Masterlog4

User Handbook

Masterlog 4 “Version 2”

(from the 11st march 2008)

Code +050004036 Rel. 1.0 – 11/03/2008

3

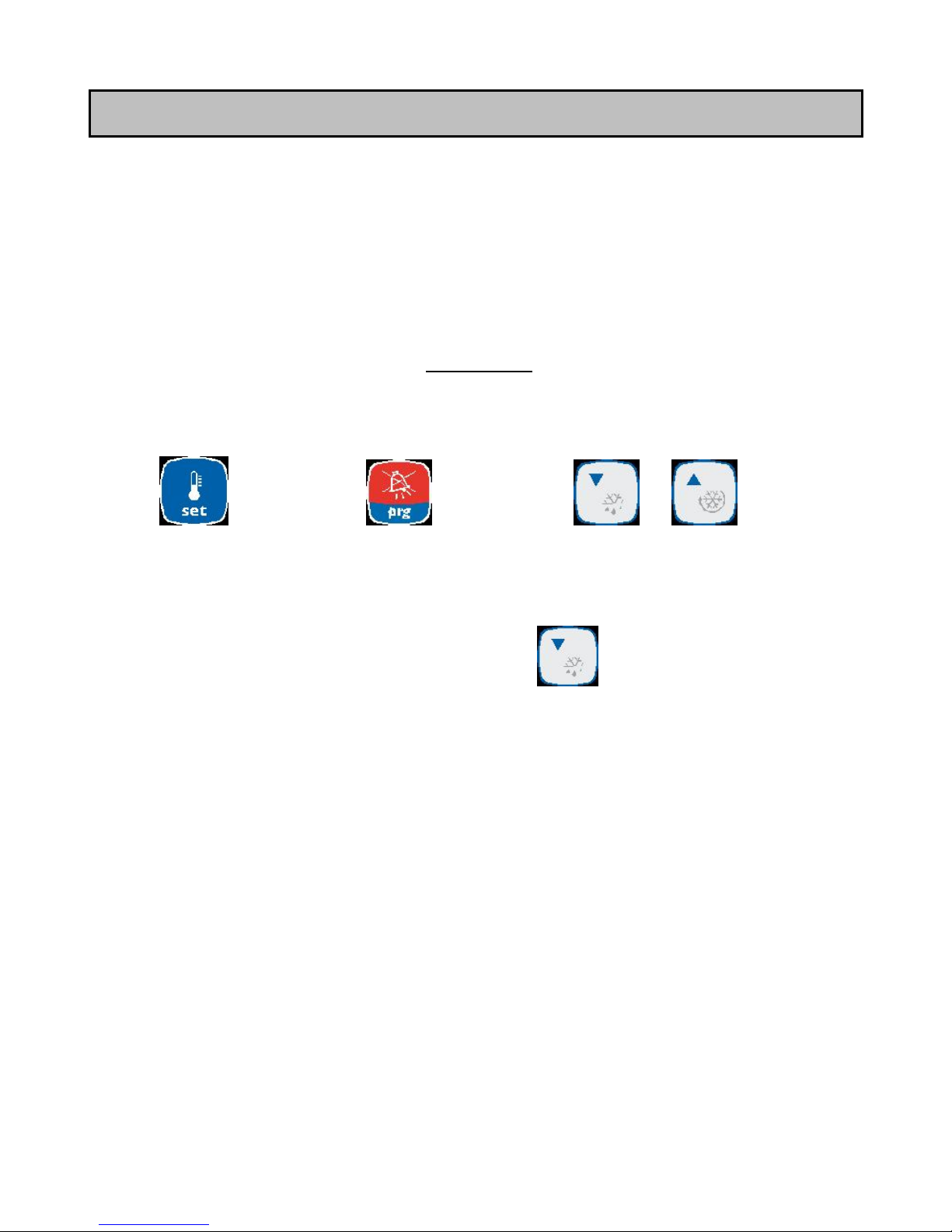

OPERATING INSTRUCTIONS

MASTERLOG 4 “Version 2”

The default parameter settings for the MASTERLOG 4 (bn1) are selected for operation with chilling evaporators

equipped with an air defrost system. For a different operating mode one of the following programs may be

selected:

‘bn1’= chilling with air defrost

‘bn2’= chilling with electrical defrost

‘bn3’= refrigeration with electrical defrost

‘bn4’= ambient chilling with air defrost

‘bn5’=‘bn2’ with 2 evaporators

‘bn6’=‘bn3’ with 2 evaporators

”DO NOT USE ‘bn0’”

Proceed as follows to select one of these programs:

1. Switch off the Masterlog4.

2. Switch the Masterlog4 back on again while simultaneously

pressing the “prg” button until the value ‘bn0’

appears.

3. Select the program required using the “up” and “down” keys

4. Press “set” to confirm the selection.

”Set” Key ”prg” Key “Up/Down” Keys

ATTENTION:

¾ The defrost parameters [‘dI’: interval between 2 defrosts, ‘dT’: temperature at end of defrost (electrical) and ‘dP’:

maximum defrost duration] are factory-set values. Depending on use of the cold storage room, these parameters

must be modified to ensure correct defrosting of the evaporator.

¾ To carry out a manual defrost cycle, press the “defrost” key

for more than 5 sec.

¾ The MASTERLOG 4 relays are “potential-free” contacts. To supply these contacts, it is essential to connect

terminals 1, 4, 7 and 10 as well as aux. terminals 13 and 16 if necessary (refer to the electrical wiring diagram

enclosed with the products).

¾ The MASTERLOG 4 possesses three configurable inputs (terminals 22/23, 24/25 et 26/27). Input n°1

(terminals 22 and 23) may be set as an external alarm coming from the unit (parameter A4=1, except

application 2 evaporators). Some units are equipped with a standard ‘fault contact’ (refer to wiring diagram).

We recommend you connect this alarm contact to the MASTERLOG 4.

¾ If the keypad is locked, modify the parameter H2 (H2=1).

IMPORTANT: Standard and modified parameters are saved in case of an electrical power failure. When

downloading a program, these values are reset in compliance with the basic parameter setting chart.

