Heatcraft Refrigeration Products PRO3 User Manual

Installation and

Operations Manual

Bulletin H-IM-PSM May 2008 Part Number 25008001

PRO3 Side Mount

Packaged Refrigeration System

Table of Contents

Inspection............................................................................3

Installation Requirements .................................................3

Recommended Unit Placement

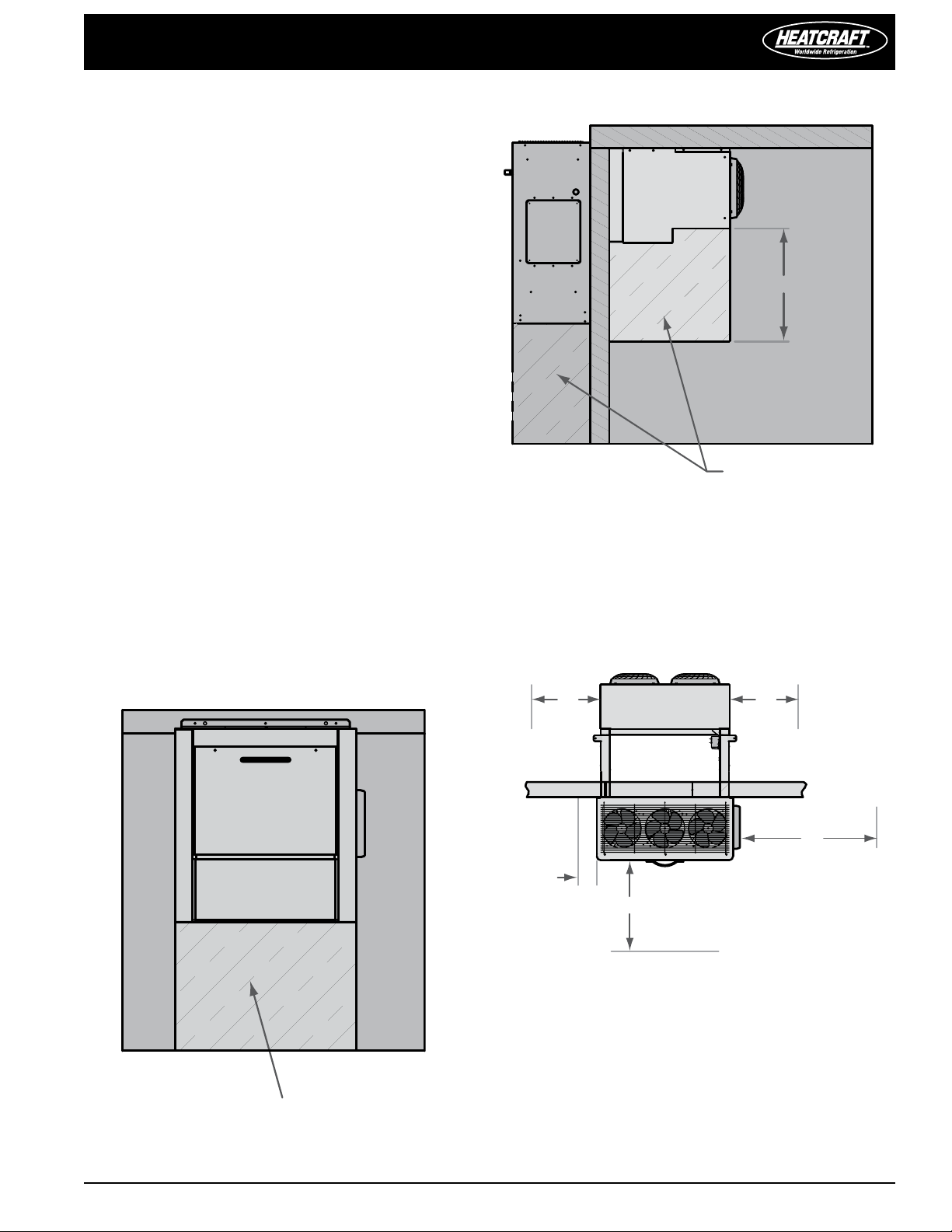

FIGUR E 1: System Space Requirements | Back View

FIGUR E 2: System Space Requirements | Side View

Access Requirements .........................................................3

Condensing Unit Section (Exterior of box)

FIGUR E 3: Access Requirements | Top View

Evaporator Section (Interior of box)

