Heatcraft Refrigeration Products HCS User Manual

Bulletin AH-TB

January 2011

(Replaces AH-91C)

Air Handlers

Tech Bulletin

For Air Conditioning, Heating and Ventilation

Available in Bohn™, Climate Control™, Chandler™ & Larkin™

Models HCS, HCL

VCS, HD

Size 03 thru 75

Index

Index

Features, Accessories 3 - 10

Performance, Selection 11 - 23

Fan Data 24 - 29

Dimensional Data 29 - 38

Weight 39

Static, Air Pressure Drop 40 - 41

Physical Data 42-43

Mechanical Specications 44

VCS MODELS 03 - 41

11 Standard Models

Capacities From

1000 to 24000 CFM

Quality Standard

Heatcraft has built high performance air handlers

for the building trade for over forty years.

Our hallmark has been a continuing process of design improvements to keep pace with new system requirements. This bulletin presents the complete line of air handling units oered

by Heatcraft for air conditioning, heating, and

ventilation applications.

Quick Cues for the ve cabinet styles:

S = SHORT in model HCS

L = LONG in model HCL

V = VERTICAL in model VCS

HD = HEATING DUTY in model HD

Our highest design priorities are for units with low operating costs,

rugged construction, and the features most needed for simple

trouble free installation and maintenance.

Heatcraft Refrigeration Products' ISO 9000 certication guarantees

consistent quality products for you and your customers.

Customers can specify brand at time of order, availabe

in Bohn, Climate Control, Chandler and Larkin.

2

Features

Nomenclature

HCL 0 6 F C

Cabinet style Fan Type:

HCS — (S for Short) Insulated fan section with motor FC - Forward curved fans, available

base and access door(s), horizontally adjacent (same with all cabinet styles, sizes 3 thru 41

elevation) with insulated short depth coil section with

drain pan. AF - Air foil type fans, available with

sizes 20 thru 75, all cabinets except

HCL — (L for Long) Insulated fan section with motor VCS style

base and access door(s), horizontally adjacent (same

elevation) with insulated long coil section with drain pan. Nominal coil face area (square feet):

Size 03 thru size 75

VCS — (V for Vertical, fan on top of coil section) See inside back cover for actual coil face

Insulated fan section with motor base and access area for each model size.

door(s), vertically adjacent to (on top of ) insulated AHV

coil section with drain pan.

HD — (HD for Heating Duty) Uninsulated fan section

with motor base and access door(s), horizontally

adjacent (same elevation) with 1, 2, 3, 4 or 6 row

heating section.