Code +050004036 Rel. 1.0 – 11/03/2008

4

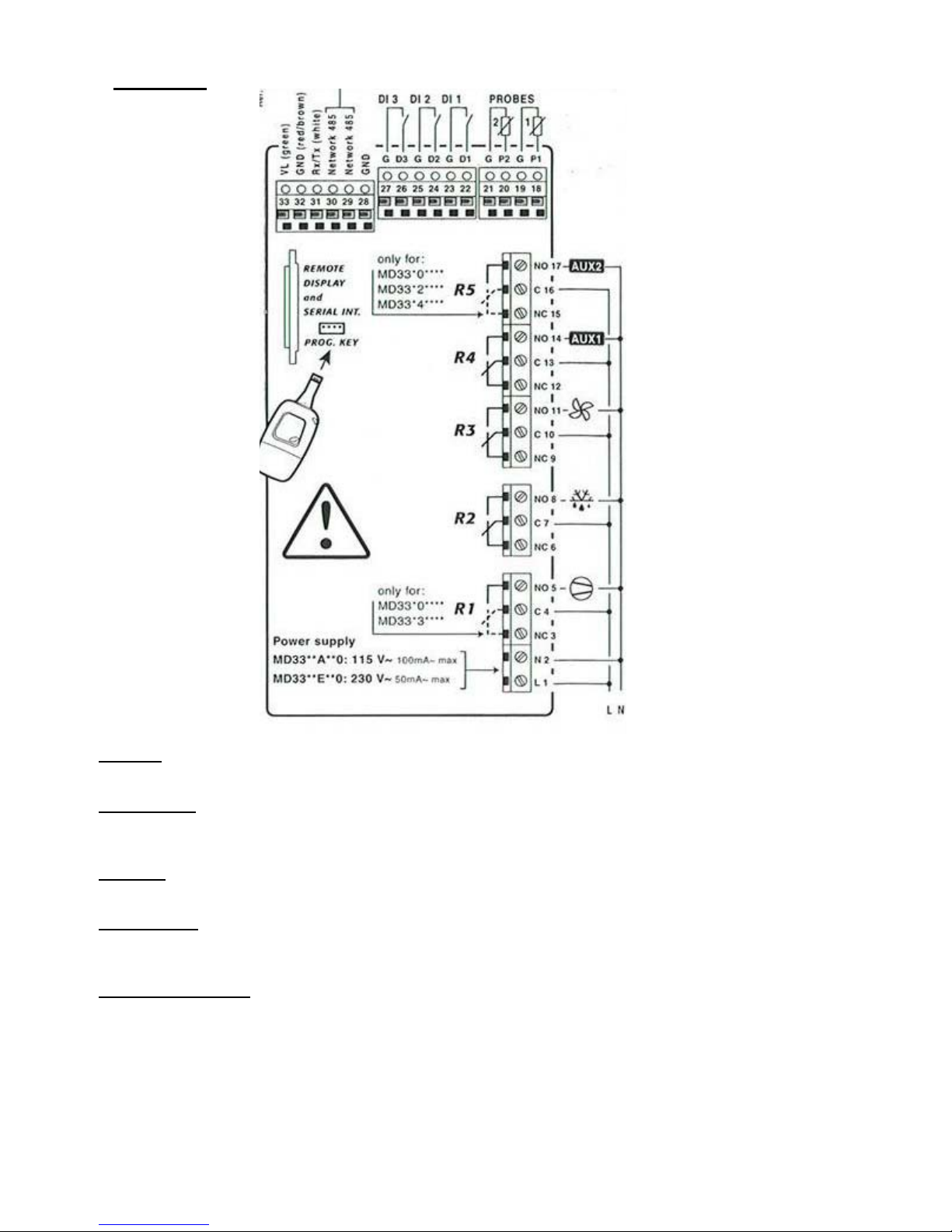

1 - Wiring

Sensors:

18 - 19 Ambient pro be (PROBE 1)

20 - 21 End of defrost probe (PROBE 2)

Digital inputs:

22 - 23 Digital input 1 (DI 1) - Parameters A4

24 - 25 Digital input 2 (DI 2) - Parameters A5

26 - 27 Digital input 3 (DI 3) - Parameters A9

Auxiliary:

13 - 14 AUX 1 – Parameters H1

16 - 17 AUX 2 – Parameters H5

Wiring RS485:

28 GND

29 TX/RX+

30 TX/RX-

Relay characteristics:

Refer to chapter 8. Technical characteristics

R1 =30A

R2=16A

R3=8A

R4=8A

R5=16A

Code +050004036 Rel. 1.0 – 11/03/2008

5

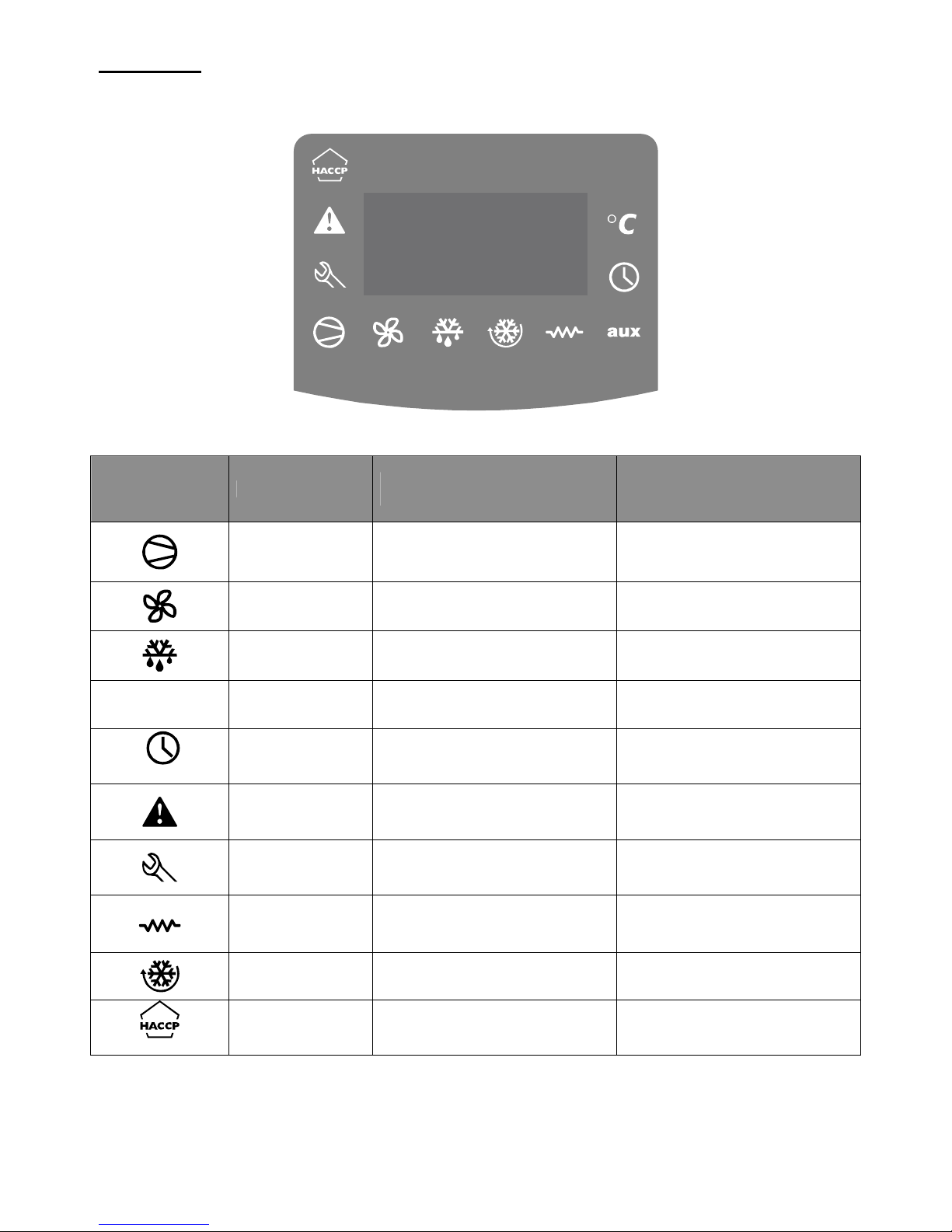

2 - Display

Symbols Colour

Meaning with the symbol

illuminated

Meaning with the symbol

blinking

Amber

Compressor operational

Compressor in standby and ready

to start

Amber

Condenser fan operational

Condenser fan in standby and

ready to start

Amber

Defrost in progress

Condenser fan in standby and

ready to start

AUX

Amber Auxiliary output set as AUX output

Heating element blocking function

enabled at start up

(Option)

Yellow

At least 1 defrost is programmed in

real time

Red External alarm delayed

Alarm present or alarm on digital

input immediate or delayed

Red

Malfunction (e.g. probe

disconnected)

Amber Auxiliary output set as heater

Heating element blocking function

enabled at start up

Amber Activation of a continuous cycle

Continuous cycle cannot be

enabled

(Option)

Red HACCP function enabled New HACCP alarm memorised

Code +050004036 Rel. 1.0 – 11/03/2008

6

3 - Parameters:

3-1 . Access to parameters:

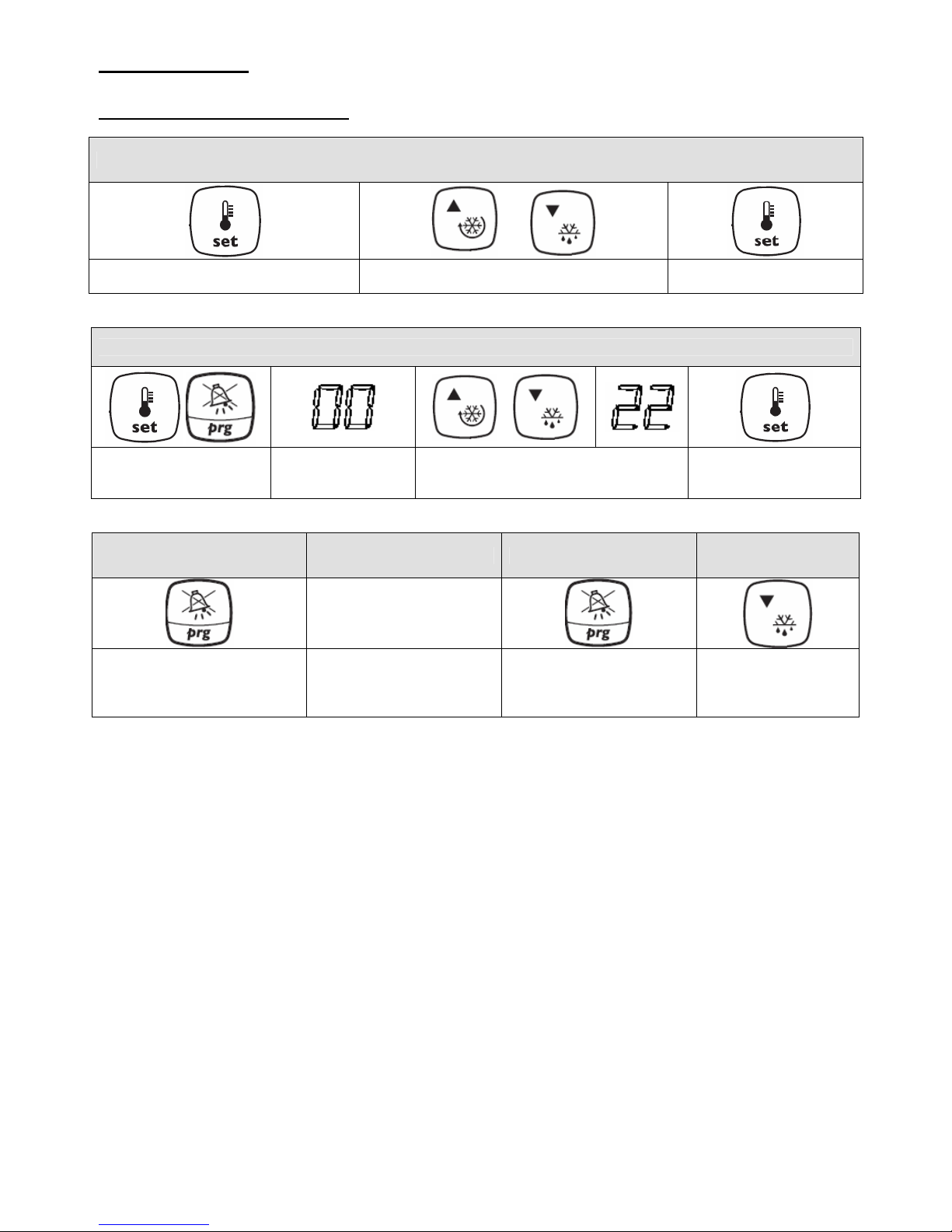

Modify the set point only

Press and hold SET for 1 second

Use the up and down keys to modify the set

point

Press SET to confirm the

value

Access to all parameters

Press and hold PRG and

SET at the same time for

5 seconds

"00" is displayed

Use the up and down keys to select

“22”

