Page 1

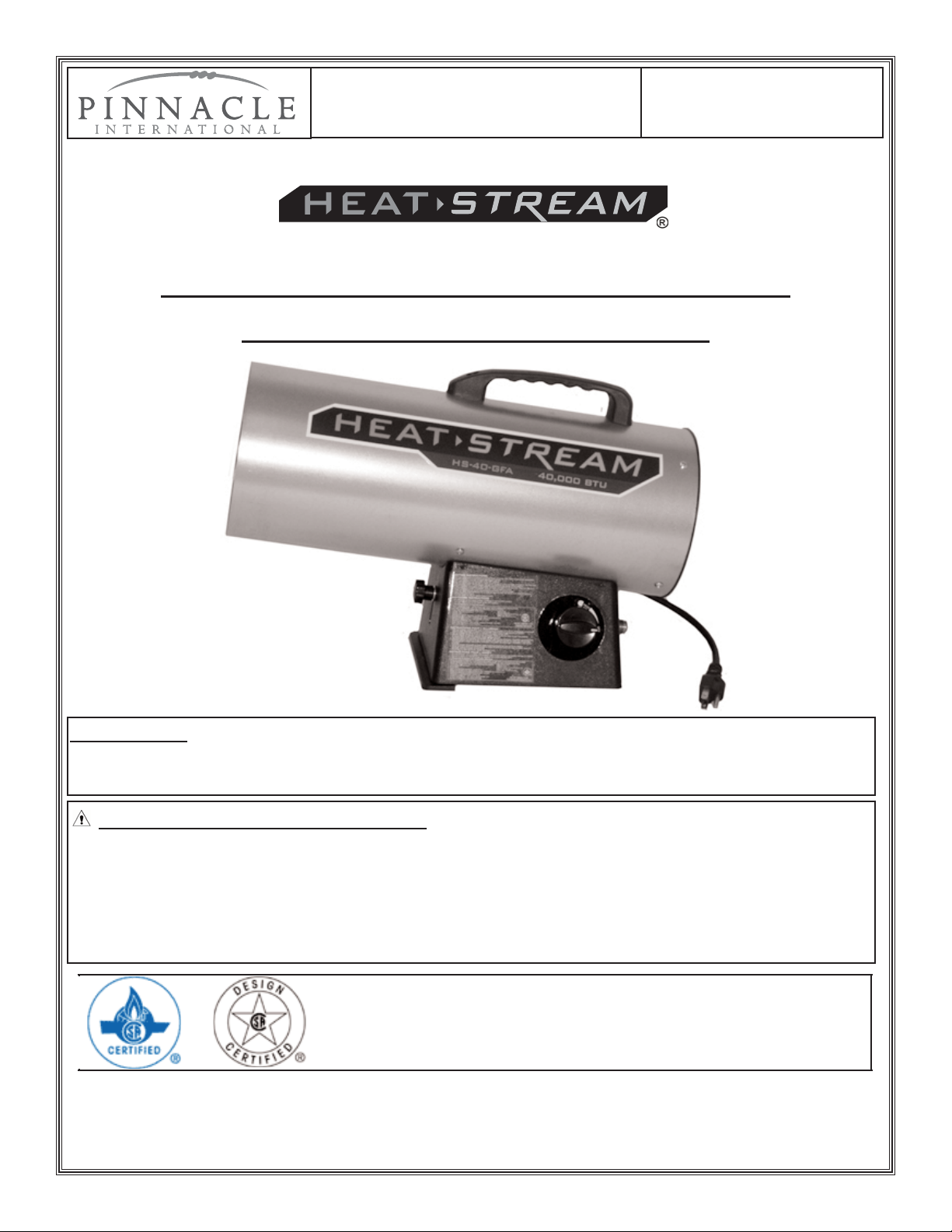

User’s Manual and

Propane

Operating Instructions

Forced Air Heaters

Model #s: HS-40-GFA, HS-50V-GFA,

HS-100V-GFA, HS-150V-GFA

IMPORTANT: Read and understand all of the directions in this manual before assembling,

starting or servicing the heater. Improper use of this heater can cause serious injury.

Table of Contents

Specifications ..........................................................2

Unpacking ................................................................2

Product Features .....................................................2

Propane Supply / Information .................................2

HS-40-GFA , HS-50V-GFA

and HS-150V-GFAare CSA

Certified in USA and

Canada.

HS-100V-GFA is CSA

Certified in USA only.

S

E

D

C

E

R

T

Safety Information.................................................3-4

Operation ..............................................................4-5

Checking for Leaks ..................................................5

Lighting Instructions ................................................5

Storage.....................................................................5

Wiring Diagrams.......................................................6

Replacement Parts ..............................................6-7

Exploded Parts Drawing .......................................7

Troubleshooting Guide .......................... Back Cover

Warranty................................................. Back Cover

GENERAL HAZARD WARNING:

with the precautions and instructions provided with this

heater, can result in death, serious bodily injury and property loss, or damage from the hazards of fire, explosion,

burn, asphyxiation, carbon monoxide poisoning, and/or

electric shock.

Only persons who can understand and follow the instructions should use or service this heater. If you need assistance or heater information such as an instruction manual,

labels, etcetera, contact the manufacturer.

CONSUMER: Retain this manual for future reference.

Pinnacle Products International, Inc. 668 Stony Hill Road #302 Yardley, PA 19067 USA

Phone: (215) 891-8460 Fax: 215-891-8461 Web: www.pinnacleint.com Email: info@pinnacleint.com

I

G

N

D

E

I

I

F

Failure to comply

CERTIFIED

221000120-10

Page 2

NEVER LEAVE HEATER UNATTENDED

WHILE BURNING, CONNECTED TO A

POWER SOURCE, OR WHILE

CONNECTED TO A FUEL SOURCE

Forced Air Heaters

Propane

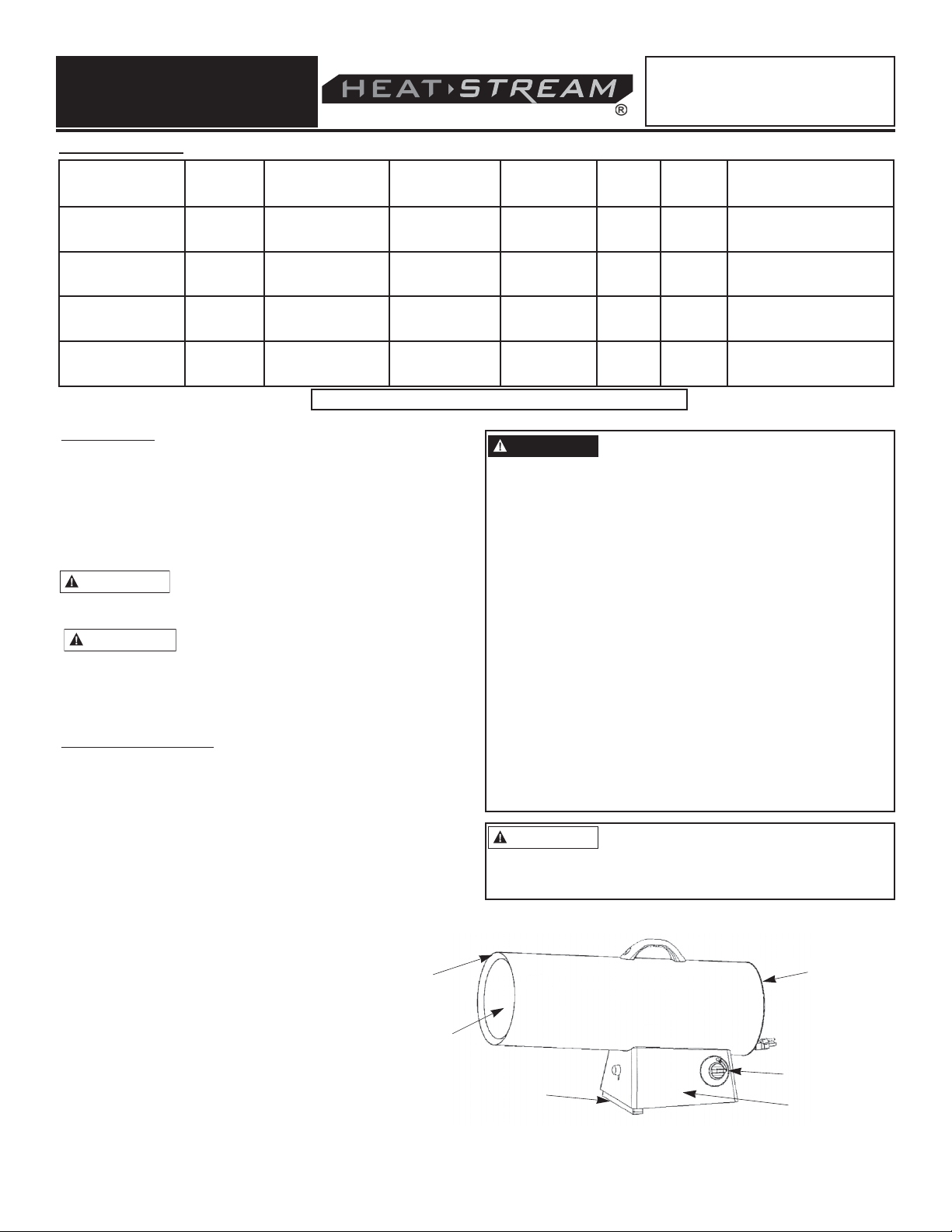

Specifications

Model #

Rating

BTU/Hr

Fuel

Consumption

Electrical

Input

Manifold

Pressure

Amps

Weight

(Lbs)

HS-40-GFA 40,000 1.9 Lbs/Hr 120V, 60 Hz 11” W.C. 0.6 15.2 18.1” x 7.7” x 12.8”

Size

(L x W x H)

HS-50V-GFA

HS-100V-GFA

HS-150V-GFA

Table 1: Specifications

30,000 -

50,000

70,000 100,000

120,000-

150,000

1.4 to 2.3 Lbs/Hr 120V, 60 Hz 10.5” W.C. 0.6 15.2 18.1” x 7.7” x 12.8”

3.3 to 4.6 Lbs/Hr 120V, 60 Hz 10” W.C. 0.8 22.7 25.12” x 9” x 15.5”

5.6 to 7.0 Lbs/Hr 120V, 60 Hz 8” W.C. 0.8 22.7 25.12” x 9” x 15.5”

Specifications subject to change without notice

Unpacking

1. Remove all packing items applied to heater for shipment. Keep

plastic cover caps attached to inlet connector and hose/regulator assembly for storage.

2. Remove all items from carton.

3. Check all items for shipping damage. If heater is damaged,

promptly inform dealer where you purchased the heater.

CAUTION

heater must be used without alteration.

CAUTION

used. Ample combustion and ventilation air must be provided. See VENTILATION on page 5.

