Page 1

Installation & Operating Manual

The BH 105 Pellet Boiler

“Ce manuel est disponible en Français sur demande”

R9

SAFETY NOTICE

PLEASE READ THIS ENTIRE MANUAL BEFORE YOU INSTALL AND USE YOUR NEW BOILER. FAILURE TO FOLLOW

INSTRUCTIONS MAY RESULT IN PROPERTY DAMAGE, BODILY INJURY, OR EVEN DEATH.

FOR USE IN THE U.S. AND CANADA.

IF THIS PELLET BOILER IS NOT PROPERLY

INSTALLATION DIRECTIONS.

CONTACT LOCAL BUILDING OR FIRE OFFICIALS ABOUT RESTRICTIONS AND INSTALLATION INSPECTION

REQUIREMENTS IN YOUR AREA.

CONTACT YOUR LOCAL AUTHORITY (SUCH AS MUNICIPAL BUILDING DEPARTMENT, FIRE DEPARTMENT, FIRE

PREVENTION BUREAU, ETC.) TO DETERMINE THE NEED FOR A PERMIT.

CETTE GUIDE D’UTILISATION EST DISPONIBLE EN FRANCAIS. CHEZ VOTRE CONCESSIONNAIRE.

SAVE THESE INSTRUCTIONS

INSTALLED, A HOUSE FIRE MAY RESULT. FOR YOUR SAFETY, FOLLOW

#3-90-07205H

Page 2

Page 3

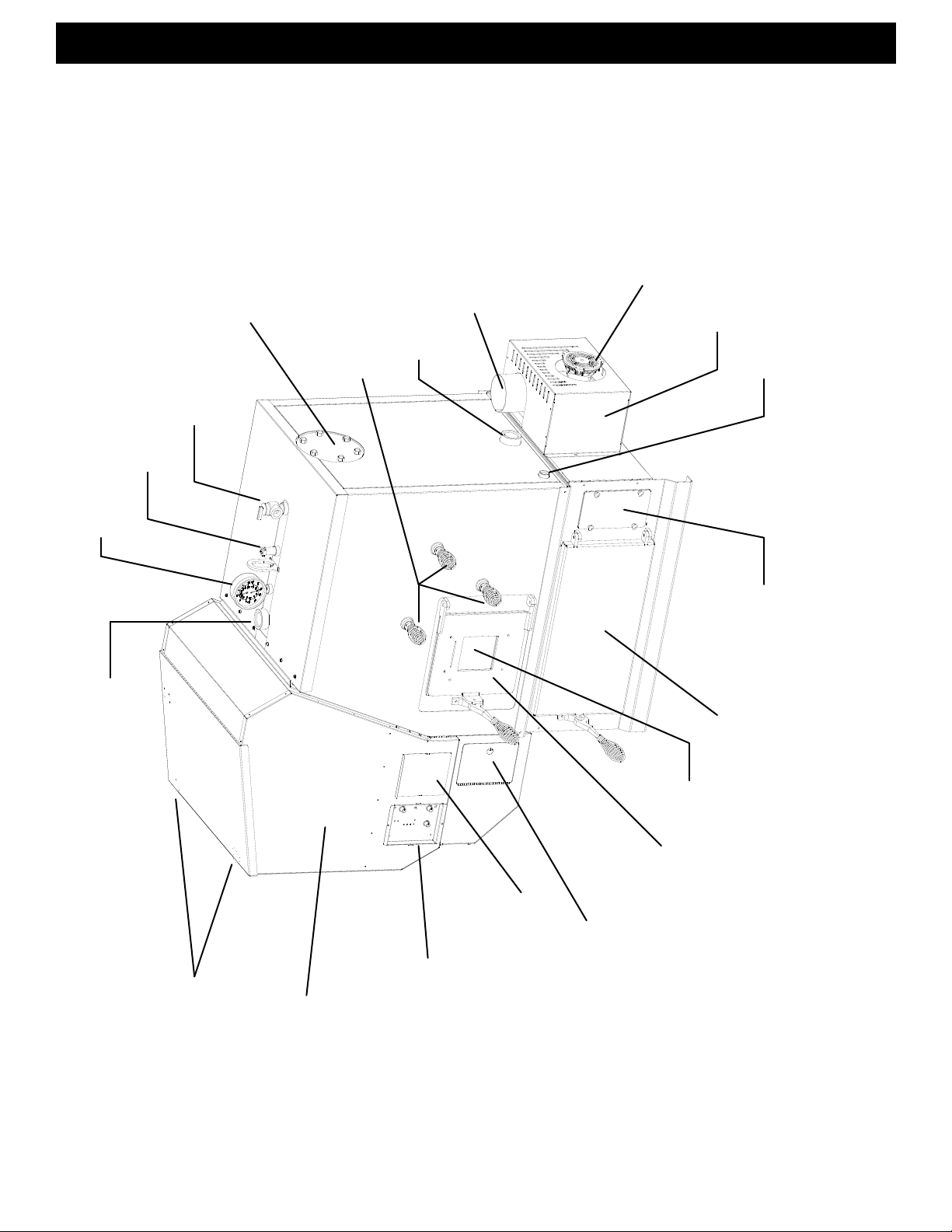

Hopper Lid

Latches

Hopper

Control Board Cover

Control Board

Combustion Blower

Combustion Blower Cover

Temperature / Pressure Gauge

Pressure Relief Valve

Aquastat Well

1-1/4” FMPT Supply

1-1/4” FMPT Return

Ash Door

Firebox Door

Access Cover To

Hopper / Swing Plate Knob

Access Cover To Secondary Ash Chamber

Blank Cover

(Removed w/ Domestic

Hot Water Option)

Vent Pip e

1/2” FMPT Boiler Drain

Viewing Glass

Parts Locations

3/4”

3

Page 4

Table Of Contents

Warranty 5

Assembly 6

Venting 9

Installation 12

Operation 23

Maintenance 30

Troubleshooting 34

Atmospheric Conversion 35

Service Parts 36

Introduction

Appliance Certication.

Model: Pellet Burning Boiler - BH105

Test Lab: Omni-Test Laboratories, Inc.

Report #: 135-S-16-6

Type: Pellet Fueled Central/Supplementary For

Residential Use

Standard(s): CAN/CSA B366.1-M91, and

UL 391

Specications 42

Wiring Diagram 43

Note: This appliance is also approved for

installation into a shop.

Testing Label 45

Quick Reference Start-Up Back Cover

WARNING! RISK OF FIRE! Hearth & Home Technologies disclaims any responsibility for, and the warranty

and agency listing will be voided by the following actions:

DO NOT:

• Install or operate a damaged appliance

• Modify the appliance

• Install other than as instructed by Hearth & Home Technologies

• Operate the appliance without fully assembling all components

• Overretheappliance

• Install any component or part not approved by Hearth & Home Technologies

Improper installation, adjustment, alteration, service, or maintenance can cause injury or property damage.

Forassistanceoradditionalinformation,consultaqualiedinstaller,serviceagencyoryourdealer.

Please read this entire manual before you install and use your new

boiler. Failure to follow instructions may result in

property damage, bodily injury, or even death.

SAVE THESE INSTRUCTIONS

Hearth & Home Technologies, Inc.

352 Mountain House Road

Halifax, PA 17032

4

Page 5

Warranty

ECO-CHOICE™ LIMITED WARRANTY

Hearth & Home Technologies Inc., on behalf of its Heatilator® brand (”HHT”), extends the following warranty for all

ECO-CHOICE™ furnace and boiler products (“Products”) that are purchased from an HHT authorized dealer.

Warranty Coverage: Subject to the conditions, exclusions and limitations set forth below, HHT warrants to the original

owner of the Products, and to any transferee taking ownership of the Products at the site of original installation within two

years following the date of original purchase, that the Products will operate free from defects in material and workmanship under normal conditions and use, as described in the operating instructions furnished with the Product, during the

warranty period described below. HHT will, at its option, repair or replace any Product covered by this warranty that is

determined to be defective in material or workmanship.

Warranty Period: The warranty period runs for six years, except for mechanical and electrical components, which are

warranted for three years. The warranty period begins on the earlier of: (i) the date of invoice for the Product; (ii) in the

case of new home construction, the date of rst occupancy of the residence or six months after the date of sale of the Product by an HHT authorized dealer, whichever occurs rst; or (iii) the date 24 months following the date of Product ship-

ment from HHT, regardless of the invoice or occupancy date.

Warranty Conditions: This warranty applies only to Products: (i) installed, operated, and maintained as recommended in

the Product user’s manual; (ii) purchased through an HHT authorized dealer; (iii) while remaining at the site of original

installation; and (iv) that have not been altered after leaving the factory.

How to File a Claim: Claims must be made within the warranty period to the dealer who sold the Product. If that dealer

cannot provide the warranty service, contact the nearest HHT authorized dealer. Additional service fees may apply if you

are seeking warranty service from a dealer other than the dealer from whom you originally purchased the Product. Travel

and shipping charges for parts are not covered by this warranty.

Warranty Exclusions: This warranty does not cover the following: (1) consumable and normal wear items, including,

without limitation, ame guides, grates, coal bars, afterburner hoods, re brick, gaskets, paint, glass discoloration, burnpot housing weldments, burnpot grate weldments (pellet or corn), burnpot front plates (pellet or corn), burnpot front plate

locks, corn auger extensions, ceramic inserts, and ceramic insert plates; (2) noise caused by minor expansion, contraction

or movement of parts; (3) damage resulting from: (i) failure to install, operate or maintain the Product according to the

installation and operating instructions and listing agent identication label furnished with the Product; (ii) failure to install

the Product according to local building codes; (iii) shipping or improper handling; (iv) abuse, misuse, continued operation

with damaged, corroded or failed components, accident, or incorrectly performed repairs; (v) environmental conditions,

inadequate ventilation, negative pressure or drafting caused by tightly sealed construction, insufcient make-up air supply, or handling devices such as exhaust fans or forced air furnaces or other such causes; (vi) use of fuels other than those

specied in the operating instructions; (vii) installation or use of components or accessories not supplied with the Product

or authorized and approved in writing by HHT; (viii) modication of the product not expressly authorized and approved

by HHT in writing; or (ix) interruptions or uctuations of electrical power supply to the Product; (4) non-HHT compo-

nents or accessories used in conjunction with the Product; (5) the Products’ capability to heat a desired space; information

is provided to assist the consumer and the dealer in selecting the proper Product for the application; consideration must be

given to Product location and conguration, environmental conditions, insulation and air tightness of the structure; or (6)

additional or unusual utility bills incurred due to any malfunction or defect in Products.

Limitations of Liability: Repair or replacement in accordance with the provisions of this warranty will be the owner’s

exclusive remedy for and will constitute HHT’s sole obligation under this warranty, under any other warranty (express or

implied), or in contract, tort or otherwise. No employee, agent, dealer, or other person is authorized to give any warranty

on behalf of HHT. TO THE EXTENT ALLOWED BY LAW, HHT MAKES NO OTHER WARRANTY, EXPRESS OR

IMPLIED, INCLUDING ANY WARRANTY OF MERCHANTABILITY OR FITNESS FOR A PARTICULAR PURPOSE. HHT WILL NOT BE LIABLE FOR ANY CONSEQUENTIAL OR INCIDENTAL DAMAGES ARISING OUT

OF DEFECTS IN OR USE OF THE PRODUCTS. Some states do not allow exclusions or limitation of incidental or con-

sequential damages, so these limitations may not apply to you. This warranty gives you specic rights; you also may have

other rights, which vary from state to state. The duration of any implied warranty is limited to the duration of the warranty

period specied herein.

5

Page 6

Assembly

Boiler Kit Materials: (Refer to page 2)

List of items contained within the boiler kit shipped with

the unit.

