Page 1

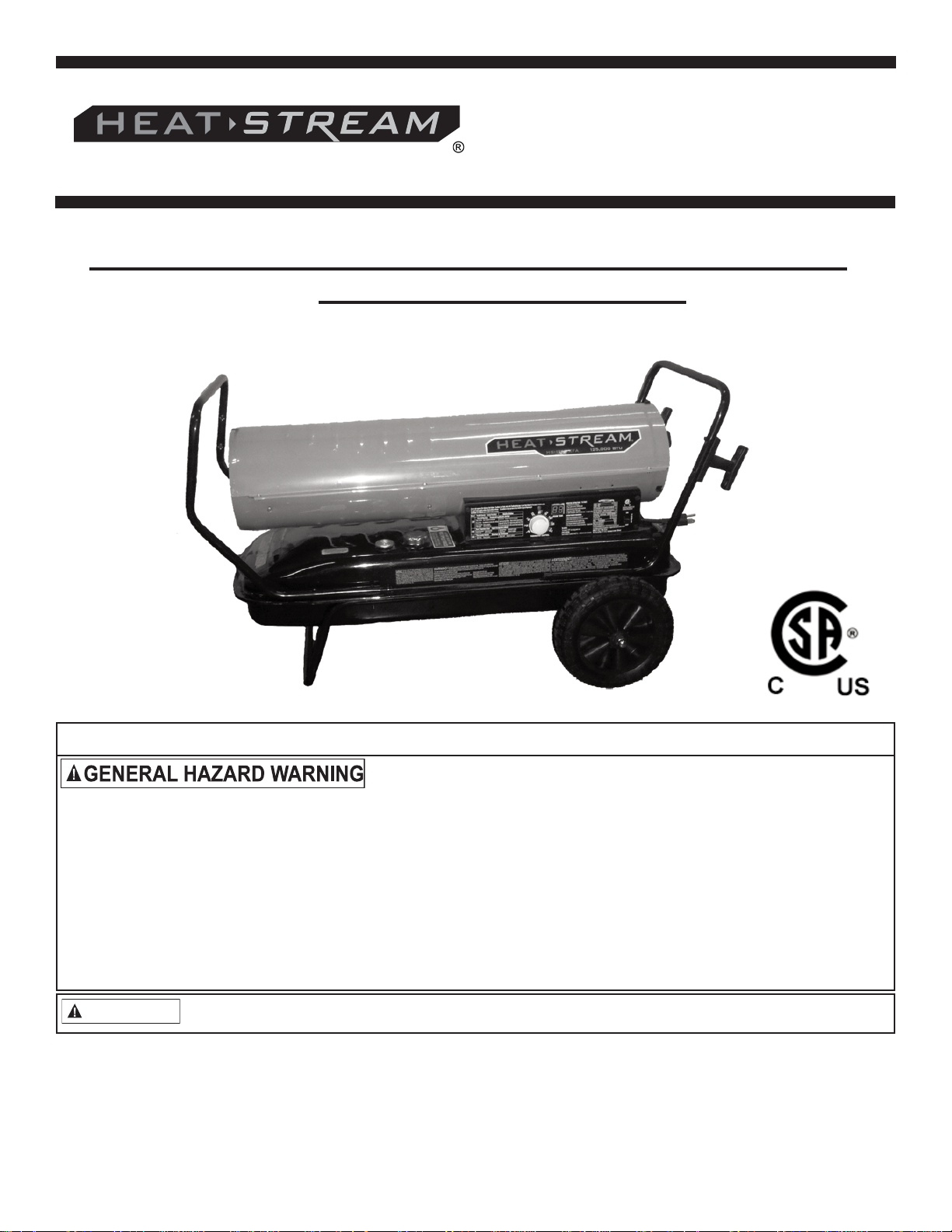

User ’s Manual and

Operating Instructions

Model Numbers: HS-45-KFA, HS-70T-KFA, HS-125T-KFA,

HS-175T-KFA, HS-215T-KFA

Consumer: Please Read These Instructions And Keep For Your Reference

FAILURE TO COMPLY WITH THE PRECAUTIONS AND INSTRUCTIONS PROVIDED WITH THIS

HEATER, CAN RESULT IN DEATH, SERIOUS BODILY INJURY AND PROPERTY LOSS OR

DAMAGE FROM HAZARDS OF FIRE, EXPLOSION, BURN. ASPHYXIATION, CARBON

MONOXIDE POISONING AND / OR ELECTRIC SHOCK.

ONLY PERSONS WHO CAN UNDERSTAND AND FOLLOW THE INSTRUCTIONS SHOULD USE

OR SERVICE THIS HEATER.

IF YOU NEED ASSISTANCE OR HEATER INFORMATION SUCH AS AN INSTRUCTIONS

MANUAL, LABEL, ETC. CONTACT THE MANUFACTURER.

WARNING

This is an unvented portable heater. It uses air (oxygen) from the area in which it is used. Adequate combustion

and ventilation air must be provided. Refer to VENTILATION on Page 7.

© Pinnacle Products International, Inc.

668 Stony Hill Road #302 Yardley, PA 19067 USA Toll Free: (800) 641-6996

Fax: (215) 891-8461 Web: www.heatstream.us Email: info@pinnacleint.com

701000273-12

Page 2

Table of Contents

DANGER

DANGER

NEVER LEAVE HEATER

UNATTENDED WHILE BURNING OR WHILE CONNECTED

TO A POWER SOURCE

Safety Information........................................... 2-3

Unpacking ...........................................................3

Features ......................................................... 3-4

Assembly ........................................................ 5-6

Operation .........................................................7-9

Fuels .................................................................. 7

Theory of Operation ........................................... 7

Ventilation .......................................................... 7

Safety Information

WARNING

KEEP SOLID COMBUSTIBLES, SUCH AS

BUILDING MATERIALS, PAPER OR CARDBOARD, A SAFE DISTANCE AWAY FROM THE

HEATER AS RECOMMENDED BY THESE

INSTRUCTIONS. NEVER USE THE HEATER

IN SPACES WHICH DO OR MAY CONTAIN

VOLATILE OR AIRBORNE COMBUSTIBLES,

OR PRODUCTS SUCH AS GASOLINE,

SOLVENTS, PAINT THINNERS, DUST

PARTICLES OR UNKNOWN CHEMICALS.

WARNING

WARNING

these safety and operating instructions.

California Residents: Combustion by-products

produced when using this product contain carbon monoxide, a

chemical known to the state of California to cause cancer and

birth defects (or other reproductive harm).

Massachusetts Residents: Massachusetts state law

prohibits the use of this heater in any building which is used in

whole or in part for human habitation. Use of this heating device

in Massachusetts requires local fire department permit (M.G.L.C.

148, Section 10A).

New York City Residents: The New York City Fire

Code prohibits the storage, handling and use of kerosene fueled

heaters for space heating. Any person violating that provision

may be punished by a fine up to $10,000 and a term of

imprisonment up to 6 months.

WARNING

the filter and seals. Any damage caused by using BioDiesel will not be covered by warranty.

result in death or serious injury.

FIRE, BURN, INHALATION,

AND EXPLOSION HAZARD.

NOT FOR HOME OR

RECREATIONAL USE.

Do not operate this heater until you

have read, and thoroughly understand

This heater is NOT suitable for use with

Bio-Diesel; use of Bio-Diesel will damage

Indicates an im minen tly hazardous

situation which, if not avoided, WILL

Long Term Storage ......................................... 8-9

Maintenance ................................................. 9-11

Exploded View ................................................. 12

Replacement Parts .......................................... 13

Wiring Diagram ................................................ 14

Troubleshooting ............................................... 15

Warranty ............................................ Back Cover

WARNING

COULD result in death or serious injury.

CAUTION

result in minor or moderate injury.

This is a kerosene, direct-fired, forced air heater. It is primarily

intended for use for temporary heating of buildings under

construction, alteration or repair. Direct-fired means that all of the

combustion products of the heater enter the heated space. This

appliance is rated at 98% combustion efficiency, but does produce

small amounts of carbon monoxide. Carbon monoxide is toxic.

Humans can tolerate small amounts of carbon monoxide, and

precautions should be taken to provide proper ventilation. Failure

to provide proper ventilation according to this manual can result in

death. Early signs of carbon monoxide poisoning resemble the flu.

Symptoms of improper ventilation are:

headache * dizziness * burning of the nose and eyes

*

For optimal performance of this heater, it is strongly suggested

that 1-K kero sene be used. 1-K kerosene has been refined to

virtually eliminate contami nants, such as sulfur, which can cause a

rotten egg odor during the operation of the heater. However, #1 or

#2 fuel oil (diesel fuel) may also be used if 1-K kero sene is not

available. Be advised that these fuels do not burn as clean as 1-K

kerosene, and care should be taken to provide more fresh air

ventilation to accommodate any added contaminants that may be

added to the heated space. Use of #1 or #2 fuel oil may result in

more periodic maintenance.

*

WARNING

- Use this heater only in well ventilated areas! Provide at least a

three square foot (2,800 sq cm) opening of outside air for every

100,000 BTU/hr of heater rating.

- People with breathing problems should consult a physician

before using the heater.

- Carbon Monoxide Poisoning: Early signs of carbon monoxide

poisoning resemble flu-like symptoms such as headaches,

dizziness, and/or nausea. If you have these symptoms, your

heater may not be working properly.

Indicates a poten tially hazardous

situation which, if not avoided,

Indicates a poten tially hazardous

situa tion which, if not avoided, MAY

Carbon Monoxide poisoning may lead to

death!

nausea * dry mouth * sore throat

Risk of indoor air pollution!

© 2012, Pinnacle Products International, Inc.

2

Kerosene User’s Manual

Page 3

Safety Information (continued)

NEVER LEAVE HEATER

UNATTENDED WHILE BURNING OR WHILE CONNECTED

TO A POWER SOURCE

Simply locate fan in safe, desired position on level ground,

and connect to approved power source.

-

Get fresh air at once! Have the heater serviced. Some people

are more affected by carbon monoxide than others. These

include pregnant women, those with heart or lung problems,

anemia, or those under the influence of alcohol, or at high

altitudes.

WARNING

Risk of burns / fire / explosion!

- NEVER use fuels such as gasoline, benzene, paint thinners, or

other oil compounds in this heater (RISK OF FIRE OR

EXPLOSION).

- NEVER refill the heater’s fuel tank while heater is operating or

still hot. This heater is EXTREMELY HOT while in operation.

- Keep all combustible materials away from this heater.

- NEVER block air inlet (rear) or air outlet (front) of heater.

- NEVER use duct work in front or at rear of heater.

- NEVER move or handle heater while still hot.

- NEVER transport heater with fuel in its tank.

- If equipped with a thermostat, the heater may start at any time.

- ALWAYS locate heater on a stable and level surface.

Unpacking

- ALWAYS keep children and animals away from heater.

- Bulk fuel storage should be a minimum of 25 ft. from heaters,

torches, portable generators, or other sources of ignition. All

fuel storage should be in accordance with federal, state, or

local authorities having jurisdiction.

- Never use this heater in living or sleeping areas.

- NEVER use this heater where flam mable vapors may be

present.

WARNING

- Use only the electrical power (voltage and frequency) specified

on the model plate of the heater. Use only a three- prong,

grounded outlet and extension cord.

Risk of electric shock!

- ALWAYS install the heater so that it is not directly exposed to

water spray, rain, dripping water, or wind.

- ALWAYS unplug the heater when not in use.

Minimum clearance from Combustibles:

45k 70k 125k 175k 215k

Top 4 ft. 4 ft. 4 ft. 4 ft. 4 ft.

Sides 4 ft. 4 ft. 4 ft. 4 ft. 4 ft.

Front 8 ft. 8 ft. 8 ft. 8 ft. 10 ft.

Remove the heater and all of the packaging materials from the

shipping carton.

NOTE: Save the box and packaging materials for future storage.

Check the chart below to be sure that you have all of the parts

Features

required to assembly your heater. If you find that any parts are

missing, call 215-891-8460 for assistance in receiving the

missing components.

