Henny Penny 106 Installation Manual

PRODUCT DATA &

04/30/14

INSTALLATION

AIR COOLED MODELS

FROM 103 THRU 182

40 TO 115 TONS

Bulletin T50-TAB-PDI-2

1097722

For the latest product updates and further

information, visit www.trentonrefrigeration.com

TAB Centrifugal

Fan Air Cooled

Condensers

CONTENTS

Nomenclature.......................................................................................................................

Features and Options...........................................................................................................

Capacity Data.......................................................................................................................

Selection Data .....................................................................................................................

Multiple Compressor Applications........................................................................................

Blower Components.............................................................................................................

Fan Performance Data ........................................................................................................

Blower Data..........................................................................................................................

Calculation of Total Static Pressure .....................................................................................

Component and Air Friction .................................................................................................

Sound Data ..........................................................................................................................

Performance and Physical Data ......................................................................................

Fan Motor Locations ............................................................................................................

Dimensional Data.............................................................................................................

Engineering Specications..................................................................................................

Installation and Assembly Instructions.............................................................................

Lifting Instructions ...........................................................................................................

Wiring Diagrams..................................................................................................................

Electrical Data..................................................................................................................

Maintenance .......................................................................................................................

Approximate Weights ..........................................................................................................

Optional Internal Spring Isolators ........................................................................................

Warranty...............................................................................................................................

Project Information...............................................................................................................

Page

11 - 12

14 - 19

21 - 22

23 - 24

26 - 27

2

2

3

4

5

6

7

8

9

10

10

13

20

25

28

29

30

31

31

NOMENCLATURE

04/30/14

T50-TAB-PDI-2

- 2 -

T AB 1 28 F - N - T4 A - 0000

T = Trenton

Unit Style

AB = Air Handler, Bolt-On Air Cooled Condenser/Heat Reclaim

Model Number

1 = Number Of Fans

28 = Model Number

Blower Type

F = Forward Curved

A = Air Foil

STANDARD FEATURES

Manufacturing Options

Series / Generation

A = First Generation

Unit Electrical Designation

S1 = 115/1/60

S2 = 208/230/1/60

T3 = 208-230/3/60

T4 = 460/3/60

T5 = 575/3/60

Cabinet Type

I = Insulated

N = Non-Insulated

● Indoor Applications Only ● Large Face Area Centrifugal Fan

● “Bolt-On” Coil for Maximum Capacity in Minimum Space

● Single Wall Heavy Gauge Galvanized Cabinet

● Full Size Access Doors for Easy Maintenance ● Efcient Forward Curved Blower

● 14 Models ● Up to 6” Total Static Pressure

● Up to 55,000 CFM ● Internal Motor ● Up to 50 HP

● Horizontal and Vertical Air Discharge

● External Electrical Box Mounted to Cabinet

● Extended Grease Lines with External Access

OPTIONAL FEATURES (Factory Mounted)

● Double Wall Cabinet with 2” mineral wool Insulation

● Internal Vibration Isolators

● Airfoil (Up to 8” Total Static Pressure)

● Disconnect Switch ● Flat Filter

● Angle Filters

OTHER OPTIONS ARE AVAILABLE AT YOUR REQUEST. CONSULT FACTORY FOR PRICING.