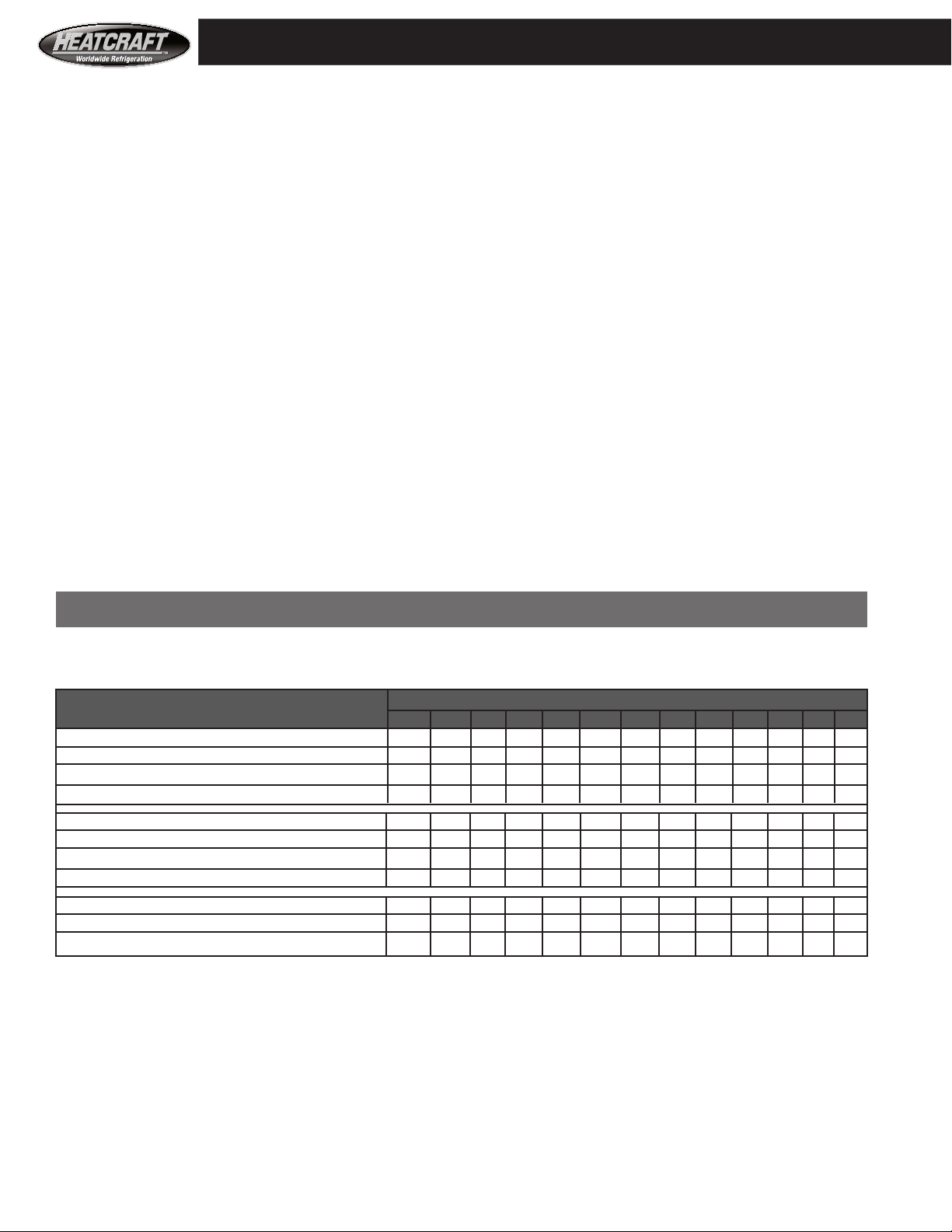

Standard Features, Basic Cabinet Models Per Unit Size

‘S’ = Standard ‘A’ = Available

Standard Feature Description Unit Size

03 06 08 10 12 14 18 20 26 34 41 50 65 75

HCS (short coil section) cabinet style S S S S S S S S S S S S S A

HCL (long coil section) cabinet style S S S S S S S S S S S S S S

VCS (fan above coil section) cabinet style S S S S S S S S S S S A A A

HD (heating duty) cabinet style S S S S A A A A A A A A A A

Universal (can be oor or ceiling) mount S S S S S S S S S S S

Floor or platform mounting only S S S

16 gauge casing - fan and coil section S S S S S S S S S S S S S S

Hinged access door motor side of fan section

removable panel on opposite side S S S S S S S

Hinged access doors, both sides of fan section A A A A A A A S S S S S S S

Blower - forward curved (FC), low pressure S S S S S S S

Blower - forward curved (FC), medium pressure A A A A A A A S S S S

Blower - air foil (AF), Not available as VCS unit A A A A S S S

200,000 hour lifetime lubricated bearings S S S S S

Pillow block bearings, extended lube lines A A A A A S S S S S S S S S

Adjustable motor base S S S S S S S S S S S S S S

Left or right hand motor positions S S S S S S S S S S S S S S

Combined fan & coil sections (HCS & HCL only) S S S S S S S

Split fan & coil sections (HCS, HCL, & HD only) A A A A A A A S S S S S S S

Coil section drain pan (HCS & HCL models only) S S S S S S S S S S S S S S

Coil section drain pan (VCS models only) S S S S S S S S S S S S S S

1" by 3/4 lbs Insulation, berglass (HCS, HCL, & VCS) S S S S S S S S S S S S S S

Horizontal or vertical fan discharge arrangements,

see drawings pp.31-35 for S S S S S S S S S S S S S S

actual placement and bottom discharge

3

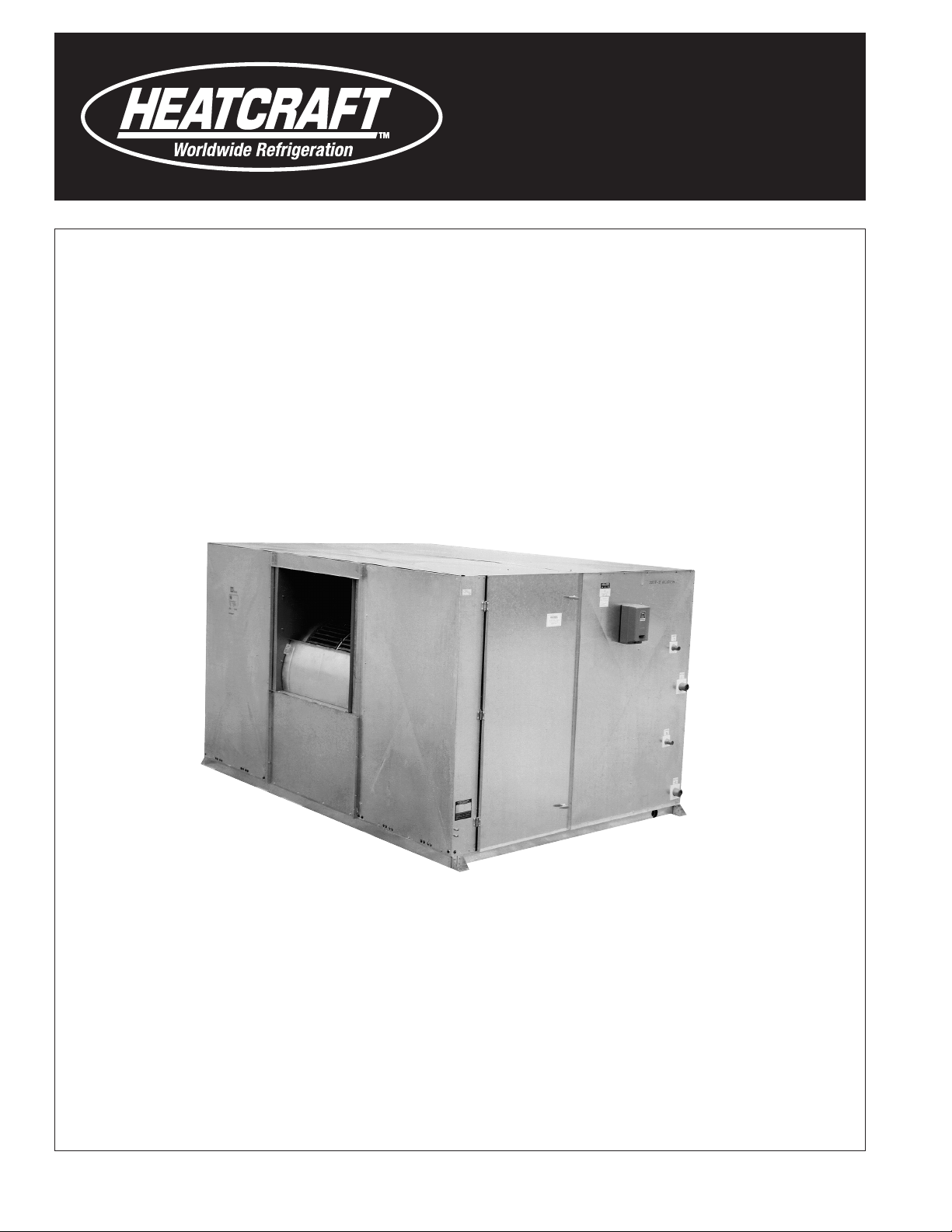

Standard Unit Features

Basic Ca

Basic Cabinet

Consists of a fan section and a coil section with double wall drain

pan. The housing panels are die formed from mill galvanized steel

and insulated with 1" - 3/4 pound density mat faced fiberglass

insulation. All fan sections have hinged and latched access doors.

Unit below has fan and coil section.

Fans

All units have single, double width, double inlet fan

wheels for quiet performance and low energy consumption.

Single wheels eliminate the problem of unequal loading which is

characteristic of units with multiple wheels. Also, the expense of a

“pants” type duct connection is avoided. Sizes 03 through 41 units

have forward curved and size 50 through size 75 units have airfoil

fan as standard.

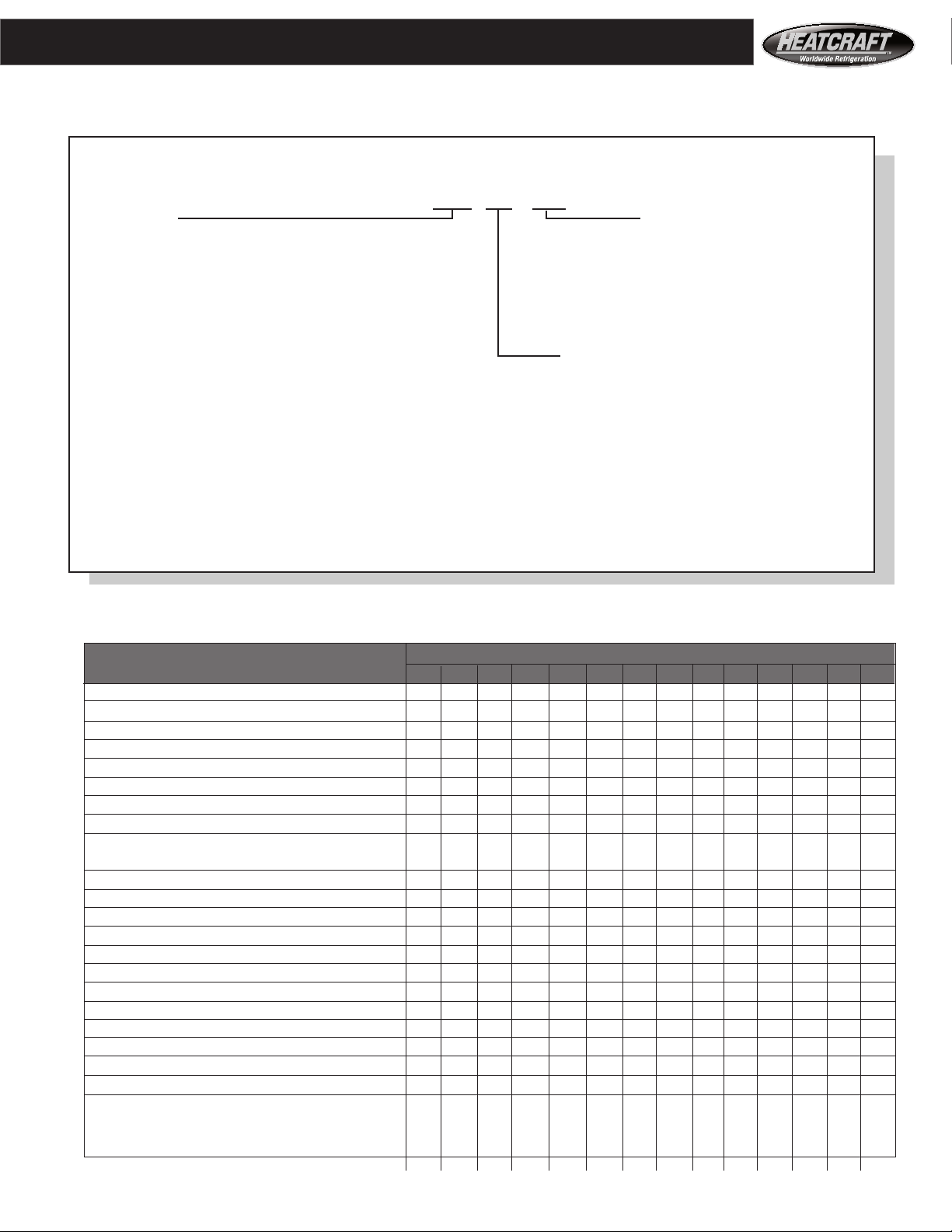

Motor Mount

Heatcraft puts the motor inside the fan section cabinet. It is

mounted on a heavy gauge steel slide rail base. There are several

advantages with internal motor location. It eliminates the need for

a bulky belt guard. Another advantage is that Heatcraft balances

the factory mounted motor and drive components, which can

eliminate additional balancing at start-up.

Coil Section

Coil sections cover a wide range of heating and cooling

requirements. Side, top and bottom panels are 16 gauge mill

galvanized steel. All coil sections accommodate either small or

large face area coils.

The HCS coil section will hold 15 1/2" of coils and spacers. The

HCS section covers most applications. Use the HCL coil section

if the coil or access space is more than 15 1/2". (See page 38 for

maximum per model.)

Forward

Curved Fans

Air Foil

Fans

Bearings

Unit sizes 03 through 12 have lifetime lubricated fan bearings as

standard. Unit sizes 03 through 12 with optional medium pressure

fan have pillow block bearings rigidly supported on a heavy steel

frame. Unit sizes 14 through 75 have pillow block bearing rigidly

supported on a heavy steel frame as standard. The bearings are

self aligning and are selected for an average service life in excess

of 200,000 hours. There are extended lube lines and grease fittings

on the drive side of all units that have pillow block bearings. The

bearings on these models can be lubricated without opening the

blower section access door. Maximum operating temperature is

140°F.

Fan Shaft

The fan shaft is solid polished steel, and keyed for both fan and

drive. It is designed so that critical speed is at least 1.25 times the

maximum operating speed.

Cooling coil sections have a drain pan with double wall

construction. Insulation is sandwiched between the outer panel

and the inner drain pan. The pans are heavy gauge mill galvanized

steel. Heatcraft welds the corners of the drain pans and puts drain

connections on both sides of the coil section for field convenience.

The coils sit in an upright position inside the coil section. The

air flows horizontally through the coils. Larger models (sizes 50

through 75) have cooling coils stacked two high.These larger

models come with an intermediate drain pan, so that condensate

from the upper coil does not flow over the lower coil.

Coils come in either small or large sizes (pages 42-43). A large

face area coil fills the total face area of the coil section. The

coil section’s total air volume passes through the large coil. A

small coil is shorter in height and does not fill the total face

height of the coil section. Air may bypass above the coil through

balance dampers or internal face and bypass dampers. With either

combination, it is possible to adjust and control the amount of air

passing through the small size coil.

Chilled water and direct expansion coil face velocities

over 550 FPM should be avoided--WATER CARRYOVER.

If desired, a blank off plate above the small coil can force total coil

section air volume through the small coil.

4

Air Handler Coils

There are a wide variety of coil types to meet the load requirements of conditioned spaces. Heatcraft’s four coil types are: water, direct

expansion, heat reclaim and steam coils. All standard coils have copper tubes and aluminum fins and a heavy gauge mill galvanized steel

casing. Staggered tube designs increase air turbulence and improve coil performance. The plate type, die formed, corrugated fin design

provides optimum strength. The fin design also enhances air turbulence for peak performance. Each fin has die formed, self-spacing fin

collars which completely surround the tubes. Heatcraft mechanically expands the tubes into the fins to provide maximum heat transfer.

Fin spacing selections of six to fourteen fins per inch insure that an optimum coil is offered to meet specific design needs.

Water Coils

A wide range of choices leads to the best coil selection for each

particular job. Select water cooling coils from 4, 5, 6, or 8 row

coil depth options. Select water heating coils from 1, 2, or 3 row

coil depth options. All water coils offer five fin densities (6, 8, 10,

Water

Coils

Direct Expansion Coils

Select direct expansion coils from 3, 4, 5, 6, or 8 row coil depth

options. All direct expansion coils offer five fin densities (6, 8, 10,

12, or 14 FPI). Specify either 1/2" (Type A) or 5/8" (Type 5) tube

diameters. Each coil has a brass, sweat connection type distributor

and copper suction header. Distributor leads of equal length work

for equal refrigerant distribution to all the circuits. Working with

Heatcraft software or your representative, select from a among

variety of circuit designs. Heatcraft has an optimum design to

deliver the proper refrigerant pressure drop for your conditions.