The Propane (LP) gas pressure regulator

and hose assembly supplied with the

This is an unvented portable heater. It

uses air (oxygen) from the area which it is

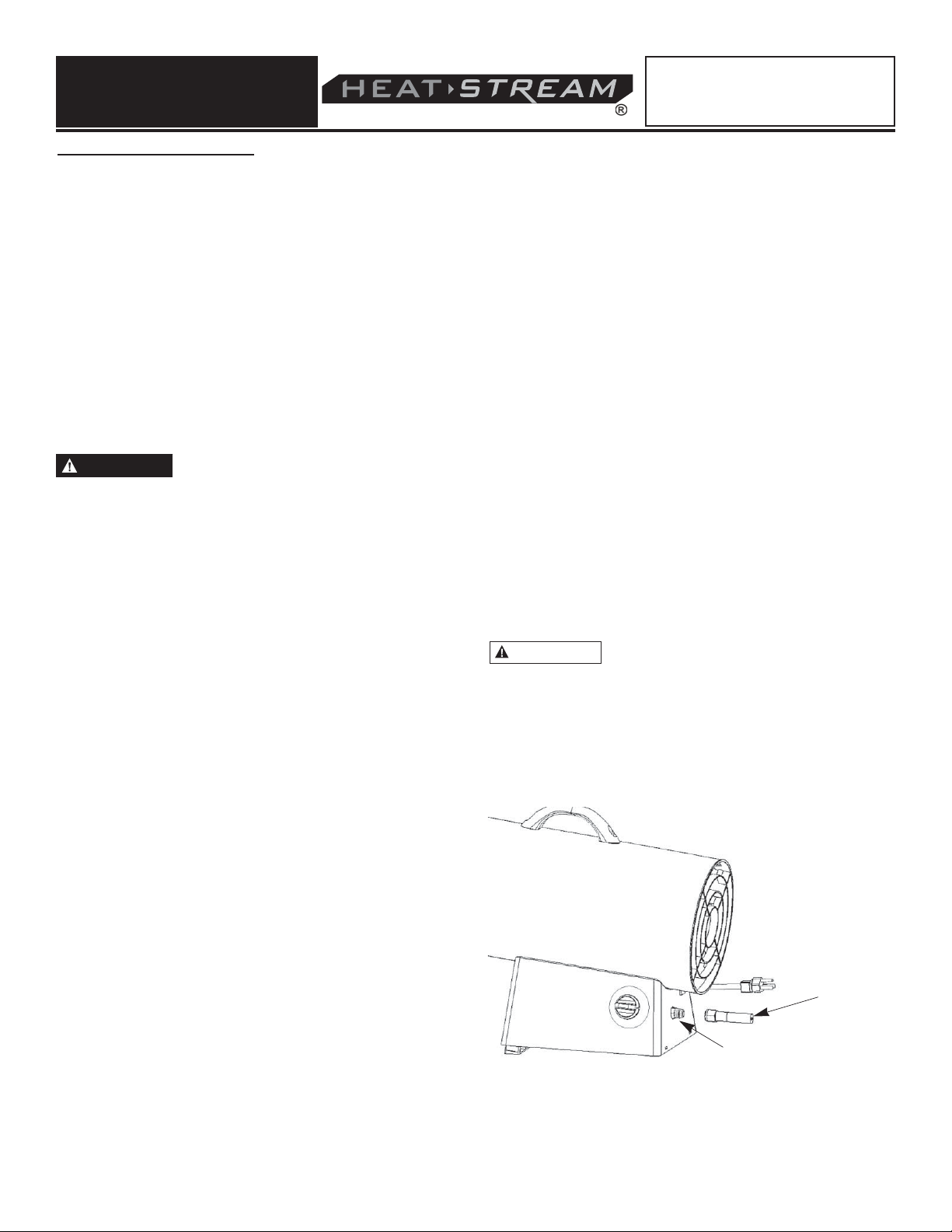

Product Features

- Portable, stable and fully assembled.

- Wind resistant and rain protected.

- Continuous spark ignition or piezo spark ignition.

- 100% safety shut-off system.

- Adjustable input ratings (Except HS-40-GFA).

- Adjustable Height Controller.

PROPANE INFORMATION

The Propane (LP) cylinder must also be

equipped with the following:

- A collar to protect the gas valve.

- A shut-off valve terminating a LP cylinder

valve outlet as specified in the American

National Standard for Compressed Gas

Cylinder Valve Outlets and Inlet Connections.

- A safety relief valve having direct communica-

tions with the vapor space of the LP cylinder.

- An arrangement of vapor withdrawal.

Outer Shell

Inlet Shell

Height Controller

Figure 1. Product Features

DANGER

result causing property damage, personal injury or loss of

life.

- Do not store or use gasoline or other flammable vapors

and liquids in the vicinity of this or any other appliance.

- An LP cylinder not connected for use shall not be stored

in the vicinity of this or any other appliance.

If the information in this manual is not

followed exactly, a fire or explosion may

- WHAT TO DO IF THE SMELL OF GAS IS PRESENT:

- DO NOT attempt to light heater

- Extinguish any open flame

- Shut off gas to heater

- If odor continues, contact your local gas supplier or

fire department.

- Do not touch any electric switch, do not use any

phone in your building

- Immediately call your gas supplier from a neighbors

phone. Follow the gas suppliers instructions

- If you can not reach your gas supplier, call the fire

department

- Service must be done by a qualified service agency

or the gas supplier.

WARNING

Combustion by-products produced when using this product contain carbon monoxide, a chemical known to the state of California to cause cancer and birth defects (or other reproductive harm).

The state of California requires the following

warning:

Guard

Gas Valve Knob

Base

Page 2 Pinnacle Products International, Inc. Propane Forced Air User’s Manual

Page 3

NEVER LEAVE HEATER UNATTENDED

WHILE BURNING, CONNECTED TO A

POWER SOURCE, OR WHILE

CONNECTED TO A FUEL SOURCE

General Safety Information

DANGER

death or serious injury.

WARNING

death or serious injury.

CAUTION

or moderate injury.

WARNING

building materials, paper, or cardboard, at a safe distance

away from heater as recommended by the instructions.

Never use the heater in spaces which do or may contain

volatile or airborne com bustibles or products such as gasoline, solvents, paint thinner, dust particles, or unknown

chemicals.

Consumer: Retain these instructions for future reference.

DANGER

explosion, electrical shock and /or carbon monoxide poisoning.

This heater is designed and approved for use as a construction

heater under ANSI Z83.7a/ CSA2.14a-2007.. Other standards

govern the use of fuel gases and heating products for specific

uses. Your local authority can advise you about these. The primary purpose of construction heaters is to provide temporary

heating of buildings under construction, alteration, or repair.

Properly used, the heater provides safe economical heating.

Products of com bustion are vented into the area being heated.

WARNING

WARNING

ating instructions.

WARNING

ide, a chemical known to the State of California to cause

cancer, birth defects, or other reproductive harm.

WARNING

from traffic, building material and contact with hot surfaces

both during use and while in storage.

IMPORTANT: Read this User's Manual carefully and completely

before attempting to operate or service this heater. Improper use

of the heater can cause serious injury or death from fire,

explosion and carbon monoxide poisoning.

Every possible circumstance that may involve a hazard cannot be

anticipated. The warnings in this manual and at tach ed to the unit

are therefore not all-inclusive. If a procedure, work method or operating technique

you must be sure it is safe for you and others. You should also

insure that equipment will not be damaged or made unsafe by the

operating or maintenance method you choose. CHECK WITH

YOUR LOCAL FIRE SAFETY AUTHORITY IF YOU HAVE ANY

Indicates an im minen tly hazardous situation which, if not avoided, WILL result in

Indicates a poten tially hazardous situation

which, if not avoided, COULD result in

Indicates a poten tially hazardous situa tion

which, if not avoided, MAY result in minor

Fire, burn, inhalation, and explosion hazard. Keep solid combustibles such as

Improper use of this heater can result in

serious injury or death from burns, fire,

Not for use with ductwork.

Do not operate this heater until you read and

thoroughly understand the safety and oper-

Combustible by-prod ucts produced when

using this product contain carbon monox-

Not for home or recreational vehicle use.

The hose assembly shall be pro tected

not specifically recommended by Pinnacle is used,

Propane

Forced Air Heaters

QUESTIONS ABOUT APPLICATIONS.

Other standards govern the use of fuel gasses and heat produc-

ing products in specific applications. Your local authority can advise

you of these.

This is a direct-fired, forced-air construc tion heater for either

indoor or outdoor use. It's intended use is primarily for the temporary heating of buildings under construction, alteration or repair.

All of the products of combustion generated by this heater are

forced through the heater and released into the area being heated. This heater operates at approx imately 98%+ combustion efficiency, but still produces small amounts of carbon monoxide.

Humans can tolerate small amounts of carbon monoxide for short

periods. Carbon monoxide can build up in a heated space, and

failure to provide adequate ventilation could result in poisoning or

death.

You must provide the propane gas and cylinder(s). Use this

heater only with a propane vapor withdrawal supply system.

Refer to Chapter 5 of the Standard for Storage and Handling of

Liquefied Petroleum Gas , ANSI/NFPA 58. Your local library or

fire department will have this booklet.

IMPORTANT SAFETY INFORMATION

- Children should be kept away.

- Always maintain proper clearance from combustible materials.

Minimum clearance should be:

Sides - 24” Top - 36” Front - 72”

- Heater must be placed on level and solid footing.

- Never place anything, including clothes or other flammable items

on heater.

- Do not modify heater, or operate a heater that has been

modified.

- Adequate clearance for accessibility, combustion and ventilation

(air supply) must be maintained at all times when heater is

operating.

- Service and repair should be performed by a qualified service

person. The heater should be inspected before each use, and at

least annually by a qualified person. More frequent cleaning may

be required as necessary. Do not service heater while hot or

operating.

- Never connect heater to

- Use only the electrical/power cord specified. Electrical and

grounding connection must comply with National Electrical

Code - ANSI/NFPA 70 (USA) and CSA C22.1 Canadian

Electrical Code, Part 1 (Canada).

- To prevent injury, always wear gloves when handling heater.

Never handle an operating or hot heater, as severe burns may

result.

- Use heater in accordance with all local codes. In the absence

of local codes, refer to The National Fuel Code, ANSI Z223.1

an unregulated gas supply.

Pinnacle Products International, Inc. Propane Forced Air User’s Manual Page 3

Page 4

NEVER LEAVE HEATER UNATTENDED

WHILE BURNING, CONNECTED TO A

POWER SOURCE, OR WHILE

CONNECTED TO A FUEL SOURCE

Propane

Forced Air Heaters

General Safety Information (Continued)

- This heater is shipped from the factory for use with LP

(propane) gas only. Do not convert to any other gas. Installation

must conform to local codes, or in their absence, with the standard for the Storage and Handling of Liquefied Petroleum Gases

ANSI/NFPA 58.

- Use only the regulator and hose assembly provided with this

heater. Inspect the regulator/hose assembly prior to each use of

the heater. If there is excessive abrasion or wear, or if the hose

is cut, replace it with the proper assembly shown in the parts

list, prior to using the heater.

- Gas supply connections should be checked by using a 50/50

soap and water solution. Never use a flame to check for gas

leaks.

- Locate LP cylinder at least 6 feet from the heater, and do not

direct heater discharge towards the LP cylinder unless it is at

least 20 feet from the heater.

- The electrical connection and grounding must comply with the

National Electrical Code, ANSI/NFPA 70. Use only a properly

grounded three (3) prong receptacle.

- Do not restrict air inlet or outlet areas of the heater.

