Page 1

INSTALLATION

INSTRUCTIONS

Air Handler

HDG Series

1.5 to 5 Ton

Heat Controller, Inc. • 1900 Wellworth Ave. • Jackson, MI 49203 • (517)787-2100 • www.heatcontroller.com

Page 2

HDG Series Air Handler INSTALLATION INSTRUCTIONS Heat Controller, Inc.

Table of Contents

1.0 NOMENCLATURE ...............................................................................................................2

2.0 SAFETY ................................................................................................................................3

3.0 GENERAL ............................................................................................................................6

3.1 UNIT DIMENSIONS ......................................................................................................7

4.0 APPLICATIONS ...................................................................................................................8

4.1 VERTICAL UPFLOW. ...................................................................................................8

4.2 VERTICAL DOWNFLOW.............................................................................................. 8

4.3 HORIZONTAL ...............................................................................................................9

4.4 INSTALLATION IN AN UNCONDITIONED SPACE .................................................... 11

5.0 ELECTRICAL WIRING ....................................................................................................... 11

5.1 POWER WIRING ........................................................................................................ 11

5.2 CONTROL WIRING ....................................................................................................12

5.3 GROUNDING ............................................................................................................. 12

5.4 ELECTRICAL DATA ....................................................................................................13

6.0 AIRFLOW PERFORMANCE .............................................................................................. 14

7.0 DUCTWORK ......................................................................................................................17

8.0 REFRIGERANT CONNECTIONS ......................................................................................18

8.1 CONDENSATE DRAIN TUBING ................................................................................18

8.2 FLOW RATER PISTON CHANGE ..............................................................................19

9.0 AIR FILTER (not factory-installed) ..................................................................................21

10.0 FILTER INSTALLATION DIMENSIONS ..........................................................................22

10.0 WIRE DIAGRAMS ............................................................................................................ 23

1

Page 3

Heat Controller, Inc. INSTALLATION INSTRUCTIONS HDG Series Air Handler

1.0 Nomenclature

H D G 18 F B - 1 A

A = Revision

Code

H = DX Air Handler

A = Hydronic Air Handler

F = Front Return

1 = 208/230V 1 Phase 60Hz

2 = 208/230V 3 Phase 60Hz

Design Series

R-410A Refrigerant

F = Flowrater (Piston)

T = TXV

V = TXV w/ ECM Drive

18 = 18,000 BTUH

24 = 24,000 BTUH

30 = 30,000 BTUH

36 = 36,000 BTUH

42 = 42,000 BTUH

48 = 48,000 BTUH

60 = 60,000 BTUH

NOTE: Not all model congurations are available. The nomenclature exists for future product line development. Consult

your local distributor or Heat Controller’s customer service department regarding available options.

Condenser/Heat Pump Matching Guide:

H = Heat Pump

C = Air Conditioner

B = Both A/C & H/P use

Warning

These instructions are intended as an aid to qualied licensed service personnel for proper

installation, adjustment and operation of this unit. Read these instructions thoroughly before

attempting installation or operation. Failure to follow these instruction may result in improper

installation,adjustment, service or maintenance possibly resulting in re, electrical shock,

property damage, personal injury or death.

2

Page 4

HDG Series Air Handler INSTALLATION INSTRUCTIONS Heat Controller, Inc.

This document is customer property and is to remain with this unit.

These instructions do not cover all the different variations systems nor does it provide for every possible contingency to be met in connection with installtion.

All phases of this installation must comply with NATIONAL STATE AND LOCAL CODES. If additional

information is required please contact your local distributor.

2.0 Safety

This is a safety alert symbol. When you see this symbol on labels or in manuals, be alert to the

potential for personal injury.

This is an attention alert symbol. When you see this symbol on labels or in manuals, be alert to the

potential for personal injury.

Warning

Disconnect all power to unit before installing or servicing. More than one disconnect switch may be

required to de-energize the equipment. Hazardous voltage can cause server personal injury or death.

Warning

If removal of the blower assembly is required, all disconnect switches supplying power to the

equipment must be de-energized and locked (if not in sight of unit ) so the eld power wires can

be safely removed from the blower assembly. Failure to do so can cause electrical shock resulting in personal injuring or death.

Warning

Because of possible damage to equipment or personal injury, installation, service, and maintenance

should be performed by a trained, qualied service personnel. Consumer service is recommended

only for lter cleaning / replacement. Never operate the unit with the acess panels removed.

Warning

These instructions are intended as an aid to qualied, licensed service personnel for proper

installation, adjustment and operation of this unit. Read these instructions thoroughly before

attempting installation or operation. failure to follow these instructions may result in improper installation, adjustment, service or maintenance possibly resulting in re, electrical shock, property

damage, personal injury or death.

3

Page 5

Heat Controller, Inc. INSTALLATION INSTRUCTIONS HDG Series Air Handler

Warning

The unit must be permanently grounded. Failure to do so can result in electrical shock causing

personal injury or death.

Warning

PROPOSITION 65: This appliance contains berglass insulation. Respirable particles of

berglass are known to State of California to cause cancer.

All manufacturer products meet current federal OSHA Guidelines for safety. California Proposition

65 warnings are required for certain products, which are not covered by the OSHA standards.

California’s Proposition 65 requires warnings for products sold in California that contain or

produce any of over 600 listed chemicals known to the State of California to cause cancer or birth

defects such as berglass insulation, lead in brass, and combustion products from natural gas.

All “new equipment” shipped for sale in California will only have labels stating that the product

contains and /or produces Proposition 65 chemicals. We cannot always know “when, or if”

products will be sold in the California market, thus all products may not be labeled when their

nal destination is unknown.

You may receive inquiries from customers about chemicals found in, or produced by, some

of our heating and air-conditioning equipment, or found in natural gas used with some of our

products. Listed below are those chemicals and substances commonly associated with similar

equipment in our industry and other manufacturers.

Glass Wool (Fiberglass) Insulation

Carbon Monoxide (CO).

Formaldehyde

Benzene

More details are available at the websites for OSHA (Occupational Safety and Health

Administration), at www.osha.gov and the State of California’s OEHHA (Ofce of Environmental

Health Hazard Assessment), at www.oehha.org. Consumer education is important since the

chemicals and substances on the list are found in our daily lives. Most consumers are aware

that products present safety and health risks, when improperly used, handled and maintained.

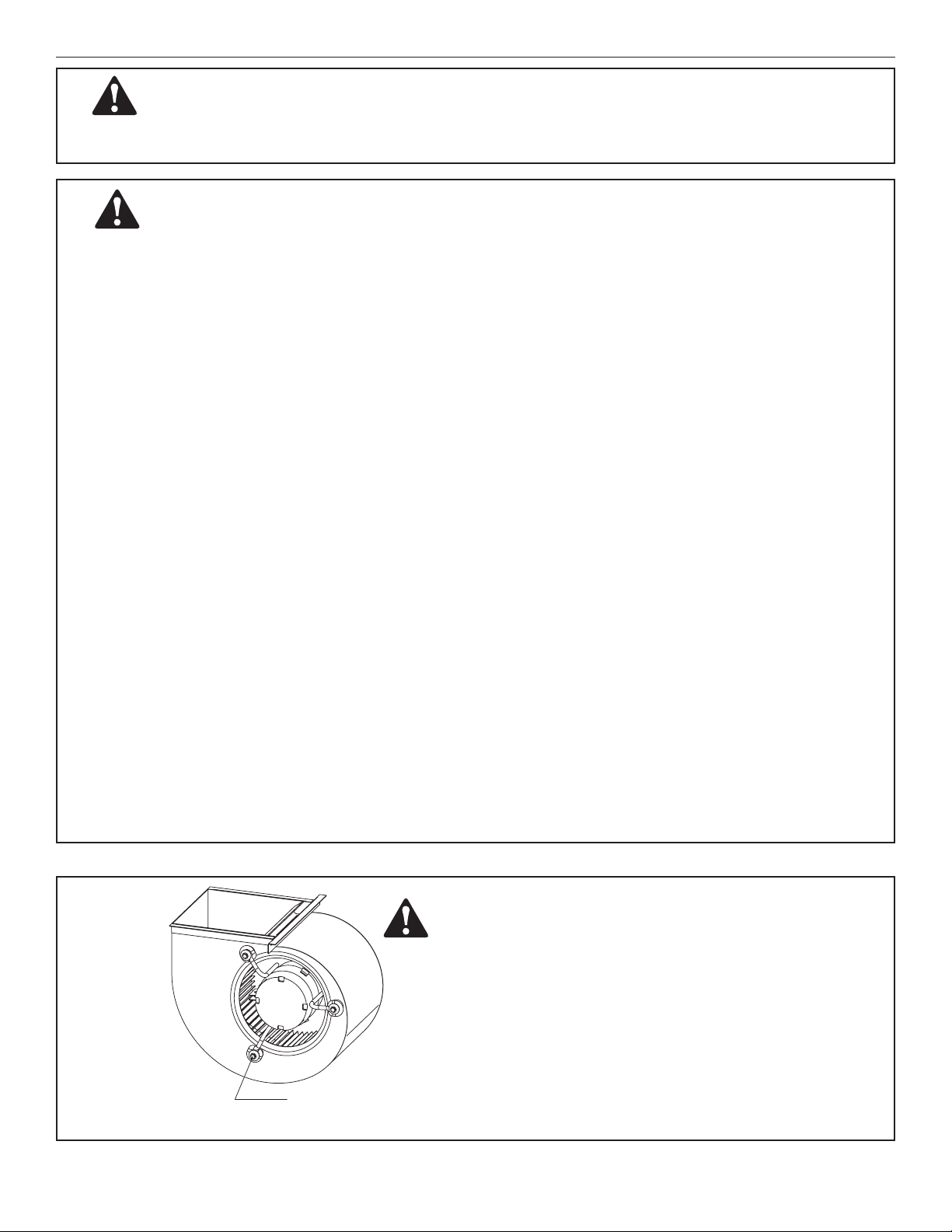

Warning

Make sure the blower motor support is tight (3-motor

mount bolts) then check to see if wheel is secured to

motor shaft before operating unit. To avoid electrical

shock, which can result in injury or death, use only the

screws furnished with the motor from the manufacturer.

