Page 1

Owner’s Manual

Care and Operation

INSTALLER: Leave this manual with party responsible for use and operation.

OWNER: Retain this manual for future reference.

Contact your dealer with questions regarding installation, operation or service.

NOTICE: DO NOT discard this manual!

Models:

6000CMOD-IFT

8000CMOD-IFT

WARNING:

FIRE OR EXPLOSION HAZARD

Failure to follow safety warnings exactly

could result in serious injury, death, or

property damage.

• DO NOT store or use gasoline or other am-

mable vapors and liquids in the vicinity of this

or any other appliance.

• What to do if you smell gas

- DO NOT try to light any appliance.

- DO NOT touch any electrical switch. DO

NOT use any phone in your building.

- Leave the building immediately.

- Immediately call your gas supplier from

a neighbor’s phone. Follow the gas supplier’s instructions.

- If you cannot reach your gas supplier, call

the re department.

• Installation and service must be performed

by a qualied installer, service agency, or the

gas supplier.

This appliance may be installed as an OEM

installation in manufactured home (USA

only) or mobile home and must be installed

in accordance with the manufacturer’s

instructions and the Manufactured Home

Construction and Safety Standard, Title 24

CFR, Part 3280 in the United States, or the

Standard for Installation in Mobile Homes,

CAN/CSA Z240 MH Series, in Canada.

This appliance is only for use with the type(s)

of gas indicated on the rating plate. This

appliance is not convertible for use with other

gases, unless a certied kit is used.

Heat & Glo • 6000CMOD-IFT, 8000CMOD-IFT Owner’s Manual • 2509-981 Rev. E • 1/19

DANGER

HOT GLASS WILL

CAUSE BURNS.

DO NOT TOUCH GLASS

UNTIL COOLED.

NEVER ALLOW CHILDREN

TO TOUCH GLASS.

A barrier designed to reduce the risk of

burns from the hot viewing glass is provided

with this appliance and shall be installed for

the protection of children and other at-risk

individuals.

In the Commonwealth of Massachusetts installation must be

performed by a licensed plumber or gas tter.

See appliance installation manual for additional

Commonwealth of Massachusetts requirements.

1

Page 2

1

Welcome

Read this manual before operating this appliance.

Please retain this Owner’s Manual for future reference.

Read the Installation Manual before making any installation or nishing changes.

A. Congratulations

Congratulations on selecting a Heat & Glo gas replace, an

elegant and clean alternative to wood burning replaces.

The Heat & Glo gas replace you have selected is designed

to provide the utmost in safety, reliability, and efciency.

As the owner of a new replace, you’ll want to read and

carefully follow all of the instructions contained in this

owner’s manual. Pay special attention to all cautions and

warnings.

This owner’s manual should be retained for future

reference. We suggest that you keep it with your other

important documents and product manuals.

The information contained in this owner’s manual, unless

noted otherwise, applies to all models and gas control

systems.

Your new Heat & Glo gas replace will give you years of

durable use and trouble-free enjoyment. Welcome to the

Heat & Glo family of replace products!

Local Dealer Information

DEALER: Fill in

your name, address,

phone and email

information here and

appliance information

below.

Appliance Information:

Brand: ________________________________________________ Model Name: ___________________________

Dealer Name: ________________________________________________________

Address: ____________________________________________________________

____________________________________________________________

Phone: _____________________________________________________________

Email: _____________________________________________________________

Serial Number: __________________________________________ Date Installed: __________________________

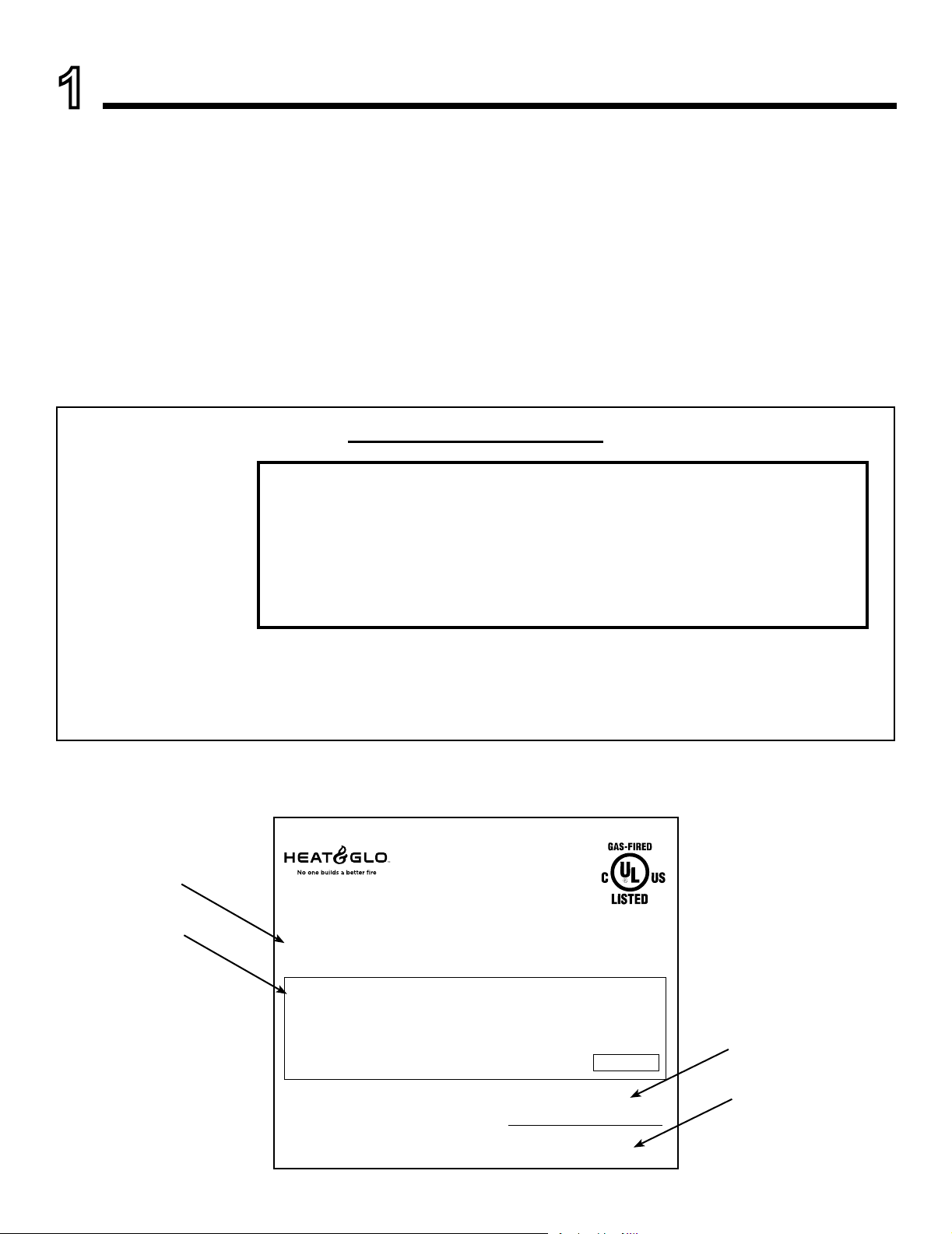

Listing Label Information/Location

The model information regarding your specic replace can be found on

the rating plate usually located in the control area of the replace.

Model Number

Serial Number

Type of Gas

Gas and Electric

Information

Heat & Glo, a brand of Hearth & Home Technologies

7571 215th Street West, Lakeville, MN 55044

Not Not for for use use with with solid solid fuel.fuel.

((Ne Ne doit doit pas pas entre entre utilise utilise avec avec un un combustible combustible solide).solide).

Type Type of of Gas Gas (Sorte (Sorte De De Gaz)Gaz)::

NNAATURALTURAL GASGAS

Minimum Minimum Permissible Permissible Gas Gas Supply Supply for for Purposes Purposes of of Input Input Adjustment.Adjustment.

Approved Approved Minimum Minimum (De (De Gaz) Gaz) AcceptableAcceptable 0.00.0 in in w. c.w. c. (Po. (Po. Col. Col. d’eau)d’eau)

Maximum Maximum Pressure Pressure (Pression)(Pression) 0.00.0 in in w.c.w.c. (Po. (Po. Col. Col. d’eau)d’eau)

Maximum Maximum Manifold Manifold Pressure Pressure (Pression)(Pression) 0.00.0 in in w.c.w.c. (Po. (Po. Col. Col. d’eau)d’eau)

Minimum Minimum Manifold Manifold Pressure Pressure (Pression)(Pression) 0.00.0 in in w.c.w.c. (Po. (Po. Col. Col. d’eau)d’eau)

Total To tal Electrical Electrical Requirements: Requirements: 000Vac, 000Vac, 00Hz., 00Hz., less less than than 00 00 AmperesAmperes

ALTITUDE:ALTITUDE: 0-0000 0-0000 FT.FT. 0000-0000FT.0000-0000FT.

MAX. MAX. INPUT INPUT BTUH:BTUH: 00,00000,000 00,00000,000

MIN. MIN. INPUT INPUT BTUH:BTUH: 00,00000,000 00,00000,000

ORIFICE ORIFICE SIZE:SIZE: #XXXXX#XXXXX #XXXXX#XXXXX

This This appliance appliance must must be be installed installed in in accordance accordance with with local local codes, codes, if if any; any; if if not, not, follow follow ANSI ANSI Z223.1Z223.1

in in the the USA USA or or CAN/CGA CAN/CGA B149 B149 installation installation codes. codes. (Installer (Installer l’appareil l’appareil selon selon les les codes codes ou ou reglementsreglements

locaux locaux ou, ou, en en l’absence l’absence de de tels tels reglements, reglements, selon selon les les codes codes d’installation d’installation CAN/CGA-B149.)CAN/CGA-B149.)

ANSI ANSI Z21XX-XXXX Z21XX-XXXX · · CSA CSA 2.XX-MXX 2.XX-MXX

IN IN CANADACANADA

Model:Model:

(Modele):(Modele):

SerialSerial

(Serie):(Serie):

MADE MADE IN IN USAUSA

XXXXXXXXXXXXXXXX

XXXXXXXXXXXXXXXX

2

Heat & Glo • 6000CMOD-IFT, 8000CMOD-IFT Owner’s Manual • 2509-981 Rev. E • 1/19

Page 3

Safety Alert Key:

• DANGER! Indicates a hazardous situation which, if not avoided will result in death or serious injury.