1 - Control board cover

1 - Access cover (Hopper Swing Plate Knob)

5 - Spring Handles

1 - 1/2” Boiler Drain

1 - 3/4” Safety Relief Valve

1 - 1/2” Aquastat Well

1 - 1/2” Dual Temperature/Pressure Gauge

1 - 100ft. Sensor Cable (Outdoor Air Sensor)

1 - Outdoor Air Sensor

1 - Flue Tunnel Weldment

1 - Combustion Blower Assembly

1 - Heat Shield (Comb. Blower)

2 - UY Connectors

2 - Terminals 1/4 Female

1 - #8 X 1/2” TEK

3 - 1/4-20 X 5/8” Wing Screw

4 - 1/4” Lock Washer

4 - 1/4-20 Nuts

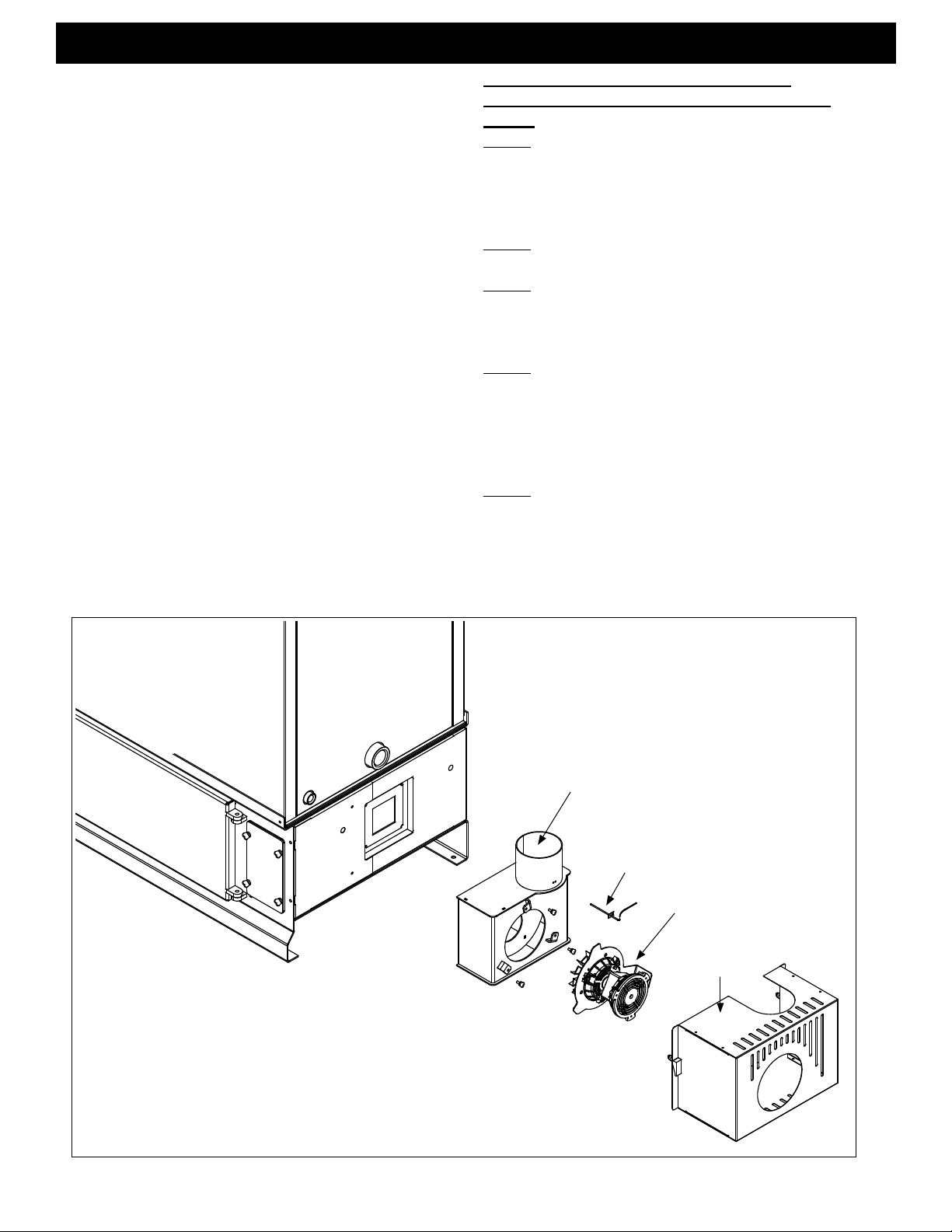

Installation of the Flue Tunnel Weldment,

Combustion Blower and Wiring, ESP and Heat

Shield:

Step 1: First install the ue tunnel weldment by

aligning the (4) studs with the (4) holes in the ash

chamber base. Fasten the (4) nuts and lock washers

provided, to the studs by removing the access cover on

the secondary ash chamber.

Step 2: Place the combustion motor onto the ue tunnel

weldment and tighten the (3) wing screws provided.

Step 3: Insert the Exhaust Sensing Probe (ESP) into the

1/8” hole provided on the ue pipe stub. Fasten with

the (1) #8x1/2” TEK screw also provided. ESP will be

taped to the sheet metal jacket for shipping purposes.

Step 4: Connect the ex conduit 90 degree elbow(Not

Shown) to the heat shield in the hole provided. Then

connect the (3) wires from the combustion blower with

the (3) wires in the ex conduit by using the push-on

connectors and matching the wire colors as follows:

Red to Black, White to White and Green to Green.

Step 5: Place Heat Shield over combustion blower and

align the swell latches with the holes in the sheet metal

and tighten.

NOTE: Refer to Fig’s 22, 23, and 24 located on page 31 of this manual.

6

Flue Tunnel Weldment

ESP

Combustion Blower

Heat Shield

Page 7

Assembly

Refer to the illustration on page 3 to identify the components listed below:

1. Install the control board cover as well as the access cover

located on the feeder cover.

2. Install the spring handles provided with the unit on the

ash door, rebox door and the heat exchanger cleanout rod

handles. (Fasten handles by turning them counterclockwise

and pushing inward simultaneously).

3. Install 3/4” MPT boiler drain in the tting as shown.

Note: Use pipe thread sealant or teon tape on ALL

threads before connections are made.

4. Install 3/4” MPT pressure relief valve as shown.

5. Install the 1/2” MPT aquastat well in tting as shown,

then place aquastat in the well and fasten with a zip tie. The

aquastat sensor is located under the top sheet metal jacket.

6. Install the 1/2” MPT temperature/pressure gauge in

tting as shown.

7. Locate and install outside air temperature sensor. Location of this sensor should be on the north side of the home or

building and out of direct sunlight. Use the cable supplied

with the boiler to attach the sensor to the terminals located

on the hopper. (Place at the back side just above and to the

right of the main power connection box) The wires can be

connected to the sensor with the connectors supplied. Wire

nut or butt splice connectors could also be used. The con-

nections at the boiler can be done with the two 1/4” female

push on connectors supplied.

8. Fasten the conduit to the ash base with the clamps

provided.

Design:

The rst thing that needs to be done is deciding where and

how the boiler will be installed.

Things that need to be taken into consideration are the

intended use of the boiler for example, is the boiler going to

be used as your primary heating system or is it going to be

used as a secondary or backup heating system. If it is to be

used in conjunction with an existing oil or gas boiler system

will it be piped in parallel or in series? The answers to these

and other questions can be determined by talking to your

certied dealer or a qualied HVAC or plumbing contractor. This will ensure that the boiler is installed and piped to

accommodate your needs and expectations.

Consideration must be given to the venting as well as

electrical and clearance requirements. (Clearances must be

maintained to combustibles and also for service)

Make sure fans are not used in the fuel storage area, unless

they are installed so as not to create a negative pressure in the

room where the solid fuel burning appliance is located.