Installation Procedures ..................................................4-7

FIGUR E 4: Cutout Location

FIGUR E 5: Cutout Dimensions | Small Cabinet

FIGUR E 6: Cutout Dimensions | Large Cabinet

FIGUR E7: Plug Detail

FIGUR E 8: Plug Detail | Small Cabinet

FIGUR E9: Plug Detail | Large Cabinet

Rigging

FIGUR E10: Rigging Holes

FIGUR E 11: Rigging Holes | Front View

Mounting

FIGUR E12: Mounting Holes | Side View

FIGUR E 13: Mounting Holes | Front View

FIGUR E 14: Mounting Holes | Top View

Electrical Connection

Refrigeration Sequence of Operation ...............................7

TABLE 1 Model PST | Default Temperature Control Settings

Cooler Temperature Control

Coolers: Air-defrost Operation

Cooler with Electric Defrost and Freezer Temperature/

Defrost Control

Cooler with Electric Defrost and Freezer Sequence of

Operation

Programming Electronic Controller ............................ 8-16

Dixell Electronic Controller (XR40CX and XR60CX)

Front Panel Commands ..................................................................8

Use of LEDs...........................................................................................8

Max. & Min. Temperature Memorization: .................................9

How to See the Min. Temperature

How to See the Max. Temperature

How to Reset the Max. & Min. Temperature Recorded

Main Functions: .................................................................................9

How to see the set-point

How to change the set-point

How to start a manual defrost

How to change a parameter value

Installation and Operations Manual

The Hidden Menu .............................................................................9

How to Enter the Hidden Parameters

How to Move a Parameter from the Hidden Menu

How to Lock the Keyboard

The Continuous Cycle

The On/O Function

Parameters .................................................................................10-11

Regulation

Display

Defrost

Fans (XR60CX ONLY)

Alarms

How to use the Hot Key ................................................................11

How to program a Hot Key from the Instrument

Alarm Signals ...................................................................................12

Alarm Recovery

Other Messages ..............................................................................12

Technical Data .................................................................................12

Connections .....................................................................................13

Service Information..........................................................13

Maintenance

System Standard Maintenance Guidelines

Drain Pan Removal..............................................................................14

FIGURE 15: Drain Pan Removal | View A

FIGURE 16: Drain Pan Removal | View B

Wiring Diagrams ......................................................... 15-18

DIAGRAM 1 High Temperature Cooler | Air Defrost | Large Cabinet

DIAGRAM 2

DIAGRAM 3 Freezer and Medium Temperature Cooler | Electric Defrost | Small Cabinet

DIAGRAM

Performance, Capacities and Specications ..................19

TABLE 2 Cooler Application | Air Defrost | BTUH at 95°F ambient

TABLE

TABLE

TABLE

Dimensions ................................................................. 20-21

DIAGRAM 5 Dimensions | Small Cabinet: 1-fan | Top view

DIAGRAM

DIAGRAM

DIAGRAM

DIAGRAM

DIAGRAM

Replacement Parts by InterLink .....................................22

TABLE 6 Replacement Parts List

Warranty Statement ........................................................23

High Temperature Cooler | Air Defrost | Small Cabinet

4 Freezer and Medium Temperature Cooler | Electric Defrost | Large Cabinet

3 Cooler Application | Electric Defrost | BTUH at 95°F ambient

4 Freezer Application | Electric Defrost | BTUH at 95°F ambient

5 Specications

6 Dimensions | Small Cabinet: 1-fan | Side view

7 Dimensions | Small Cabinet: 1-fan | Back view

8 Dimensions | Large Cabinet: 2-fan | Top view

9 Dimensions | Large Cabinet: 1-fan | Side view

10 Dimensions | Large Cabinet: 1-fan | Back view

2

© 2008 Heatcraft Refrigeration Products LLC

PRO3 Side Mount Packaged Refrigeration System

Leave this area unobstructed

Leave these areas

unobstructed

24"

4.00

18"18"

24"

36"

8"

Inspection

1. Each shipment should be carefully checked against the bill

of lading.

2. The shipping receipt should not be signed until all items listed

on the bill of lading have been accounted for.

3. Check packaging for signs of damage.

4. Any shortage or damages should be immediately reported to

the delivering carrier.

5. Damaged material becomes the delivering carrier’s

responsibility, and should not be returned to the manufacturer

unless prior approval is given to do so.

6. All units are shipped on heavy skids and enclosed in open

crating. Generally, it is advisable to bring the unit as close to

its nal location as possible before removing crating.

7. When unpacking the system, care should be taken to

prevent damage.

8. Avoid removing the shipping base until the unit has been

moved to the nal destination.

Installation Requirements

Recommended Unit Placement

1. Ensure that the structural integrity of the box can withstand

the weight of the side-mounted equipment.

2. The air pattern must cover the entire room

3. Location of aisles, racks, etc. must be known

4. For space requirements,

see FIGURES 1 and 2

2: System Space Requirements | Side View

FIGUR E

Access Requirements

Condensing Unit Section (Exterior of box)

Provide adequate access space (minimum 36") on the right side of

the unit for electric box clearance. The front of the unit should have

a minimum of 24" clearance for compressor and fan motor service.

The left side of the unit should be a minimum of 8" clearance.

FIGUR E

3: Access Requirements | Top View

FIGUR E 1: System Space Requirements | Back View

Evaporator Section (Interior of box)

The front of the evaporator should have no obstructions since this

is the leaving airside of the evaporator. There should also be no

obstructions under the evaporator. A minimum of 8" clearance should

be held on each side of the evaporator for drain pan removal.

