Heat Controller HDG48, HDG42, HDG30, HDG60, HDG24 User Manual

...

INSTALLATION

INSTRUCTIONS

Air Handler

HDG Series

1.5 to 5 Ton

Heat Controller, Inc. • 1900 Wellworth Ave. • Jackson, MI 49203 • (517)787-2100 • www.heatcontroller.com

HDG Series Air Handler |

INSTALLATION INSTRUCTIONS |

Heat Controller, Inc. |

Table of Contents |

|

|

1.0 NOMENCLATURE................................................................................................................ |

|

2 |

2.0 SAFETY................................................................................................................................ |

|

3 |

3.0 GENERAL............................................................................................................................. |

|

6 |

3.1 UNIT DIMENSIONS...................................................................................................... |

|

7 |

4.0 APPLICATIONS.................................................................................................................... |

|

8 |

4.1 VERTICAL UPFLOW..................................................................................................... |

|

8 |

4.2 VERTICAL DOWNFLOW.............................................................................................. |

|

8 |

4.3 HORIZONTAL................................................................................................................ |

|

9 |

4.4 INSTALLATION IN AN UNCONDITIONED SPACE..................................................... |

11 |

|

5.0 ELECTRICAL WIRING....................................................................................................... |

|

11 |

5.1 POWER WIRING........................................................................................................ |

|

11 |

5.2 CONTROL WIRING.................................................................................................... |

|

12 |

5.3 GROUNDING.............................................................................................................. |

|

12 |

5.4 ELECTRICAL DATA.................................................................................................... |

|

13 |

6.0 AIRFLOW PERFORMANCE.............................................................................................. |

|

14 |

7.0 DUCTWORK....................................................................................................................... |

|

17 |

8.0 REFRIGERANT CONNECTIONS....................................................................................... |

18 |

|

8.1 CONDENSATE DRAIN TUBING................................................................................. |

18 |

|

8.2 FLOW RATER PISTON CHANGE............................................................................... |

19 |

|

9.0 AIR FILTER (not factory-installed)................................................................................... |

21 |

|

10.0 FILTER INSTALLATION DIMENSIONS .......................................................................... |

22 |

|

10.0 WIRE DIAGRAMS............................................................................................................ |

|

23 |

1

Heat Controller, Inc. |

|

|

INSTALLATION INSTRUCTIONS |

HDG Series Air Handler |

|||||||||||||||||||||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

1.0 Nomenclature |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||||||||

|

H |

|

|

D |

|

G |

|

18 |

|

F |

|

|

B |

|

- |

1 |

|

A |

|

||||||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

A = Revision |

|||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Code |

||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||

H = DX Air Handler |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

1 = 208/230V 1 Phase 60Hz |

||||||||||||||

A = Hydronic Air Handler |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||||||||||||||||

F = Front Return |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

2 = 208/230V 3 Phase 60Hz |

|||||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Design Series |

|

|

|

|

|

|

|

|

|

|

Condenser/Heat Pump Matching Guide: |

|

|

|

|

|

|

||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

H = Heat Pump |

|

|

|

|

|

|

|

|

|

|||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

C = Air Conditioner |

|

|

|

|

|

|

|

|

|

|||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

B = Both A/C & H/P use |

|

|

|

|

|

|

|

|

||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||||||

|

|

|

|

|

|

|

|

|

R-410A Refrigerant |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

F = Flowrater (Piston) |

|

|

|

|

|

|

|

|

|

|||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

T = TXV |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

V = TXV w/ ECM Drive |

|

|

|

|

|

|

|

|

|

|||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

18 = 18,000 BTUH

24 = 24,000 BTUH

30 = 30,000 BTUH

36 = 36,000 BTUH

42 = 42,000 BTUH

48 = 48,000 BTUH

60 = 60,000 BTUH

NOTE: Not all model configurations are available. The nomenclature exists for future product line development. Consult your local distributor or Heat Controller’s customer service department regarding available options.

Warning

These instructions are intended as an aid to qualified licensed service personnel for proper installation, adjustment and operation of this unit. Read these instructions thoroughly before attempting installation or operation. Failure to follow these instruction may result in improper installation,adjustment, service or maintenance possibly resulting in fire, electrical shock, property damage, personal injury or death.

