Heat Wagon P600, P900, P1800-1, P1800-3, P1800D User Manual

...

342 N. Co. Rd. 400 East

Valparaiso, IN 46383

219-464-8818 • Fax 219-462-7985

www.heatwagon.com

Installation and Maintenance Manual

Please retain this manual for future reference.

Electric

Construction

Heaters

Revision 9-15

For your safety: Do not use this heater in

a space where gasoline or other liquids

having flammable vapors are stored.

IMPORTANT INSTRUCTIONS

READ ALL INSTRUCTIONS BEFORE USING THIS HEATER

1. This heater is hot when in use. To avoid burns, do not let bare skin touch hot surfaces. Use

handle when moving this heater. Keep combustible materials at least 6 feet (2 meter) from the

front of the heater and keep them away from sides and rear

2. Extreme caution is necessary when the heater is used near children or invalids and whenever

the heater is left unattended

3. Always unplug the heater when not in use

4. Do not operate any heater with a damaged cord or plug or after the heater malfunctions, has

been dropped or damaged in any manner. Return heater to authorized service facility for

examination, electrical or mechanical adjustment or repair

5. Do not expose to rain, water spray or dripping water

6. This heater is not intended for use in bathrooms, laundry areas and similar indoor locations.

Never locate the heater where it may fall into a bathtub or other liquid container

7. Do not run cord under carpeting. Do not cover cord with throw rugs, runners, or the like.

Arrange cord away from traffic area and where it will not be tripped over

8. TO DISCONNECT HEATER,

(P1800,4000,6000) until unit cools and shuts down automatically, turn switches off,

disconnect power. For P600, P900 let fan run one minute then after cooldown, turn switch off,

disconnect power.

9. Connect to properly grounded outlets only

10. Do not insert or allow foreign objects to enter any ventilation or exhaust opening as this may

cause an electric shock or fire, or damage the heater

11. To prevent a possible fire, do not block air intakes or exhaust in any manner. Do not use on

soft surfaces, where openings may become blocked

12. A heater has hot and arcing or sparking parts inside. Do not use in areas where gasoline, paint

or flammable liquids are used or stored

13. Do not point to flammable materials

reduce ambient thermostat to zero. Fan will continue to run

14. Use heater only as described in this manual. Any other use not recommended by the

manufacturer may cause fire, electric shock or injury to persons

15. Always plug heaters directly into a wall outlet/receptacle. Never use with an extension cord or

relocatable power tap (outlet/power strip)

16. SAVE THESE INSTRUCTIONS

Installation and Maintenance Manual

Models P600, P900, P1800-1,

P1800-3, P1800D, P4000 and P6000

Construction Heaters

Table of Contents:

Page

Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3

Principal of Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4

Set Up and Operation Instructions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5

Maintenance and Storage . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6

Parts Breakdowns . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .9 -16

Electrical Diagrams . . . . . . . . . . . . . . . . . . . . . . . . . . . . .10, 12, 14, 17-19

Troubleshooting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .20

WARRANTY

All new Heat Wagon and Sure Flame heaters and fans are guaranteed against defective materials and workmanship for one (1) year from invoice date.

Warranty repairs may be made only by an authorized, trained and certified Heat Wagon dealer. Warranty

repairs by other entities will not be considered. Warranty claims must include model number and serial

number.

LIMITATIONS

Evidence of improper electric power, misapplication or evidence of abuse may be cause for rejection of

warranty claims.

Travel time, mileage and shipping charges will not be allowed. Minor adjustments of heaters are dealers’

responsibility. Defective parts must be tagged and held for possible return to the factory for 60 days from

date of repair. The factory will provide a return goods authorization, (RGA) for defective parts to be

returned.

No warranty will be allowed for parts not purchased from Heat Wagon.

Heater is not intended for use in pest remediation.