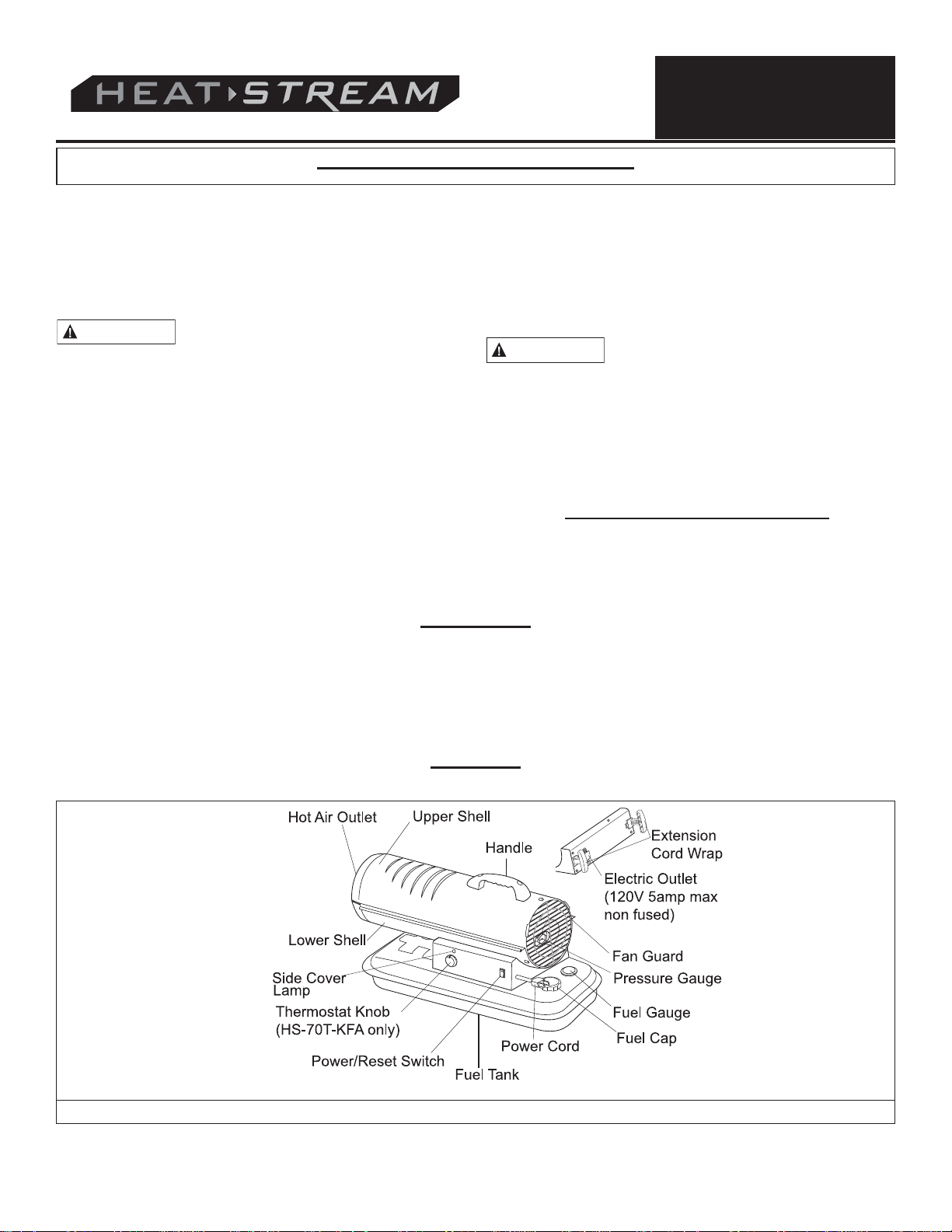

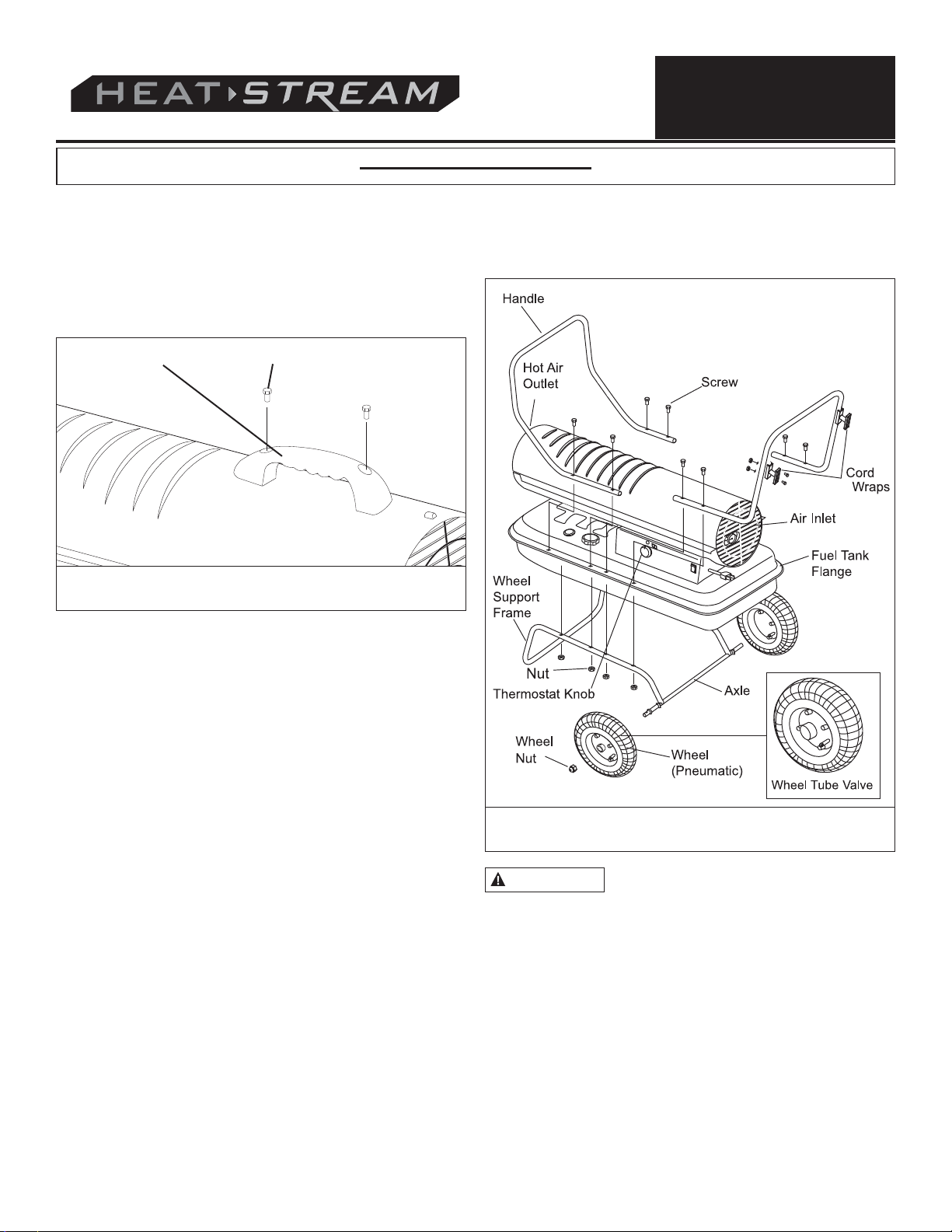

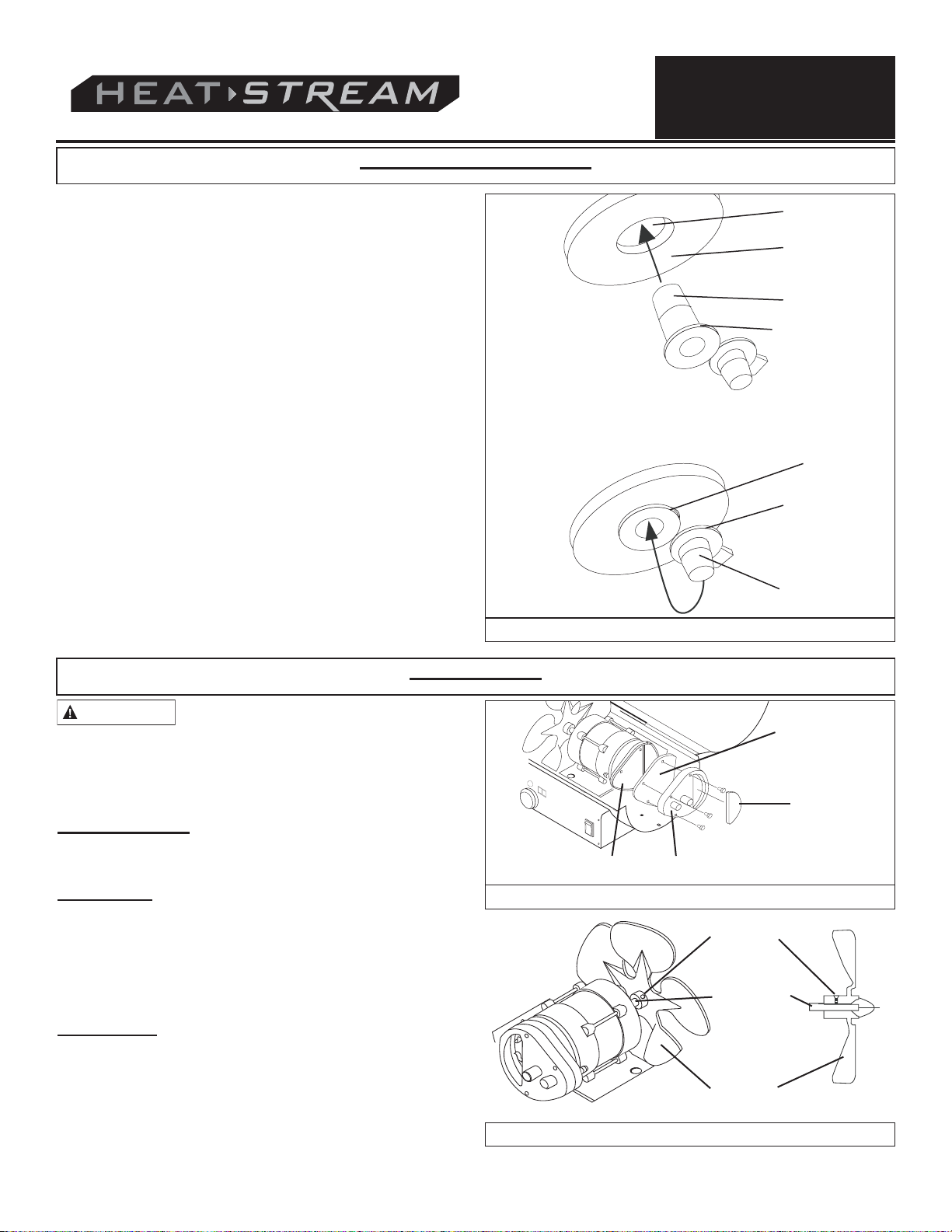

Figure 1: Features of Models HS-45/70T-KFA

© 2012, Pinnacle Products International, Inc.

3

Kerosene User’s Manual

Page 4

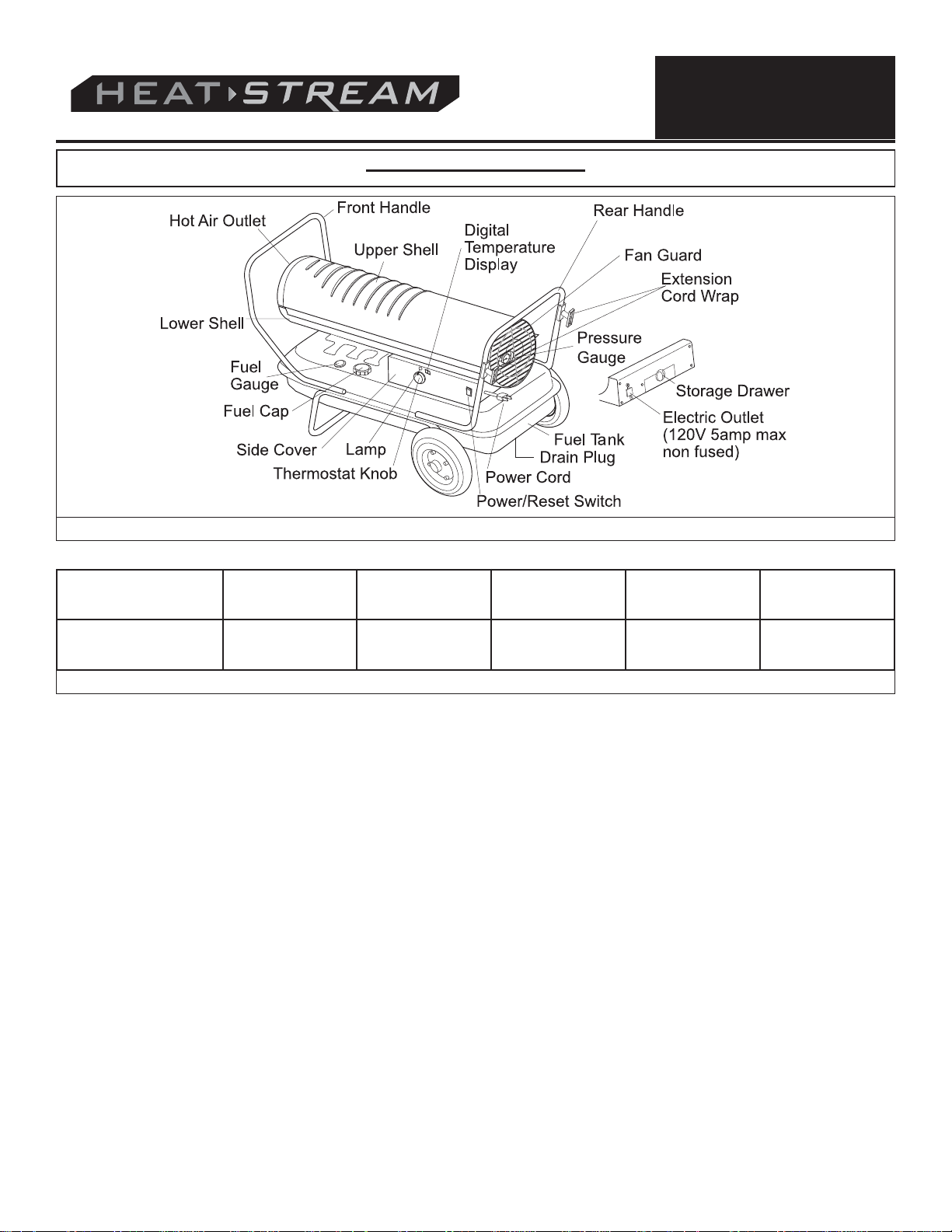

Features (Continued)

NEVER LEAVE HEATER

UNATTENDED WHILE BURNING OR WHILE CONNECTED

TO A POWER SOURCE

Figure 2: Features of Models HS-125T/175T/215T-KFA

HS-45-KFA HS-70T-KFA HS-125T-KFA HS-175T-KFA HS-215T-KFA

Fuel Consumption

Rate (Gallons)

.35 .53 .95 1.34 1.63

Figure 3: Product Specifications

© 2012, Pinnacle Products International, Inc.

4

Kerosene User’s Manual

Page 5

NEVER LEAVE HEATER

UNATTENDED WHILE BURNING OR WHILE CONNECTED

TO A POWER SOURCE

Assembly

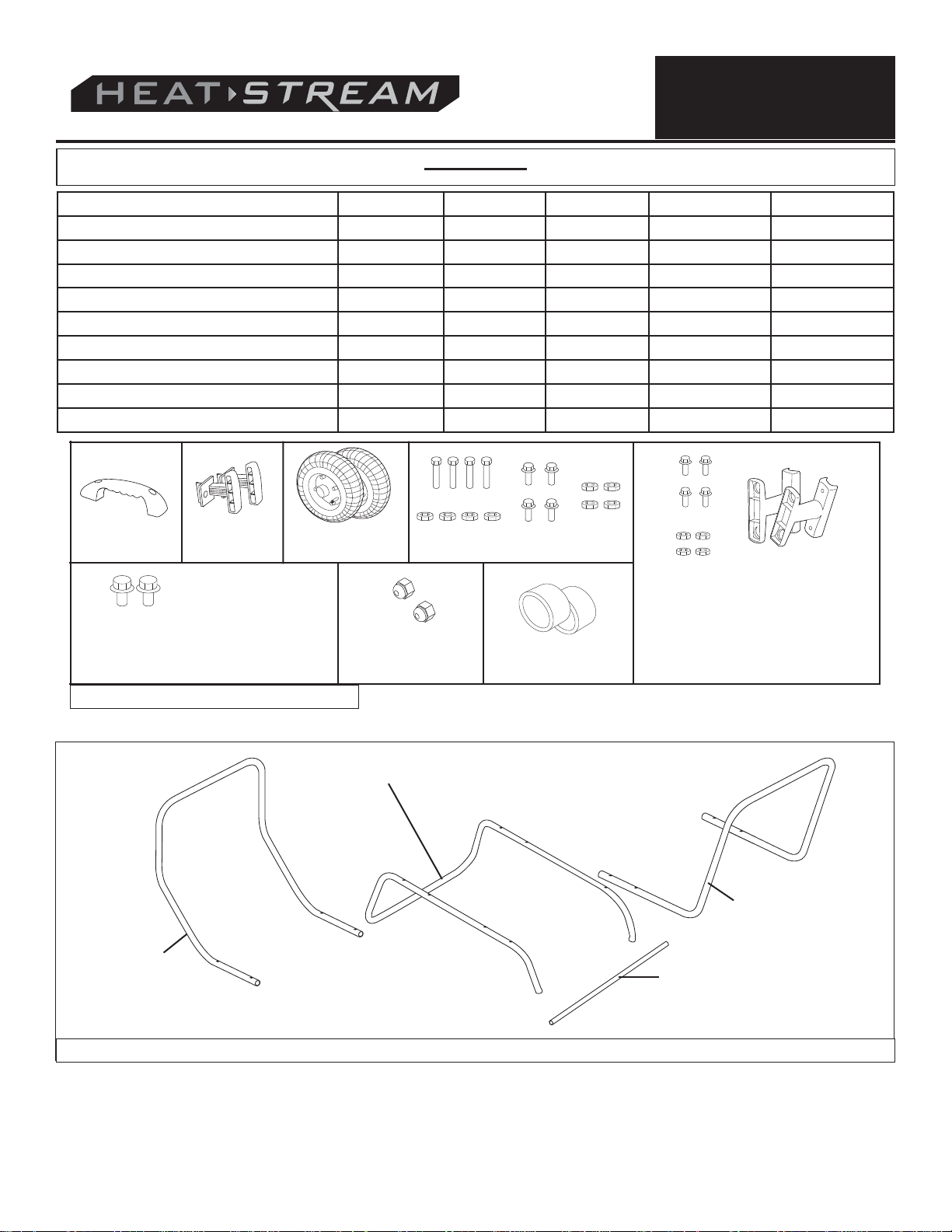

HS-45-KFA HS-70T-KFA HS-125T-KFA HS-175T-KFA HS-215T-KFA

Wheel support frame NO NO YES YES YES

Wheel (2 pieces) NO NO YES YES YES

Front and Rear Handle NO NO YES YES YES

Axle NO NO YES YES YES

Top Handle YES YES NO NO NO

Screws & Nuts (A) 8 each NO NO YES YES YES

Screws & Nuts (B) 4 each YES YES NO NO NO

Wheel Nuts and Bushings NO NO YES YES YES

Cord Wrap YES YES YES YES YES

Handle

Hardware Kit Part#

70-056-0100

(HS-45 / 70T-KFA)

Cord Wraps Wheels

Screws and

Nuts(4 ea.)