BLOWER MOTOR BOLT

4

Page 6

HDG Series Air Handler INSTALLATION INSTRUCTIONS Heat Controller, Inc.

Warning

Do not install this unit in manufactured (mobile) homes. Improper installation is more likely in

manufactured housing due to ductwork material, size, location and arrangement. Installations in

manufactured housing can cause re resulting in property damage, personal injury or death.

EXCEPTION: Manufactured housing installations are approved only with documentation by a

recognized inspection authority that veries that the installation has been made in compliance

with the instructions and all warnings have been observed.

Warning

Duct leaks can create an unbalanced system and draw pollutants such as direct, dust, fumes

and odors into the home causing property damage. Fumes and odors from toxic, volatile or

ammable chemicals, as well as automobile exhaust and carbon monoxide (CO), can be drawn

into the living space through leaking ducts and unbalanced duct systems causing personal injury

or death (see Figure 1).

• If air-moving equipment or ductwork is located in garages or off-garage storage areas, all joints,

seams, and openings in the equipment and duct must be sealed to limit the migration of toxic

fumes and odors including carbon monoxide from migrating into the living space.

• If air-moving equipment or ductwork is located in spaces containing fuel burning appliances

such as water heaters or boilers, all joints, seams and openings in the equipment and duct

must be sealed to prevent depressurization of the space and possible migration of combustion

byproducts including carbon monoxide into the living space.

Notice

When used in cooling applications, excessive sweating may occur when unit is installed in an

unconditioned space. This can result in property damage.

Notice

In compliance with recognized codes, it is recommended that an auxiliary drain pan be installed

under all evaporator coils or units containing evaporator coils that are located in any area of a

structure where damage to the building or building contents may occur as a result of an overow

of the coil drain pan or a stoppage in the primary condensate drain piping.

Warning

The rst 36 inches of supply air plenum and ductwork must be constructed of sheet metal as

required by NFPA 90B. The supply air plenum or duct must have a solid sheet metal bottom

directly under the unit with no openings, registers or exible air ducts located in it. If exible supply

air ducts are used they may be located only in the vertical walls of rectangular plenum, a minimum

of 6 inches from the solid bottom. Metal plenum of duct may be connected to the combustible oor

base, if not, it must be connected to the unit supply duct exposed to the supply air opening from the

downow unit. Exposing combustible (non-metal) material to the supply opening of a downow unit

can cause a re resulting in property damage, personal injury or death.

Exception warning to downow:

Installations on concrete oor slab with supply air plenum and ductwork completely encased

must be not less than 2 inches of concrete (See NFPA 90A).

5

Page 7

Heat Controller, Inc. INSTALLATION INSTRUCTIONS HDG Series Air Handler

3.0 General

The unit can be positioned for bottom return air in the upow position, left and right return in the horizontal position, top return in downow position.

This Air Handler provides the exibility for installation in any upow or downow horizontal application.

The direct drive motors provides a selection of air volume to match any application. 3-Speed motors

provide selections of air ow to meet desired applications.

Top and side power and control wiring, accessible screw terminals for control wiring all combine to

make the installation easy, and minimize installation cost. Please contact your local distributor.

See Fig. 1 on Pg. 7

6

Page 8

HDG Series Air Handler INSTALLATION INSTRUCTIONS Heat Controller, Inc.