PRO3 Side Mount Packaged Refrigeration System Installation and Operations Manual, May 2008 3

Installation and Operations Manual

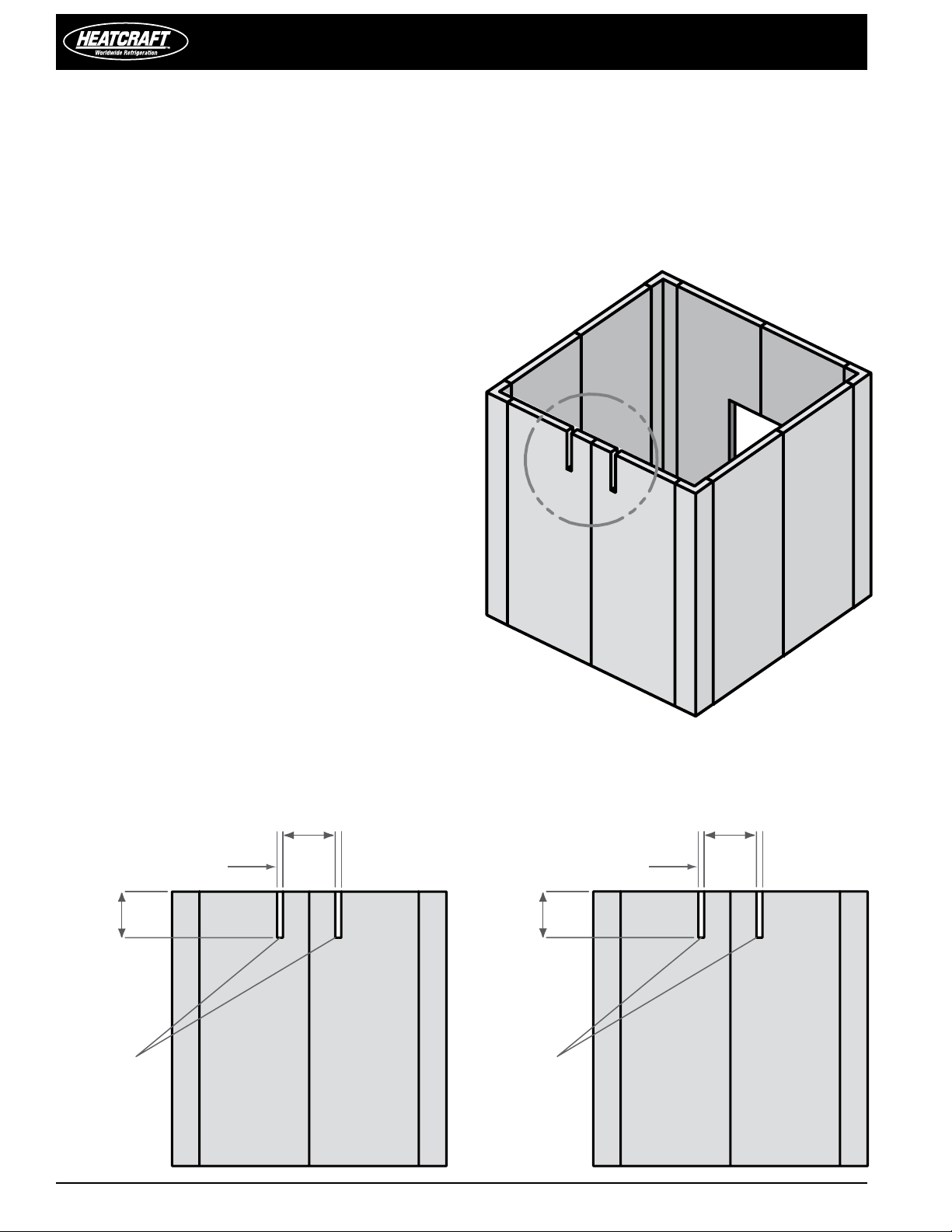

2.62" TYP

20.25" TYP

22.75" TYP

CUTOUTS

2.62" TYP

20.25" TYP

28.75" TYP

CUTOUTS

Installation Procedures

NOTE: Installation and maintenance to be performed only

by qualied personnel who are familiar with local codes and

regulations and are experienced with this type of equipment.

CAUTION: Make sure all power sources are disconnected

before any service work is done on units.

A.) Inspect packaging/unit for shipping damage

B.) Review the space and location requirements provided for your

method of installation.

C.) Follow installation instructions listed in method #1 or #2

Installation Method #1

Top Installation (See FIGURES 4, 5 and 6)

This installation method is the recommended installation method

in applications where it is feasible.

In order to install a unit using this method, you will need to provide

cutout slots for the “arms.” The unit should be placed on the wall

prior to setting and securing the roof of the box.