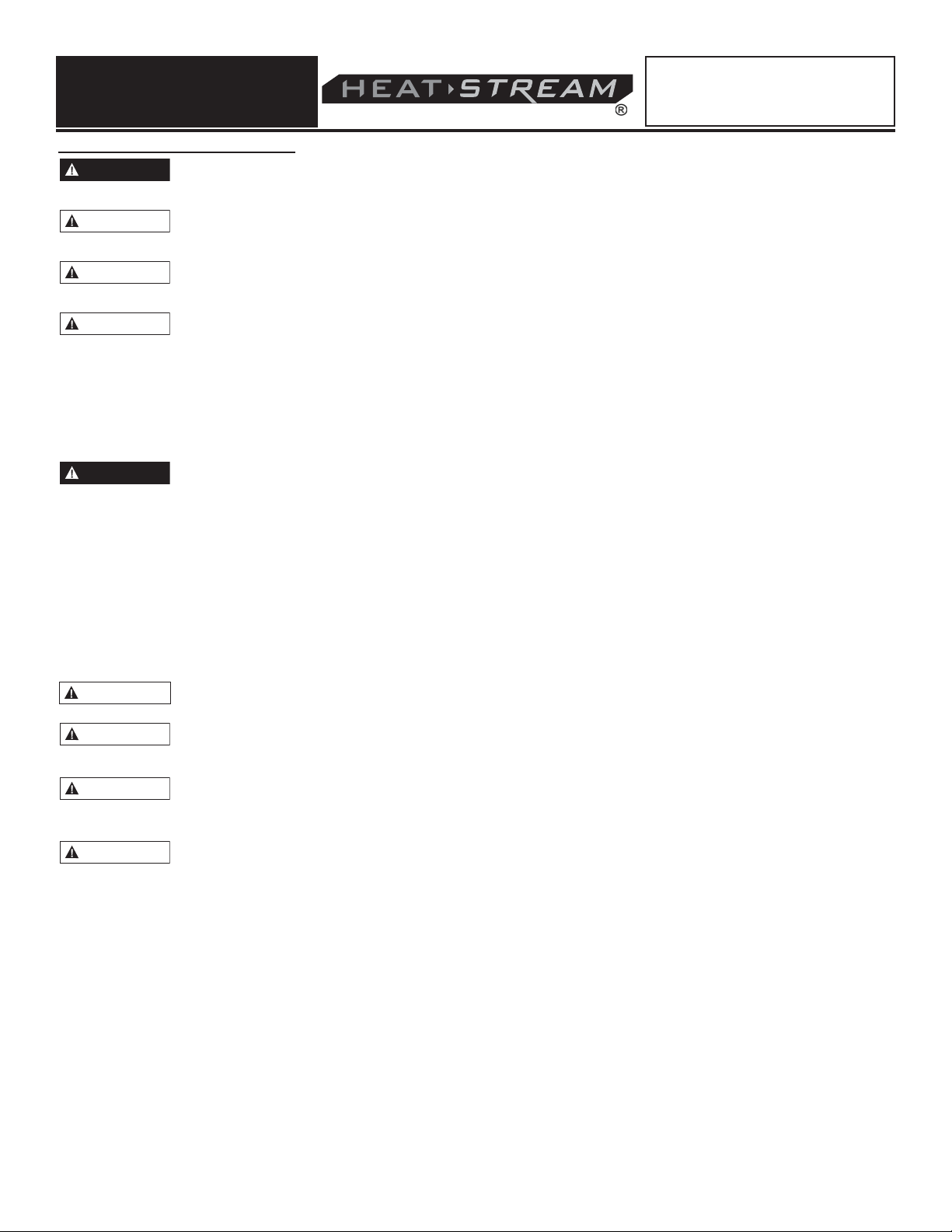

Operation

REFILLING THE LP CYLINDER

ALL NEW LP CYLINDERS MUST BE PURGED BEFORE THE

FIRST FILLING.

WARNING

thoroughly trained in accepted LP gas industry procedures.

Failure to follow these instructions may result in explosion,

fire, severe personal injury or death.

Average

Temp.(oF)

°

32

Purging and filling of LP cylinders must be

performed by personnel who have been

HS-40

20 or 100lb.

cylinder

HS-50V

20 or 100lb.

cylinder

HS-100V

100lb. cylinder

HS-150V

100lb. cylinder

1 1 2 2

- Turn heater gas valve knob and LP cylinder valve to OFF position.

- LP cylinder valve equipped with old style fitting has LEFTHANDED THREADS. Turn fitting CLOCKWISE to loosen.

Protect this fitting when disconnected from LP cylinder.

- Have your LP cylinder filled by your local Propane gas supplier.

- Some LP cylinders have a bleed-off valve. This valve should be

inspected for leaks after each filling of the LP cylinder. Turn the

valve clockwise to close.

- Fasten full Propane tank and connect proper fitting to LP cylinder valve by turning COUNTERCLOCKWISE.

- With heater gas valve knob still in OFF position, turn ON LP

cylinder valve and check for leaks with soap solution.

CAUTION

could result in a fire and/or an explosion. Therefore:

- Always keep LP cylinder securely fastened and in an upright

position.

- Avoid tipping the LP cylinder on its side when connected to a

regulator, since this may cause damage to the diaphragm in the

regulator.

- Handle valves with care.

- Never connect an unregulated LP cylinder to a construction

heater.

- Do not subject LP cylinder to excessive heat.

- Tightly close the gas shutoff valve on the LP cylinder after each

use.

- All fittings must be protected when disconnected from the LP

cylinder.

- Never store an LP cylinder inside a building or in the vicinity of

any gas burning appliance.

CAUTION

enclosed area.

- Do not restrict inlet or outlet of heater. Heater is never to be

used with ductwork.

Propane is safe to use when properly handled. Careless handling of the LP cylinder

The disconnected tank must never be

stored in a building, garage or any other

20

10

0

-10

-20

°

°

°

°

°

1 1 2 2

1 1 3 3

1 1 3 3

2 2

2 2

Use larger

tank

Use larger

tank

Use larger

tank

Use larger

tank

Supply Valve

Regulator

Hose

Table 2: The table above shows the minimum number of 100 lb

LP cylinders required in cold weather. Your local LP dealer will

help you select the proper LP supply system.

Figure 2. Connecting Hose / Regulator to LP Cylinder

Page 4 Pinnacle Products International, Inc. Propane Forced Air User’s Manual

Propane

Tank

Page 5

NEVER LEAVE HEATER UNATTENDED

WHILE BURNING, CONNECTED TO A

POWER SOURCE, OR WHILE

CONNECTED TO A FUEL SOURCE

Propane

Forced Air Heaters

Operation (Continued)

CHECKING FOR LEAKS

- To check for leaks, make up a 50/50 solution of dish soap and

water. Apply this solution to all gas connections. If bubbles

appear, there is a leak. If a leak is found, turn off the gas supply,

and re-connect the leaking connection. If the leak persists after

several tries, contact Pinnacle Customer Service at 215-891-

8460.

- The installation of this heater must meet all local codes and/or

gas utility requirements. In the absence of local codes, the

National Fuel Code ANSI Z223.1 should be followed.

- The minimum clearances to any combustible construction materials must be maintained at all times (See Page 3).

VENTILATION

DANGER

ed space of at least three square feet (2,800 sq. cm.) for each

100,000 BTU/Hr of heater output. For example, a HS-150V-GFA

will require:

- a two-car garage door open 6 inches, or

- a single car garage open 9 inches, or

- two thirty two inch wide windows open 15 inches.

LIGHTING INSTRUCTIONS

1. Connect power cord to a properly grounded three (3) prong

120V, 60 Hz, extension cord.

Extension Cord Wire Requirements:

6 to 10 feet (1.8 to 3 meters) long, use 18 AWG conductor.

11 to 100 feet (3.4 to 30.53 meters) long, use 16 AWG conduc-

tor.

101 to 200 feet (30.8 to 61 meters) long, use 14 AWG conduc-

tor.

2. Connect heater to a proper LP cylinder.

3. Turn gas valve clockwise to OFF position.

4. Wait five (5) minutes for any gas to clear. Smell for gas; if you

do not smell gas, go to Step 5.

5. Push in and turn gas control knob counterclockwise to

LOW/IGN position. This will light the burner. If needed, keep

pressing control knob until the burner lights and keep pressing

and turning from OFF to LOW/ IGN on Piezo electric spark

models (HIGH/IGN on Model HS-40-GFA).

6. Keep the valve knob depressed for at least 30 seconds after

lighting the burner. After

7. If burner does not stay lit, repeat lighting procedure.

8. When burner stays lit, turn gas valve knob counterclockwise to

desired setting (All models except HS-40-GFA).

Always provide a fresh air opening in the heat-

30 seconds, release valve knob.

SHUTDOWN INSTRUCTIONS

To shut off heater:

1. Turn gas valve knob clockwise to OFF position.

2. Turn gas supply OFF by turning LP cylinder valve clockwise to

close.

3. Disconnect the power cord.

TEST FIRING THE HEATER

Test fire your construction heater following the lighting instructions

applicable to the gas control system employed.

Leak test all gas connections with 50/50 soap and water solution

prior to start-up. Soap bubbles indicate a gas leak. DO NOT use a

match or flame to test for gas leaks.

NOTE: Heater surface temperature must be cold before initiating

service, cleaning or storage.

STORAGE

Always disconnect the heater from the LP cylinder before putting

the heater into storage. If for any reason the heater is to be

stored indoors, the tank MUST be disconnected from the LP

cylinder, and the cylinder stored outdoors in a well-ventilated

area, out of the reach of children, and in accordance with the

Standard for Storage and Handling of Liquefied Gases,

ANSI/NFPA 58 - latest edition. The plastic valve plug or valve

cover supplied with the cylinder must be re-installed on the valve

to protect the fitting from damage.

WARNING

ing appliances.

NOTE: Installation and repair of this heater should be done

by a qualified service person.

Never store an LP cylinder inside of a

building, or near any other gas or oil burn-

Hose

Inlet Connector

Figure 3. Connecting Hose to Heater Inlet

Pinnacle Products International, Inc. Propane Forced Air User’s Manual Page 5

Page 6

BLUE

BLUE

WHITE

WHITE

BLACK

WHITE

BLACK

GREEN

YELLOW

IGNITOR

PCB ASS’Y

CONDENSER

FUSE

EARTH(SHELL)

POWER CORD

BLACK

HTRAE

EVLAV LORTNOC

ELPUOCOMREHT

THERMAL SWITCH

MOTOR

WOLLEY

BLUE

BLUE

BLACK

BLACK

BLUE

WHITE

WHITE

WHITE

BLACK

GREEN

IGNITOR

PCB ASS’Y

CONDENSER

FUSE

SPARK

MODULE

EARTH(SHELL)

POWER CORD

MOTOR

BLUE

YELLOW

HTRAE

EVLAV LORTNOC

ELPUOCOMREHT

THERMAL SWITCH

WOLLEY

NEVER LEAVE HEATER UNATTENDED

WHILE BURNING, CONNECTED TO A

POWER SOURCE, OR WHILE

CONNECTED TO A FUEL SOURCE

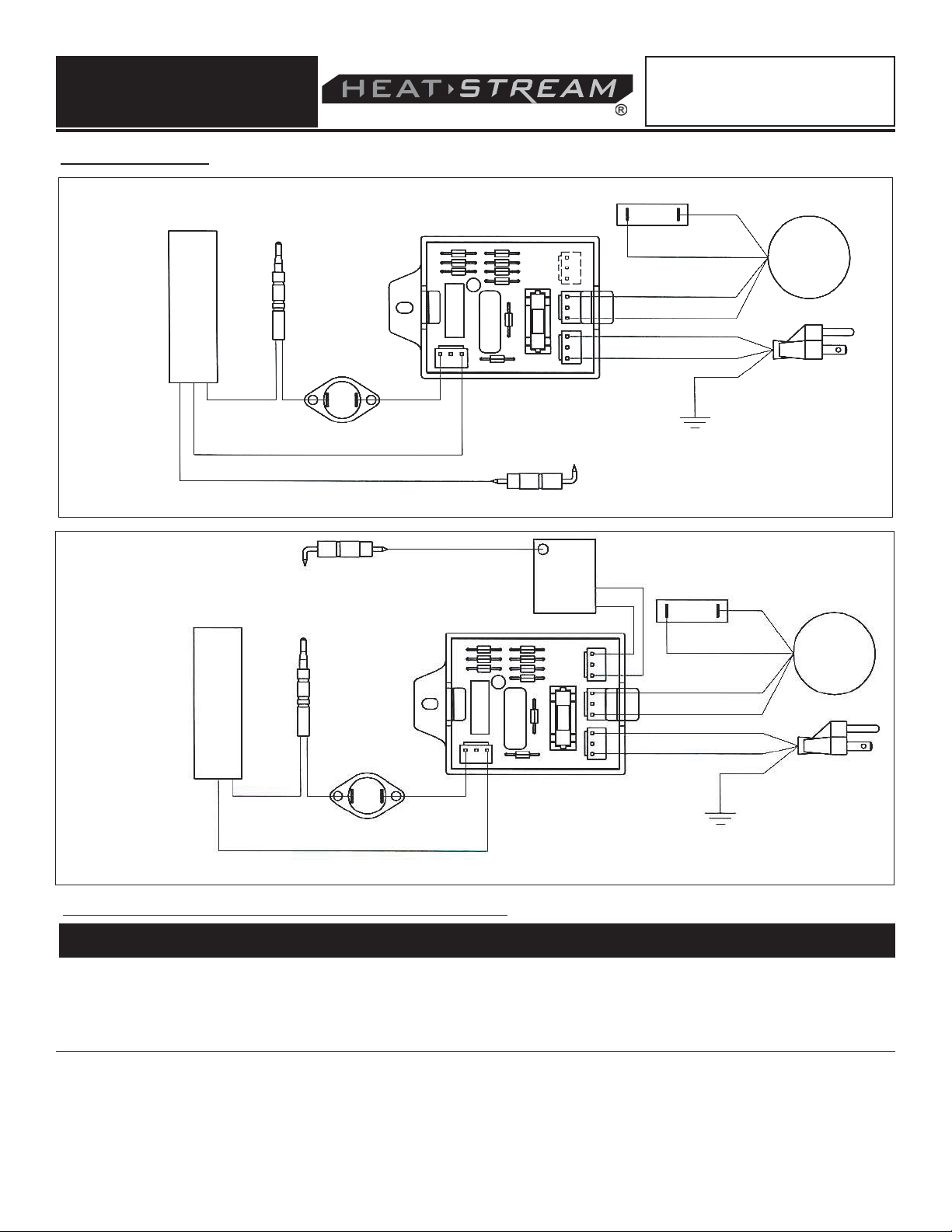

Wiring Diagrams

Figure 4. Wiring Diagram for Piezo/Manual Spark Models.