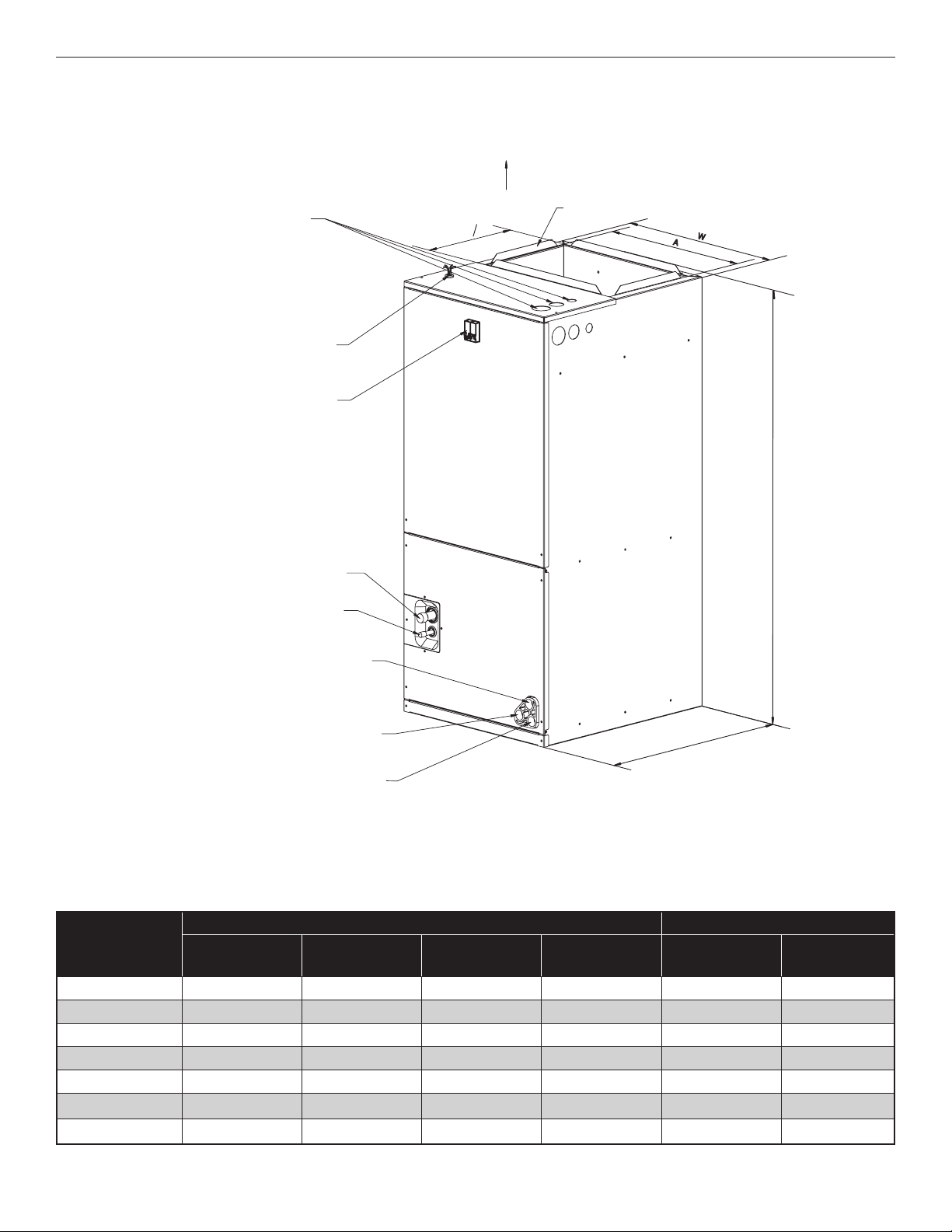

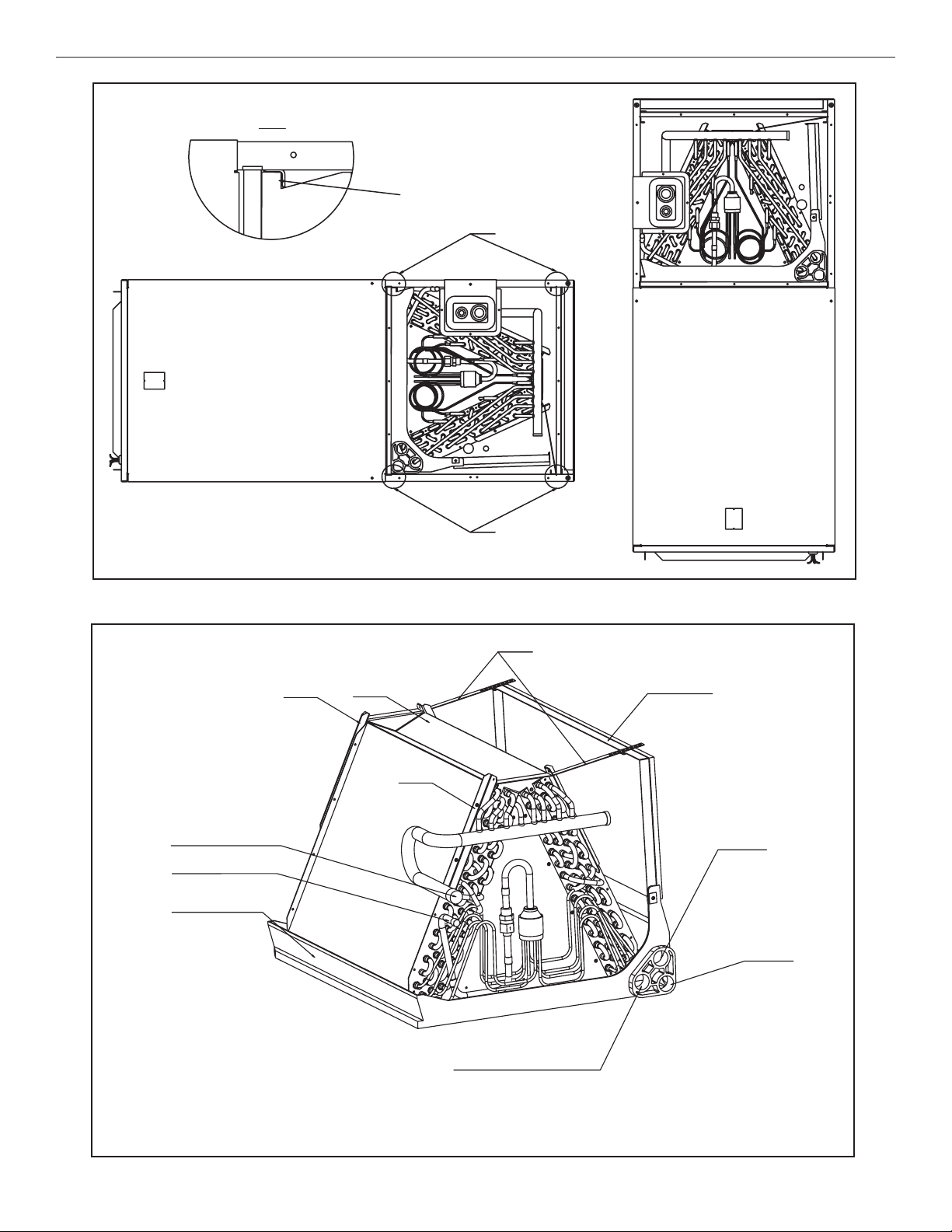

3.1 Unit Dimensions

ELECTRICAL CONNECTIOS

MAY EXIT TOP OR EITHER SIDE

HIGH VOLTAGE CONNECTION 7/8”,

HIGH VOLTAGE CONNECTION 7/8”,

1-3/8”, 1-3/4” DIAMETER KNOCK OUTS

1-23/64”, 1-23/32” DIA KNOCK OUTS

LOW VOLTAGE CONNECTION

BREAKER SWITCH

(FOR ELECTRIC HEATER ONLY)

NOTE: 24” CLEARANCE IS REQUIRED IN THE FRONT

OF THE UNIT FOR FILTER AND COIL MAINTENANCE.

SUPPLY AIR

FLANGES ARE PROVIDED

FOR FIELD INSTALLATION

5

6

1

0

1

W

A

H

VAPOR LINE CONNECTION COPPER (SWEAT)

LIQUID LINE CONNECTION COPPER (SWEAT)

AUXILIARY DRAIN CONNCECTION 3/4”

FEMALE PIPE THREAD (NPT)

AUXILIARY DRAIN CONNECTION 3/4”

FEMALE PIPE THREAD (NPT)

PRIMARY DRAIN CONNCETION 3/4”

FEMALE PIPE THREAD (NPT)

Fig. 1 Dimensions

UPFLOW UNIT SHOWN;

UNIT MAY BE INSTALLED UPFLOW, DOWNFLOW,

HORIZONTAL RIGHT, OR LEFT AIR SUPPLY.

D

Dimensional Data

Dimensions Unit Weight lbs. [kg]

Unit Height

Model Size

in. [mm]

HDG18 41 3/8" [1050] 18 1/8" [460] 20 1/2" [520] 16" [406] 106 [48] 119 [54]

HDG 24 41 3/8" [1050] 18 1/8" [460] 20 1/2" [520] 16" [406] 106 [48] 119 [54]

HDG 30 41 3/8" [1050] 18 1/8" [460] 20 1/2" [520] 16" [406] 119 [54] 132 [60]

HDG36 46 1/2" [1180] 19 5/8" [500] 20 5/8" [550] 18" [456] 141 [64] 156 [71]

HDG42 46 1/2" [1180] 19 5/8" [500] 20 5/8" [550] 18" [456] 141 [64] 156 [71]

HDG48

HDG60

54 1/2” [1385] 22” [560] 24" [610] 19

54 1/2” [1385] 22” [560] 24" [610] 19

Unit Weight

in. [mm]

Unit Lenght

in. [mm]

Supply Duct

“A” in [mm] Net Shipping

1

/2” [496] 171 [78] 187 [85]

1

/2” [496] 171 [78] 187 [85]

7

Page 9

Heat Controller, Inc. INSTALLATION INSTRUCTIONS HDG Series Air Handler

4.0 Applications

4.1 Vertical Upow

• Vertical Upow conguration is the factory set on all models (see Fig 1).

• If a side return air opening is required, eld fabricate a return air plenum with an opening large enough

to supply unit and strong enough to support unit weight.

• If return air is to be ducted, install duct ush with oor. Use reproof resilient gasket 1/8 to 1/4 in. thick

between the ducts, unit and oor. Set unit on oor over opening.

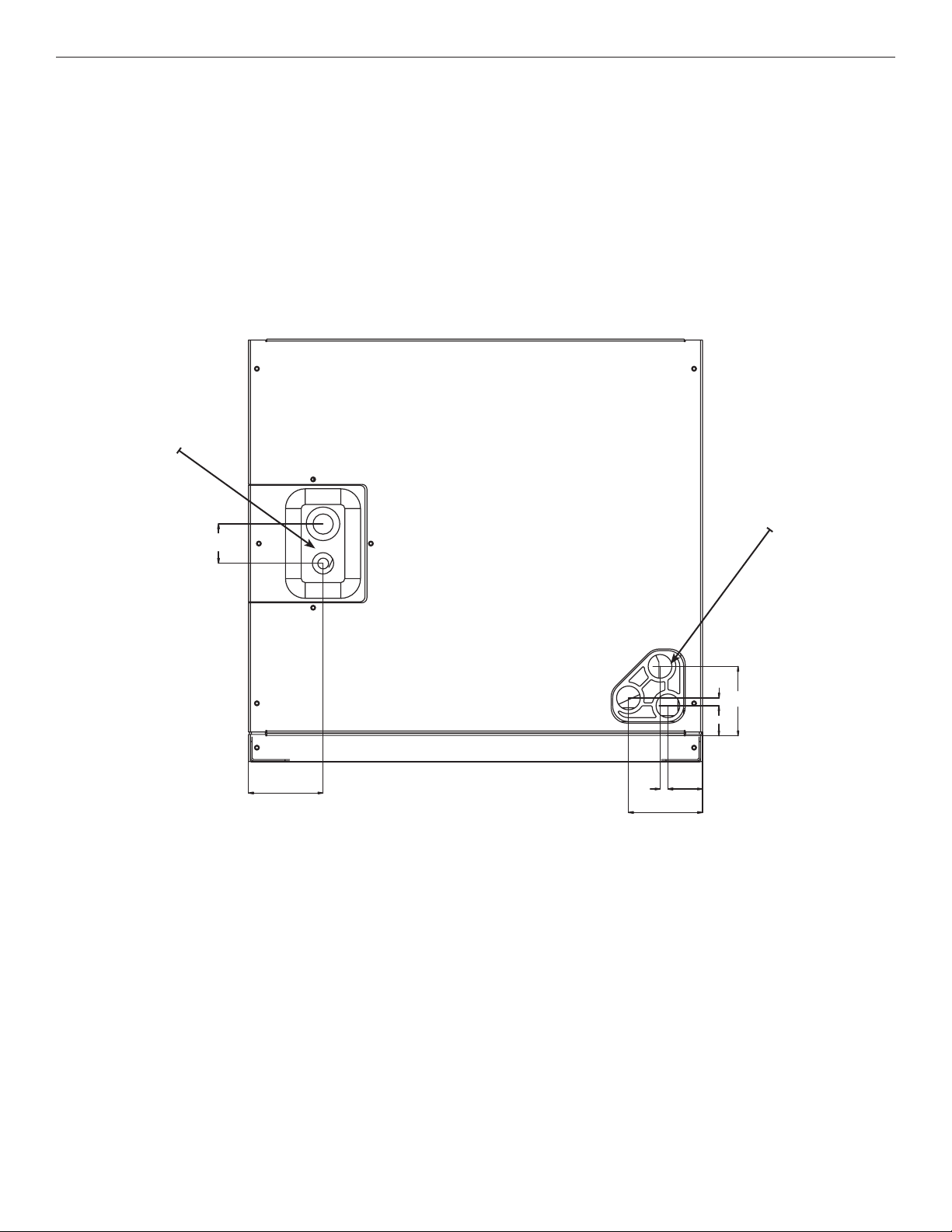

IMPORTANT NOTE

Torque applied to drain connections should not exceed 15.ft.lbs.(see Fig.1&2)

Refrigerant Line

Connections

Drain

Connections

1-9/16

5/16

2-13/16

1-1/4

5/16

2-15/16

Fig.2 Coil Connection Dimensions

Fig. 2 Coil Connection Dimensions

1-3/8

2-15/16

4.2 Vertical Downow

Conversion to Vertical Downow: A vertical upow unit may be converted to vertical downow.

Remove the door and indoor coil and reinstall 180° from original position. See Fig. 2~3.

IMPORTANT: To comply with certication agencies and the National Electric Code for horizontal

right application, the circuit breaker(s) on eld-installed electric heater kits must be re-installed per

procedure below so that the breaker switch “on” position and marking is up and, “off” position and

marking is down.

• To rotate breaker(s): Rotate one breaker set (circuit) at a time starting with the one on the

right. Loosen both lugs on the load side of the breaker. (Make sure that wires are identied

and are reinstalled into proper breaker).Wires are bundles with wire ties, one bundle going to

the right lug and one bundle going to the left lug.

8

Page 10

HDG Series Air Handler INSTALLATION INSTRUCTIONS Heat Controller, Inc.

• Using a screwdriver or pencil, lift blue plastic tab with hole away from breaker until breaker releases from mounting opening.