2

HDG Series Air Handler |

INSTALLATION INSTRUCTIONS |

Heat Controller, Inc. |

|

|

|

This document is customer property and is to remain with this unit.

These instructions do not cover all the different variations systems nor does it provide for every possible contingency to be met in connection with installtion.

All phases of this installation must comply with NATIONAL STATE AND LOCAL CODES. If additional information is required please contact your local distributor.

2.0 Safety

This is a safety alert symbol. When you see this symbol on labels or in manuals, be alert to the potential for personal injury.

This is an attention alert symbol. When you see this symbol on labels or in manuals, be alert to the potential for personal injury.

This is an attention alert symbol. When you see this symbol on labels or in manuals, be alert to the potential for personal injury.

Warning

Disconnect all power to unit before installing or servicing. More than one disconnect switch may be required to de-energize the equipment. Hazardous voltage can cause server personal injury or death.

Warning

If removal of the blower assembly is required, all disconnect switches supplying power to the equipment must be de-energized and locked (if not in sight of unit ) so the field power wires can be safely removed from the blower assembly. Failure to do so can cause electrical shock resulting in personal injuring or death.

Warning

Because of possible damage to equipment or personal injury, installation, service, and maintenance should be performed by a trained, qualified service personnel. Consumer service is recommended only for filter cleaning / replacement. Never operate the unit with the acess panels removed.

Warning

These instructions are intended as an aid to qualified, licensed service personnel for proper installation, adjustment and operation of this unit. Read these instructions thoroughly before attempting installation or operation. failure to follow these instructions may result in improper installation, adjustment, service or maintenance possibly resulting in fire, electrical shock, property damage, personal injury or death.

3

Heat Controller, Inc. |

INSTALLATION INSTRUCTIONS |

HDG Series Air Handler |

|

|

|

Warning

The unit must be permanently grounded. Failure to do so can result in electrical shock causing personal injury or death.

Warning

PROPOSITION 65: This appliance contains fiberglass insulation. Respirable particles of fiberglass are known to State of California to cause cancer.

All manufacturer products meet current federal OSHA Guidelines for safety. California Proposition 65 warnings are required for certain products, which are not covered by the OSHA standards.

California’s Proposition 65 requires warnings for products sold in California that contain or produce any of over 600 listed chemicals known to the State of California to cause cancer or birth defects such as fiberglass insulation, lead in brass, and combustion products from natural gas.

All “new equipment” shipped for sale in California will only have labels stating that the product contains and /or produces Proposition 65 chemicals. We cannot always know “when, or if” products will be sold in the California market, thus all products may not be labeled when their final destination is unknown.

You may receive inquiries from customers about chemicals found in, or produced by, some of our heating and air-conditioning equipment, or found in natural gas used with some of our products. Listed below are those chemicals and substances commonly associated with similar equipment in our industry and other manufacturers.

Glass Wool (Fiberglass) Insulation Carbon Monoxide (CO). Formaldehyde

Benzene

More details are available at the websites for OSHA (Occupational Safety and Health Administration), at www.osha.gov and the State of California’s OEHHA (Office of Environmental Health Hazard Assessment), at www.oehha.org. Consumer education is important since the chemicals and substances on the list are found in our daily lives. Most consumers are aware that products present safety and health risks, when improperly used, handled and maintained.