Specify multiple distributors for face split or row split control of

the coil.

12, or 14 FPI). Specify either 1/2" (Type A) or 5/8" (Type 5) tube

diameters. Heatcraft optimizes circuit design from the header into

the coil and delivers high internal heat transfer coefficients for each

application’s conditions. This is done without resorting to internal

devices which increase pressure drop or restrict draining. All circuit

designs avoid trapped circuits, so the coil is drainable. There are

vent and drain connections on both supply and return headers on

coils of 3 or more rows. All coil connections terminate outside the

air handler coil section cabinet. Design working pressure is 250

PSIG. Design fluid temperature for heating coils is 300°F.

Direct

Expansion

Coils

Condenser

Heat

Reclaim

Coils

Steam Coils

Nonfreeze Steam (NFS) coils have internal steam distributing

tubes which are directionally lanced for high performance and

good condensate removal. The coils are also pitched in the coil

casing. The design working pressure and temperature of standard

copper tube coils are 150 PSIG and 366ºF. respectively. Depending

upon job requirements, select the 5/8" (Type 5) tube diameter coil

at an optimum fin spacing and a one or two row coil depth for air

handler model sizes 03 through 50. For models 65 and 75, select

the 1" (Type 8) tube diameter coil with one row at an optimum fin

spacing.

Heat Reclaim Coils

Refrigerant Heat Reclaim (RHR) coils with multiple circuits

handle applications where a number of refrigeration compressors

are connected to a single coil. Each circuit has heavy wall

copper, sweat type, hot gas inlet and liquid or cooled gas outlet

connections. Heatcraft's custom coil circuiting maintains an internal

coil pressure drop below 5 PSIG for each system. Depending upon

job requirements select 1/2" (Type A) or 5/8" (Type 5) tube coils,

select one of five fin densities (6, 8, 10, 12, and 14 FPI), and select

from coil row depths of 2, 3, 4, 5, 6, an 8 rows.

Steam

Coils

5

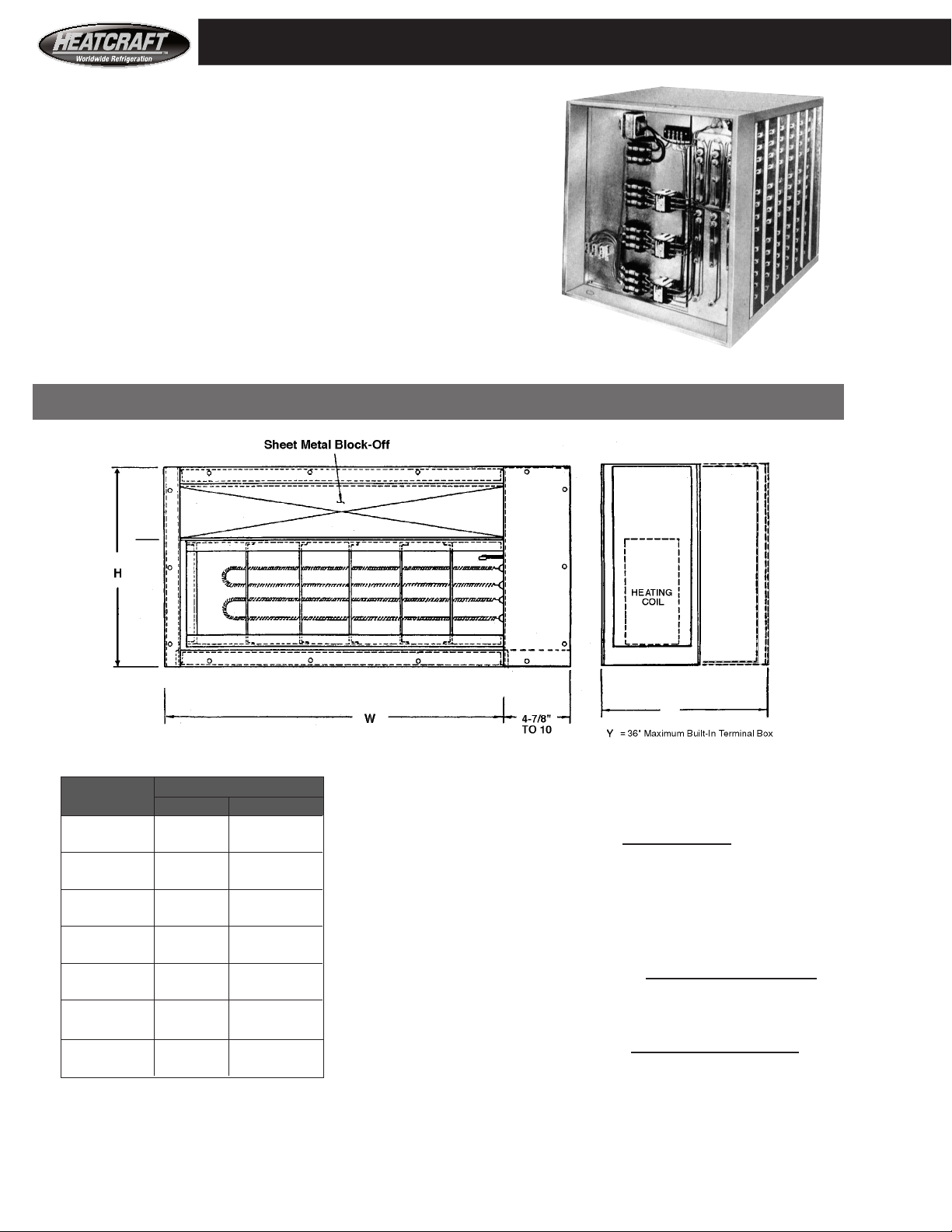

Accessories- Electric Heat

Electric heaters are UL listed for duct installation. The UL

label applies to the heater only, not the complete air handler.

Heaters are furnished as a separate section and are available

with insulated or uninsulated casings. Controls such as

contactors, fuses, etc., may be factory installed and wired in

the heater section end panel provided the number of control

steps is not excessive.

Remote control panels are also available.

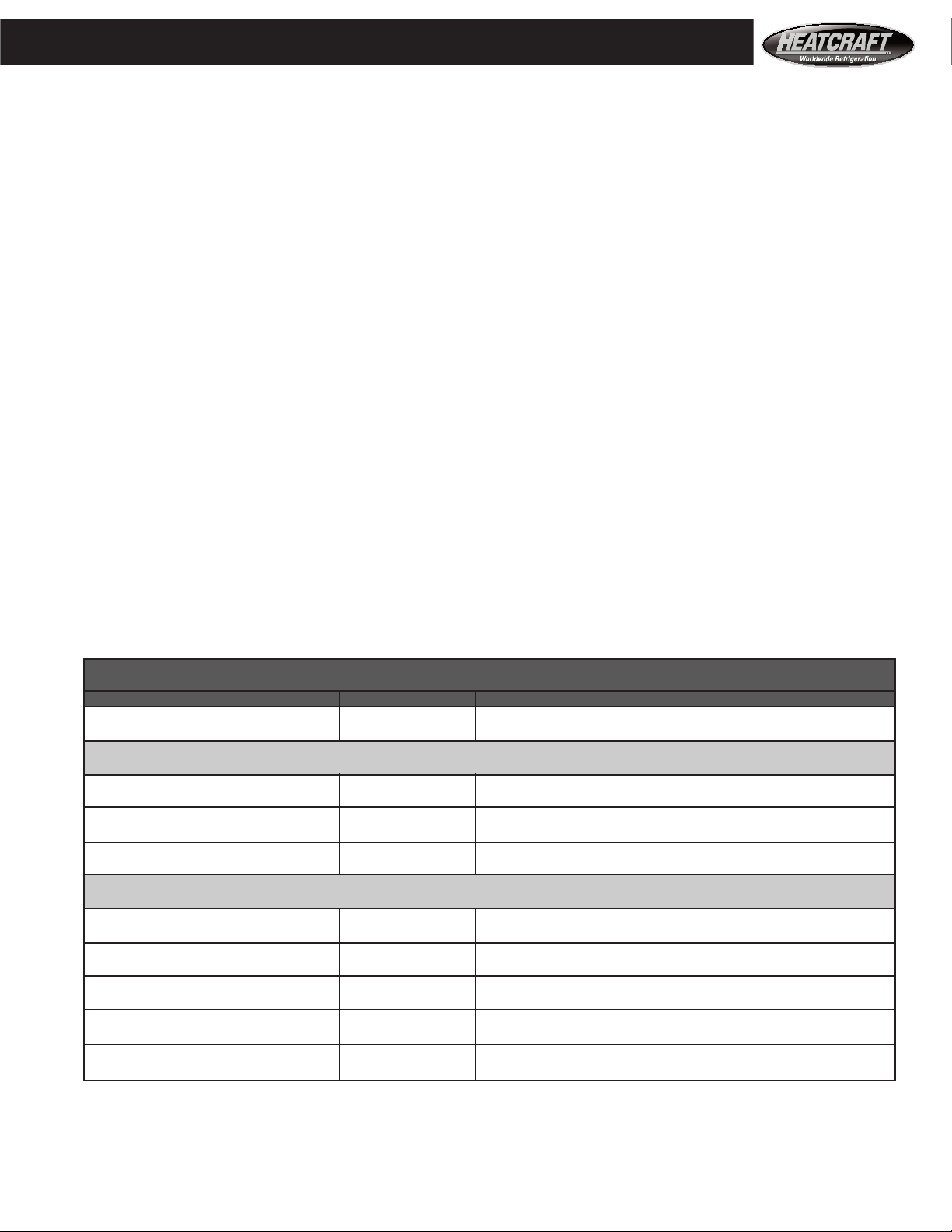

Construction & Dimensions

Unit Heater Dimensions (In.)