Figure 4: Hardware Components

Wheel Support Frame

Front Handle

Frame Component Hardware

Wheel Nuts

Bushings

Screws and Nuts (4 ea.) and Cord

Wraps

Hardware Kit Part#:

70-056-0210

(HS-125T/ 175T / 215T-KFA)

Rear Handle

Axle

Figure 5: Frame Components for models HS-125T / 175T / 215T-KFA

© 2012, Pinnacle Products International, Inc.

5

Kerosene User’s Manual

Page 6

Assembly (Continued)

CAUTION

NEVER LEAVE HEATER

UNATTENDED WHILE BURNING OR WHILE CONNECTED

TO A POWER SOURCE

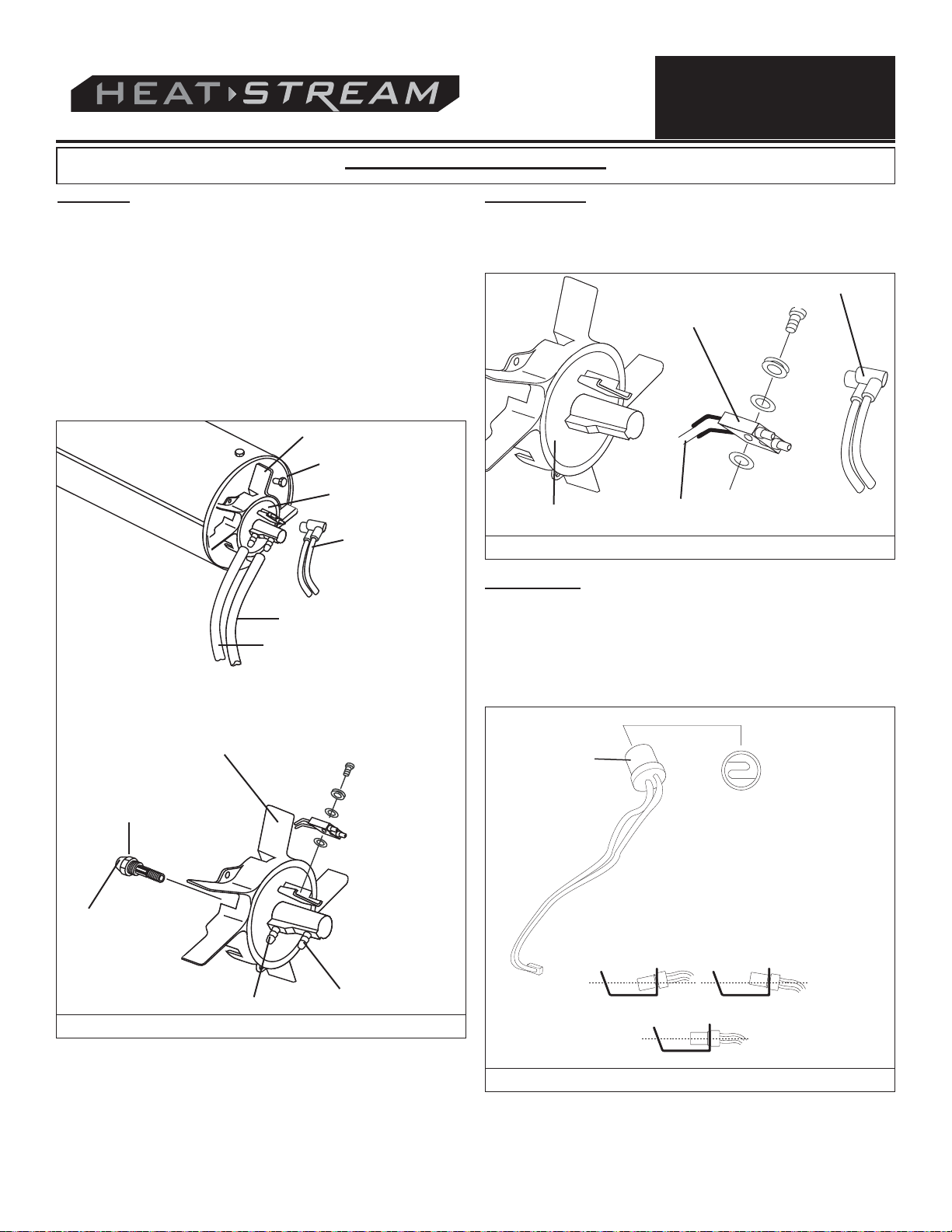

MODELS HS-45/70T-KFA ONLY

- Tools required: Medium phillips screw driver.

ASSEMBLING HANDLE

1.Align the holes in the upper housing with the 2 holes in the

handle as shown in Figure 6.

2. Insert and tighten screws securely with screw driver.

Handle

Screw

Figure 6: Attaching Handle for models HS-45 /

70T-KFA

ASSEMBLING CORDWRAP

1. Insert tabs on cordwrap into slots in shell support, lining up the

holes on the cordwrap with those on the side cover.

2. Insert and tighten screws securely with screw driver.

ASSEMBLING CORDWRAP

1. Align holes in cordwrap with corresponding holes in rear

handle. Insert screws (B) through holes, attach nuts and

tighten (see Figure 7.).

MODELS HS-125T/175T/215T-KFA ONLY

- Tools required: Medium phillips screw driver, 5/16” open end

or adjustable wrench, needle nose pliers.

ASSEMBLING FRAME AND WHEELS

1. Slide axle through holes in wheel support frame. Slide wheel

bushings and flat washer (A) on to each end of axle.

2. Slide wheels on to each axle, being sure that the valve stem (if

pneumatic) is to the outside (see Figure 7.).

3. Attach wheel nut to threaded axle and tighten.

4. Place heater on the assembled frame, making sure that the air

inlet end is by the wheels, and the mounting holes on the tank

flange of the heater align with holes in frame.

5. Take the front handle and align the mounting holes with the

corresponding holes in the tank flange/wheel frame. Slide a

screw (A) through the holes and loosely attach a nut. Repeat

for the other 3 holes, then fully tighten all 4 screws and nuts.

6. Repeat this process with the rear handle

NOTE: The front handle is longer than the rear handle.

© 2012, Pinnacle Products International, Inc.

.

Figure 7 Attaching Handle for models HS-125T /

175T / 215T-KFA

Do not operate heater without support

frame fully assembled to tank.

6

Kerosene User’s Manual

Page 7

Operation

CAUTION

KEROSENE (1-K)

For optimal performance of this heater, it is strongly suggested

that 1-K kero sene be used. 1-K kerosene has been refined to

virtually eliminate contami nants, such as sulfur, which can cause a

rotten egg odor during the operation of the heater. However, #1 or

#2 fuel oil (diesel fuel) may also be used if 1-K kerosene is not

available. Be advised that these fuels do not burn as clean as 1-K

kerosene, and care should be taken to provide more fresh air

ventilation to accommodate any added contaminants that may be

added to the heated space. Using diesel fuel can cause excess

soot production. DO NOT use any fuel that is not approved

above.

NOTE: Kerosene should only be stored in a blue container that is

clearly mark ed “kerosene”. Never store kero sene in a red

container. Red is associ ated with gasoline.

- NEVER store kerosene in the living space. Kerosene should be

stored in a well ventilated area outside the living area.

- NEVER use fuel such as gasoline, benzene, alcohol, white gas,

camp stove fuel, paint thinners, or other oil compounds in this

heater (THESE ARE VOLATILE FUELS THAT CAN CAUSE A

FIRE OR EXPLOSION).

- NEVER store kerosene in direct sunlight or near a source of

heat.

- NEVER use kerosene that has been stored from one season to

the next. Kerosene deteriorates over time. OLD KEROSENE

WILL NOT BURN PROPERLY IN THIS HEATER.

- Use 1-K kerosene in this heater. #1 fuel is a suitable substitute.

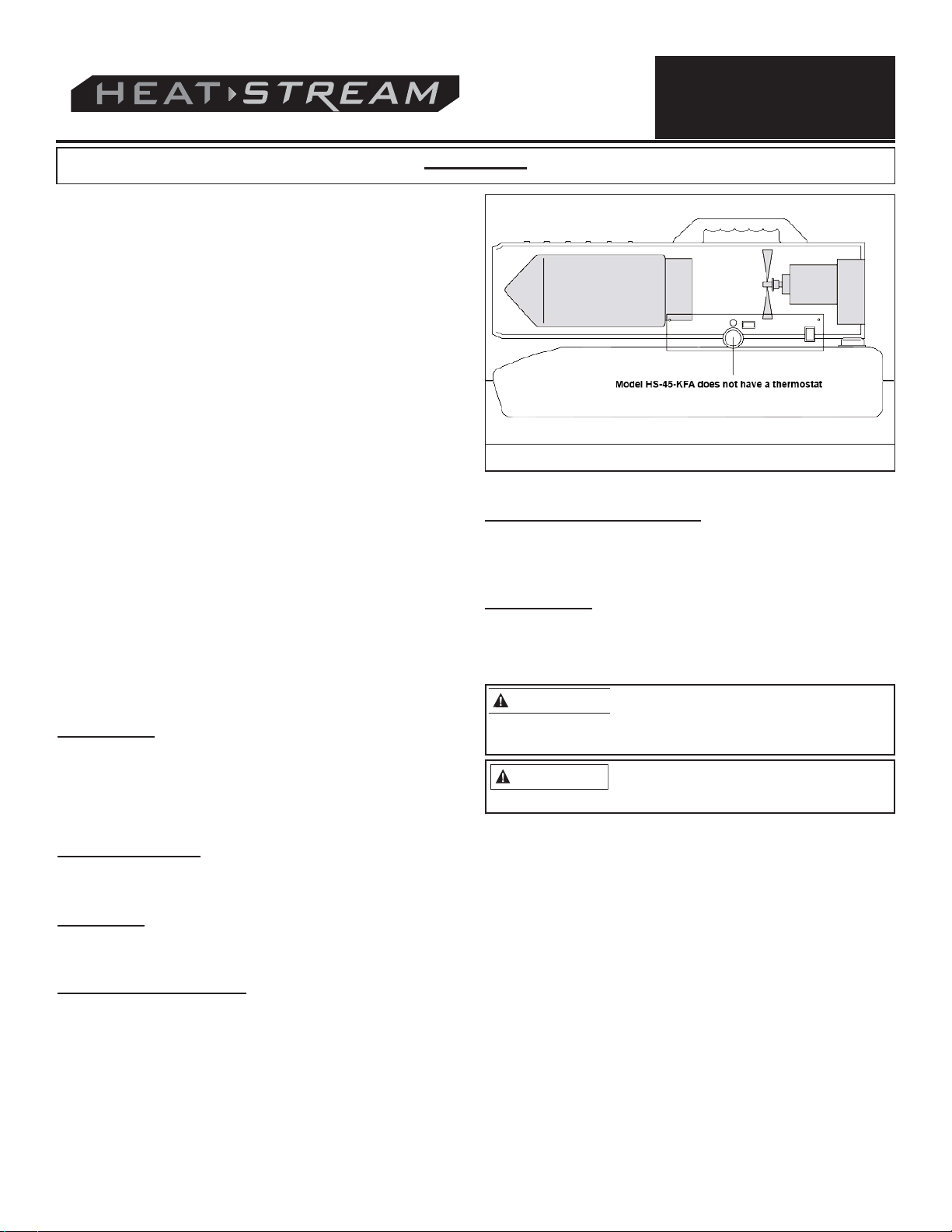

THEORY OF OPERATION

Fuel System: This heater is equipped with an air pump that

operates off of the electric motor. The pump forces air through

the air line connected to the fuel tank, drawing fuel to the nozzle

in the burner head. Air also passes through the nozzle where it

mixes with the fuel and is sprayed into the combustion chamber

in a fine mist.

Quick-Fire Ignition: A transformer sends high voltage to a two

pronged spark plug. The spark ignites the fuel/air mixture as it is

sprayed into the combustion chamber.