Please use the following guidelines when completing the installation

in this manner.

1. You will need to provide nished slots with the appropriate

dimensions in the box wall.

2. The slots can straddle a seam but they should not be on a seam.

See FIGURE 4.

3. The cut-out sections should not be placed in a location where

they would interfere with any cam locks.

4. It is preferred that a cam lock be placed in between the cutouts

to give additional support

See FIGURES 5 and 6.

5. The unit will need to be lifted to the appropriate height and

inserted into the open slots. The bottom of the unit should

be temporarily supported during the remainder of the installation

process (no portion of the unit should be supported by the

bottom of the evaporator section as this WILL cause damage to

the drain pan).

6. Set and secure the roof of the box and rmly attach the unit to

the box and carefully seal all seams and penetration points.

FIGUR E 4: Cutout Location

FIGUR E 5:

Cutout Dimensions | Small Cabinet

CAUTION: Do not support any portion of the unit by the

drain pan.

FIGUR E 6: Cutout Dimensions | Large Cabinet

4

PRO3 Side Mount Packaged Refrigeration System

SEE PLUG DETAIL

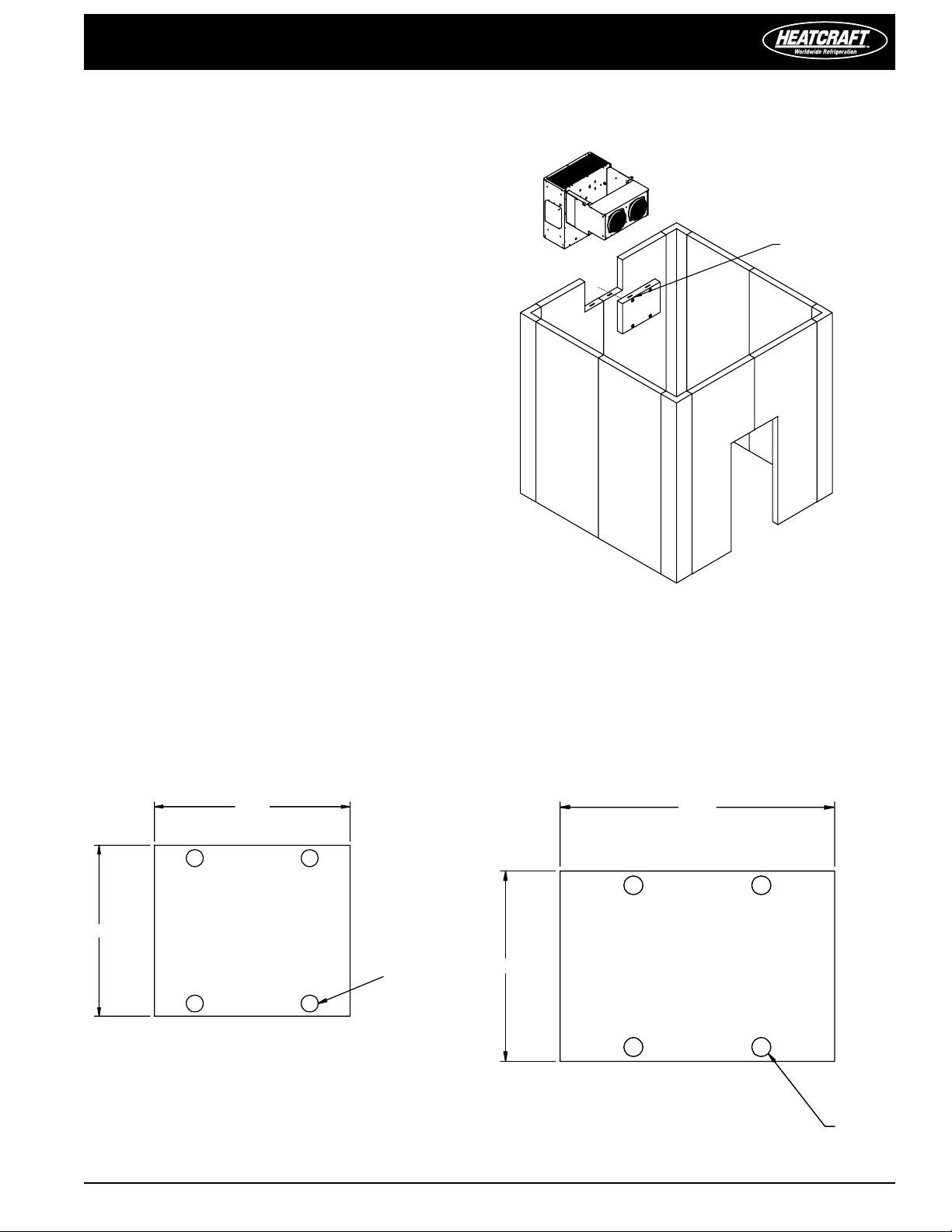

29.00

20.07

CAMLOCKS

4 PLACES

20.00

23.00

CAMLOCKS

4 PLACES

Installation Method #2

Side Installation (See FIGURES 7, 8, and 9)

This installation method is intended for applications that have

height restrictions that do not allow the unit to be installed from

above (see method #1) and installations into pre-existing boxes

where it is impractical to remove the roof.