Size H W

03 22 3/4 30 5/8

06 26 45 5/8

08 35 1/2 42 5/8

10 35 1/2 51 5/8

12 38 3/4 57 5/8

14 38 3/4 66 5/8

18 47 3/4 66 5/8

20 44 83 5/8

26 44 108 5/8

34 54 108 5/8

41 65 108 5/8

50 74 3/4 110 7/8

65 82 3/4 126 7/8

75 94 3/4 126 7/8

Notes: Heaters for constant volume units to have 35 W/in2 of wire

surface maximum.

Y

1. Total KW Needed

Approximate KW =

CFM x TD (F)

3000

2. Number Of Steps Recommended

Rule of thumb for calculating the recommended number of

steps required. Use Step A or B below, whichever is higher.

A. Number of Steps =

300 x Total Heater KW

CFM

(Based on approx. 10°F. temp. rise per step)

B. Number of Steps =

Total Heater KW

Maximum KW per step

6

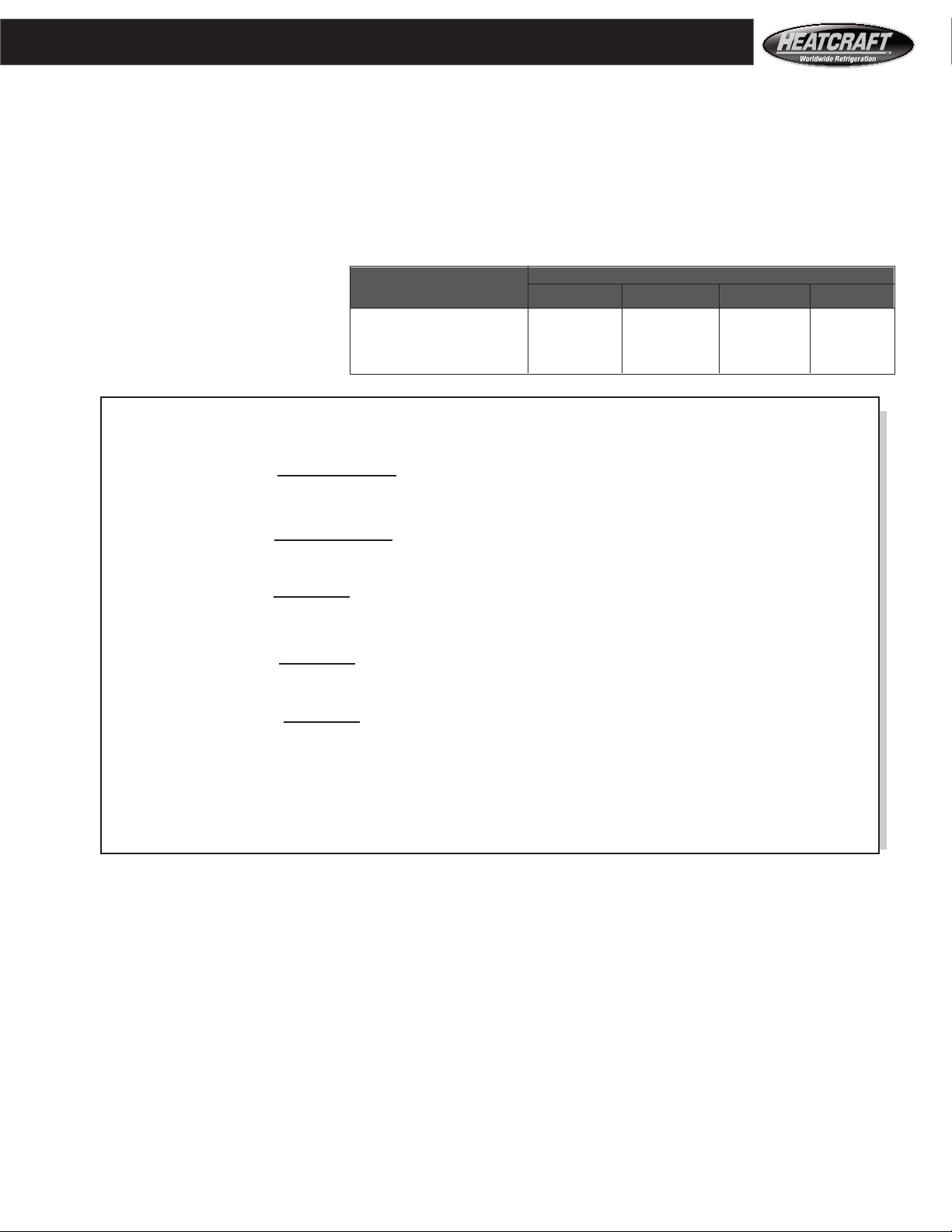

Accessories- Electric Heat

The standard electric heater section construction Typical options for the electric heater

includes: section are:

1. Automatic thermal cutout

2. Heat limiters

3. Air flow switch

1. Fiberglass insulation in cabinet

2. At least one magnetic contactor per step of

heating (two or three pole break)

3. Three phase fuse blocks and fuses

4. Transformer with primary fusing

5. Manual reset thermal cutout in control circuit

Maximum KW

Component 208 V 240 V 460 V 480 V

Low amps contactor 9.0 10.4 19.9 20.8

High amps contactor 17.3 19.3 38.2 39.9

Fuse block 17.3 19.9 38.2 39.9

Maximum KW per

contactor and per fuse

block (at least one

contactor is required per

step of heating):

Electric Heater Selection Example

A. How many KW is needed to increase temperature of 17000 CFM by 27 °F for Air Handler Model Size 34?

17000 X 27 is: 153 KW IS REQUIRED

3000

B. How many steps required at 10°F rise per step?

300 X 153 is: 2.7 STEPS ROUNDS UP TO 3 STEPS

17000

C. How many steps required at 460 volts with low amps contactors?

153 is: 7.7 STEPS ROUNDS UP TO 8 STEPS

19.9

D. How many steps required at 460 volts with high amps contactors?

153 is: 4.0 STEPS

38.2

E. How many fuse blocks required?

153 is: 4.0 FUSE BLOCKS

38.2

°F. Order the 153 KW to get the 27 degree rise.

Throw out the 3 steps (figured at 10°F. rise in part B), because it is smaller than the two values figured

per contactor size (parts D & E). Decide whether you want high amps or low amps contactors, if you

want low amps contactors, round the 7.7 to 8 and order 8 of the low amps contactors (you now have a

possible 8 steps of control). If four steps of control are satisfactory, order the high amps contactors. In

either case, the application requires four fuse blocks (part E).

Notes:

1. You must order the split shipment of the fan

and coil sections to get electric heat on unit

size 03 through unit size 18.

2. All electric heat controls are built into the heater

control box.

3. Specify two pole break contactors or three pole

break contactors. Two pole contactors only

de-energize, while three pole contactors

disconnect.

4. Be aware of requirements for heater circuits

rated more than 48 amps. According to

N.E.C. Code and U.L. you must subdivide

the heater elements of such circuits. N.E.C.

Code requires that the sub-circuit fuses be

furnished by the heater manufacturer.

Commonly Used Control Systems:

A. For small loads (up to 20 KW),consider a

multi-stage thermostat.

B. For medium loads (up to 200 KW), consider a

modulating thermostat that operates a step

controller.

C. For fine control of large loads (above 75 KW),

consider a combination step control and SCR

vernier system. This scheme has 80% of heater

capacity controlled by conventional step controller,

with the other 20% on a solid state SCR controller.

D. For 100% proportional control of any size,

consider a total SCR control.

E. Heatcraft does not supply :

multi-stage thermostats

modulating thermostats

But you will want to order contactors and fuse

blocks from Heatcraft that are appropriate for

for the control scheme specified in the field.

7

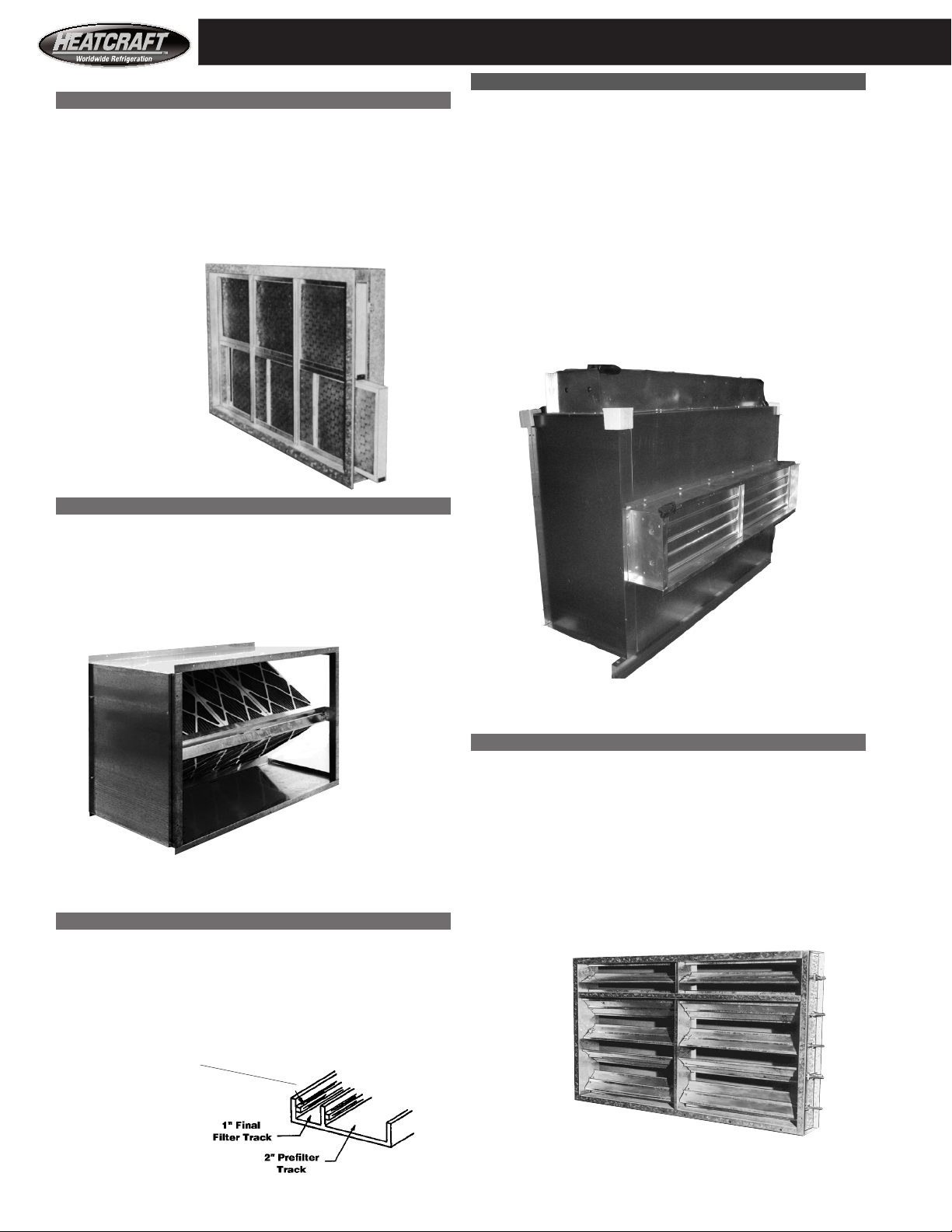

Flat Filter Sections

Flat filter sections are space saving and economical. Choose

either two inch or four inch filters. The two inch filters can be the

throwaway, the 35% pleated, or the high velocity cleanable type.