Press SET

Save parameters Do not save parameters Cancel an alarm Manual defrost

Press and hold PRG for 5

seconds

Do not press any other

keys for 60 seconds until

the display returns to the

temperature value

Press PRG

Press and hold DEF

for 5 seconds

Code +050004036 Rel. 1.0 – 11/03/2008

7

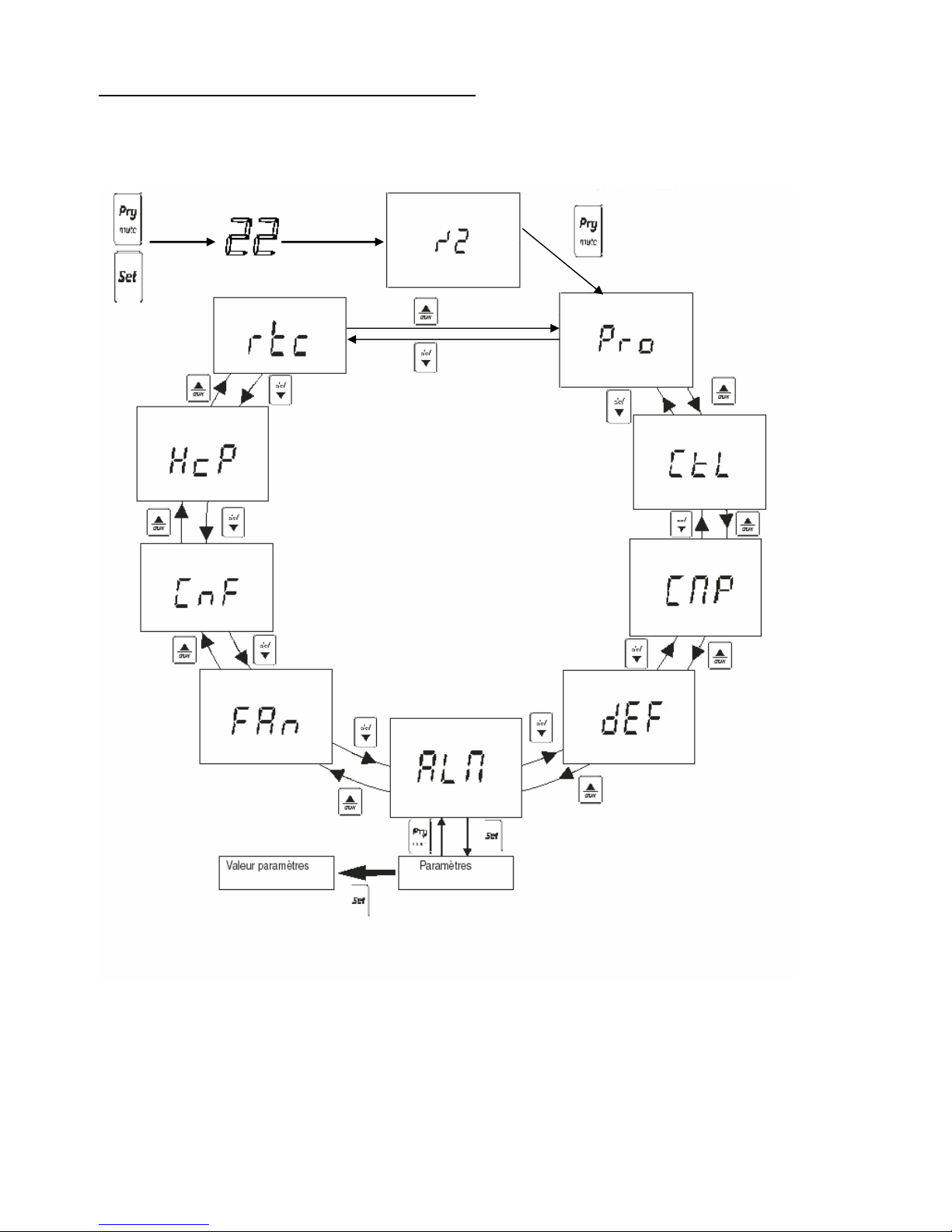

3-2 . Rotation of the parameters list menu

‘Set’= to access or quit a parameter

‘Set’= to access a block

‘Prg’= to quit a block

5s

Probe

Control

Compressor

Defrost

Alarm

Fan

Configuration

HACCP

(OPTION)

(OPTION)

Time range

Code +050004036 Rel. 1.0 – 11/03/2008

8

4- List of parameters:

The parameters may vary depending on the model of MD33

/: Probe parameters

Display

Parameter and description

Measurement

unit

Min Max

Bn 1 Bn 2 Bn 3 Bn 4 Bn 5 Bn

6

/2

Probe measurement delay

1=immediate response

15=delayed response

- 1 15 4 4 4 4 4 4

/3

Probe display speed

0=slow

15=fast

- 0 15 0 0 0 0 0 0

/4

Virtual probe (between probe 1 and probe 2)

0=Setting of probe 1

50=average between probe 1 and probe 2

100=Setting of probe 2

- 0 100 0 0 0 0 0 0

/5

Selection °C or °F

0=°C

1=°F

Select 0 1 0 0 0 0 0 0

/6

Display decimal point

0=Yes

1=No

Select 0 1 0 0 0 0 0 0

/tI

Selection of probe to be displayed on controller

1=virtual probe

2=probe 1

3=probe 2

4=probe 3

5=probe 4

6=probe 5

7=set point

- 1 7 2 2 2 2 2 2

tE

Selection of probe to be displayed on a remote

display

0=no remote display present

1=virtual probe

2=probe 1

3=probe 2

4=probe 3

5=probe 4

6=probe 5

- 0 6 0 0 0 0 0 0

/P

Selection of probe type

0=standard NTC (black probe)

1=high-temperature NTC (beige probe)

2=PTC

- 0 2 0 0 0 0 0 0

/A2

Configuration of probe 2

0=probe 2 absent or not used

1=product probe (used for display)

2=defrost probe

3=condensation probe

4=anti-frost probe

- 0 4 0 2 2 0 2 2

/A3

Configuration of probe 3 / digital input 1

Same as probe 2

- 0 4 0 0 0 0 2 2

/A4

Configuration of probe 4 / digital input 2

Same as probe 2

- 0 4 0 0 0 0 0 0

/A5

Configuration of probe 5 / digital input 3

Same as probe 2

- 0 4 0 0 0 0 0 0

/c1

Calibration of probe 1 °C/°F -20 20 0 0 0 0 0 0

/c2

Calibration of probe 2 °C/°F -20 20 0 0 0 0 0 0

/c3

Calibration of probe 3 °C/°F -20 20 0 0 0 0 0 0

/c4

Calibration of probe 4 °C/°F -20 20 0 0 0 0 0 0

/c5

Calibration of probe 5 °C/°F -20 20 0 0 0 0 0 0

Code +050004036 Rel. 1.0 – 11/03/2008

9

r: Setting parameters

Display

Parameter and description

Measurement

unit

Min Max

Bn 1 Bn 2 Bn 3 Bn 4 Bn 5 Bn

6

St

Temperature set point °C/°F r1 r2 4 0 -18 12 0 -18

rd

Differential °C/°F 0.1 20 2 2 2 1 2 2

rn

Dead zone °C/°F 0.0 60 2 2 2 1 2 2

rr

Hot differential relay (with dead zone) °C/°F 0.1 20 2 2 2 1 2 2

r1

Minimum set point value entered by user °C/°F -50 r2 1 -5 -25 2 -5 -25

r2

Maximum set point value entered by user °C/°F r1 200 20 8 -5 20 8 -5

r3

Operating mode

0=direct thermostat (cold) with defrost

1=direct thermostat (cold) without defrost

2=reverse thermostat (hot)

Select 0 2 0 0 0 0 0 0

r4

Variation of set point during nocturnal operation

(stn=st+r4)

°C/°F

-20 20

3 3 3 3 3 3

r5

Authorise recording of min. and max.