In order to install a unit using this method, you must provide an

additional “plug” section of the box to ll in the open space between

evaporator arms after installation. This section should contain cam

locks to anchor it in place.

Please use the following guidelines when completing the installation

in this manner.

1. Provide a nished opening with the appropriate dimensions

from FIGURE

2.

The cut-out section should not be placed in a location where it

would degrade the structural integrity of the box (should not

interfere with cam locks)

3. The unit will need to be lifted to the appropriate height and

inserted into the open slot. The bottom of the unit should be

temporarily supported during the remainder of the installation

process (no portion of the unit should be supported by the

bottom of the evaporator section as this WILL cause damage to

the drain pan).

4. You should use cam locks to re-connect the “plug” section after

installing the unit, rmly attach the unit to the box and carefully

seal all seams.

8 or 9.

FIGUR E 7: Plug Detail

FIGUR E 8:

Plug Detail | Small Cabinet

FIGUR E 9:

Plug Detail | Large Cabinet

PRO3 Side Mount Packaged Refrigeration System Installation and Operations Manual, May 2008 5

Installation and Operations Manual

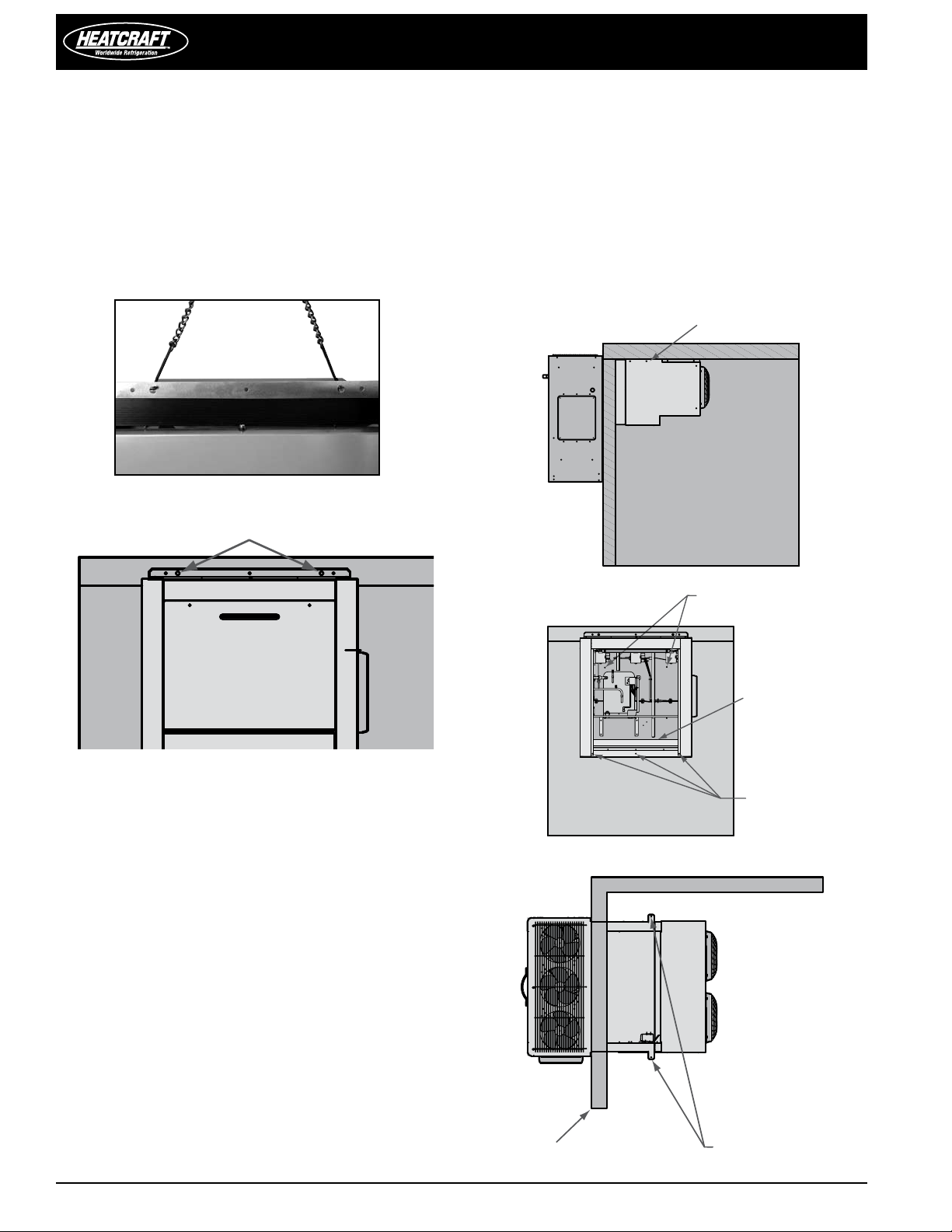

Mounting

holes

Front panels

removed

for clarity

Mounting holes

Mounting holes

Top not shown

for clarity

Mounting holes

Rigging holes

Rigging

CAUTION: Avoid contact with sharp edges and coil

surfaces. They are a potential injury hazard. Wear gloves

during moving and rigging.