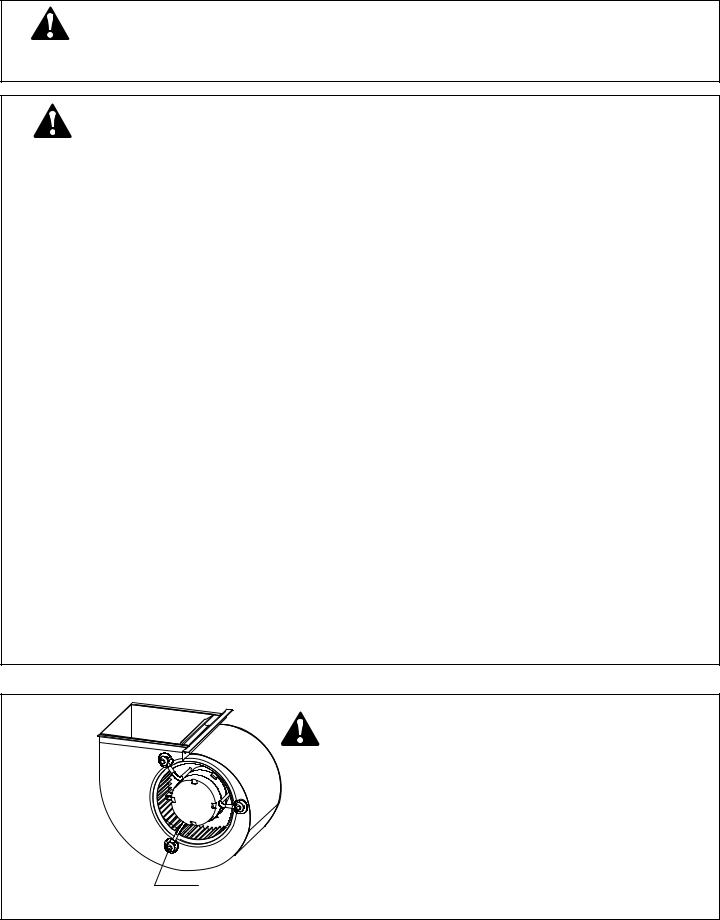

Warning

Make sure the blower motor support is tight (3-motor mount bolts) then check to see if wheel is secured to motor shaft before operating unit. To avoid electrical shock, which can result in injury or death, use only the screws furnished with the motor from the manufacturer.

BLOWER MOTOR BOLT

4

HDG Series Air Handler |

INSTALLATION INSTRUCTIONS |

Heat Controller, Inc. |

|

|

|

Warning

Do not install this unit in manufactured (mobile) homes. Improper installation is more likely in manufactured housing due to ductwork material, size, location and arrangement. Installations in manufactured housing can cause fire resulting in property damage, personal injury or death.

EXCEPTION: Manufactured housing installations are approved only with documentation by a recognized inspection authority that verifies that the installation has been made in compliance with the instructions and all warnings have been observed.

Warning

Duct leaks can create an unbalanced system and draw pollutants such as direct, dust, fumes and odors into the home causing property damage. Fumes and odors from toxic, volatile or flammable chemicals, as well as automobile exhaust and carbon monoxide (CO), can be drawn into the living space through leaking ducts and unbalanced duct systems causing personal injury or death (see Figure 1).

•If air-moving equipment or ductwork is located in garages or off-garage storage areas, all joints, seams, and openings in the equipment and duct must be sealed to limit the migration of toxic fumes and odors including carbon monoxide from migrating into the living space.

•If air-moving equipment or ductwork is located in spaces containing fuel burning appliances such as water heaters or boilers, all joints, seams and openings in the equipment and duct must be sealed to prevent depressurization of the space and possible migration of combustion byproducts including carbon monoxide into the living space.

Notice

When used in cooling applications, excessive sweating may occur when unit is installed in an unconditioned space. This can result in property damage.

Notice

In compliance with recognized codes, it is recommended that an auxiliary drain pan be installed under all evaporator coils or units containing evaporator coils that are located in any area of a structure where damage to the building or building contents may occur as a result of an overflow of the coil drain pan or a stoppage in the primary condensate drain piping.

Warning

The first 36 inches of supply air plenum and ductwork must be constructed of sheet metal as required by NFPA 90B. The supply air plenum or duct must have a solid sheet metal bottom directly under the unit with no openings, registers or flexible air ducts located in it. If flexible supply air ducts are used they may be located only in the vertical walls of rectangular plenum, a minimum of 6 inches from the solid bottom. Metal plenum of duct may be connected to the combustible floor base, if not, it must be connected to the unit supply duct exposed to the supply air opening from the downflow unit. Exposing combustible (non-metal) material to the supply opening of a downflow unit can cause a fire resulting in property damage, personal injury or death.

Exception warning to downflow:

Installations on concrete floor slab with supply air plenum and ductwork completely encased must be not less than 2 inches of concrete (See NFPA 90A).

5

Heat Controller, Inc. |

INSTALLATION INSTRUCTIONS |

HDG Series Air Handler |

3.0 General

The unit can be positioned for bottom return air in the upflow position, left and right return in the horizontal position, top return in downflow position.