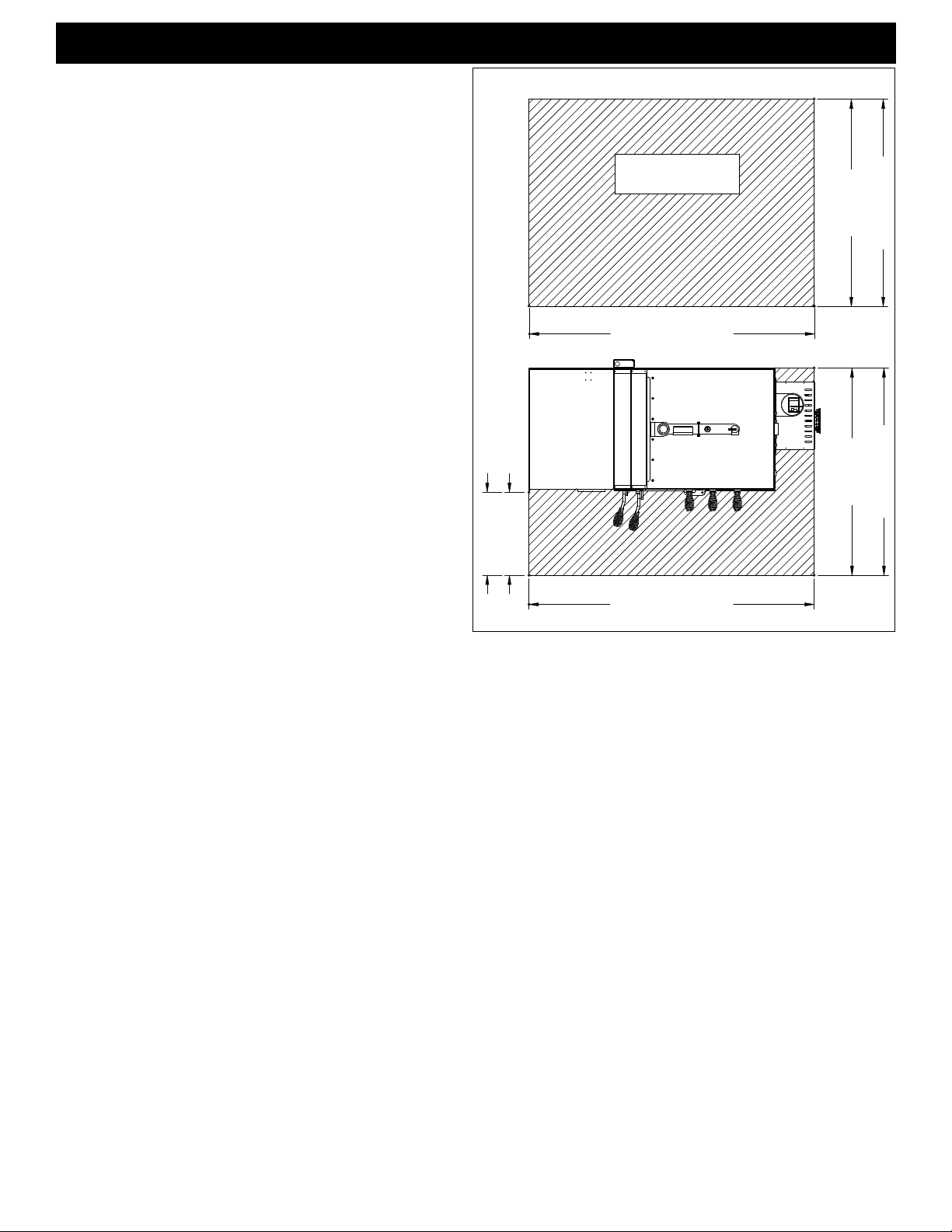

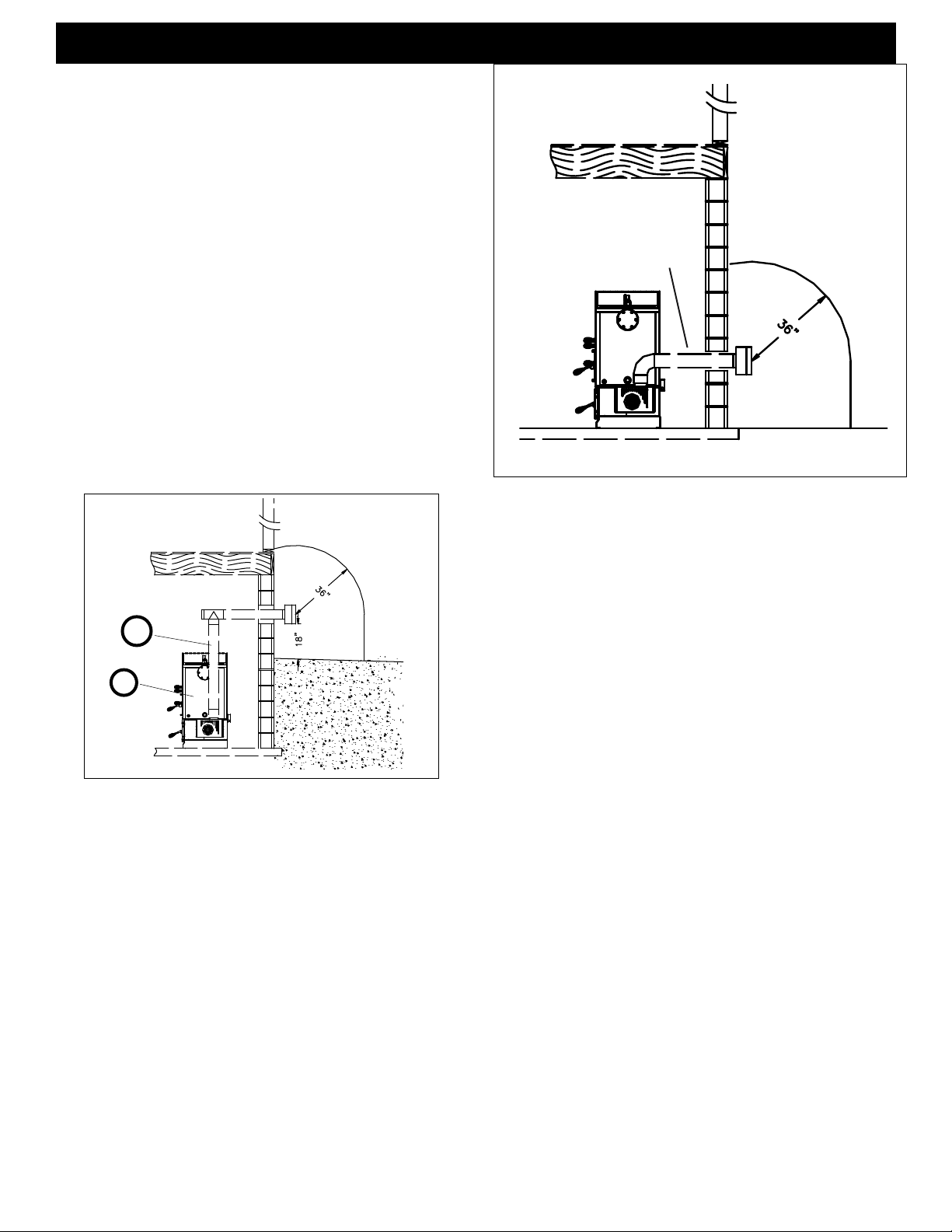

MINIMUM NON-COMBUSTIBLE FLOOR PROTECTION AREA

NON-COMBUSTIBLE

FLOOR PROTECTOR

40" USA

42" CANADA

55" USA & CAN

40" USA

42" CANADA

16" USA

18" CAN

55" USA & CAN

Floor Protection:

The striped area indicates the minimum required oor protection area if the boiler is going to be placed on a combustible

oor. It requires 40” X 55”(US) or 42” X 55”(CAN) of non

combustible oor protection as shown. 16”(US) or 18”(CAN)

of the oor protection must be in front of the rebox door

as shown. Floor protection must be a minimum of 26 gauge

sheet metal. Floor protection must also be provided under any

horizontal run of vent pipe equal to the outside diameter of the

venting plus 2” to each side.

Example: 4” type “L” or “PL” vent pipe has an outside diameter of 4-1/2” + 2” on each side equals a protected oor area

of 8-1/2” wide underneath the horizontal run.

7

Page 8

Assembly

INSTALLATION IS TO BE PERFORMED BY A

QUALIFIED INSTALLER.

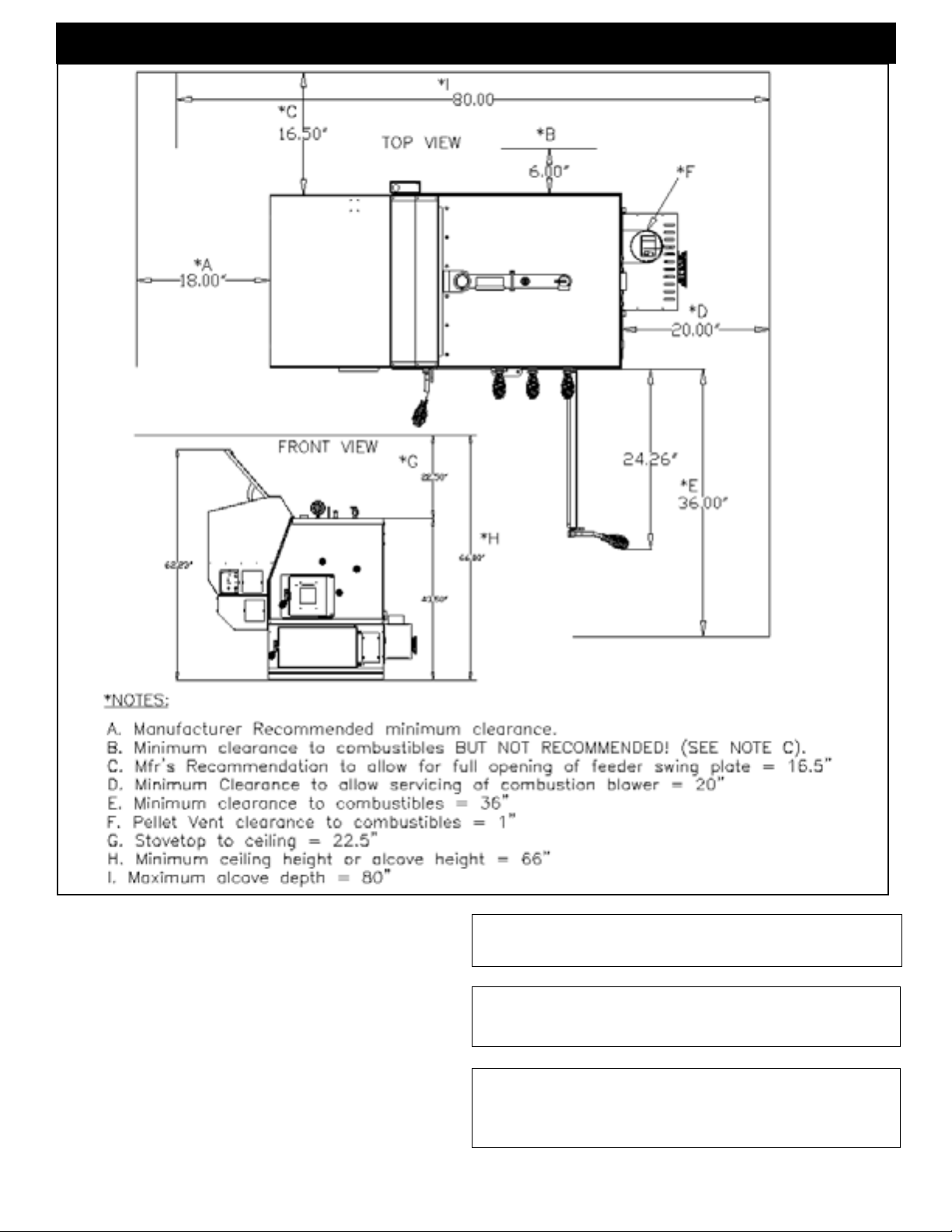

NOTE: All installation clearances and restrictions

must be adhered to.

NOTE:Use only 4” diameter type “L” or “PL” venting

system. Be sure to inspect and clean exhaust venting

system frequently.

8

Page 9

Venting

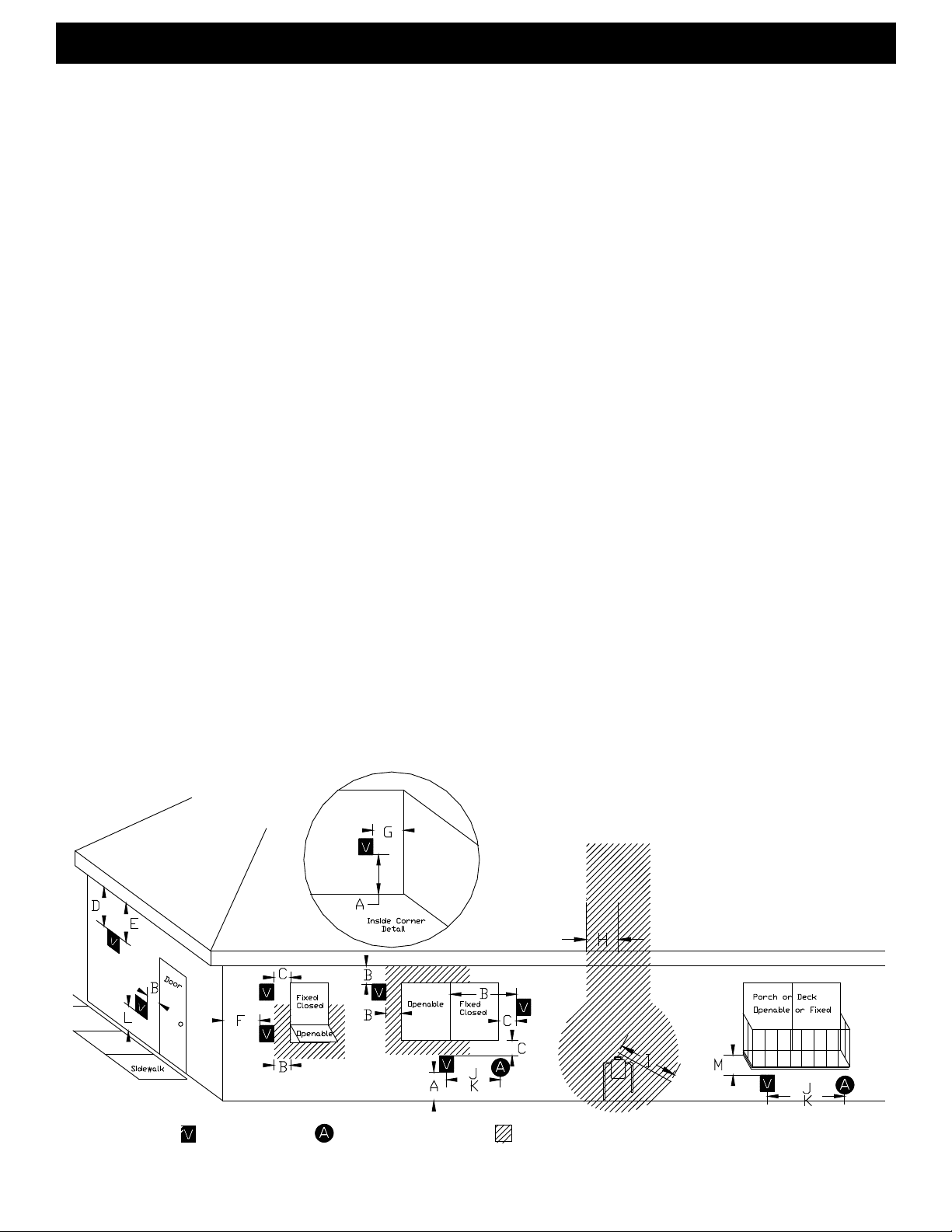

Requirements for Terminating the Venting

WARNING: Venting terminals must not be recessed into

a wall or siding.

NOTE: Only PL vent pipe wall pass-throughs and re

stops should be used when venting through combustible

materials.

NOTE: Always take into consideration the effect the

prevailing wind direction or other wind currents will

cause with yash and /or smoke when placing the termination.

In addition, the following must be observed:

A. The clearance above grade must be a minimum of

1

18”.

B. The clearance to a window or door that may be

opened must be a minimum of 48” to the side, 48”

below the window/door, and 12” above the window/

1

door.

C. A 12” clearance to a permanently closed window is

recommended to prevent condensation on the window.

D. The vertical clearance to a ventilated soft located

above the terminal within a horizontal distance of 2 feet

(60 cm) from the center-line of the terminal must be a

minimum of 18”.

E. The clearance to an unventilated soft must be a

minimum of 12”.

F. The clearance to an outside corner is 11” from center

of pipe.

G. The clearance to an inside corner is 12”.

H. A vent must not be installed within 3 feet (90 cm)

above a gas meter/regulator assembly when measured

from the horizontal center-line of the regulator.

1

I. The clearance to service regulator vent outlet must be

a minimum of 6 feet.

1

J. The clearance to a non-mechanical air supply inlet

to the building or the combustion air inlet to any other

appliance must be a minimum of 48”.

1

K. The clearance to a mechanical air supply inlet must

be a minimum of 10 feet.