342 N. Co. Rd. 400 East • Valparaiso, IN 46383

219-464-8818 • 888-432-8924 • Fax 800-255-7985

www.heatwagon.com

12”x25’ Long 14”x25’ Long 14”x25’ Long

Duct PN-WD1225 Duct PN-WD1425 Duct PN-WD1425

SPECIFICATIONS

3

P600 P900 P1800-1 P1800-3 P1800D P4000 P6000

(425 Cu. m/hr) (600 Cu. m/hr) (1,000 Cu. m/hr) (1,000 Cu. m/hr) (3,000 Cu. m/hr) (3,000 Cu. m/hr)

Amp Draw (Max) 25 38.0 75 50 50 50 75

(First Stage) 25 38.0 50 34 34 20 24

(Second Stage) N/A N/A 75 50 50 40 48

(Third Stage) N/A N/A N/A N/A N/A 50 75

(Third Stage) N/A N/A N/A N/A N/A 136,500 204,606

(Second Stage) N/A N/A 65,000 65,000 65,000 102,400 163,728

(First Stage) 20,500 30,700 41,000 41,000 41,000 51,200 81,864

Heat Output (Max BTU's) 20,500 30,700 65,000 65,000 65,000 136,000 204,700

(Second Stage) N/A N/A 18,000 18,000 18,000 32,000 48,000

Min. Voltage at Heater 208 208 208 208 208 440 440

Electrical Rating 240V 60Hz 1Ø 240V 60Hz 1Ø 240V 60Hz 1Ø 240V 60Hz 3Ø 240V 60Hz 3Ø 480V 60Hz 3Ø 480V 60Hz 3Ø

(Third Stage) N/A N/A N/A N/A N/A 40,000 60,000

(First Stage) N/A 9,000 12,000 12,000 12,000 16,000 24,000

Watts (Max) 6,000 9,000 18,000 18,000 18,000 40,000 60,000

Air Flow 250 CFM 350 CFM 590 CFM 590 CFM 940 CFM 1,800 CFM 1,800 CFM

Ambient Thermostat 32 to 100°F 32 to 100°F 32 to 100°F 32 to 100°F 32 to 100°F 32 to 100°F 32 to 100°F

Weight 32.9 lbs 48 lbs 62 lbs 62 lbs 62 lbs 130 lbs 142 lbs

Ducting (Max) N/A N/A N/A N/A 12" x 50' (straight) 14" x 50' (straight) 14" x 50' (straight)

Temp Rise 100ºF 100ºF 100ºF 100ºF 100ºF 100ºF

dB Noise 53 dB(A) 1m 55 dB(A) 1m 58 dB(A) 1m 58 dB(A) 1m 82 dB(A) 1m 82 dB(A) 1m

Dimensions 20"L x 12"W x 17"H 23"L x 12"W x 18"H 30"L x 14"W x 20"H 30"L x 14"W x 20"H 30"L x 14"W x 20"H 46"L x 20"W x 25"H 46"L x 20"W x 25"H