This Air Handler provides the flexibility for installation in any upflow or downflow horizontal application. The direct drive motors provides a selection of air volume to match any application. 3-Speed motors provide selections of air flow to meet desired applications.

Top and side power and control wiring, accessible screw terminals for control wiring all combine to make the installation easy, and minimize installation cost. Please contact your local distributor.

See Fig. 1 on Pg. 7

6

HDG Series Air Handler |

INSTALLATION INSTRUCTIONS |

|

Heat Controller, Inc. |

|||

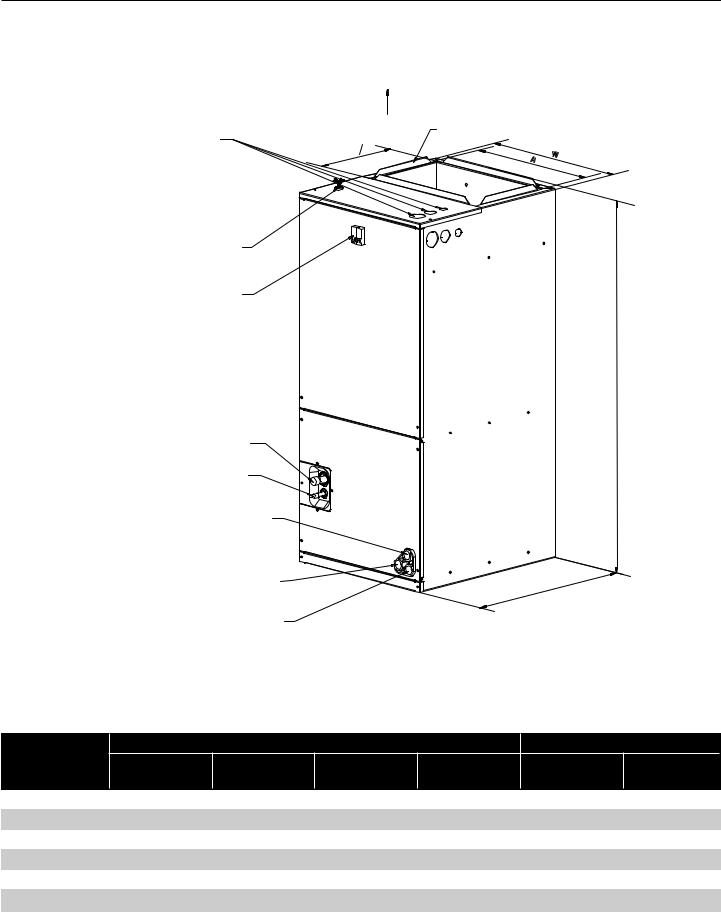

3.1 Unit Dimensions |

OF THE UNIT FOR FILTER AND COIL MAINTENANCE. |

|||||

|

|

NOTE: 24” CLEARANCE IS REQUIRED IN THE FRONT |

||||

ELECTRICAL CONNECTIOS |

|

|

|

|

|

|

MAY EXIT TOP OR EITHER SIDE |

|

|

SUPPLY AIR |

|

|

|

|

|

|

|

|

|

|

|

7/8”, |

|

|

FLANGES ARE PROVIDED |

||

HIGHVOLTAGELTAGECONNECTION 7/8”, |

|

|

||||

1-3/8”, 1-3/4” |

KNOCK |

|

|

FOR FIELD INSTALLATION |

||

1-23/64”, 1-23/32”DIAMETERKNOCK OUTOUTS |

|

|

||||

|

|

|

5 |

|

|

W |

|

|

0 |

16 |

|

||

|

|

1 |

|

A |

|

|

|

|

|

|

|

||

LOW VOLTAGE CONNECTION

BREAKER SWITCH

(FOR ELECTRIC HEATER ONLY)

H

VAPOR LINE CONNECTION COPPER (SWEAT)

LIQUID LINE CONNECTION COPPER (SWEAT)

AUXILIARY DRAIN CONNCECTION 3/4”

FEMALE PIPE THREAD (NPT)

