Heatilator GCBC36LE Installation Instructions Manual

INSTALLATION INSTRUCTIONS

Flip manual over for “Operating and Maintenance Instructions.”

CALIBER SERIES B-VENT SERIES

DECORATIVE GAS APPLIANCE

Read these installation instructions completely

before beginning installation. Failure to follow

them could cause an appliance malfunction resulting in serious injury and/or property damage.

TABLE OF CONTENTS

I. INSTALLATION

Preparation..............................................................

A.

Location and Clearances.........................................

B.

Framing....................................................................

C.

Set The Unit.............................................................

D.

Venting.....................................................................

E.

Utilities.....................................................................

36” and 42” Series

U.S. Patent 5,613,487

F.

Finishing...................................................................

G.

Firebox Preparation.................................................

H.

3

4

5

5

6

12

14

14

FOR YOUR SAFETY

What to do if you smell gas:

• Do not try to light any

appliance.

• Do not touch any electrical

switch.

• Do not use any phone in

your building.

• I m m e d i a t e ly call your gas

supplier from a neighbor’s

p h o n e. Follow the gas

supplier’s instructions.

• If you cannot reach yo u r

gas supplier, call the fire

department.

Heatilator 1915 W. Saunders Street Mt. Pleasant, IA 52641 a HON INDUSTRIES company

FOR YOUR SAFETY

Do not store or use

gasoline or other

f l a m m a ble va p o rs

and liquids in the

vicinity of this or any

other appliance.

WARNING

I m p roper installation,

adjustment, alteration,

s e rvice or maintenance can cause

i n j u ry or pro p e rt y

damage. Refer to this

m a nual. For assistance or add i t i o n a l

i n formation, consult a

qualified installer, service agency or the gas

supplier.

A. PREPARATION

12-97 2i 28887A

U.S. and Canada Certification

The CALIBER Series Gas Appliance has been tested

in accordance with the ANSI standard Z21.50-1996

(Decorative). In Canada, the current CAN/CGA 2.22M96, IR41, P4, and IR55 and have been LISTED by

Underwriters Laboratories Inc. for installation as

described in this manual. All components are UL,

AGA, CGA or CSA safety certified.

Local Codes

This installation must conform with local codes. In the

absence of local codes comply with the National Fuel

Gas Code, ANSI Z223.1-latest edition, in the U.S.A.

and the CAN/CGA B149, Installation Codes, in

Canada.

For assistance during installation contact your local

dealer or contact Heatilator Customer Relations

Department, 1915 W. Saunders Street, Mt. Pleasant,

Iowa 52641.

HEATILATOR®is a registered trademark of Hearth

Technologies, Inc., a HON INDUSTRIES company.

Note: Minimum and maximum clearances must

be maintained at all times. Illustrations

throughout these instructions reflect typical

installations and are for design purposes only.

Actual installation may vary slightly due to individual design preferences.

The illustrations and diagrams used throughout

these installation instructions are not drawn to

scale.

Tools and building supplies normally

required for installation:

Saw Wall-finishing materials

Pliers Framing material

Hammer Fireplace surround

Phillips screwdriver Caulking material

Tape measure Gloves

Plumb line Square

Level Electrical drills/bits

CALIBER Nomenclature

Catalog Number Description

GCBC36LE Appliance Order Code Number

GC Gas Caliber

B B-Vent

C Circulating

36 36 - 36” Unit

42 - 42” Unit

LE No suffix - Standing Pilot, Natural Gas

L - Standing Pilot, Propane Gas

E - Electronic Ignition, Natural Gas

LE - Electronic Ignition, Propane Gas

GCBC36LERF Appliance Order Code Number with Upgrade Code Number

R Refractory Upgrade

F Fan Kit Upgrade

EXAMPLE

GCBC36LERF Gas CALIBER, B-Vent, Heat Circulating, 36”, Propane Gas, Electronic Ignition

unit with Refractory and Fan Kit Upgrades.