• WARNING! Indicates a hazardous situation which, if not avoided could result in death or serious injury.

• CAUTION! Indicates a hazardous situation which, if not avoided, could result in minor or moderate injury.

• NOTICE: Used to address practices not related to personal injury.

Table of Contents

1 Welcome

A. Congratulations ................................. 2

B. Limited Lifetime Warranty .......................... 4

2 Product Specic Information

A. Appliance Certication ............................6

B. Glass Specications ..............................6

C. BTU Specications ............................... 6

3 Important Safety and Operating Information

A. Appliance Safety ................................ 7

B. General Operating Parts .......................... 8

C. Fuel Specications ............................... 8

D. Good Faith Wall Surface/TV Guidelines .............. 8

E. Before Lighting Appliance. . . . . . . . . . . . . . . . . . . . . . . . . 10

F. Lighting Instructions (IPI) ......................... 11

G. Appliance Break-In .............................. 12

H. Heat Management ..............................12

I. Operation During A Power Outage - IntelliFire™ Touch . 13

J. Detailed Component Operating Instructions

- IntelliFire™ Touch .............................14

4 Maintenance and Service

A. Maintenance: Frequency and Tasks ................ 16

B. Maintenance Tasks - Homeowner .................. 16

C. Maintenance Tasks - Qualied Service Technician .....18

D. Glass Refractory, Base Pan, Burner and Valve

Assembly Removal. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

E. Burner Identication .............................20

5 Frequently Asked Questions and Troubleshooting

A. Frequently Asked Questions - Appliance .............21

B. Frequently Asked Questions - IntelliFire™ Touch

Controls (IFT-RC400) (Optional Remote). . . . . . . . . . . . . 22

C. Troubleshooting ................................23

6 Reference Materials

A. Accessories ...................................25

B. Service Parts .................................. 26

C. Contact Information ............................. 30

= Contains updated information.

Heat & Glo • 6000CMOD-IFT, 8000CMOD-IFT Owner’s Manual • 2509-981 Rev. E • 1/19

3

Page 4

B. Limited Lifetime Warranty

Wood

All parts and material except as

listed

Igniters, electronic components,

and glass

X X X X X Factory-installed blowers

X Firepots and burnpots

5 years 1 year X X Castings and baffles

Manifold tubes,

HHT chimney and termination

years

Lifetime

beyond warranty period

3 years

Hearth & Home Technologies

LIMITED LIFETIME WARRANTY

Hearth & Home Technologies, on behalf of its hearth brands (“HHT”), extends the following warranty for HHT

gas, wood, pellet, coal and electric hearth appliances that are purchased from an HHT authorized dealer.

WARRANTY COVERAGE:

HHT warrants to the original owner of the HHT appliance at the site of installation, and to any transferee taking ownership

of the appliance at the site of installation within two years following the date of original purchase, that the HHT appliance

will be free from defects in materials and workmanship at the time of manufacture. After installation, if covered components manufactured by HHT are found to be defective in materials or workmanship during the applicable warranty period,

HHT will, at its option, repair or replace the covered components. HHT, at its own discretion, may fully discharge all of its

obligations under such warranties by replacing the product itself or refunding the verified purchase price of the product

itself. The maximum amount recoverable under this warranty is limited to the purchase price of the product. This warranty

is subject to conditions, exclusions and limitations as described below.

WARRANTY PERIOD:

Warranty coverage begins on the date of original purchase. In the case of new home construction, warranty coverage

begins on the date of first occupancy of the dwelling or six months after the sale of the product by an independent,

authorized HHT dealer/ distributor, whichever occurs earlier. The warranty shall commence no later than 24 months

following the date of product shipment from HHT, regardless of the installation or occupancy date. The warranty period for

parts and labor for covered components is produced in the following table.

The term “Limited Lifetime” in the table below is defined as: 20 years from the beginning date of warranty coverage for

gas appliances, and 10 years from the beginning date of warranty coverage for wood, pellet, and coal appliances. These

time periods reflect the minimum expected useful lives of the designated components under normal operating conditions.

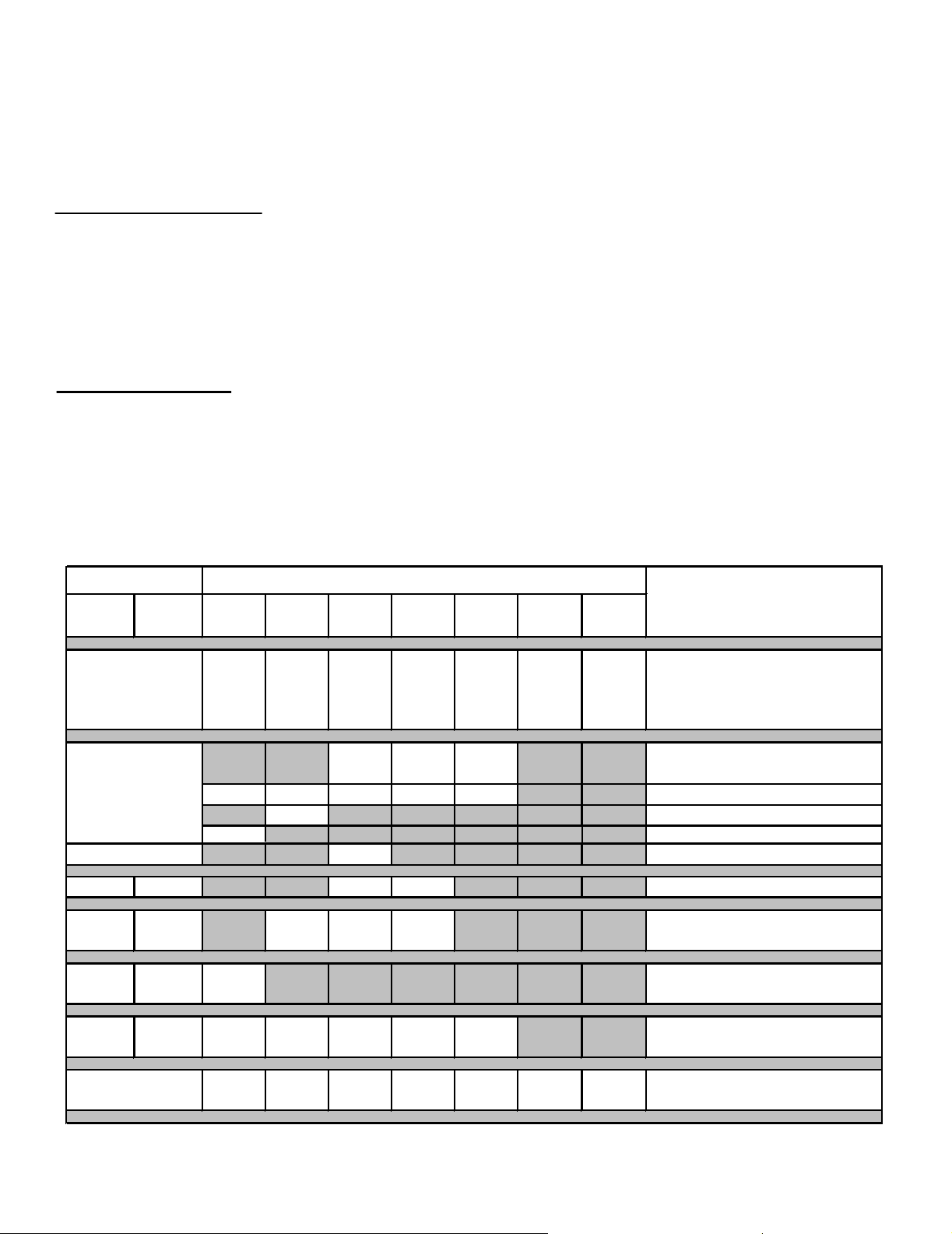

Warranty Period HHT Manufactured Appliances and Venting

Parts Labor Gas Wood Pellet

1 Year

XXXXXXX

EPA

Coal Electric Venting

XXX

2 years

X Molded refractory panels

X

7 years 3 years X X X

10

Limited

1 year X Burners, logs and refractory

3 years X X X X X Firebox and heat exchanger

Components Covered

covered by Conditions,

Exclusions, and Limitations

Ignition Modules

90 Days

4021-645H 10/15 Page 1 of 2

4

XXXXXXX

See conditions, exclusions, and limitations on next page.

Heat & Glo • 6000CMOD-IFT, 8000CMOD-IFT Owner’s Manual • 2509-981 Rev. E • 1/19

All replacement parts

Page 5

B. Limited Lifetime Warranty (continued)

WARRANTY CONDITIONS:

• This warranty only covers HHT appliances that are purchased through an HHT authorized dealer or distributor. A list of

HHT authorized dealers is available on the HHT branded websites.

• This warranty is only valid while the HHT appliance remains at the site of original installation.

• This warranty is only valid in the country in which the HHT authorized dealer or distributor that sold the appliance

resides.

• Contact your installing dealer for warranty service. If the installing dealer is unable to provide necessary parts, contact

the nearest HHT authorized dealer or supplier. Additional service fees may apply if you are seeking warranty service

from a dealer other than the dealer from whom you originally purchased the product.

• Check with your dealer in advance for any costs to you when arranging a warranty call. Travel and shipping charges

for parts are not covered by this warranty.

WARRANTY EXCLUSIONS:

This warranty does not cover the following:

• Changes in surface finishes as a result of normal use. As a heating appliance, some changes in color of interior and

exterior surface finishes may occur. This is not a flaw and is not covered under warranty.

• Damage to printed, plated, or enameled surfaces caused by fingerprints, accidents, misuse, scratches, melted items,

or other external sources and residues left on the plated surfaces from the use of abrasive cleaners or polishes.

• Repair or replacement of parts that are subject to normal wear and tear during the warranty period. These parts

include: paint, wood, pellet and coal gaskets, firebricks, grates, flame guides, batteries and the discoloration of glass.

• Expansion, contraction, or movement of certain parts causing noise. These conditions are normal and complaints

related to this noise are not covered by this warranty.