temperature values

0=not authorised

1=authorised

Select 0 1 0 0 0 0 0 0

rt

Interval between temperature recordings Time 0 999 - - - - - -

rH

Maximum temperature recorded °C/°F - - - - - - - -

rL

Minimum temperature recorded °C/°F - - - - - - - -

c: Compressor parameters

Display

Parameter and description

Measurement

unit

Min Max

Bn 1 Bn 2 Bn 3 Bn 4 Bn 5 Bn

6

c0

Delay compressor and fan start up when the

controller is switched on

Min 0 15 1 1 1 1 1 1

c1

Minimum time between 2 consecutive start ups

of the same compressor

Min 0 15 6 6 6 6 6 6

c2

Minimum compressor stoppage time Min 0 15 0 0 0 0 0 0

c3

Minimum compressor running time Min 0 15 2 2 2 2 2 2

c4

Compressor running duration in case of probe

alarm (continuous cycle)

Min 0 100 15 15 15 15 15 15

cc

Continuous cycle duration Time 0 15 4 4 4 4 4 4

c6

Temperature alarm exclusion time after a

continuous cycle

Time 0 15 2 2 2 2 2 2

c7

Maximum Pump-Down time (vacuum

generation)

Sec 0 900 0 0 0 0 0 0

c8

Compressor delayed start up after opening the

Pump-Down valve

Sec 0 60 0 0 0 0 0 0

c9

Authorisation of auto-start function during

Pump-Down

0= when the valve is closed

1= each time the valve is closed + LP pressure

switch request when no cooling request is present

Select 0 1 0 0 0 0 0 0

c10

Pump-Down operation in time or in pressure

0=Pump-down in pressure with maximum time

1=Pump-down in time

Select 0 1 0 0 0 0 0 0

c11

Active list of parameters (n° of ‘bn’ ) Sec 0 250 1 2 3 4 5 6

Code +050004036 Rel. 1.0 – 11/03/2008

10

d: Defrost parameters

Display

Parameter and description

Measurement

unit

Min Max

Bn 1 Bn 2 Bn 3 Bn 4 Bn 5 Bn

6

d0

Type of defrost

0=defrost with elec. element ends with

temperature or time

1=defrost with hot gas ends with temperature or

time

2=defrost with elec. element ends with time

3=defrost with hot gas ends with time

4= defrost with elec. element ends with time or

temperature (if defrost ends with time ED1 and ED2

are not displayed)

Select 0 4 2 0 0 2 0 0

dI

Interval between 2 defrosts Time 0 250 8 8 6 12 8 6

dt1

Temperature at end of evaporator defrost °C/°F -50 200 4 4 4 4 4 4

dt2

Temperature at end of aux. evaporator defrost °C/°F -50 200 4 4 4 4 4 4

dP1

Maximum evaporator defrost duration Min 1 250 45 45 30 45 45 30

dP2

Maximum aux. evaporator defrost duration Min 1 250 45 45 30 45 45 30

d3

Delayed defrost activation Min 0 250 0 0 0 0 0 0

d4

Defrost when the controller is switched on

0=no

1=yes

Select 0 1 0 0 0 0 0 0

d5

Delay defrost when the controller is switched on Min 0 250 120 240 240 120 240 240

d6

Block display during defrost

0=alternating display of temperature and DEF

1=display temperature present before defrost

2=always display DEF

- 0 2 2 2 2 2 2 2

dd

Dripping duration after defrost Min 0 15 0 4 4 0 4 4

d8

High-temperature alarm (AH) exclusion duration

after defrost and/or door open

Time 0 15 1 1 1 1 1 1

d8d

Alarm timer after door opening (alarm “dor”) Min 0 250 2 2 2 2 2 2

d9

Priority defrost for delayed compressor

start/stop

0=respected

1=not respected (priority defrost)

Select 0 1 0 0 0 0 0 0

d/1

Read defrost probe 1 °C/°F - - - - - - - -

d/2

Read defrost probe 2 °C/°F - - - - - - - -

dC

Defrost duration time base

0=hours/minutes

1=Minutes/seconds

Select 0 1 0 0 0 0 0 0

d10

Smart defrost: Compressor running time with an

evaporator temperature below D11 to start

defrost

0=function disabled

>0 =running time

dC 0 250 0 0 0 0 0 0

d11

Temperature threshold for smart defrost °C/°F -20 20 1 1 1 1 1 1

d12

Auto-adaptive advanced defrost

0=skip defrost disconnected, automatic variation

disconnected

1=skip defrost disconnected, automatic variation

connected

2= skip defrost connected, automatic variation

disconnected

3= skip defrost connected, automatic variation

connected

- 0 3 0 0 0 0 0 0

dn

Average defrost duration in percentage in

relation to dt1 or dt2

- 1 100 65 65 65 65 65 65

dH

Proportional variation factor of dI - 0 100 50 50 50 50 50 50

Code +050004036 Rel. 1.0 – 11/03/2008

11

A: Alarm parameters

Display

Parameter and description

Measurement

unit

Min Max

Bn 1 Bn 2 Bn 3 Bn 4 Bn 5 Bn

6

A0

Alarms and fans differential °C/°F 0.1 20 0.2 0.2 0.2 0.2 0.2 0.2

A1

Type of alarm threshold: low-temperature (AL)

and high-temperature (AH)

0=AL and AH threshold in relation to set point

(factory set)

1=AL and AH absolute values

Select 0 1 0 0 0 0 0 0

AL

Low-temperature alarm threshold (AL) Æ

differential > 0°C if factory set

°C/°F -50 200 5 5 5 6 5 5

AH

High-temperature alarm threshold (AH) Æ

differential > 0°C if factory set

°C/°F -50 200 5 5 5 6 5 5

Ad

Temperature alarm delay (AL and AH) Min 0 250 45 45 45 45 45 45

A4

Configuration of digital input 1 Æ terminals 22

& 23

0=input not used.

1=Instantaneous external alarm (IA)

2=Delayed external alarm (dA)

3=Defrost authorisation (except IR33M)

4=Start defrost with external contact

5=Door contact: Stop compressor and fans

6=Controller remote stoppage

7=Night screen contact (day/night contact)

8=Low pressure switch input for pump-down

9=Stop fans with door contact

10=Direct/reverse operation (hot/cold)

11=Light detector

12=Activation of auxiliary output

13= Door contact without light control: Stop

compressor and fans

14= Door contact without light control: Stop fans.