Caution should be exercised when moving these units. To prevent

damage to the unit housing during rigging, cables or chains used

must be held apart by spacer bars. Rigging holes are provided on

all models. See FIGURES 10 and 11.

FIGUR E 10: Rigging Holes

FIGUR E 11: Rigging Holes | Front View

4. Ensure that the condensing unit airow is not obstructed after

removing the temporary support.

5. Do not obstruct the evaporator airow with shelving. The area

below the evaporator should be left completely open.

6. Connect unit to power supply through knock-out provided

above electrical box using all local wiring codes.

7. Apply power to unit. All controls are preset to factory default

settings. See Table 1 (next page).

8. Check the unit for proper operation.

FIGUR E 12: Mounting Holes | Side View

Mounting

The system requires two through-bolts to be used to connect to

the roof panel. A minimum of four through-bolts should be used to

connect to the side panel of the box. The opposite side of the box

should be reinforced with wood or metal to prevent the bolts from

pulling through the panel. See FIGURES 12, 13 and 14 for locations.

Through bolts should be insulated or non-conductive to prevent

sweating. All penetrations to the box should be caulked to prevent

moisture from entering the box.

1. Install two through bolts to secure the unit to the wall. The inside

of the box should be reinforced with wood or metal for proper

when mounting of the unit to the box with through bolts.

2. Install and secure the roof of the box. Inside the box,

provisions have been made to secure the evaporator section

to the roof panel with through bolts.

3. The area between the evaporator section and the roof

panel should be caulked to meet NSF codes. In addition, the

openings where the unit was lowered into the box panel

should be caulked to prevent any inltration from the outside

area into the box.

FIGURE 13: Mounting Holes | Front View

FIGURE 14: Mounting Holes | Top View

6

PRO3 Side Mount Packaged Refrigeration System

Electrical Connection

1. Refer to all local codes for proper connection.

2. A knock-out is provided for 1" conduit on the side of the

condensing unit section above the electrical box. See FIGURE 12.

3. Wire will be brought into the electrical box through the

bottom of the electrical box and connected to the top of the

contactor.

Refrigeration Sequence of Operation

1. Power is provided to the temperature control, compressor

contactor and cooler evaporator fans.

2. The temperature controller closes and energizes the

compressor contactor, starting the compressor, evaporator

and condenser fan(s).

3. When the system reaches the desired box temperature, the

temperature control will de-energize the compressor contactor.

Evaporator fans will continue to operate at this point.

4. When the xture temperature rises above the set point

and minimum o-time has elapsed, the temperature control

will close and re-energize the compressor contactor.

Coolers: Air-defrost Operation

Air defrost units are pre-programmed for 4 defrost per day. These

periods are reprogrammable. When the coil temperature reaches

38°F, the control will terminate the defrost cycle.

For programming information see pages 7-16.

Cooler with Electric Defrost and Freezer

Temperature/Defrost Control

PRO3 packaged refrigeration system cooler with electric defrost and

freezer units come factory equipped with an electronic temperature/

defrost control.

For programming information see pages 7-16.

Cooler with Electric Defrost and Freezer

Sequence of Operation

Power is provided to the temperature control and compressor

contactor. The drain line heater as well as the crankcase heaters will

also have continuous power supplied to them.

The temperature controller energizes the compressor contactor,

starting the compressor and condenser fan(s). The evaporator fans

will be energized by the electronic controller.

When the system reaches the desired box temperature, the

temperature control will de-energize the compressor contactor and

the evaporator fans.

When the temperature rises above the set point and minimum otime (4 minutes) has elapsed, the temperature control will close and

re-energize the compressor contactor.

1. During normal operation, at the preset times of day, the

temperature/defrost control will de-energize the compressor

contactor and evaporator fans and energize the defrost

heaters. These functions are controlled through relays on the

controller.

2. When the coil has defrosted fully and has reached the preset

coil temperature (as sensed by the coil temperature sensor)

the defrost heater de-energizes and the fan delay and drip

sequences begin.

3. The temperature/defrost control energizes the compressor

contactor, starting the compressor and condenser fan(s).

4. Freezer evaporator fans will be energized by the temperature/

defrost control when the coil temperature reaches 35°F or fan

delay time has elapsed.