Propane

Forced Air Heaters

Figure 5. Wiring Diagram for Continuous Spark Models.

Repair Parts List for Propane Construction Heater

Reference Part Number for Models:

Number Description HS-40-GFA HS-50V-GFA HS-100V-GFA HS-150V-GFA Quantity

1 Outer Shell 22-524-0050 22-524-0060 22-524-0070 22-524-0070 1

2 Inner Shell Assembly 22-524-0004 22-524-0004 22-524-0005 22-524-0005 1

3 Base 22-501-0003 22-501-0001 22-501-0002 22-501-0002 1

4 Height Controller 22-512-0005 22-512-0005 22-512-0008 22-512-0008 1

5 Base Cover 22-508-0003 22-508-0001 22-508-0002 22-508-0002 1

6 Inner Shell Cap 22-505-0006 22-505-0006 22-505-0007 22-505-0008 1

7 Multi Bracket Assembly 22-504-0002 22-504-0002 22-504-0003 22-504-0003 1

8 Thermal Switch 22-603-0001 22-603-0001 22-603-0001 22-603-0001 1

9 Tubing Assembly 22-605-0001 22-605-0001 22-605-0005 22-605-0005 1

10 Nozzle 22-081-0007 22-081-0008 22-081-0009 22-081-0004 1

Page 6 Pinnacle Products International, Inc. Propane Forced Air User’s Manual

Page 7

NEVER LEAVE HEATER UNATTENDED

WHILE BURNING, CONNECTED TO A

POWER SOURCE, OR WHILE

CONNECTED TO A FUEL SOURCE

Exploded Drawing/Part Breakdown

2

6

10

11

Propane

Forced Air Heaters

7

8

1

12

13

14

15

16

17

24

21

23

22

20

3

4

27

19

5

25

28

9

26

18

Figure 6. Exploded View - All Models

Repair Parts List for Propane Construction Heater (Continued)

Reference Part Number for Models:

Number Description HS-40-GFA HS-50V-GFA HS-100V-GFA HS-150V-GFA Quantity

11 Nozzle Nut 22-518-0001 22-518-0001 22-518-0001 22-518-0002 1

12 Handle 22-511-0004 22-511-0004 22-511-0004 22-511-0004 1

13 Flange Hex Nut 22-518-0003 22-518-0003 22-518-0003 22-518-0003 1

14 Fan 22-514-0001 22-514-0001 22-514-0002 22-514-0002 1

15 Cushion Pad 22-509-0001 22-509-0001 22-509-0001 22-509-0001 1

16 Motor Assembly 22-061-0015 22-061-0015 22-061-0016 22-061-0016 1

17 Guard 22-101-0003 22-101-0003 22-101-0004 22-101-0004 1

18 Round Bolt 22-503-0002 22-503-0002 22-503-0003 22-503-0003 1

19 Valve Assembly 22-011-0005 22-011-0006 22-011-0007 22-011-0008 1

20 Inlet Connector 22-507-0003 22-507-0003 22-507-0003 22-507-0003 1

21 Spark Module – 22-604-0005 22-604-0005 22-604-0005 1

22 PCB Assembly 22-521-0001 22-521-0002 22-521-0002 22-521-0002 1

23 PCB Case 22-506-0001 22-506-0001 22-506-0001 22-506-0001 1

24 Valve Knob 22-516-0001 22-516-0001 22-516-0001 22-516-0001 1

25 Power Cord Assembly 22-131-0001 22-131-0001 22-131-0001 22-131-0001 1

26 Thermal Switch Cable 22-601-0001 22-601-0001 22-601-0001 22-601-0001 1

27 Hex Nut 22-518-0004 22-518-0004 22-518-0004 22-518-0004 1

28 Regulator Assembly 22-041-0004 22-041-0004 22-041-0005 22-041-0005 1

Always be sure to follow proper maintenance procedures. This should include cleaning the inside the heater

once a month, and checking the spark gap at least once a heating season.

Pinnacle Products International, Inc. Propane Forced Air User’s Manual Page 7

Page 8

NEVER LEAVE HEATER UNATTENDED

WHILE BURNING, CONNECTED TO A

POWER SOURCE, OR WHILE

CONNECTED TO A FUEL SOURCE

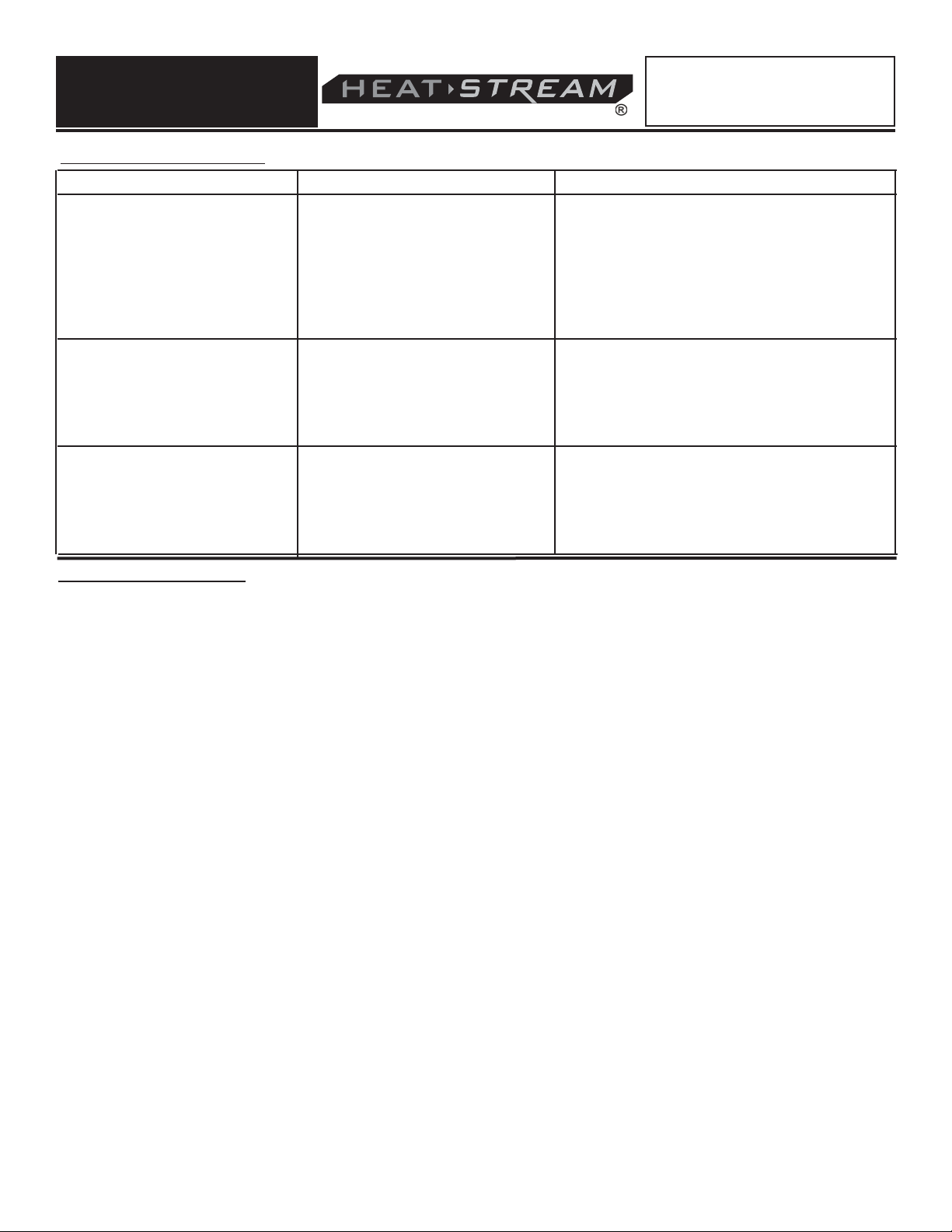

Troubleshooting Guide

Problem Possible Cause Solution

Fan does not turn when electricity is

connected

Heater will not fire (ignite) 1. No spark at module

Heater stop

s running by itself

1. No electric power to heater

2. Blades of fan in contact with heater

housing

3. Fan blades bent

4. Fan motor defective

2. Incorrect spark gap

3. Corroded electrode

Temperature inside heater is too high,

1.

causing thermal switch to shut down

operation

2. Damaged control valve

3. Dust or debris accumulated in heater

Propane

Forced Air Heaters

1. Check current at outlet. If voltage is correct,

inspect extension and power cords for cuts, frays

or breaks

2. Check housing for damage. Be sure there ar no

dents in the housing obstructing the fan

3. Straighten all fan blades

4. Replace Motor Assembly

1. Inspect module wire. Re-attach, or tighten if loose.

Inspect Spark module, and replace if necessary.

Inspect all other electrical components

2. Set plug gap to 0.16” (4mm)

3. Replace spark plug (Multi-Bracket Assembly)

If heater input or output is restricted, the inside

1.

temperature can become too hot. Keep the areas

in front and behind heater clear of obstructions

2. Replace control valve (Valve Assembly)

3. Clean inside of heater

LIMITED WARRANTY

Pinnacle Products International, Inc. warrants this heater to

the original retail purchaser only, to be free from defects in material and workmanship for a period of one (1) year from the date of

initial purchase. This product must be properly installed, maintained and operated in accordance with the instructions provided.

Pinnacle Products International, Inc. requires reasonable proof

of your date of purchase from an authorized retailer or distributor.

Therefore, you should keep your sales slip, invoice, or cancelled

check from the original purchase. This Limited Warranty shall be

limited to the repair or replacement of parts, which prove defective under normal use and service within the warranty period, and

which Pinnacle Products International, Inc. shall determine at

its reasonable discretion.

This warranty does not apply to products purchased for rental

use.

This Limited Warranty does not cover any failures or operating

difficulties due to normal wear and tear, accident, abuse, misuse,

alteration, misapplication, improper installation or improper maintenance and service by you or any third party. Failure to perform

normal and routine maintenance on the heater, shipping damage,

damage related to insects, birds, or animals of any kind, and

damage due to weather conditions are also not covered. In addition, the Limited Warranty does not cover damage to the finish,

such as scratches, dents, discoloration, rust or other weather

damage, after purchase.

All transportation costs for the return of the damaged product or

parts will be the responsibility of the purchaser. Upon receipt of

damaged item, Pinnacle Products International, Inc. will examine the item and determine if defective. Pinnacle Products

International, Inc. will repair or replace and return the item,

freight pre-paid. If Pinnacle Products International, Inc. finds

the item to be in normal operating condition, or not defective, the

item will be returned freight collect.This Limited Warranty is in

lieu of all other express warranties. Pinnacle Products

International, Inc. disclaims all warranties for products that

purchased from sellers other than authorized retailers or distributors.

AFTER THE PERIOD OF THE ONE (1) YEAR EXPRESS WARRANTY EXPIRES, Pinnacle Products International, Inc. DISCLAIMS ANY AND ALL IMPLIED WARRANTIES, INCLUDING

WITHOUT LIMITATION THE IMPLIED WARRANTIES OF MERCHANTABILITY AND FITNESS FOR A PARTICULAR APPLICATION. FURTHER, Pinnacle Products International, Inc. SHALL

HAVE NO LIABILITY WHATSOEVER TO PURCHASER OR ANY

THIRD PARTY FOR ANY SPECIAL, INDIRECT, PUNITIVE, INCIDENTAL, OR CONSEQUENTIAL DAMAGES. Pinnacle

Products International, Inc. assumes no responsibility for any

defects caused by third parties. This Limited Warranty gives the

purchaser specific legal rights; a purchaser may have other rights

depending upon where he or she lives. Some states do not allow

the exclusion or limitation of special, incidental or consequential

damages, or limitations on how long a warranty lasts, so the

above exclusion and limitations may not apply to you.