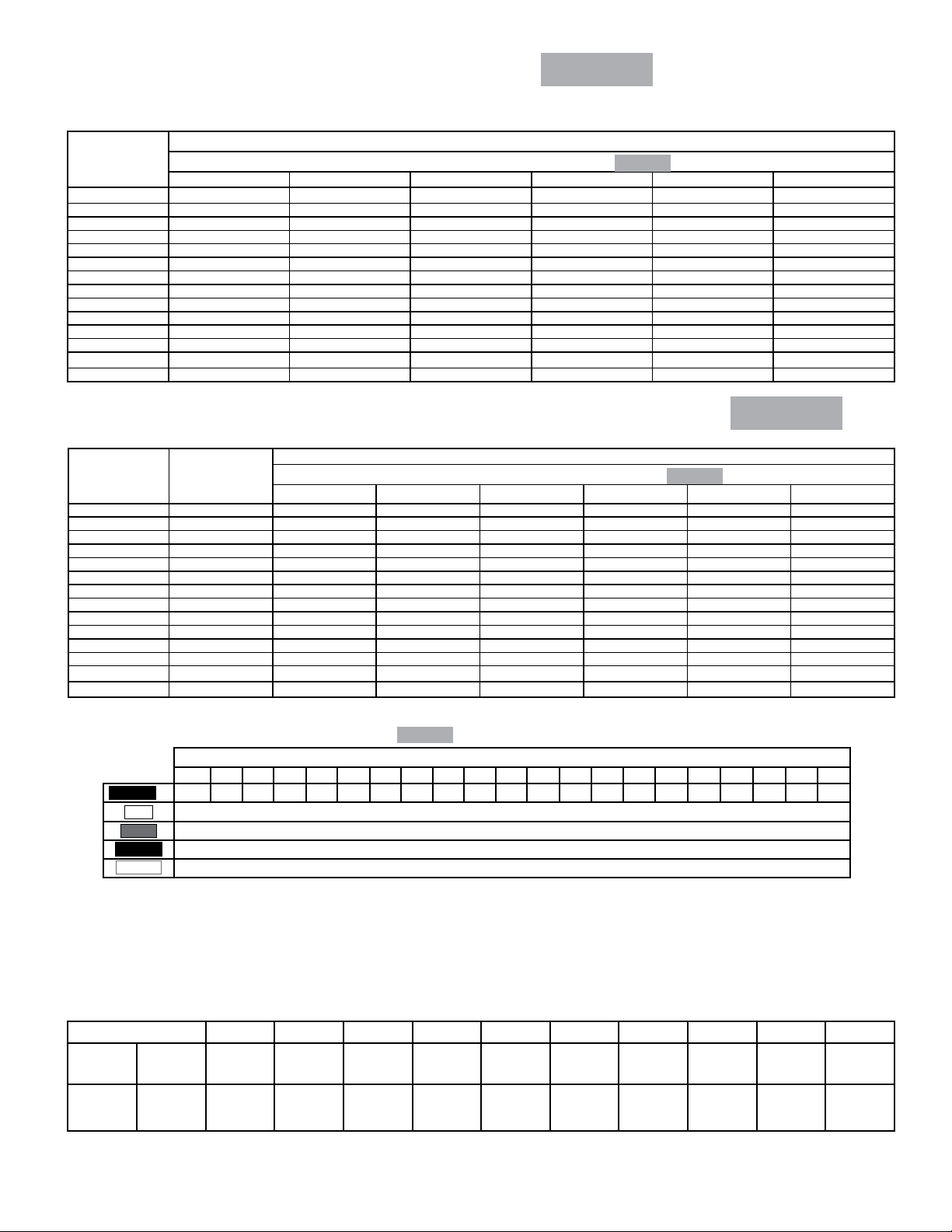

CAPACITY DATA -

04/30/14

T50-TAB-PDI-2

- 3 -

R404A

TAB 60Hz

Table 1

TAB

MODEL

NUMBER

103 1750 17500 26250 35000 43750 52500

104 2650 26500 39750 53000 66250 79500

106 3780 37800 56700 75600 94500 113400

108 5040 50400 75600 100800 126000 151200

111 6720 67900 100800 134400 168000 201600

114 8590 85900 128850 171800 214750 257700

117 10190 101900 152850 203800 254750 305700

122 12640 126400 189600 252800 316000 379200

128 15870 158700 238050 317400 396750 476100

137 20820 208200 312300 416400 520500 624600

141 24440 244400 366600 488800 611000 733200

150 28110 281100 421650 562200 702750 843300

164 35480 354800 532200 709600 887000 1064400

182 46100 461000 691500 922000 1152500 1383000

1 °F 10 °F 15 °F 20 °F 25 °F 30 °F

TOTAL HEAT OF REJECTION BTU/hr

TEMPERATURE DIFFERENCE (TD)

R404A

HEAT REJECTION CAPACITY PER FACE TUBE -

R404A

Table 2

TAB

MODEL

NUMBER

103 12 146 1460 2190 2920 3650 4380

104 14 189 1890 2835 3780 4725 5670

106 16 236 2360 3540 4720 5900 7080

108 22 229 2290 3435 4580 5725 6870

111 22 305 3050 4575 6100 7625 9150

114 22 390 3900 5850 7800 9750 11700

117 22 463 4630 6945 9260 11575 13890

122 26 486 4860 7290 9720 12150 14580

128 26 610 6100 9150 12200 15250 18300

137 34 612 6120 9180 12240 15300 18360

141 40 611 6110 9165 12220 15275 18330

150 46 611 6110 9165 12220 15275 18330

164 58 612 6120 9180 12240 15300 18360

182 58 795 7950 11925 15900 19875 23850

R407C

R22

R507

R134a

R410A

FACE

TUBES

10 11 12 13 14 15 16 17 18 19 20 21 22 23 24 25 26 27 28 29 30

(4)

0.67 0.69 0.72 0.73 0.75 0.77 0.78 0.80 0.81 0.82 0.83 0.84 0.85 0.86 0.86 0.87 0.87 0.88 0.88 0.89 0.89

1 °F 10 °F 15 °F 20 °F 25 °F 30 °F

Correction Factors for Other Refrigerants

Use

R404A

TD (Condensing dew point temperature - ambient temperature)

TOTAL HEAT OF REJECTION BTU/hr

TEMPERATURE DIFFERENCE (TD)

Values Multiplied By:

1.02

1.00

0.97

1.02

R404A

NOTES:

(1) Capacity based on 12 FPI, 6 rows and 1/2” O.D. tubes.

(2) Above capacity data based on 0°F subcooling and at sea level.

(3) TD = Condensing temperature - ambient temperature.

Table 3

† - On a circuit that uses only 1 face tube, a connection tube will be provided instead of a header.

When used as a desuperheater, the inlet and outlet connections will be the same and based on Hot Gas sizing.

MULTIPLE CIRCUIT CONNECTION SIZES

NET TONS 3 - 9 † 9.5 - 12 12.5 - 16 16.5 - 22 22.5 - 34 34.5 - 42 42.5 - 52 52.5 - 68 68.5 - 77 77.5 - 95

HOT GAS

INLET

LIQUID

OUTLET

inches 1 1/8 1 3/8 1 3/8 1 5/8 2 1/8 2 1/8 2 5/8 2 5/8 3 1/8 3 1/8

inches 7/8 7/8 1 1/8 1 1/8 1 3/8 1 5/8 1 5/8 2 1/8 2 1/8 2 5/8

SELECTION DATA

04/30/14

T50-TAB-PDI-2

- 4 -

TAB 60Hz

The selection of an air cooled condenser is based on the

heat rejection capacity at the condenser rather than net

refrigeration effect at the evaporator because the refrigerant gas absorbs additional energy in the compressor. This

additional energy, the heat of compression, varies appreciably with the operating conditions of the system and

with compressor design, whether open or suction cooled

hermetic type.

Some compressor manufacturers publish heat rejection

gures as part of their compressor ratings. Since heat rejection varies with compressor design, it is recommended

that the compressor manufacturer’s data be used whenever available in selecting an air cooled condenser.

If the compressor manufacturer does not publish heat

rejection ratings, factors from Table Nos. 4 and 5 may be

used to estimate total heat rejection-THR.

HEAT REJECTION FACTORS

CONDENSER LOAD = COMPRESSOR CAPACITY X FACTOR

TABLE 4:

OPEN COMPRESSORS

EVAP.

TEMP

°F °C

-30 -34 1.37 1.42 1.47 - - -

-20 -29 1.33 1.37 1.42 1.47 - -

-10 -23 1.28 1.32 1.37 1.42 1.47 -

0 -18 1.24 1.28 1.32 1.37 1.41 1.47

10 -12 1.21 1.24 1.28 1.32 1.36 1.42

20 -7 1.17 1.2 1.24 1.28 1.32 1.37

30 -1 1.14 1.17 1.2 1.24 1.27 1.32

40 4 1.12 1.15 1.17 1.2 1.23 1.28

50 10 1.09 1.12 1.14 1.17 1.2 1.24

CONDENSING TEMPERATURE - °F (°C)

90

(32)

100

(38)

110

(43)

120

(49)

130

(54)

170

(60)

For systems outside the normal limits of single stage

compressor application, (such as compound or cascade

refrigeration systems) the following formulas may be used

to arrive at the heat rejection requirements for selection of

the condenser:

Open Compressors

THR = Compressor Capacity (BTUH) + 2545 x BHP

Suction Cooled Hermetic Compressors

THR = Compressor Capacity (BTUH) + 3413 x KW

TABLE 5:

SUCTION COOLED HERMETIC COMPRESSORS

EVAP.