• With breaker held in hand, rotate breaker so that “on” position is up, “off” position is down with unit

in planned vertical mounting position. insert right wire bundle into top right breaker lug, ensuring all

strands of all wires are inserted fully into lug, and no wire insulation is in lug.

• Tighten lug as tight as possible while holding circuit breaker. Check wires and make sure each wire

is secure and none are loose. Repeat for left wire bundle in left top circuit breaker lug.

• Replace breaker by inserting breaker mounting tab opposite white pull tab in opening, hook mounting tab over edge in opening.

• With screwdriver or pencil, pull blue tab with hole away from breaker while setting that side of

breaker into opening. When breaker is in place, release tab, locking circuit breaker into location in

opening.

• Repeat above operation for remaining breaker(s) (if more than one is provided).

• Replace single point wiring jumper bar, if it is used, on line side of breaker and tighten securely.

• Double check wires and lugs to make sure all are secure and tight. Check to make sure unit wiring

to circuit breaker load lugs match that shown on the unit wiring diagram.

Caution

When using the unit with electrical heater, the switch is used only for electrical heater

on the front of panel.

4.3 HORIZONTAL

Horizontal right is the default factory conguration for the units.

Horizontal left isn’t the default factory conguration for the units.

Conversion to Horizontal: A vertical upow unit may be converted to horizontal right by removing indoor

coil assembly and reinstalling coil as shown for right hand air supply. And reinstall coil in unit as shown

for right hand air supply.

• Reinstall the indoor coil 180° from original position. Ensure the retaining channel is fully engaged

with the coil rail. See Fig. 3.

• Rotate unit into the downow position, with the coil compartment on top and the blower compartment on bottom. See Fig. 3.

• Secondary drain pan kits are required when the unit is congured for the horizontal right position

over a nished ceiling and/or living space.

9

Page 11

Heat Controller, Inc. INSTALLATION INSTRUCTIONS HDG Series Air Handler

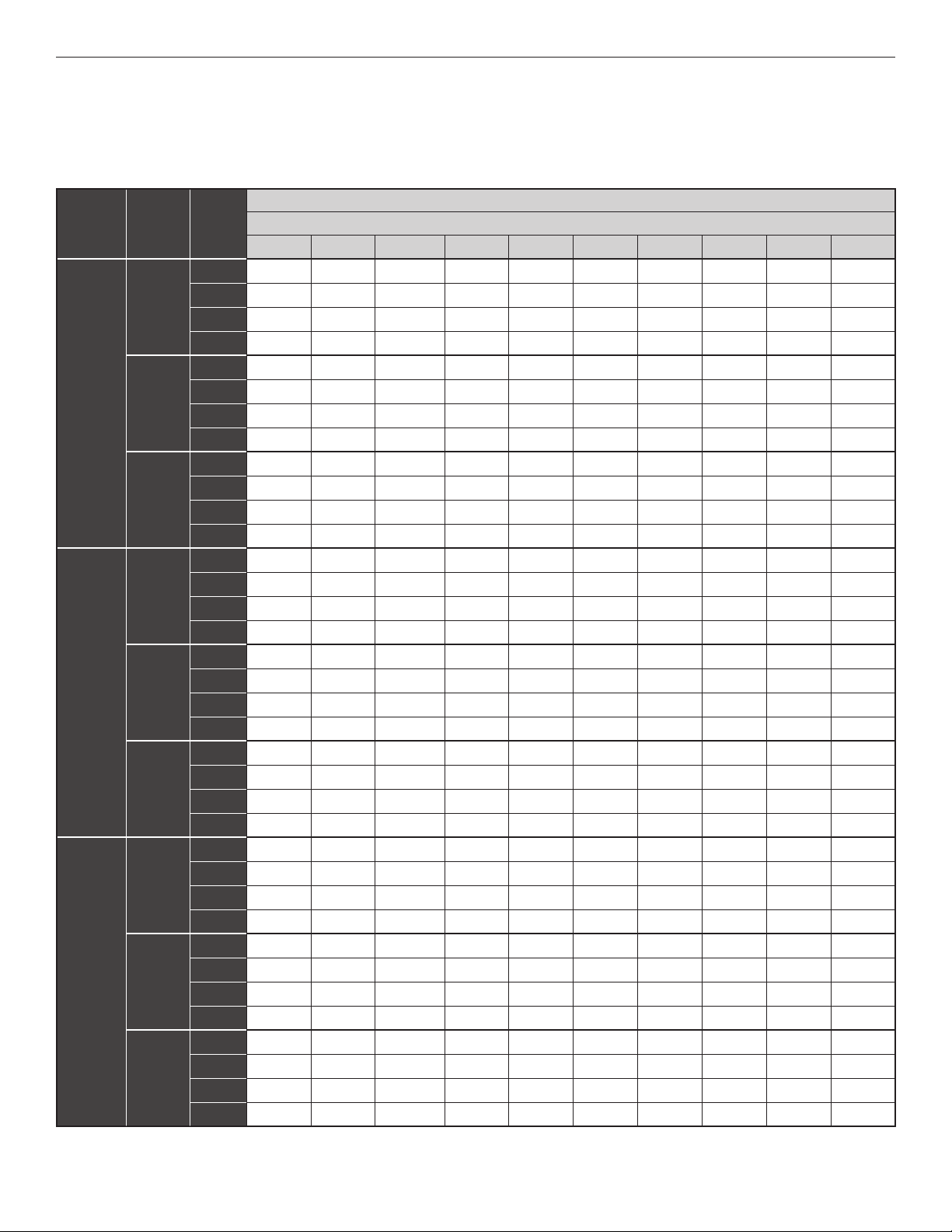

A

1:4

ENSURE THE RETAINING

CHANNEL IS FULLY ENGAGED

WITH THE COIL RAIL.

DETAIL A

RAILS

A

RAILS

Fig.3 VERTICAL DOWNFLOW & HORIZONTAL LEFT APPLICATIONS

(lower front service panel removed “view”.)

STRAPS

REAR WATER CATCHER

VAPOR LINE CONNECTION

LIQUID LINE CONNECTION

VERTICAL DRAIN PAN

TOP AIR STOP

FRONT WATER

CATCHER

HORIZONTAL ADAPTER KIT

AUXILIARY HORIZONTAL

DRAIN CONNECTION

PRIMARY DRAIN

CONNECTION

AUXILIARY UPFLOW/DOWNFLOW

DRAIN CONNECTION

The Max. resistant pressure of evaporator is up to 16MPa (2320PSI)

Fig.4 INDOOR COIL AND DRAIN PAN SET-UP

10

Page 12

HDG Series Air Handler INSTALLATION INSTRUCTIONS Heat Controller, Inc.

Caution

Horizontal units must be congured for right hand air supply or left hand air supply. Horizontal

drain pan must be located under indoor coil. Failure to use the drain pan can result in property

damage.

Conversion in Horizontal Direction: Horizontal left-hand supply can be changed to horizontal

right-hand supply by removing the indoor coil and reinstalling 180° from original.

4.4 INSTALLATION IN AN UNCONDITIONED SPACE

IMPORTANT: There are two pairs of coil rails in the air handler for default and counter ow

application. If the air handler is installed in an unconditioned space, the two unused coil rails

should be removed to minimize air handler surface sweating. The coil rails can be easily removed by taking off the 6 mounting screws from both sides of the cabinet.

5.0 ELECTRICAL WIRING

Field wiring must comply with the National Electric Code (C.E.C. in Canada) and any applicable

local ordinance.

Disconnect all power to unit before installing or servicing. More than one disconnect switch may

be required to de-energize the equipment. Hazardous voltage can cause severe personal injury

or death.

5.1 POWER WIRING

It is important that proper electrical power is available for connection to the unit model

being installed. See the unit nameplate, wiring diagram and electrical data in the installation

instructions.

• If required, install a branch circuit disconnect of adequate size, located within sight of,

and readily accessible to the unit.

• IMPORTANT: After the Electric Heater is installed, units may be equipped with one, two,

or three 30/60 amp. circuit breakers. These breaker(s) protect the internal wiring in the

event of a short circuit and serve as a disconnect. Circuit breakers installed within the

unit do not provide over-current protection of the supply wiring and therefore may be

sized larger than the branch circuit protection.

• Supply circuit power wiring must be 167°F [75°C] minimum copper conductors only. See

Electrical Data In this section for ampacity, wire size and circuit protector requirement.

Supply circuit protective devices may be either fuses or “HACR” type circuit breakers.

• Power wiring may be connected to either the right, left side or top. Three 7/8”, 1-3/8”,

1-3/4” diameter concentric knockouts are provided for connection of power wiring to unit.

• Power wiring is connected to the power terminal block in unit electric cabinet.

11

Page 13

Heat Controller, Inc. INSTALLATION INSTRUCTIONS HDG Series Air Handler

5.2 CONTROL WIRING

IMPORTANT: Class 2 low voltage control wiring should not be run in conduit with main power

wiring and must be separated from power wiring, unless class 1 wire of proper voltage rating is

used.

• Low voltage control wiring should be 18 Awg. color-coded. For lengths longer than 100 ft.,

16 Awg. wire should be used.

• Low voltage control connections are made to low voltage pigtails extending from top of air

handler (upow position - see Figure 3). Connections for control wiring are made with wire

nuts. Control wiring knockouts (518 and 7/8) are also provided on the right and left side of

the unit for side connection.

• See wiring diagrams attached to indoor and outdoor sections to be connected.

• Make sure, after installation, separation of control wiring and power wiring has been

maintained.

5.3 GROUNDING

Caution

The unit must be permanently grounded. FaIlure to do so can result In electrical shock

causing personal injury or death.

• This product must be sufciently ground in accordance with National Electric Code (C.E.C.

in Canada) and any applicable local ordinace.