Four inch filters are 35% pleated, they have more filter surface

than two inch filters. Four inch filters impose less static on air flow

and do not need to changed as often as two inch filters. The filters

slide into metal channels and are removable from either side of the

section.

Flat Filter Section

High Capacity Filter Sections

Designed for high air volume applications. Filters are arranged in

a V or W pattern for the greatest surface possible which provides

extended filter life and reduced resistance to air flow. This means

less fan horsepower. The sections have access doors on each side

to ease filter change.

Mix Box Sections

The Mixbox is an entering air section. Typically, themixbox

accepts air from two sources. Many system designers economize

performance by varying the two air flows to deliver conditioned

air with minimum energy consumption. Mixbox sections are

constructed with heavy gauge mill galvanized steel. Select from

three inlet opening locations: the air can enter through openings

at the top, at the back, or at the bottom of the section. Order the

mixbox with or without dampers. The section with dampers has

parallel blades at each opening and an interconnecting linkage

between the openings. The damper rods rotate in frictionless

sleeve bearings, and the drive rod extends from both sides of the

section for either left or right hand drive.

Mixbox

High capacity

Filter Section

High Efficiency Filter Sections

High Efficiency Filter Sections

Select 22", 28", or 44" bag filter sections. Choose medium or high

efficiency bag or cartridge filters for this section. See pages 9,

29, 42, and 43. Sections are complete with prefilter and bag filter

tracks. The sections have an extruded aluminum final filter track

with a reinforced nylon pile seal. The postive seal forces the air

flow through the high efficiency final filter.

Extruded Aluminum

Filter Track

Final Filter Tracks Have

Reinforced Nylon Pile

For A Postive Seal

8

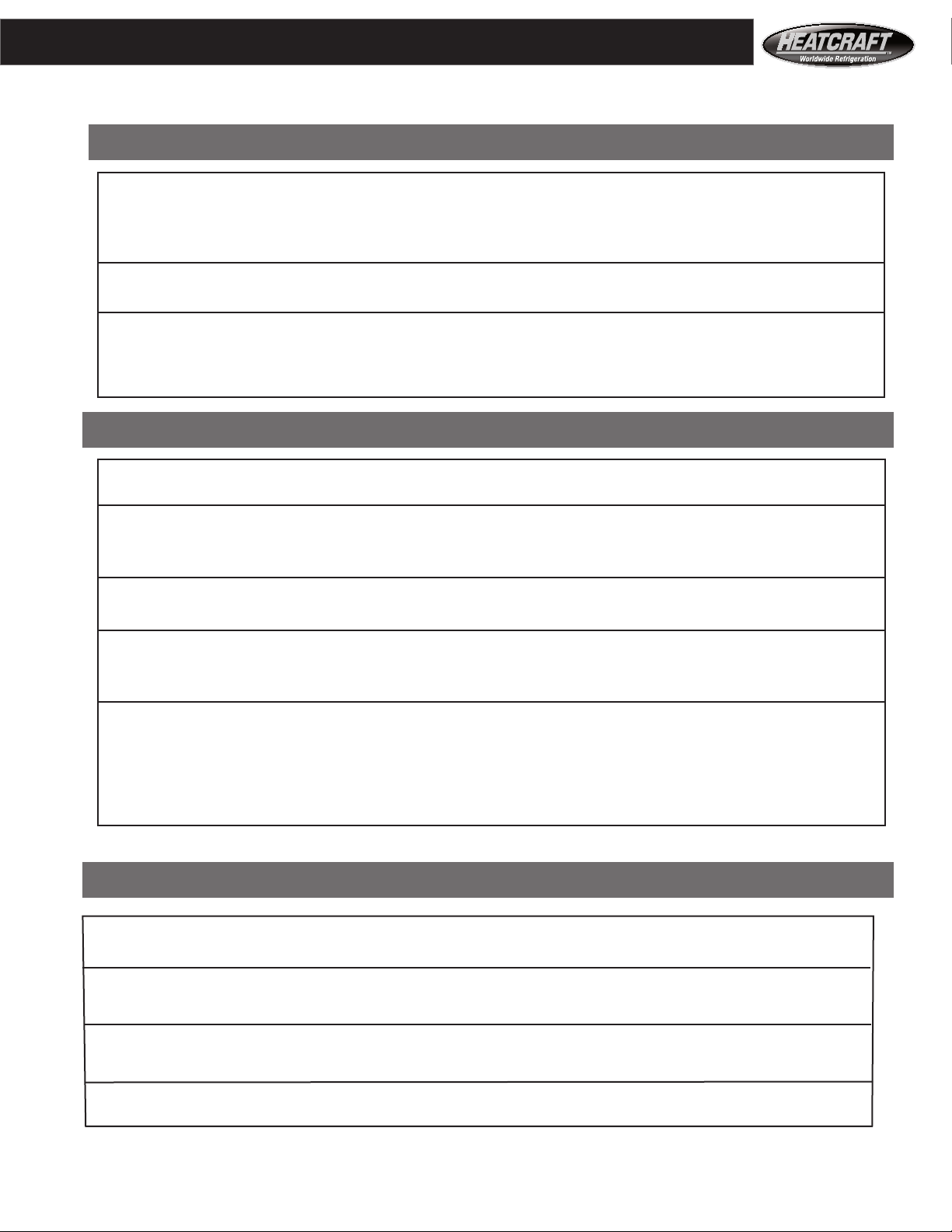

Face And Bypass Dampers

For damper applications, choose either the internal face and bypass

section or the external face and bypass section. If used with a

large coil the damper section must be the external face and bypass

damper type. When used with a small coil, select the internal face

and bypass damper section. The damper sections have balanced

opposed blades with interconnecting linkage. The blades positively

lock to the damper shafts. The shafts rotate freely in frictionless

sleeve bearings.

Face

and

Bypass

Dampers

Accessories

Filters And Auxiliary Sections

(see pages 42 and 43 for number and quantity of filters per model)

Flat and High Capacity Filter Sections- All Unit Sizes: (Dimensions, Page 29 to 37)

2" flat filter section with choice of three standard filter types:

• 2" throwaway filters

• 2" 35% efficient pleated filters

• 2" permanent high velocity cleanable filters

4" flat filter section:

• with 4" 35% efficient pleated filters

High capacity filter section with choice of three standard filter types:

• 2" throwaway filters

• 2" 35% efficient pleated filters

• 2" permanent high velocity cleanable filters

High Effeciency Filter Sections- All Unit Sizes: (Dimensions, Page 29 to 37)

Prefilters: select either 2" throw-away or 2" 35% efficient filters as prefilters. All three high

efficiency filter sections accept prefilters, without reducing final filter depth capacity.

• 2" high efficiency filter section (accommodates up to 12" of final filter depth):

• Prefilter and either 6"or 12" cartridge filters at 60% to 65%, or 80% to 85%,

or 90% to 95% efficiency

• 28" high efficiency filter section (accommodates up to 21" of final filter depth):

• Prefilter and 21" bag filters at 60-65%, or 80-85%, or 90-95% efficiency

• 44", high efficiency filter section (accommodates up to 37" of final filter depth):

• Prefilter and 30" bag filters at 60% to 65%, or 80% to 85%, or 90% to 95% efficiency

• OR prefilter and thirty-seven inch bag filters at 60% to 65%, or 80% to 85%, or 90% to 95% efficiency

High efficiency filter section options:

• 1" depth by 3/4 lbs per cu. ft. density fiber glass insulation (standard section not insulated)

• Diffuser section, must be used when high efficiency filter section is downstream of fan (blow-through unit)

• Double wall construction on high efficiency filter section, adds 4" to the width and 2" to the height of the unit.

Insulation is 2" depth and 1.5 lbs per cu. ft. fiberglass. The insulation is sandwiched

between standard unit and outer skin.

Auxilary Sections- All unit Sizes: (Dimensions, Page 29 to 37)

• Mixbox section, without dampers, with top, bottom, or back inlet openings,

• HCS type coil module, includes insulation, drain pan and four mounting legs, 15.5" max coil depth, see page 38.

• HCL type coil module, includes insulation, drain pan and four mounting legs, and more coil depth, see page 38.

• internal face and bypass sections, must be used with small coil for air bypass. See page 8.

• external face and bypass section, must be used with HCL type coil section or module. See page 8.

• Insulated access section, same size as high capacity filter section, hinged and latched doors, both sides.

• Uninsulated access section, same size as high capacity filter section, hinged and latched doors, both sides.