NEVER LEAVE HEATER

UNATTENDED WHILE BURNING OR WHILE CONNECTED

TO A POWER SOURCE

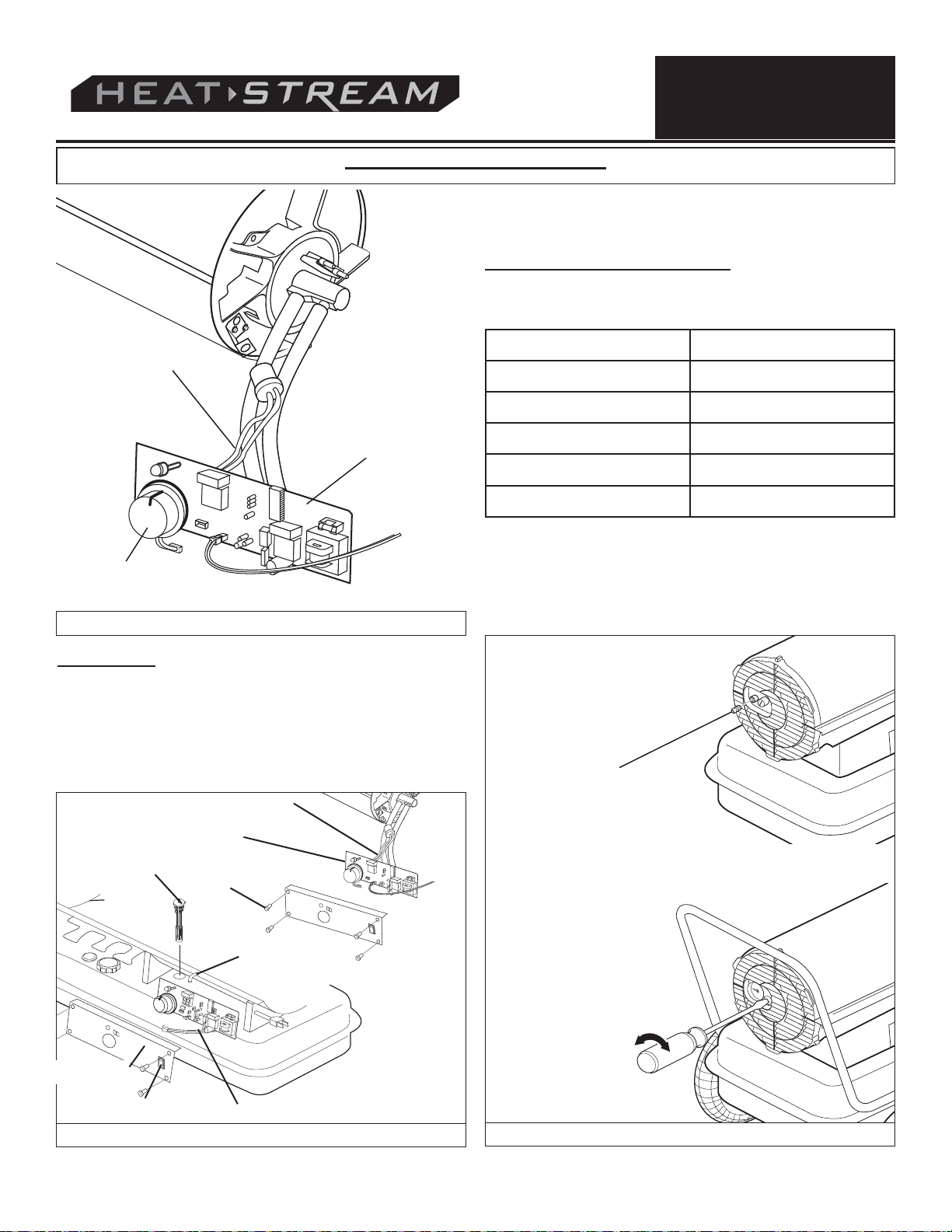

Figure 8 Theory of Operation

Electrical System Protection: The heaters’ electrical system

is protected by a circuit breaker that protects the system

components from damage. If the heater fails, check the fuse first,

and replace if necessary.

Flame Sensor: The heater uses a photocell to “see” the flame

in the combustion chamber. Should the flame extinguish, the

sensor will stop electrical current and the heater will shut off.

FUELING THE HEATER

NEVER FILL THE FUEL TANK INDOORS.

ALWAYS FILL THE TANK OUTDOORS.

BE SURE THAT THE HEATER IS ON LEVEL GROUND WHEN

FUELING, AND NEVER OVERFILL THE FUEL TANK.

WARNING

EXPLOSION COULD RESULT.

It is always a good idea to fire the heater outdoors for the first

time. This will allow any oils used in the manufacturing process to

be burned off in a safe environment. This initial burn should last

at least 10 minutes

NEVER REFUEL THIS HEATER WHILE IT

IS HOT OR OPERATING. FIRE OR

Air System: A fan is turned by the heavy duty motor, which

forces air around and into the combustion chamber, where it is

super-heated and forced out the front of the chamber.

Temperature Limit Control: This heater is equipped with a

Temperature Limit Control designed to turn the heater off should the

internal temperature rise to an unsafe level. If this device activates

and turns your heater off, it may require service.

Once the temperature falls below the reset temperature, you will

be able to start your heater.

© 2012, Pinnacle Products International, Inc.

VENTILATION

Risk of indoor air pollution. Use heater only in well

ventilated areas.

Always provide a fresh air opening in the heated space of at

least three square feet (2,800 sq. cm) for each 100,000 BTU/Hr.

of heater output. Provide a larger opening if more heaters are

being used. As an example, an HS-215T-KFA heater will require:

- a two-car garage door open 6 inches, or

- a single car garage open 9 inches, or

- two thirty two inch wide windows open fifteen inches.

7

Kerosene User’s Manual

Page 8

Operation (Continued)

NEVER LEAVE HEATER

UNATTENDED WHILE BURNING OR WHILE CONNECTED

TO A POWER SOURCE

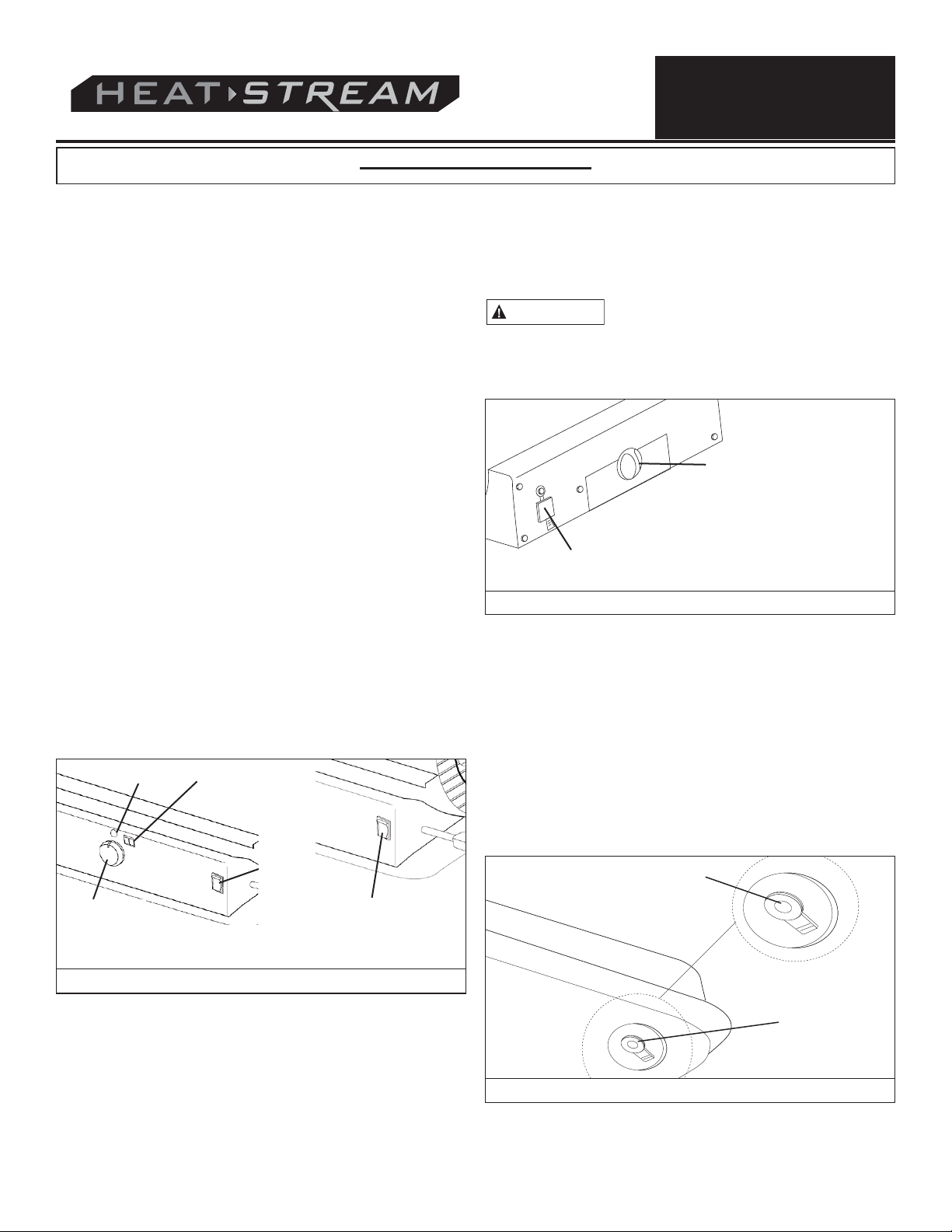

TO START THE HEATER

1. Fill the tank with kerosene until fuel gauge points to “F”.

2. Be sure fuel cap is secure.

3. Plug power cord into three prong, grounded extension cord

and plug extension cord into three prong 120V grounded outlet. The extension cord should be at least six feet long.

- Extension cord wire size requirements are as follows:

› 6 to 10 feet (1.8 to 3 meters), use 18 AWG wire.

› 11 to 100 feet (3.4 to 30.4 meters), use 16 AWG wire.

› 101 to 200 feet (30.8 to 61 meters), use 14 AWG wire.

4. Turn thermostat control knob to desired temperature setting

(70/125/175/215 only). The setting range is from 40°F to 110

F. Push the Power switch to the “ON” position (See figure 9).

The power indicator lamp and room temperature display

(125/175/215 only) will light and the heater will start.

NOTE: The room temperature display (125/175/215 only) will

indicate the following:

- When temperature is less than 0°F, display says “LO”.

- When temperature is above 99°F, display says “HI”.

- Between 0°and 99°F display shows actual temperature.

5. If the heater does not fire, the thermostat may be set too low.

Turn the Control Knob to a higher setting until heater fires. If

the heater still does not start, push Power Switch to “OFF”,

then back to “ON”. If heater still does not fire, see

Troubleshooting Guide on Page 15.

NOTE: The electrical components of this heater are protected by

a fuse mounted in the PC board. If the heater fails to fire, check

this fuse first, and replace if necessary. Also check the power

source to be sure that the proper voltage is being provided to the

heater.

Lamp

Room Temp.

Display(Except

HS-70T-KFA)

TO RESTART THE HEATER

1. Wait ten seconds after shutting off heater.

2. Turn the Power Switch to “ON” position.

3. Be sure to follow all starting procedure precautions.

ELECTRICAL OUTLET

WARNING

- Never plug in an appliance with more than a 5 amp rating into

this outlet.

- Always keep outlet covered when not in use.

°

Shock Hazard!

Storage Drawer (except

HS-45 / 70T-KFA)

Electric Outlet (120v 5amp max

non fused)

Figure 10: Electric Outlet Detail

LONG TERM STORAGE

Drain Fuel Tank

For models HS-45/70T-KFA, drain fuel through the fuel cap opening using an approved siphon. For models HS-125/175/215-KFA,

drain fuel through the Drain Plug at the bottom of the Fuel Tank.

2. To remove the Drain Plug (125/175/215), pull the Plug Grip

downward and remove seal head from drain hole in tank (See

Figure 11).

Power

Switch

Thermostat

Control Knob

Models HS-70T / 125T / 175T / 215T-KFA

Power Switch

Model HS-45-KFA

Figure 9: Control Panel for all models

TO STOP THE HEATER

Simply turn the Power switch to “OFF” position and unplug the

Power Cord.

© 2012, Pinnacle Products International, Inc.

Plug Grip

Figure 11: Drain Plug Removal

8

Kerosene User’s Manual

Drain Plug

Page 9

Operation (Continued)

NEVER LEAVE HEATER

UNATTENDED WHILE BURNING OR WHILE CONNECTED

TO A POWER SOURCE

3. Using a small amount of kerosene, rinse and swirl the

kerosene inside of the Fuel Tank. Empty the tank fully.

4. To replace, push the drain head fully into the drain hole and

secure by pushing the seal cap fully into the head hole (See

Figure 12).

IMPORTANT: Never store leftover kerosene over the summer.

Using old fuel can damage your heater.

Drain Plug

Fuel Tank

Seal Head

Head Flange

Head

Flange

Cap Flange

Seal Cap

Figure 12: Drain Plug Reinstall

Maintenance

WARNING

Use only original equipment replacement parts. The use of

alternate or third party components can cause unsafe operating

conditions, and will void your warranty.

We suggest following a maintenance schedule as follows:

FUEL/FUEL TANK:

Flush every 200 hours of operation or as needed. Do not use

water to flush the tank. Use fresh 1-K kerosene only.

AIR FILTERS:

The Air Intake Filter should be replaced or washed with soap and

water and dried thoroughly every 500 hours of operation, or less,

depending on conditions.

The Output and Lint Filters should be replaced every 500 hours

of operation or less, depending on conditions.

NOTE: Use of diesel may require additional maintenance..

FAN BLADES:

Blades should be cleaned at least once per heating season,

depending on conditions.

Remove all accumulated dust and dirt with a damp cloth, taking

care not to bend any of the fan blades. Be sure fan blades are

dry before re-starting the heater. For Fan removal, see Figure

14.

Never service heater while it is plugged in

or while hot!

Lint Filter

End Filter Cover

Figure 13: Filter Replacement

Set Screw

Motor Shaft

Fan Blade

Figure 14: Fan Replacement

Air Output Filter

Intake Filter

Flush

© 2012, Pinnacle Products International, Inc.

9

Kerosene User’s Manual

Page 10

Maintenance (Continued)

NEVER LEAVE HEATER

UNATTENDED WHILE BURNING OR WHILE CONNECTED

TO A POWER SOURCE

NOZZLES:

Nozzles should be cleaned or replaced at least once per heating

season. Contaminated fuel could make this necessary

immediately

To clean dirt from nozzle, blow compressed air through nozzle

front. It may be necessary to soak nozzle in clean 1-K kerosene

to help loosen any particles.

NOTE: Use of diesel may require additional maintenance. Using

this heater without proper maintenance or with contaminated or

old fuel may lead to improper combustion and possible soot

production. BE SURE FUEL USED IS APPROVED (see

OPERATION on page 6).

.

Burner Head

Screw

Spark Plug

Ignitor Wire

Fuel Line Hose

Air Line Hose

SPARK PLUG:

Clean and re-gap every 600 hours of operation, or replace as

needed.After removing the Spark Plug, clean the terminals with a

wire brush. Re-gap the terminals to 0.140” (3.5mm).

Ignitor Wire

Spark Plug

Burner Head

Gap

Figure 16: Spark Plug Replacement

PHOTOCELL:

The Photocell should be cleaned at least once per heating

season or more depending on conditions.

Use a cotton swap dipped in water or alcohol to clean the lens of

the Photocell. Note the proper Photocell position as noted in

Figure 17 and Figure 18.