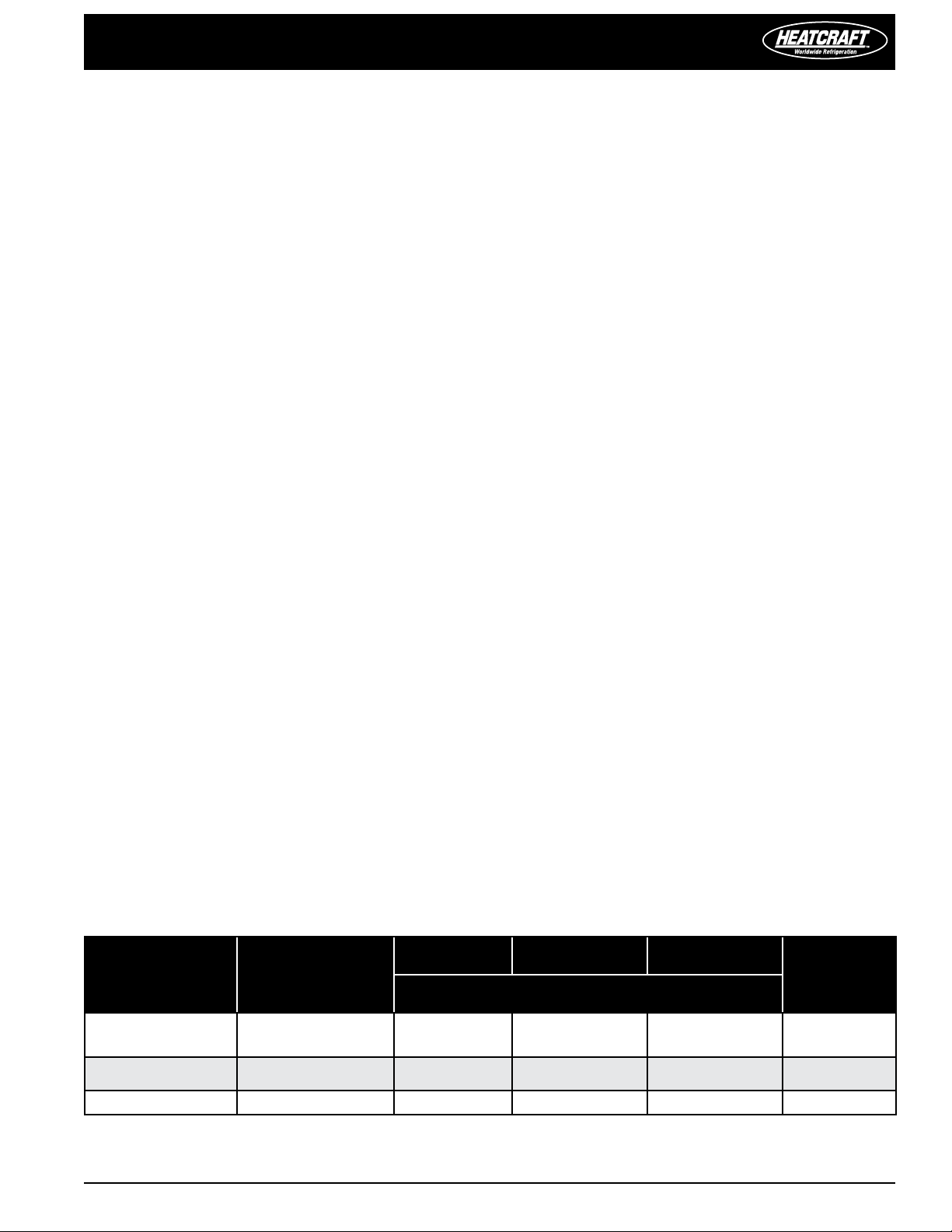

TABLE 1 Model PST | Default Temperature Control Settings

Application:

Temperature set

points

Cooler: 35˚ F

Cooler w/ Electric

Defrost: 34˚ F

Defrost start times

Every 3 hours of

compressor run time

Defrost

Duration

60 – – 38˚ F

40 2 2 65˚ F

Drip Time Fan Delay

Minutes

Defrost

Termination

Set Point

Freezer: -10˚ F 4 times / day 40 2 2 65˚ F

PRO3 Side Mount Packaged Refrigeration System Installation and Operations Manual, May 2008 7

Installation and Operations Manual

Programming XR-40CX or XR-60CX

Dixell Electronic Controller

Reprinted with permission from Dixell.

The Dixell XR-40CX (High Temperature) and XR-60CX (Medium

and Low Temperature) are fully configurable electronic

refrigeration controllers. These controls are used on PRO3 Side

Mount units. All parameter values are reprogrammable and are

stored in the non-volatile memory.

The controller uses two levels of programming that can be

accessed through the keypad. The rst level is the user level. It

gives access to six settings — temperature dierential, defrost

cycle intervals, defrost termination temperature, draining time,

defrost fan delay and fan stop temperature.