1

L. The clearance above a paved sidewalk or a paved

driveway located on public property must be a minimum

of 7 feet.

M. The clearance under a veranda, porch, deck or

balcony must be a minimum of 12 inches.

1,2

1,3

(B Also

applies)

NOTE: The clearance to vegetation and other exterior

combustibles such as mulch is 36” as measured from the

center of the outlet or cap. This 36” radius continues to

grade or a minimum of 7 feet below the outlet.

1

Certain Canadian and or Local codes or regulations

may require different clearances.

2

A vent shall not terminate directly above a sidewalk or paved driveway which is located between two

single family dwellings and serves both dwellings.

3

Only permitted if veranda, porch, deck, or balcony is

fully open on a minimum of 2 sides beneath the oor.

NOTE: Where passage through a wall, or

partition of combustible construction is desired,

the installation shall conform to CAN/CSA-B365.

(if in Canada)

= Vent terminal

9

= Air supply inlet

= Area where terminal is not permitted

Fig. 2

Page 10

Fig. 3

Venting

Avoiding Smoke and Odors - Negative Pressure,

Shut-down and Electrical Power Failure.

To reduce the probability of back-drafting or burn

back in the pellet boiler during a power failure,

it must be able to draft naturally without exhaust

blower operation. Negative pressure in the house will

resist this natural draft if not accounted for during installation. Heat rises in a house, and leaks out at upper

levels. This air must be replaced with air from outside

the dwelling, which normally ows into lower levels.

Vents and chimneys into basements and lower levels

can become the conduit for return air and reverse under these conditions.

Hearth & Home Technologies strongly recommends

the use of outside air in all pellet boiler installa-

tions, especially those on lower level and main oor

locations. Per national building codes, consideration

must be given to combustion air supply to all combustion appliances. Failure to supply adequate combustion

air for all appliance demands may lead to back-drafting of those and other appliances within the home.

To reduce the probability of reverse drafting during shut-down conditions, Hearth & Home Technologies strongly recommends:

• Installing the pellet vent with a minimum vertical

run of 5 feet. Preferably terminating above the roof

line.

• Installing the outside air intake at least four feet

below the vent termination.

To prevent soot damage to exterior walls, and to prevent re-entry of soot or ash into the house:

• Maintain specied clearances to windows, doors

and air inlets, including air conditioners.

• Vents should not be placed below ventilated softs.

Run the vent above the roof.

• Avoid venting into alcove locations.

• Vents should not terminate under overhangs, decks

or onto covered porches.

• Maintain minimum clearance of 12” from the vent

termination to the exterior wall. Extending this distance may be required if visual accumulation occurs.

10

Page 11

Venting

Venting

Venting

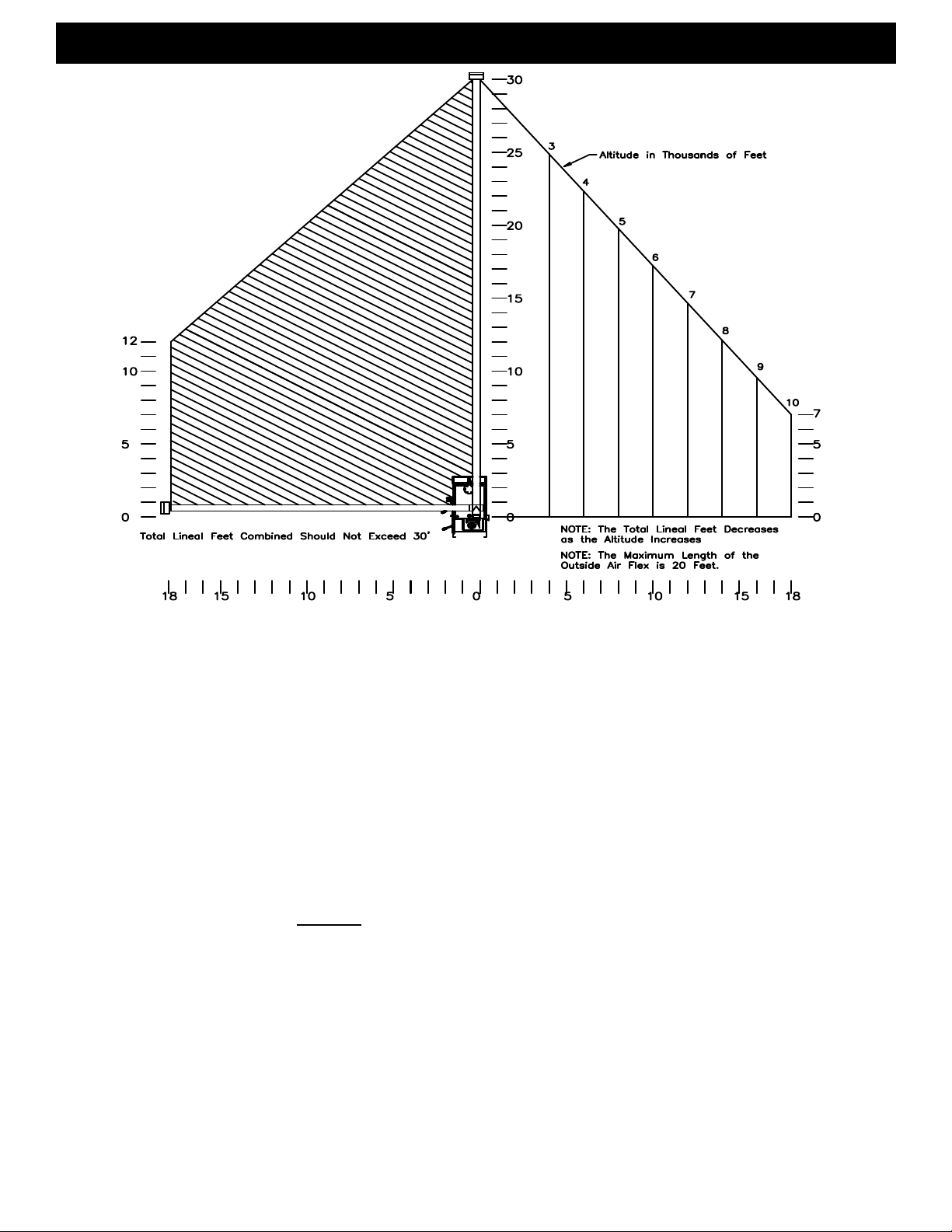

Use 4” pellet vent pipe only.

A combustion blower is used to extract the combustion

gases from the rebox. This creates a negative pressure in

the rebox and a positive pressure in the venting system

as shown in Fig. 4. The longer the vent pipe and more

elbows used in the system, the greater the ow resistance.

Because of these facts we recommend using as few elbows

as possible and 30 feet or less of vent pipe. The maximum

horizontal run should not exceed 18 feet.

Be sure to use wall and ceiling pass through ttings

(which are approved for pellet vent pipe ) when going

through combustible materials. Be sure to use a starting

collar to attach the venting system to the stove. The start-

ing collar must be sealed to the stove ue collar with

high temp silicone caulking or aluminum tape, and

screwed into the stove ue collar at least three (3) places.

4” Type “L” or

“PL” Vent pipe

Fig. 5

This is the minimum venting conguration.

+

-

Fig. 4

Vent Pipe

4” pellet vent pipe (also known as “PL” vent) is constructed of two layers with air space between the layers.

This air space acts as an insulator and reduces the outside

surface temperature to allow a minimum clearance to

combustibles as low as 1 inch. In Canada the minimum

clearance to combustibles is 3 inches.

The sections of pipe lock together to form an air tight

seal in most cases; however, in some cases a perfect seal

is not achieved. For this reason and the fact that the boiler

operates with a positive vent pressure, we specify that all

joints within the structure should also be sealed with

silicone.

NOTE:Use only 4” diameter approved PELLET

venting system. Be sure to inspect and clean exhaust

venting system frequently.

The minimum vent conguration is a 90o or Tee on

a starter collar and a 24” length horizontal through an

exterior wall. A cap on the end should direct the ue

gasses down and away from the structure. See Fig. 5.

The maximum horizontal length is 18 feet. The

minimum termination height above the exterior grade

is 18”. The maximum total length of any conguration

is 30 feet*.

* ( see venting graph on page 9 for exceptions )

NOTE: Cleanout Tee’s should always be used on the

transitions to horizontal pipe to allow easy access for

cleaning.

The venting graph allows for one(1) 90 deg. or Tee

tting in any conguration.

If more 90’s, T’s, or 45’s are needed, the total length

must be adjusted to allow for the added restriction.

Up to four (4) additional 90’s, Tee’s, or equivalent 45’s

can be added as long as the overall length is adjusted in

accordance with the values listed below.

( See the venting graph on page 10.)

Each Vertical ---- 90 deg. or T subtract 2.5 feet

Each Vertical ---- 45 deg. subtract 1.5 feet

Each Horizontal - 90 deg. or T subtract 5.0 feet

Each Horizontal - 45 deg. subtract 2.5 feet

Any exterior venting (vent pipe exposed to outside

ambient temperatures) should be kept to a minimum,

due to potential condensation problems.

This is especially important in high humidity cold

weather climates, such as maritime areas, lake shores,

and low river valleys.

11

Page 12

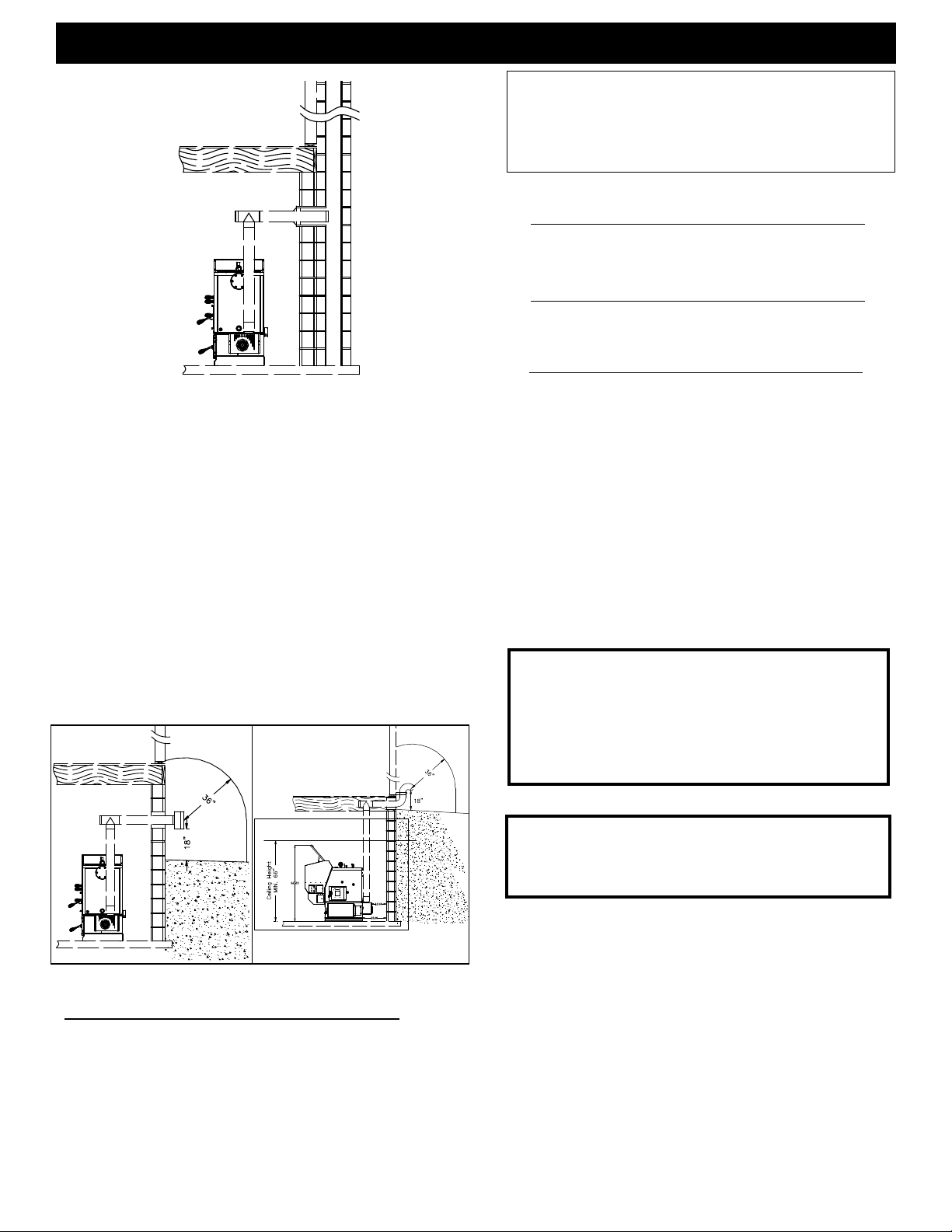

Venting Installation

Chimneys taller than 20’ above the connection will

require a draft test to determine if the draft is too high.