TEMP

°F °C

-30 -34 1.57 1.62 1.68 - - -

-20 -29 1.49 1.53 1.58 1.65 - -

-10 -23 1.42 1.46 1.50 1.57 1.64 -

0 -18 1.36 1.40 1.44 1.50 1.56 1.62

10 -12 1.31 1.34 1.38 1.43 1.49 1.55

20 -7 1.26 1.29 1.33 1.37 1.43 1.49

30 -1 1.22 1.25 1.28 1.32 1.37 1.42

40 4 1.18 1.21 1.24 1.27 1.31 1.35

50 10 1.14 1.17 1.20 1.23 1.26 1.29

CONDENSING TEMPERATURE - °F (°C)

90

(32)

100

(38)

110

(43)

120

(49)

130

(54)

170

(60)

SELECTION EXAMPLE

GIVEN:

Compressor Capacity: 310,000 Btuh

Evaporator Temperature : 30°F.

Refrigerant: R-404A

Ambient Air: 95°F.

Maximum Condensing Temp.: 110°F.

Suction Cooled Hermetic Compressor

PROCEDURE:

(1) Assuming the compressor manufacturer’s heat rejec-

(2) Multiply the compressor capacity by the heat rejection

tion data is not available, determine the heat rejec-

tion factors for the specied conditions from Table

No. 5 above (1.28).

factor to estimate the required condenser capacity .

(3) Since R-404A is specied, select the proper con-

denser from Capacity Data tables (page 3) based on

the specied difference between condensing refrigerant and the ambient air (T.D.).

SELECTION:

Using the heat rejection factor from Table No. 4 above, the

required condenser capacity is:

1.28 x 310,000 = 396,800 Btuh

From Capacity Data tables (page 3) for the specied T.D.

of 15°F the proper selection is the Model AB 150 with a

capacity of 421,650 Btuh. In this instance the condenser is

slightly oversized and the condenser will balance the compressor heat rejection at less than the maximum condensing temperature of 110°F.

MULTIPLE COMPRESSOR

04/30/14

T50-TAB-PDI-2

- 5 -

TAB 60Hz

APPLICATIONS

Multi circuit condenser coils are available for applications

where more than one compressor is used, either on the

same system or separate systems.

Multi circuit condensers are factory circuited to meet the

specied capacities.

The fan on a multi circuited unit should remain operative

as long as a condensing requirement exists on any circuit

of the coil.

SELECTION EXAMPLE

GIVEN:

Six hermetic compressors with capacities and evaporator

temperatures (tabulated below).

Refrigerant: R-404A

Ambient Air T emperature 90°F .

Maximum Condensing Temp.: 110°F.

PROCEDURE:

1. Tabulate the compressor capacities, evaporator

temperatures and heat rejection factors for each

compressor. (See Sample Tabulation, below.)

2. Determine the required heat rejection capacity for

each compressor.

3. Total the sectional heat rejection capacities for the

six compressors.

SELECTION:

Based on the total heat rejection capacity for the six compressors of 186,160 BTUH, it can be seen from Table No.

2 that the smallest unit which will meet this requirement is

the Model AB 117 with 203,800 BTUH at 20 °F. T.D. Table

No. 2 lists the heat rejection capacity per “face tube” at

various T.D.’s.

At 20 °F. T.D., the AB 117 has a capacity of 9260 Btuh

per “face tube”. To determine the required number of face

tubes for each section, divide the required sectional capacity by the capacity per “face tube”. For example, compressor No. 1 requires 18,000 : 9260 = 2 “face tubes”. Section

No. 1 should be circuited with 2 “face tubes” for Compressor No. 1. Following this same procedure will determine

the size of each section for the remaining compressors.

The sample tabulation shows the results of this selection and indicates that 22 “face tubes” are required when

using the Model AB 117. Since the Model AB 117 has 22

“face tubes” available, the selection has been satised.

If the total required number of “face tubes” exceeds the

number of “face tubes” available as listed in Table No. 2

it will be necessary to permit a slightly higher condensing

temperature than planned for one or two of the sections. A

second alternative would be to select the next larger size

condenser.

SAMPLE TABULATION

No. of

COMPRESSOR

1 13500 +20 -7 1.37 18000 2

2 10000 -15 -23 1.57 17440 2

3 36000 +15 -9 1.40 51400 6

4 11000 +20 -7 1.37 15070 2

5 31000 -10 -23 1.57 50000 6

6 25000 +20 -7 1.37

COMPRESSOR

CAPACITY (BTUH)

EVAPORATOR

TEMPERATURE

°F °C

HEAT REJECTION

FACTOR

total: 186160 22

REQUIRED CONDENSER

CAPACITY (BTUH)

34250 4

REQUIRED NUMBER

OF FACE TUBES

BLOWER COMPONENTS

04/30/14

T50-TAB-PDI-2

- 6 -

TAB 60Hz

FEATURES A NEW ADVANCED DYNAMIC DESIGN BLOWER SECTION

• HIGH EFFICIENCY FAN PERFORMANCE

• FANS TESTED PER AMCA CODE No. 210

• MINIMUM FAN TIP SPEEDS

• CLASS II CONSTRUCTION

The air handler blower section is a matched assembly

combining advanced engineering techniques with the nest materials available.

Forward-curved centrifugal fans were designed specically to operate at low tip-speeds with minimum power

consumption. To meet the low noise level requirements of

comfort air conditioning, fan outlet velocities have been

reduced without sacricing good fan performance. Blowers

are fully performance tested and certied in accordance

with DIN, ISO, BS and AMCA 210 standards. Blowers are

rated for CLASS II operation and have bearings selected

to guarantee a minimum L50 life time of 200,000 hours.

The fan section is complete with a rugged drive assembly. The heavy duty motor base is designed for quick

and simple belt adjustment. All drives are furnished with

matched V-belts.

EXCLUSIVE STEEL FRAME CONSTRUCTION

Sectionalized construction provides complete exibility of

unit arrangements with each individual section structurally

designed to provide the absolute maximum in unit strength

and rigidity. All static and dynamic forces are directly transmitted to the unit framework. The blowers are supported

entirely by rigid frame members, eliminating all dynamic

forces from the casing panel. Optional internal blower

isolators are also available on all models.