- 0 14 0 0 0 0 0 0

A5

Configuration of digital input 2 Æ terminals 24

& 25

Same as digital input 1

- 0 14 0 0 0 0 0 0

A6

Authorisation to stop the compressor with

external alarm

0=compressor always off

100=compressor always on

Min 0 100 0 0 0 0 0 0

A7

Alarm timer with contact Min 0 250 0 0 0 0 0 0

A8

Authorisation of alarms Ed1and Ed2 (defrost

end with time)

0=no

1=yes

Select 0 1 0 1 1 0 1 1

A9

Configuration of digital input 3 Æ terminals 26

& 27

Same as digital input 1

- 0 14 0 0 0 0 0 0

Ado

Light control with door contact

0=off

1=on

Select 0 1 0 0 0 0 0 0

Ac

Condenser high-temperature alarm threshold

(CHT)

°C/°F 0.0 200 70 70 70 70 70 70

AE

Condenser high-temperature alarm differential

(CHT)

°C/°F 0.1 20 10 10 10 10 10 10

Acd

Condenser high-temperature alarm delay (CHT) Min 0 250 0 0 0 0 0 0

AF

Light output switch-off timer with light detector

0=door detector

>0=room detector

Sec 0 250 0 0 0 0 0 0

ALF

Anti-frost alarm threshold (AFr) °C/°F -50 200 -5 -5 -5 -5 -5 -5

AdF

Anti-frost alarm delay (AFr) Min 0 15 1 1 1 1 1 1

Code +050004036 Rel. 1.0 – 11/03/2008

12

F: Ventilation parameters

Display

Parameter and description

Measurement

unit

Min Max

Bn 1 Bn 2 Bn 3 Bn 4 Bn 5 Bn

6

F0

Fans control

0=fan always on except in phases F2, F3, Fd

1=fan thermostat controlled according to

difference between controller temperature and

evaporator temperature (in relation to F1)

2=fan thermostat controlled according to

evaporator temperature (in relation to F1)

Select 0 2 0 0 0 0 0 0

F1

Fan start up temperature °C/°F -50 200 5 5 5 5 5 5

F2

Fan control according to compressor

0=fan on when the compressor is off

1=fan off when the compressor is off

Select 0 1 0 0 0 0 0 0

F3

Fan operation during defrost

0=fan on during defrost

1=fan off during defrost

Select 0 1 0 1 1 0 1 1

Fd

Fans stoppage time after dripping Min 0 15 0 2 2 0 2 2

F4

Condenser fan switch off temperature °C/°F -50 200 40 40 40 40 40 40

F5

Condenser fans differential °C/°F 0.1 20 5 5 5 5 5 5

h: Configuration parameters

Display

Parameter and description

Measurement

unit

Min Max

Bn 1 Bn 2 Bn 3 Bn 4 Bn 5 Bn

6

H0

Serial address - 0 207 1 1 1 1 1 1

H1

Operating mode of relay 4

0=relay open in case of alarm

1=relay closed in case of alarm

2=auxiliary output: Open or close relay 4 by

pressing the AUX key

3=light output

4=auxiliary evaporator defrost output

5=pump-down valve output

6=condenser fan output

7=output for compressor star/delta start up

8=auxiliary output if the controller is off

9=light output is open if the controller is off

10=no function associated with this output

11=controller reverse (hot) output with dead

zone

12=2

nd

compressor output

13=2

nd

compressor output with rotation

Select 0

13

1 1 1 1 4

4

H2

Keypad and/or remote control authorisation

0=Prohibit SET (modification of parameters type

F) and modification of the set point

1 =authorise all

2= Prohibit SET (modification of parameters type

F), modification of the set point and modification via

remote control

3=Prohibit modification via remote control

4=Prohibit UP/AUX, SET (modification of

parameters type F) and DOWN/DEF (defrost)

5= Prohibit UP/AUX, SET (modification of

parameters type F), DOWN/DEF (defrost) and

modification of set point.

6= Prohibit UP/AUX, SET (modification of

parameters type F), DOWN/DEF (defrost) and

modification of set point.

Select 0 6 1 1 1 1 1 1

H3

Remote control parameter access code

0=access to parameters without code

- 0 255 0 0 0 0 0 0

Code +050004036 Rel. 1.0 – 11/03/2008

13

Display

Parameter and description

Measurement

unit

Min Max

Bn 1 Bn 2 Bn 3 Bn 4 Bn 5 Bn

6

H4

Buzzer operation

0=in case of an alarm

1=always off

Select 0 1 0 0 0 0 0 0

H5

Operating mode of relay 5

0=relay open in case of alarm

1=relay closed in case of alarm

2=auxiliary output: Open or close relay 4 by

pressing the AUX key

3=light output

4=auxiliary evaporator defrost output

5=pump-down valve output

6=condenser fan output

7=output for compressor star/delta start up

8=auxiliary output if the controller is off

9=light output is open if the controller is off

10=no function associated with this output

11=controller reverse (hot) output with dead

zone

12=2nd compressor output

13=2nd compressor output with rotation

Select 0 13 10 10 10 11 10 10

H6

Blocking of keys:

0=all keys enabled

1=set disabled

2=down key disabled

3=set and down key disabled

4=up key disabled

5=up key and set disabled

6=up and down keys disabled

7=up, down and set keys disabled

8=prg disabled

9=prg and set disabled

10=prg and down key disabled

11=prog, down key and set disabled

12=prg and up key disabled

13=prg, up key and set disabled

14=prg, up and down keys disabled

15=all keys disabled

- 0 255 0 0 0 0 0 0

H8

Selection of the light or auxiliary output for

activation of the time range

0=time range linked to the light

1=time range linked to the auxiliary output

Select 0 1 0 0 0 0 0 0

H9

Validation of set point variation with the time

range

0=not enabled (tof set point +r4)

1=enabled (ton set point normal)

Select

0

1 0 0 0 0 0 0

Hdh

Heating element blocking at start up

differential

°C/°F -50 200 0 0 0 0 0 0

Code +050004036 Rel. 1.0 – 11/03/2008

14

HA: HACCP alarm parameters (OPTIONAL)

Display Parameter and description

Measurement

unit

Min Max

HAn

Number of HA alarm events recorded

- 0 15

HA

Time/date of last HA recorded

- -

y__

Year Year 0 99

M__

Month Month 1 12

d__

Day Day 1 7

h__

Hour Hour 0 23

n__

Minute Min 0 59

t__

Duration Duration 0 99

HA1

Time/date of last HA recorded

- - -

y__

Year Year 0 99

M__

Month Month 1 12

d__

Day Day 1 7

h__

Hour Hour 0 23

n__

Minute Min 0 59

t__

Duration Duration 0 99

HA2

Time/date of last HA recorded

- - -

y__

Year Year 0 99

M__

Month Month 1 12

d__

Day Day 1 7

h__

Hour Hour 0 23

n__

Minute Min 0 59

t__

Duration Duration 0 99

HFn

Number of HF alarm events recorded

- 0 15

HF

Time/date of last HF recorded

- - -

y__

Year Year 0 99

M__

Month Month 1 12

d__

Day Day 1 7

h__

Hour Hour 0 23

n__

Minute Min 0 59

t__

Duration Duration 0 99

Code +050004036 Rel. 1.0 – 11/03/2008

15

Display Parameter and description

Measurement

unit

Min Max

HF1

Time/date of last HF recorded

- - -

y__

Year Year 0 99

M__

Month Month 1 12

d__

Day Day 1 7

h__

Hour Hour 0 23

n__

Minute Min 0 59

t__

Duration Duration 0 99

HF2

Time/date of last HF recorded

- 0 -

y__

Year Year 0 99

M__

Month Month 1 12

d__

Day Day 1 7

h__

Hour Hour 0 23

n__

Minute Min 0 59

t__

Duration Duration 0 99

Htd

HACCP alarm delay

Htd=0 function disabled

Min 0 250

td: Defrost time parameters (OPTIONAL)