• Grounding may be accomplished by grounding metal conduit when installed in accord

ance with electrical codes to the unit cabinet.

• Grounding may also be accomplished by attaching ground wire(s) to ground lug(s)

provided in the unit wiring compartment.

• Ground lug(s) are located close to wire entrance on left side of unit (up-ow). Lug(s) may

be moved to marked locations near wire entrance on right side of unit (upow). If alternate

location is more convenient.

• Use of multiple supply circuits require grounding of each circuit to lug(s) provided in unit.

12

Page 14

HDG Series Air Handler INSTALLATION INSTRUCTIONS Heat Controller, Inc.

5.4 Electrical Data– BLOWER ONLY, NO ELECTRIC HEAT

Model Voltage HP RPM SPEEDS

CIRCUIT

AMPS.

MINIMUM

CIRCUIT

AMPACITY

MAXIMUM

CIRCUIT

PROTECTOR

HDG18 208/230-1-60 1/8 580 3 0.68 1 15(A)

HDG24 208/230-1-60 1/5 701 3 0.95 1.5 15(A)

HDG30 208/230-1-60 1/4 872 3 1.48 2 15(A)

HDG36 208/230-1-60 1/2 794 3 1.63 3 15(A)

HDG42 208/230-1-60 1/2 882 3 1.80 3 15(A)

HDG48 208/230-1-60 1/2 845 3 2.11 3 15(A)

HDG60 208/230-1-60 3/4 963 3 2.79 3 15(A)

5.5 Electrical Data– ELECTRIC HEAT

Air

Handler

Model

HDG18

HDG24

HDG30

HDG36

HDG42

HDG48

HDG60

Minimum

Heater

Heater

Model No.

7800-505-1D 3.8 5

7800-508-1D 5.6 7.5 27.1 31.3 0.68 34.8 40 35 45

7800-510-1D 7.5 10 36.1 41.7 0.68 46 53 50 60

7800-505-1D 3.8 5

7800-508-1D 5.6 7.5 27.1 31.3 0.95 35.1 40.3 40 45

7800-510-1D 7.5 10 36.1 41.7 0.95 46.4 53.3 50 60

7800-505-1D 3.8 5

7800-508-1D 5.6 7.5 27.1 31.3 1.48 35.8 41 40 45

7800-510-1D 7.5 10 36.1 41.7 1.48 47 54 50 60

7800-505-1D 3.8 5

7800-508-1D 5.6 7.5 27.1 31.3 1.63 35.9 41.1 40 45

7800-510-1D 7.5 10 36.1 41.7 1.63 47.2 54.2 50 55

7800-515-1D 11 15 54.2 62.5 1.63 69.8 80.2 70 90

7800-520-1D 15 20 72.2 83.3 1.63 92.4 106.3 100 125

7800-505-1D 3.8 5

7800-508-1D 5.6 7.5 27.1 31.3 1.80 36.2 41.4 40 45

7800-510-1D 7.5 10 36.1 41.7 1.80 47.4 54.4 50 60

7800-515-1D 11 15 54.2 62.5 1.80 70 80.4 80 90

7800-520-1D 15 20 72.2 83.3 1.80 92.6 106.5 100 125

7800-505-1D 3.8 5

7800-508-1D 5.6 7.5 27.1 31.3 2.11 36.5 41.7 40 45

7800-510-1D 7.5 10 36.1 41.7 2.11 47.8 54.8 50 60

7800-515-1D 11 15 54.2 62.5 2.11 70.4 80.8 80 90

7800-520-1D 15 20 72.2 83.3 2.11 93 106.9 100 125

7800-505-1D 3.8 5

7800-508-1D 5.6 7.5 27.1 31.3 2.79 37.4 42.6 40 45

7800-510-1D 7.5 10 36.1 41.7 2.79 48.7 55.6 50 60

7800-515-1D 11 15 54.2 62.5 2.79 71.2 81.7 80 90

7800-520-1D 15 20 72.2 83.3 2.79 93.8 107.7 100 125

(208V)

Heater

kW

(240V) PH/Hz

kW

1Ph/60Hz

1Ph/60Hz

1Ph/60Hz

1Ph/60Hz

1Ph/60Hz

1Ph/60Hz

1Ph/60Hz

Circuit

Amps

(208V)

18.1 20.8 0.68 23.5 26.9 25 30

18.1 20.8 0.95 23.8 27.3 25 30

18.1 20.8 1.48 24.5 27.9 25 30

18.1 20.8 1.63 24.7 28.1 25 30

18.1 20.8 1.80 24.9 28.3 25 30

18.1 20.8 2.11 25.3 28.7 30 30

18.1 20.8 2.79 26.1 29.6 30 30

Circuit

Amps

(240V)

Motor

Ampacity

Circuit

Ampacity

(208V)

Minimum

Circuit

Ampacity

(240V)

Maximum

Circuit

Protection

(208V)

Maximum

Circuit

Protection

(240V)

13

Page 15

Heat Controller, Inc. INSTALLATION INSTRUCTIONS HDG Series Air Handler

6.0 Airow Performance

Airow performance data is based on cooling performance with a coil and no lter in place. Select performance table for appropriate unit size. Make sure external static applied to unit allows operation within the

minimum and maximum limits shown in table below for both cooling and electric heat operation.

Airow Performance Data

CFM (Watts)

Model

Number

HDG18

HDG24

HDG30

Motor

Speed

Low

Middle

High

Low

Middle

High

Low

Middle

High

CFM 551 509 - 462 393 345 280 ---

RPM 440 518 - 595 679 726 781 ----

Watts 122.4 120 - 116.8 116.3 109.9 106.2 ---

Amps 0.62 0.62 - 0.62 0.61 0.61 0.60 ---

CFM 661 622 - 577 506 443 400 ---

RPM 518 580 - 640 731 770 812 ---

Watts 145.2 143 - 140.8 136.3 133.6 131.2 ---

Amps 0.69 0.68 - 0.68 0.67 0.67 0.66 ---

CFM -- -- -- 590 550 487 400

RPM -- -- -- 894 911 940 975

Watts -- -- -- 232 229.5 224.4 217.4

Amps -- -- -- 1.16 1.15 1.14 1.12

CFM 646 623 - 592 553 506 453 ---

RPM 528 591 - 650 728 790 840 ---

Watts 169.4 166.4 - 163 157.5 151.3 146.3 ---

Amps 0.79 0.78 - 0.78 0.77 0.76 0.75 ---

CFM 815 802 - 771 733 681 613 ---

RPM 658 701 - 743 790 841 888 ---

Watts 218 216.6 - 214.4 211.4 207.4 203 ---

Amps 0.96 0.95 - 0.95 0.94 0.93 0.92 ---

CFM -- -- -- 780 695 607 515

RPM -- -- -- 919 956 986 1014

Watts -- -- -- 262.6 256.4 250.1 243

Amps -- -- -- 1.21 .181 .171 .15

CFM 962 913 886 870 813 750 690 - - -

RPM 729 754 798 809 858 873 902 - - -

Watts 315 304 298 292 280 269 258 - - -

Amps 1.39 1.35 1.32 1.30 1.26 1.22 1.19 - - -

CFM 1094 1043 1012 988 927 861 788 - - -

RPM 809 845 859 885 911 932 954 - - -

Watts 334 325 319 315 303 290 279 - - -

Amps 1.46 1.43 1.40 1.38 1.35 1.30 1.26 - - -

CFM 1374 1311 1268 1240 1164 1084 996 910 828 744

RPM 910 937 947 954 972 989 1004 1018 1033 1043

Watts 440 427 419 413 398 381 366 352 340 331

Amps 1.94 1.90 1.86 1.84 1.79 1.74 1.68 1.63 1.60 1.56

continued on next page

0 [0] 0.1 [.02] 0.16 [.04] 0.2 [.05] 0.3 [.07] 0.4 [.10] 0.5 [.12] 0.6 [.15] 0.7 [.17] 0.8 [.20]

External Static Pressure-Inches W.C. [kPa]

14

Page 16

HDG Series Air Handler INSTALLATION INSTRUCTIONS Heat Controller, Inc.

CFM (Watts)

Model

Number

HDG36

HDG42

HDG48

HDG60

Motor

Speed

Low

Middle

High

Low

Middle

High

Low

Middle

High

Low

Middle

High

0 [0] 0.1 [.02] 0.16 [.04] 0.2 [.05] 0.3 [.07] 0.4 [.10] 0.5 [.12] 0.6 [.15] 0.7 [.17] 0.8 [.20]