• Damages resulting from: (1) failure to install, operate, or maintain the appliance in accordance with the installation

instructions, operating instructions, and listing agent identification label furnished with the appliance; (2) failure to

install the appliance in accordance with local building codes; (3) shipping or improper handling; (4) improper operation, abuse, misuse, continued operation with damaged, corroded or failed components, accident, or improperly/

incorrectly performed repairs; (5) environmental conditions, inadequate ventilation, negative pressure, or drafting

caused by tightly sealed constructions, insufficient make-up air supply, or handling devices such as exhaust fans or

forced air furnaces or other such causes; (6) use of fuels other than those specified in the operating instructions; (7)

installation or use of components not supplied with the appliance or any other components not expressly authorized

and approved by HHT; (8) modification of the appliance not expressly authorized and approved by HHT in writing;

and/or (9) interruptions or fluctuations of electrical power supply to the appliance.

• Non-HHT venting components, hearth components or other accessories used in conjunction with the appliance.

• Any part of a pre-existing fireplace system in which an insert or a decorative gas appliance is installed.

• HHT’s obligation under this warranty does not extend to the appliance’s capability to heat the desired space. Information is provided to assist the consumer and the dealer in selecting the proper appliance for the application. Consideration must be given to appliance location and configuration, environmental conditions, insulation and air tightness of

the structure.

This warranty is void if:

• The appliance has been over-fired or operated in atmospheres contaminated by chlorine, fluorine, or other damaging

chemicals. Over-firing can be identified by, but not limited to, warped plates or tubes, rust colored cast iron, bubbling,

cracking and discoloration of steel or enamel finishes.

• The appliance is subjected to prolonged periods of dampness or condensation.

• There is any damage to the appliance or other components due to water or weather damage which is the result of, but

not limited to, improper chimney or venting installation.

LIMITATIONS OF LIABILITY:

• The owner’s exclusive remedy and HHT’s sole obligation under this warranty, under any other warranty, express or

implied, or in contract, tort or otherwise, shall be limited to replacement, repair, or refund, as specified above. In no

event will HHT be liable for any incidental or consequential damages caused by defects in the appliance. Some states

do not allow exclusions or limitation of incidental or consequential damages, so these limitations may not apply to you.

This warranty gives you specific rights; you may also have other rights, which vary from state to state. EXCEPT TO

THE EXTENT PROVIDED BY LAW, HHT MAKES NO EXPRESS WARRANTIES OTHER THAN THE WARRANTY

SPECIFIED HEREIN. THE DURATION OF ANY IMPLIED WARRANTY IS LIMITED TO DURATION OF THE

EXPRESSED WARRANTY SPECIFIED ABOVE.

4021-645H 10/15 Page 2 of 2

Heat & Glo • 6000CMOD-IFT, 8000CMOD-IFT Owner’s Manual • 2509-981 Rev. E • 1/19

5

Page 6

2

Product Specic Information

A. Appliance Certication

MODELS: 6000CMOD-IFT, 8000CMOD-IFT

LABORATORY: Underwriters Laboratories, Inc. (UL)

TYPE: Direct Vent Heater

STANDARD: ANSI Z21.88-2017 • CSA 2.33-2017

This product is listed to ANSI standards for “Vented Gas

Fireplace Heaters” and applicable sections of “Gas Burning Heating Appliances for Manufactured Homes and

Recreational Vehicles”, and “Gas Fired Appliances for

Use at High Altitudes”.

NOTICE: This installation must conform with local codes.

In the absence of local codes you must comply with the

National Fuel Gas Code, ANSI Z223.1-latest edition in

the U.S.A. and the CAN/CGA B149 Installation Codes in

Canada.

B. Glass Specications

This appliance is equipped with 5 mm ceramic glass with

an anti-reective coating. Replace glass only with glass

with identical specications. Please contact your dealer

for replacement glass.

C. BTU Specications

Models

(U.S. or Canada)

6000CMOD-IFT (NG)

8000CMOD-IFT (NG)

(0-2000 FT)

(0-2000 FT)

Maximum

Input

BTU/h

34,000 17,500 35

35,500 19,000 33

Minimum

Input

BTU/h

Orice

Size

(DMS)

NOT INTENDED FOR USE AS A PRIMARY HEAT SOURCE.

This appliance is tested and approved as either supplemental room heat or as a decorative appliance. It should not be

factored as primary heat in residential heating calculations.

Installation and service of this appliance should be performed by

qualied personnel. Hearth & Home Technologies recommends

HHT Factory Trained or NFI certied professionals.

6

Heat & Glo • 6000CMOD-IFT, 8000CMOD-IFT Owner’s Manual • 2509-981 Rev. E • 1/19

Page 7

Important Safety and Operating Information

3

A. Appliance Safety

WARNING! DO NOT operate replace before reading

and understanding operating instructions. Failure

to operate replace according to operating instructions

could cause re or injury.

DANGER

HOT GLASS WILL

CAUSE BURNS.

DO NOT TOUCH GLASS

UNTIL COOLED.

NEVER ALLOW CHILDREN

TO TOUCH GLASS.

• Keep children away.

• CAREFULLY SUPERVISE children in same room

as replace.

• Alert children and adults to hazards of high

temperatures.

High temperatures may ignite clothing or other

ammable materials.

• Clothing, furniture, draperies, and other ammable

materials must not be placed on or near the

appliance.

• Never leave children alone near a hot replace, whether

operating or cooling down.

• Teach children to NEVER touch the replace.

• Consider not using the replace when children will be

present.

Contact your dealer for more information, or visit: www.

hpba.org/Product-Info/Fireplace-Stove-Heater/GlassFronts-Safety.

To prevent unintended operation when not using your replace for an extended period of time (summer months,

vacations, trips, etc):

• Remove batteries from remote controls.

• Turn off wall controls.

• Set the selector switch on the control module to the

OFF position and remove batteries from battery pack (if

installed).

WARNING: This product and the fuels used to

operate this product (liquid propane or natural

gas), and the products of combustion of such fuels, can

expose you to chemicals including benzene, which is

known to the State of California to cause cancer and

reproductive harm. For more information go to: www.

P65Warnings.ca.gov.

A barrier designed to reduce the risk of burns from the

hot viewing glass is provided with this appliance and

shall be installed for the protection of children and other

at-risk individuals. DO NOT operate the appliance with

the barrier removed. If the barrier becomes damaged,

the barrier shall be replaced with the manufacturer’s

barrier for this appliance.

Contact your dealer or Hearth & Home Technologies if the

barrier is not present or help is needed to properly install one.

WARNING! Choking Hazard! Keep rock media out of

reach of children.

Young children should be carefully supervised when they

are in the same room as the appliance. Toddlers, young

children and others may be susceptible to accidental

contact burns.

• A physical barrier is recommended if there are at risk

individuals in the house.

• To restrict access to a replace or stove, install an

adjustable safety gate to keep toddlers, young children

and other at risk individuals out of the room and away

from hot surfaces.

• Install a switch lock or a wall/remote control with child

protection lockout feature.

• Keep remote controls out of reach of children.

Clear Space

WARNING! DO NOT place combustible objects in front of

the replace or block replace openings. High temperatures could start a re. See Figure 3.1.

Avoid placing candles and other heat-sensitive objects

on mantel or hearth. Heat could damage these objects.

CLEAR SPACE

3 FT. IN

FRONT OF

FIREPLACE

Figure 3.1 Clear Space Requirement - All Models

Heat & Glo • 6000CMOD-IFT, 8000CMOD-IFT Owner’s Manual • 2509-981 Rev. E • 1/19

7

Page 8

B. General Operating Parts

Figure 3.2 references the general operating parts of the

appliance and the section of this manual in which they are

discussed.

DECORATIVE FRONTS

(NOT SHOWN)

SECTION 4.B.

FIXED GLASS ASSEMBLY

(NOT SHOWN)

SECTION 4.B.

FAN KIT

SECTION 3.H

HEARTH

(not required)

CLEAR SPACE

SECTION 3.A.

CONTROL CAVITY

SECTION 3.I

Figure 3.2 General Operating Parts

MANTEL

C. Fuel Specications

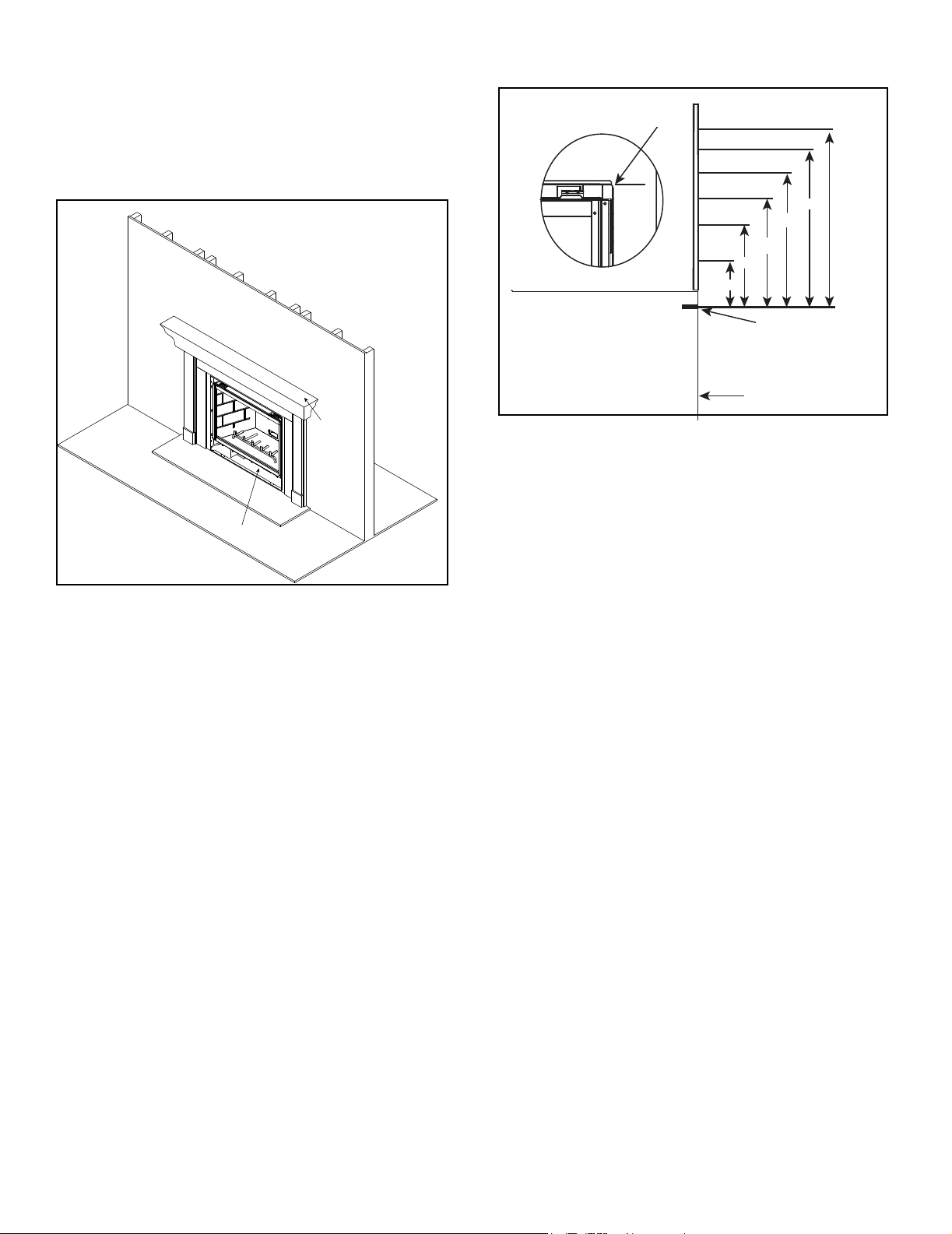

D. Good Faith Wall Surface/TV Guidelines

FIREPL ACE

OPENI NG

135°F

147°F

6 in.