12-97 3i 28887A

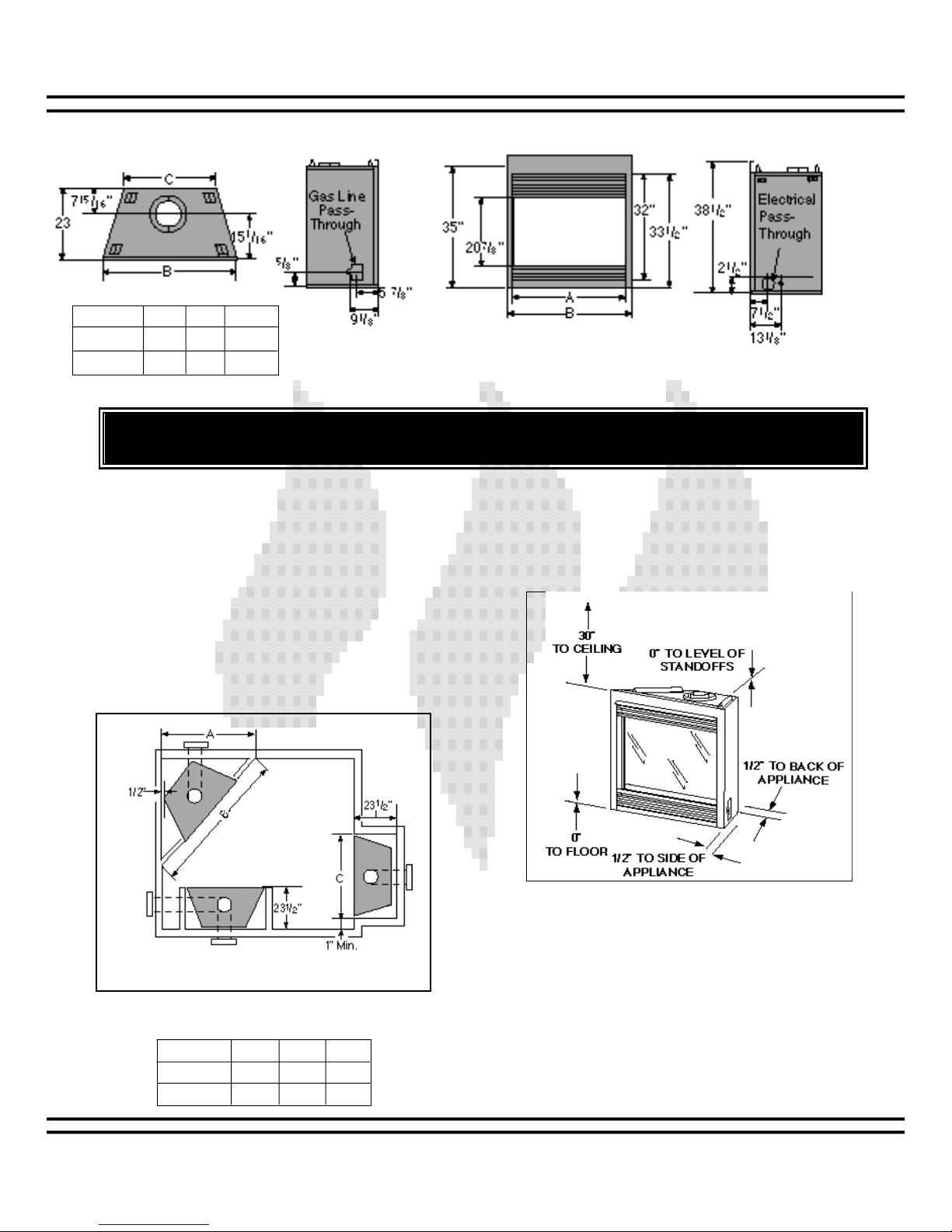

B. LOCATION AND CLEARANCES

Model A B C

36" Series 36" 41" 241/2"

42" Series 42" 47" 301/2"

DUE TO HIGH TEMPERATURES, THE APPLIANCE SHOULD BE LOCATED OUT OF TRAFFIC AND

AWAY FROM FURNITURE AND DRAPERIES.