Burner Head

Nozzle

Nozzle Face

Air Line Fitting

Fuel Line Fitting

Figure 15: Nozzle Replacement

© 2012, Pinnacle Products International, Inc.

Photocell

Installing Photocell:

1) Incorrect

2) Correct

Figure 17: Photocell Positioning

10

Kerosene User’s Manual

Photocell

Lens

Page 11

Maintenance (Continued)

NEVER LEAVE HEATER

UNATTENDED WHILE BURNING OR WHILE CONNECTED

TO A POWER SOURCE

Photocell

Wire

Circuit Board

except

HS-45-KFA

Figure 18: Photocell Position in Heater

Use of diesel may require additional maintenance.

maintenance can lead to poor combustion and soot

production!

PUMP PRESSURE ADJUSTMENT:

While heater is operating, turn relief valve clockwise to increase,

counterclockwise to decrease (see Figure 20). Use flat blade

screwdriver to turn valve. Correct pump pressure is as follows:

Improper

Model # Pump Pressure

HS-45-KFA 3.0 PSI

HS-70T-KFA 4.0 PSI

HS-125T-KFA 5.0 PSI

HS-175T-KFA 7.5 PSI

HS-215T-KFA 9.0 PSI

Tolerance ± 10%

For best measurement of pressure, test with full tank of

fuel. Optimum pressure occurs when the nose cone is

cherry red and there are no extending flames from the

heater.

FUEL FILTER:

The Fuel Filter should be cleaned at least twice per heating

season by rinsing it in clean 1-K kerosene. Contaminated fuel

could make this necessary immediately (See Figure 19).

NOTE: To remove the filter from models HS-45 / 70T-KFA, turn

filter 90°clockwise. To remove the filter from models HS-125T /

175T / 215T-KFA, turn filter 90°counter-clockwise.

Photocell Wire

Circuit Board

Fuel Filter

Side Cover

Power Switch

Screw

Fuel Line

Power Switch Wire

Adjusting

Screw

Figure 19: Fuel Filter Replacement

© 2012, Pinnacle Products International, Inc.

Figure 20: Pump Pressure Adjustment

11

Kerosene User’s Manual

Page 12

Exploded View

NEVER LEAVE HEATER

UNATTENDED WHILE BURNING OR WHILE CONNECTED

TO A POWER SOURCE

Figure 21: Exploded View for Models HS-45 / 70T / 125T / 175T / 215T-KFA

© 2012, Pinnacle Products International, Inc.

12

Kerosene User’s Manual

Page 13

NEVER LEAVE HEATER

UNATTENDED WHILE BURNING OR WHILE CONNECTED

TO A POWER SOURCE

Parts List

Item Part Number for Models:

No. Description HS-45-KFA HS-70T-KFA HS-125T-KFA HS-175T-KFA HS-215T-KFA

1 Fuel Tank Assembly 70-002-0100 70-002-0100 70-002-0200 70-002-0300 70-002-0300

2 Drain Plug – – 70-002-0105 70-002-0105 70-002-0105

3 Fuel Gauge Assembly 70-007-0110 70-007-0115 70-007-0210 70-007-0210 70-007-0215

4 Fuel Filter Assembly 70-003-0100 70-003-0100 70-003-0200 70-003-0200 70-003-0200

5 Fuel Cap 70-006-0100 70-006-0100 70-006-0100 70-006-0100 70-006-0100

6 Power Cord 70-034-0100 70-034-0100 70-034-0200 70-034-0200 70-034-0200

7 Power Switch 70-038-0100 70-038-0100 70-038-0100 70-038-0100 70-038-0100

8 Window Display – – 70-040-0100 70-040-0100 70-040-0100

9 Thermostat Control Knob – 70-031-0100 70-031-0100 70-031-0100 70-031-0100

10 Lower Shell – – – – –

11 Air Line 70-035-0100 70-035-0200 70-035-0300 70-035-0400 70-035-0500

12 Thermostat Limit Control 70-019-0100 70-019-0100 70-019-0100 70-019-0100 70-019-0200

13 Combustion Chamber Assembly 70-011-0100 70-011-0200 70-011-0300 70-011-0400 70-011-0500

14 Photocell Bracket 70-010-0101 70-010-0101 70-010-0101 70-010-0101 70-010-0101

15 Fuel Line 70-036-0100 70-036-0200 70-036-0300 70-036-0400 70-036-0500

16 Photocell Assembly 70-016-0100 70-016-0100 70-016-0100 70-016-0100 70-016-0100

17 Burner Head Assembly 70-014-0100 70-014-0200 70-014-0300 70-014-0400 70-014-0500

18 Nozzle Kit 70-015-0100 70-015-0200 70-015-0300 70-015-0400 70-015-0500

19 Nozzle Seal Washer – – – – –

20 Nozzle Seal Spring – – – – –

21 Nozzle Sleeve – – – – –

22 Burner Head – – – – –

23 Spark Plug Kit 70-052-0100 70-052-0100 70-052-0200 70-052-0200 70-052-0200

24 Motor and Pump Assembly 70-020-0550 70-020-0550 70-020-0555 70-020-0560 70-020-0565

25 Motor 70-021-0500 70-021-0500 70-021-0510 70-021-0520 70-021-0520

26 Pump Body 70-020-0101 70-020-0101 70-020-0101 70-020-0101 70-020-0401

27 Rotor Kit 70-022-0100 70-022-0100 70-022-0100 70-022-0100 70-022-0200

28 Blade – – – – –

29 End Pump Cover 70-020-0102 70-020-0102 70-020-0102 70-020-0102 70-020-0102

30 Filter Kit 70-054-0100 70-054-0100 70-054-0100 70-054-0100 70-054-0100

31 Lint Filter – – – – –

32 Output Filter – – – – –

33 End Filter Cover 70-020-0103 70-020-0103 70-020-0103 70-020-0103 70-020-0103

34 Plug/Pump Adjustment Kit 70-055-0100 70-055-0100 70-055-0100 70-055-0100 70-055-0100

35 Ball – – – – –

36 Spring – – – – –

37 Adjusting Screw – – – – –

38 Nipple 70-014-0104 70-014-0104 70-014-0104 70-014-0104 70-014-0104

39 Capacitor 70-020-0125 70-020-0125 70-020-0200 70-020-0201 70-020-0201

40 Fan Assembly 70-024-0100 70-024-0200 70-024-0300 70-024-0400 70-024-0400

41 Ignitor 70-037-0300 70-037-0300 70-037-0300 70-037-0300 70-037-0300

42 Right Side Cover 70-008-0100 70-008-0200 70-008-0300 70-008-0400 70-008-0450

43 Left Side Cover 70-009-0100 70-009-0100 70-009-0200 70-009-0300 70-009-0300

44 Fan Guard 70-016-0700 70-016-0700 70-016-0200 70-016-0200 70-016-0220

45 Main PCB Assembly 70-027-0100 70-027-0200 70-027-0300 70-027-0300 70-027-0300

46 Fuse 70-027-0101 70-027-0101 70-027-0101 70-027-0101 70-027-0101

47 Clip Nut 70-001-0105 70-001-0105 70-001-0105 70-001-0105 70-001-0105

48 Upper Shell – – – – –

49 Storage Box – – 70-053-0100 70-053-0100 70-053-0100

50 Bushing Grommet 70-017-0100 70-017-0100 70-017-0100 70-017-0100 70-017-0100

51 Socket Cover 70-030-0100 70-030-0100 70-030-0100 70-030-0100 70-030-0100

52 Air Pressure Gauge 70-025-0100 70-025-0100 70-025-0100 70-025-0100 70-025-0100

53 Cord Bushing 70-033-0100 70-033-0100 70-033-0200 70-033-0200 70-033-0200

54 Electric Outlet 70-029-0100 70-029-0100 70-029-0100 70-029-0100 70-029-0100

55 Handle 70-001-0103 70-001-0103 – – –

56 Front Handle – – 70-042-0100 70-042-0200 70-042-0200

57 Rear Handle – – 70-043-0105 70-043-0205 70-043-0205

58 Wheel Support Frame – – 70-041-0101 70-041-0201 70-041-0201

59 Wheel Axle – – 70-041-0115 70-041-0205 70-041-0205

60 Wheel – – 70-041-0415 70-041-0415 70-041-0415

61 Wheel Nut – – 70-041-0550 70-041-0550 70-041-0550

62 Hardware Kit 70-056-0100 70-056-0100 70-056-0210 70-056-0210 70-056-0210

63 Cord Wrap 70-032-0100 70-032-0100 70-032-0200 70-032-0200 70-032-0200

© 2012, Pinnacle Products International, Inc.

13

Kerosene User’s Manual

Page 14

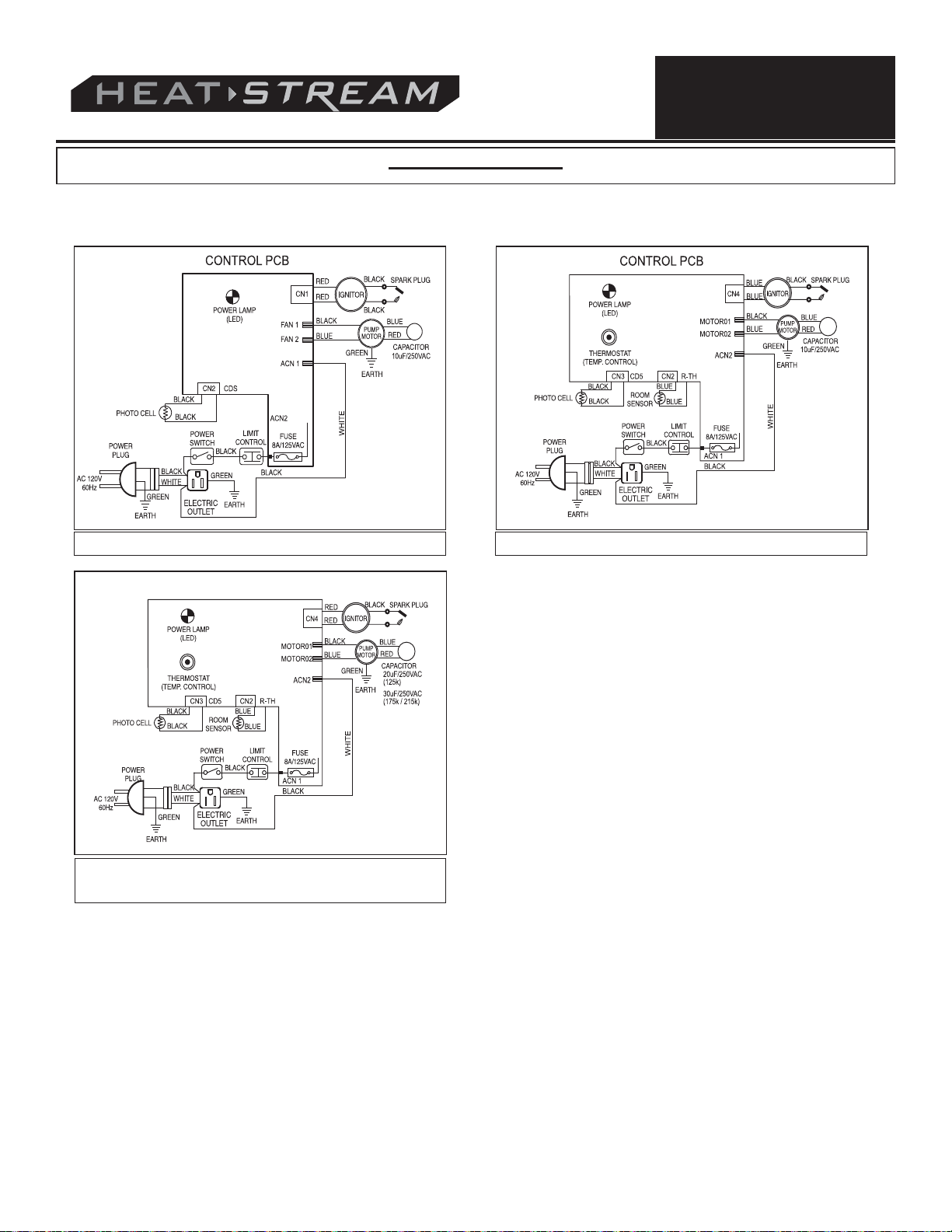

Wiring Diagrams

NEVER LEAVE HEATER

UNATTENDED WHILE BURNING OR WHILE CONNECTED

TO A POWER SOURCE

Figure 22: Model HS-45-KFA Figure 23: Model HS-70T-KFA

Figure 24: Model HS-125T / 175T / 215T-

KFA

© 2012, Pinnacle Products International, Inc.

14

Kerosene User’s Manual

Page 15

Troubleshooting

NEVER LEAVE HEATER

UNATTENDED WHILE BURNING OR WHILE CONNECTED

TO A POWER SOURCE

Problem

Heater fires, but Main PCB shuts

heater off after a short period of time.

Lamp is flickering, and LED display

shows “E1”.

Heater will not operate, or motor runs

for short time. Lamp flickers and LED

display shows “E1”.

Possible Cause Solution

1. Incorrect pump pressure

2. Dirty Input, Output or Lint Filter

3. Dirty Fuel Filter

4. Nozzle is Dirty

5. Photocell lens is Dirty

6. Photocell not installed properly

7. Photocell Defective

8. Improper electrical connection between

Main PCB and Photocell.

1. No kerosene in fuel tank

2. Incorrect pump pressure

3. Corroded Spark Plug or incorrect plug

gap.

4. Dirty Fuel Filter

5. Dirty Nozzle

6. Moisture in Fuel/Fuel Tank

7. Improper electrical connection between

Transformer and Circuit Board

8. Ignitor Wire not connected to Spark

Plug

9. Defective Ignitor

1. Adjust Pump Pressure (Page 11)

2. Clean/replace Air Filter (Page 9)

3. Clean/replace Fuel Filter (Page 11)

4. Clean/replace Nozzle (Page 10)

5. Clean/replace Photocell (Page 10)

6. Adjust Photocell position (Page 10)

7. Replace Photocell (Page 10)

8. Check wiring connections (See Wiring

Diagrams, Page 14)

1. Fill tank with fresh kerosene

2. Adjust Pump Pressure (Page 11)

3. Clean/replace Spark Plug (Page 10)

4. Clean/replace Fuel Filter (Page 11)

5. Clean/replace Nozzle (Page 10)

6. Rinse out fuel tank with clean fresh

kerosene (Page 9)

7. Inspect all electrical connections. See

Wiring Diagrams (Page 14)

8. Re-attach Ignitor wire to Spark Plug

(Page 10)

9. Replace Ignitor

Fan does not operate when heater is

plugged in and Power Switch is in the

“ON” position. The lamp is flickering or

on and LED Display shows “E1” or

“E2”.