Pinnacle Products International, Inc. does not authorize any

person or company to assume for it any other obligation or liability in connection with the sale, installation, use, removal, return,

or replacement of its equipment, and no such representations are

binding on Pinnacle Products International, Inc.

Always be sure to specify model number and serial number when

making any claim with Pinnacle Products International, Inc.

For your convenience use the space provided below to list this

information:

Model #: ____________________

Serial #: _________________________

Date of Purchase: _________________

are

Page 9

Manual del Propietario e

Instrucciones de Operación

Calentador para Uso en

Tareas de Construcción a

Propano

Modelos No: HS-40-GFA, HS-50V-GFA,

HS-100V-GFA, HS-150V-GFA

IMPORTANTE: Lea y entienda todas las instrucciones que se dan en este manual antes de armar,

encender o darle servicio al calentador. El uso indebido de este calentador puede causar lesiones

graves. Guarde este manual para referencia en el futuro.

ADVERTENCIA GENERAL DE PELIGRO:

Asegúrese de cumplir con las instrucciones y advertencias suministradas con este calentador, o de lo

contrario se puede sufrir la muerte, lesiones corporales y pérdida de la propiedad debido a los peligros

de incendio, explosión, quemaduras, asfixia e intoxicación por monóxido de carbono.

Sólo las personas que puedan seguir y entender estas instrucciones pueden utilizar o darle servicio

a este calentador. Si necesita información sobre el calentador tal como un manual de instrucciones,

etiquetas, etcétera, póngase en contacto con el fabricante.

Los modelos HS-40-GFA, HS-50V-GFA y HS-150V-GFA tienen la certificación CSA en

EE.UU. y Canadá.

El modelo HS-100V-GFA tienen la certificación CSA sólo en EE.UU.

Consumidor: Guarde estas instrucciones para referencia en el futuro.

Pinnacle Products International, Inc. 668 Stony Hill Road #302 Yardley, PA 19067 EE.UU.

Teléfono: (800) 641-6996 Fax: 215-891-8461

Sitio Web: www.pinnacleint.com Correo electrónico: info@pinnacleint.com

Page 10

NUNCA DEJE DESATENDIDO EL CALENTADOR

MIENTRAS ÉSTE ESTÉ ENCENDIDO, CONECTADO A UNA FUENTE DE ALIMENTACIÓN, O

MIENTRAS ESTÉ CONECTADO A UNA FUENTE

DE COMBUSTIBLE.

Especificaciones

Modelo Capacidad de

entrada

Consumo de

gas

Entrada

Eléctrica

Presión del

múltiple

Calentador para Uso en Tareas

de Construcción a Propano

Amperaje Peso Kg

(Lb)

Tamaño

L x A x Al (cm)

HS-40-GFA

HS-50V-GFA

HS-100V-GFA

HS-150V-GFA

40,000 BTU/Hr 0.86 kg/hr 120V, 60 Hz 26.7 cm C.A. 0.60 6.9 (15.2) 46.0 x 19.6 x 32.5

30,000 a 50,000

BTU/Hr

70,000 a 100,000

BTU/Hr

120,000 a 150,000

BTU/Hr

0.64 a 1.04 kg/hr 120V, 60 Hz 25.4 cm C.A. 0.60 6.9 (15.2) 46.0 x 19.6 x 32.5

1.50 a 2.09 kg/hr 120V, 60 Hz 24.1 cm C.A. 0.80 10.3 (22.7) 63.8 x 22.9 x 39.4

2.54 a 3.18 kg/hr 120V, 60 Hz 20.3 cm C.A. 0.80 10.3 (22.7) 63.8 x 22.9 x 39.4

Especificaciones sujetas a cambio sin previo aviso

Desempaque

1. Retire todos los materiales de embalaje aplicados al calentador

para su envío. Mantenga montadas las tapas de plástico en el

conector de entrada y en el conjunto del regulador y manguera

cuando almacene la unidad.

2. Retire todos los artículos de la caja de envío.

3. Inspeccione los artículos para comprobar que no se hayan

dañado durante el envío. Si el calentador está dañado,

infórmele prontamente al concesionario de quien compró el

calentador sobre dicho daño.

Características del producto

- Portátil, estable y totalmente armado.

- Resistente al viento y protegido contra la lluvia.

- Ignición de chispa continua o ignición de chispa piezoeléctrica.

- Sistema de apagado 100% seguro.

- Capacidades de entrada ajustables(excepto el PT-40-GFA-A).

INFORMACION SOBRE EL PROPANO

El tanque de gas propano (LP) también deberá estar equipado

con lo siguiente:

- Un collar para proteger la válvula de gas.

- Una válvula de cierre conectada en la salida de la válvula del

cilindro o tanque de gas propano según la especificación de la

Norma Nacional Americana para la conexión de entradas y salidas de válvulas de cilindros de gas comprimido.

- Una válvula de alivio de seguridad con comunicación directa

con el espacio de vapor del tanque.

- Una forma para retirar o sacar el vapor.

AVISO: El conjunto de la manguera y el regulador de presión del

gas Propano (LP) suministrado con este calentador debe utilizarse sin hacerle ninguna alteración.

Información de Seguridad General

Indica una situación de peligro inminente que, de no evitarse, CAUSARA la

muerte o una lesión grave.

Indica una situación de posible peligro

que, de no evitarse, PODRIA causar la

muerte o una lesión grave.

Indica una situación de posible peligro

que, de no evitarse, PODRIA causar

lesiones leves o moderadas.

Coraza exterior Protección

Outer Shell

Conjunto de la

Inlet Shell

coraza interior

Height Controller

Controlador de altura

Figura 1. Características del producto

Guard

Perilla de la válvula

Gas Valve Knob

Base

Base

Página 2 Pinnacle Products International, Inc. Manual del Propietario del Calentador de Propano

Page 11

NUNCA DEJE DESATENDIDO EL CALENTADOR

MIENTRAS ÉSTE ESTÉ ENCENDIDO, CONECTADO A UNA FUENTE DE ALIMENTACIÓN, O

MIENTRAS ESTÉ CONECTADO A UNA FUENTE

DE COMBUSTIBLE.

Calentador para Uso en Tareas

de Construcción a Propano

Información de Seguridad General (Continuación)

Advertencia general de peligro: Si no se

cumple con las precauciones e instrucciones suministradas con este calentador, se puede sufrir la

muerte, lesiones corporales graves, y pérdida de la

propiedad o daños debido a los peligros de incendio,

explosión, quemadura, asfixia, intoxicación por monóxido

de carbono y/o choque eléctrico. Sólo las personas que

puedan entender y seguir estas instrucciones pueden utilizar o darle servicio a este calentador. Si necesita asistencia

o información sobre el calentador tal como un manual de

instrucciones, etiquetas, etcétera, póngase en contacto con

el fabricante.

Peligro de incendio, quemaduras,

inhalación y explosión. Mantenga los

combustibles sólidos, tales como materiales de construcción, papel, cartón a una distancia prudente lejos del calentador según lo recomiendan las instrucciones. Nunca use el

calentador en espacios que contengan o puedan contener

productos como gasolina, disolventes, solventes de pintura,

partículas de polvo, combustibles volátiles o en suspensión

en el aire, o productos químicos desconocidos.

Consumidor: Guarde estas instrucciones para referencia en

el futuro.

El uso inadecuado de este calentador

puede ocasionar lesiones graves o la

muerte debido a quemaduras, incendio, explosión, choque

eléctrico y/o envenenamiento por monóxido de carbono.

Este calentador ha sido diseñado para uso en construcciones de

acuerdo con la normas ANSI Z83.7a/CSA2.14a-2007. Otras normas rigen el uso de gases combusti bles y productos de calefacción para usos específicos. Sus autoridades locales pueden

asesorarle sobre esas normas. Los calentadores para uso en tareas de construcción están diseñados principalmente para proporcionar calefacción temporal en edificios en construcción,

alteración o reparación.

El calentador, usado correctamente, proporciona una calefacción

económica y segura. Los productos de combustión se ventilan en

el área siendo calentada.

No ha sido diseñado para uso domésti-

co o en vehículos recreacionales.

No haga funcionar este calentador hasta

que haya leído y entendido completamente las instrucciones de seguridad y operación. Si no se

cumple con las precauciones e instrucciones suministradas

con este calentador, se puede sufrir la muerte, lesiones corporales graves, pérdida de la propiedad o daños debido a

los peligros de incendio, explosión, quemadura, asfixia o

intoxicación por monóxido de carbono. Sólo las personas

que puedan entender y seguir estas instrucciones pueden

utilizar o darle servicio a este calentador.

Los productos derivados de combustión

resultantes del uso de este producto

contienen monóxido de carbono, un químico que el Estado

de California reconoce como causante de cáncer, malformaciones congénitas u otros daños reproductivos.

No ha sido diseñado para uso domésti-

co o en vehículos recreacionales. El

conjunto de la manguera debe estar protegido contra el trá-

fico, materiales de construcción y el contacto con superficies calientes tanto durante el uso como durante el almacenamiento.

IMPORTANTE: Lea detenida y com pleta mente este Manual del

usuario antes de intentar usar o darle manteni miento a este

calentador. El uso inade cuado del calentador puede ocasionar

lesiones graves o la muerte debido a incendio, explosión o envenenamiento por monóxido de carbono.

Toda posible circunstancia que podría implicar un peligro no

puede ser antici pada. Las advertencias que aparecen en este

manual y en la unidad no cubren por tanto todo. Si se utiliza un

procedimiento, método de trabajo o técnica de operación no

específica mente recomendado por Pinnacle, usted deberá asegurarse que es seguro para usted y para otros.

También deberá asegurarse que no se dañará el equipo ni se hará

éste inseguro por el método de operación o manteni miento que

usted elija. CONSULTE CON LAS AUTORIDADES DE SEGURIDAD DE INCENDIOS DE SU LOCALIDAD SI TIENE ALGUNA

DUDA SOBRE EL USO DE ESTE CALENTADOR. Este calentador ha sido diseñado y aprobado para uso como un calentador

para uso en tareas de construcción bajo ANSI Z83.7.

Otras normas rigen el uso de gases combustibles y materiales

productores de calor en aplicaciones específicas. Sus autoridades

locales pueden asesorarle sobre esas normas.

Éste es un calentador para construcciones, de aire forzado, de

acción directa para uso en interiores o exteriores. La unidad ha

sido diseñada principalmente para la calefacción temporal de edificios en construcción, o a los que se les están haciendo modificaciones o reparaciones. Todos los productos de combustión

generados por este calentador son forzados a través del calentador y emitidos en el área siendo calentada. Este calentador funciona con una eficacia de combustión de aproximadamente mejor

que un 98%, pero aún produce

do de carbono. Los humanos pueden tolerar pequeñas cantidades

de monóxido de carbono durante cortos períodos de tiempo. El

monóxido de carbono puede acumularse en un espacio calentado,

y la falta de proporcionar una ventilación adecuada puede resultar

en envenenamiento o la muerte.

IMPORTANTE INFORMACION SOBRE SEGURIDAD

- Los niños deben mantenerse lejos.

- Siempre mantenga las distancias de separación adecuadas de

los materiales combustibles. Las distancias de separación mínimas deberán ser:

Lados – 61 cm, Parte superior – 91.4 cm;

Frente – 183 cm.

- El calentador debe colocarse en una base sólida y nivelada.

- Nunca ponga nada en el calentador, incluyendo vestimentas u

otros artículos inflamables.

- No modifique el calentador ni utilice un calentador que haya

sido modificado.

pequeñas cantidades de monóxi-

Pinnacle Products International, Inc. Manual del Propietario del Calentador de Propano Página 3

Page 12

NUNCA DEJE DESATENDIDO EL CALENTADOR

MIENTRAS ÉSTE ESTÉ ENCENDIDO, CONECTADO A UNA FUENTE DE ALIMENTACIÓN, O

MIENTRAS ESTÉ CONECTADO A UNA FUENTE

DE COMBUSTIBLE.

