Page 1

ENGINEERING

DESIGN GUIDE

Commercial Horizontal & Vertical

Packaged Water-Source Heat Pumps:

HBH/V Compact

Heat Controller, Inc. • 1900 Wellworth Ave. • Jackson, MI 49203 • (517)787-2100 • www.heatcontroller.com

Page 2

Engineering Design Guide HBH/V SERIES Heat Controller, Inc.

Table of Contents

Unit Features ........................................................................................................................................ 2

Selection Procedure .......................................................................................................................... 3-4

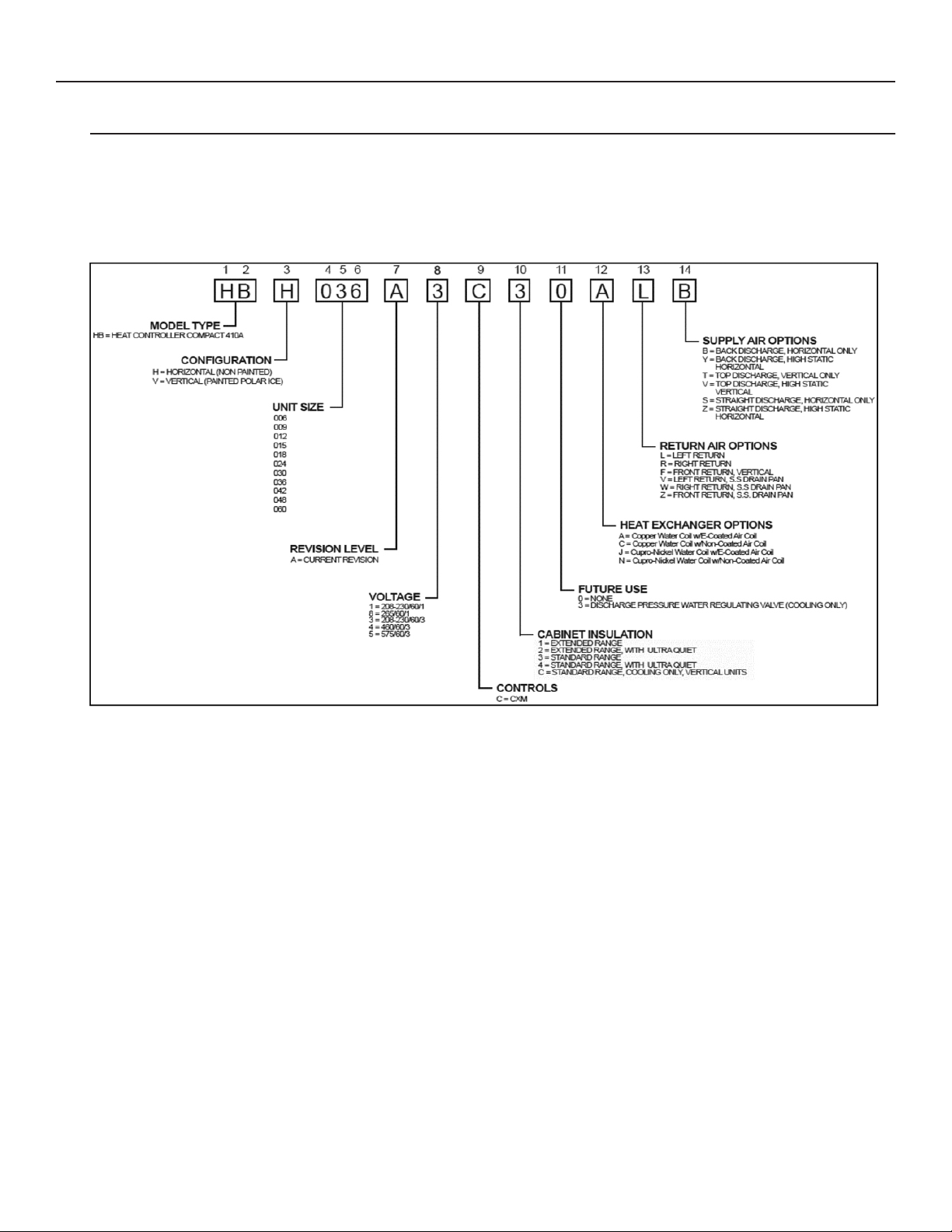

HB Series Nomenclature ...................................................................................................................... 5