Lamp is flickering, and LED display

shows “E3”

Poor Combustion and / or excess soot

production

Heater does not turn on and the lamp

is not lit

1. Thermostat is set too low (Does not

apply to HS-45-KFA)

2. Broken electrical connection between

Main PCB and motor

1. Thermostat Switch has failed 1. Replace Thermostat Switch. Wiring

1. Dirty Input, Output or Lint Filter

2. Dirty Fuel Filter

3. Poor quality of fuel

4. PSI is too high or too low

1. Temperature limit sensor has

overheated

2. No electrical power

3. Fuse Blown

4. Improper electrical connection between

Temperature Limit Sensor and Circuit

Board

1. Rotate thermostat to a higher setting

2. Inspect all electrical connections. See

Wiring Diagrams (Page 14)

Diagrams (Page 14

1. Clean/replace Air Filter (Page 9)

2. Clean/replace Fuel Filter (Page 10)

3. Be sure fuel is not contaminated or old

4. Use proper pressure (Page 11)

1. Push Power Switch to “OFF” and allow

heater to cool for 10 minutes. Push

Power Switch to back to “ON”

2. Check power cord and extension cord

to insure of proper connection. Test

power supply

3. Check/replace Fuse

4. Inspect all electrical connections. Wiring

Diagrams (Page 14)

)

© 2012, Pinnacle Products International, Inc.

15

Kerosene User’s Manual

Page 16

NEVER LEAVE HEATER

UNATTENDED WHILE BURNING OR WHILE CONNECTED

TO A POWER SOURCE

LIMITED WARRANTY

Pinnacle Products International, Inc. warrants this

heater to the original retail purchaser only, to be free from

defects in material and workmanship for a period of one

(1) year from the date of initial purchase. This product

must be properly installed, maintained and operated in

accordance with the instructions provided.

Pinnacle Products International, Inc. requires reasonable proof of your date of purchase from an authorized

retailer or distributor. Therefore, you should keep your

sales slip, invoice, or cancelled check from the original

purchase. This Limited Warranty shall be limited to the

repair or replacement of parts, which prove defective

under normal use and service within the warranty period,

and which Pinnacle Products International, Inc. shall

determine at its reasonable discretion.

This warranty does not apply to products purchased for

rental use.

This Limited Warranty does not cover any failures or operating difficulties due to normal wear and tear, accident,

abuse, misuse, alteration, misapplication, improper installation or improper maintenance and service by you or any

third party. Failure to perform normal and routine maintenance on the heater, shipping damage, damage related to

insects, birds, or animals of any kind, and damage due to

weather conditions are also not covered. In addition, the

Limited Warranty does not cover damage to the finish,

such as scratches, dents, discoloration, rust or other

weather damage, after purchase.

All transportation costs for the return of the damaged

product or parts will be the responsibility of the purchaser.

Upon receipt of damaged item, Pinnacle Products

International, Inc. will examine the item and determine if

defective. Pinnacle Products International, Inc. will

repair or replace and return the item, freight pre-paid. If

Pinnacle Products International, Inc. finds the item to be

in normal operating condition, or not defective, the

item will be returned freight collect.This Limited Warranty

is in lieu of all other express warranties. Pinnacle

Products International, Inc. disclaims all warranties for

products that are purchased from sellers other than

authorized retailers or distributors.

AFTER THE PERIOD OF THE ONE (1) YEAR EXPRESS

WARRANTY EXPIRES, Pinnacle Products International,

Inc. DISCLAIMS ANY AND ALL IMPLIED WARRANTIES,

INCLUDING WITHOUT LIMITATION THE IMPLIED WARRANTIES OF MERCHANTABILITY AND FITNESS FOR A

PARTICULAR APPLICATION. FURTHER, Pinnacle

Products International, Inc. SHALL HAVE NO LIABILITY

WHATSOEVER TO PURCHASER OR ANY THIRD PARTY

FOR ANY SPECIAL, INDIRECT, PUNITIVE, INCIDENTAL,

OR CONSEQUENTIAL DAMAGES. Pinnacle Products

International, Inc. assumes no responsibility for any

defects caused by third parties. This Limited Warranty

gives the purchaser specific legal rights; a purchaser may

have other rights depending upon where he or she lives.

Some states do not allow the exclusion or limitation of

special, incidental or consequential damages, or limitations

on how long a warranty lasts, so the above exclusion and

limitations may not apply to you.

Pinnacle Products International, Inc. does not authorize

any person or company to assume for it any other

obligation or liability in connection with the sale,

installation, use, removal, return, or replacement of its

equipment, and no such representations are binding on

Pinnacle Products International, Inc.

Always be sure to specify model number and serial

number when making any claim with Pinnacle Products

International, Inc. For your convenience use the space

provided below to list this information:

Model #: ____________________

Serial #: _________________________

Date of Purchase: _________________

Page 17

Manual del Usuario e

Instrucciones de Operación

Modelos No: HS-45-KFA, HS-70T-KFA, HS-125T-KFA,

HS-175T-KFA, HS-215T-KFA

CONSUMIDOR: Guarde este manual para futuras consultas.

SI NO CUMPLE CON LAS PRECAUCIONES Y LAS INSTRUCCIONES QUE SE LE PROPORCIONAN

CON ESTE CALENTADOR, PUEDE PROVOCAR LA MUERTE, LESIONES CORPORALES GRAVES,

Y PÉRDIDA DE LA PROPIEDAD O PELIGRO DE INCENDIO, EXPLOSIÓN O QUEMADURA, ASFIXIA,

ENVENENAMIENTO POR MONÓXIDO DE CARBONO, Y/O CHOQUE ELÉCTRICO.

ESTE CALENTADOR SOLAMENTE LO DEBEN USAR O DARLE MANTENIMIENTO LAS PERSONAS

QUE PUEDAN COMPRENDER Y SEGUIR LAS INSTRUCCIONES.

SI NECESITA AYUDA O INFORMACIÓN SOBRE EL CALENTADOR, TAL COMO UN MANUAL DE

INSTRUCCIONES, ETIQUETAS, ETCÉTERA, PÓNGASE EN CONTACTO CON EL FABRICANTE.

Éste es un calentador portátil sin ventilación. La unidad utiliza el aire (oxígeno) del área o zona donde se usa.

Página 8.

Fax: (215) 891-8461 • Sitio Web: www.heatstream.us • Correo electrónico: info@pinnacleint.com

Será necesario suministrar el aire adecuado de combustión y de ventilación. Consulte VENTILACIÓN en la

© Pinnacle Products International, Inc.

668 Stony Hill Road #302 Yardley, PA 19067 USA Teléfono gratuito: (800) 641-6996

Page 18

Tabla de contenidos

ADVERTENCIA

NUNCA DEJE DESATENDIDO EL

CALENTADOR MIENTRAS ESTÉ

ENCENDIDO O MIENTRAS ESTÉ

CONECTADO A UNA FUENTE DE

ALIMENTACIÓN

Información sobre seguridad ......................................... 2-3

Desempaque ..................................................................... 3

Características .................................................................. 4

Montaje ........................................................................... 5-6

Operación ....................................................................... 7-9

Teoría de Operación ......................................................... 7

Ventilación ......................................................................... 8

Información sobre seguridad

ADVERTENCIA

EXPLOSIÓN. MANTENGA LOS COMBUSTIBLES SÓLIDOS COMO, POR EJEMPLO,

MATERIALES DE CONSTRUCCIÓN, PAPEL Y

CARTÓN, A UNA DISTANCIA PRUDENCIAL

DEL CALENTADOR SEGÚN LO RECOMIENDAN LAS INSTRUCCIONES. NUNCA USE EL

CALENTADOR EN ESPACIOS QUE CONTENGAN O PUEDAN CONTENER COMBUSTIBLES VOLÁTILES O EN SUSPENSIÓN

EN EL AIRE NI PRODUCTOS COMO, POR

EJEMPLO, GASOLINA, DISOLVENTES, SOLVENTES DE PINTURA, PARTÍCULAS DE

POLVO O QUÍMICOS DESCONOCIDOS.

ADVERTENCIA

RECREATIVO NI TIENDAS.

ADVERTENCIA

instrucciones de seguridad y operación.

Residentes de California: Los productos derivados de

la combustión que produce este producto contienen monóxido

de carbono, un compuesto químico que el estado de California

reconoce como causante de cáncer y malformaciones congénitas (y otros daños del sistema reproductor).

Residentes de Massachusetts: La ley del Estado

de Massachusetts prohíbe el uso de este calentador en

cualquier edificio que se utilice total o parcialmente para la

habitación humana. El uso de este dispositivo de calefacción en

Massachusetts requiere la autorización del departamento de

bomberos de la localidad (M.G.L.C. 148, Sección 10A).

Residentes de la Ciudad de Nueva York: El

Código de Incendios de la Ciudad de Nueva York prohíbe el

almacenamiento, la manipulación y el uso de calentadores alimentados por keroseno para calentamiento de espacios.

Cualquier persona que infrinja esa disposición estará sujeta a

una multa de hasta 10,000 dólares y una pena de prisión de

hasta 6 meses.

Biodiesel dañará el filtro y sellos. La garantía no cubrirá

cualquier daño causado por el uso de Biodiesel.

PELIGRO DE INCENDIO, QUEMADURAS, INHALACIÓN Y

NO DEBE USARSE EN CASAS,

VEHÍCULOS DE USO

No use este calentador hasta que haya

leído y entendido totalmente estas

Este calefactor no es adecuado para

usarse con Biodiesel; el uso de

Almacenamiento a largo plazo .......................................... 9

Mantenimiento .............................................................. 9-11

Dibujo de despiece de piezas .......................................... 12

Lista de Recambios .................................................... 12-13

Diagramas eléctricos ....................................................... 14

Guía de solución de problemas ....................................... 15

Garantía ....................................................... Contraportada

Indica una situación de peligro inminente que, de no evitarse, CAUSARÁ

la muerte o una lesión grave.

Indica una situación de posible peligro que, de no evitarse, PODRÍA

causar la muerte o una lesión grave.

CAUTION

causar lesiones leves o moderadas.

Éste es un calentador de keroseno, de tiro forzado, de acción

directa. Está diseñado principalmente para uso como un

calentador temporal en edificios en construcción, alteración o

reparación. Acción directa significa que todos los productos de

combustión del calentador ingresan en el espacio que se está

calentando. Este aparato tiene una eficiencia de combustión del

98%, pero produce pequeñas cantidades de monóxido de

carbono. El monóxido de carbono es tóxico.

Los humanos pueden tolerar pequeñas cantidades de monóxido

de carbono, y por tanto, deben tomarse las medidas de precaución necesarias para suministrar una ventilación adecuada. No

proporcionar la ventilación adecuada de acuerdo con este manual

puede ocasionar la muerte. Las primeras etapas de intoxicación

por monóxido de carbono producen síntomas similares a los de la

gripe. Los síntomas de una ventilación inadecuada son los siguientes:

dolor de cabeza *mareo *irritación de la nariz y los

*

ojos *náusea *boca seca *irritación de la garganta

Para obtener el mejor rendimiento de este calentador, se sugiere

muy enfáticamente utilizar el combustible keroseno 1-K. El

keroseno 1-K ha sido refinado para prácticamente eliminar los

contaminantes como el sulfuro, el cual puede producir un olor a

huevos podridos durante el funcionamiento del calentador. Sin

embargo, también se puede utilizar el aceite combustible No. 1 o

No. 2 (combustible diesel) si el keroseno 1-K no está disponible.

Tenga en mente que estos combustibles no queman tan limpio

como el keroseno 1-K, y por tanto, se debe proporcionar una

mayor ventilación de aire fresco para compensar contra los contaminantes adicionales que podrían agregarse al espacio calentado. El uso del aceite combustible No. 1 o No. 2 puede hacer

necesario un mantenimiento periódico más frecuente.

Indica una situación de posible peligro que, de no evitarse, PODRÍA

¡La intoxicación por monóxido de

carbono puede producir la muerte!

© 2012, Pinnacle Products International, Inc.

2

Manual del usuario del calentador a keroseno

Page 19

NUNCA DEJE DESATENDIDO EL

CALENTADOR MIENTRAS ESTÉ

ENCENDIDO O MIENTRAS ESTÉ

CONECTADO A UNA FUENTE DE

ALIMENTACIÓN

Información sobre seguridad (continuación)

¡Riesgo de contaminación del aire interior!

- ¡Utilice este calentador sólo en áreas bien ventiladas!

Proporcione una abertura de al menos 2,800 cm cuadrados

(tres pies cuadrados) de aire fresco exterior por cada 100,000

BTU/Hr de capacidad útil del calentador.

- Las personas con problemas respiratorios deberían consultar

con un médico antes de usar el calentador.

- Intoxicación por monóxido de carbono: Los síntomas iniciales

de la intoxicación por monóxido de carbono se parecen a los

síntomas de la gripe como dolor de cabeza, mareo y/o

náusea. Si usted presenta estos síntomas, es posible que su

calentador no esté funcionando correctamente.

- ¡Respire inmediatamente aire fresco! Haga que le reparen el

calentador. El monóxido de carbono afecta más a unas personas que a otras: Estas incluyen las mujeres embarazadas,

aquellos con enfermedades del pulmón o corazón, anemia, o

aquellos que estén bajo la influencia del alcohol o a altas

alturas o elevaciones.

¡Riesgo de quemaduras, incendio y/o

explosión!

- NUNCA use combustibles como gasolina, bencina, solventes

de pintura u otros compuestos de aceite en este calentador

(RIESGO DE INCENDIO O EXPLOSIÓN).

- NUNCA llene el tanque de combustible del calentador mientras

esté funcionando o todavía esté caliente. Este calentador está

SUMAMENTE CALIENTE cuando está funcionando.

- Mantenga todos los materiales combustibles lejos del

calentador.

- NUNCA bloquee u obstruya la entrada de aire (en la parte

posterior) ni la salida de aire (en la parte anterior) del

calentador.

- NUNCA use conductos en las partes anterior o posterior del

calentador.

- NUNCA mueva o sujete el calentador cuando todavía esté

caliente.

- NUNCA transporte un calentador con combustible en su

tanque.

- Si está equipado con un termostato, el calentador podría

encenderse en cualquier momento.

- SIEMPRE coloque el calentador en una superficie estable y

nivelada.

- SIEMPRE mantenga a los niños y animales lejos del

calentador.

- El almacenamiento de combustible a granel deberá estar

situado a no menos de 7.62 metros (25 pies) de distancia de

calentadores, antorchas, generadores portátiles u otras

fuentes de ignición. Todo almacenamiento de combustible

deberá realizarse de acuerdo con las autoridades federales,

estatales o locales que tengan jurisdicción.

- Nunca use este calentador en áreas habitables o áreas para

dormir.

- NUNCA use este calentador donde puedan haber presentes

vapores inflamables.

¡Peligro de electrocución!

- Utilice únicamente la energía eléctrica (voltaje y frecuencia)

especificada en la placa de modelo del calentador. Utilice únicamente un cordón de extensión de tres puntas y una toma de

corriente para tres puntas conectada a tierra.