9

Accessories for Fan and Coil Sections

Fan Section Accessory:

Forward curved blower for total static of 3.5" to 6" ........................................................................Models 03 - 18 for all cabinet styles

Internal spring isolation (discharge arrangement 2 and 3 only).......................................................All models except size 14 and VCS cabinets

Internal spring isolation (discharge arrangement 2, 3, 4, 5 only) ....................................................All VCS cabinets except size 14

Inlet vanes (does not include damper motor), forward curve (FC) ..................................................Models 20 - 41 for all cabinet styles

Inlet vanes (does not include damper motor), air foil (AF) fan .......................................................Models 20 - 75 for all cabinet styles

Dual drive (extended shaft blowers with motors and drives

installed on each side of fan, select 2 motors and 2 drives .........................................................Models 20 - 75 for all cabinet styles

Coil Section Accessory: Available on:

Large face area and small face area coils (see pages 42 & 43) ........................................................All HCS, HCL, HD, and VCS coil cabinets

Balancing dampers above small coil (to adjust air flow over coil in the field) ................................All HCS, HCL, HD, and VCS cabinets

Blank off plate above small sized coil (to force entire air flow over coil) .......................................All HCS, HCL, HD, and VCS cabinets

Stainless steel drain pan (in coil sections)....................................................................................... All HCS, HCL, HD, and VCS coil cabinets

Coil section access door (standard section has removable panels) ..................................................All HCL and VCS coil cabinets

Coil spacer, a preheat coil can be spaced apart from a cooling coil with a

coil spacer, the spacer prevents air bypass around the downstream

coil. The standard spacer is 6" wide and is furnished with a 4" x 6" .......................................All HCL and VCS coil cabinets

removable inspection plate. See below for reheat coil.

Mount reheat coil to leaving air side of section (see page 38).................. .......................................All HCL and VCS coil cabinets

Gaskets

Gaskets between sections......................................................................................... ........................All HCS, HCL, HD, and VCS cabinets

Gaskets between sections and gasketed panels (outdoor application)..........................Available on all five cabinets

Double Wall:

Double wall construction, adds 4" to the width and 2" to the height and length of

cabinet. Insulation is 2" of fiberglass at 1.5 lbs per cubic foot density. Available on all five

The insulation is sandwiched between the standard unit and the outer skin. fan and coil cabinets

Available on:

Available on:

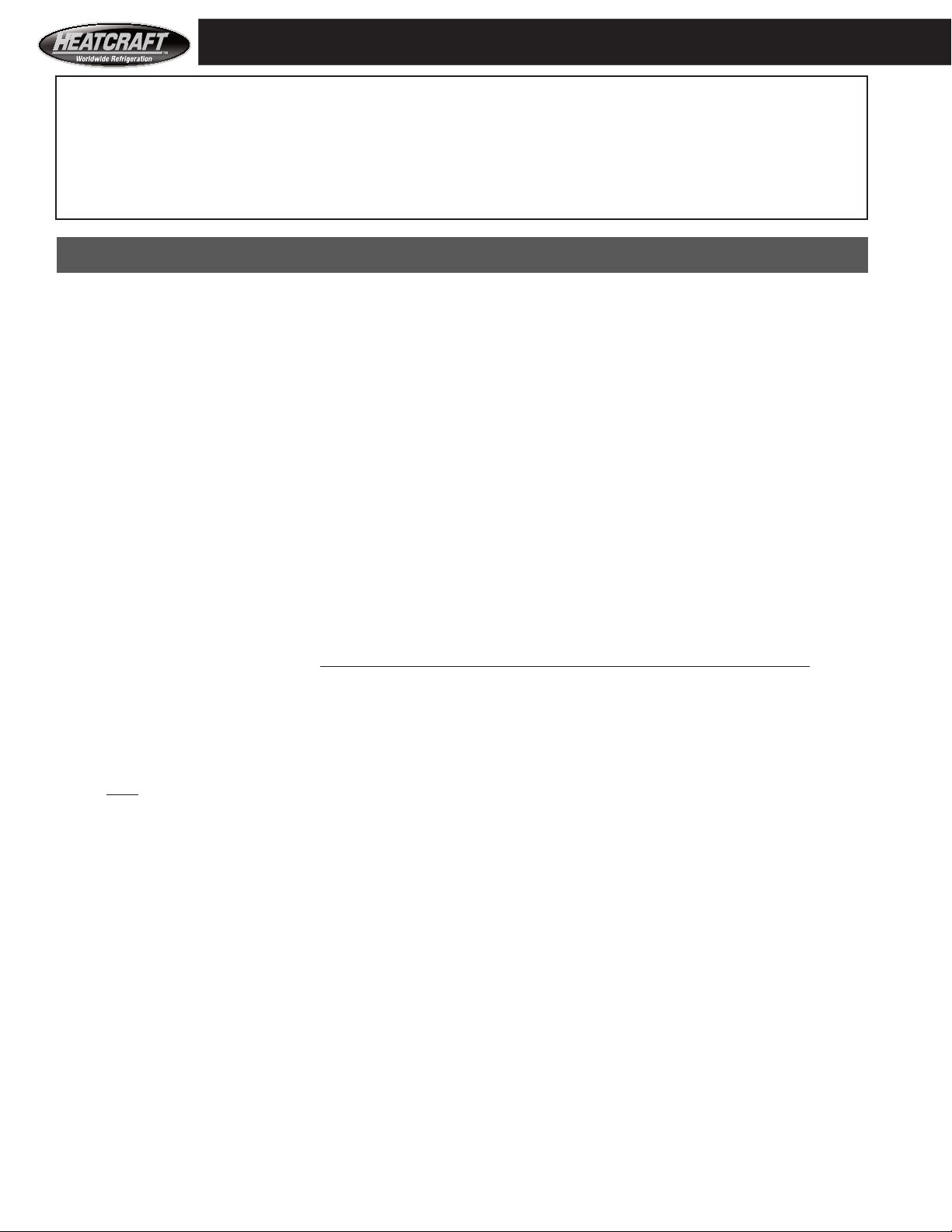

Available Motors, Drives, Motor Starters per Horsepower

Motors are three phase, ball bearing, rigid base and belt duty.

‘A’ = Available

Motor Drive* Starter Motor Horsepower

Description 1 1.5 2 3 5 7.5 10 15 20 25 30 40 50

Open single speed motor, EPAct A A A A A A A A A A A A A

Totally enclosed fan cooled (TEFC) motor, EPAct A A A A A A A A A A A A A

Open 2 speed 2 winding, 1800-1200 RPM motor A A A A A A A A A A

Open single speed premium high efficiency motor A A A A A A A A A A A A A

Fixed drive - at a 120% Safety Factor of HP A A A A A A A A A A A A A

Fixed drive - selected at a 150% SF of HP A A A A A A A A A A A A A

Adjustable drive - selected at a 120% SF of HP A A A A A A A A A A

Adjustable drive - selected at a 150% SF of HP A A A A A A A A A A

Motor starter at 460/3/60, 120 volt holding coil A A A A A A A A A A A A A

Motor starter at 230/3/60, 120 volt holding coil A A A A A A A A A A A

Motor starter at 200-208/3/60, 120 volt holding coil A A A A A A A A A A

* The percentage means the belts can handle an extra 20% or 50% BHP.

10

Air Handler Selection

1. Air handler selections vary with each application. Use the index below to find Heatcraft Products air handler

performance tables for:

• Standard comfort cooling (either direct expansion or chilled water)

• Heating (either steam or hot water, either make up air or return air)

• Supermarket air conditioning (direct expansion refrigerant)

• Heat reclaim (coil performance, refrigerant condenser, typically supermarket)

2. The air handler performance tables give ARI ratings for the specific applications, conditions and coils

listed. All performance tables (except reclaim) rate: 10 FPI coils at 500 FPM coil air velocity.

To select air handlers for other applications, conditions, or components:

• Call your representative. With your representative, you can have specific

computer selected coils rated for your job conditions.

• Use tables on pages 21 to 23 for estimates of coil performance at various

conditions.

3. See page 12, step 5 to calculate total static pressure. Consult fan tables, pages 24 to 29 and

select fan motor.

4. Heatcraft builds each air handler to your components specifications.

Please specify the following as needed with your order:

• CFM

• External or total static pressure

• Motor HP, motor type, motor voltage, motor location (left hand or right hand)

• Describe coils or specify with Heatcraft Products model numbers.

Coil description can include:

Rows, FPI, refrigerant, design capacity (BTUH),

Number of circuits, coil location inside air handler (preheat, reheat, etc.)

Location of coil connections (left hand or right hand)

• Filter sections and filter types

• Vibration isolators

5. Go to page 12 for air handler selection example.

Index To Air Handler Performance Tables - Typical Applications & Coil Selections

Application & Table Coil Type Selection Conditions

Heating and cooling Refrigerant Selected conditions for each coil type presented

Table 1 “Quick Reference”, page 13 Water & Steam in a single table. See Table 1 notes for conditions.

Cooling:

Standard comfort cooling DX Refrigerant 80°F. DB entering air 35°F., 40°F., and

Tables 2 & 3, page 14 4 & 6 Row Coils 67°F. WB entering air 45°F. evaporating temp

Supermarket air conditioning DX Refrigerant 75°F. DB entering air 35°F., 40°F., and

Tables 4 & 5, page 15 4 & 6 Row Coils 63°F. WB entering air 45 °F. evaporating temp

Standard comfort cooling Chilled Water 80°F. DB entering air 42°F. ,44°F., 45°F. entering

Tables 6 to 9, page 16 4 & 6 Rows 67°F. WB entering air water temperature

Heating:

Refrigerant Hot Gas Reclaim Refrigerant 2, 3, 50°F. Temperature Difference Between Condensing

Table 16 page 20 4, 6, 8 Row Coils Temperature and Coil Entering Air Temp.

Preheating, Tempering Hot Water 0 °F. entering air 180°F. entering water and

Tables 10 & 11, page 18 1 & 2 Rows 200°F. entering water

Preheating, Tempering Steam 0°F. entering air 5 PSIG steam*

Table 11, page 18 1 Row Only

Heating Return Air Hot Water 60°F. entering air 180°F. entering water

Tables 12 & 13, page 19 1 & 2 Rows 200°F. entering water

Heating Return Air Steam 60°F. entering air 5 PSIG steam*

Table 13, page 19 1 & 2 Rows

* Steam coils for model sizes 65 and 75 have a 1" tube diameter.