Performance Data - ARI/ASHRAE/ISO 13256-1 .................................................................................. 6

Performance Data Selection Notes ...................................................................................................... 7

Performance Data - HB H/V 006 .......................................................................................................... 8

Performance Data - HB H/V 009 .......................................................................................................... 9

Performance Data - HB H/V 012 ........................................................................................................ 10

Performance Data - HB H/V 015 .........................................................................................................11

Performance Data - HB H/V 018 ........................................................................................................ 12

Performance Data - HB H/V 024 ........................................................................................................ 13

Performance Data - HB H/V 030 ........................................................................................................ 14

Performance Data - HB H/V 036 ........................................................................................................ 15

Performance Data - HB H/V 042 ........................................................................................................ 16

Performance Data - HB H/V 048 ........................................................................................................ 17

Performance Data - HB H/V 060 ........................................................................................................ 18

Air Flow Correction Tables ................................................................................................................. 19

Antifreeze Correction Table ................................................................................................................ 20

Blower Performance Data ............................................................................................................. 21-22

Physical Data ..................................................................................................................................... 23

HB - Horizontal Dimensional Data................................................................................................. 24-25

HB - Vertical Upow Dimensional Data ......................................................................................... 26-27

Corner Weights for HB Series Units ................................................................................................... 28

Electrical Data .................................................................................................................................... 29

Electrical Data - (High Static Table) .................................................................................................... 30

Typical Wiring Diagram Single Phase HB Units With CXM Controller ............................................... 31

Typical Wiring Diagram Three Phase 208/230V HB Units With CXM Controller ............................... 32

Typical Wiring Diagram Three Phase 460/575V HB Units with CXM Controller ................................ 33

1

Page 3

Heat Controller, Inc. HBH/V SERIES Engineering Design Guide

HB Series

The HBH/V Series exceeds ASHRAE 90.1 efciencies,

and uses R-410A zero ozone depletion refrigerant,

making it an extremely environmentally-friendly option.

HBH/V is eligible for additional LEED™ (Leadership in

Energy and Environmental Design) points because of

the “green” technology design. With one of the smallest

cabinets in the industry, the HBH/V will easily t into

tight spaces. Designed to be backward compatible with

thousands of older water-source heat pumps.

Available in sizes from 1/2 ton (1.76 kW) through 5 tons

(17.6 kW) with multiple cabinet options (vertical upow

and horizontal) the HBH/V offers a wide range of units for

most any installation. The HBH/V has an extended range

refrigerant circuit, capable of geothermal ground loop

applications (with optional extended range insulation) as

well as boiler-tower water loop applications. Standard

features include: Copeland scroll compressors (rotary for

size 018 and below), microprocessor controls, galvanized

steel cabinet, galvanized steel with epoxy powder painted

drain pan and sound absorbing air handler insulation.

Heat Controller’s exclusive double isolation compressor

mounting system makes the HBH/V the quietest unit

on the market. Compressors are mounted via rubber

vibration isolators to a heavy gauge mounting plate,

which is further isolated from the cabinet base with

rubber grommets for maximized vibration/sound

attenuation. The easy access control box and large

access panels make installing and maintaining the unit

easier than other water-source heat pumps currently

in production, proving that a small unit can be easy to

service.

The HBH/V Series is full of options, such as an

e-coated air coil. Optional high static fan motor expands

the operating range and helps overcome some of

the challenges associated with ductwork for retrot

installations. A Cupro-Nickel water-coil and sound

absorbing mute package are options that make a great

unit even better.