For maximum durability, the entire cabinet assembly is fabricated of continuous galvanized steel. This heavy protec-

tive nish is maintained intact, completely undisturbed and

is complimented with the use of corrosion resistant permanent fasteners. The positive fastening principle of a permanent fastener provides the rigidity and stability necessary

for lifetime performance. Optional 2” insulated panels are

available on all models. Outdoor construction is available

on all models. These exclusive construction features offer

you the ultimate in air handling design.

INTERNAL BLOWER CONSTRUCTION

All blower housings are manufactured in galvanized sheet

steel. Impellers are also manufactured in galvanized sheet

steel with tab locked blades. All impellers are balanced,

both statically and dynamically, to an accuracy grade of G

= 6.3 in accordance to DIN ISO 1940-1 and ANSI S2.19

– 1989. Bearings are self-aligning, single row, and deep

groove ball type, in pillow block cast iron housings. All

bearings have been selected to guarantee a minimum L50

life time of 200,000 hours. Operating temperatures range

from -25°F to + 131°F (-31°C to +55°C) for all blowers. For

operating temperatures outside these limits please consult

factory. Extended lubrication lines are standard. Airfoil

constructed blowers available for all models for static

pressures above 6” – consult factory (models 103 & 104

excluded).

FAN PERFORMANCE

04/30/14

T50-TAB-PDI-2

- 7 -

TAB 60Hz

DETERMINATION OF FAN SPEED AND MOTOR

HP REQUIREMENTS

Final determination of the actual fan performance requires

an accurate calculation of the total resistance to air ow

through the entire system. This total static pressure (TSP)

will consist of two parts: (1) the external resistance due to

air ow through the ducts, discharge grilles, diffusers, etc.

of the distribution system, and (2) the internal resistance

of the unit which results from air ow through the coils,

lters, unit cabinet and other accessories. The method of

calculating the resistance for the various components of

the distribution system are well established. The internal

resistances are easily determined from Blower Data table

(see page 4) which tabulates the resistance values for the

various unit components in increments of air volume. For

the internal resistances as shown in Blower Data table

(see page 4). The resistances of the cooling coil must be

added. These may be obtained from the charts on page 4.

After calculating the total static pressure, the fan speed

and motor horsepower requirements can be accurately determined. With the unit model, CFM and TSP known, the

fan RPM and BHP is easily determined from the Blower

Data Tables. (page 9)

FAN PERFORMANCE INFORMATION

This catalogue contains all of the blower data for central station air handlers. Units are equipped with forward

curved fan wheels as standard.

SELECTION RULES

The fan performance calculation procedure is predicated

on the fact that a fan is a constant volume machine, provided the RPM and static pressure do not change. This

means the delivered air volume (CFM) will not change,

even though the temperature may. The BHP required is

inversely proportional to nal air temperature and altitude;

consequently BHP decreases with an increase in nal

air temperature or higher altitude and increases with a

decrease in nal air temperature or lower altitude. This

requires that the static pressure be adjusted for any air

conditions other than standard. After the calculation of

RPM and BHP, only the BHP need be corrected to the

specied conditions.

SELECTION PROCEDURE

The following data is required to determine the ___. The

unit type, unit size, CFM, total static pressure, operating

temperature and altitude.

1. From table below, obtain the temperature and

altitude conversion factor.

2. Divide the specied total static pressure by the

conversion factor to obtain a corrected total static

pressure.

3. At the specied CFM and corrected total static pressure, determine the RPM and BHP. (page 9)

4. Multiply the BHP by the conversion factor to obtain

the BHP required at the specied altitude and temperature.

EXAMPLE OF SELECTION PROCEDURE

TAB111 with 5000 CFM @ 1.0” total static pressure, 20°F

air temp, 5000 feet elevation:

