Heat Wagon 1800, 1800L Installation And Maintenance Manual

C US

342 N. Co. Rd. 400 East

Valparaiso, IN 46383

219-464-8818 • Fax 219-462-7985

www.heatwagon.com

Installation and Maintenance Manual

Please retain this manual for future reference.

1800(L)

Construction

Heater

Revision 5-14

For your safety: Do not use this heater in

a space where gasoline or other liquids

having flammable vapors are stored.

IMPORTANT INFORMATION! READ FIRST

The heater is designed for use as a construction heater under ANSI Z83.7a-1993. Heater is not

intended for use in pest remediation. The primary purpose of construction heaters is to provide

temporary heating of buildings under construction, alteration, or repair and to provide emergency heat. Properly used, the heater provides safe, economical heating. Products of combustion

are vented into the area being heated.

The heater

SHOULD NOT

ANSI A119.2(NFPA 501C)-1987 Recreational Vehicle Standard prohibits the installation or storage of LP-gas containers even temporarily inside any recreational vehicle. The standard also prohibits the use of Unvented Heaters in such vehicles.

Use of the heater must be in accordance with this Standard and in compliance with all governing

state and local codes. Storage and handling of propane gas and propane cylinders must be in

accordance with NFPA 58 and all local governing codes.

We cannot anticipate every use which may be made for our heaters. CHECK WITH YOUR

LOCAL FIRE SAFETY AUTHORITY IF YOU HAVE QUESTIONS ABOUT LOCAL REGULATIONS.

Other standards govern the use of fuel gases and heat producing products in specific applications. Your local authority can advise you about these.

IS NOT

designed as an Unvented Gas Fired Room Heater under ANSI-Z21.11.2 and

be used in the home.

NFPA-58 1989 STANDARD FOR THE STORAGE AND

HANDLING OF LIQUEFIED PETROLEUM GASES

FOR YOUR SAFETY

DO NOT USE THIS HEATER IN A SPACE WHERE GASOLINE OR OTHER LIQUIDS HAVING FLAMMABLE VAPORS ARE STORED OR USED.

CONSTRUCTION HEATER GENERAL HAZARD WARNING:

F

ailure to comply with the precautions and instructions provided with this heater,

can result in death, serious bodily injury and property loss or damage from hazards

of fire, explosion, burn, asphyxiation, carbon monoxide poisoning, and/or electrical

shock.

Only persons who can understand and follow the instructions should use or service

this heater.

If you need assistance or heater information such as an instruction manual, labels,

etc. Contact your local Heat Wagon dealer or the manufacturer.

W A R N I N G

Fire, burn, inhalation, and explosion hazard. Keep solid combustibles, such as building materials, paper or cardboard, a safe distance away from the heater as recommended by the instructions. Never use the heater in spaces which do or may contain

volatile or airborne combustibles, or products such as gasoline, solvents, paint thinner, dust particles or unknown chemicals.

Not for home or recreational vehicle use!

If you have read this entire manual and you still have

questions, please call us at 888-heatwagon

Installation and Maintenance Manual

Model 1800(L)

Construction Heater

Table of Contents:

Page

Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4

Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5

Proper Set Up . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6

On-site Safety Problems & Operating Instructions . . . . . . . . . . . . . . . . .7

Preventative Maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .8

Trouble Shooting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .9-12

Parts Breakdown . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .13-14

Wiring Diagrams . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .15-16

WARRANTY

All new Heat Wagon and Sure Flame heaters and fans are guaranteed against defective materials and workmanship for one (1) year from invoice date.

Warranty repairs may be made only by an authorized, trained and certified Heat Wagon dealer. Warranty

repairs by other entities will not be considered. Warranty claims must include model number and serial

number.

LIMITATIONS

Warrant claims for service parts (wear parts) such as spark plugs, igniters, flame rods will not be allowed.

Diagnostic parts such as voltage meters and pressure gauges are not warrantable.

Evidence of improper fuel usage, fuel pressures outside of manufacturer’s specification, poor fuel quality,

and improper electric power, misapplication or evidence of abuse may be cause for rejection of warranty

claims.

Travel time, mileage and shipping charges will not be allowed. Minor adjustments of heaters are dealers’

responsibility. Defective parts must be tagged and held for possible return to the factory for 60 days from

date of repair. The factory will provide a return goods authorization, (RGA) for defective parts to be

returned.

No warranty will be allowed for parts not purchased from Heat Wagon.

342 N. Co. Rd. 400 East • Valparaiso, IN 46383

219-464-8818 • 888-432-8924 • Fax 800-255-7985

www.heatwagon.com

DESIGN RELATED SAFETY FEATURES

1) FLAME FAILURE

The electronic ignition control shuts off the gas supply in .8 seconds if flame is lost to prevent

raw gas from leaving the heater.