Calentador para Uso en Tareas

de Construcción a Propano

Información de Seguridad General (Continuación)

- Será necesario mantener una separación adecuada para el

acceso, la combustión y la ventila-ción (suministro de aire) en

todo momento cuando el calentador está funcionando.

- Todo trabajo de mantenimiento y reparación deberá ser realizado por un técnico de servicio calificado. El calentador

deberá ser inspeccionado antes de cada uso y al menos

anualmente por una persona calificada. Es posible que se

requiera una limpieza más frecuente según sea necesario. No

repare ni le dé mantenimiento al calentador mientras está

caliente o funcionando

- Nunca conecte el calentador en una fuente de gas no regulada.

- Este calentador se envía de la fábrica para uso con gas LP

(propano) únicamente. No lo convierta a ningún otro gas. La

instalación deberá conformar con los códigos locales, o a falta

de ellos, con la norma para el almacenamiento y la manipulación de gases de petróleo licuado ANSI/NFPA 58.

- Utilice únicamente el conjunto de regulador y manguera suministrado con este calentador. Inspeccione el conjunto del regulador y manguera antes de cada uso del calentador. Si está

demasiado desgastado, o si la manguera está cortada, reemplace el conjunto con el conjunto correcto mostrado en la lista

de partes, antes de usar el calentador.

- Las conexiones de suministro de gas deben revisarse usando

una solución de 50/50 de agua y jabón. Nunca use una llama

para verificar la presencia de fugas de gas.

- Sitúe el cilindro de propano al menos a 1.8 metros del calentador, y no oriente la descarga del calentador hacia el cilindro de

gas a menos que éste se encuentre a una distancia de 6 metros del calentador.

Número de tanques necesarios

Temperatura

(°C) en el

tanque

0.0 1 2 2

-6.6 1 2 2

-12.2 1 3 3

-17.7 1 3 3

-23.3 2

-28.8 2

El cuadro que aparece arriba muestra el número de tanques de 100 libras

(45.4 kg) necesarios para operar los calentadores a una cierta temperatura.Se

vaporiza menos gas a temperaturas más bajas. Es posible que necesite dos o

más tanques de 100 libras (45.4 kg), o un tanque más grande en climas fríos.

Su distribuidor local de gas propano le ayudará a seleccionar el sistema de

suministro adecuado.

40,000 a

50,000

BTU/Hr

100,000 BTU/Hr 150,000 BTU/Hr

Usar un tanque

más grande

Usar un tanque

más grande

Usar un tanque

más grande

Usar un tanque

más grande

- La conexión eléctrica y a tierra deberán cumplir con el Código

Eléctrico Nacional (NEC), ANSI/NFPA 70. Utilice únicamente

un receptáculo para tres (3) clavijas debidamente conectado a

tierra.

- No obstrya las áreas de entrada y salida de aire del calentador.

Operación

RELLENO DEL TANQUE DE GAS PROPANO

TODO CILINDRO NUEVO DEBE PURGARSE ANTES DE

LLENARLO POR PRIMERA VEZ.

Las acciones de purga y llenado de los

personal que esté completamente capacitado en los procedimientos aceptados de la industria de gas LP. El incumplimiento de estas instrucciones podría resultar en explosión,

incendio, lesiones personales graves o la muerte.

- Gire la perilla de la válvula de gas del calentador y la válvula

del tanque de gas a la posición OFF (apagado).

- Las válvulas de tanque de propano equipadas con un accesorio de estilo antiguo tienen ROSCAS DE MANO IZQUIERDA.

Gire el accesorio HACIA LA DERECHA para aflojarlo. Proteja

este accesorio cuando esté desconectado del tanque.

- Haga que su distribuidor de gas propano le llene su tanque.

- Algunos tanques de propano tienen una válvula de purga. Esta

válvula deberá inspeccionarse para ver si tiene fugas después

de cada vez que se llene el tanque. Gire la válvula hacia la

derecha para cerrarla.

- Sujete el tanque de propano lleno y conecte el accesorio adecuado en la válvula del tanque, girándolo HACIA LA IZQUIERDA.

- Con la perilla de la válvula de gas del calentador en la posición

OFF (apagado), abra la válvula del tanque y revise para ver si

hay fugas usando una solución de jabón.

lación negligente del tanque de gas propano podría resultar

en un incendio y/o una explosión. Por consiguiente:

- Siempre mantenga firmemente sujetado y en posición vertical

el tanque o cilindro.

- Evite inclinar el tanque hacia un lado cuando esté conectado a

un regulador, ya que eso podría causar daño al diafragma en

el regulador.

- Trate las válvulas con cuidado.

- Nunca conecte un tanque de propano no regulado en un

calentador para construcción.

- No someta el tanque de propano a un calor excesivo.

- Cierre firmemente la válvula de cierre de gas en el tanque de

propano después

- Todos los accesorios deben protegerse cuando están

desconectados del tanque de LP.

tanques de LP deben ser realizadas por

El propano es seguro para usar cuando

se manipula correctamente. La manipu-

de cada uso.

Página 4 Pinnacle Products International, Inc. Manual del Propietario del Calentador de Propano

Page 13

NUNCA DEJE DESATENDIDO EL CALENTADOR

MIENTRAS ÉSTE ESTÉ ENCENDIDO, CONECTADO A UNA FUENTE DE ALIMENTACIÓN, O

MIENTRAS ESTÉ CONECTADO A UNA FUENTE

DE COMBUSTIBLE.

Calentador para Uso en Tareas

de Construcción a Propano

Operación (Continuación)

- Nunca almacene un tanque de gas propano dentro de un edificio o cerca de cualquier aparato que queme gas.

El tanque desconectado nunca debe

almacenarse en un edificio, garaje o

cualquier otra área cerrada.

INSPECCIÓN DE FUGAS

- Revise todas las conexiones con una solución de 50/50 de

agua y jabón para asegurarse que estén bien apretadas y herméticas.

- La instalación de su calentador deberá cumplir con todos los

códigos locales y/o requisitos de la compañía de servicio de

gas, o a falta de códigos locales, con el Código Nacional de

Combustibles ANSI Z223.1.

- Las distancias mínimas de separación de materiales de construcción combustibles mostradas en la Página 3 deberán mantenerse en todo momento.

INSTRUCCIONES DE ENCENDIDO

1. Conecte el cordón de alimentación en un cable de extensión de

tres (3) clavijas, de 120V, 60 Hz, debidamente conectado a

tierra.

Requisitos de tamaño de conductor del cordón de extensión:

1.8 a 3 metros (6 a 10 pies) de largo, utilice un conductor 18

AWG.

3.4 a 30.5 metros (11 a 100 pies) de largo, utilice un conductor

16 AWG.

30.8 a 61 metros (101 a 200 pies) de largo, utilice un conductor

14 AWG.

2. Conecte el calentador a un cilindro LP adecuado.

3. Gire la válvula de gas hacia la derecha a la posición OFF (apagado).

4. Espere cinco (5) minutos para que el gas presente se disipe.

Use el olfato para oler gas; si no huele gas, proceda al Paso 5.

5. Empuje hacia adentro la perilla de control del gas y gírela hacia

la izquierda a la posición LOW/IGN (Bajo/Ign). Esto encenderá

el quemador. Si es necesario, mantenga presionada la perilla

de control del gas hasta que el quemador se encienda y continúe presionando y girando de OFF a LOW/IGN en los modelos de chispa piezoeléctrica (HIGH/IGN en el Modelo HS-40GFA).

6. Mantenga la perilla de la válvula presionada por espacio de 30

segundos luego de que se encienda el quemador. Luego de

transcurridos 30 segundos, suelte la perilla de la válvula.

7. Si el quemador se apaga, repita el procedimiento de encendido.

8. Cuando el quemador permanezca encendido, gire la perilla de

la válvula de gas hacia la izquierda hasta el ajuste deseado

(todos los modelos, excepto el HS-40-GFA).

INSTRUCCIONES DE APAGADO

Para apagar el calentador:

1. Gire la perilla de la válvula de gas hacia la derecha a la posición OFF (apagado).

2. Gire hacia la derecha la válvula del tanque de propano para

cerrar la válvula y cortar el suministro de gas.

3. Desconecte el cordón de alimentación eléctrica.

INTENTE ENCENDER EL CALENTADOR

Intente encender su calentador para construcción de acuerdo con

las instrucciones de encendido aplicables al sistema de control de

gas empleado.

Someta todas las conexiones de gas a una prueba de fugas con

una solución de 50/50 de agua y jabón antes de encender el

calentador. Las burbujas de jabón indican que hay una fuga

de gas. NUNCA use un fósforo o una llama para comprobar si

hay fugas.

AVISO: La temperatura de la superficie del calentador deberá

estar fría antes de almacenar el calentador o iniciar el mantenimiento o la limpieza del mismo.

ALMACENAMIENTO

Nunca almacene un tanque de gas propano dentro de un edificio

o cerca de cualquier aparato que queme gas o aceite. Cuando el

tanque de propano no se desconecta del calentador

para uso en tareas de construcción, el tanque de gas y el calentador deben almacenarse afuera en un área bien ventilada y fuera

del alcance de los niños. Si por cualquier razón ha de almacenarse el calentador en un lugar interior, el tanque, primero se

debe desconectar y desmontar del conjunto de la base del calentador y almacenar en un área exterior bien ventilada y fuera del

alcance de los niños, de acuerdo con la más reciente edición de

la Norma para el almacenamiento y la manipulación de gases de

petróleo licuado ANSI/NFPA 58. El tapón de plástico de la válvula

del tanque suministrado con su tanque deberá estar firmemente

instalado cuando el tanque esté desconectado del calentador.

AVISO: Todo trabajo de inst

izado por un técnico de servicio calificado.

alación y reparación deberá ser real-

Pinnacle Products International, Inc. Manual del Propietario del Calentador de Propano Página 5

Page 14

NUNCA DEJE DESATENDIDO EL CALENTADOR

MIENTRAS ÉSTE ESTÉ ENCENDIDO, CONECTADO A UNA FUENTE DE ALIMENTACIÓN, O

MIENTRAS ESTÉ CONECTADO A UNA FUENTE

DE COMBUSTIBLE.

Diagramas eléctricos

Calentador para Uso en Tareas

de Construcción a Propano

Termocupla

Válvula de Control

Azul

Amarillo

Negro

Tierra

Amarillo

Interruptor

Térmico

Figura 2 – Modelos de Chispa Piezoeléctrica/Manual

Fusible

Conjunto de la

Placa de Circuitos

Impresos

Encendedor

Condensador

Tierra (Coraza)

Blanco

Azul

Arial

Negro

Blanco

Negro

Verde

Motor

Córdon de

Alimentación

Encendedor

Termocupla

Válvula de Control

Amarillo

Tierra

Interruptor

Térmico

Figura 3 – Modelos de Chispa Continua

Negro

Azul

Amarillo

Módulo de

Chispa

Fusible

Conjunto de la

Placa de Circuitos

Impresos

Azul

Azul

Condensador

Tierra (Coraza)

Blanco

Azul

Blanco

Negro

Blanco

Negro

Verde

Motor

Córdon de

Alimentación

Página 6 Pinnacle Products International, Inc. Manual del Propietario del Calentador de Propano

Page 15

NUNCA DEJE DESATENDIDO EL CALENTADOR

MIENTRAS ÉSTE ESTÉ ENCENDIDO, CONECTADO A UNA FUENTE DE ALIMENTACIÓN, O

MIENTRAS ESTÉ CONECTADO A UNA FUENTE

DE COMBUSTIBLE.

Tabla de Identificación de Problemas

Síntoma Causa(s) Posible(s) Medida Correctiva

El ventilador no gira

cuando se le conecta

la energía eléctrica

El calentador no se enciende

El calentador se apaga cuando está funcionando

1. El calentador no recibe alimentación

eléctrica.