Figure 3.3 Good Faith Wall Surface Temperatures Above Appliance

NOTICE: Temperatures listed above are taken with a

temperature measuring probe as prescribed by the test

standard used for appliance certication. Temperatures

on walls or mantels taken with an infrared thermometer

may yield increased temperatures of up to 30 degrees or

more depending on the thermometer settings and material

characteristics being measured. Use appropriate nishing

materials that are able to withstand these conditions.

For additional nishing guidelines, see Section 10 in the

appliance Installation Manual.

TO CEILIN G

127°F

123°F

132°F

12 in.

TOP EDGE O F THE OPENI NG

APPLIA NCE FRONT

30 in.

24 in.

18 in.

MEASU REMENTS FROM

WARNING! Risk of Fire or Explosion! Appliance must

be set up for compatible gas type!

• This appliance is designed to operate using only

natural gas. Gas conversion is NOT allowed for this

appliance.

8

Heat & Glo • 6000CMOD-IFT, 8000CMOD-IFT Owner’s Manual • 2509-981 Rev. E • 1/19

Page 9

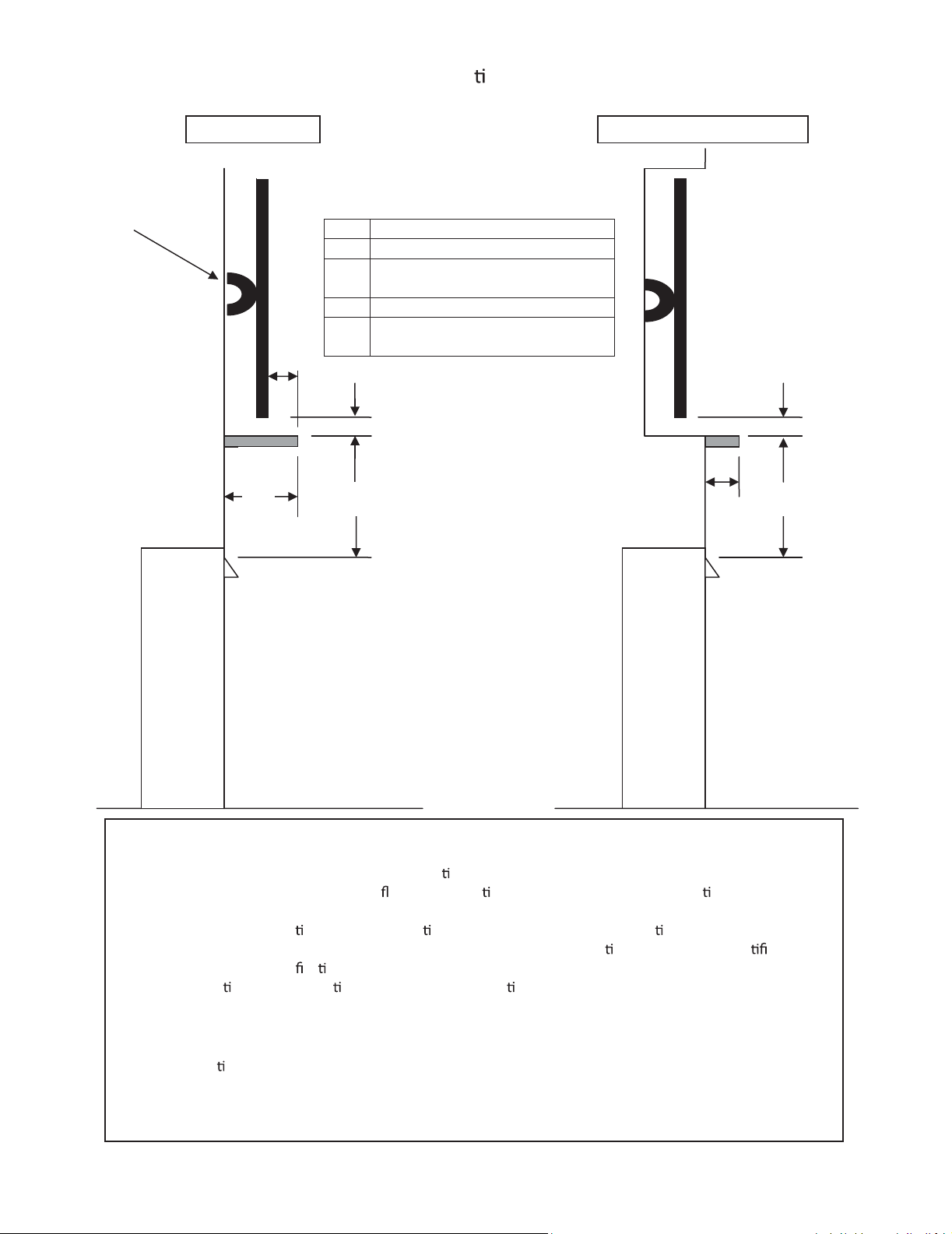

TV Wall

Bracket

Good Faith Guidelines for TV Installa ons above a Typical Gas Fireplace

TV on the wall

TV

A

Mantel

Item Minimum Dimensions

A 2.5 inches

2 inches minimum to 3 inches

B

maximum

C 18 inches

Wall Brkt + TV Thickness + 2.5

D

inches

TV recessed into the wall

BB

D

Fireplace

Notes:

1. These are good faith recommended clearances only and not a guarantee of compliance with all TV

manufacturers’ maximum allowable opera

2. Since every home has unique air

can vary from manufacturer to manufacturer and from model to model, actual TV temperatures should

be validated at the

temperature exceeds the manufacturers’ maximum allowable opera

TV’s technical speci

informa

3. Mantel height and depth must conform to mantle requirements specified in the fireplace installaon

manual.

on or have ques ons regarding the informa

C

Fireplace

ng temperatures.

ow characteris cs and maximum allowable opera ng temperatures

me of each installa on. TVs should not be used in situa ons where the actual TV

ng temperatures iden ed in the

ca ons. Contact the TV’s manufacturer directly if you cannot locate this

on.

A

4. “C” dimension taken from the top of the hood or fireplace opening.

Sugges ons on how to further reduce TV temperatures:

5.

a. Increase “A” dimension.

b. Increase “C” dimension, however, increasing “B” dimension beyond maximum recommended

typically results in higher temperatures.

C

Figure 3.4 Good Faith TV Guidelines

Heat & Glo • 6000CMOD-IFT, 8000CMOD-IFT Owner’s Manual • 2509-981 Rev. E • 1/19

9

Page 10

E. Before Lighting Appliance

Before operating this replace for the rst time, have a

qualied service technician:

• Verify all shipping materials have been removed from

inside and/or underneath the rebox.

• Review proper placement of logs, ember material and/or

other decorative materials.

• Check the wiring.

• Check the air shutter adjustment.

• Ensure that there are no gas leaks.

• Ensure that the glass is sealed and in the proper position

and that the integral barrier is in place.

WARNING! Risk of Fire or Asphyxiation! DO NOT op-

erate replace with xed glass assembly removed.

10

Heat & Glo • 6000CMOD-IFT, 8000CMOD-IFT Owner’s Manual • 2509-981 Rev. E • 1/19

Page 11

F. Lighting Instructions (IPI)

FOR YOUR SAFETY READ BEFORE LIGHTING

WARNING

A. This appliance is equipped with an intermittent pilot ignition (IPI) device which

automatically lights the burner. DO NOT try to light the burner by hand.

B. BEFORE LIGHTING, smell all around the appliance area for gas. Be sure to smell

WHAT TO DO IF YOU SMELL GAS

• DO NOT try to light any appliance.

• DO NOT touch any electric switch; do not use any phone in your building.

LIGHTING INSTRUCTIONS (IPI)

1. This appliance is equipped with an ignition device which

automatically lights the burner. DO NOT try to light the burner by hand.

GAS

VALVE

TO TURN OFF GAS TO APPLIANCE

1. Equipped with wall switch: Turn ON/OFF switch to OFF.

Equipped with remote or wall control: Press OFF button.

Equipped with thermostat: Set temperature to lowest setting.

• Immediately call your gas supplier from a neighbor’s phone. Follow the gas supplier’s instructions.

•

C. Use only your hand to push in or turn the gas control knob. Never use tools. If

the knob will not push in or turn by hand, DO NOT

D. DO NOT use this appliance if any part has been under water. Immediately call

the control system and any gas control which has been under water.

2.

top of this label. If you do not smell gas, go to next step.

3. To light the burner:

Equipped with wall switch: Turn ON/OFF switch to ON.

Equipped with remote or wall control: Press ON or FLAME button.

Equipped with thermostat: Set temperature to desired setting.

4. If the appliance does not light after three tries, call your service technician or gas

supplier.

2. Service technician should turn off electric power to the control when performing

service.

DANGER

HOT GLASS WILL CAUSE BURNS.

DO NOT TOUCH GLASS UNTIL COOLED.

NEVER ALLOW CHILDREN TO TOUCH GLASS.

A barrier designed to reduce the risk of burns from the hot viewing glass is provided with this

appliance and shall be installed for the protection of children and other at-risk individuals.

WARNING:

DO NOT CONNECT LINE VOLTAGE (110/120 VAC OR 220/240 VAC) TO THE CONTROL VALVE.

Improper installation, adjustment, alteration, service or maintenance can cause injury

or property damage. Refer to the owner’s information manual provided with this ap-

agency or the gas supplier.