1. Conversion factor = 0.92

2. New TSP = 1.0” / 0.92 = 1.09”

3. 1.09” = 586 RPM and 1.35 BHP

4. New BHP = 1.35 x 0.92 = 1.24

Selection = 5000 CFM @ 586 RPM and 1.24 BHP

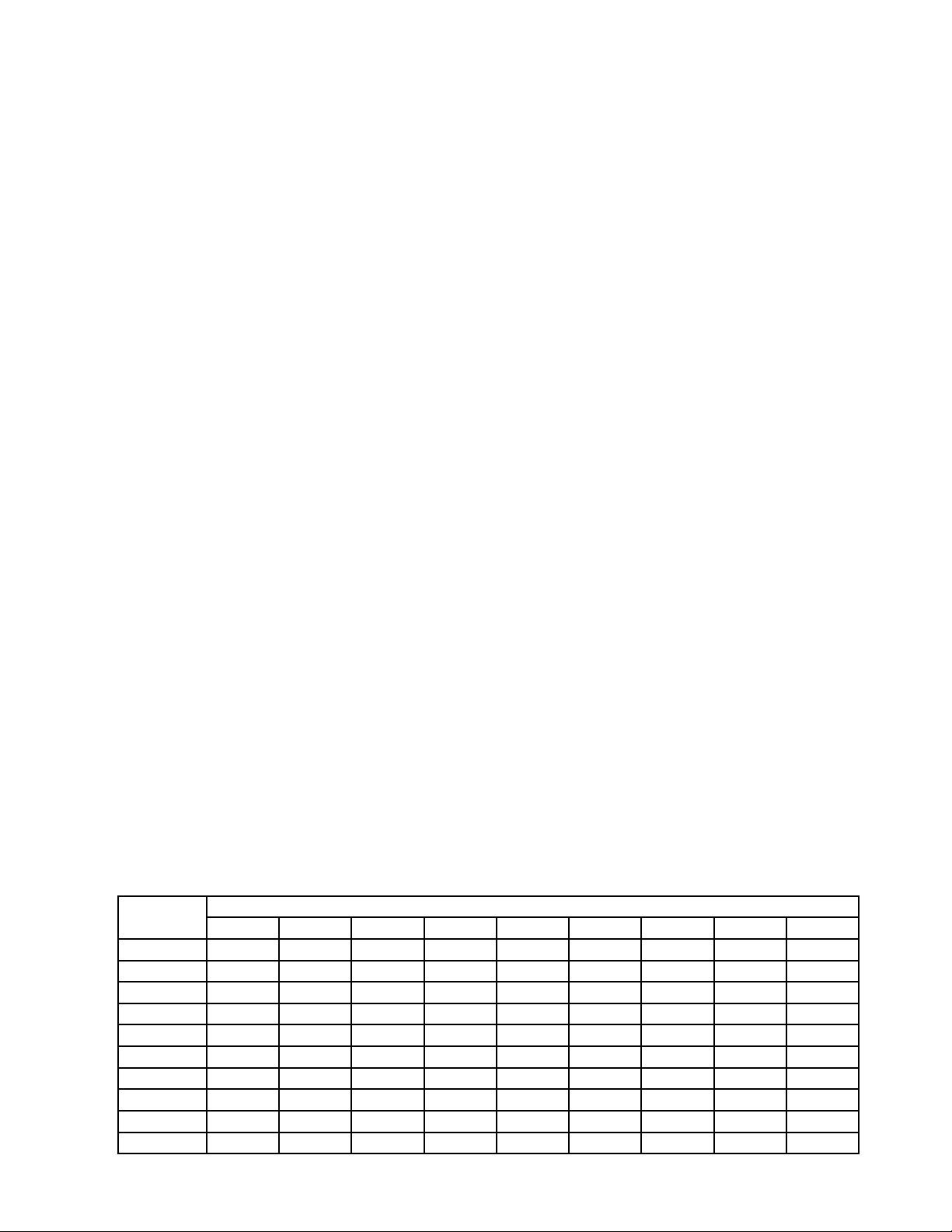

TEMPERA TURE AND ALTITUDE CONVERSION FACTORS

AIR TEMP.

°F

-20 1.2 1.16 1.12 1.08 1.04 1 0.97 0.93 0.89

0 1.15 1.1 1.08 1.02 0.99 0.95 0.92 0.88 0.85

20 1.11 1.06 1.02 0.98 0.95 0.92 0.88 0.85 0.82

40 1.06 1.02 0.98 0.94 0.91 0.88 0.84 0.81 0.78

60 1.02 0.98 0.94 0.91 0.88 0.85 0.81 0.79 0.76

70 1 0.96 0.93 0.89 0.86 0.83 0.8 0.77 0.74

80 0.98 0.94 0.91 0.88 0.84 0.81 0.78 0.75 0.72

100 0.94 0.91 0.88 0.84 0.81 0.78 0.75 0.72 0.7

120 0.92 0.88 0.85 0.81 0.78 0.76 0.72 0.7 0.67

140 0.89 0.85 0.82 0.79 0.76 0.73 0.7 0.68 0.65

0 1000 2000 3000 4000 5000 6000 7000 8000

ALTITUDE (FEET)