The HBH/V Series Water-Source Heat Pumps are

designed to meet the challenges of today’s HVAC

demands with one of the most innovative products

available on the market.

Unit Features

• Sizes 006 (1/2 ton, 1.76 kW) through 060 (5 tons, 17.6 kW)

• R-410A refrigerant

• Exceeds ASHRAE 90.1 efciencies

• Galvanized steel construction

• Epoxy powder painted galvanized steel drain pan

• Sound absorbing glass ber insulation

• Unique double isolation compressor mounting via

vibration isolating rubber grommets for quiet operation

• Insulated divider and separate compressor/air handler

compartments

• Copeland scroll compressors (rotary for size 018 and

below)

• TXV metering device

• Microprocessor controls standard

• Field convertible discharge air arrangement for

horizontal units

• PSC three-speed fan motor

• Internally trapped condensate drain line (vertical units

only)

• Unit Performance Sentinel performance monitoring

system

• Eight Safeties Standard

• Extended range (20 to 120°F, -6.7 to 48.9°C) capable

• High static blowers available

• Cupro-Nickel water-coil available

• Sound absorbing UltraQuiet package available

2

Page 4

Engineering Design Guide HBH/V SERIES Heat Controller, Inc.

To convert Inch-Pound (English) to SI (Metric)

LWT = EWT -

HE

GPM x 500

LAT = EAT +

HC

CFM x1.08

LWT = EWT +

HR

GPM x 500

LAT (DB) = EAT (DB) -

SC

CFM x1.08

LC = TC - SC

S/T =

SC

TC

Heating

Cooling

Selection Procedure

Reference Calculations

Legend and Glossary of Abbreviations

BTUH = BTU( British Thermal Unit) per hour

CFM = airow, cubic feet/minute

COP = coefcient of performance = BTUH output/BTUH input

DB = dry bulb temperature (°F)

EAT = entering air temperature, Fahrenheit (dry bulb/wet bulb)

EER = energy efciency ratio = BTUH output/Watt input

EPT = external pipe thread

ESP = external static pressure (inches w.g.)

EWT = entering water temperature

GPM = water ow in U.S. gallons/minute

HE = total heat of extraction, BTUH

HC = air heating capacity, BTUH

HR = total heat of rejection, BTUH

HWC = hot water generator (desuperheater) capacity, Mbtuh

IPT = internal pipe thread

KW = total power unit input, kilowatts

LAT = leaving air temperature, °F

LC = latent cooling capacity, BTUH

LWT = leaving water temperature, °F

MBTUH = 1000 BTU per hour

S/T = sensible to total cooling ratio

SC = sensible cooling capacity, BTUH

TC = total cooling capacity, BTUH

WB = wet bulb temperature (°F)

WPD = waterside pressure drop (psi & ft. of hd.)

Conversion Table - to convert inch-pound (English) to SI (Metric)

Air Flow Water Flow Ext Static Pressure Water Pressure Drop

Airflow (L/s) = CFM x 0.472 Water Flow (L/s) = gpm x 0.0631 ESP (Pa) = ESP (in of wg) x 249 PD (kPa) = PD (ft of hd) x 2.99

3

Page 5

Heat Controller, Inc. HBH/V SERIES Engineering Design Guide

Selection Procedure

Step 1 Determine the actual heating and cooling loads at the

desired dry bulb and wet bulb conditions.

Step 2

Step 3 Select a unit based on total and sensible cooling

Step 4 Enter tables at the design water ow and water

Step 5 Read the heating capacity. If it exceeds the design

Obtain the following design parameters: Entering water

temperature, water ow rate in GPM, air ow in CFM,

water ow pressure drop and design wet and dry bulb

temperatures. Air ow CFM should be between 300 and

450 CFM per ton. Unit water pressure drop should be

kept as close as possible to each other to make water

balancing easier. Go to the appropriate tables and nd

the proper indicated water ow and water temperature.

conditions. Select a unit which is closest to, but no

larger than, the actual cooling load.

temperature. Read the total and sensible cooling

capacities (Note: interpolation is permissible,

extrapolation is not).

criteria it is acceptable. It is quite normal for WaterSource Heat Pumps to be selected on cooling capacity

only since the heating output is usually greater than the

cooling capacity.