This appliance needs fresh air for safe operation and must be installed so there are

provisions for adequate combustion and ventilation air.

WARNING: This product and the fuels used to operate this

product (liquid propane or natural gas), and the products

of combustion of such fuels, can expose you to chemicals

including benzene, which is known to the State of California to cause

cancer and reproductive harm. For more information go to: www.

P65Warnings.ca.gov.

Keep burner and control compartment clean. See installation and operating instructions

accompanying appliance.

CAUTION:

Hot while in operation. DO NOT touch. Keep children, clothing, furniture, gasoline

DO NOT operate the appliance with removed, cracked or

broken. Replacement of the

NOT FOR USE WITH SOLID FUEL

For use with natural gas and propane. A conversion kit, as supplied by the manufacturer, shall be used to convert this appliance to the alternate fuel.

This appliance must be installed in accordance with local codes, if any; if none,

follow the National Fuel Gas Code, ANSIZ223.1/ NFPA 54, or the National Gas and

Propane Installation code, CSA B149.1.

For additional information on operating your

refer to www.hearthnhome.com.

should be done by a licensed or

Heat & Glo • 6000CMOD-IFT, 8000CMOD-IFT Owner’s Manual • 2509-981 Rev. E • 1/19

11

Page 12

G. Appliance Break-In

Follow the initial break-in procedure below to cure the

materials used to manufacture the replace and the

nishing materials around it.

• The fireplace should be run three to four hours

continuously on high.

• Turn the replace off and allow it to cool completely.

• Remove xed glass assembly. See Section 4.B.

• Clean xed glass assembly. See Section 4.B.

• Replace the xed glass assembly and run continuously

on high an additional 12 hours.

Note: The IntelliFire™ Touch system has a safety feature

that automatically shuts down the replace after 9 hours of

continuous operation without receiving a command from

the remote control. If this occurs, restart the appliance.

NOTICE! Open windows for air circulation during replace break-in.

• Some people may be sensitive to smoke and odors.

• Smoke detectors may activate.

H. Heat Management

Heat Output

This model has a variable burn rate which is controlled by

the command on the optional remote control, if installed.

The control module is located in the control cavity of the

appliance.

If an optional fan is installed, the fan speed is controlled by

adjusting the speed control knob or using the command

on the optional remote control, if installed.

If the rheostat included in the optional fan kit is installed,

turn the knob clockwise to increase the fan speed and

counterclockwise to decrease the fan speed.

If both the optional remote and optional fan are installed,

use the RC400 remote to set the fan speed or to turn the

fan off. The “fan speed” dynamic icon is used to change

the setting.

12

Heat & Glo • 6000CMOD-IFT, 8000CMOD-IFT Owner’s Manual • 2509-981 Rev. E • 1/19

Page 13

I. Operation During A Power Outage - IntelliFire™ Touch

The IntelliFire™ Touch intermittent pilot ignition system

comes with a battery backup system that enables the

system to operate in a power outage. The system offers

seamless transition from household AC power to battery

backup. A factory-installed battery pack is located in the

control cavity of the appliance. See Figure 3.5. Battery

longevity and performance will be affected by long term

exposure to the service temperatures of this appliance.

IntelliFireTM Touch Ignition System

NOTICE: Batteries should only be used as a power source

in the event of an emergency power outage. Batteries

should not be used as a primary long-term power source.

Battery polarity must be correct when installing batteries.

When using batteries as a power source, the 6-volt

transformer must be unplugged from the receptacle.

To Operate Fireplace Using Battery Power (DC):

1. Access the control cavity of the appliance. See Figure

3.5 for location. The decorative front may need to be

removed.

2. Locate the battery tray and insert four AA cell batteries.

Battery polarity must be correct or module damage

will occur. See Figure 3.5. A complete wiring diagram

is included in the Electrical section of the appliance

Installation Manual.

3. Turn the appliance on according to the instructions

below for the appropriate type of control:

Standard Wall Switch or Factory-Installed ON/OFF

Switch:

• Toggle the switch as you would under normal

circumstances.

Wireless Remote:

• Remote receiver is integrated into the ignition module

• Use the remote to turn the appliance on.

• To preserve battery life, do not use the HI/LO ame or

THERMOSTAT options.

Ignition Module:

• Locate the ignition module in the control cavity.

• Slide the ON/REMOTE/OFF switch to the ON position.

To Return to Operation Using Electrical (AC) Power

Standard Wall Switch or Factory-Installed ON/OFF

Switch:

• Toggle the switch to OFF and remove the batteries

from the battery tray. Replace decorative front on

appliance.

Wireless Remote:

• Slide the ON/REMOTE/OFF switch to the REMOTE

position. Remove the batteries from the battery tray.

Replace decorative front on appliance.

Ignition Module:

• Slide the ON/REMOTE/OFF switch to the REMOTE

position.

• Remove the batteries from the battery tray. Replace

decorative front on appliance.

CONTROL CAVITY

3.5 Control Cavity / Battery Pack Location

NOTICE: Some functionality will be lost when using battery

backup including remote control, fan, lights, or any other

auxiliary functions that require household 110-120 VAC

power.

Heat & Glo • 6000CMOD-IFT, 8000CMOD-IFT Owner’s Manual • 2509-981 Rev. E • 1/19

13

Page 14

J. Detailed Component Operating

Instructions - IntelliFire™ Touch

IFT-ECM Detailed Operating Instruction

The IFT-RC400 and IFT-RC150 remotes are an option

for these models.

1. The Electronic Control Module (IFT-ECM) has a

three-position ON/OFF/REMOTE selector switch

that must be set for proper operation. See Figure

3.6. When changing switch positions, it is important

to pause in each position for 1-2 seconds.

OFF Position:

The appliance will not respond to any commands

from a wired wall switch, IFT-RC150 or IFT-RC400

remote controls. The unit should be in the OFF

position during service, fuel conversion, and to

reset the IFT-ECM in the event the system goes

into a LOCK-OUT mode as the result of a system

error. When switched to the OFF position while the

appliance is operating, the system will shut down.

ON Position:

The appliance will ignite and run continuously at

the HI ame setting. No adjustment in ame height

is possible.

Remote Position:

The remote position allows operation of the

appliance from a wired wall switch, IFT-RC400 or

IFT-RC150 remote controls. The IFT-ECM switch

must be in this position to pair the IFT-ECM with the

IFT-ACM (if installed), and/or IFT-RC400 and IFTRC150 remote controls. See the IFT-RC400 or IFTRC150 installation manual for detailed instructions

on pairing the IFT-ECM with the remote controls.

After successfully pairing a IFT-RC400, all installed

accessories can be controlled by the IFT-RC400

(see IFT-RC400 user manual). The RC150 allows

the user to turn ON/OFF the ame in the appliance

and activate the Cold Climate mode if desired. The

IFT-ECM has a safety feature that will automatically

shut down the replace after 9 hours of continuous

operation without receiving a command from the

IFT-RC400 or IFT-RC150.

The IFT-ECM has a safety feature that will

automatically shut down the replace after

9 hours of continuous operation in the ON

position, except when operated in active

thermostat mode.

2. If multiple control options are installed, the IFT-ECM

will respond to the last command from the wired wall

switch, IFT-RC400 or IFT-RC150. The wired wall

switch is NOT available if a Power Vent is used.

14

Heat & Glo • 6000CMOD-IFT, 8000CMOD-IFT Owner’s Manual • 2509-981 Rev. E • 1/19

3. The Pilot button on the IFT-ECM activates the Cold

Climate function of the replace. This function lights

the pilot ame ONLY to provide enough heat in the

rebox to reduce condensation in cool, high humidity

ambient conditions. To activate the Cold Climate

press and hold the Pilot button for one second and

release. The IFT-ECM will ash two green LED blinks,

beep twice and light and rectify the pilot ame when

pressed to activate. To turn off Cold Climate, press

and hold the Pilot button for one second and release.

The IFT-ECM will ash one green LED blink, beep once

and shut down the pilot ame. If remote controls are

paired with the IFT-ECM, this feature can also be

activated with the IFT-RC400 and/or IFT-RC150.

TOP VIEW

3 POSITION SWITCH

LED INDICATOR

Figure 3.6 IFT-ECM

DANGER

DANGER

Risk of Explosion

Risk of Explosion

DO NOT cycle the ON/OFF/REM selector

DO NOT cycle the ON/OFF/REM selector

switch more than one time within a ve minute

switch more than one time within a ve minute

period. Gas may accumulate in rebox. Call

period. Gas may accumulate in rebox. Call

a qualied service technician.

a qualied service technician.

4. An IFT-ECM reset is required if the module is in a

lock-out condition. When this occurs, the appliance

is shut down and the IFT-ECM status indicator LED

will be blinking a RED/GREEN error code along with a

one-time audible double- beep. If the IFT-ECM is in a

lock-out condition, refer to the troubleshooting chart to

interpret the error code and take corrective action as

required. To reset the IFT-ECM after a lock-out error:

CAUTION! Risk of burns! Appliance surfaces are hot

when operating and during cool down. Use care and

wear gloves when opening the front and accessing com-

ponents inside the appliance.

- Be aware the appliance may be HOT, use

care in accessing the IFT-ECM.

- Set the IFT-ECM 3-position selector switch to

OFF position.

Page 15

- Wait ve (5) minutes to allow possible

accumulated gas to clear.

- Set the IFT-ECM 3-position selector switch to ON

or REMOTE position. Module will beep once and

ash a three GREEN LED code on successful

startup.

- If placed in ON position, the appliance will ignite

normally if the error condition was corrected.

- If placed in REMOTE position, use the paired IFT-

RC400, IFT-RC150 or wired wall switch to start

the appliance; appliance will ignite normally if the

error condition was corrected.

- If the IFT-ECM re-enters the lock-out condition

after these steps, call your dealer for service.

IntelliFireTM Touch Ignition System

NOTICE: Batteries should not be placed in the battery

pack while using the transformer. Remove batteries before

using the transformer, and unplug the transformer before

installing the batteries. Battery polarity must be correct or

module damage will occur.

Appliance ON/OFF:

A wall control, thermostat or remote control may be used

to control the ON/OFF function of the appliance. Follow

instructions included with the installed control.

Optional Heat-Zone

The Heat-Zone®-Gas heat management option is available

for use with the 6000CMOD-IFT and 8000CMOD-IFT

appliances. The Heat-Zone®-Gas Kit draws heat from

your replace to an adjacent room in your home, up to

20 feet away.