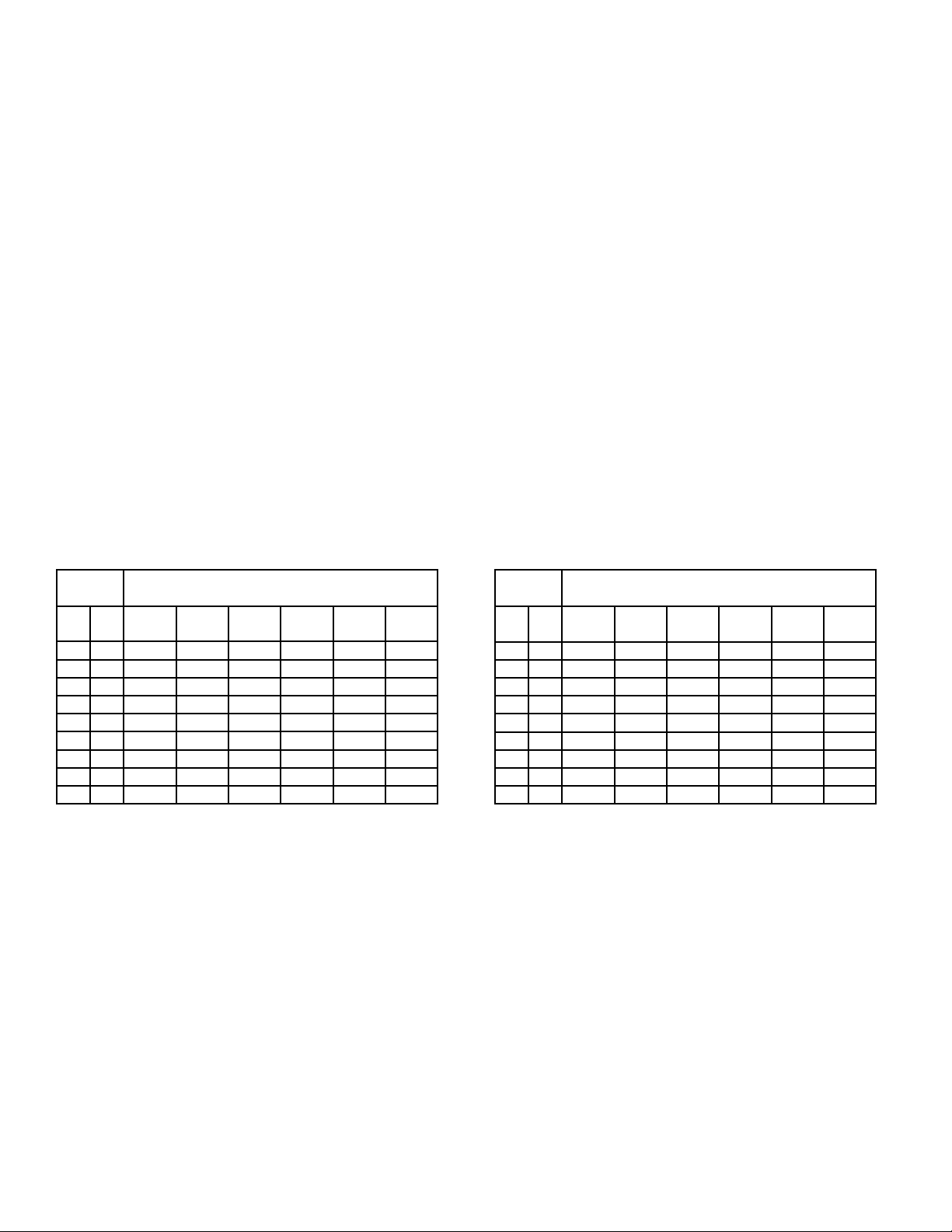

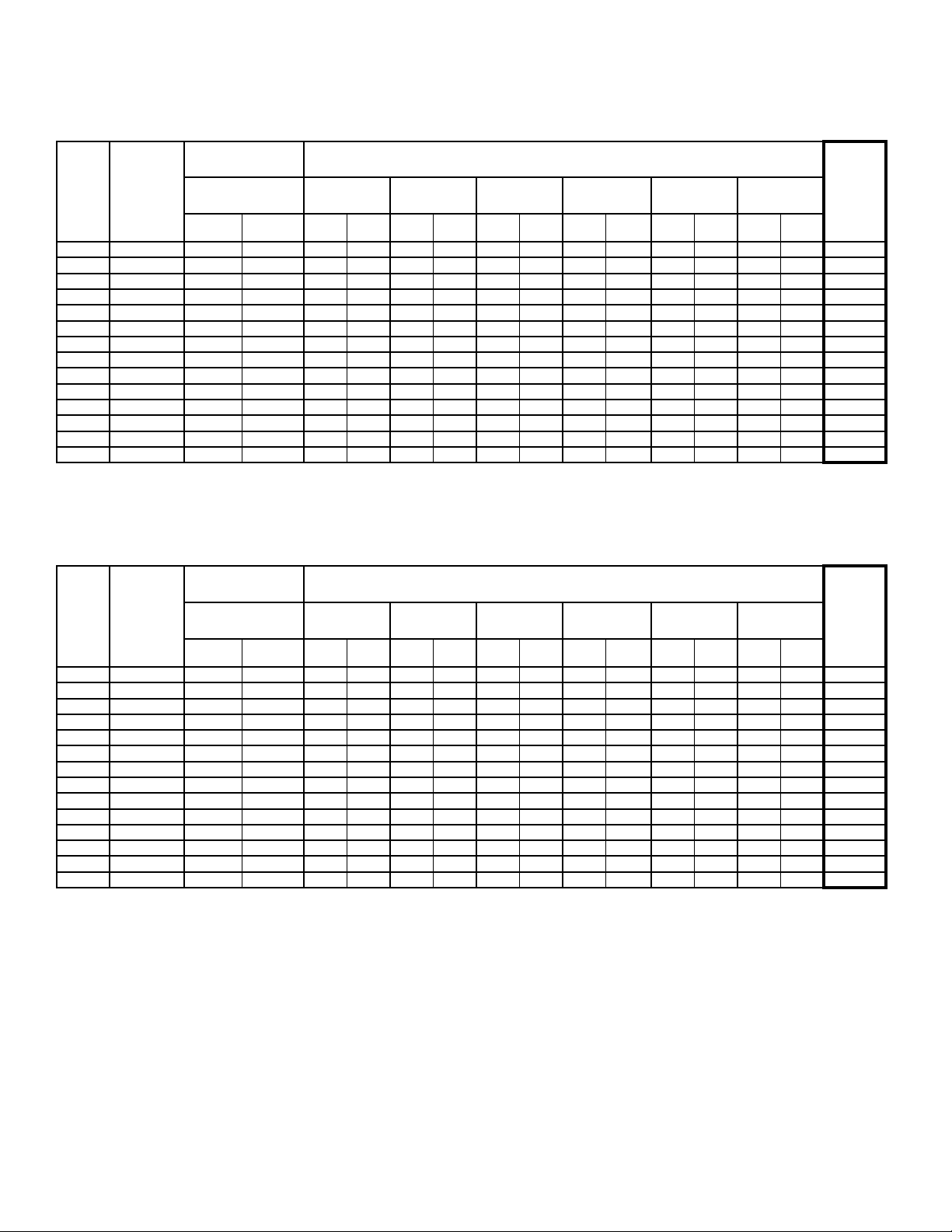

BLOWER DATA

04/30/14

T50-TAB-PDI-2

- 8 -

TAB 60Hz

Fan RPM and Motor HP Requirements

STANDARD - 6

ROW COIL ONLY

MODEL

103 2000 991 0.62 1035 0.66 1134 0.75 1314 0.93 1480 1.12 1640 1.33 1794 1.56 0.1

104 3150 959 1.24 981 1.28 1050 1.4 1191 1.64 1328 1.9 1461 2.19 1590 2.5 0.13

106 4500 832 1.76 854 1.82 931 2.03 1072 2.45 1198 2.87 1313 3.31 1422 3.76 0.13

108 6000 647 2.12 658 2.16 713 2.41 823 2.9 928 3.42 1030 3.99 1129 4.62 0.16

114 10000 606 3.9 629 4.09 675 4.53 760 5.41 840 6.31 915 7.23 988 8.17 0.09

117 12000 677 6.19 699 6.41 742 6.91 819 7.95 891 9.01 958 10.1 1023 11.2 0.08

122 15000 562 6.61 574 6.8 612 7.41 685 8.75 755 10.2 823 11.7 890 13.2 0.12

128 19000 482 8.17 500 8.62 532 9.5 594 11.3 655 13.1 715 15 773 16.9 0.07

137 23000 413 9.46 428 9.91 458 11 517 13.2 572 15.4 625 17.6 678 19.9 0.09

141 29000 373 11.99 380 12.3 407 13.6 459 16.3 508 19.1 556 22 603 24.9 0.14

150 34000 329 14.05 333 14.2 357 15.3 405 18.1 451 21.2 493 24.5 534 27.9 0.17

164 42000 293 15.98 292 15.8 316 17.9 360 22 400 26 438 30.1 474 34.2 0.22

182 55000 269 21.1 272 21.4 291 24 328 29.2 364 34.4 399 39.6 434 45.1 0.17

NOMINAL

AB

111 8000 539 2.32 564 2.47 617 2.83 714 3.55 805 4.3 891 5.08 975 5.9 0.09

CFM

0.55

+ CABINET SP

RPM BHP RPM BHP RPM BHP RPM BHP RPM BHP RPM BHP RPM BHP

(Based on DUCTED OUTLET)

TOTAL STATIC PRESSURE (lnches - Water Gauge)

(Includes Coil, Ductwork etc.)