2) OVERHEATING

The totally enclosed motor is protected by thermal overload. A manual reset high temperature

limit switch is mounted in the heated air stream.

3) LOW SUPPLY VOLTAGE

A panel mounted voltmeter indicates supply voltage before heater start up and also during

heater operation.

4) BLOCKED AIR SUPPLY

An airflow switch detects the differential pressure in the combustion chamber and shuts off

the gas flow when airflow is insufficient.

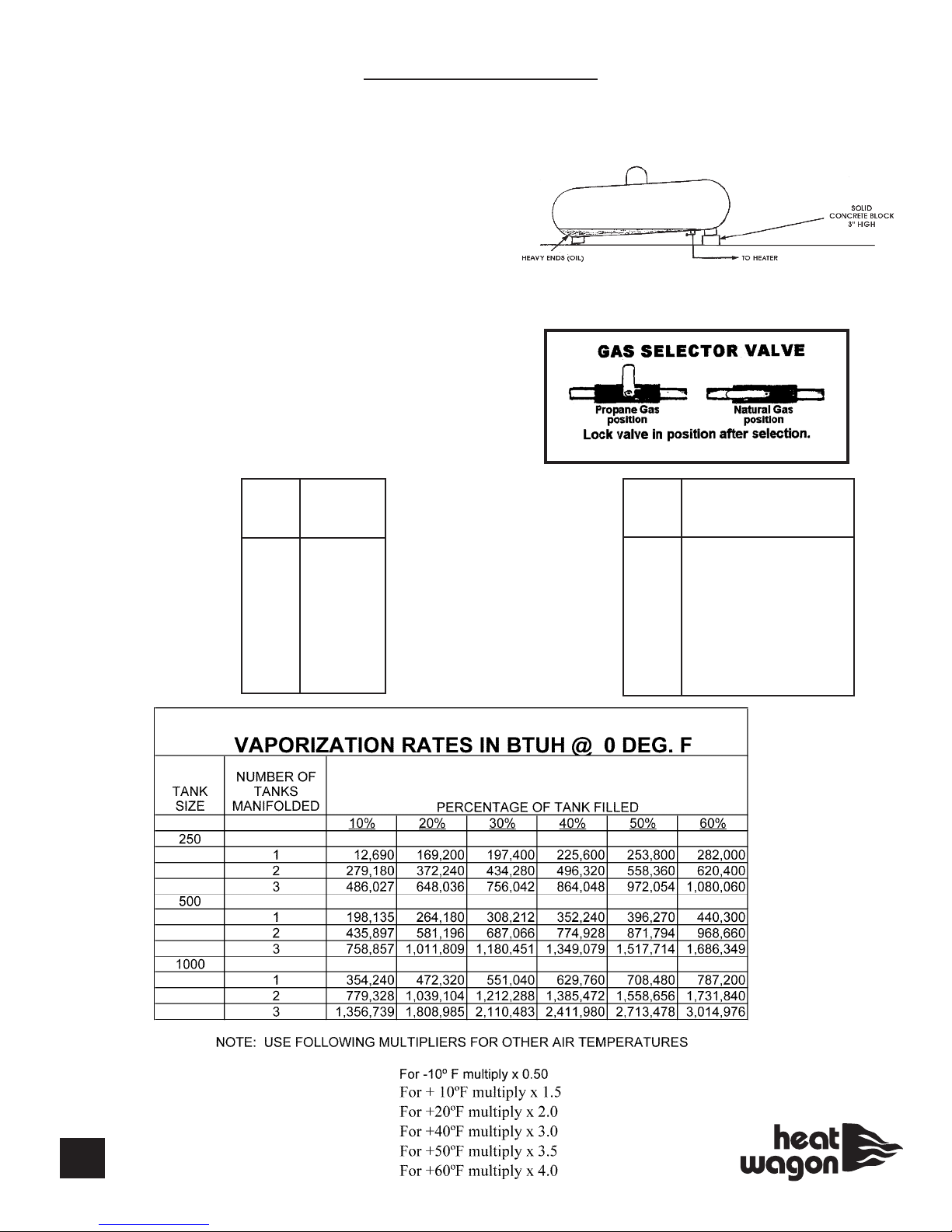

5) LOCKING GAS SELECTOR LEVER

To avoid over firing of the heater and damage to property, make sure the lever is locked in

position when using propane.

6) LOW SHELL TEMPERATURE

The Model 1800(SL) is designed with a burner heat shield to keep the outside shell cool for

added safety in the work place.

7) DURABLE CONSTRUCTION

The Model 1800(SL) uses a heavy gauge steel housing and a stainless steel burner for long life

and consistent performance.

NOTE: In order to maintain the highly efficient combustion of the heater, the combustion chamber must remain as manufactured. Any change or distortion could alter the fuel/air mixture and

create excessive products of combustion.