Optional Heat-Out-Gas Kit

The Heat-Out-Gas heat management option is available

for use with the 6000CMOD-IFT and 8000CMOD-IFT

appliances and must be used in conjunction with the IFT-

RC400 remote control. The Heat-Out-Gas kit draws heat

from your replace and directs it outside, up to 25 feet

away.

®

-Gas Kit

Optional Heat-Duct Kit

The Heat-Duct heat management option is available

for use with the 6000CMOD-IFT and 8000CMOD-IFT

appliances. The Heat-Duct redistributes heat from the

replace via the furnace ductwork.

Optional Fan Kit

If desired, a fan kit may be added. Contact your dealer

to order the correct fan kit. Detailed instructions are included with the fan kit.

Heat & Glo • 6000CMOD-IFT, 8000CMOD-IFT Owner’s Manual • 2509-981 Rev. E • 1/19

15

Page 16

Maintenance and Service

4

Any safety screen or guard removed for servicing must be

replaced prior to operating the replace.

When properly maintained, your replace will give you

many years of trouble-free service. Contact your dealer

to answer questions regarding proper operation, troubleshooting and service for your appliance. Visit www.

heatnglo.com to locate a dealer. We recommend annual

service by a qualied service technician.

A. Maintenance: Frequency and Tasks

Task Frequency To be completed by

Glass Cleaning Seasonally

Decorative

Fronts/

Surrounds

Optional

Remote Control

Venting Seasonally

Gasket Seal

and Glass

Inspection

Interior

Ceramic Glass

Panel Cleaning

Firebox

Inspection

Control

Compartment &

Firebox Top

Burner Ignition

& Operation

Glass

Refractory,

Base Pan,

Burner and

Valve Assembly

Removal

Annually

Seasonally

Annually

Seasonally

Annually

Annually

Annually

As Needed

Homeowner

Qualied Service

Technician

Qualied Service

Technician

B. Maintenance Tasks - Homeowner

Installation and repair should be done by a qualied service

technician only. The appliance should be inspected before

use and at least annually by a professional service person.

The following tasks may be performed annually by the

homeowner. If you are uncomfortable performing any of

the listed tasks, please call your dealer for a service appointment.

More frequent cleaning may be required due to excessive

lint from carpeting, bedding material, etc. It is imperative

that control compartments, burners and circulating air

passageways of the appliance be kept clean. Any safety

screen, guard, or barrier removed for servicing the appliance must be replaced prior to operating the appliance.

CAUTION! Risk of Burns! The replace shall be turned

off and cooled before servicing.

Glass Cleaning

Frequency: Seasonally

By: Homeowner

Tools Needed: Protective gloves, glass cleaner, drop

cloth and a stable work surface.

CAUTION! Handle xed glass assembly with care.

Glass is breakable.

• Avoid striking, scratching or slamming glass

• Avoid abrasive cleaners

• DO NOT clean glass while it is hot

• Prepare a work area large enough to accommodate xed

glass assembly and decorative front by placing a drop

cloth on a at, stable surface.

Note: Fixed glass assembly and gasketing may have residue that can stain carpeting or oor surfaces.

• Remove decorative front from replace and set aside

on work surface.

WARNING! Risk of Asphyxiation! Handle xed glass

assembly with care. Inspect the gasket to ensure it is

undamaged and inspect the glass for cracks, chips or

scratches.

• DO NOT strike, slam or scratch glass.

• DO NOT operate replace with glass removed, cracked,

broken or scratched.

• Replace as a complete assembly.

16

Heat & Glo • 6000CMOD-IFT, 8000CMOD-IFT Owner’s Manual • 2509-981 Rev. E • 1/19

Page 17

Removing/Replacing Fixed Glass Assembly

• Pull the four glass assembly latches out of the groove

on the glass frame. Remove glass assembly from the

appliance See Figure 4.1.

• Clean glass with a non-abrasive commercially available

cleaner.

- Light deposits: Use a soft cloth with soap and water

- Heavy deposits: Use commercial fireplace glass

cleaner (consult with your dealer)

• Replace the glass assembly on the appliance. Pull out

and latch the four glass assembly latches into the groove

on the glass frame.

• Inspect and operate all glass latches to ensure they

move freely and no obstructions are present.

• Reinstall decorative front.

LATCHES

(BOTH BOTTOM

AND TOP)

GLASS

ASSEMBLY

Figure 4.1 Fixed Glass Assembly

Decorative Fronts, Surrounds

Frequency: Annually

By: Homeowner

Tools needed: Protective gloves, stable work surface

• Assess condition of screen and replace as necessary.

• Inspect for scratches, dents or other damage and repair

as necessary.

• Check that replace openings are not blocked.

• Vacuum and dust surfaces.

Optional Remote Control

Frequency: Seasonally

By: Homeowner

Tools needed: Replacement batteries and remote con-

trol instructions.

• Locate remote control transmitter and receiver.

• Verify operation of remote. Refer to remote control

operation instructions for proper calibration and setup

procedure.

• Place batteries as needed in remote transmitters and

battery-powered receivers.

• Place remote control out of reach of children.

If not using your replace for an extended period of time

(summer months, vacations/trips, etc), to prevent unintended operation:

• Remove batteries from remote controls.

• Unplug 6 volt adapter plug on IPI models.

Venting

Frequency: Seasonally

By: Homeowner

Tools needed: Protective gloves and safety glasses.

• Inspect venting and termination cap for blockage or

obstruction such as plants, bird nests, leaves, snow,

debris, etc.

• Verify termination cap clearance to subsequent construc-

tion (building additions, decks, fences, or sheds).

• Inspect for corrosion or separation.

• Verify weather stripping, sealing and ashing remains

intact.

• Inspect draft shield to verify it is not damaged or missing.

Heat & Glo • 6000CMOD-IFT, 8000CMOD-IFT Owner’s Manual • 2509-981 Rev. E • 1/19

17

Page 18

C. Maintenance Tasks - Qualied Service

Technician

The following tasks must be performed by a qualied ser-

vice technician.

Gasket Seal and Glass Assembly Inspection

Frequency: Annually

By: Qualied Service Technician

Tools needed: Protective gloves, drop cloth and a stable

work surface.

• Inspect gasket seal and its condition.

• Inspect xed glass assembly for scratches and nicks that

can lead to breakage when exposed to heat.

• Conrm there is no damage to glass or glass frame.

Replace as necessary.

• Verify that xed glass assembly is properly retained and

attachment components are intact and not damaged.

Replace as necessary.

Interior Ceramic Glass Panel Cleaning

Frequency: Seasonally

By: Qualied Service Technician

Tools Needed: Protective gloves, glass cleaner.

CAUTION! Handle glass with care. Glass is breakable.

• Avoid striking, scratching or slamming glass

• Avoid abrasive cleaners

• DO NOT clean glass while it is hot

• Clean glass with a non-abrasive commercially available

cleaner.

- Light deposits: Use a soft cloth with soap and water

- Heavy deposits: Use commercial fireplace glass

cleaner (consult with your dealer)

Firebox Inspection

Frequency: Annually

By: Qualied Service Technician

Tools needed: Protective gloves, sandpaper, steel wool,

cloths, mineral spirits, primer and touch-up paint.

• Inspect for paint condition, warped surfaces, corrosion

or perforation. Sand and repaint as necessary.

• Replace replace if rebox has been perforated.

Control Compartment and Firebox Top

Frequency: Annually

By: Qualied Service Technician

Tools needed: Protective gloves, vacuum cleaner, dust

cloths

• Vacuum and wipe out dust, cobwebs, debris or pet hair.

Use caution when cleaning these areas. Screw tips that

have penetrated the sheet metal are sharp and should

be avoided.

• Remove all foreign objects.

• Verify unobstructed air circulation.

Burner Ignition and Operation

Frequency: Annually

By: Qualied Service Technician

Tools needed: Protective gloves, vacuum cleaner, whisk

broom, ashlight, voltmeter, indexed drill bit set, and a

manometer.

• Verify burner is properly secured and aligned with pilot

or igniter.

• Clean off burner top, inspect for plugged ports, corrosion

or deterioration. Replace burner if necessary.

• Replace Glowing embers with new dime-size pieces.

DO NOT block ports or obstruct lighting paths. Refer

to appliance installation manual for proper ember

placement.

• Verify batteries have been removed from battery back-

up IPI systems to prevent premature battery failure or

leaking.

• Check for smooth lighting and ignition carryover to all

ports. Verify that there is no ignition delay. Inspect and

ensure the lighting of the main burner occurs within four

seconds of the main gas valve opening.

• Inspect for lifting or other ame problems.

• Verify air shutter setting is correct. See Installation

Manual for required air shutter setting. Verify air shutter

is clear of dust and debris.

• Inspect orice for soot, dirt and corrosion. Verify orice

size is correct. See Service Parts List for proper orice

sizing.

• Verify manifold and inlet pressures. Adjust regulator as

required.

• Check all accessible gas-carrying tubes, connections,

pipes and other components for leaks.

• Inspect pilot ame pattern and strength. See Figure 4.2

for proper pilot ame pattern. Clean or replace orice

spud as necessary.

• Inspect IPI ame sensing rod for soot, corrosion and

deterioration. Polish with ne steel wool or replace as

required.

• Verify that there is not a short in ame sense circuit

by checking continuity between pilot hood and ame

sensing rod. Replace pilot as necessary.

Figure 4.2 IPI Pilot Flame Patterns

18

Heat & Glo • 6000CMOD-IFT, 8000CMOD-IFT Owner’s Manual • 2509-981 Rev. E • 1/19

Page 19

D. Glass Refractory, Base Pan, Burner and

Valve Assembly Removal

It may become necessary to remove the glass panels,

base pan, burner and valve assembly. This task should

be performed by a qualied service technician.

1. Remove the media.

2. Remove the side glass panel retainers. See Figure

4.3. Slide the side glass panels out of the appliance

as shown in Figure 4.4.

3. Remove the rear glass panel retainer, shown in Figure

4.3, and lift the rear glass panel out of the appliance.

REAR PANEL RETAINER

SIDE PANEL RETAINERS

4. Remove the base pan by removing the screws circled

in Figure 4.5.

5. Remove the burner assembly by removing the two

screws as shown in Figure 4.6. To disengage the burner

from the orice, slide the burner to the right and lift it out.