Note: The high burn draft should not exceed .85 IWC.

Some form of a restrictor plate may be required at the

top of high chimneys to reduce the draft. See page 21

for the Draft Test procedure.

This boiler may be used and installed into an existing

masonry or Class A metal chimney.

Certain Canadian and Local Codes may require that

the chimney be fully relined.

The venting Can Not be installed in a chimney serv-

ing another appliance.

The chimney should be cleaned and or inspected before

installation of the venting.

NOTE: Use only 4” diameter approved pellet

venting system. Be sure to inspect and clean

exhaust venting system frequently.

INSTALLATION IS TO BE PERFORMED BY

A QUALIFIED INSTALLER.

DO NOT INSTALL A FLUE DAMPER IN THE

EXHAUST VENTING SYSTEM OF THIS UNIT.

DO NOT CONNECT THIS UNIT TO A

CHIMNEY FLUE SERVING ANOTHER

APPLIANCE.

INSTALL VENT WALL PASS-THROUGHS AT

CLEARANCES SPECIFIED BY THE VENT

MANUFACTURER

NOTE: All installation clearances and restrictions

must be adhered to.

NOTE: Read and follow all of the vent pipe

manufacturers’ instructions on the proper

installation and support of the vent pipe. Adhere

to all clearances.

WARNING

KEEP COMBUSTIBLE MATERIALS SUCH

AS GRASS, LEAVES, ETC. AT LEAST 3 FEET

AWAY FROM THE POINT DIRECTLY UNDER

THE VENT TERMINATION. (BETWEEN THE

VENT AND THE GROUND)

CAUTION

KEEP COMBUSTIBLES AWAY

FROM FLUE OUTLET.

Other examples of possible installations of the venting.

Creosote - Formation and Need for Removal - When wood is burned slowly, it produces tar and other organic vapors,

which combine with expelled moisture to form creosote. The creosote vapors condense in the relatively cool chimney ue

of a slow-burning re. As a result, creosote residue accumulates on the ue lining. When ignited, this creosote makes an

extremely hot re. The pellet vent pipe should be inspected at least twice monthly during the heating season to determine

if a creosote buildup has occurred. If creosote has accumulated it should be removed to reduce the risk of a chimney re.

Guidance on minimizing creosote formation and the need for periodic creosote removal: The chimney should be

inspected during the heating season to determine if a creosote build-up has occurred. If a signicant layer of creosote has

accumulated (3mm or more) it should be removed to reduce the risk of a chimney re.

12

Page 13

Inlet Cover part#

1-10-09542

Outside Air Pipe

Knockout

Feeder Cover

Fig. 7

Outside Air Inlet Pipe

Installation

Outside Air

To install outside air, use 2 3/4” I.D.galvanized

steel ex pipe, part # 2-00-08544 ( 12’ 6” length) or part

# 2-00-08545 ( 25’ length) See Fig. 6. There is a break-

away hole on the rear panel which must be removed

before connecting the ex pipe. See Fig. 7.

When the appliance is side wall vented: The air

intake is best located on the same exterior wall as the

exhaust vent outlet, and located lower on the wall than

the vent outlet.

When the appliance is roof vented: The air intake

is best located on the exterior wall oriented toward the

Fig. 6

prevailing wind direction during the heating season.

Never terminate the outside air above the vent pipe

outlet. The maximum length of this pipe is 20 feet. Inlet

cover part number 1-10-09542 should be used to keep

birds, rodents etc.out of the inlet pipe. See Fig.6.

NOTE: The inlet cover should not be placed in an

area where drifting of snow or ice will build up, blocking the intake air supply.

The Outside Air knockout is located on the face of

the Feeder Cover. It is pre-cut except for several small

tabs. There is also a ller plate screwed to the inside

to cover the top of the hole after the Outside Air Pipe

has been installed. This will allow for removal of the

Feeder Cover without disconnecting the Outside Air

Pipe. See Fig. 7.

Only metal Intake Flex should be used for the

Outside Air Supply connection.

The Outside Air Intake Pipe is inside the Feeder

Cover and to the right of the feeder motor. The 2 3/4”

steel ex pipe is made to slide over the outside of the

Air Intake Pipe. See Fig. 8. It should be held into place

with some silicone, foil tape, or a hose clamp. (not

supplied)

13

Hopper/Feeder

Swing Plate

Knob

Heat Reclaiming Ventilation System (HRV)

When installing in a house with a Heat Reclaim-

ing Ventilation System (HRV) be sure the system is

balanced and is not creating a negative pressure in the

house.

Fig. 8

Page 14

Main Wiring Installation

14

NOTE: If other sources of electrical power are to be used ( such as a generator ) for normal operation or emergency operation, this source

To install power to the boiler, rst remove the cover on the 4” X 4” junction box located on the back of the unit. There are several knockout

holes provided for the incoming main power wires. Also, a knockout hole can be used for the auxiliary output overheat zone (if used).

The minimum recommended circuit is 6 AMP - 120 VAC - 60 HZ. This boiler should be the only appliance on the circuit.

This boiler should never be powered by the use of an extension cord.

The recommended high and low voltages are, 130 V.A.C. 60 Hz maximum high voltage, and 113 V.A.C. 60 Hz minimum low voltage.The furnace will

continue to operate at voltages as low as 105 V.A.C. , although it can not be guaranteed that automatic ignition will occur.

should be checked before installation. Many generators and inverters may not supply 120V.A.C. 60Hz. power stable enough to operate the control

board properly. (Control board damage could occur).

Page 15

Installing Duct

Installation

3/4”

NOTE: Cold return water temperature (Sustained temperatures below 140 degrees Fahrenheit) will lead to condensation in the

rebox.Thismoisturecanleadtocreosoteformation.Tohelpminimizemoistureandcreosote,itisstronglyrecommendedthat

some form of temperature balance is incorporated into the return water system.

NOTICE: When installing with the atmospheric conversion:Allofthepressurizedsystemcomponentsshownarenotnec-

essary. Air vents or bleeders will need to be removed from the plumbing system to prevent air from entering the lines. Control

Dipswitch #6 will need to be turned “ON”.

15

3/4”

Page 16

Installing Duct/Air Conditioning

Boilers intended to be connected to an existing boiler or boiler system shall:

1. Be capable of being installed without interfering with the normal delivery of heated water from the original boiler to the radiation

system.

2. Be capable of being installed to operate as intended without affecting the operation of the electrical and mechanical safety controls

of the original boiler.

3. Provide, upon completion of the installation, for a change over from one fuel to the other without requiring the manual adjustment

of any controls or components other than the thermostats.

4. Be compatible with the operation of a service water-heating coil within the original boiler without bypassing the operation of the

solid-fuel boiler.

5. Have provision for preventing, or adequate water capacity within the boiler to prevent, damage to the boiler from loss of circulation

due to electrical power failure.

6. Be capable of being installed without changing the function of the control or rewiring of the original boiler. A wiring interconnection is permitted. The electrical system of both boilers shall be powered from a single branch circuit without exception.

(CAN/CSA-B366.1-M91)

7. Pertaining to CAN/CSA- B365-01, Have a clearly labelled device, located at each entrance to the boiler area, which can be thrown

to discontinue operation of the feed system.

Installation

NOTICE: When installing with the atmospheric conversion:Allofthepressurizedsystemcom-

ponents shown are not necessary. Air vents or bleeders will need to be removed from the plumbing

system to prevent air from entering the lines. Control Dipswitch #6 will need to be turned “ON”.

16

Page 17

Installation

EXAMPLE OF TYPICAL TANKLESS DOMESTIC HOT WATER PIPING

INLET

AQUASTAT WELL LOCATION

HOSE BIB

OPTIONAL DOMESTIC

HOT WATER COIL

OUTLET

HOSE BIB TO

BACKFLUSH COIL

IF NEEDED

HIGH TEMPERATURE

WATER (IF NEEDED)

FLOW REGULATOR

MIXING VALVE

TEMPERED HOT WATER TO

SHOWERS AND FAUCETS

NOTE: ALWAYS REFER TO THE INDIVIDUAL COMPONENTS

RECOMMENDED INSTALLATION INSTRUCTIONS FOR THE PROPER

MOUNTING POSITION AND LOCATION WITHIN THE PIPING SYSTEM.

MIXING VALVE SET TO DESIRED WATER TEMPERATURE.

NORMALLY NOT MORE THAN 120 DEGREES.

SAFETY RELIEF VALVE

ISOLATION VALVE

COLD WATER SUPPLY

FLOW REGULATOR WILL NEED TO MATCH THE GPM RATING OF THE DOMESTIC COIL. (IF USING A DOMESTIC COIL, 4 GPM IS REQUIRED.)

FROM BOILER

CIRCULATOR

TO BOILER

EXAMPLE #1

EXAMPLES OF TYPICAL DOMESTIC HOT WATER STORAGE PIPING

EXAMPLE #2

FROM BOILER

COLD

HOT

DOMESTIC HOT

WATER STORAGE

HEATER

IN

OUT

CIRCULATOR

TO BOILER

COLD

HOT

DOMESTIC HOT

WATER STORAGE

HEATER

IN

OUT

NOTE: TYPICALLY, AS LONG AS THE WATER

TEMPERATURE NEEDED IS NOT MORE THAN

120 F, THE MIXING VALVE SHOWN ABOVE

(EXAMPLE 2) IS NOT NEEDED

HIGHER TEMPERATURE

WATER (IF NEEDED)

TEMPERED HOT WATER FOR

SHOWERS AND FAUCETS

MIXING VALVE

NOTE: ALWAYS REFER TO THE INDIVIDUAL COMPONENTS

RECOMMENDED INSTALLATION INSTRUCTIONS FOR THE PROPER

MOUNTING POSITION AND LOCATION WITHIN THE PIPING SYSTEM.

MIXING VALVE SET TO DESIRED WATER TEMPERATURE.

NORMALLY NOT MORE THAN 120 DEGREES.

17

Page 18

Installation

TYPICAL BOILER HOT WATER PIPING SHOWING AIR REMOVAL SYSTEM, PROVISIONS FOR THE EXPANSION OF

WATER AND THE AUTOMATIC COLD WATER SUPPLY. ALSO SHOWN IS THE AUTOMATIC MIXING VALVE. THIS

COULD ALSO BE DONE BY (2) CLOSELY SPACED TEE'S. THE PROPER PIPING FOR THE INTENDED USE WILL BE

DETERMINED BY THE INSTALLING CERTIFIED PLUMBER OR HVAC CONTRACTOR.

SHUT-OFF

VALVE

UNION

SYSTEM SUPPLY 1-1/4"

* TEMPERATURE/PRESSURE

GAUGE

* AQUASTAT

WELL

* PRESSURE

RELIEF VALVE

AIR VENT

PIPE TO WITHIN 6" OF THE

FLOOR OR A FLOOR DRAIN

UNION

AIR SCOOP

EXPANSION TANK

(DIAPHRAGM TYPE)

SHUT-OFF VALVE

* BOILER DRAIN, 1/2" NPT MALE X

*BOILER DRAIN, 3/4” NPT MALE X

3/4" HOSE MALE (NOT SHOWN)

3/4” HOSE MALE (NOT SHOWN)

SENSING BULB

SYSTEM RETURN 1-1/4"

NOTE: ALWAYS REFER TO THE INDIVIDUAL COMPONENTS RECOMMENDED

INSTALLATION INSTRUCTIONS FOR THE PROPER MOUNTING POSITION AND

LOCATION WITHIN THE PIPING SYSTEM.

