaker

supply failure tones are quiet, probably I/O board failure

“E-48” Input system Have PC board replaced

error

“E-70 B” Faulty power Have power switch checked, along with its wiring; have

switch, or switch Input/Output board replaced if necessary

wiring; faulty

I/O board

“E-92” 24 V AC fuse Have components, in 24-volt circuit (I.E., hi limit, drain switch)

on I/O board open checked for shorts

904 1-10

Loading...

Loading...