2. El aspa del ventilador hace contacto con

la parte interior del alojamiento del

calentador

3. El aspa(s) del ventilador está doblada

4. El motor del ventilador está defectuoso

1. No hay chispa en el encendedor

2. Separación de chispa incorrecta

3. Electrodo dañado

1. La temperatura interior es demasiado

alta y causa que el interruptor limitador

apague la unidad

2. Válvula de control dañada

3. Hay polvo o restos de material acumulados dentro del calentador

1. Verifique la corriente en el tomacorriente. Si

el voltaje es correcto, inspeccione el cordón de alimentación para ver si está cortado o está roto

2. Asegúrese que el alojamiento no esté dañado.

Asegúrese que el ventilador no esté obstruido

3. Enderece el aspa(s) para que quede como

las otras

4. Reemplace el motor

1. Inspeccione el conductor del encendedor.

Reconéctelo o apriételo si está suelto. Revise

el módulo de chispa. Reemplace según sea necesario. Revise todos los componentes eléctricos

2. Ajuste la separación a 4.1 mm (0.16 pulg.)

3. Reemplace la bujía

1. Si se restringe la salida del calentador,

la temperatura interior sube demasiado.

Mueva el calentador lejos de toda

obstrucción

2. Reemplace la válvula de control

3. Limpie el interior del calentador

Calentador para Uso en Tareas

de Construcción a Propano

Pinnacle Products International, Inc. Manual del Propietario del Calentador de Propano Página 7

Page 16

de Construcción a Propano

Calentador para Uso en Tareas

13

14

17

16

15

20

25

28

19

5

23

22

12

27

1

21

4

3

24

8

7

26

18

6

9

11

10

2

NUNCA DEJE DESATENDIDO EL CALENTADOR

Dibujo de despiece de piezas

DE COMBUSTIBLE.

TADO A UNA FUENTE DE ALIMENTACIÓN, O

MIENTRAS ESTÉ CONECTADO A UNA FUENTE

MIENTRAS ÉSTE ESTÉ ENCENDIDO, CONEC-

Página 8 Pinnacle Products International, Inc. Manual del Propietario del Calentador de Propano

Figura 4 – IIlustración de las Partes de Reparación para el Calentador para Uso en Tareas de Construcción a Propano

Page 17

NUNCA DEJE DESATENDIDO EL CALENTADOR

MIENTRAS ÉSTE ESTÉ ENCENDIDO, CONECTADO A UNA FUENTE DE ALIMENTACIÓN, O

MIENTRAS ESTÉ CONECTADO A UNA FUENTE

DE COMBUSTIBLE.

Calentador para Uso en Tareas

de Construcción a Propano

Lista de Partes de Reparación para el Calentador para Uso en Tareas de Construcción a Propano

Número de Número de Parte para Modelos:

Referencia Descripción HS-40-GFA HS-50V-GFA HS-100V-GFA HS-150V-GFA

1 Coraza exterior 22-524-0050 22-524-0060 22-524-0070 22-524-0070

2 Conjunto de la coraza interior 22-524-0004 22-524-0004 22-524-0005 22-524-0005

3 Base 22-501-0003 22-501-0001 22-501-0002 22-501-0002

4 Controlador de altura 22-512-0005 22-512-0005 22-512-0008 22-512-0008

5 Cubierta de la base 22-508-0003 22-508-0001 22-508-0002 22-508-0002

6 Tapa de la coraza interior 22-505-0006 22-505-0006 22-505-0007 22-505-0008

7 Conjunto de soportes múltiples 22-504-0002 22-504-0002 22-504-0003 22-504-0003

8 Interruptor térmico 22-603-0001 22-603-0001 22-603-0001 22-603-0001

9 Conjunto de tuberías 22-605-0001 22-605-0001 22-605-0005 22-605-0005

10 Boquilla 22-081-0007 22-081-0008 22-081-0009 22-081-0004

11 Tuerca de la boquilla 22-518-0001 22-518-0001 22-518-0001 22-518-0002

12 Asidero 22-511-0004 22-511-0005 22-511-0005 22-511-0005

13 Tuerca hexagonal de pestaña 22-518-0003 22-518-0003 22-518-0003 22-518-0003

14 Ventilador 22-514-0001 22-514-0001 22-514-0002 22-514-0002

15 Bloque de cojín 22-509-0001 22-509-0001 22-509-0001 22-509-0001

16 Conjunto del motor 22-061-0015 22-061-0015 22-061-0016 22-061-0016

17 Protección 22-101-0003 22-101-0003 22-101-0004 22-101-0004

18 Perno redondo 22-503-0002 22-503-0002 22-503-0003 22-503-0003

19 Conjunto de la válvula 22-011-0005 22-011-0006 22-011-0007 22-011-0008

20 Conector de entrada 22-507-0003 22-507-0003 22-507-0003 22-507-0003

21 Módulo de chispa – 22-604-0005 22-604-0005 22-604-0005

22 Conjunto de la placa de circuitos impresos 22-521-0001 22-521-0002 22-521-0002 22-521-0002

23 Caja de la placa de circuitos impresos 22-506-0001 22-506-0001 22-506-0001 22-506-0001

24 Perilla de la válvula 22-516-0001 22-516-0001 22-516-0001 22-516-0001

25 Conjunto del cordón de alimentación 22-131-0001 22-131-0001 22-131-0001 22-131-0001

26 Cable del interruptor térmico 22-601-0001 22-601-0001 22-601-0001 22-601-0001

27 Tuerca hexagonal 22-518-0004 22-518-0004 22-518-0004 22-518-0004

28 Conjunto del regulador 22-041-0004 22-041-0004 22-041-0005 22-041-0005

Pinnacle Products International, Inc. Manual del Propietario del Calentador de Propano Página 9

Page 18

NUNCA DEJE DESATENDIDO EL CALENTADOR

MIENTRAS ÉSTE ESTÉ ENCENDIDO, CONECTADO A UNA FUENTE DE ALIMENTACIÓN, O

MIENTRAS ESTÉ CONECTADO A UNA FUENTE

DE COMBUSTIBLE.

Calentador para Uso en Tareas

de Construcción a Propano

GARANTÍA LIMITADA DE 1 AÑO

Pinnacle Products International, Inc. garantiza este

calentador al comprador minorista original solamente

con respecto a lo siguiente: que estará libre de defectos

de material y de mano de obra por un período de un (1)

año a partir de la fecha de compra original. Este producto

debe instalarse, mantenerse y operarse correctamente

de acuerdo con las instrucciones suministradas.

Pinnacle Products International, Inc. requiere una

prueba razonable de su fecha de compra de un minorista

o distribuidor autorizado. Por lo tanto, usted debe guardar

su recibo de venta, factura o el cheque cancelado de la

compra original. Esta Garantía limitada estará limitada

a la reparación o el reemplazo de piezas que se comprueben están defectuosas bajo un uso y mantenimiento

normal dentro del período de la garantía, y que Pinnacle

Products International, Inc. determinará a su discreción

razonable.

Esta garantía no se aplica a los productos adquiridos

para uso alquilado.

Esta Garantía limitada no cubre ningún fallo ni dificultad

de funcionamiento debido a un desgaste normal, accidente, abuso, mal uso, alteración, aplicación incorrecta,

instalación incorrecta o un mantenimiento y servicio inadecuados realizados por usted o cualesquiera terceros.

Asimismo, la garantía no cubre los siguientes: la falta

de realizar los mantenimientos normales y de rutina en

el calentador, daños de envío, daños relacionados con

los insectos, aves o animales de cualquier tipo, y daños

debido a las condiciones climáticas. Adicionalmente,

la Garantía limitada no cubre daños del acabado, como

rayaduras, abolladuras, cambios de color, oxidación

u otros daños climáticos, después de la compra.

El comprador será responsable de todos los gastos de

transportación para la devolución del producto dañado

o piezas dañadas. Al recibir el artículo dañado, Pinnacle

Products International, Inc. lo examinará y determinará

si está defectuoso. Pinnacle Products International, Inc.

reparará o reemplazará y devolverá el artículo con porte

pagado. Si Pinnacle Products International, Inc. determina que el artículo está en condición normal de funcionamiento o no defectuoso, el artículo será devuelto

con flete por pagar.

Esta Garantía limitada sustituye toda otra garantía expresa.

Pinnacle Products International, Inc. excluye todas las

garantías de los productos comprados de otros vendedores que no sean minoristas o distribuidores autorizados.

DESPUÉS DEL VENCIMIENTO DEL PERÍODO DE UN (1)

AÑO DE LA GARANTÍA LIMITADA, Pinnacle Products

International, Inc. EXCLUIRÁ CUALESQUIERA Y TODAS

LAS GARANTÍAS IMPLÍCITAS, INCLUYENDO SIN

LIMITACIÓN, LAS GARANTÍAS IMPLÍCITAS DE

COMERCIABILIDAD Y ADECUACIÓN PARA UNA

APLICACIÓN EN PARTICULAR. ADEMÁS, Pinnacle

Products International, Inc. NO ASUME NINGUNA

RESPONSABILIDAD ANTE EL COMPRADOR O

CUALQUIER TERCERO POR CUALESQUIERA DAÑOS

ESPECIALES, INDIRECTOS, PUNITIVOS, INCIDENTALES O CONSECUENTES. Pinnacle Products

International, Inc. no asume ninguna responsabilidad

por cualquier defecto causado por terceros. Esta Garantía

limitada le otorga derechos legales específicos al comprador,

y es posible que el comprador tenga otros derechos,

dependiendo del lugar donde vive. Algunos Estados no

permiten la exclusión ni limitación de daños especiales,

incidentales o consecuentes, ni limitaciones de la duración

de una garantía; por lo que es posible que la exclusión

y las limitaciones anteriores no se apliquen a usted.

Pinnacle Products International, Inc. no autoriza a

ninguna persona o compañía a asumir a nombre de ella

cualquier otra obligación o responsabilidad relacionada

con la venta, instalación, uso, desmontaje, devolución o

reemplazo de su equipo y ninguna tal representación será

obligatoria para Pinnacle Products International, Inc.

Siempre asegúrese de especificar el número de modelo y

el número de serie cuando presente reclamos a Pinnacle

Products International, Inc. Para su conveniencia, use

el espacio suministrado a continuación para escribir

esta información:

Número de modelo: ____________________

Número de serie: ______________________

Fecha de compra: _____________________

Page 19

Manuel du propriétaire et

Radiateurs propane à

instructions d'utilisation

air pulsé

Modèles No: HS-40-GFA, HS-50V-GFA,

HS-100V-GFA, HS-150V-GFA

Veuillez lire et conserver ces instructions. Lire attentivement avant de commencer à assembler, installer, faire fonctionner ou entretenir l'appareil décrit. Protégez-vous et les autres en observant toutes les informations sur la sécurité.

Négliger d'appliquer ces instructions peut résulter en des blessures corporelles et/ou en des dommages matériels

HS-40-GFA, HS-50V-GFA et PT-150V-GFA sont homologués CSA aux É-U et au Canada.

HS-100V-GFA sont homologués aux É-U seulement.

CONSOMMATEUR : Conserver ce manuel pour consultation ultérieure.

Pinnacle Products International, Inc. 668 Stony Hill Road #302 Yardley, PA 19067 USA

Téléphone : (800) 641-6996 Télécopieur : 215-891-846

Web : www.pinnacleint.com Courriel : info@pinnacleint.com

Page 20

NE JAMAIS LAISSER UN RADIATEUR

SANS SURVEILLANCE LORSQU'IL

BRÛLE OU LORSQU'IL EST BRANCHÉ À

UNE SOURCE D'ALIMENTATION.

Spécifications

Radiateurs propane à

air pulsé

Modèle

HS-40-GFA 40 000 Btu/h 0,86 kg/h 120V, 60 Hz 267 mm CE 0,60 6,9 (15,2) 46,0 x 19,6 x 32,5

HS-50V-GFA

HS-100V-GFA

HS-150V-GFA

Spécifications

Débit

calorifique

70 000 à 100

000 Btu/h

30 000 à 50

000 Btu/h

120 000 à 150

000 Btu/h

Déballage

1. Déballer tous les articles appliqués au radiateur pour l’expédition. Garder les capuchons en plastique attachés

à l'ensemble connecteur d'entrée et tuyau/régulateur pour l'entreposage.

2. Enlever tous les articles du carton.

3. Vérifier qu’aucun article n’a été endommagé pendant le transport. Si le radiateur est endommagé, informer immédiatement

le détaillant qui vous l’a vendu.