** THERMOMETER

SYSTEM SUPPLY 1-1/4"

AUTOMATIC

MIXING VALVE

PRESSURE REDUCING VALVE (PRV)

OR COMBINATION PRV AND

RELIEF VALVE

** THERMOMETER

SHUT-OFF VALVE

* ITEMS SUPPLIED

** OPTIONAL

COLD WATER

SUPPLY 1/2"

CHECK VALVE (OR BACKFLOW

PREVENTER IF REQUIRED)

NOTE: Cold return water temperature (Sustained temperatures below 140 degrees Fahrenheit) will lead to condensation in the

rebox.Thismoisturecanleadtocreosoteformation.Tohelpminimizemoistureandcreosote,itisstronglyrecommendedthat

some form of temperature balance is incorporated into the return water system.

NOTICE: When installing with the atmospheric conversion:Allofthepressurizedsystemcomponentsshownarenotnec-

essary. Air vents or bleeders will need to be removed from the plumbing system to prevent air from entering the lines. Control

Dipswitch #6 will need to be turned “ON”.

18

Page 19

Installation

NOTE: Cold return water temperature (Sustained temperatures below 140 degrees Fahrenheit) will lead to condensation in the

rebox.Thismoisturecanleadtocreosoteformation.Tohelpminimizemoistureandcreosote,itisstronglyrecommendedthat

some form of temperature balance is incorporated into the return water system.

NOTICE: When installing with the atmospheric conversion:Allofthepressurizedsystemcomponentsshownarenotnec-

essary. Air vents or bleeders will need to be removed from the plumbing system to prevent air from entering the lines. Control

Dipswitch #6 will need to be turned “ON”.

19

Page 20

Over Heat Safety Zone

OverHeat Safety Zone (Dump Zone): STRONGLY RECOMMENDED in all installations.

When the pellet boiler is operating at High burn, and all demand from the heating system stops, the control

will reduce the feed rate and shut down completely as necessary. This may take several minutes, and the remain-

ing heat may cause the water temperature to continue to rise. If the temperature gets too high, the OVERHEAT

SAFETY ZONE light on the control (see page 23) will illuminate, and the DARK BLUE circuit in the junction box

is energized(see wiring diagram). This circuit will ow 120V to operate a circulator pump installed to ow to the

overheat dump zone established in the original installation plan. If opening a zone valve is the chosen method of

dumping the excess heat, a voltage reduction relay will most likely be needed. If the water temperature continues

to rise to the risk of boiling point, the feed system will stop and the boiler will shut-down. A manual reset will then

be required to operate the boiler. Without a dump zone in place, the excess temperature will build pressure to the

point of opening the relief valve, or with the atmospheric conversion it will allow the water to boil and over-ow

the atmospheric tank. Both scenarios may create water damage and/or slip hazard.

The boiling temperature of water varies at different altitudes and atmospheric pressures. Therefore, at eleva-

tions above 3000 feet, and when using the atmospheric conversion, circuit board dipswitch #6 must be in the “ON”

position.

Power Failure / Heat Dissipation Loop

EXAMPLE OF PIPING IN ACCORDANCE

WITH (CAN/CSA-B366.1)

A POWER FAILURE HEAT DISSIPATION LOOP

BALANCING

VALVE

POWER FAILURE SYSTEM SUPPLY 3/4"

* TEMPERATURE/PRESSURE GAUGE

UNION

* AQUASTAT WELL

* PRESSURE RELIEF VALVE

SYSTEM SUPPLY

PIPE TO WITHIN

6" OF THE

FLOOR OR A

FLOOR DRAIN

UNION

(HIGH TEMPERATURE) BASEBOARD HEAT

120VAC,NORMALLY OPEN,FULL FLOW,

SOLENOID VALVE or EQUIVALENT

THE SOLENOID SHOULD BE

POWERED BY THE SAME

CIRCUIT AS THE BOILER

POWER FAILURE SYSTEM RETURN 3/4"

SHUT-OFF VALVE

SHUT-OFF VALVE

SYSTEM RETURN

MINIMUM OF 72" OF 3/4"

FINNED BASEBOARD

BASEBOARD MUST BE AT LEAST

24" HIGHER THAN BOILER FOR

PROPER GRAVITY FLOW

NOTE: ALWAYS REFER TO THE INDIVIDUAL COMPONENTS

RECOMMENDED INSTALLATION INSTRUCTIONS FOR THE PROPER

* ITEMS SUPPLIED

MOUNTING POSITION AND LOCATION WITHIN THE PIPING SYSTEM.

20 20

Page 21

Installation

Draft Bolt Location

Viewing Window

Air wash Slot

Firebox Door

Draft Test Procedure

After the venting is completed, the rebox low draft

will need to be checked and possibly adjusted. After

removing the 3/8” bolt from the draft hole shown in Fig.

9, insert the draft meter tube. The appliance doors and

hopper lid must be latched during this test. (It is recommended that the draft meter have a scale of 0 to 1” WC.)

Air Wash Slot

Fig. 9

“Test”

Turn the feed adjuster to “Test”. this will start the

combustion blower and allow you to check and record

the High Draft ______ - IWC date _______ The

maximum draft must not exceed -.85” W.C. Some form

of vent restrictor may be needed. (There is no control

board adjustment for the High Draft)

After the rst 60 seconds the “Test” mode lowers the

combustion blower voltage to the Low Burn voltage.

During this lowered voltage cycle the Low Burn Draft

must be checked and adjusted if necessary. The recom-

mended low draft setting should be between -.25 & -.35

IWC. Depending on the amount of vertical rise, it may

not be possible to get a low draft reading in this range.

In this case, a maximum low draft of -.55 is acceptable.

The adjustment screw is through the small hole to the

right of the Igniter Light. See Fig. 10. Adjusted Low

Draft is __________ -IWC.

Don’t forget to turn the feed adjuster off of “Test”.

Covered

Low Draft

Adjustment Pot

Un-Covered

Fig. 10

Do not operate if the high draft exceeds -.85” W.C.

Excessive draft readings may be due to restriction in

the combustion air supply. Check for obstructions.

The Control

The boiler has the option to have the control panel

covered or un-covered See Fig. 11. There is a pair of

slots provided for each position. Simply move the cover

to the desired position by placing the tabs on the cover

in the proper slots.

CAUTION: Hot while in operation. Do not

touch. Keep children, clothing, furniture,

and other combustible material out of the

installation clearance area.

WARNING: Do not operate with the hopper

lid or re chamber or ash removal doors open.

21

Fig. 11

WARNING: Do not store fuel or other

combustible material within installation

clearance area.

Page 22

Fuel Specications

Fuel and Fuel Storage

Pellet fuel quality can uctuate from manufacturer to

manufacturer, and even from bag to bag.

Hearth & Home Technologies recommends using only

fuel that is certied by the Pellet Fuels Institute (PFI).

Fuel Material

• Made from sawdust and/or other wood by-products

• Source material typically determines ash content

Higher Ash Content Material

• Hardwoods with high mineral content

• Bark and leaves as source material

• “Standard” grade pellets, corn and other biomass

Lower Ash Content Material

• Softwood; pine, r, etc.

• Materials with lower mineral content

• “Premium” grade pellets

CAUTION! Do not burn fuel that contains an additive;

(such as soybean oil)

• May cause hopper re

• Damage to product may result

Read the list of ingredients on the packaging. If you are

buying wood pellets, the only ingredient listed should be

wood ber or sawdust.

Clinkers

Minerals and other non-combustible materials, like sand,

will turn into a hard glass-like substance when heated.

Trees from different areas will vary in mineral content.

For this reason, some fuels will produce more clinkers

than others.

Performance

• Higher ash content requires more frequent maintenance.

• “Premium” grade pellets will produce the highest

heat output.

• Burning pellets longer than 1-1/2 inches (38mm)

can cause inconsistent feeding and/or ignition.

We recommend that you buy fuel in multi-ton lots

whenever possible. However, we do recommend trying different brands prior to purchasing multi-ton lots,

to ensure your satisfaction.

CAUTION! Tested and approved for use with wood

pellets ONLY. Burning of any other fuel will void your

warranty.

When changing from “Premium” grade pellets to a

“Standard” or “Economy” grade fuel, the FEED ADJUSTER will likely need adjusted to a lower setting.

When under maximum demand, ensure there is no

unburned fuel being pushed into the ash pan.

Storage

• Wood pellets should be left in their original sealed

bag until ready to use, to prevent moisture.

• Do not store fuel within the specied clearance areas, or in a location that will interfere with routine

cleaning and maintenance procedures.

Moisture

Always burn dry fuel. Burning fuel with high moisture

content takes energy to dry and tends to cool the appliance thus, robbing heat from your home. Damp pellet

fuel could turn back into sawdust which does not ow

properly through the feed system.

Size

• Pellets are either 1/4 inch or 5/16 inch (6-8mm) in

diameter

• Length should be no more than 1-1/2 inches (38mm)

• Pellet length can vary from lot to lot from the same

manufacturer

22

CAUTION

Tested and approved for use with wood pellets

ONLY. Burning of any other fuel will void your

warranty.

NOTICE

Hearth & Home Technologies is not responsible for

stove performance or extra maintenance required

as a result of using fuel with higher ash or mineral

content.

Page 23

Operation

Power Light

Indicates power to the

control board.

Status Light

Will be lit anytime there is a

call for heat.

Overheat Safety Zone Light

Indicates elevated boiler

water temperature. Power

owing to Overheat circuit.

Combustion Blower Light

Indicates Power to

combustion blower

Feed Motor Light Indicates

Power to the feed motor.

Igniter Light

Indicates power to the igniter

Feed adjuster

Sets the maximum feed rate

Test

Combustion blower, feed motor

and safety dump zone are fully

energized for the rst minute.

Afterward, combustion blower

remains on low only.

Lighting Mode Selector

Switched between Auto and

Manual lighting

Mode Selector/Min Temp

Dial

Used to turn the boiler on

or off and set the desired

minimum operating

temperature of the boiler.

Diagnostic Port

For diagnostic purposes only.

Requires special DDM monitor

supplied to trained technicians

exclusively.

Max Temp dial

The “Max Temp Dial” is used to set the desired

maximum operating temperature of the boiler.

Status light error messages:

3 Blinks: Indicates that the ESP (Exhaust Sensing Probe) has

gone out of range, too many times. May indicate axcessive

ash build-up in the exhaust stream. If the unit seems to be

operating normally, perform a manual reset by cycling the

main power off for a few seconds and re-connect.

4 Blinks: Indicates miscommunication with the aquastat, or

the sensor is not attached properly. May require a manual

reset.

5 Blinks: (In Auto Light Mode Only)

Indicates that the igniter has failed to light the re after 40

Minutes. To reset - Turn the Mode Selector/Min. Temp. to

OFF and then back to the desired temperature.

6 Blinks : Indicates that the control has calculated poor or

incomplete combustion occurring for 25 or more minutes.

A six blink status may be set if the stove is allowed to run

out of pellets. To reset, turn Mode Selector/Min Temp dial

to “OFF” then back on to the desired temperature. If the unit

was not out of pellets, see Troubleshooting section, Page 34,

for more details.

23

7 Blinks: Boiler water over heat safety shut down. This requires a manual reset by cycling the main power off for a few

seconds and re-connect. See explanation on page 20.

Mode Selector/Min. Temp.

Used to turn the boiler on or off and set the desired

minimum operating temperature of the boiler.

Max. Temp./ Min. Temp. Water Temperature Settings

See “Setting the boiler temperature” found on page 24.

OFF Mode

Turning the Mode Selector/Min.Temp. to OFF will shut down

the boiler.

Page 24

WATER TEMPERATURE

Operation

Setting The Boiler Temperature

Without the Outdoor Air Temperature Sensor

Installed

To set the maximum boiler water temperature, simply turn the Max. Temp. water temperature dial to the

desired setting. The control and the boiler will then

perform to achieve and maintain the set temperature.

The Min. Temp. Knob is the boiler water temperature minimum, or the lowest temperature the water

will go before the unit re-starts. Turning the knob fully

counter-clockwise is the “OFF” position, while turn-

ing the knob clockwise, past the 140 degree marking,

is the “ON” position..

With The Outdoor Air Temp - Sensor Installed

Maximum boiler temp setting is as described above.

The MIN. TEMP. knob in addition to being the

mode setting (on or off) now also has the function of

setting the minimum boiler water temperature. This

would be the lowest boiler water temperature that you

want to have based on the following factors.