0.75 1.00 1.50 2.00 2.5 3.0

(In. W.G)

CABINET SP

BLOWER DATA

(Based on FREE OUTLET)

STANDARD - 6

ROW COIL ONLY

MODEL

103 2000 1108 0.72 1142 0.76 1225 0.84 1384 1.01 1537 1.19 1687 1.4 1835 1.63 0.1

104 3150 1097 1.48 1114 1.51 1175 1.62 1298 1.85 1421 2.1 1541 2.38 1660 2.7 0.13

106 4500 978 2.17 995 2.22 1054 2.41 1169 2.78 1277 3.17 1380 3.59 1479 4.02 0.13

108 6000 735 2.51 743 2.55 791 2.76 887 3.22 982 3.72 1076 4.29 1167 4.9 0.16

114 10000 711 4.9 727 5.06 763 5.45 834 6.25 903 7.08 970 7.94 1036 8.83 0.09

117 12000 818 7.94 833 8.15 863 8.61 923 9.53 982 10.49 1040 11.47 1097 12.48 0.08

122 15000 659 8.26 669 8.44 700 9.04 761 10.31 822 11.66 882 13.07 942 14.53 0.12

128 19000 567 10.52 581 10.91 607 11.69 660 13.3 713 14.97 767 16.71 820 18.53 0.07

137 23000 486 12.02 497 12.43 522 13.39 570 15.35 618 17.35 666 19.42 714 21.54 0.09

141 29000 436 15.02 441 15.3 463 16.5 506 18.99 550 21.57 593 24.24 635 26.98 0.14

150 34000 384 16.78 386 16.92 406 18.18 446 20.91 486 23.86 524 26.99 561 30.27 0.17

164 42000 336 19.73 334 19.59 353 21.37 389 25.01 425 28.73 459 32.51 493 36.38 0.22

182 55000 309 26.7 311 26.96 327 29.2 359 33.78 392 38.53 423 43.52 455 48.76 0.17

NOMINAL

AB

111 8000 611 2.79 630 2.93 674 3.25 759 3.93 842 4.64 923 5.39 1001 6.18 0.09

CFM

0.55

+ CABINET SP

RPM BHP RPM BHP RPM BHP RPM BHP RPM BHP RPM BHP RPM BHP

0.75 1.00 1.50 2.00 2.5 3.0

TOTAL STATIC PRESSURE (lnches - Water Gauge)

(Includes Coil, no discharge duct work)

(In. W.G)

CABINET SP

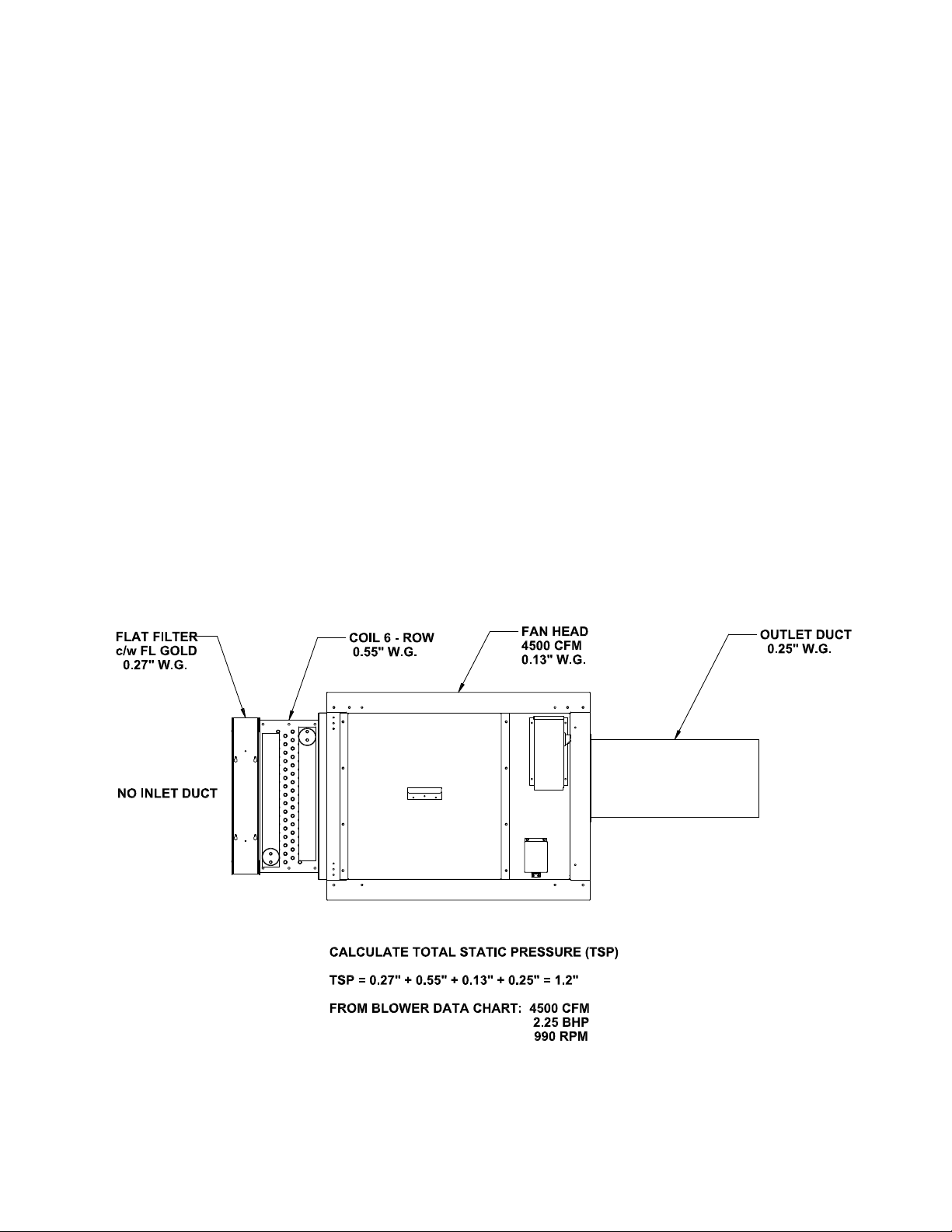

CALCULATION OF

04/30/14

T50-TAB-PDI-2

- 9 -

TAB 60Hz

Example #1

1. Select model based on CFM requirement and estimated static pressure.

2. Example model selected TAB106F-N-T3A- 4500 CFM @ 0.25” ESP.

3. Verify total internal airside resistance using charts on page 7.

a) For coil static pressure ref. page 9 - 0.55” used for 6 Row Coil.

b) For cabinet static pressure ref. page 9 - 0.13”

c) For lter area ref. page 11 (4500 CFM / 8.4 ft2 ) = 535 FPM.

d) For lter static pressure ref. page 10 - FL GOLD @ 535 FPM = 0.27”

e) external duct is example only - used 0.25”

4. Recalculate total static press - TSP = 0.27” + 0.55” + 0.13” + 0.25” = 1.2”

Note: this example does not allow for detailed velocity inlet and outlet pressure.