AUXILIARY DRAIN CONNECTION 3/4” |

|

FEMALE PIPE THREAD (NPT) |

D |

|

PRIMARY DRAIN CONNCETION 3/4”

FEMALE PIPE THREAD (NPT)

Fig. 1 Dimensions

Dimensional Data

UPFLOW UNIT SHOWN;

UNIT MAY BE INSTALLED UPFLOW, DOWNFLOW, HORIZONTAL RIGHT, OR LEFT AIR SUPPLY.

|

|

Dimensions |

|

Unit Weight lbs. [kg] |

||

|

Unit Height |

Unit Weight |

Unit Lenght |

Supply Duct |

|

|

Model Size |

in. [mm] |

in. [mm] |

in. [mm] |

“A” in [mm] |

Net |

Shipping |

HDG18 |

41 3/8" [1050] |

18 1/8" [460] |

20 1/2" [520] |

16" [406] |

106 [48] |

119 [54] |

HDG 24 |

41 3/8" [1050] |

18 1/8" [460] |

20 1/2" [520] |

16" [406] |

106 [48] |

119 [54] |

HDG 30 |

41 3/8" [1050] |

18 1/8" [460] |

20 1/2" [520] |

16" [406] |

119 [54] |

132 [60] |

HDG36 |

46 1/2" [1180] |

19 5/8" [500] |

20 5/8" [550] |

18" [456] |

141 [64] |

156 [71] |

HDG42 |

46 1/2" [1180] |

19 5/8" [500] |

20 5/8" [550] |

18" [456] |

141 [64] |

156 [71] |

HDG48 |

54 1/2” [1385] |

22” [560] |

24" [610] |

19 1/2” [496] |

171 [78] |

187 [85] |

HDG60 |

54 1/2” [1385] |

22” [560] |

24" [610] |

19 1/2” [496] |

171 [78] |

187 [85] |

7

Heat Controller, Inc. |

INSTALLATION INSTRUCTIONS |

HDG Series Air Handler |

|

|

|

4.0Applications

4.1Vertical Upflow

• Vertical Upflow configuration is the factory set on all models (see Fig 1).

•If a side return air opening is required, field fabricate a return air plenum with an opening large enough to supply unit and strong enough to support unit weight.

•If return air is to be ducted, install duct flush with floor. Use fireproof resilient gasket 1/8 to 1/4 in. thick between the ducts, unit and floor. Set unit on floor over opening.

IMPORTANT NOTE

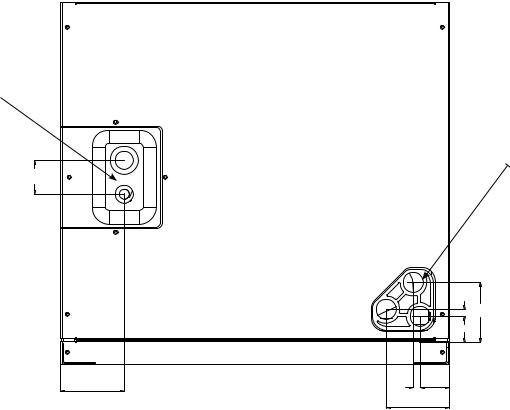

Torque applied to drain connections should not exceed 15.ft.lbs.(see Fig.1&2)

Refrigerant Line

Connections

Drain

Connections

1-9/16

2-15/16

Fig.22CoilCoilConnectionDimensionsDimensions

5/16 |

2-13/16 |

1-1/4 |

5/16 1-3/8 |

2-15/16 |

4.2 Vertical Downflow

Conversion to Vertical Downflow: A vertical upflow unit may be converted to vertical downflow. Remove the door and indoor coil and reinstall 180° from original position. See Fig. 2~3.

IMPORTANT: To comply with certification agencies and the National Electric Code for horizontal right application, the circuit breaker(s) on field-installed electric heater kits must be re-installed per procedure below so that the breaker switch “on” position and marking is up and, “off” position and marking is down.

•To rotate breaker(s): Rotate one breaker set (circuit) at a time starting with the one on the right. Loosen both lugs on the load side of the breaker. (Make sure that wires are identified and are reinstalled into proper breaker).Wires are bundles with wire ties, one bundle going to the right lug and one bundle going to the left lug.

8

Loading...

Loading...