- SIEMPRE instale el calentador en forma que no esté directamente expuesto al agua rociada, lluvia, agua goteante o viento.

- SIEMPRE desconecte el calentador cuando no lo esté usando.

Separación mínima entre el calentador y materiales

combustibles (cm):

70k 125k 175k 215k

45k

Parte superior 122 122 122 122 122

Lados 122 122 122 122 122

Frente 244 244 244 244 305

Desempaque

Extraiga el calentador y todos los materiales de embalaje de la

caja de envío.

AVISO: Guarde la caja y los materiales de embalaje para almacenar la unidad en el futuro.

© 2012, Pinnacle Products International, Inc.

Consulte el cuadro que se da abajo para asegurarse que tiene

todas las piezas necesarias para armar su calentador. Si descubre que faltan piezas, llame al 215-891-8460 para solicitar

asistencia para recibir los componentes que faltan.

3

Manual del usuario del calentador a keroseno

Page 20

Características

Figura 1: Características de los Modelos HS-45/70T-KFA

NUNCA DEJE DESATENDIDO EL

CALENTADOR MIENTRAS ESTÉ

ENCENDIDO O MIENTRAS ESTÉ

CONECTADO A UNA FUENTE DE

ALIMENTACIÓN

Figura 2: Características del Modelo HS-125T / 175T / 215T-KFA

HS-45-KFA HS-70T-KFA HS-125T-KFA HS-175T-KFA HS-215T-KFA

CONSUMO DE

COMBUSTIBLE

(G/HORA)

.35 .53 .95 1.34 1.63

Figura 3: Especificaciones

© 2012, Pinnacle Products International, Inc.

4

Manual del usuario del calentador a keroseno

Page 21

NUNCA DEJE DESATENDIDO EL

CALENTADOR MIENTRAS ESTÉ

ENCENDIDO O MIENTRAS ESTÉ

CONECTADO A UNA FUENTE DE

ALIMENTACIÓN

Montaje

HS-45-KFA HS-70T-KFA HS-125T-KFA HS-175T-KFA HS-215T-KFA

Armazón de soporte de las ruedas NO NO SÍ SÍ SÍ

Rueda (2 piezas) NO NO SÍ SÍ SÍ

Asideros frontal y posterior NO NO SÍ SÍ SÍ

Eje NO NO SÍ SÍ SÍ

Asidero superior SÍ SÍ NO NO NO

Tornillos y tuercas (A) 8 de cada uno NO NO SÍ SÍ SÍ

Tornillos y tuercas (B) 4 de cada uno SÍ SÍ NO NO NO

Tuercas de la rueda, bujes NO NO SÍ SÍ SÍ

Enrolla cable SÍ SÍ SÍ SÍ SÍ

Asidero

No. de parte del juego de

herrajes: 70-056-0100

(HS-45 / 70T-KFA)

Enrolla

cables

Screws and

Nuts(4 ea.)

Ruedas

Figura 4: Componentes de Herrajes

Armazón de soporte de las ruedas

Asidero frontal

Herrajes de los componentes

Tuercas de

la rueda

del armazón

Bujes

Pasador de aletas, tornillos y tuercas (4 cada uno) y enrolla cables

No. de parte del juego de herrajes:

70-056-0210

(HS-125T/ 175T / 215T-KFA)

Asidero posterior

Eje

Figura 5: Componentes del Armazón, Modelos HS-125T / 175T / 215T-KFA

© 2012, Pinnacle Products International, Inc.

5

Manual del usuario del calentador a keroseno

Page 22

Montaje (continuación)

NUNCA DEJE DESATENDIDO EL

CALENTADOR MIENTRAS ESTÉ

ENCENDIDO O MIENTRAS ESTÉ

CONECTADO A UNA FUENTE DE

ALIMENTACIÓN

SÓLO PARA LOS MODELOS HS-45/70T-KFA

- Herramientas necesarias: Destornillador Phillips mediano.

MONTAJE DEL ASIDERO

1.Alinee los orificios en el alojamiento superior con los 2 orificios

en el asidero, como se muestra en la Figura 6.

2. Inserte tornillos y apriételos firmemente con un destornillador.

Asidero

Tornillo

Figura 6: Montaje del Asidero, Modelos HS45/70T-KFA

MONTAJE DEL ENROLLA CABLE

1. Alinee los agujeros en la coraza con aquellos en la cubierta

lateral e inserte las lengüetas del enrolla cable en el soporte de

la coraza.

2. Inserte tornillos y apriételos firmemente con un destornillador.

5. Agarre el asidero frontal y alinee los agujeros de montaje con

los agujeros correspondientes en el reborde del tanque y el

armazón para las ruedas. Inserte un tornillo (A) a través de los

agujeros y póngale una tuerca, pero no la apriete. Repita para

los otros 3 agujeros, luego apriete totalmente todos los 4

tornillos y tuercas.

6. Repita este proceso con el asidero posterior.

AVISO: El asidero frontal es más largo que el asidero posterior.

MONTAJE DEL ENROLLA CABLE

1. Alinee los agujeros en el enrolla cable con los agujeros correspondientes en el asidero posterior. Inserte tornillos (B) a

través de los agujeros, instale tuercas y apriételas (véase la

Figura 7).

No use el calentador sin el armazón de

soporte completamente montado en el

tanque.

SÓLO PARA LOS MODELOS HS-125T / 175T /

215T-KFA

- Herramientas necesarias: : Destornillador Phillips mediano,

llave ajustable o de extremo abierto de 5/16 pulgada, alicates

MONTAJE DEL ARMAZÓN Y LAS RUEDAS

1. Deslice el eje a través de los agujeros en el armazón de

soporte de las ruedas. Deslice los bujes y arandela plana (A)

para las ruedas en cada extremo del eje.

2. Deslice las ruedas en cada extremo del eje, y asegúrese que

el vástago de la válvula (si son neumáticas) esté hacia afuera

(véase la Figura 7).

3. Instale una tuerca de la rueda en el eje roscado y apriete.

4. Coloque el calentador en el armazón ya armado, y asegúrese

que el extremo de la entrada de aire esté situado donde están

las ruedas, y los agujeros de montaje en el reborde del tanque

del calentador estén alineados con los agujeros en el

armazón.

© 2012, Pinnacle Products International, Inc.

Figura 7 Montaje de los Modelos HS-125T/

175T/ 215T-KFA

6

Manual del usuario del calentador a keroseno

Page 23

Operación

KEROSENO (1-K)

Para obtener el mejor rendimiento de este calentador, se sugiere

muy enfáticamente utilizar el combustible keroseno 1-K. El

keroseno 1-K ha sido refinado para prácticamente eliminar los

contaminantes como el sulfuro, el cual puede producir un olor a

huevos podridos durante el funcionamiento del calentador. Sin

embargo, también se puede utilizar el aceite combustible No. 1 o

No. 2 (combustible diesel) si el keroseno 1-K no está disponible.

Tenga en mente que estos combustibles no queman tan limpio

como el keroseno 1-K, y por tanto, se debe proporcionar una

mayor ventilación de aire fresco para compensar contra los

contaminantes adicionales que podrían agregarse al espacio

calentado. El uso de combustible diesel puede causar una

excesiva producción de hollín. NO utilice ningún combustible

que no esté aprobado arriba.

AVISO: El keroseno debe almacenarse únicamente en un

contenedor azul que esté claramente identificado con la palabra

“keroseno”. Nunca almacene keroseno en un contenedor rojo. El

color rojo se asocia con la gasolina.

- NUNCA almacene keroseno en el área habitable. El keroseno

debe almacenarse en un área bien ventilada, situada fuera del

espacio habitable.

- NUNCA use un combustible como gasolina, bencina, alcohol,

gas blanco, combustible para hornos de campamento, solventes

de pintura u otros compuestos de aceite en este calentador

(ESTOS SON COMBUSTIBLES VOLÁTILES QUE PUEDEN

CAUSAR INCENDIOS O EXPLOSIONES).

- NUNCA almacene el keroseno expuesto directamente a la luz

solar ni cerca de cualquier fuente de calor.

- NUNCA utilice keroseno que se haya tenido almacenado de una

temporada a la siguiente. El keroseno se deteriora con el paso

del tiempo. EL KEROSENO ANTIGUO O VIEJO NO QUEMARÁ

ADECUADAMENTE EN ESTE CALENTADOR.

- Utilice keroseno 1-K en este calentador. El combustible No. 1 es

un sustituto adecuado.

TEORÍA DE FUNCIONAMIENTO

Sistema de combustible: Este calentador está equipado con

una bomba de aire que funciona por medio del motor eléctrico.

La bomba fuerza el aire a través de la línea de aire que está

conectada al tanque de combustible y el combustible avanza

hacia la boquilla en el cabezal del quemador. El aire también

pasa a través de la boquilla, donde se mezcla con el

combustible, y la mezcla es rociada en la cámara de combustión

como un fino rocío.

Ignición rápida de llama: Un transformador suministra un

voltaje alto a una bujía de dos puntas. La chispa enciende la

mezcla de combustible y aire en el momento en que es rociado

dentro de la cámara de combustión.

NUNCA DEJE DESATENDIDO EL

CALENTADOR MIENTRAS ESTÉ

ENCENDIDO O MIENTRAS ESTÉ

CONECTADO A UNA FUENTE DE

ALIMENTACIÓN

Figura 8 Teoría de Funcionamiento

Sistema de aire: El motor para trabajo pesado hace girar el

ventilador y éste fuerza el aire alrededor y hacia el interior de la

cámara de combustión, donde es supercalentado y finalmente

expulsado a través de la parte anterior de la cámara.

Control de límite de temperatura: Este calentador está equipa-

do con un Control de límite de temperatura, diseñado para apagar el

calentador si la temperatura interna sube a un nivel peligroso. Si este

dispositivo se activa y apaga su calentador, es posible que necesite

servicio.

Una vez que la temperatura cae por debajo de la temperatura de

reposición, usted podrá encender su calentador.

Protección del sistema eléctrico: El sistema eléctrico del

calentador está protegido con un cortacircuito que protege los

componentes del sistema contra daño. Si el calentador falla,

revise primero el fusible y reemplácelo si es necesario.

Sensor de llama: El calentador utiliza una fotocélula para “ver”

la llama en la cámara de combustión. En el caso de que la llama

se apague, el sensor detendrá la corriente eléctrica y el

calentador se apagará.

CÓMO LLENAR COMBUSTIBLE EN EL CALENTADOR

NUNCA LLENE EL TANQUE DE

COMBUSTIBLE EN UN LUGAR

INTERIOR. SIEMPRE LLENE EL TANQUE AFUERA.

ASEGÚRESE QUE EL CALENTADOR ESTÉ EN UN SUELO

NIVELADO CUANDO LLENE DE COMBUSTIBLE, Y NUNCA

LLENE EL TANQUE DE COMBUSTIBLE DEMASIADO.

NUNCA LLENE DE COMBUSTIBLE ESTE

CALENTADOR MIENTRAS ESTÉ

CALIENTE O EN FUNCIONAMIENTO. ESO PUEDE

OCASIONAR UN INCENDIO O UNA EXPLOSIÓN.

Siempre es buena idea encender el calentador afuera en la

primera vez. Esto permitirá quemar en un entorno seguro

cualquier aceite utilizado en el proceso de fabricación. Este

quemado inicial deberá durar por lo menos 10 minutos.

© 2012, Pinnacle Products International, Inc.

7

Manual del usuario del calentador a keroseno

Page 24

Operación (continuación)

NUNCA DEJE DESATENDIDO EL

CALENTADOR MIENTRAS ESTÉ

ENCENDIDO O MIENTRAS ESTÉ

CONECTADO A UNA FUENTE DE

ALIMENTACIÓN

VENTILACIÓN

Riesgo de contaminación del aire interior. Utilice el calentador sólo en áreas bien ventiladas.

En el espacio que busca calentar, proporcione una entrada de

aire fresco de al menos 2,800 cm2 (3 pies2) por cada 100,000

Btu/h de salida del calentador. Proporcione una abertura más

grande si se utilizan más calentadores. Por ejemplo, un

calentador HS-215T-KFA requerirá:

- dejar abierta 15.2 cm (6 pulg.) una puerta de garaje para dos

vehículos, o

- dejar abierta 22.9 cm (9 pulg.) una puerta de garaje para un solo

vehículo, o

- dejar abiertas 38.1 cm (15 pulg.) dos ventanas de 81.3 cm. (32

pulg.) de ancho.

PARA ENCENDER EL CALENTADOR

1. Llene el tanque de keroseno hasta que el indicador de com-

bustible indique “F”.

2. Asegúrese que la tapa del tanque de combustible esté bien

apretada.

3. Enchufe el cordón de alimentación eléctrica en un cordón de

extensión de tres puntas con conexión a tierra y luego enchufe

el cordón de extensión en una toma de corriente de 120V, de

tres puntas, conectada a tierra. El cordón de extensión deberá

ser de 182.9 cm (seis pies) de largo como mínimo.

- Los requisitos de tamaño de conductor para el cordón de

extensión son los siguientes:

› 1.8 a 3 metros (6 a 10 pies), utilice alambre 18 AWG.

› 3.4 a 30.4 metros (11 a 100 pies), utilice alambre 16 AWG.

› 30.8 a 61 metros (101 a 200 pies), utilice alambre 14 AWG.

AVISO: El indicador de temperatura ambiente (125/175/215 únicamente) indicará lo siguiente:

- Cuando la temperatura es inferior a 0° F, el indicador mostrará

“LO” (baja).

- Cuando la temperatura es superior a 37.2° C (99° F), el indicador mostrará “HI” (alta).

- Entre -17.8° y 37.2° C (0° y 99° F), el indicador mostrará la temperatura actual.

5. Si el calentador no enciende, es posible que el ajuste del ter-

mostato esté demasiado bajo. Gire la perilla de control del termostato a una temperatura más alta hasta que el calentador

se encienda. Si el calentador aún no enciende, ponga el interruptor de energía en la posición OFF (apagado) y luego en la

posición ON (encendido). Si el calentador aún no enciende,

consulte la Guía de solución de problemas en la Página 15.

AVISO: Los componentes eléctricos de este calentador están

protegidos por medio de un fusible que está montado en la placa

de circuitos impresos. Si el calentador no se enciende, revise

primero este fusible, y reemplácelo si es necesario. También

revise la fuente de alimentación eléctrica para asegurarse que el

voltaje correcto esté siendo suministrado al calentador.

PARA APAGAR EL CALENTADOR

Sencillamente lleve el interruptor a la posición OFF (apagado) y

desenchufe el cordón de alimentación eléctrica.