TOTAL STATIC PRESSURE

Model: TAB106F-N-T3A-

FIL TER AIR FRICTION

04/30/14

T50-TAB-PDI-2

- 10 -

TAB 60Hz

FILTER FACE

VELOCITY

FPM 2" 4" 2" 2"

250 0.1 0.08 0.03 0.1

300 0.14 0.12 0.05 0.13

350 0.17 0.15 0.06 0.15

400 0.21 0.19 0.07 0.18

450 0.26 0.23 0.09 0.21

500 0.31 0.27 0.11 0.25

550 NR NR 0.14 0.29

600 NR NR 0.16 0.33

To determine lter face velocity, divide the CFM by the lter area (see Physical Data table).

NR = Not Recommended

Ratings are at initial resistance.

(Inches Of Water)

FARR 30/30 FARR 44 FL GOLD

(throw-aways) (washable)

(metal /

Renu frame)

ALUM. MESH

(washable)

2"

0.08

0.1

0.12

0.15

0.18

0.21

0.24

0.27

SOUND DATA

SOUND

with the necessary attenuation analysis, which may

include considerations of unit placement (away from

occupied areas), acoustical insulation in the equipment room, duct silencers, or acoustical duct lining.

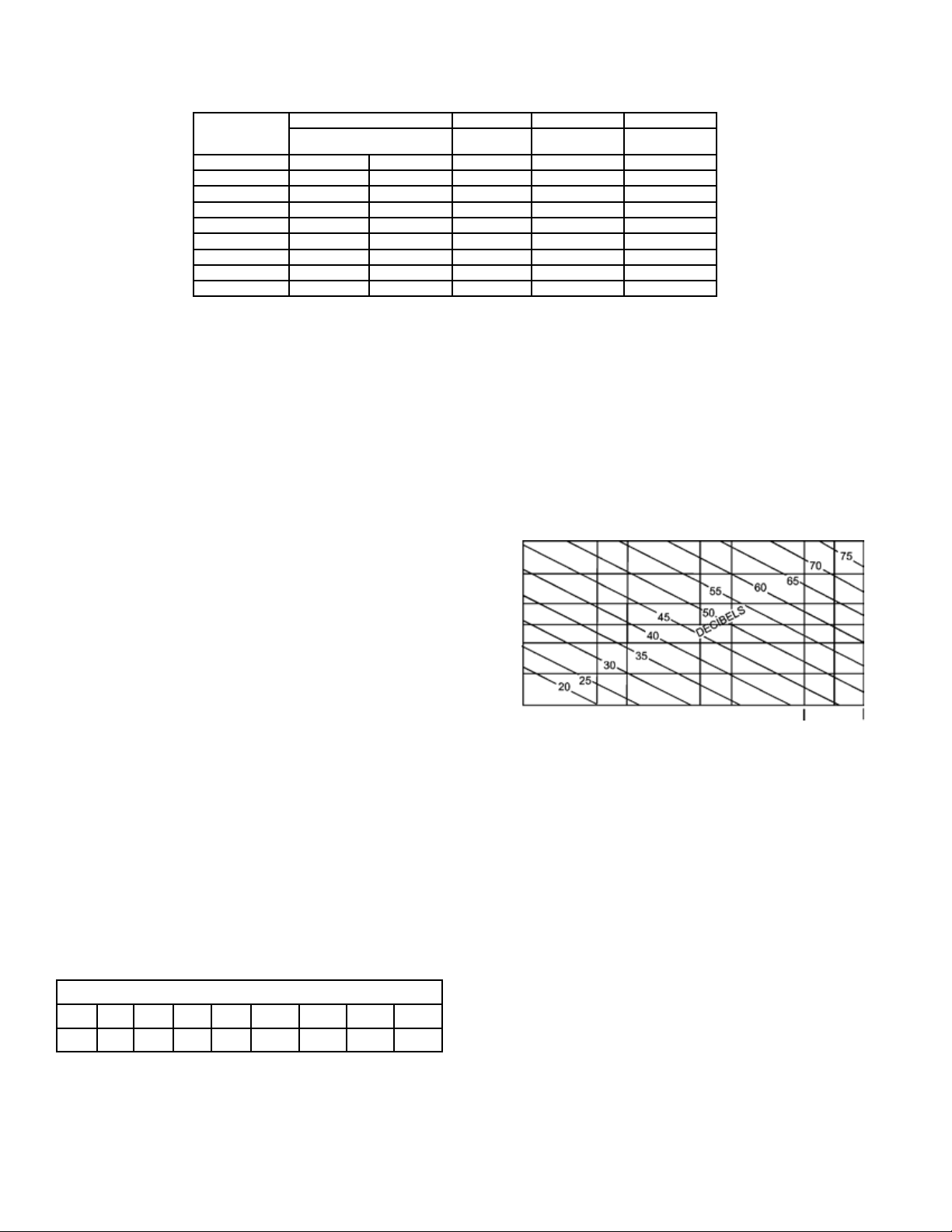

SOUND POWER LEVEL ESTIMATING

The following method of estimating centrifugal fan

sound power level spectrums is taken from the latest

ASHRAE sources. The method does not take into

consideration such factors as cabinet attenuation or

inefcient unit selection, but does provide conservative approximate values upon which to base an

acoustical attenuation analysis.

Sound power levels in decibels are 10-12 watts in

each of the eight octave bands may be estimated

with the following formula:

dB = (Base dB) + (System dB) + (Blade Passage

Frequency dB)

Base dB

The base dB is found in the table below by entering

the octave band and reading the dB in the appropriate row.

SYSTEM dB

The system dB is found in the chart below by enter-

ing the chart at the ow rate, rise vertically to the

pressure of the system and read the decibels

20

O)

2

10

5.0

3.0

2.0

1.0

PRESSURE (INCHES H

0.5

100 500 1000 5000

CFM - PRESSURE CHART

10000

50000

100000

200000

BLADE PASSAGE FREQUENCY dB

The Blade Passage Frequently dB is found:

1. For forward curved fan wheel units - add 2 dB to

the one octave band which contains the frequency

equal to the RPM of the fan.

2. For airfoil units - add 3 dB to the one octave band

which contains the frequency equal to the RPM of the

fan.

Hz 63 125 250 500 1000 2000 4000 8000

dB 47 43 39 33 28 25 23 20

OCTAVE BAND CENTRE FREQUENCY

Loading...

Loading...