CFM 1129 1088 1061 1040 988 941 819 - - -

RPM 642 675 706 732 771 817 853 - - -

Watts 322 312 306 301 289 269 254 - - -

Amps 1.54 1.52 1.51 1.50 1.47 1.42 1.39 - - -

CFM 1317 1268 1237 1217 1157 1111 1027 - - -

RPM 776 810 841 874 905 935 966 - - -

Watts 360 354 348 345 335 323 309 - - -

Amps 1.69 1.67 1.66 1.65 1.63 1.60 1.57 - - -

CFM 1643 1581 1544 1518 1446 1356 1261 1123 915 812

RPM 868 883 895 906 931 955 978 1013 1028 1050

Watts 463 451 443 438 429 415 401 371 356 343

Amps 2.22 2.20 2.18 2.17 2.14 2.12 2.09 2.03 1.99 1.96

CFM 1239 1203 1178 1161 1117 1070 1000 - - -

RPM 738 775 797 808 844 872 905 - - -

Watts 396 385 376 371 360 345 327 - - -

Amps 1.73 1.68 1.64 1.62 1.57 1.52 1.44 - - -

CFM 1480 1431 1399 1379 1319 1259 1187 - - -

RPM 843 865 882 893 915 937 959 - - -

Watts 430 416 407 401 388 375 359 - - -

Amps 1.87 1.81 1.77 1.75 1.69 1.63 1.57 - - -

CFM 1738 1682 1639 1618 1548 1477 1378 1286 1042 908

RPM 921 941 949 955 970 985 1002 1016 1042 1059

Watts 508 493 486 478 460 445 431 412 373 354

Amps 2.22 2.15 2.12 2.08 2.01 1.94 1.89 1.81 1.65 1.58

CFM 1471 1427 1395 1374 1316 1247 1180 -- -

RPM 694 732 753 769 803 833 864 -- -

Watts 381 376 372 370 364 357 349 -- -

Amps 1.66 1.64 1.63 1.62 1.61 .581 .550 --

CFM 1729 1678 1646 1625 1558 1491 1402 -- -

RPM 790 817 833 845 876 898 920 -- -

Watts 485 477 473 470 460 451 240 -- -

Amps 2.14 2.12 2.09 2.08 2.06 2.03 1.99 -- -

CFM 2045 1992 1951 1928 1847 1763 1677 1563 1450 1317

RPM 895 920 932 938 956 972 987 1002 1015 1030

Watts 641 627 617 612 596 582 566 546 528 507

Amps 2.86 2.82 2.82 .782 .732 .682 .642 .572 .522 .450

CFM 1786 1740 1709 1688 1630 1562 1489 -- -

RPM 830 843 849 856 890 921 942 -- -

Watts 584 569 560 552 536 516 497 -- -

Amps 2.64 2.59 2.55 2.54 2.58 2.42 2.37 -- -

CFM 2140 2071 2039 2006 1932 1799 1677 -- -

RPM 917 930 938 943 957 970 990 -- -

Watts 645 630 623 617 602 585 569 -- -

Amps 2.87 2.81 2.78 2.76 2.71 2.65 2.59 -- -

CFM 2357 2276 2225 2188 2100 2004 1902 1764 1554 1393

RPM 964 976 982 990 1001 1012 1022 1032 1042 1063

Watts 754 733 718 710 693 673 650 630 607 575

Amps 3.34 3.27 3.22 3.19 3.12 3.05 2.98 2.91 2.83 2.71

External Static Pressure-Inches W.C. [kPa]

15

Page 17

Heat Controller, Inc. INSTALLATION INSTRUCTIONS HDG Series Air Handler

Fan speed switch congurations:

1. All motors are shipped from the factory at medium speed as default.

2. To charge the fan speed to high speed:

• Connect the black wire to the fan terminal

• Connect the blue wire to the M1 terminal

• Connect the red wire to the M2 terminal

3. To charge the fan spped to low speed

• Connect the blue wire to the fan terminal

• Connect the red wire to the M1 terminal

• Connect the black wire to the M2 terminal

Fan speed

Medium

High

Low

Terminal

Fan

Red

Black

Blue

M1

Blue B lack

Blue

Red

M2

Red

Black

The air distribution system has the greatest effect on airow. The duct system is totally controlled by the

contractor. For this reason, the contractor should use only industry-recognized procedures.

Heat pump systems require a specied airow. Each ton of cooling requires between 350 and 450 cubic

feet of air per minute (CFM), or 400 CFM nominally.

Duct design and construction should be carefully done. System performance can be lowered dramatically through bad planning or workmanship.

Air supply diffusers must be selected and located carefully. They must be sized and positoined to deliver

treated air along the perimerter of the space. If they are too small for their intended airow, they become

noisy. If they are not located properly, they cause drafts. Return air grilles must be properly sized to carry

air back to the blower.If they are too small, they also cause noise.

The installers should balance the air distribution system to ensure proper quiet airow to all rooms in the

home. This ensures a comfortable living space.

An air velocity meter or airow hood can give a reading of system CFM.

16

Page 18

HDG Series Air Handler INSTALLATION INSTRUCTIONS Heat Controller, Inc.

7.0 DUCTWORK

Field ductwork must comply with the National Fire Protection Association NFPA 90A, NFPA 90B and any

applicable local ordinance.

Warning

Do not, under any circumstances, connect return ductwork to any other heat producing device such

as replace insert, stove, etc. Unauthorized use of such devices may result in re, carbon monoxide

poisoning, explosion, personal injury or property damage.

Sheet metal ductwork run in unconditioned spaces must be insulated and covered with a vapor barrier. Fibrous ductwork may be used if constructed and installed in accordance with SMACNA Construction Standard on Fibrous Glass Ducts. Ductwork must comply with National Fire Protection Association as tested by

U/L Standard 181 for Class I Air Ducts. Check local codes for requirements on ductwork and insulation.

• Duct system must be designed within the range of external static pressure the unit is designed

to operate against. It is important that the system airow be adequate. Make sure supply and

return ductwork, grills, special lters, accessories, etc. are accounted for in total resistance.

See airow performance tables in this manual.

• Design the duct system in accordance with “ACCA” Manual “D” Design for Residential Winter

and Summer Air Conditioning and Equipment Selection. Latest editions are available from:

“ACCA” Air Conditioning Contractors of America, 1513 16th Street, N.W., Washington, D.C.

20036. If duct system incorporates exible air duct, be sure pressure drop Information (straight

length plus all turns) shown in “ACCA” Manual “D” is accounted for in system.

• Supply plenum is attached to the 3/4” duct anges supplied with the unit. Attach anges

around the blower outlet.

IMPORTANT: If an elbow is included in the plenum close to the unit, it must not be smaller than the

dimensions of the supply duct ange on the unit.

• IMPORTANT: The front ange on the return duct if connected to the blower casing must not

be screwed into the area where the power wiring is located. Drills or sharp screw points can

damage insulation on wires located inside unit.

• Secure the supply and return ductwork to the unit anges, using proper fasteners for the type

of duct used and tape the duct-to-unit joint as required to prevent air leaks.

17

Page 19

Heat Controller, Inc. INSTALLATION INSTRUCTIONS HDG Series Air Handler

8.0 REFRIGERANT CONNECTIONS

Keep the coil connections sealed until refrigerant connections are made. See the Installation Instructions

for the outdoor unit for details on line sizing, tubing installation, and charging information.

Coil is shipped with “No charge”. Evacuate the system before charging with refrigerant.

Install refrigerant tubing so that it does not block service access to the front of the unit.

Nitrogen should ow through the refrigerant lines while brazing.

Use a brazing shield to protect the cabinet’s paint and a wet rag to protect the rubber grommet from being damaged by torch ames. After the refrigerant connections are made, seal the gap around the connections with pressure sensitive gasket.

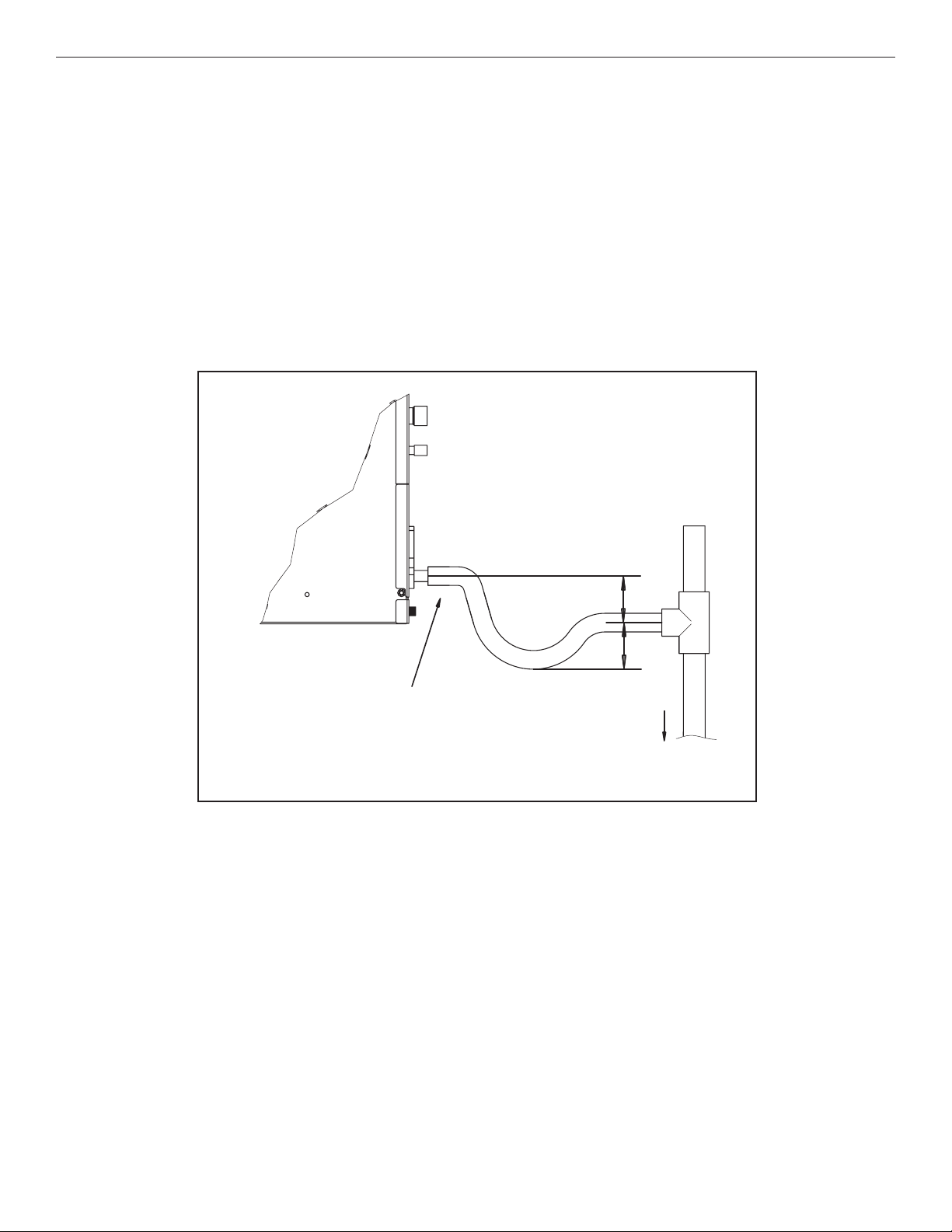

8.1 CONDENSATE DRAIN TUBING

Consult local codes for specic requirements.