SPECIFICATIONS

Model No. 1800 & 1800SL

Designed to ANSI Z83.7-1990 Standard Construction Heater

Gases: Natural or Propane

Capacity: 750,000 Btu/h maximum

Orifice Size: 36DMS (X18)

Blower: 4,200 CFM

Electrical Rating: 115V 60Hz 15 amps, single phase

Minimum Temperature Rating: Minus 20 degrees F

Gas Supply: Inlet Pressure Manifold Pressure

Max PSI Min PSI W.C.

Propane 50 lbs. 5 PSI 7.0”

Natural Gas 50 lbs. 5 PSI 7.0”

(Minimum inlet pressure as low as 9.5” W.C. can be achieved by removing 2nd stage 40SV06 regulator)

Inlet Connection: Weight (approximate)

Model 1800SL 1/4” FNPT Duct Part#: WD2010UTH

Model 1800 3/4” FNPT Maximum Duct Length Straight: 50 Ft. @ 18” Diameter

4

:

200 lbs.

INSTALLATION

The Heat Wagon Model 1800(SL) is a direct fired gas heater intended to be used primarily for the

temporary heating of building under construction, alteration, or repair. Since all the products of

combustion are released into the area being heated, it is imperative that adequate ventilation is provided. The flow of supply air and combustion gases must not be obstructed in any way.

1. The heater is designed for indoor or outdoor installation in a horizontal position. Allow the

following clearances from any combustible material or fuel containers.

Front Outlet: 10 feet Sides: 2 feet

Intake: 1.5 feet Top: 4 feet

Also make sure that no flammable vapors are present in the space where the heaters is being used.

2. The heater should be inspected before each use, and at least annually by a qualified service

person.

3. The hose assembly must be inspected prior to each use of the heater. If it is evident that there is

excessive abrasion or wear, or the hose is cut, it must be replaced prior to the heater being put

into operation. The replacement hose assembly shall be that specified by the manufacturer.

See parts list.

4. When connecting the heater to a natural gas or propane supply line ensure that the pressure at

the heater inlet is within the specified range. Excessive pressure (over 50 psig) will damage the

controls and void the warranty.

5. Connect the hose assembly to the heater gas inlet elbow. The 1800 elbow has 3/4” Female NPT

thread, 1800SL elbow has a 1/4” Female NPT thread. The hose assembly is supplied with a

swivel connector to avoid kinking or twisting the hose. Use a minimum inside diameter of 1/2”

on LP or 3/4” on natural gas installations. Ensure that the hose assembly is protected from

traffic, building materials, and contact with hot surfaces.

6. After installation, check hose assembly for gas leaks by applying a soap and water solution to

each connection.

7. Connect the heater to an adequate 115 volt electrical supply as specified on the rating plate. For

protection against shock hazard the supply cord should be plugged directly into a properly

grounded three-prong receptacle.

EXTENSION CORDS:

Properly Wired and Grounded

Use #14 wire up to 100’

Use #12 wire up to 200’

Use #10 wire up to 300’

8. Replacement parts are available from any Heat Wagon distributor or by calling 1-888-432-8924

for parts information.

5

MODEL 1800 & 1800SL

PROPER SET UP:

Model 1800SL is a liquid withdrawal unit. This unit

will use 8.25 gal of LP per hour. Use at least (1) 200

gal. withdrawal tank. This will insure 20 hours of

continuous operation. Since the 1800(L) is a Liquid

Propane unit, it must be set up outside of the building. Use 3/8” or 1/2” LPG approved hose or copper

tube.

Model 1800S is a Vapor Propane or Natural Gas unit.

When using Propane (liquid or vapor) turn the fuel selector valve (located on the lower manifold) to the Propane

position. When using Natural Gas turn the selector valve

to the Natural Gas position. This unit can be set up

indoors or out.

VAPOR PROPANE QUICK

REFERENCE HOSE

CHART

Hose BTU

Length 750,000

in Feet 1/2PSI 10PSI

10 1 3/4

25 1-1/4 3/4

35 1-1/4 3/4

50 1-1/2 3/4

75 1-1/2 3/4

100 1-1/2 3/4

125 2 3/4

150 2 3/4

175 2 3/4

200 2 3/4

225 2 3/4

NATURAL GAS QUICK

REFERENCE HOSE

CHART

Hose BTU

Length 750,000

in Feet <1PSI 1PSI 2PSI 5PSI

10 1-1/2 1 3/4 3/4

25 1-1/2 1 3/4 3/4

35 1-1/2 1 3/4 3/4

50 21 13/4

75 2 1-1/4 1 3/4

100 2 1-1/4 1 3/4

125 2 1-1/4 1-1/4 3/4

150 2 1-1/4 1-1/4 3/4

175 2 1-1/4 1-1/4 3/4

200 2-1/2 1-1/4 1-1/4 3/4

225 2-1/2 1-1/4 1-1/4 3/4

6

Loading...

Loading...