Example Equipment Selection For Cooling

Step 1 Load Determination:

Assume we have determined that the appropriate cooling load

at the desired dry bulb 80°F and wet bulb 65°F conditions is

as follows:

Total Cooling ......................................23,700 BTUH

Sensible Cooling ................................. 16,500 BTUH

Entering Air Temp .... 80°F Dry Bulb / 65°F Wet Bulb

Step 2 Design Conditions:

Similarly, we have also obtained the following design parameters:

Entering Water Temp ....................................... 90°F

Water Flow (Based upon 10°F rise in temp.) 6.0 GPM

Air Flow .................................................... 800 CFM

Step 3, 4 & 5 HP Selection:

After making our preliminary selection (TC024), we enter the

tables at design water ow and water temperature and read

Total Cooling, Sens. Cooling and Heat of Rej. capacities:

Total Cooling .......................................23,400 BTUH

Sensible Cooling ................................. 17,500 BTUH

Heat of Rejection ................................30,200 BTUH

Step 6 Determine the correction factors associated with the

variable factors of dry bulb, wet bulb and air ow.

Corrected Total Cooling =

tabulated total cooling x wet bulb correction x air ow

correction

Corrected Sensible Cooling =

tabulated sensible cooling x dry bulb correction x air

ow correction

Step 7 Compare the corrected capacities to the load

requirements. Normally if the capacities are within 10%

of the loads, the equipment is acceptable. It is better

to undersize than oversize, as undersizing improves

humidity control, reduces sound levels and extends the

life of the equipment.

Step 8 When completed, calculate water temperature rise

and assess the selection. If the units selected are not

within 10% of the load calculations, then review what

effect changing the GPM, water temperature and/or air

ow and air temperature would have on the corrected

capacities. If the desired capacity cannot be achieved,

select the next larger or smaller unit and repeat the

procedure. Remember, when in doubt, undersize

slightly for best performance.

Step 6 & 7 Entering Air and Airow Corrections:

Next, we determine our correction factors.

Table Ent Air Air Flow Corrected

Corrected Total Cooling = 23,400 x 0.9681 x 1.0050 = 22,767

Corrected Sens Cooling = 17,500 x 1.1213 x 0.9820 = 19,270

Corrected Heat of Reject = 30,200 x 0.9747 x 1.0434 = 30,713

Step 8 Water Temperature Rise Calculation & Assessment:

Actual Temperature Rise 10.2°F

When we compare the Corrected Total Cooling and Corrected

Sensible Cooling gures with our load requirements stated

in Step 1, we discover that our selection is within +/- 10% of

our sensible load requirement. Furthermore, we see that our

Corrected Total Cooling gure is within 1,000 Btuh the actual

indicated load.

4

Page 6

Engineering Design Guide HBH/V SERIES Heat Controller, Inc.

HEAT CONTROLLER OEM PRICE LIST

HBH & HBV COMPACT Horizontal & Vertical HFC-410a Units

H B H A0 3 6 C3 3 0 A L B

1 2 3 4 5 6 7

8

9 10 11 12 13 14

HB = HEAT CONTROLLER COMPACT 410A

MODEL TYPE

H = HORIZONTAL (NON PAINTED)

CONFIGURATION

V = VERTICAL (PAINTED POLAR ICE)