CONDENSATE DRAIN TRAP

DO NOT OPERATE UNIT WITHOUT

CONDENSATE DRAIN TRAP.

UNIT

DO NOT OVERTIGHTEN DRAIN FITTING

UNIT MUST BE SLIGHTLY INCLINED

TOWARD DRAIN CONNECTION

Fig. 5 CONDENSATE DRAIN TRAP

3"

3"

TO APPROVED DRAIN

IMPORTANT:

1. When making drain tting connections to the drain pan, use a thin layer of Teon paste, silicone

or Teon tape and install, hand tighten.

2. When making drain tting connections to drain pan, do not overtighten. Over tightening ttings

can split pipe connetions on the drain pan.

• Install drain lines so they do not block service access to front of the unit. Minimum clearance of 24

inches is required for lter, coil or blower removal and service access.

• Make sure unit is level or pitched slightly toward primary drain connection so that water will drain

completely from the pan. (See Fig. 5)

• Do not reduce drain line size less than connection size provided on condensate drain pan.

• All drain lines must be pitched downward away from the unit a minimum of 1/8” per foot of line to

ensure proper drainage.

• Do not connect condensate drain line to a closed or open sewer pipe. Run condensate to an open

drain or run line to a safe outdoor area.

18

Page 20

HDG Series Air Handler INSTALLATION INSTRUCTIONS Heat Controller, Inc.

• The drain line should be insulated where necessary to prevent sweating and damage due to condensate forming on the outside surface of the line.

• Make provisions for disconnecting and cleaning of the primary drain line should it become necessary. Install a 3 inch trap in the primary drain line as close to the unit as possible. Make sure that the

top of the trap is below connection to the drain pan to allow complete drainage of pan (See Fig. 5).

• Auxiliary drain line should be run to a place where it will be noticeable if it becomes operational.

Homeowner should be warned that a problem exists if water should begin running from the auxiliary

drain line.

• Plug the unused drain connection with the plugs provided in the parts bag, using a thin layer of teflon paste, silicone or teon tape to form a water tight seal.

• Test condensate drain pan and drain line after installation is complete. Pour water into drain pan,

enough to ll drain trap and line. Check to make sure drain pan is draining completely, no leaks are

found in drain line ttings, and water is draining from the termination of the primary drain line.

8.2 Flowrator Piston Change

In most applications, there is no need to change the piston (orice). However, in some applications,

changing the piston size is required. If the application requires a different piston/owrator, change the

piston in the distributor of indoor coil before installing the coil. See Table 1 for orice size.

To change the piston, use following steps:

1. Remove cover panel.

2. Use Two wrenches.

Loosen one turn to release pressure. (High pressure gas)

3. After releasing pressure.

Loosen and carefully pull a part the two ttings to expose piston.

4. Remove factory installed piston and replace with recommended piston from Table 1 as shown in Fig.7.

5. Carefully reassemble assembly. (Hand tighten)

Be sure to use teon tape on thread for a complete seal.

6. Hand tighten and make sure assembly is properly connected and then torque to 10-30 ft/lb.

NOTE: Be careful not to bend tubing

LIQUID LINE

PISTON

NUT

(MOMENT:15±2N.m)

Fig. 6: Flowrator Piston Change

19

Page 21

Heat Controller, Inc. INSTALLATION INSTRUCTIONS HDG Series Air Handler

Flowrator Piston Size Chart

NOTE: Pistons are factory installed for use with HRG-1D series heat pump. To use the

coil with a RSG-1D series condenser, a piston change may be required. Refer to table below.

Scroll Heat Pump Applications*

Air Handler: Heat Pumps Piston Size

HDG18FB-1A HRG18S-1D 0.052 inch

HDG24FB-1A HRG24S-1D 0.058 inch

HDG30FB-1A HRG30S-1D 0.065 inch

HDG36FB-1A HRG36S-1D 0.068 inch

HDG42FB-1A HRG42S-1D 0.080 inch

HDG48FB-1A HRG48S-1D 0.090 inch

HDG60FB-1A HRG60S-1D 0.108 inch

Scroll Compressor Condenser Applications**

Air Handler: Condeners Piston Size

HDG18FB-1A RSG18S-1D 0.052 inch

HDG24FB-1A RSG24S-1D 0.058 inch

HDG30FB-1A RSG30S-1D 0.065 inch

HDG36FB-1A RSG36S-1D 0.073 inch

HDG42FB-1A RSG42S-1D 0.077 inch

HDG48FB-1A RSG48S-1D 0.105 inch

HDG60FB-1A RSG60S-1D 0.097 inch

Rotary Compressor Condenser Applications**

Air Handler: Condeners Piston Size

HDG18FB-1A RSG18R-1D 0.054 inch

HDG24FB-1A RSG24R-1D 0.061 inch

HDG30FB-1A RSG30R-1D 0.065 inch

*PISTON REQUIRED FOR THIS APPLICATION IS FACTORY INSTALLED.

**PISTON REQUIRED FOR THIS APPLICATION IS NOT FACTORY INSTALLED, REQUIRES

FIELD CONVERSION.

20

Page 22

HDG Series Air Handler INSTALLATION INSTRUCTIONS Heat Controller, Inc.

9.0 AIR FILTER (not factory-installed)

• External lter or other means of ltration is required. Units should be sized for a maximum of 300 feet/

min. air velocity or what is recommended for the type lter installed.

Filter application and placement are critical to airow, which may affect the heating and cooling system

performance. Reduced airow can shorten the life of the system’s major components, such as motor,

limits, elements, heat relays, evaporator coil or compressor. Consequently, we recommend that the

return air duct system have only one lter location. For systems with a return air lter grill or multiple lter

grills, can have a lter installed at each of the return air openings.

If adding high efciency lters or electronic air ltration systems, it is very important that the air ow is

not reduced. If air ow is reduced the overall performance and efciency of the unit will be reduced. It

is strongly recommended that a profesional installation technician is contacted to ensure installation of

these such ltration systems are installed correctly.

IMPORTANT: DO NOT DOUBLE FILTER THE RETURN AIR DUCT SYSTEM. DO NOT FILTER THE

SUPPLY AIR DUCT SYSTEM.THIS WILL CHANGE THE PERFORMANCE OF THE UNIT AND REDUCE AIRFLOW .

Warning

Do not operate the system without lters. A portion of the dust entrained in the air may temporarily

lodge In the duct runs and at the supply registers. Any circulated dust particles could be heated

and charred by contact with the air handler elements. This residue could soil ceilings, walls,

drapes, carpets and other articles in the house.

Soot damage may occur with lters in place, when certain types of candles, oil lamps or standing

pilots are burned.

21

Page 23

Heat Controller, Inc. INSTALLATION INSTRUCTIONS HDG Series Air Handler

10.0 FILTER INSTALLATION DIMENSIONS

FILTER RAILS

R

ETU

R

N

AIR

O

DIMENSIONAL DATA

“A”

PE

“D”

UNIT MUST BE SLIGHTLY INCLINED

N

IN

G

D

EPTH

Fig. 7: External Filter Base

Fig. 6 EXTERNAL FILTER BASE

“H”

FILTER COVER

MANUAL BOLT

“B”

“W”

NOTE:

NOTE:

Air Filter is NOT factory supplied

Air filter is factory supplied (optional)

MODEL

HDG 18/24/30

HDG 36/42

HDG 48/60

* Air lter is not factory installed. Filter rack is provided. Field supplied lters must be installed per recommended sizes.

FILTER SIZE

IN [mm]

16x20 [406x508]

18x20 [457x508]

20x22 [508x559]

*

"W" IN [mm] "D" IN [mm]

16.8[426] 20.4[518] 1[25.4] 19.6

18.3[466] 21.6[548] 1[25.4] 20.8

20.7[526] 23.9[608] 1[25.4] 23

"H" IN [mm]

Return width

"A" IN

AIR FILTER REMOVAL

1.Remove bolts manually, remove air lter recover, see in Fig 7;

2. Hold the edge of the air lter and extract out .

3. Replace the lter with a properly sized lter using the table above.

22

Return length

"B" IN

14.8

16.3

18.8

Page 24

HDG Series Air Handler INSTALLATION INSTRUCTIONS Heat Controller, Inc.