1.) Outdoor Air Temperature (OAT)

2.) Domestic Hot Water Use

a.) Hot Water Coil Option

b.) Indirect Hot Water Storage

3.) Overall Volume of the Heating System

MAX. TEMP.

MIN. TEMP.

Control Board Operation

Aquastat Sensor - This sensor is located in the aqua-

stat well on the top of the water jacket. This sensor

along with the outdoor air sensor is what the control

board uses to regulate the feed rate based on these two

observed conditions. (Boiler Temp. & Outdoor Air

Temperature)

Outdoor Air Temp. Sensor (OAT) - This sensor is

located outside the building (on the north side of the

house and out of direct sunlight). The Outdoor Air

Sensor is used to perform hot water reset based on outdoor air temperatures.

When the OAT sensor is installed, at 20° F. or below

(outside temperature), the boiler will operate at the

temperature set on the MAX. TEMP. knob. The boiler

water temperature will decrease by 1 degree F. for

every 1 degree F. in temperature rise (above 20°) of

the outdoor air.

NOTE: Pellet Boiler Outdoor Air Reset Operation

Graph located on page 23.

24

The boiler is designed to withstand lower return water

temperatures however, extended return temperatures below

140 degrees F can cause condensation in the secondary

ash chamber area and also in the venting system, which

could cause damage in these areas.

NOTE:

If the system is run at the lower temperature settings, con-

ditions of the rebox, boiler tubes, secondary ash chamber

and venting should be monitored closely. If conditions show

excess condensation, the boiler water minimum temperature will need to be increased until condensation does not

occur. You should also consider some form of tempering of

the return water system. Discuss this with your plumber.

Page 25

-45°

-40°

o

o

140

145

o

o

65

60

-35°

-30°

o

o

150

155

o

o

55

50

o

o

-25

-20

o

o

160

165

o

o

45

40

Operation

o

o

o

o

o

-15

-10

-5

0

o

o

180

185

o

o

25

20

0

o

185

o

15

o

o

170

175

o

o

30

o

0

0°

o

o

185

185

o

o

10

5

o

185

o

0

*

*

o

o

150

150

o

o

65

60

o

*

-30

o

o

150

150

o

o

55

50

o

o

-25

-20

o

o

155

160

o

o

45

40

o

o

-15

-10

o

o

165

170

o

o

30

o

o

-5

0

o

o

175

180

o

o

25

20

o

o

0

0

o

o

180

180

o

o

15

10

o

o

0

0

o

o

180

180

o

o

5

0

Pellet Boiler Outdoor Air Reset Operation

When the outdoor sensor is installed, at 20° F. or below OAT (Outdoor Air

Temperature), the boiler will operate at the temperature set on the Maximum

Temperature knob. The boiler water temperature will decrease by 1 degree for

every 1 degree in temperature rise of the Outside Air.

Example 1 OAT Water Temp Degree Change

o

o

Min set at 140

Max set at 185

35

o

o

Example 2 OAT Water Temp Degree Change

Min set at 150

Max set at 180

35

* No change in boiler temperature after reaching minimum setpoint temperature.

25

Page 26

Scrape burnpot to remove any carbon

build-up that may have occurred

Operation

Starting A Fire Automatically

1. Turn Mode Selector to “OFF”.

This resets the control in addition to turning

it off.

2. Clean Burnpot with scraper, if necessary.

This is usually a weekly maintenance proce-

dure. Cleaning the burn pot with the scraper with

a small amount of new fuel in the bottom is not a

problem. First, scrape the ashes on the front of the

burn pot into the ash pan. Then scrape the hole grid

surface downward into the burn pot. When the stove

is ignited these scrapings will be pushed out by the

feeder.

The illustration at left shows the hopper swing plate

open for easy access to the burn pot. The burn pot

can also be reached through the rebox door.

NOTE: To minimize the amount of stress placed

on the hopper swing plate hinges, opening of the

hopper swing plate should be done with the least

amount of fuel in the hopper as possible.

26

3. Fill Hopper with pellets.

When lling the hopper check for excessive nes

in the bottom of the hopper. Fines are small pieces of

broken pellets (sawdust). Fines do not ow easily and

often build up on the hopper funnel bottom angles.

These nes can be pushed into the feeder opening

and then ll the hopper with pellets. As the system

works, they will be burned.

Page 27

Operation

WATER TEMPERATURE

4. If Starting After an Empty Hopper, Turn Feed

Adjuster to “TEST” (for one 60 second cycle).

This will feed pellets into the auger tube and also

allow you to check the motors for operation. NOTE:

The auger motor will not operate with any of the

doors open.

5. Turn Feed Adjuster to #4.

If this is your rst re or you are trying differ-

ent pellets, set the feed adjuster to #4, This is an

average number for most pellets and may need to

be adjusted for your particular fuel. After you know

a feed rate setting that works well for your application, use that setting.

NOTE: You know your feed rate is too high when:

The overheat safety feature is energized each time

the heating zone demand turns off during a high burn.

OR, If unburned or partially burned pellets are found

in the ash pan.(this may also be an indication of a

burn pot in need of scraping.)

MAX. TEMP.

MIN. TEMP.

6. Flip the Igniter Switch up into the “AUTO”

position.

7. Turn the MAX. TEMP. Dial on the control

board to the desired temperature. This setting must

always be at least 5° F. higher than the MIN. TEMP.

setting.

WARNING: HOT WHILE IN OPERATION.

KEEP CHILDREN, CLOTHING, AND

FURNITURE AWAY. CONTACT MAY CAUSE

SKIN BURNS.

27

Page 28

Operation

8. Turn the MIN. TEMP. Dial on the control board

to the desired Minimum temperature. This will start the

lighting process if the temperature at the aquastat sensor

is approximately 5° F. less than the set temperature on

the MAX TEMP. dial.

This is more than just an automatic ignition pellet

boiler. The automatic system will allow the re size to

be adjusted to match the heating needs and even put the

re out if necessary. If heat is needed after the re is out,

the boiler will automatically re-ignite and adjust the re

size to match the heating need.

9. Fill hopper with pellets and remove ashes as

required.

Type of Fuel

Use pelletized wood only. The lower the ash content of

the pellets the less cleaning that will be needed of the

heat exchanger surfaces. The cleaner these surfaces are

kept, the more efcient the boiler will be.

NOTE: Do not burn garbage, gasoline, naphtha, engine

oil, or other inappropriate materials in this unit.

Store pellets in the manufacturer’s wrapping until

needed to prevent pellets from absorbing moisture.

Do not store fuel within the appliance installation

clearances, or within the space required for fueling,

ash removal, and other routine maintenance

operations.

Lighting A Fire Manually

Lighting the re manually will not be necessary unless

the igniter system fails.

Follow steps 1 through 5 of the instructions for

automatic lighting.

6. Flip the Igniter Switch Down into the “MANUAL-

LIGHT” position. See Fig. 12.

Fig. 12

7. Open hopper swing plate as shown in Fig. 13 (See

“NOTE” on page 26.)

Fig. 13

8. Fill burnpot with pellets as shown.

See Fig. 14. Only ll level with the front edge.

( ------- DO NOT OVERFILL ------- )

Fig. 14

9. Have matches or other ignition source ready.

10. Turn Mode Selector to desired MIN TEMP setting.

This will start the combustion blower and allow the

ESP to control the re in relation to the MAX TEMP

Dial setting. (The MAX TEMP dial setting must always

be set above the MIN TEMP setting) Once the re is

well established the MAX TEMP dial can remain on

any temperature setting desired.

NOTE: When the Switch is set to Manual ignite position

the boiler will function as in auto ignite except the re will

not be allowed to go out. It will only be allowed to go to a

minimum burn rate between the times the aquastat is calling

for heat. This rate is about 1.1 pound of fuel per hour. If used

in the Manual ignite mode, be sure there is an overheat dump

zone in place. Note that if the dump zone does not provide

sufcient cooling, and the water temperature continues rising,

the feed motor will be forced to shut off. Because the unit is

in Manual Ignite mode, it will not re-ignite when the water

temperature cools below the control settings.

28

Page 29

Operation

Fig. 15

NOTE: Stirring the starting gel into the pellets usually

allows the re to become established quicker.

CAUTION: A vapor ash could occur if too much

time is allowed to pass before lighting the starting gel.

11. Apply starting gel as shown in Fig.15

12. Light The Starting Gel With A Match.

13. Close The Doors

The re will light and the control will adjust the re

to the proper level according to the MAX TEMP dial

setting.

CAUTION: Care must be taken not to get starting gel

on your hands or clothing. Serious burns could occur

during the lighting process.

CAUTION: Never try to apply more starting gel to an

already burning re, or a re with smoldering pellets.

“NEVER USE GASOLINE, GASOLINE-TYPE

LANTERN FUEL, KEROSENE, CHARCOAL

LIGHTER FLUID, OR SIMILAR LIQUIDS TO

START OR “FRESHEN UP “ A FIRE IN THIS

APPLIANCE. KEEP ALL SUCH LIQUIDS WELL

AWAY FROM THE UNIT WHILE IN USE”.

NOTICE: When burning the boiler in the

manual ignition mode, there must be an

overheat dump zone incorporated into the

plumbing system.

If heating demand stops during manual operation, the

control will take the unit to low burn. If no heat is used

during this time, the water temperature will continue to

rise. When the temperature gets too high, the feeder will

be turned off and the re will go out. This will require a

manual re-start of the system. (see page 23 “7 Blinks”)

Solid-fuel burning appliances need to be cleaned

frequently because soot, creosote, and ash may accumulate. If you suspect a chimney/vent pipe re do

the following:

1. Call the re department.

2. Remove fuel from the burn pot using the burnpot

scraping tool to scrape the pellets into the ash pan.

3. Remove the ash pan from the unit and take outside.

Do not place ash pan on a combustible material.

4. Turn off circuit breaker at unit.

5. Do not use the unit until a qualied person has in-

spected your appliance and venting.

29

Fig. 16

Page 30

Scrape the burnpot to remove any carbon

deposits which may have formed.

Scraping can be done while the boiler

is in operation, accessed through the

rebox door opening.

Maintenance

Burnpot Cleaning:

The burnpot should be cleaned no less than once a week.

For best operation the burnpot should be cleaned every time

the hopper is lled with pellets. The re does not have to be

out to scrape the burnpot although it is recommended the

boiler be on minimum burn at the time of cleaning.

Note: Scraping can be done while in operation if per-

formed through the rebox door opening. See Fig. 17

Use the at end of the scraper provided to scrape down

over the holed surface of the burnpot grate. See Fig. 18. It

is not necessary to clean out the scrapings from this cleaning because they will be pushed out the next time the auger

operates.

Note: Make a special effort to scrape the bottom inside

corners of the burnpot where the auger tube enters the

burnpot. Carbon deposits can build up over time in this

area that may cause a restriction to the ow of pellets into

the burnpot.

Note: An old long shank screwdriver with the end sharp-

Fig. 17

ened is an ideal aid in the removal of these deposits.

Fines area

30

Cleanout cover

Feeder cover

Fig. 19

Fig. 20

Fig. 18

Cleaning the Burnpot Air Chamber:

This area only needs to be cleaned twice a heating season, unless excessive buildup is noticed during scheduled

cleanings.

There is a cover on the front of the burnpot to gain access

to the air chamber. The cover is held into place by two thumb

screws. Loosen the thumb screws and remove the cover. See

Fig. 19. The air chamber can be cleaned of any ash that has

fallen through the holes during operation and cleaning. Also

at this time, remove the feeder assembly cover and remove

any nes that may have accumulated.

NOTE: ALWAYS REMEMBER TO CLOSE THE CLEA-

NOUT COVER AFTER CLEANING.

Feeder Chamber (Fig. 20):

This chamber may get a buildup of nes from the feeder

mechanism movement. This area should be checked and

cleaned at least once a year.

To remove the feeder cover:

• Loosen the 5/16” wing nut.

• Slide the cover off of the threaded stud and lift upward.

• Inspect and clean the inner chamber if necessary. See Fig. 20.

• Reinstall the cover making certain it is centered on the

feeder body and hand-tighten the wing nut.

Page 31

Maintenance

Ash Door Handle

Ash Door

Ash Pan

Ash Pan Handle

WARNING! RISK OF FIRE!