6. See Figure 4.7 for valve assembly removal.

APPEAR ANCE

MAY VARY

Figure 4.3 Remove Glass Panel Retainers

Figure 4.5 Base Pan Removal

Figure 4.4 Glass Panel Removal

Heat & Glo • 6000CMOD-IFT, 8000CMOD-IFT Owner’s Manual • 2509-981 Rev. E • 1/19

Figure 4.6 Burner Assembly Removal

19

Page 20

Figure 4.7 Valve Assembly Removal

Appearance of valve

components may vary.

E. Burner Identication

6000CMOD-IFT (NG)

Figure 4.8 Burner Identication - 6000CMOD-IFT

8000CMOD-IFT (NG)

Figure 4.9 Burner Identication - 8000CMOD-IFT

20

Heat & Glo • 6000CMOD-IFT, 8000CMOD-IFT Owner’s Manual • 2509-981 Rev. E • 1/19

Page 21

5

Frequently Asked Questions and Troubleshooting

A. Frequently Asked Questions - Appliance

ISSUE SOLUTIONS

Condensation on the glass

Blue ames

Odor from replace

Film on the glass

Metallic noise

Is it normal to see the pilot ame burn

continually?

Power Outages

(battery backup)

Wall above appliance feels hot to

the touch.

This is a result of gas combustion and temperature variations. As the replace warms, this

condensation will disappear.

This is a result of normal operation and the ames will begin to yellow as the replace is allowed to burn for 20 to 40 minutes.

When rst operated, this replace may release an odor for the rst several hours. This is caused

by the curing of the paint and the burning off of any oils remaining from manufacturing. Odor

may also be released from nishing materials and adhesives used around the replace. These

circumstances may require additional curing related to the installation environment.

This is a normal result of the curing process of the paint and logs. Glass should be cleaned

within 3 to 4 hours of initial burning to remove deposits left by oils from the manufacturing

process. A non-abrasive cleaner such as gas replace glass cleaner may be necessary. See

your dealer.

Noise is caused by metal expanding and contracting as it heats up and cools down, similar to

the sound produced by a furnace or heating duct. This noise does not affect the operation or

longevity of the replace.

In an intermittent pilot ignition system (IPI), the pilot ame should turn off when appliance is

turned off. Some optional control systems available with IPI models may allow pilot ame to

remain lit.

This appliance can be operated on battery power in the event of a power outage. To access

the battery pack, the decorative front, mesh and glass assembly must be removed. Refer to

Section 3 for more details.

No action necessary. This appliance ships with a non-combustible material attached. Speci-

cations of the attached non-combustible material are listed in the Installer’s Manual for this

appliance.

Contact your dealer for additional information regarding operation and troubleshooting. Visit www.heatnglo.com to

locate a dealer.

Heat & Glo • 6000CMOD-IFT, 8000CMOD-IFT Owner’s Manual • 2509-981 Rev. E • 1/19

21

Page 22

B. Frequently Asked Questions - IntelliFire™ Touch Controls (IFT-RC400) (Optional Remote)

Symptom Possible Cause Corrective Action

The appliance does not respond to

commands from the remote control

display does not light up when

screen is touched.

Batteries are depleted. Verify batteries are new.

Batteries are incorrectly

oriented.

Verify batteries are installed in correct orientation as shown on

batteries receptacle.

The display on remote lights up

when screen is touched but it does

not respond to commands.

The remote displays the following

message on-screen:

No dealer info available

The remote displays the following

message on-screen:

Call “Dealer Name & Number” to

schedule maintenance.

The room temperature displayed

on the remote is either slow or

quick to respond while operating in

thermostat mode.

The appliance turns OFF the ame

after extended periods of operation

The remote displays the following

message on-screen: Fan will turn

on within 3 minutes

The remote displays the following

message on-screen:

“Replace remote batteries."

The remote is displaying an

incorrect brand.

After turning ame ON using

remote, the ame does not turn

ON immediately and instead a two

minute timer is displayed.

The remote displays the following

message on-screen:

“Remote Control Communication

Error.”

Touchscreen has lost

calibration.

Child Lock is ON.

Dealer information not

programmed into remote.

300 hours of use. Appliance is

still fully functional.

Remote is placed at a very

short distance or too far away

from the appliance.

Remote is placed in the path

of an air draft or vent.

Flame Modulation

9 hour safety shutdown timer

Functioning as intended.

Low batteries in remote. Install new batteries in the remote.

Remote was programmed

incorrectly.

Power vent is installed on the

appliance.

No power to appliance.

Power outage. Install new batteries in battery backup.

Touchscreen needs to be re-calibrated. Call dealer to have

screen re-calibrated.

Check child lock icon located at the top of the remote display. If

ON, it will show as a ‘locked’ symbol. To unlock, remove battery

compartment door, locate child lock switch and move to ‘unlock’ position. Verify child lock icon on screen is now displayed

in ‘unlock’ position.

Remote will still provide all available functions, and appliance is

fully available for use. Call dealer to have them program.

The appliance has been burning for 300 hours and is due for a

regular maintenance. Call dealer to have them perform maintenance.

Try to keep the remote close to the appliance but not directly

in front of it. The remote acts as the thermostat.

Move the remote away from the direct path of air ow. The

remote acts as the thermostat.

The control system is designed to automatically adjust the

ame intensity based on the difference between the desired

room temperature, and actual temperature. In thermostat

mode, the hearth appliance will start in HI ame, but as the

actual temperature approaches the desired set temperature

on the remote, the ame intensity will automatically decrease.

Automatic ame modulation will result in more control of the

temperature, but will cause the appliance to cycle OFF/ON

less.

This is normal behavior. The appliance has a safety timer that

will automatically turn OFF the ame after nine hours of

uninterrupted operation.

The appliance has a three minute delay timer before the fan is

turned ON. This allows the air surrounding the appliance to be

heated before being pushed into the room.

Call dealer to have them program the remote with correct

branding. Remote is still fully functional and the appliance is

unaffected.

This is expected behavior and the two minute timer is called a

pre-purge timer. The ame will turn ON at the expiration of the

timer.

Verify home circuit breaker is on and master reset is on (if

equipped).

22

Heat & Glo • 6000CMOD-IFT, 8000CMOD-IFT Owner’s Manual • 2509-981 Rev. E • 1/19

Page 23

C. Troubleshooting

With proper installation, operation, and maintenance your gas appliance will provide years of trouble-free service. If you do

experience a problem, this troubleshooting guide will assist a qualied service technician in the diagnosis of a problem and

the corrective action to be taken. This troubleshooting guide can only be used by a qualied service technician. Contact

your dealer to arrange a service call by a qualied service technician.

IntelliFire™ Touch

Error Codes:

ECM LED Error

Codes

Description

3 Red: 1 Green IFT-RC400 error message: ‘Appliance Safely Disabled’, pilot sparks for 60 sec, no ame

rectication.

2 Red: 1 Green IFT-RC400 display: ‘Error Pilot Flame’, pilot valve solenoid not detected.

2 Red: 2 Green Sparking feedback signal error, spark coil failure.

5 Red: 1 Green IFT-RC400 display: ‘Error Power Vent’ (if installed).

See Troubleshooting matrix for more detail on Lock-out Error Codes, Possible Causes and Corrective Actions.

Troubleshooting:

Symptom Possible Cause Corrective Action

Verify ‘S’ (White) sense wire and ‘I’ (orange) ignitor wire are

connected to correct terminals on

Verify no loose connections or electrical shorts in wiring from

module to pilot assembly. Verify wire insulation is not damaged. Verify wires are not grounding out to chassis, pilot burner, or any other metal object. Replace any damaged wires.

Verify spark gap is approximately 0.095” (2.41 mm) to 0.135”

(3.43 mm).

IFT-ECM slider switch is in ON or IFT-REM position.

Verify

Verify AC power available to junction box. Verify AC/DC adaptor is plugged into junction box and ECM. Verify AC/DC adaptor

output voltage is between 5.7-6.3 Vdc. If battery pack is used,

check battery pack voltage is >4.2 V (if not, replace batteries).

Verify system wiring conguration. Remove and reinstall wiring harness that plugs into module. Check continuity of wires

in valve wiring harness. Replace any damaged components.

Verify black ground wire in valve harness is connected to metal

chassis of replace.

Check if valve harness orange wire is connected to pilot solenoid valve. Check pilot solenoid resistance, nominal is 40

ohms. If open or shorted, replace valve. Check valve harness

wire continuity, if open replace 6-pin harness.

IFT-ECM.

Pilot won’t light, module clicks but

no spark 60 sec, 3 Red/1 Green

Lock out.

Pilot won’t light, there is no noise

or spark.

Pilot won’t light, there is no noise

or spark, 2 Red/1 Green Lockout.

Pilot won’t light, there is no noise

or spark, 2 Red/2 Green Lockout.

Incorrect wiring.

Loose connections or electrical

shorts in wiring.

Ignitor gap is too large.

No AC power, AC/DC adaptor

faulty, backup batteries (if

being used) depleted,

ECM slider switch in OFF

position.

Shorted or loose connection

in system wiring or wiring

harness.

Poor or no system ground.

Pilot solenoid not detected.

Spark coil failure. Replace ECM.

IFT-

Heat & Glo • 6000CMOD-IFT, 8000CMOD-IFT Owner’s Manual • 2509-981 Rev. E • 1/19

23

Page 24

IntelliFire™ Touch - (continued)

Symptom Possible Cause Corrective Action

No gas supply.

Pilot sparks for 60 sec, but will not

light, 3 Red/1 Green Lockout.

Pliot lights but main burner does

not light. Pilot continues to spark

for 60 sec then goes into 3 Red/1

Green Lockout.

Pilot lights and recties, but main

burner does not light.

Pilot and main do not light, ECM

goes into 5 Red/1 Green Lockout.

Appliance lights and runs for a few

minutes then shuts down and/or

appliance cycle ON and OFF with

less than 60 sec of ON time.

ECM has poor ground.

Gas valve defective.

No ame detected. Flame

rectication issue.

No ame detected or sense

rod contamination.

Main valve solenoid.

Power Vent (PV) Failure.

Shorted or loose connection in

ame detection circuit.

Poor ame rectication or

contaminated sense rod.

Logs are set up wrong. Remove and re-install logs per the log placement instructions.

Damaged pilot assembly.

Verify incoming gas line ball valve is ‘Open’. Verify inlet pressure is within requirement for gas type used. Contact gas supplier.

Verify wiring, check valve harness black wire is securely

grounded to metal chassis.