Left Hand

Side

Unit Dimensions

Right Hand

Side

1. APPLIANCE LOCATIONS AND SPACE

REQUIREMENTS

Figure 1 illustrates a variety of ways the appliance

may be located in a room. The CALIBER Series may

be installed directly on the floor or raised on a hearth.

These appliances are certified for installation in a bedroom or a bed/sitting room in the U.S. and Canada

provided that the bedroom or bathroom have a volume

of at least 1500 cubic feet.

Common venting of this gas appliance with other gas

appliances is NOT allowed in multi-family dwellings.

2. CLEARANCES

Figure 2 shows all clearances that must be maintained around the appliance. See page 9 for termination cap clearances. See Figures 4 and 15

for vent clearances.

Figure 2

Appliance Clearances to Combustible Materials

A hearth extension is not required for this appliance.

Figure 1

Appliance Locations

Model A B C

36" Series 505/8" 715/8" 42"

42" Series 551/4" 775/8" 48"

12-97 4i 28887A

C. FRAMING

Figure 3

Framing

Figure 3 shows a typical framing of this appliance

using combustible materials. All required clearances

to combustibles must be adhered to.

*** from base of appliance

CAUTION

WEAR GLOVES AND SAFETY GLASSES

FOR PROTECTION.

CAUTION

PROVIDE ADEQUATE CLEARANCES

AROUND THE AIR OPENINGS INTO THE

COMBUSTION CHAMBER AND ADEQUATE

ACCESSIBILITY CLEARANCES FOR SERVICING AND PROPER OPERATION.

Model 36" Series 42" Series

A 421/4" 481/4"

D. SETTING THE UNIT

1. Positioning the firebox

This appliance may be placed on a smooth

combustible or noncombustible continuous, flat

surface. When the appliance is installed direct-

ly on carpeting, tile or other combustible material

other than wood flooring, the appliance shall be

installed on a metal or wood panel extending the

full width and depth of the appliance.

unit into position and level the appliance from

Slide the

side-to-side and front-to-back. Shim with noncombustible material as necessary.

Secure the appliance by bending out the nailing

flanges on each side of the appliance and nail to

framing. The nailing flanges have been positioned

5/8" back from the front of the unit to allow the addition of drywall.