11

Selection Example

Air Handler Selection Conditions:

“I want a ceiling mounted air handler that gives 35 tons of cooling and 35 tons of heating. I have 44°F. water for

cooling and I have 200°F. water for heating. My entering air temperatures on the coil are standard, that is 80°F. dry bulb and 67°F. wet

bulb (50% relative humidity) for cooling. For heating, the entering air temperature is 60°F. I will supply duct work,

you should select the motor to handle a half inch of external static pressure. Select the smallest air handler possible and tell me what kind

of CFM, flow rates, fluid pressure drops, and sensible cooling performance your selection will give me. I want a filter too.”

Selection Procedure:

1. Which air handler for cooling performance?

Look at index of air handler performance

on page 11. Find that tables 6 through 9

give chilled water performance. You need 35 tons or 35 x 12 = 420 MBH

Compare 1/2" and 5/8" and 4 row and 6 row performance:

Select size 20 air handler with six row 1/2" tube coil with capacity of: 430 MBH

Note that 4 row 5/8" tube coil is not enough at: 374 MBH

2. Which air handler for heating performance?

Look at index of air handler performance on

page 11. Find that tables 12 & 13 are for hot

water performance with 60°F. air. You need 35 tons or 35 x 12 = 420 MBH

Compare 1/2" and 5/8" and 1 row and 2 row performance:

Select one row 5/8" tube coil for size 20 air handler with capacity of: 502 MBH

Note that 1 row 1/2" tube coil is much too small at capacity of 395 MBH

3. Comparing steps 1 & 2, select:

Size 20 air handler at 10025 CFM with

6 row, 1/2" tube chilled water coil with

1 row, 5/8" tube hot water coil.

4. Look at page 38, “Characteristics of standard coil sections “ and confirm that:

1 row depth coil casing: 3.25 inches

+ 6 row depth coil casing: +9.75 inches

Total 13.00 inches fits into HCS type cabinet

5. Look at page 40 & 41, “Air pressure drop tables” and calculate total pressure drop:

0.17 inch Pressure drop through 1 row coil, see dry 5/8" tube at: 10025 Divided By 19.25 = 521 FPM

0.79 inch Pressure drop through 6 row coil see wet 1/2" tube at: 500 FPM

0.22 inch Pressure drop for flat filter section, pleated 2" filter at: 10025 Divided By 24.4 = 411 FPM

+ 0.50 inch External static pressure

1.68 inch Total static pressure

6. Look at page 27, “Fan performance”:

Select a 5 HP motor for the condition of 10000 CFM and less than 1.75 inches of water.

7. Air handler description and performance:

Description: Performance:

HCS model size 20 10025 CFM at 1.68" total static and

with 6 row 10FPI, type A, cooling coil 0.5" external static pressure

with 1 row 10 FPI, type 5, heating coil 430 MBH total cooling capacity and

with open 5 HP motor at 230/3/60 volts 292 MBH sensible cooling capacity with

(See page 10) 80°F. DB/ 67°F. WB entering air

with 120% adjustable drive and 44 °F entering water at

with motor starter 85.8 GPM and 13.5 feet of

with flat filter section fluid pressure drop

with 35% efficient 2" filters 502 MBH of heating capacity with

with (6) rubber in shear vibration isolators 60°F. entering air and 200°F.

for ceiling mount (see page 38) entering water at 64.5 gpm

and 12.3 feet of fluid pressure drop

8. To estimate performance of coils at other than 10 FPI, or different row depths, or different air speeds or

temperature conditions see tables on page 20 - 23, or call your representative. With your representative,

you can have specific computer selected coils for your job conditions.

12

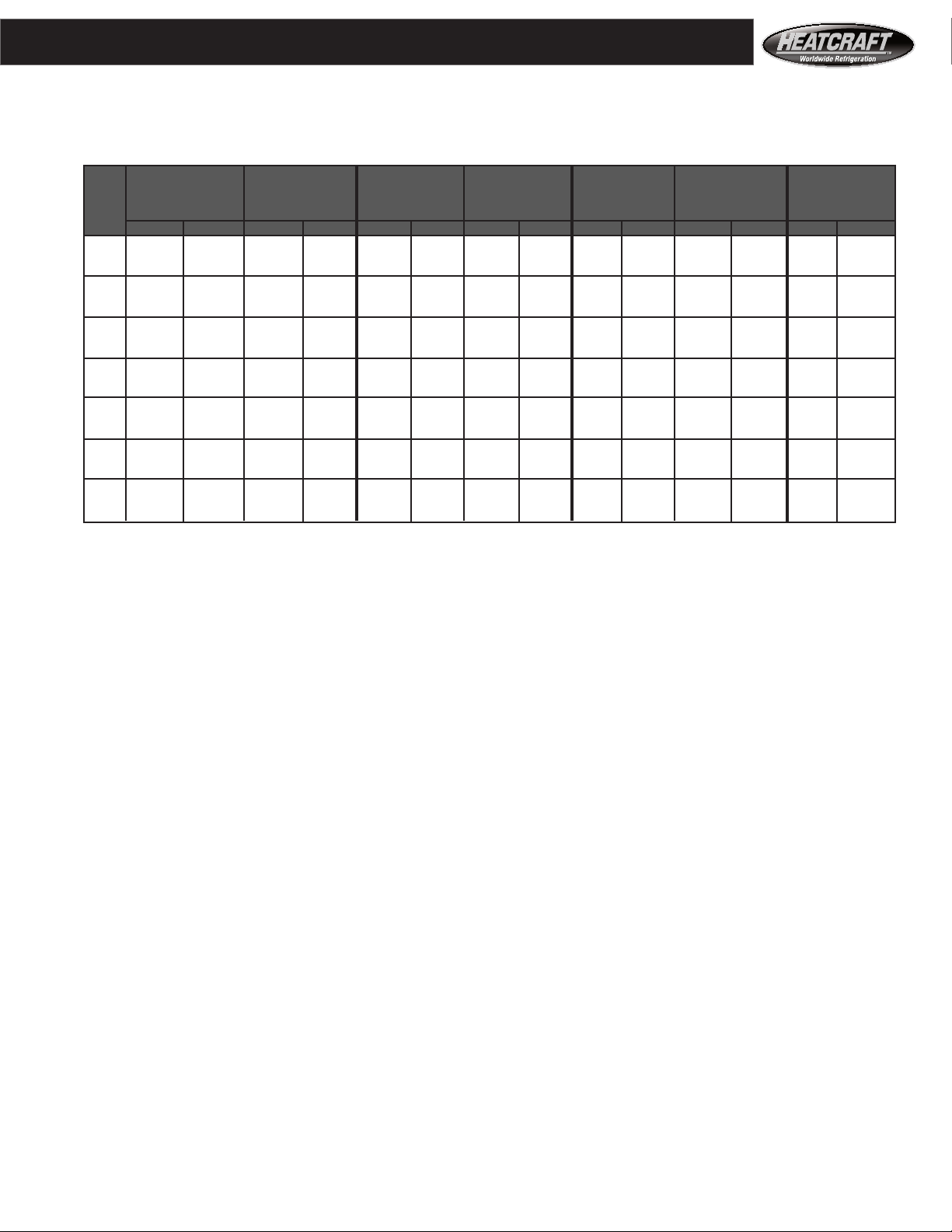

Air Handler Performance - Quick Reference

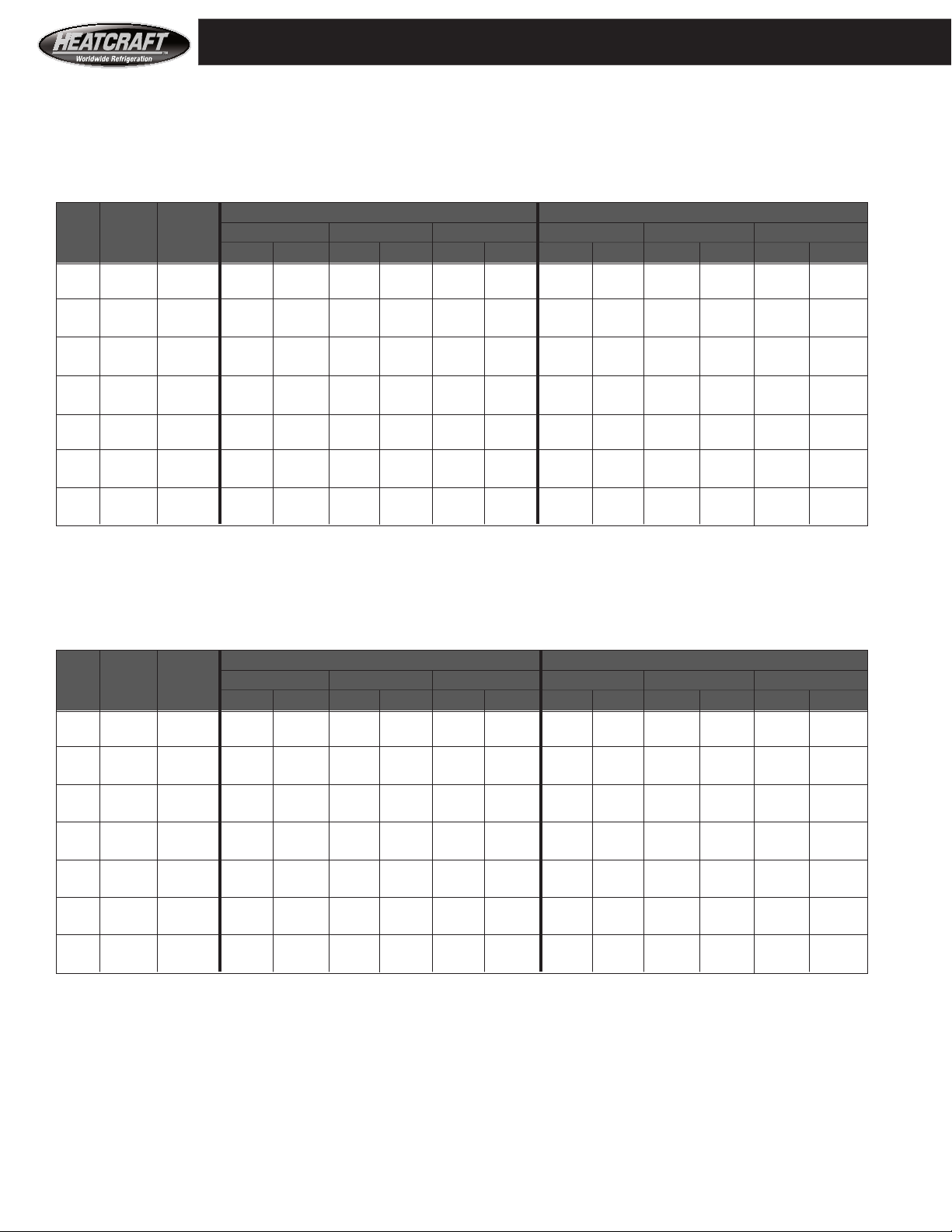

Table 1 Heating and Cooling Performance for Selected Coils

At 500 FPM (2.54 m/s) and 10 FPI.