Display Parameter and description

Measurement

unit

Min Max

td1

Defrost 1 time range

- - -

d__

Day

0=disabled

1=Monday

2=Tuesday

3=Wednesday

4=Thursday

5=Friday

6=Saturday

7=Sunday

8=Monday to Friday

9=Monday to Saturday

10=Saturday and Sunday

11=Every day

Day 0 11

h__

Hour Hour 0 23

n__

Minute Min 0 59

td2

Defrost 2 time range

- - -

d__

Day Day 0 11

h__

Hour Hour 0 23

n__

Minute Min 0 59

Code +050004036 Rel. 1.0 – 11/03/2008

16

Display Parameter and description

Measurement

unit

Min Max

td3

Defrost 3 time range

- - -

d__

Day Day 0 11

h__

Hour Hour 0 23

n__

Minute Min 0 59

td4

Defrost 4 time range

- - -

d__

Day Day 0 11

h__

Hour Hour 0 23

n__

Minute Min 0 59

td5

Defrost 5 time range

- - -

d__

Day Day 0 11

h__

Hour Hour 0 23

n__

Minute Min 0 59

td6

Defrost 6 time range

- - -

d__

Day Day 0 11

h__

Hour Hour 0 23

n__

Minute Min 0 59

td7

Defrost 7 time range

- - -

d__

Day Day 0 11

h__

Hour Hour 0 23

n__

Minute Min 0 59

td8

Defrost 8 time range

- - -

d__

Day Day 0 11

h__

Hour Hour 0 23

n__

Minute Min 0 59

ton

Light illumination/auxiliary time range

- - -

d__

Day

0=disabled

1=Monday

2=Tuesday

3=Wednesday

4=Thursday

5=Friday

6=Saturday

7=Sunday

8=Monday to Friday

9=Monday to Saturday

10=Saturday and Sunday

11=Every day

Day 0 11

h__

Hour

Hour 0 23

n__

Minute

Min 0 59

Code +050004036 Rel. 1.0 – 11/03/2008

17

Display Parameter and description

Measurement

unit

Min Max

tof

Light/auxiliary off time range

- - -

d__

Day (same as ton)

Day 0 11

h__

Hour

Hour 0 23

n__

Minute

Min 0 59

tc

Time/date programming

- - -

y__

Year

Year 0 99

M__

Month

Month 1 12

d__

Day

Day 1 31

u__

Day of the week

1=Monday

2=Tuesday

3=Wednesday

4=Thursday

5=Friday

6=Saturday

7=Sunday

Day 1 7

n__

Hour

Hour 0 23

t__

Minute

Min 0 59

Code +050004036 Rel. 1.0 – 11/03/2008

18

5 – List of alarm codes

Code Description Display icon

Alarm relay Buzzer

Reset

Before any intervention, always check the wiring.

rE

Controller virtual probe damaged or disconnected

Flashing

On On Automatic

E0

Ambient probe S1 damaged or disconnected

Flashing

Off Off Automatic

E1

Defrost probe S2 damaged or disconnected

Flashing

Off Off Automatic

E2

Probe S3 damaged or disconnected

Flashing

Off Off Automatic

E3

Probe S4 damaged or disconnected

Flashing

Off Off Automatic

E4

Probe S5 damaged or disconnected

Flashing

Off Off Automatic

‘---‘

Probe not validated None Off Off Automatic

LO

Low temperature alarm

Flashing

On On Automatic

HI

High temperature alarm

Flashing

On On Automatic

AFr

Anti-frost alarm

Flashing

On On Manual

IA

Instantaneous alarm with external contact

Flashing

On On Automatic

dA

Delayed alarm with external contact

Flashing

On On Automatic

dEF

Defrost in progress

On

Off Off Automatic

Ed1

Defrost on evaporator 1 finished with time None Off Off Automatic/manual

Ed2

Defrost on evaporator 2 finished with time None Off Off Automatic/manual

Pd

Maximum pump-down time alarm

Flashing

On On Automatic/manual

LP

Low-pressure alarm

Flashing

On On Automatic/manual

AtS

Pump-down automatic start up

Flashing

On On Automatic/manual

cht

Condenser high temperature pre-warning None Off Off

Automatic/manual

CHT

Condenser high temperature alarm

Flashing

On On

Manual

dor

Door open too long alarm

Flashing

On On Automatic

Etc

Internal clock defective

Flashing

Off Off Automatic

EE

Machine parameters Eprom error

Flashing

Off Off Automatic

EF

Operating parameters Eprom error

Flashing

Off Off Automatic

HA

HACCP alarm type HA

Flashing

Off Off Automatic

HF

HACCP alarm type HF

Flashing

Off Off Automatic

rCt

Controller validated for remote programming None Off Off Automatic

Add

Automatic address attribution procedure in progress None Off Off Automatic

Prt

Report print-out in progress None Off Off Automatic

ccb

Start continuous cycle request Indication

ccE

End continuous cycle request Indication

dFb

Start defrost request Indication

dFE

Stop defrost request Indication

On

On Indication

Off

Off Indication

rES

Reset manual-reset alarms; reset HACCP

alarms; reset temperature monitoring

Indication

n1 - n6

Indicates an alarm on units 1-6 present in the system

Flashing

On On Automatic

dnL

Download in progress Indication

d1 - d6

Download errors on units 1-6

Flashing

Off Off

Code +050004036 Rel. 1.0 – 11/03/2008

19

6 – Spare parts:

*Controller Masterlog 4 with 2 probes (ambient and end of defrost)

Æcode PDEL01957

*Ambient probe

Æcode PDEL00490

*End of defrost probe

Æcode PDEL00455

7 – Miscellaneous:

7 – 1 ÆTest NTC probe for damage:

Temp. °C -35 -30 -25 -20 -15 -10 -5 0 5 10 15 20 25 30

Value KΩ 144 111 86 68 53 42 34 27 22 18 15 12 10 8

7 – 2 ÆSet lighting parameters:

Use AUX 2 (relay 5)

Parameter: H5=3

Bulb connected between terminals 17 & 2

Note: the key must be pressed and held for 2s to switch the lighting on or off.

7 – 3 Æ Connection of the defrost element:

Connect “Element” contactor coil between terminals 8 and 2

7 – 4 Æ Connection of heating element for wine cellars:

Connect “Element” contactor coil between terminals 17 and 2

7 – 5 Æ Operation with 2 Masterlog4 Æ 1 master and 1 slave:

Master Slave

PF contact “NO” ÆÆ connection to ÆÆ Digital input available:

of element contactor if terminals 22 &23 Æ A4=4

if terminals 24 &25 Æ A5=4

if terminals 26 &27 Æ A9=4

Interval between 2 defrosts: Interval between 2 defrosts:

Parameter ‘’dI’’=6 hours Parameter ‘’dI’’=8 hours

Note: When using an external defrost timer, the configuration is identical to above except that the master is replaced

by a timer.