The second level is the service level. It allows access to all other

parameters. It is recommended that changes in this level be

made only by a qualied technician.

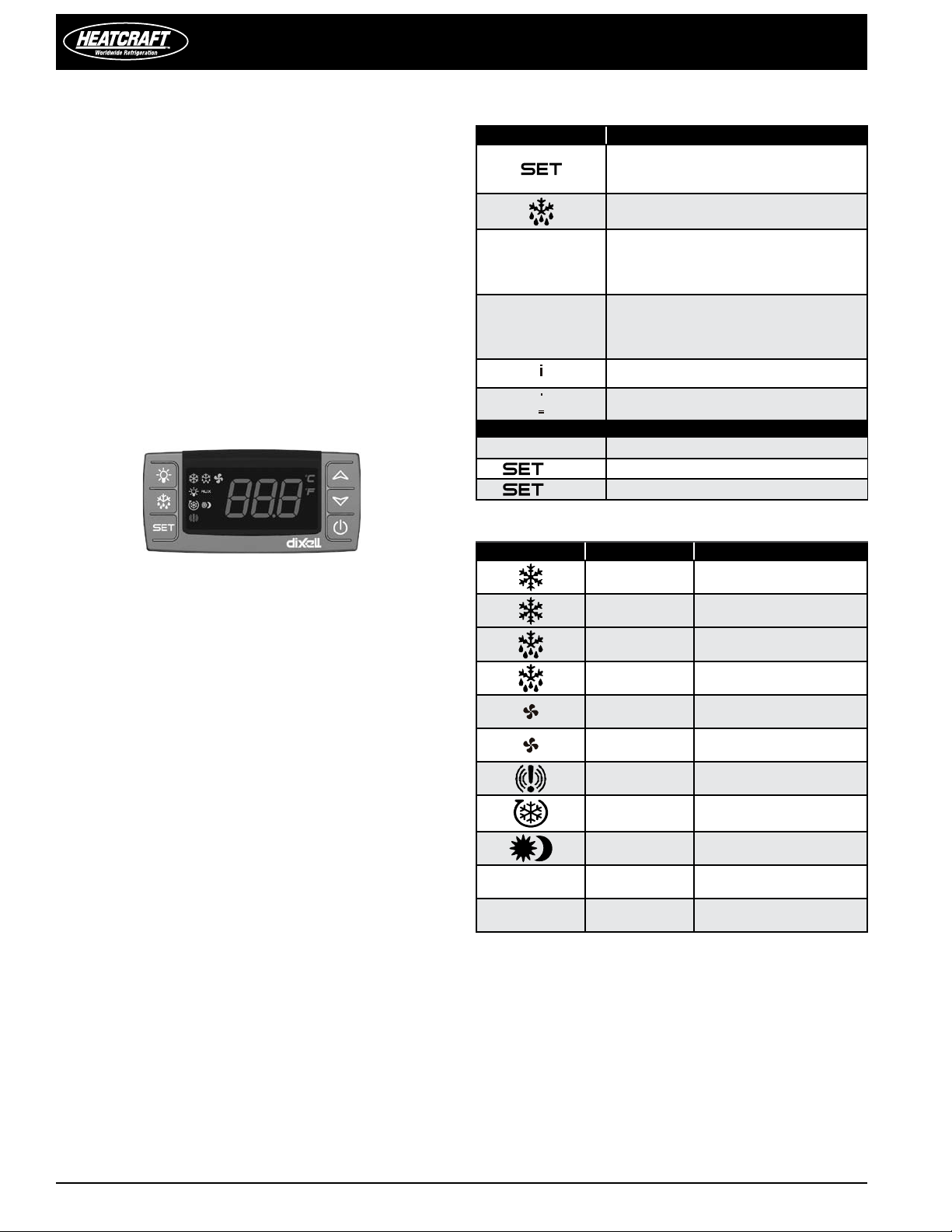

Front Panel Commands

BUTTON COMMAND

To display target set point; in

programming mode it selects a parameter

or conrm an operation

(DEF) To start a manual defrost

(UP): To see the max. stored temperature;

in programming mode it browses

the parameter codes or increases the

displayed value

(DOWN) To see the min stored

temperature; in programming mode it

browses the parameter codes or decreases

the displayed value

To switch the instrument o, if onF = oFF

Not enabled

KEY COMBINATIONS

+

+

+

To lock & unlock the keyboard

To enter in programming mode

To return to the room temperature display

Use of LEDs

LED LED MODE FUNCTION

ON Compressor enabled

Flashing

ON Defrost enabled

Anti-short cycle delay

enabled

Flashing Drip time in progress

ON Fans enabled (XR60CX only)

Flashing

ON An alarm is occurring

ON Continuous cycle is running

ON Energy saving enabled

°C/°F ON Measurement unit

°C/°F Flashing Programming phase

Fans delay after defrost in

progress (XR60CX only)

8

Loading...

Loading...