Check pilot valve solenoid kick and hold voltages during ignition cycle. Kick V should be >1 V, hold V minimum 0.26 V. If

voltages are OK, replace gas valve.

Check if white sense lead is securely connected to ‘S’ terminal

of

IFT-ECM. Check resistance of sense lead between sense

rod tip and connector to

- if not, replace pilot assembly. Check system ground, ensure

black valve harness wire is securely attached to metal chassis.

Check wiring for damage. With system OFF, check resistance

between tip of sense rod and pilot hood, should be resistance

(>1 M-ohm).

With glass assembly installed, verify pilot ame is engulng

ame sense rod on pilot assembly. Verify inlet gas pressure

is correct for gas type. Polish ame sense rod with ne steel

wool to remove any contaminants that may have accumulated.

Check if green wire in valve harness is connected to green

main valve solenoid. Check main valve solenoid resistance,

nominal is 60 ohms. If open or shorted, replace valve. Verify

valve inlet pressure is correct for gas type.

Power Vent blower defective - check wiring to

if blower is working. Check if PV pressure switch is connected

to brown and black wire in 6-pin valve wire harness. Check if

pressure switch is closed (shorted) when PV blower is running.

Refer to PV troubleshooting instructions.

Check if white sense lead is securely connected to ‘S’ terminal

of

IFT-ECM. Check resistance of sense lead between sense

rod tip and connector to

- if not, replace pilot assembly. Check system ground, ensure

black valve harness wire is securely attached to metal chassis.

Check wiring for damage. With system OFF, check resistance

between tip of sense rod and pilot hood, should be resistance

(>1 M-ohm).

With glass assembly installed, verify pilot ame is engulng

ame sense rod on pilot assembly. Verify inlet gas pressure

is correct for gas type. Polish ame sense rod with ne steel

wool to remove any contaminants that may have accumulated.

Verify no soot deposits are in sense rod to pilot hood gap.

Verify the pilot assembly ceramic insulator around the ame

sensing rod is not cracked, damaged or loose. Check re-

sistance between tip of sense rod and

should be less than 1 ohm. Replace pilot assembly if damage

is detected.

IFT-ECM, should be less than 1 ohm

IFT-ACM, check

IFT-ECM, should be less than 1 ohm

IFT-ECM connector,

24

Heat & Glo • 6000CMOD-IFT, 8000CMOD-IFT Owner’s Manual • 2509-981 Rev. E • 1/19

Page 25

Reference Materials

6

A. Accessories

Install approved accessories per instructions included

with accessories. Contact your dealer for a list of approved accessories.

WARNING! Risk of Fire and Electric Shock! Use ONLY

Hearth & Home Technologies-approved optional accessories with this appliance. Using non-listed accessories

could result in a safety hazard and will void the warranty.

Heat & Glo • 6000CMOD-IFT, 8000CMOD-IFT Owner’s Manual • 2509-981 Rev. E • 1/19

25

Page 26

B. Service Parts

Service Parts

6000CMOD-IFT

36” Gas Fireplace - DV

6

7

8

5

4

4.1

4.2

3

Beginning Manufacturing Date: Mar 2018

Ending Manufacturing Date: Active

1

2

11

4.4

4.3

10

9

IMPORTANT: THIS IS DATED INFORMATION. Parts must be ordered from a dealer or distributor. Hearth and

Home Technologies does not sell directly to consumers. Provide model number and serial number when

requesting service parts from your dealer or distributor.

Stocked

at Depot

ITEM DESCRIPTION COMMENTS PART NUMBER

1 Non-Combustible Board 2166-136

2 Refractory Bracket

Qty 2 req

2241-115

3 Rock Fixture Assembly 2241-040 Y

4 Base Pan Assembly 2241-015

4.1 Base Pan Back 2241-114

4.2 Base Pan Front 2241-101

4.3 Pilot Hood 2241-117

4.4 Pilot Shield

5 Burner Assembly

Stainless

2241-116

2509-006 Y

6 Glass Refractory, Back 2509-700

7 Glass Refractory, Sides

8 Glass Retainer Clips

Qty 2 req

Pkg of 25

2509-701

060-235-25 Y

9 Surround Assembly 2166-019

10 Glass Assembly GLA2506-018 Y

11 Junction box SRV4021-013 Y

Additional service part numbers on following page. 10/18

26

Heat & Glo • 6000CMOD-IFT, 8000CMOD-IFT Owner’s Manual • 2509-981 Rev. E • 1/19

Page 27

Service Parts

8000CMOD-IFT

42” Gas Fireplace - DV

6

7

8

5

4

4.1

4.2

3

Beginning Manufacturing Date: Mar 2018

Ending Manufacturing Date: Active

1

2

11

4.4

4.3

10

9

IMPORTANT: THIS IS DATED INFORMATION. Parts must be ordered from a dealer or distributor. Hearth and

Home Technologies does not sell directly to consumers. Provide model number and serial number when

requesting service parts from your dealer or distributor.

Stocked

at Depot

ITEM DESCRIPTION COMMENTS PART NUMBER

1 Non-Combustible Board 2170-136

2 Refractory Bracket

Qty 2 req

2241-115

3 Rock Fixture Assembly 2241-040 Y

4 Base Pan Assembly 2242-015

4.1 Base Pan Back 2242-114

4.2 Base Pan Front 2242-101

4.3 Pilot Hood 2241-117

4.4 Pilot Shield

5 Burner Assembly

Stainless

2241-116

2510-006 Y

6 Glass Refractory, Back 2510-700

7 Glass Refractory, Sides

8 Glass Retainer Clips

Qty 2 req

Pkg of 25

2510-701

060-235-25 Y

9 Surround Assembly 2170-019

10 Glass Assembly GLA2507-018 Y

11 Junction box SRV4021-013 Y

Additional service part numbers on following page. 10/18

Heat & Glo • 6000CMOD-IFT, 8000CMOD-IFT Owner’s Manual • 2509-981 Rev. E • 1/19

27

Page 28

#12 Valve Assembly

Service Parts

12.2

6000CMOD-IFT, 8000CMOD-IFT

Beginning Manufacturing Date: Mar 2018

Ending Manufacturing Date: Active

12.3

12.4

12.5

12.6

12.7

12.8

12.9

IMPORTANT: THIS IS DATED INFORMATION. Parts must be ordered from a dealer or distributor. Hearth and

Home Technologies does not sell directly to consumers. Provide model number and serial number when

requesting service parts from your dealer or distributor.

ITEM DESCRIPTION COMMENTS PART NUMBER

12.1

12.2

12.3

12.4

12.5

12.6

12.7

12.8

12.9

12.10

12.11

12.12

12.13

12.14

12.15

**Fuse for battery pack can be sourced locally, not a warranty item. Specs are 250v, 3A fuse, 3/4” long

Additional service part numbers on following page.

Shutter Bracket Assembly 2118-121 Y

Pilot Assembly, NG SRV2090-012 Y

Pilot Bracket SRV2241-109-BK

3-Hole Grommet SRV2118-420

Valve Bracket 2118-104

Flex Ball Valve Assembly SRV302-320 Y

Valve, NG 2166-302 Y

Male Connector

Bulkhead w/FlexTube SRV7000-156 Y

Module, IFT Control 2326-130 Y

Harness, IFT 6 Pin Wiring SRV2326-132 Y

Transformer, 6 Volt Wall SRV2326-131 Y

Jumper Wire SRV2187-198 Y

Battery Pack** SRV2326-134 Y

Thermostat Wire Assembly SRV2118-170 Y

Ori ce, NG (#35C)

Ori ce, NG (#33C)

12.1

12.10

12.11

12.12

Pkg of 5

6000CMOD-IFT

8000CMOD-IFT

12.15

12.14

12.13

303-315/5 Y

SRV582-835 Y

582-833 Y

Stocked

at Depot

28

Heat & Glo • 6000CMOD-IFT, 8000CMOD-IFT Owner’s Manual • 2509-981 Rev. E • 1/19

Page 29

Service Parts

IMPORTANT: THIS IS DATED INFORMATION. Parts must be ordered from a dealer or distributor. Hearth and

Home Technologies does not sell directly to consumers. Provide model number and serial number when

requesting service parts from your dealer or distributor.

ITEM DESCRIPTION COMMENTS PART NUMBER

Flue Restrictor

Glass Latch Assembly

Gasket Assembly

Includes Vent, Seal Cap, Burner Neck, Shutter

Bracket, Manifold and Valve Plate gaskets

Media, Standard (5 LB bag) Black Qty 3 req 2188-850

Media, (Optional 7 LB bag) Clear Qty 2 req 4065-111

Media (Optional 14 LB bag)

Touch Up Paint TUP-GBK-12

6000CMOD-IFT, 8000CMOD-IFT

Beginning Manufacturing Date: Mar 2018

Ending Manufacturing Date: Active

385-328

Qty 4 req

Amber MEDIA-AMBER-14

Cobalt (Blue) MEDIA-COBALT-14

2382-400 Y

2166-081

Stocked

at Depot

Conversion Kits

*This unit is not conversion compatible

Pilot Ori ce, NG SRV593-528 Y

Regulator, NG NGK-DXV-50 Y

Heat & Glo • 6000CMOD-IFT, 8000CMOD-IFT Owner’s Manual • 2509-981 Rev. E • 1/19

29

Page 30

C. Contact Information

Heat & Glo, a brand of Hearth & Home Technologies

7571 215th Street West, Lakeville, MN 55044

www.heatnglo.com

Please contact your Heat & Glo dealer with any questions or concerns.

For the location of your nearest Heat & Glo dealer,

please visit www.heatnglo.com.

- NOTES -

________________________________________________________________________________

________________________________________________________________________________

________________________________________________________________________________

________________________________________________________________________________

________________________________________________________________________________

________________________________________________________________________________

________________________________________________________________________________

________________________________________________________________________________

________________________________________________________________________________

NOTICE

DO NOT DISCARD THIS MANUAL

• Important operating

and maintenance

instructions included.

• Read, understand and follow

these instructions for safe

installation and operation.

• Leave this manual with

party responsible for use

and operation.

This product may be covered by one or more of the following patents: (United States) 5613487, 6006743, 6019099,

6053165, 6145502, 6374822, 6484712, 6601579, 6769426, 6863064, 7077122, 7074035, 7098269, 7258116, 7322819,

7470729, 7726300, 8147240, 9625149 or other U.S. and foreign patents pending.

2000-945D

Printed in U.S.A. - Copyright 2019

30