PARA VOLVER A ENCENDER EL CALENTADOR

1. Espere diez segundos después de apagar el calentador.

2. Ponga el interruptor de energía en la posición ON (encendido).

3. Asegúrese de acatar todas las precauciones del procedimiento

de arranque

TOMA DE CORRIENTE ELÉCTRICA

Modelos HS-70T / 125T / 175T /

215T-KFA

Modelo HS-45-KFA

Figura 9: Panel de Control para todos los

Modelos

4. Gire la perilla de control del termostato al ajuste de temperatura deseado (70/125/175/215 únicamente). El rango de ajustes

es de 4.44° C a 43.3° C (40° F a 110°F). Ponga el interruptor

de energía en la posición ON (encendido) (véase la Figura 9).

La lámpara de indicación de energía y el indicador de temperatura ambiente (125/175/215 únicamente) se iluminarán y el

calentador se encenderá.

© 2012, Pinnacle Products International, Inc.

¡Peligro de descarga eléctrica!

- Nunca enchufe un aparato eléctrico con una capacidad de más

de 5 amperios en esta toma de corriente eléctrica.

- Siempre mantenga cubierta la toma de corriente cuando no se

utilice.

Cajón de almacenamiento

(excepto en los modelos

HS-45 / 70T-KFA)

Toma de corriente eléctrica

(120V 5 amperios máximo sin fusión)

Figura 10: Detalle de la Toma de Corriente

Eléctrica

8

Manual del usuario del calentador a keroseno

Page 25

Agarre del tapón

Tapón de

drenaje

NUNCA DEJE DESATENDIDO EL

CALENTADOR MIENTRAS ESTÉ

ENCENDIDO O MIENTRAS ESTÉ

CONECTADO A UNA FUENTE DE

ALIMENTACIÓN

Operación (continuación)

4. Para reinstalarlo, presione e inserte completamente el cabezal

de drenaje en el orificio de drenaje, y luego presione e inserte

completamente la tapa de sellado en el orificio del cabezal de

drenaje para fijar éste en posición (véase la Figura 12).

IMPORTANTE: Nunca almacene el keroseno sobrante

durante el verano. El uso de todo combustible antiguo

puede dañar su calentador.

Tanque de combustible

Tapón de drenaje

Figura 11: Extracción del Tapón de Drenaje

ALMACENAMIENTO A LARGO PLAZO

Drene el tanque de combustible

1. En los modelos HS-45 / 70T-KFA, drene el combustible a

través de la abertura de la tapa del tanque de combustible,

usando un sifón aprobado. En los modelos HS-125 / 175 /

215-KFA, drene el combustible a través del Tapón de drenaje

que está en la parte inferior del Tanque de combustible.

2. Para extraer el tapón de drenaje (125 / 175 / 215), tire del

agarre del tapón hacia abajo y extraiga el cabezal de sellado

del orificio de drenaje en el tanque (véase la Figura 11).

3. Con una pequeña cantidad de keroseno, enjuague y

arremoline el keroseno dentro del tanque de combustible.

Vacíe completamente el tanque.

Mantenimiento

Nunca realice el mantenimiento del calentador mientras esté enchufado o caliente.

Utilice únicamente piezas de repuesto auténticas para el equipo.

El uso de componentes alternativos o de terceros puede causar

condiciones peligrosas de funcionamiento y anulará su garantía.

Le sugerimos seguir un programa de mantenimiento como el

siguiente:

COMBUSTIBLE Y TANQUE DE COMBUSTIBLE:

Purgue el tanque después de cada 200 horas de funcionamiento

o según sea necesario. No use agua para purgar el tanque.

Utilice únicamente keroseno 1-K fresco.

FILTROS DE AIRE:

El Filtro de entrada de aire debe reemplazarse o lavarse con

Filtro de salida

de aire

Filtro de

entrada

Cabezal de sellado

Brida del cabezal

Brida del

cabezal

Brida de la tapa

Tapa de sellado

Figura 12: Reinstalación del Tapón de Drenaje

jabón y agua y secarse completamente después de cada 500

horas de funcionamiento, o menos, dependiendo de las condiciones.

Los Filtros de salida y de pelusas deben reemplazarse después

de cada 500 horas de funcionamiento o menos, dependiendo de

las condiciones.

AVISO: Es posible que se necesite un mantenimiento adicional

si se usa combustible diesel.

ASPAS DEL VENTILADOR:

Las aspas del ventilador deben limpiarse al menos una vez por

cada temporada de calefacción, dependiendo de las condiciones.

Limpie todas las acumulaciones de polvo y tierra con un trapo

húmedo, teniendo cuidado de no doblar ninguna de las aspas

del ventilador. Asegúrese que las aspas del ventilador estén

secas antes de volver a encender el calentador. Para desmontar

el ventilador, véase la Figura 14.

Tornillo de

fijación

Eje del

motor

Filtro de pelusas

Cubierta del filtro extremo

Figura 13: Reemplazo de los Filtros

© 2012, Pinnacle Products International, Inc.

Aspa del

ventilador

Figura 14: Reemplazo del Ventilador

9

Manual del usuario del calentador a keroseno

Page 26

Mantenimiento (continuación)

NUNCA DEJE DESATENDIDO EL

CALENTADOR MIENTRAS ESTÉ

ENCENDIDO O MIENTRAS ESTÉ

CONECTADO A UNA FUENTE DE

ALIMENTACIÓN

BOQUILLAS:

Las boquillas deben limpiarse o reemplazarse al menos una vez

por cada temporada de calefacción. El combustible contaminado

podría hacer esto inmediatamente necesario.

Para limpiar la suciedad de la boquilla, sople aire comprimido a

través del frente de la boquilla. Es posible que sea necesario

remojar la boquilla en keroseno 1-K limpio para facilitar el

aflojamiento de las partículas.

AVISO: Es posible que se necesite un mantenimiento adicional

si se usa combustible diesel. El uso de este calentador sin un

mantenimiento adecuado o con combustible contaminado o

antiguo podría dar lugar a una combustión inadecuada y una

posible producción de hollín. ASEGÚRESE DE UTILIZAR UN

COMBUSTIBLE APROBADO (consulte OPERACIÓN en la

página 6).

Cabezal del quemador

Tornillo

Bujía

Conductor del

encendedor

Manguera de la línea de

combustible

Manguera de la línea de aire

BUJÍA:

Límpiela y reajuste la separación entre los electrodos de la bujía

después de cada 600 horas de funcionamiento, o reemplácela

según sea necesario. Después de extraer la bujía, limpie las terminales con una escobilla metálica. Reajuste la separación de

las terminales (o electrodos) a 3.5 mm (0.140 pulg).

Conductor del encendedor

Bujía

Cabezal del

quemador

Separación

Figura 16: Reemplazo de la Bujía

FOTOCÉLULA:

La fotocélula debe limpiarse al menos una vez por cada temporada de calefacción o más, dependiendo de las condiciones.

Utilice un hisopo de algodón remojado en agua o alcohol para

limpiar la lente de la fotocélula. Observe la posición correcta de

la fotocélula, tal como se indica en la Figura 17 y la Figura 18.

Fotocélula

Cabezal del quemador

Boquilla

Cara de la

boquilla

Conector de la línea

Conector de la línea de aire

de combustible

Figura 15: Reemplazo de la Boquilla

© 2012, Pinnacle Products International, Inc.

Lente de la

fotocélula

Instalación de la fotocélula:

1) Incorrecto

2) Correcto

Figura 17: Posición de la Fotocélula

10

Manual del usuario del calentador a keroseno

Page 27

Conductor de

la fotocélula

NUNCA DEJE DESATENDIDO EL

CALENTADOR MIENTRAS ESTÉ

ENCENDIDO O MIENTRAS ESTÉ

CONECTADO A UNA FUENTE DE

ALIMENTACIÓN

Mantenimiento (continuación)

AJUSTE DE LA PRESIÓN DE LA BOMBA:

Mientras el calentador está funcionando, gire la válvula de

seguridad hacia la derecha para aumentar, o hacia la izquierda

para disminuir (véase la Figura 20). Utilice un destornillador de

punta plana para girar la válvula. A continuación se muestra la

presión correcta de la bomba:

Núm. de modelo Presión de la bomba

Panel de circuitos

Sólo el

HS-70T-KFA

Figura 18: Posición de la Fotocélula para los

Modelos HS-45 / 70T-KFA

FILTRO DE COMBUSTIBLE:

El filtro de combustible debe limpiarse al menos dos veces por

cada temporada de calefacción, enjuagándolo con keroseno 1-K

limpio. El combustible contaminado podría hacer esto

inmediatamente necesario (véase la Figura 19).

AVISO: Para extraer el filtro de los modelos HS-45 / 70T-KFA,

gire el filtro 90º hacia la derecha. Para extraer el filtro de los

modelos HS-125T / 175T / 215T-KFA, gire el filtro 90º hacia la

izquierda.

Es posible que se necesite un mantenimiento adicional si se usa

combustible diesel.

ocasionar una mala combustión y producción de

hollín.

Conductor de la fotocélula

El mantenimiento inadecuado puede

HS-45-KFA 20.6 Kpa / 3.0 PSI

HS-70T-KFA 27.5 Kpa / 4.0 PSI

HS-125T-KFA 34.4 Kpa / 5.0 PSI

HS-175T-KFA 51.7 Kpa / 7.5 PSI

HS-215T-KFA 62.05 Kpa / 9.0 PSI

Tolerancia ± 10%

Para obtener la mejor medida de la presión, pruebe con el

tanque lleno de combustible. La presión es óptima cuan-

do el color del cono de la ojiva está rojo cereza y no

hay llamas que se extienden del calentador.

Tornillo

de ajuste

Panel de circuitos

Filtro de

combustible

Cubierta

lateral

Interruptor de energía

Tornillo

Línea de

combustible

Conductor del interruptor de

energía

Figura 19: Reemplazo del Filtro de Combustible

© 2012, Pinnacle Products International, Inc.

Figura 20: Ajuste de la Presión de la Bomba

11

Manual del usuario del calentador a keroseno

Page 28

Dibujo de despiece de piezas

NUNCA DEJE DESATENDIDO EL

CALENTADOR MIENTRAS ESTÉ

ENCENDIDO O MIENTRAS ESTÉ

CONECTADO A UNA FUENTE DE

ALIMENTACIÓN

Figura 21: Vista Detallada de los Modelos HS-45 / 70T / 125T / 175T / 215T-KFA

Lista de Recambios

No Número de Parte para los Modelos:

de Ref. Descripción HS-45-KFA HS-70T-KFA HS-125T-KFA HS-175T-KFA HS-215T-KFA

1 Conjunto del tanque de 70-002-0100 70-002-0100 70-002-0200 70-002-0300 70-002-0300

2 Tapón de drenaje – – 70-002-0105 70-002-0105 70-002-0105

3 Conjunto del indicador de 70-007-0110 70-007-0115 70-007-0210 70-007-0210 70-007-0215

4 Conjunto del filtro de 70-003-0100 70-003-0100 70-003-0200 70-003-0200 70-003-0200

5 Tapa del tanque de combustible 70-006-0100 70-006-0100 70-006-0100 70-006-0100 70-006-0100

6 Cordón de alimentación eléctrica 70-034-0100 70-034-0100 70-034-0200 70-034-0200 70-034-0200

7 Interruptor de energía 70-038-0100 70-038-0100 70-038-0100 70-038-0100 70-038-0100

© 2012, Pinnacle Products International, Inc.

combustible

combustible

combustible

12

Manual del usuario del calentador a keroseno

Page 29

NUNCA DEJE DESATENDIDO EL

CALENTADOR MIENTRAS ESTÉ

ENCENDIDO O MIENTRAS ESTÉ

CONECTADO A UNA FUENTE DE

ALIMENTACIÓN

Lista de Recambios (continuación)

No. Número de Parte para los Modelos

de Ref. Descripción HS-45-KFA HS-70T-KFA HS-125T-KFA HS-175T-KFA HS-215T-KFA

8 Ventana de visualización – – 70-040-0100 70-040-0100 70-040-0100

9 Perilla de control del termostato – 70-031-0100 70-031-0100 70-031-0100 70-031-0100

10 Coraza inferior – – – – –

11 Línea de aire 70-035-0100 70-035-0200 70-035-0300 70-035-0400 70-035-0500

12 Control de límite del termostato 70-019-0100 70-019-0100 70-019-0100 70-019-0100 70-019-0200

13 Conjunto de la cámara de 70-011-0100 70-011-0200 70-011-0300 70-011-0400 70-011-0500

14 Soporte de la fotocélula 70-010-0101 70-010-0101 70-010-0101 70-010-0101 70-010-0101

15 Línea de combustible 70-036-0100 70-036-0200 70-036-0300 70-036-0400 70-036-0500

16 Conjunto de la fotocélula 70-016-0100 70-016-0100 70-016-0100 70-016-0100 70-016-0100

17 Conjunto del cabezal 70-014-0100 70-014-0200 70-014-0300 70-014-0400 70-014-0500

18 Juego de boquilla 70-015-0100 70-015-0200 70-015-0300 70-015-0400 70-015-0500

19 Arandela del sello de la boquilla – – – – –

20 Resorte del sello de la boquilla – – – – –

21 Manguito de la boquilla – – – – –

22 Cabezal del quemador – – – – –

23 Juego de bujía 70-052-0100 70-052-0100 70-052-0200 70-052-0200 70-052-0200

24 Conjunto del motor y la bomba 70-020-0100 70-020-0100 70-020-0300 70-020-0400 70-020-0500

25 Motor 70-021-0500 70-021-0500 70-021-0510 70-021-0520 70-021-0520

26 Cuerpo de la bomba 70-020-0101 70-020-0101 70-020-0101 70-020-0101 70-020-0401

27 Juego de rotor 70-022-0100 70-022-0100 70-022-0100 70-022-0100 70-022-0200

28 Aspa – – – – –

29 Cubierta extrema de la bomba 70-020-0102 70-020-0102 70-020-0102 70-020-0102 70-020-0102

30 Juego de filtro 70-054-0100 70-054-0100 70-054-0100 70-054-0100 70-054-0100

31 Filtro de pelusas – – – – –

32 Filtro de salida – – – – –

33 Cubierta del filtro extremo 70-020-0103 70-020-0103 70-020-0103 70-020-0103 70-020-0103

34 Juego de ajuste de la 70-055-0100 70-055-0100 70-055-0100 70-055-0100 70-055-0100

35 Bola – – – – –

36 Resorte – – – – –

37 Tornillo de ajuste – – – – –

38 Niple 70-014-0104 70-014-0104 70-014-0104 70-014-0104 70-014-0104

39 Capacitor 70-020-0125 70-020-0125 70-020-0200 70-020-0201 70-020-0201

40 Conjunto del ventilador 70-024-0100 70-024-0200 70-024-0300 70-024-0400 70-024-0400

41 Encendedor 70-037-0300 70-037-0300 70-037-0300 70-037-0300 70-037-0300

42 Cubierta del lado derecho 70-008-0100 70-008-0200 70-008-0300 70-008-0400 70-008-0450