• Ash, soot or creosote build-up may cause

overheating or re.

• Routine cleaning of heat exchangers and

venting is required.

Ash Removal

It is recommended to remove the ashes when the boiler

is not in operation. This lessens the chances of coming in

contact with hot surfaces. Ashes can be removed while

in operation but, extra care must be taken.

Open Ash Door

Lift the latch and open the door as shown in g. 21.

NOTE: Keep hopper lid, hopper swing plate, rebox

door and ash pan door closed during operation and

maintain all seals in good condition.

Remove Ash Pan

Always wear gloves to remove ash pan. Grab the ash

pan by the nger hold and pull it out of the boiler. Lift

the ash pan by the nger hold and use it for carrying the

ash pan. Close the ash door before disposing the ashes.

Fig. 21

Disposal of Ashes

Ashes should be placed in a steel container with a tight

tting lid. The closed container of ashes should be moved

outdoors immediately and placed on a non-combustible

oor or on the ground, well away from all combustible

materials, pending nal disposal. If ashes are disposed

of by burial in soil or otherwise locally dispersed, they

should be retained in the closed container until all cinders

have thoroughly cooled. Other waste shall not be placed

in this container.

Soot and Flyash: Formation and Need for

Removal

The products of combustion will contain small particles

of yash. The yash will collect in the exhaust venting

system and restrict the ow of the ue gases. Incomplete

combustion, such as occurs during startup, shutdown,

or incorrect operation of the room heater will lead to

some soot formation which will collect in the exhaust

venting system. The exhaust venting system should be

inspected at least twice monthly to determine if cleaning

is necessary. Pay particular attention to screening in the

vent cap. The screen, if present, will accumulate with

ashes rather quickly.

31

Page 32

Fines Cleanout Cover

Maintenance

Heat Exchanger Cleanout Rod Handles

Firebox Door

Heat Exchanger Tube

Secondary Ash

Chamber Access Plate

Firebox Wall

Cleaning

This cleaning should be done after each ton of pellets

used. The frequency of this cleaning will be directly

related to the quality and the ash content of the pellets being used. Keep in mind that the cleaner the heat

exchanger surface is kept, the higher the heat transfer

efciency will be.

Due to it’s ease of restarting it is recommended that the

boiler be OFF and COOL before cleaning.

Start by actuating the (3) heat exchanger cleanout rods

by pulling and pushing these rods vigorously several

times. This action will remove any y ash built up on the

heat exchanger tubes. This can also be done at any time

during the operation of the boiler to maintain higher ef-

ciencies. Make sure that these rods are pushed in when

cleaning is completed.

Cleaning Steps

-Open the hopper swing plate to access burnpot and

also the rebox. With a wisp brush, wire brush, stiff

bristled paint brush or a soot vac, clean the rebox walls

and any y ash that has accumulated on the ledges of the

burnpot, or burnpot opening. At this time you can scrape

and clean the burnpot and nes cleanout area.

-Open rebox door and vacuum ash from ledges and

ash deector. You can also clean the rebox door viewing

glass using a typical glass cleaner and soft cloth.

Ash Door

-Open the ash door and remove the ash pan. Dispose

of any ash that has accumulated in the ash pan as well

as any y ash from within the ash pan area.

-Remove the (4) thumbscrews on the secondary

ash chamber access plate and remove it to access the

secondary ash chamber. Remove all y ash from this

area. This process should be done as needed.

-Inspect all sealing gaskets to ensure a proper seal

and re-install all components removed for cleaning.

CAUTION: Cleanout of the heat exchanger, ue

pipe, chimney, and combustion blower fan housing,

is especially important at the end of the heating

season to minimize corrosion during the summer

months, caused by accumulated ash.

NOTE: To minimize the amount of stress placed on

the hopper swing plate hinges, opening of the hopper

swing plate should be done with the least amount of

fuel in the hopper as possible.

32

Page 33

Thumb Screws (3 Total)

Combustion

Blower Motor

Heat Shield

Latch

Fig. 22

Exhaust Probe

Fig. 23

Maintenance

The boiler MUST be OFF and COOL before you

should attempt to clean the combustion blower.

The wire to the combustion blower doesn’t need to be

disconnected during the cleaning process.

Loosen the three (3) thumb screws about 4 turns each.

See Fig. 23. Hold the motor head with one hand and the

blower plate handle with the other hand. Pull outward

on the plate handle until the complete unit comes loose.

Now rotate the plate counter-clockwise about 1/8 turn.

This will allow the complete assembly to be removed

from the blower chamber.

Clean the blower fan blades and the blower plate

sealing overlap. See Fig. 24.

NOTE: Be careful not to bend the fan blades, this will

throw the fan blade out of balance or it may rub the inner

chamber, which may affect the performance of the boiler.

Any horizontal and vertical ue pipe directly above the unit

should be cleaned at this time

NOTE: The horizontal ue pipe directly above the boiler

is the rst place y ash will settle, due to the slowing of ue

gas velocity through horizontal pipe. Cleaning of horizon-

tal venting pipes is very important to the efciency of this

boiler.

Clean the ue outlet throat as well as the inner chamber

of the ue tunnel (this is the hole that goes up into the

ue pipe). See Fig. 24.

NOTE: The exhaust probe sensing tip extends into

this same area. CARE MUST BE TAKEN NOT TO

DAMAGE THE ESP DURING CLEANING. Bending

of the ESP will make it difcult to remove if it should

become necessary. See Fig. 23.

Sealing Overlap

5” Double

Bladed Fan

Fig. 24

Combustion Blower Cleaning

Remove the combustion blower heat shield. There are

two latches that hold the shield in place (See Fig. 22). Flip

the latches up and pull the shield away from the boiler.

It can not be fully removed, it can only be moved down

over the wire until it hangs on the junction box.

33

Clean the boiler blower plate, sealing overlap. See Fig

24. Make sure there are no y ash buildups that may

block the easy ow of ue gasses into the combustion

blower inlet hole. ( A ashlight may be necessary. )

Cleaning the Tube Heat Exchangers:

The heat exchanger tubes have external handles that

operate the cleaning mechanisms. See picture on page 32.

This cleaning should be done at least once a week,

although it can be done as often as desired. The cleaner

the heat exchangers are, the more efcient the boiler

will be. This cleaning can be done at any time and in

any mode of operation. During high re periods, the

cleaning rods may stick due to heat related expansion.

CAUTION: Inspect ue pipes, ue pipe joints and

ue pipe seals regularly to ensure that smoke and

ue gases are not entering the home.

Page 34

Troubleshooting

FEEDER DOES NOT FEED

1. No pellets in hopper.

2. Firebox draft may be too low for low draft pressure switch in feeder circuit to operate. Check

for improperly closed doors, loose or missing

gasket on doors or hopper lid, or a faulty pressure switch.

3. Feed motor will not run until the ESP

senses 170 deg. F. Maybe you did not put

enough pellets in the burn pot before lighting the

remanually.

4.Somethingisrestrictingowinthehopperor

causing the slide plate to stick.

5. Feed motor has failed.

PARTIALLY BURNED PELLETS

1. Feed rate too high.

2. Draft too low. (Check burn pot clean-out slide

and door gasket).

3. Burn pot or heat exchanger tubes may need

to be cleaned.

4. Combination of all the above.

5. #6 status blink: A 6 blink control board status indication is caused by poor or incomplete

combustion. The Automatic Ignition circuit board

has the ability to track the combustion through

feed settings and ESP temperatures. When the

control board has calculated poor or incomplete

combustion, it will shut down the unit as a safety

feature. (Poor or incomplete combustion is a

contributer of creosote which may cause a chim-

neyre)

A 6 blink status may be caused by several

things:

1.Blockedorpartiallyblockedue.

2. Blocked or partially blocked inlet air.

a. Backdraft damper on the inlet pipe may be

stuck closed.

b. If outside air is installed, the inlet cover may

be blocked.

3. The air chamber under the burnpot may be

lledwithnesandsmallbitsofash.

4.Theholesintheburnpotmaybegettinglled

with ash or carbon buildup.

5. Combustion blower fan blades may need

cleaned.

6. There is no fuel in the hopper.

SMOKE SMELL

Seal the vent pipe joints and connection to stove

with silicone.

FIRE HAS GONE OUT

1. No pellets in hopper.

2. Draft setting is too low.

3.Somethingisrestrictingfuelow.

4. Feed motor or combustion blower has failed.

34

5. Power failure or blown fuse.

SMOKE IS VISIBLE COMING OUT OF VENT

1. Air-fuel ratio is too rich.

A. Feed rate too high.

B. Draft too low caused by a gasket leak.

LOW HEAT OUTPUT

1. Feed rate too low

2. Draft too low because of gasket leak.

3. Poor quality or damp pellets

4. Combination of 1 and 2.

Cleaning Burn Pot

Whenever your boiler is not burning, take

the opportunity to scrape the burn pot to remove

carbon buildup. A vacuum cleaner is handy to

remove the residue. Be sure the boiler is cold if

you use a vacuum.

Carbon buildup can be scraped loose with

thereburningusingthespecialtoolprovided

withyourstove.Scrapetheoorandsidesofthe

burn pot. The carbon will be pushed out by the

incoming fuel. Always wear gloves to do this.

Removing Ashes

Ashes can be removed while in operation,

but extra care must be taken and always wear

gloves.

Maximum Feed Adjuster settings are not

needed in most cases. Operating in the normal

range (#4) is recommended when maximum heat

output is not required. The ESP prevents the

stovefrombeingover-red.

Keep the boiler free of dust and dirt.

Helpful Hints

Fuel

Pellet fuels are put into 3 categories in terms of

ash content. Premium at 1% or less, Standard at

3% or less and all others at 3% or more.

This unit is capable of burning all 3 categories

of pellets due to a patented feeder and burn pot

system.

It should be noted, however, that higher ash

content will require more frequent ash removal,

scraping of the burn pot, and may provide less

BTU’s per pound. Normally, standard and high ash

pellets cost less than premium pellets and can be

cost effective when burned in this boiler.

The moisture content must not exceed 8%.

Higher moisture will rob BTU’s and may not burn

properly.

Page 35

Atmospheric Conversion

AtmosphericConversion:Item#1-00-232200,providesautomaticll,andconvertstheheating

systemplumbingfrompressurizedtoazeropressuresystem.Allowsforinstallationintomore

placeswherecodesandstandardsrestrictpressurizedsystems.Notethatwhenusingtheatmo-

spheric conversion, air bleeders and check valves may actually allow air into the lines. Another

reason it is important to have a licensed Plumber involved in each phase of your installation.

35

When using the atmospheric conversion, the circuit board dipswitch #6 must

be in the “ON” position. This will lower the overheat temperature parameters

to prevent boiling of the water. Since altitude affects the boiling point, it is also

recommended to set #6 to “ON” at elevations above 3000 ft.

Page 36

Specications

36

BTU Input Range= 0, and 9350 to 113,900*

0 BTU if system is satised.

Min. Burn = 1.1 pound per hour

Max. Burn = 13.4 pounds per hour

* 8500 BTU per pound gures

Electrical 120 VAC 60 Hz

Combustion blower 1.4 AMP

Auger motor .7 AMP

Igniter element 3.6 AMP

Control board .05 AMP

Approximate operating wattage .2 KWH

Page 37

6 AMP GLASS FUSE

Wiring Diagram

WHITE 11 PIN PLUG

2

EXHAUST PROBE

(ESP)

9

1

8

4

3

11

10

1

BROWN

3

PLUGGED

WHITE

4

5

WHITE

EMPTY

6

7

EMPTY

EMPTY

10911

8

BLACK

PART NO. 3-90-72194A

RED

YELLOW

DK BLUE

PELLET BOILER WIRING DIAGRAM

BROWN

AQUA TEMP SENSOR

WHITE

DARK BLUE

RED

3/8"FLEX CONDUIT

GREEN/YELLOW

ESP

BOARD

CONTROL

TCP

BLACK

GREEN/YELLOW WIRE

TWISTED WIRE

OUTDOOR AIR EXTENSION

120 VAC

YELLOW

YELLOW

SKY BLUE

SKY BLUE

WHITE

BLACK

N.O. CONTACTS

LOW PRESSURE SWITCH

IS GROUND BONDED TO

STOVE BODY

MOTOR WIRE MALE/FEMALE CONNECTION