12-97 5i 28887A

12-97 6i 28887A

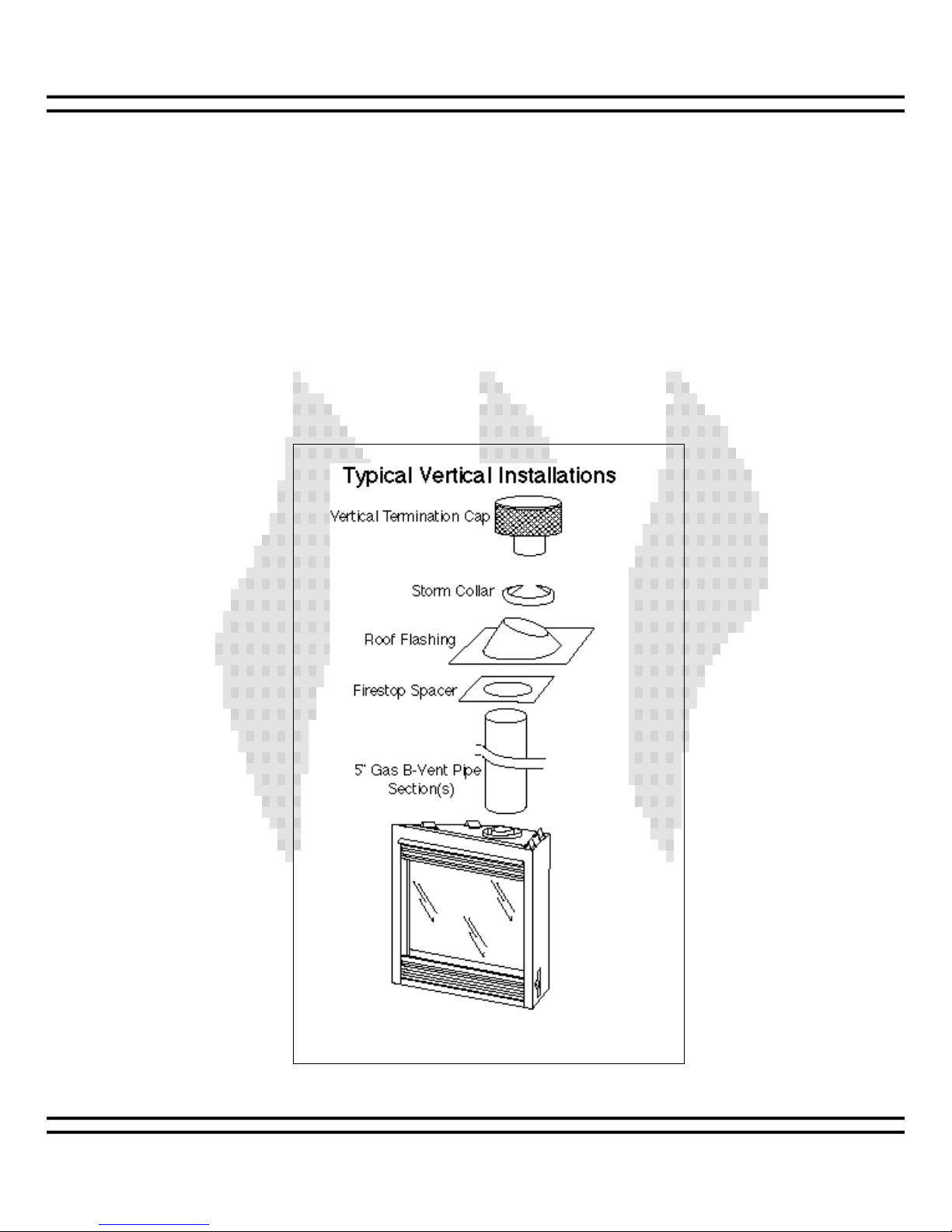

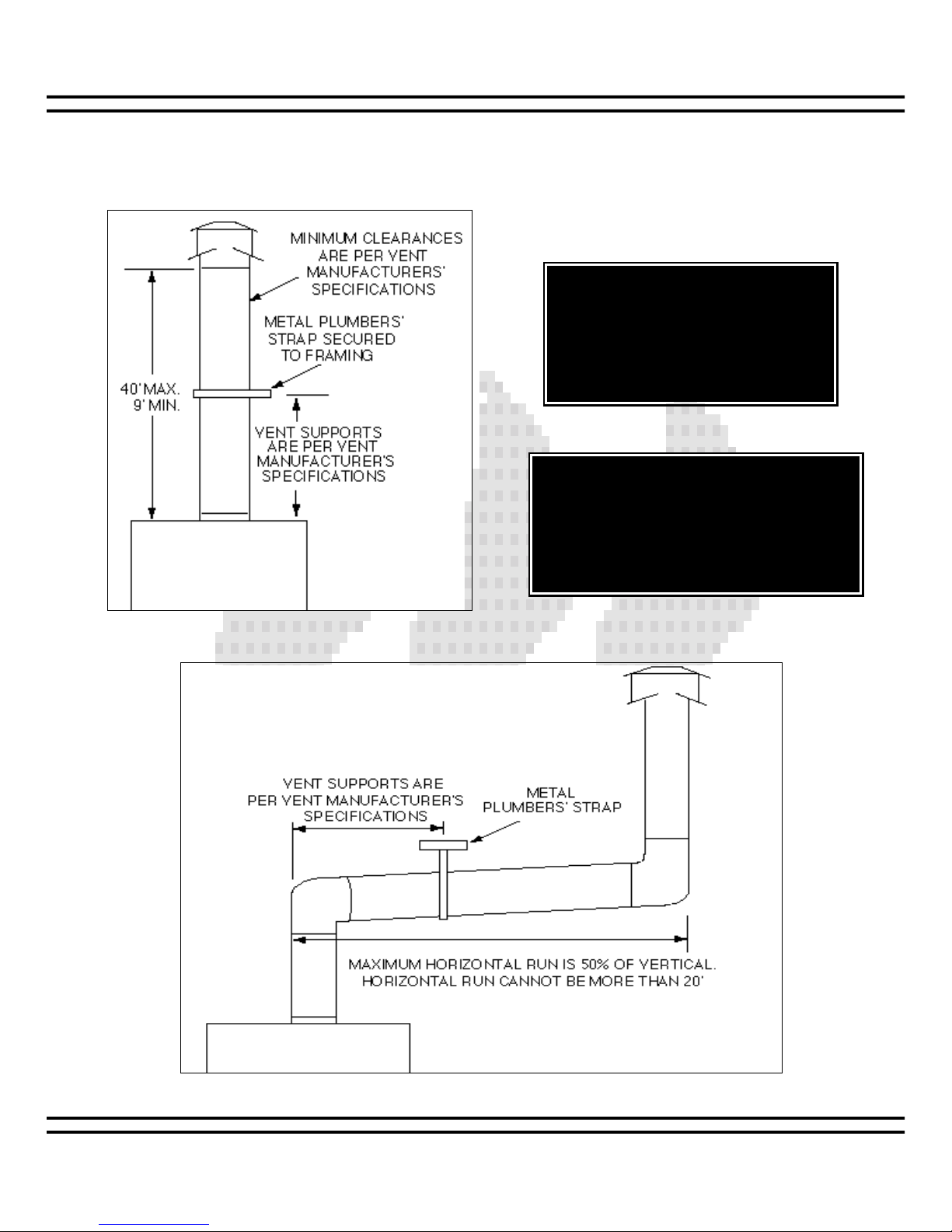

E. VENTING

NOTE: THIS APPLIANCE REQUIRES A 5 INCH B-VENT FOR OPERATION. NEVER DOWNSIZE PIPE.

a. Clearances. See Figure 4 for clearance information.

b. Vent Lengths. Various venting configurations are

shown in Figures 5 and 6 from which maximum vent

runs can be determined.

WARNING - RISK OF FIRE

ALWAYS MAINTAIN MINIMUM CLEARANCES OR GREATER AROUND THE

VENT SYSTEM. DO NOT PACK AIR

SPACES WITH INSULATION OR OTHER

MATERIAL.

WARNING

THE HORIZONTAL RUN OF VENT MUST HAVE

A 1/4" RISE FOR EVERY 1 FT. OF RUN

TOWARDS THE TERMINATION. NEVER

ALLOW THE VENT TO RUN DOWNWARD.

THIS COULD CAUSE HIGH TEMPERATURES

AND MAY CREATE A FIRE HAZARD.