Code +050004036 Rel. 1.0 – 11/03/2008

20

Code +050004036 Rel. 1.0 – 11/03/2008

21

8. TECHNICAL CHARACTERISTICS

Power Supply: Model E= Voltage: 230 V~, 50/60 Hz; Power: 11.3 VA, 50 mA~ max.

Model A= Voltage: 115 V~, 50/60 Hz; Power: 11.3 VA, 100 mA~ max.

Model H= Voltage: 115...230 V~, 50/60 Hz; Power: 12 VA, 110 mA~ max.

Insulation: guaranteed by the p. supply:

Model E,A,H= Insulation from very low voltage parts: reinforced; 6 mm in air, 8 mm on surface; 3750 V insulation.

Insulation from relay outputs: primary; 3 mm in air, 4 mm on surface; 1250 V insulation.

Input: S1: NTC or PTC, depending on the model

S2: NTC or PTC, depending on the model

D11, S3: voltage-free contact, contact resistance < 10 Ω, closing current 6 mA NTC or PTC, depending on the model

D12, S4: voltage-free contact, contact resistance < 10 , closing current 6 mA NTC or PTC,

depending on the model

D13, S5: voltage-free contact, contact resistance < 10 , closing current 6 mA NTC or PTC, depending on the model.

Maximum distance from probes and digital inputs less than 10 m.

Note: in the installation, keep the power supply and load connections separate from the probe, digital inputs, repeater display and

supervisor cables.

Probe type: NTC std. CAREL= 10 kΩ at 25 °C, range from –50T90 °C; measurement error: 1 °C in the range from –50T50 °C;

3°C in the range from +50T90 °C

NTC high temperature= 50 kΩ at 25 °C, range from –40 T150 °C; measurement error 1.5 °C in the range from –20T115 °C; 4 °C

in the range outside of –40T150 °C

PTC std. CAREL (specifi c model)= 985 Ω at 25 °C, range from –50T150 °C; measurement error: 2 °C in the range –50T50 °C;

4°C in the range +50T150 °C

Relay outputs: according to the model

EN60730-1 (250 V~) UL 873 (250 V~)

8A 8 (4) A on N.O.; 6 (4) A on N.C.; 2 (2) A on N.C. and N.O. (100000

cycles)

8 A resistive 2 FLA 12 LRA C 300 (30000

cycles)

16 A 10 (4) A up to 60 °C on N.O.; 12 (2) A on N.O. and N.C. (100000

cycles)

12 A resistive 5 FLA 30 LRA C 300 (30000

cycles)

2 Hp 10 (10) A (100000 cycles) 12 A resistive, 12FLA, 72 LRA (30000 cycles)

30 A 12 (10) A (100000 cycles) 12 A resistive, 2HP, 12 FLA (30000 cycles)

• insulation from the very low voltage parts: reinforced; 6 mm in air, 8 on surface; 3750 V insulation

• insulation between the independent relay outputs: basic; 3 mm in air, 4 on surface; 1250 V insulation

Connections: Type of connection

= fixed screw, plug-in for screw blocks or spade with crimped contact; Cross-section=

for cables from 0.5 a 2.5 mm

2

Type of connection

= wire cross-section for probes and digital inputs; Cross-section= from 0.5 to 2.5 mm2

(from 20 to 13 AWG)

Type of connection= wire cross-section for power supply and loads; Cross-section= from 1.5 to 2.5 mm2

(from 15 to 13 AWG)

Notes: The correct sizing of the power and connection cables between the instrument and the loads is the

responsibility of the installer. In the max load and max operating temp. conditions, the cables used must be

suitable for operation up to 105 °C.

Case: plastic: dimensions 200 x 240 x 93 mm; bare board and front panel: base dimensions 178 x 86 x 40 mm: front

dimensions 100 x 90 x 12 mm

Assembly: wall mounting (with plastic case): using fastening screws (spacing 162.5 x 218.5); panel (with plastic front

panel): using fastening screws (spacing 159.5 x 197.5); panel (bare board): using fastening screws for base

board and using fastening screws for front board.

The controller must be protected against accidental contact to prevent electric shock.

Display: digits: 3 digit LED; display: from -99 to 999; operating status: indicated with LEDs and graphic icons made in the

polycarbonate label applied to the plastic case.

Keypad: 8 mechanical buttons, keypad made in the polycarbonate label applied to the plastic case.

Infrared receiver: available according to the model.

Clock with backup battery: available according to the model.

Buzzer: available on all models.

Clock: error at 25 °C: ± 10 ppm (±5.3 min/year); error in the temperature range –10T60°C: - 50 ppm (-27 min/year);

ageing: < ±5 ppm (±2.7min/year);

Code +050004036 Rel. 1.0 – 11/03/2008

22

Discharge time: typically 6 months (8 months maximum); recharge time: typically 5 hours (<8 hours maximum).

Operating conditions: Bare board= -10T65°C; <90% rH non-condensing.

With plastic case= -10T50°C; <90% rH non-condensing.

Current= Relay 1 12 A; Relay 2 0 A; Relay 3 4 A; Relay 4 4 A; Relay 5 4 A; Relay 1 0 A; Relay 2 12 A;

Relay 3 4 A; Relay 4 4 A; Relay 5 4 A.

The currents indicated above are reduced according to the relays used.

Storage conditions: -20T70°C; <90% r.H. non-condensing.

Panel installation: with plastic case: IP65 without disconnecting switch; IP54 with disconnecting switch; panel: IP54 with

disconnecting switch.

Environmental pollution: 2 (normal situation).

PTI of insulating materials: printed circuits 250, plastic and insulating materials 175.

Period of stress across the insulating parts: long.

Category of resistance to fire: category D and category B (UL 94-V0).

Class of protection against the voltage surges: category 1.

Type of action and disconnection: relay contacts 1B (micro-disconnection).

Construction of the control device: incorporated electronic control device.

Classification according to protection against electric shock: Class II when appropriately incorporated.

Device designed to be hand-held or incorporated into equipment designed to be hand-held: no.

Software class and structure: Class A.

Cleaning the front panel of the instrument: only use neutral detergents and water.

Serial interface per CAREL network: Internal, available on all models, upon request.

Interface for repeater display: Internal, available in all models, upon request.

Maximum distance between interface and repeater display: 10 m.

Power supply disconnecting switch: available upon request on all models with plastic case .

Programming key: available on all models.

HEATCRAFT

42 Rue Roger SALENGRO

69741 GENAS (LYON) France

A

gency

Loading...

Loading...