UL LIsted Yes Yes Yes Yes Yes

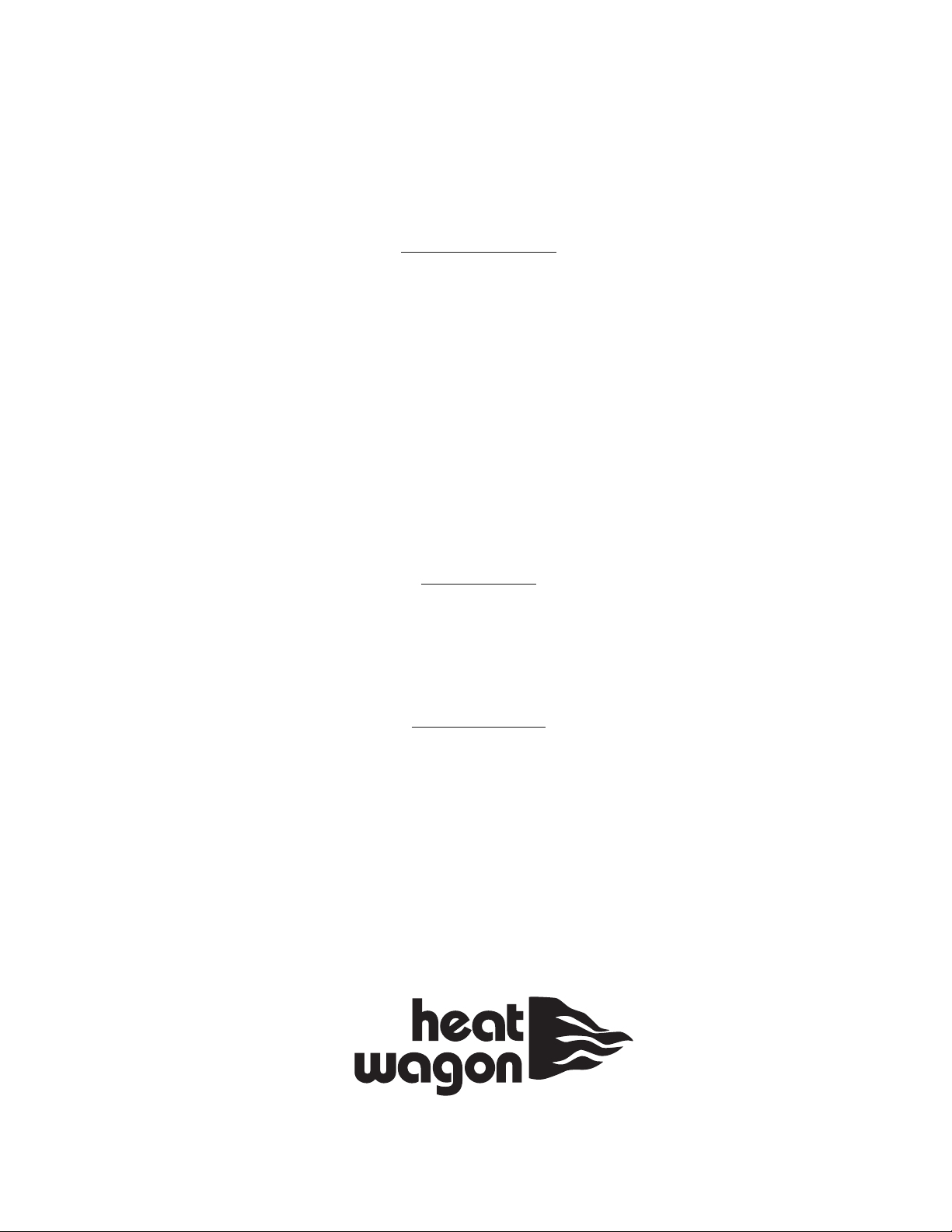

PRINCIPAL OF OPERATION

P600, P900, P1800-1, P1800-3

2 PCS - P600

3 PCS - P900

9 PCS - P1800’s

STEEL

HANDLE

THERMOSTAT +

COOL

AIR

IN

AMBIENT THER-

MOSTAT SEN-

SOR TUBE

SWITCHES

ELECTRIC

MOTOR

FAN

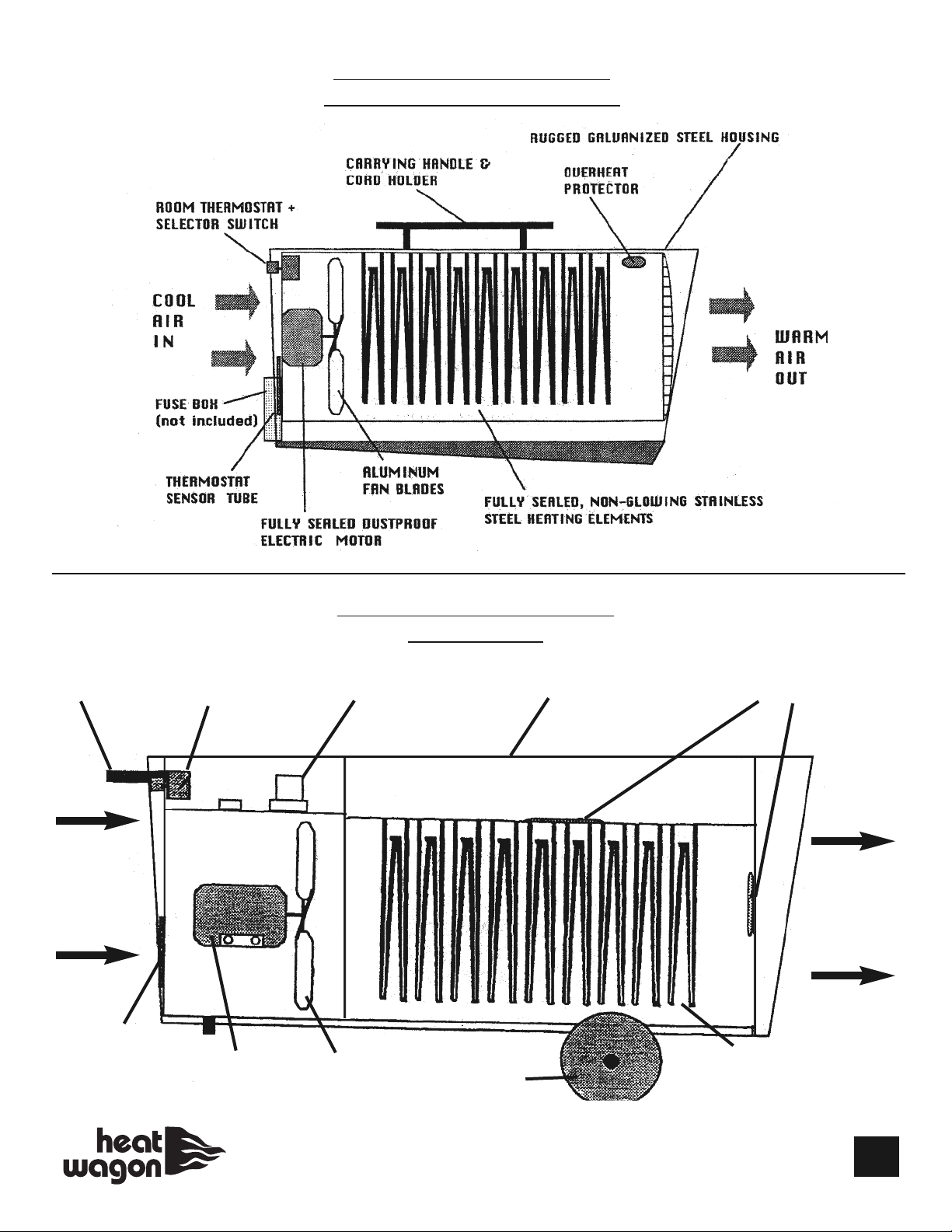

PRINCIPAL OF OPERATION

P4000, P6000

POWER SELECTOR

CONTACTORS

ALUMINUM

FAN BLADES

SOLID PLASTIC

RUGGED GALVANIZED

STEEL HOUSING

WHEELS

OVERHEAT SENSORS

WARM

AIR

OUT

FULLY SEALED, NONGLOWING STAINLESS

STEEL HEATING ELE-

MENT 15 PCS

4

OPERATION

REVIEW AND UNDERSTAND ALL WARNINGS IN THIS MANUAL. THEY ARE

ESSENTIAL FOR SAFE USE OF THE HEATER. FOLLOW ALL LOCAL CODES.

To start heating:

1. Place the heater on a stable, level surface. Make sure that no explosive or combustible fumes

or dust are present. See that the heater is not exposed to water spray, rain, or dripping water.

Minimum clearances from combustible materials:

Outlet: 6 feet, Sides: 1 foot, Top: 2 feet, Rear: 2 feet

Floor: combustible

2. Connect heater to proper power source. The P600 requires a 240V, 60Hz single phase 25 Amp

power source. The P900 requires a 240V, 60Hz single phase, 40 Amp power source. The

P1800-1 requires a 240V, 60 Hz single phase, 75 Amp power source. The P1800-3 requires a

240V, 60 Hz three phase, 50 Amp power source. The P4000 requires a 480V, 60 Hz three

phase, 50 Amp power source. The P6000 requires a 480V three phase, 75 Amp power source.