Figure 4

Vertical Termination Clearances

Figure 5

Vertical Termination Vent Lengths

12-97 7i 28887A

Figure 7

Vent Height for Vertical Termination

Table 1

Vent Height

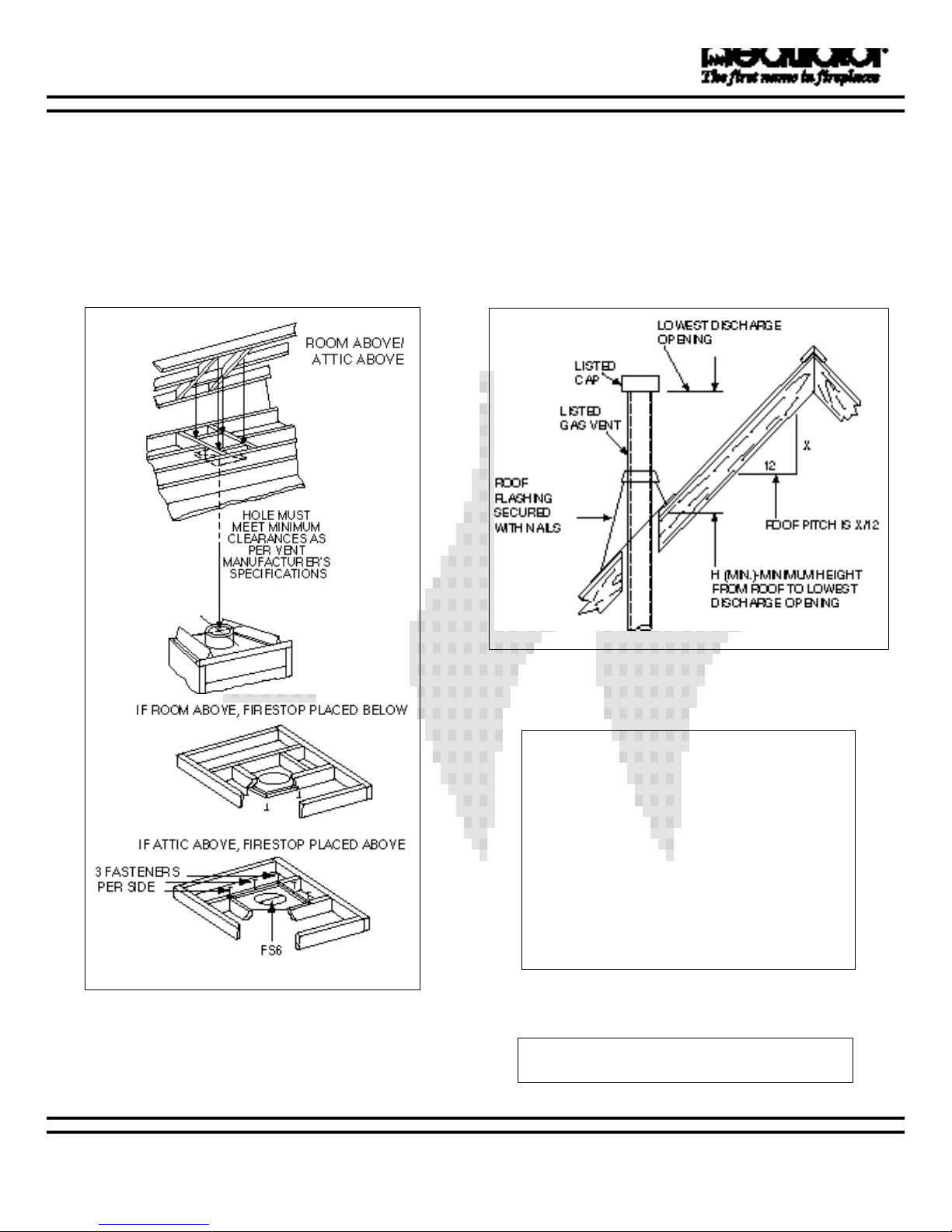

c. Firestop Spacer/Vent Installation.

Frame an opening and install a firestop spacer whenever the vent penetrates a ceiling/floor area, as

shown in Figure 6. Frame the opening with the same

sized lumber as used in the ceiling/floor joists. Unless

the flue is offset, the hole should be directly above the

appliance. DO NOT pack insulation around the vent.

Assemble vent sections with three screws per joint.

d. Chase/Termination Installation. Figure 7 a n d

Table 1 specify minimum vent heights for various

pitched roofs. Vent sections may have to be cut to a

certain length.

These vent heights are necessary for safety and do

not ensure draft-free operation. Trees, buildings,

adjoining roof lines, adverse conditions, etc., may

create a need for a taller vent should down drafting

occur.

Figure 6

Installing the firestop spacer

Roof Pitch H (Min.) Ft.

Flat to 6/12 ...........................................1.0

6/12 to 7/12 ..........................................1.25

Over 7/12 to 8/12..................................1.5

Over 8/12 to 9/12..................................2.0

Over 9/12 to 10/12................................2.5

Over 10/12 to 11/12..............................3.25

Over 11/12 to 12/12..............................4.0

Over 12/12 to 14/12..............................5.0

Over 14/12 to 16/12..............................6.0

Over 16/12 to 18/12..............................7.0

Over 18/12 to 20/12..............................7.5

Over 20/12 to 21/12..............................8.0

Note: To ensure proper operation, verify all

venting and the termination is unobstructed.

Loading...

Loading...