Consommation

de gaz

0,64 à 1,04 kg/h 120V, 60 Hz 254 mm CE 0,60 6,9 (15,2) 46,0 x 19,6 x 32,5

1,50 à 2,09 kg/h 120V, 60 Hz 241 mm CE 0,80 10,3 (22,7) 63,8 x 22,9 x 39,4

2,54 à 3,18 kg/h 120V, 60 Hz 203 mm CE 0,80 10,3 (22,7) 63,8 x 22,9 x 39,4

Entrée

électrique

Pression du

distributeur

- Un robinet d’arrêt au bout de la sortie du robinet de la bouteille

de propane, comme spécifié dans les normes américaines

pour les sorties et les entrées de robinets d’évacuation pour

bouteille de gaz.

- Une soupape de sûreté en communication directe avec l’espace de vapeur du réservoir.

- Un dispositif de retrait de vapeur.

REMARQUE : Le régulateur de pression et le tuyau du GPL fournis avec ce radiateur doivent être utilisés sans être modifiés.

Ampérage

Poids

kg (lb)

Dimensions

L x lar x H (cm)

Caractéristiques du produit

- Portable, stable et entièrement assemblé.

- Résistant au vent et protégé contre la pluie.

- Allumage à étincelle continue ou piézo.

- Système de fermeture entièrement sécuritaire.

- Débit calorifique réglable.

INFORMATIONS SUR LE PROPANE

Le réservoir de GPL doit aussi être équipé des accessoires suivants :

- Un collier qui protège le robinet de gaz

Informations générales sur la sécurité

Indique un danger imminent qui, s’il

n’est pas évité ENTRAÎNERA la mort ou

des blessures graves.

Indique un danger potentiel qui, s’il

n’est pas évité PEUT entraîner la mort

ou des blessures graves.

Indique un danger potentiel qui, s’il

n’est pas évité POURRAIT entraîner la

mort ou des blessures graves.

Enveloppe

Outer Shell

Ensemble d'enveloppe

Figure 1. Caractéristiques du produit

extérieure

Inlet Shell

intérieure

Height Controller

Contrôleur de hauteur

Protection

Guard

Bouton de robinet

Gas Valve Knob

Base

Base

Page 2 Pinnacle Products International, Inc. Manuel du propriétaire pour radiateur propane à air pulsé

Page 21

NE JAMAIS LAISSER UN RADIATEUR

SANS SURVEILLANCE LORSQU'IL

BRÛLE OU LORSQU'IL EST BRANCHÉ À

UNE SOURCE D'ALIMENTATION.

Radiateurs propane à

air pulsé

Informations générales sur la sécurité (suite)

AVERTISSEMENT

instructions fournies avec ce radiateur peut entraîner la

mort, des blessures graves, des pertes ou des dommages

matériels suite aux risques d’incendie, d’explosion, de

brûlures, d’asphyxie, d’empoisonnement au monoxyde de

carbone et ou de décharge électrique. Seules des personnes

aptes à comprendre et suivre ces instructions doivent utiliser ou entretenir ce radiateur. Contacter le fabricant en cas de

besoin de manuel d’instructions, d’étiquettes, etc.

AVERTISSEMENT

bustibles solides, comme les matériaux de construction, le

papier ou le carton, à une distance sécuritaire du radiateur,

suivant les recommandations de ce manuel. Ne jamais utiliser le radiateur dans des endroits qui contiennent ou pourraient contenir des matières combustibles volatiles ou en

suspension dans l’air, ou encore des produits comme

l’essence, les solvants, les diluants à peinture, les particules

de poussière ou des produits chimiques inconnus.

Consommateur : Conserver ces instructions pour consultation ultérieure.

DANGER

mortelles suite à des brûlures, un incendie, une explosion, une

décharge électrique et/ou un empoisonnement au monoxyde

de carbone.

Ce radiateur est conçu pour les sites de construction en conformité avec ANSI Z83.7a/CSA2.14a-2007. D'autres normes régissent l'utilisation des gaz combusti bles et des produits de

chauffage pour des utilisations spécifiques. Les autorités locales

peuvent vous informer sur ces dernières. La fonction principale

des radiateurs de construction est de fournir un moyen de

chauffage temporaire des édifices en construction ou en réparation. Lorsqu’ils sont utilisés correctement, ils permettent de chauffer de manière économique. Les produits de la combus tion sont

ventilés dans l’aire chauffée.

AVERTISSEMENT

AVERTISSEMENT

de sécurité et d’utilisation. Le non respect des précautions

et des instructions fournies avec ce radiateur peut entraîner

la mort, des blessures graves, des pertes ou des dommages

matériels suite aux risques d’incendie, d’explosion, de

brûlures, d’asphyxie ou d’empoisonnement au monoxyde de

carbone. Seules des personnes aptes à comprendre et suivre ces instructions doivent utiliser ou entretenir ce radiateur.

AVERTISSEMENT

monoxyde de carbone, un produit chimique reconnu par l’État de Californie pour causer le cancer, des anomalies congénitales ou d’autres effets nocifs sur la reproduction.

AVERTISSEMENT

L’ensemble des tuyaux doit être protégé contre le trafic, les

matériaux de construction et un contact avec des surfaces

chaudes, durant l’utilisation et pendant l’entreposage.

Avertissement général de danger : Le

non respect des précautions et des

Risque d’incendie, de brûlure, d’inhalation et d’explosion. Garder les com-

L’utilisation inappropriée de ce radiateur

peut causer des blessures graves ou

N’est pas conçu pour un usage résidentiel ou dans un véhicule de plaisance.

Ne pas utiliser ce radiateur avant d’avoir

lu et entièrement compris ces directives

Les sous-produits de combustion

dégagés par cet appareil

N’est pas conçu pour un usage résidentiel ou dans un véhicule de plaisance.

contiennent du

IMPORTANT : Lire ce manuel de l'utili sa teur attentivement et

complètement avant de tenter de faire fonctionner ou d'entretenir

de radiateur. L’utilisation inappropriée de ce radiateur peut causer

des blessures graves ou mortelles suite à un incendie, une explosion et un empoisonnement au monoxyde de carbone.

Il est impossible de prévoir toutes les circonstances susceptibles

de présenter des risques. Les avertissements dans ce manuel et

ceux apposés sur l’appareil ne sont donc pas complets. Si on

utilise une procédure, une méthode de travail ou une technique

d'utilisation qui n’est pas spécifiquement recommandée par

Pinnacle, on doit s'assurer qu’elle est sûre pour soi et pour les

autres.

S’assurer également que l’équipement ne sera pas endommagé

ou rendu non sécuritaire par la méthode d'utilisation ou d’entretien

choisie. VÉRIFIER AVEC LE SERVICE LOCAL DES INCENDIES

SI L'ON A DES QUESTIONS SUR L'APPLICATION. Ce radiateur

est conçu et homologué pour une utilisation comme radiateur de

construction sous ANSI Z83.7.

D'autres normes régissent l'utilisation des gaz combustibles et

des produits de chauffage pour des applications spécifiques. Les

autorités locales peuvent vous informer sur ces dernières.

Ce radiateur de construction est de type direct, à air pulsé, utilisable à l'intérieur ou à l'extérieur. Il est surtout conçu pour le

chauffage temporaire des édifices en construction, réfection ou

réparation. Tous les produits de combustion générés par ce radiateur sont pulsés à travers celui-ci et expulsés dans la zone

réchauffée. Ce radiateur fonctionne à une efficacité de combus tion d’environ 98 %+, mais produit encore de petites quantités de

mon oxyde de carbone. Les humains peuvent tolérer de petites

quantités de monoxyde de carbone pendant de courtes périodes

de temps. Le monoxyde de carbone peut s’accumuler dans un

espace chauffé, et le fait de négliger de garantir une ventilation

adéquate peut causer un empoisonne ment ou la mort.

INFORMATIONS IMPORTANTES SUR LA SÉCURITÉ

- Garder les enfants loin.

- Toujours maintenir un dégagement adéquat des matériaux

combustibles. Le dégagement minimal doit être de :

Côtés – 61 cm, Dessus – 91,4 cm, Avant – 183 cm.

- Placer le radiateur sur une base solide et de niveau.

- Ne placer aucun objet, y compris des vêtements ou d’autres

articles inflammables sur le radiateur.

- Ne pas modifier le radiateur ou utiliser un radiateur qui a été

modifié.

- Maintenir un dégagement adéquat pour l'accessibilité, la combustion et la ventilation (alimentation en air) en tout temps

lorsque le radiateur fonctionne.

Pinnacle Products International, Inc. Manuel du propriétaire pour radiateur propane à air pulsé Page 3

Page 22

NE JAMAIS LAISSER UN RADIATEUR

SANS SURVEILLANCE LORSQU'IL

BRÛLE OU LORSQU'IL EST BRANCHÉ À

UNE SOURCE D'ALIMENTATION.

Radiateurs propane à

air pulsé

Informations générales sur la sécurité (suite)

- L'entretien et les réparations doivent être effectués par du personnel de service qualifié. Ce radiateur doit être inspecté avant

chaque utilisation et au moins une fois par année par du personnel qualifié. Un nettoyage plus fréquent peut être requis si

nécessaire. Ne pas réparer un radiateur chaud ou qui fonctionne.

- Ne jamais connecter le radiateur à une alimentation en gaz

sans régulation.

- Ce radiateur est expédié de l’usine pour être utilisé avec du

gaz propane (GPL) seulement. Ne pas convertir vers un quelconque autre gaz. L’installation doit être conforme aux codes

locaux, ou en leur absence, avec la norme du Storage and

Handling of Liquefied Petroleum Gases ANSI/NFPA 58.

- N’utiliser que l’ensemble régulateur et tuyau fournis avec ce

radiateur. Inspecter l’ensemble régulateur/tuyau avant chaque

utilisation du radiateur. Si l’abrasion ou l’usure est excessive,

ou si le tuyau est coupé, le remplacer par l’ensemble qui convient, illustré dans la liste des pièces, avant d’utiliser le radiateur.

- Vérifier les connexions d’alimentation en gaz avec une solution

de 50/50 d'eau et de savon. Ne jamais utiliser de flamme pour

flamme pour vérifier la présence de fuites de gaz.

- Placer la bouteille de propane à au moins 1,8 m du radiateur et

ne pas diriger l'évacuation du radiateur vers la bouteille de gaz

à moins que celle-ci ne soit à au moins 6 m du radiateur.

- La connexion électrique et la mise à la terre doivent être conformes au Code national de l’électricité, ANSI/NFPA 70.

N’utiliser qu’une prise à trois (3) trous correctement mise à la

terre.

- Ne placer aucun obstacle à l’avant ni à l’arrière du radiateur.

Nombre de réservoirs requis

Température (°C)

au niveau du

réservoir

0,0 1

-6,6 1

-12,2 1

-17,7 1

-23,3 2

-28,8 2

Le tableau ci-dessus affiche le nombre de réservoirs de 45,4 kg requis pour

faire fonctionner les radiateurs à des températures données.

Une plus petite quantité de gaz est vaporisée à des températures plus basses.

Deux réservoirs supplémentaires de plus de 45,4 kg ou un réservoir plus gros

peuvent s'avérer nécessaires par temps plus froid. Votre détaillant local de gaz

propane vous aidera à sélectionner le système d’alimentation qui convient.

40 000 à 50

000 BTU/h

100 000 BTU/h 150 000 BTU/h

2 2

2 2

3 3

3 3

Utiliser un réser-

voir plus gros

Utiliser un réser-

voir plus gros

Utiliser un réser-

voir plus gros

Utiliser un réser-

voir plus gros

Fonctionnement

REMPLISSAGE DU RÉSERVOIR DE GAZ PROPANE

TOUTES LES NOUVELLES BOUTEILLES DOIVENT ÊTRE

PURGÉES AVANT D’ÊTRE REMPLIES DE NOUVEAU.

La purge et le remplissage des réser-

du personnel entièrement formé aux procédures acceptées

dans l’industrie du GPL. La non-conformité à ces directives

peut entraîner une explosion, un incendie, des blessures

graves ou mortelles.

- Tourner les boutons des robinets de gaz du radiateur et du

réservoir à la position d'arrêt (OFF).