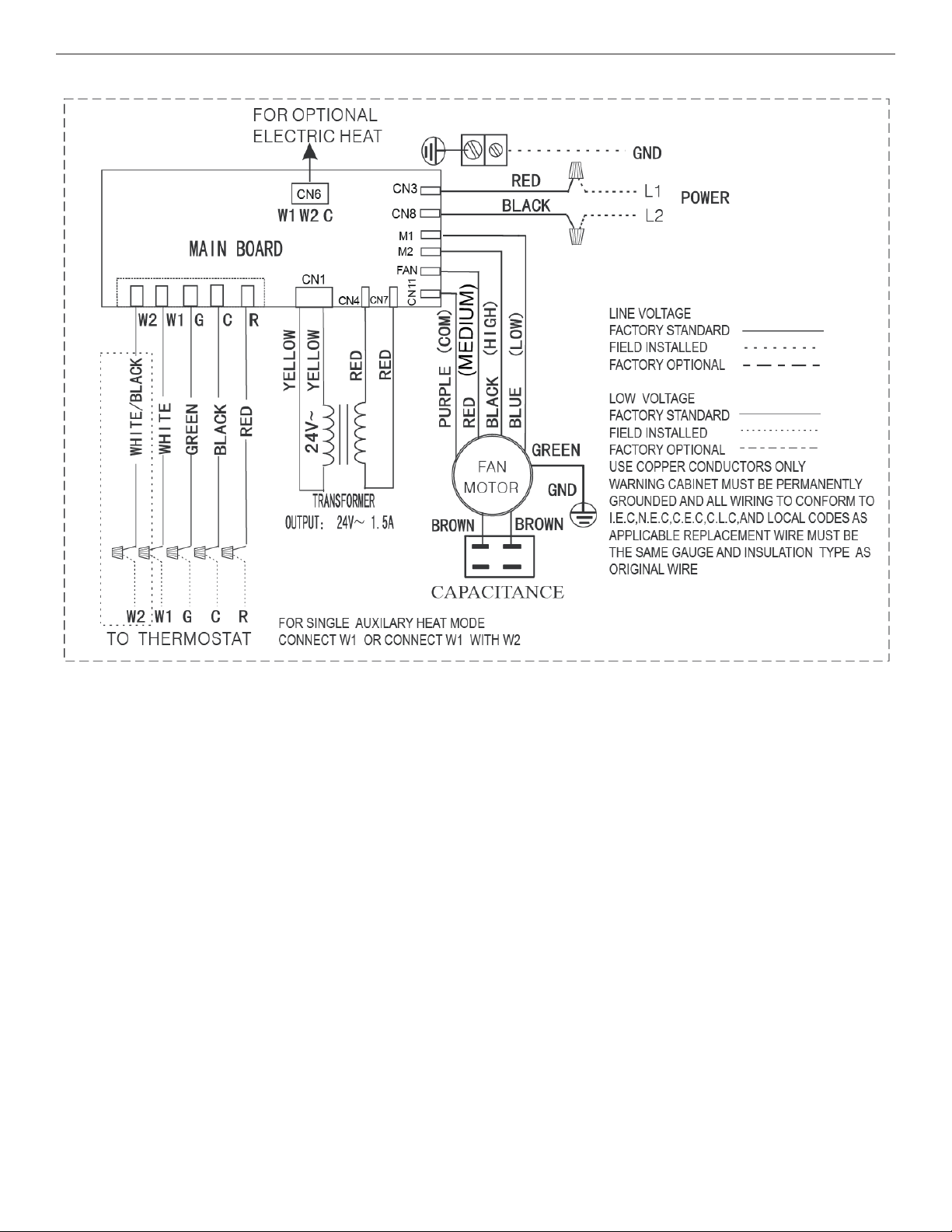

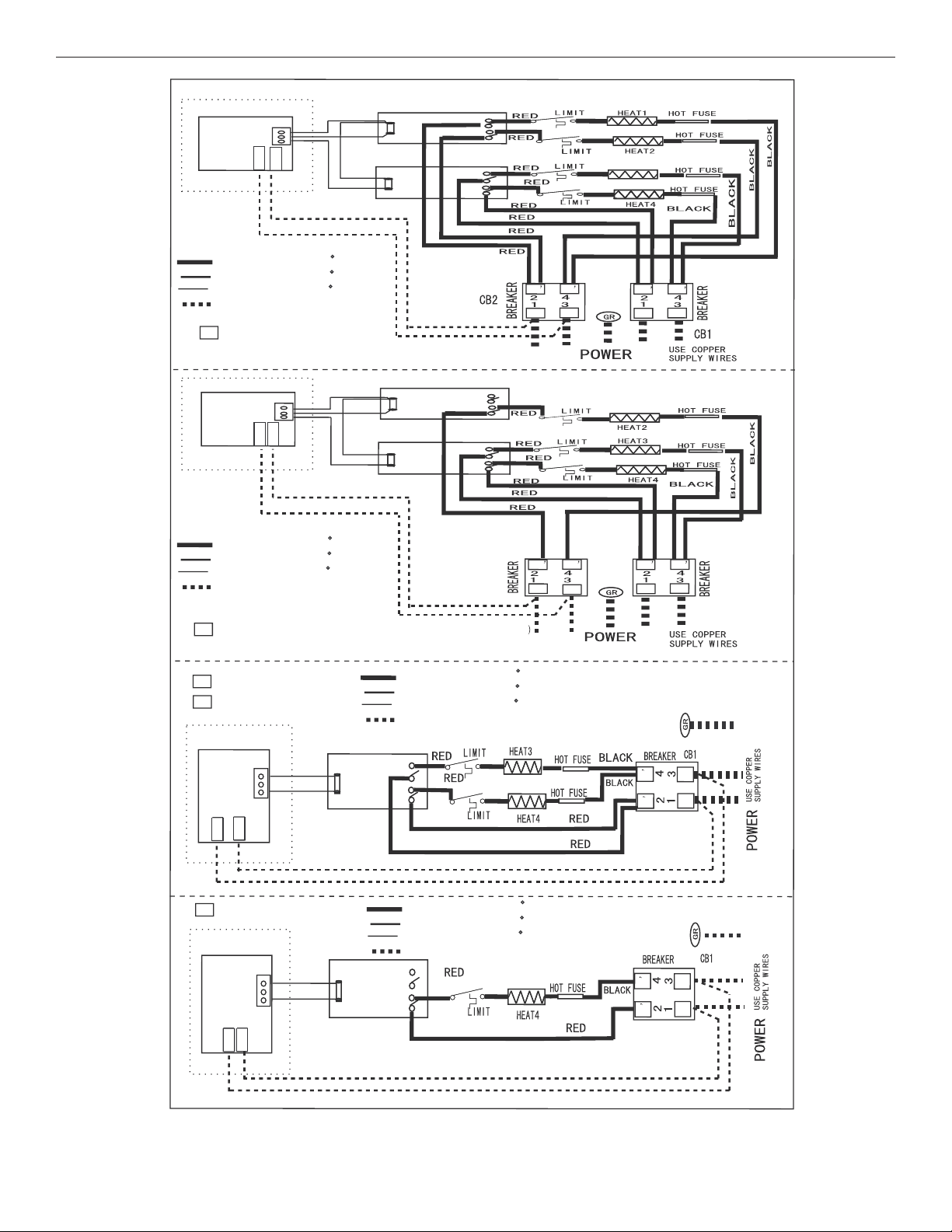

11.0 Wiring Diagram

1. To avoid the electrical shock, connect the air conditioner with the ground lug. The main power plug in

the air conditioner has been joined with the ground wiring, please don’t alter it.

2. The power socket is used as the air conditioner specially.

3. Don’t pull the power wiring hard.

4. When connecting the air conditioner with the ground, observe the local codes.

5. If necessary, use the power fuse or the circuit, breaker or the corresponding scale ampere.

TH ER MO STAT

C

R

Y

G

N

D

EE

G R

R E

G

R

INDOOR UNIT

LACK

B

C

O W

E LL

Y

Y

OUTDOOR UNIT

LACK

B

C

Fig. 8: Typical Thermostat Wiring for Cooling-Only Models

W2

B

C

R

Y

G

THERMOSTAT

INDOOR UNIT

RED

GREEN

R

G

WHITE

BLACK

w1

C

RED

RY

OUTDOOR UNIT

BLACK

C

YELLOW

Fig. 9: Typical Thermostat Wiring for Heat Pump Models

23

BLUE

B

PURPLE

D

Page 25

Heat Controller, Inc. INSTALLATION INSTRUCTIONS HDG Series Air Handler

Fig. 10: Indoor Unit Wiring Diagram for A/C Systems and H/P Systems

24

Page 26

HDG Series Air Handler INSTALLATION INSTRUCTIONS Heat Controller, Inc.

BLACK

PCB

C

6NC

W2

W1

CN8

CN3

WHITE

BLACK

WHITE

C

W2

W1

RED

BLACK

12 GA 1015 600V 105

14 GA 1015 600V 105 C

18 GA 1015 600V 105 C

FIE LD WIRI NG PER LO CAL CODE

C

20kW HEAT KIT

1

0

1

0

8

6

4

2

8

6

4

2

L1

L2

L1

L2

NEER

L1

L2

G

L1

L2

BLACK

C

6NC

PCB

W2

W1

CN3

CN8

WHITE

BLACK

WHITE

RED

BLACK

12 GA 1015 600V 105

14 GA 1015 600V 105

18 GA 1015 600V 105 C

FIE LD WIRI NG PER LO CAL CODE

C

C

15kW HEAT KIT

7.5kW HEAT KIT

10kW HEAT KIT

1

BLACK

C

6NC

PCB

CN8

W1

WHITE

0

CN3

C

1

W2

0

1

W1

0

12 GA 1015 600V 105 C

14 GA 1015 600V 105

18 GA 1015 600V 105

FIE LD WIRI NG PER LO CAL CODE

8

6

4

2

8

6

4

2

8

6

CB1(3 2A

C

4

2

L1

L2

L1

L2

C

NEERG

L1

L2

L1

L2

7.5 kW CB1 5 0A

10k W C B1 63A

GREEN

2L

1

L

CB2(6 3A)

2L

1L

RED

BLACK

5kW HEAT KIT

C

6NC

PCB

W1

CN3

CN8

BLACK

WHITE

1

0

12 GA 1015 600V 105 C

14 GA 1015 600V 105

18 GA 1015 600V 105 C

FIE LD WIRI NG PER LO CAL CODE

C

8

6

4

2

Fig. 11: Indoor Unit Wiring Diagram for Electric Heat

25

GREEN

2L

1L

2L

1L

RED

BLACK

Page 27

05/2011

Loading...

Loading...