Also, ALL POWER SOURCES NEED TO BE EQUIPPED WITH A CIRCUIT BREAKER!

Note: When power is first applied to unit, the heater fan may blow

air out of heater INLET. If this condition occurs, (after first

removing power from cord) reverse the first two hot wires at heater

terminal inlet block. (3 Phase Models Only)

3. Set the remote thermostat to a temperature above the ambient room temperature by turning

the knob. NOTE: The heater will start only if the thermostat “calls for heat” meaning that it is

set to higher than prevailing ambient temperature.

4. Set the selector switch to the desired heating setting. For the P1800 series, the options are #1

for ventilation (fan only), #2 for low heat output of 12Kw (41,000 Btu’s), or #3 for high

output of 18Kw (65,000 Btu’s).

For the P4000, the switches are labeled S1 with a heat output of 16Kw (54,600 Btu’s), S1 and

S2 with a heat output of 32Kw (109,200 Btu’s) or S1, S2 and S3 with a heat output of 40Kw

(136,000 Btu’s).

For the P6000, the switches are labeled S1 with a heat output of 24Kw (81,900 Btu’s), S1 and

S2 with a heat output of 48Kw (163,800 Btu’s) or S1, S2 and S3 with a heat output of 60Kw

(204,700 Btu’s).

The heater will now operate automatically, controlled by the thermostat.

5

To Stop Heating: (P1800, P4000, P6000)

1. Turn all switches to “Off”.

2. Allow fan to run until unit stops automatically, controlled by unit cooldown thermostat (fan

switch). Heater may cycle more than once.

3. Unplug the power supply cable after the fan has stopped cooling down the heater completely.

To Stop Heating: (P600, P900)

1. Reduce ambient (room) thermostat to “Heat Off” position.

2. Allow fan to run for at least two minutes.

3. Flip switch to “Off” position.

4. Unplug heater.

NOTE: The heater is equipped with an overheat limit switch which may cause the heater to

stop. Check and remove the cause for overheating before re-starting.

Never disconnect supply plug to stop the heater while in operation!!

MAINTENANCE

Never service heater while it is plugged in, running or hot. Severe bodily injury or electric

shock may occur.

Only qualified persons are allowed to open heater for service.

1. Keep heater clean (ex. dry wall dust). Use pressurized air to blow fan blades clean.

NOTE: Use moderate pressure to avoid damage to fan blades.

2. Inspect heater before and after each use.

3. The bearings of the fan motor are permanently lubricated and sealed No additional lubrication

is needed.

6

GENERAL ELECTRIC HEATER SIZING ISSUES

When running Heat Wagon electric heaters from a generator, it is extremely important to make sure

that the generator selected for your heater is not undersized. The single largest service issue with

Heat Wagon electric heaters is improper set up relating to inadequate voltage due to too small of an

electric source and/or too small of a power cord.

Generator Selection for Heat Wagon Electric Heaters

The chart below will help you when it comes to selecting the correct generator required for your

Heat Wagon heater:

Model Watts Phase BTU'S Volts Amps CFM Recommendations

P1500 1,500 1 Phase 5,100 120 15 120 3KW

P600 6,000 1 Phase 20,500 240 25 250 10KW

P900 9,000 1 Phase 30,700 240 38 350 15KW

P1800-1 18,000 1 Phase 64,000/41,000 240 75 590 25KW

P1800-3 18,000 3 Phase 64,000/41,000 240 50 590 25KW

P1800D 18,000 3 Phase 64,000/41,000 240 50 950 25KW

P4000 40,000 3 Phase 136,000/109,200/54,600 480 50 1,800 50KW

P6000 60,000 3 Phase 204,700/163,800/81,900 480 70 1,800 75KW

So, by reviewing the above chart, a P1800-1 would require a minimum 18,000 Watt (18KW),

240 volt single phase generator that can provide 75 amps of continuous power.

7

Loading...

Loading...