See notes for coil descriptions and rating conditions.

Note 1 Note 2 Note 3 Note 4 Note 5 Note 6 Note 7

air volume at air handler DX air Refrigerant Chilled water Hot water Steam

Unit 500 fpm 2.54 m/s face area conditioning Heat reclaim A/C Heating Heating

Size CFM cu m/h SQ FT sq m MBH KW MBH KW MBH KW MBH KW MBH KW

03 1565 2659 3.13 0.29 58 17.0 50 14.7 73 21.4 177 51.9 93 27.3

06 2880 4893 5.76 0.54 110 32.2 92 27.0 136 39.9 341 99.9 179 52.4

08 3905 6635 7.81 0.73 150 44.0 124 36.3 179 52.5 452 132.4 254 74.4

10 4885 8300 9.77 0.91 190 55.7 156 45.7 229 67.1 548 160.6 317 92.9

12 6200 10534 12.40 1.15 241 70.6 198 58.0 286 83.8 684 200.4 395 115.7

14 7290 12386 14.58 1.36 284 83.2 232 68.0 328 96.1 812 237.9 465 136.2

18 8855 15045 17.71 1.65 345 101.1 282 82.6 418 122.5 1034 303.0 571 167.3

20 10025 17033 20.05 1.86 390 114.3 319 93.5 472 138.3 1162 340.5 651 190.7

26 13280 22563 26.56 2.47 520 152.4 423 124.0 616 180.5 1520 445.4 859 251.7

34 16825 28586 33.65 3.13 659 193.1 536 157.1 814 238.5 2026 593.6 1145 335.5

41 20365 34601 40.73 3.79 797 233.5 649 190.2 978 286.6 2406 705.0 1360 398.5

50 25313 43008 50.63 4.70 992 290.7 807 236.5 1196 350.4 2637 772.6 1586 464.7

65 32290 54861 64.58 6.00 1253 367.1 1029 301.5 1549 453.9 3798 1112.8 1848 541.5

75 37675 64011 75.35 7.00 1462 428.4 1200 351.7 1792 525.1 4407 1291.3 2156 631.7

Notes

Note 1 - Air volume in CFM and cubic meters per hour for air speed of 500 fpm or 2.54 meter per second

through a large face area 1/2" tube diameter (Type A) coil for each air handler model.

See pages 42 & 43 for range of air volumes for each model.

Note 2 - Face area of large size 1/2" diameter tube coil for each air handler in square feet and square meters.

5/8" & 1" diameter tube coils have slightly smaller face areas. See page 42 & 43 for other coils.

Note 3 - Direct expansion halocarbon air conditioning in thousands of BTUH and kilowatts. Performance is for a

1/2" tube, 4 row, 10 FPI coil with 40°F. (4.4ºC.) evaporating temperature and entering air

temperatures at 80°F. (26.7ºC.) dry bulb and 67°F. (19.4ºC.) wet bulb. See pages 14, 15, and 21 for

other coils and conditions.

Note 4 - Halocarbon refrigerant gas heat reclaim (thousands of BTUH and kilowatts). Performance is for a 1/2"

tube, 3 row, 10FPI coil with a 50°F. TD (or 27.7 degrees centigrade of temperature difference)

between entering air and condensing temperature. See page 20 for other coils and conditions.

Note 5 - Chilled water air conditioning in thousands of BTUH or kilowatts. Performance is for a 5/8" tube, 6

row, 10FPI coil with 44°F. (6.7ºC.) entering water temperature. Entering air temperatures are 80°F.

(26.7ºC.) dry bulb and 67°F. (19.4ºC.) wet bulb. The fluid pressure drop is less than 25 feet (0.76

kilogram per square centimeter) and the water velocity is less than 6 fps (1.83 meters per second).

See pages 16,17,and 22 for other coils and conditions.

Note 6 - Hot water heating performance in thousands of BTUH or kilowatts. Performance is for a 5/8" tube, 2

row, 10 FPI coil with 200°F. (93.3ºC.) entering water temperature. The entering air temperature is 0°F.

(-18°C.). The fluid pressure drop is less than 25 feet (0.76 kilogram per square centimeter) and the water

velocity is less than 6 fps (1.83 meters per second). See pages 18, 19, and 23 for more coils.

Note 7 - Steam heating performance in thousands of BTUH or kilowatts. The coils are 5/8" tube, 1 row, and 10

FPI (coils for models 65 and 75 are 1" diameter tubes). The entering air temperature is 60°F. (15.6ºC.)

and the steam pressure is 5 psig (1.38 kilogram per square centimeter). See pages 18, 19, and 23 for

other coils and conditions.

13

Air Handler Performance- Direct Expansion

Table 2

Comfort Cooling

1/2" tube, entering air at 80°F. DB and 67°F. WB**

1/2" Tube , direct expansion, cooling capacities

10 FPI**, large coils, 500 FPM**

CFM Coil MBH - 4 ROWS MBH - 6 ROWS

Unit Std Face 35°F. SST 40°F. SST 45°F. SST 35°F. SST 40°F. SST 45°F. SST

Size Air Area Total Sens. Total Sens. Total Sens. Total Sens. Total Sens. Total Sens.

03 1565 3.13 70 44 58 38 44 33 87 53 75 48 61 42

06 2880 5.76 132 81 110 72 90 64 163 99 138 88 114 78

08 3905 7.81 177 110 150 99 123 88 219 133 189 119 154 105

10 4885 9.77 224 139 190 125 152 109 278 168 235 150 192 131

12 6200 12.40 284 177 241 157 194 140 353 214 301 191 242 166

14 7290 14.58 336 207 284 187 231 165 416 253 354 225 290 197

18 8855 17.71 408 250 345 226 280 201 505^ 308 428 272 352 242

20 10025 20.05 459 282 390 256 319 226 568 343 489 308 399 273

26 13280 26.56 614 379 520 338 418 300 762^ 461 648^ 411 524 358

34 16825 33.65 778^ 480 659^ 428 530^ 380 966^ 584 821^ 520 664^ 454

41 20365 40.73 942^ 581 797^ 518 641^ 460 1168^^ 706 994^^ 630 804^ 549

50 25313 50.63 1169^ 721 992^ 648 803^ 577 1488* 875 1239* 788 1002* 686

65 32290 64.58 1447^ 905 1253^ 827 1035^ 742 1820* 1104 1574* 995 1293* 884

75 37675 75.35 1689* 1056 1462* 965 1208* 866 2124* 1288 1836* 1161 1509* 1032

Table 3

Comfort Cooling

5/8" tube, entering air at 80°F. DB and 67°F. WB**

5/8" Tube, direct expansion, cooling capacities

10 FPI**, large coils, 500 FPM**

CFM Coil MBH - 4 ROWS MBH - 6 ROWS

Unit Std Face 35°F. SST 40°F. SST 45°F. SST 35°F. SST 40°F. SST 45°F. SST

Size Air Area Total Sens. Total Sens. Total Sens. Total Sens. Total Sens. Total Sens.

03 1500 3.00 75 47 62 42 48 37 88 54 76 49 63 43

06 2844 5.69 138 88 111 77 84 67 173 105 147 94 118 81

08 3750 7.50 178 114 157 106 129 95 228 139 192 122 152 106

10 4690 9.38 234 148 192 130 157 116 283 173 244 156 198 136

12 5844 11.69 296 186 246 165 192 144 346 212 301 192 249 169

14 6875 13.75 349 220 295 196 235 172 412 253 345 221 290 199

18 8750 17.50 444 280 375 249 299 219 536 326 455 289 369 254

20 9625 19.25 467 297 408 273 335 245 591 360 500 317 412 279

26 12750 25.50 651 408 540 362 422 314 779^ 475 665 421 547 371

34 17000 34.00 868^ 544 720^ 482 563 418 1039^ 633 886^ 562 729^ 495

41 20188 40.38 1030^ 646 855^ 573 669 497 1234^ 752 1052^ 667 866^ 587

50 24750 49.50 1268^ 790 1059^ 709 830^ 610 1520* 923 1282^ 817 1062^ 722

65 32292 64.58 1651^ 1032 1401^ 933 1116^ 809 1989* 1212 1692* 1067 1369^ 937

75 37458 74.92 1915^ 1197 1625^ 1082 1295^ 939 2307* 1405 1962* 1238 1588^ 1087

SST = Saturated Suction Temperature All coils have single refrigerant distributors unless noted as below:

MBH = BTU per Hour in Thousands ^ These selections require two circuits.

Sens. = Sensible Capacity ^^ These selections require three circuits.

* These selections require four circuits.

** To estimate performance of coils at other than 10 FPI or at other air speeds or with other refrigerant or air

temperatures see page 21, or call your representative. With your representative, you can have specific computer

selected coils rated for your job conditions.

14

Loading...

Loading...