UNIT SIZE

018 - 1,8

024 - 1,3,4,8

030 - 1,3,4,8

036 - 1,3,4,8

042 - 1,3,4,5

048 - 1,3,4,5

060 - 1,3,4,5

REVISION LEVEL

A = CURRENT REVISION FOR SIZES 006 - 060

VOLTAGE

C = CXM

CONTROLS

3 = STANDARD RANGE

CABINET INSULATION

0 = NONE

FUTURE USE

A = Copper Water Coil w/E-Coated Air Coil

HEAT EXCHANGER OPTIONS

C = Copper Water Coil w/Non-Coated Air Coil

L = LEFT RETURN

RETURN AIR OPTIONS

R = RIGHT RETURN

F = FRONT RETURN, VERTICAL 009-030

B = BACK DISCHARGE, HORIZONTAL ONLY

SUPPLY AIR OPTIONS

Y = BACK DISCHARGE, HIGH STATIC

HORIZONTAL 018 - 060

T = TOP DISCHARGE, VERTICAL ONLY

V = TOP DISCHARGE, HIGH STATIC

VERTICAL 018 - 060

S = STRAIGHT DISCHARGE, HORIZONTAL ONLY

Z = STRAIGHT DISCHARGE, HIGH STATIC

HORIZONTAL 018 - 060

J = Cupro-Nickel Water Coil w/E-Coated Air Coil

N = Cupro-Nickel Water Coil w/Non-Coated Air Coil

4 = STANDARD RANGE, WITH ULTRA QUIET

015 - 1,8

1 = 208-230/60/1

8 = 265/60/1

3 = 208-230/60/3

4 = 460/60/3

5 = 575/60/3

C = STANDARD RANGE, COOLING ONLY, VERTICAL UNITS

3 = DISCHARGE PRESSURE WATER REGULATING VALVE (COOLING ONLY)

NOT AVAILABLE ON UNIT SIZES 006, 009 AND 012

V = LEFT RETURN, S.S DRAIN PAN

W = RIGHT RETURN, S.S DRAIN PAN

Z = FRONT RETURN, S.S. DRAIN PAN 009-030

}

Voltage Code

Entering Water Temperature Range: 20 - 120°F (-6.7 - 48.9°C)

Horizontal Water Source Heat Pump

Sizes 015-060

006-060

Vertical Water Source Heat Pump

Sizes 015-060

006-060

HBH & HBV Model Structure

Basic Unit Description:

The basic unit price includes sealed heat pump refrigerant circuit and

air handler within cabinetry, lter, and a factory installed hanger kit on

horizontal units.

• Cabinetry - Compact design - galvanized steel construction -

• Cabinetry – Compact design - galvanized steel construction -

powder coat nish on front access panels - controls access panel

controls access panel - compressor access panels - FPT water

- com pres sor access panels - FPT water con nec tions - high and low

connections - high and low voltage knockouts - 1” (25mm), air lter

voltage knock outs - 1” (25mm), air lter and lter rack. All vertical

and lter rack. All vertical units have a left or right return air option,

units have a left or right return air option, sizes 015 - 030 have a front

sizes 006-030 have a front return option. All horizontal units have eld

return option. All hor i zon tal units have eld convertible dis charge air

convertible discharge air patterns with extra parts required.

patterns with no extra parts required.

• Standard Controls - CXM Controller, loss of charge switch, high

pressure switch, water coil low temperature cutout, lockout safety

circuit resetable at ther mo stat or dis con nect, LED fault indication,

ve minute anti-short cycle protection, random start, high and low

voltage pro tec tion, con den sate over ow pro tec tion, dry contact for

alarm.

• Compressor - High ef ciency hermetic scroll or rotary, overload

pro tect ed - internally sprung & externally isolated using dual vibration

dampening system for extra quiet operation. Mounting system

incorporates rubber grommet isolation under the compressor and

rubber grommet isolation between the compressor mounting tray and

unit base.

006

5

• Reversing Valve - 4-way, pilot operated, solenoid activated in the

cool mode.

• Refrigerant Circuit - Utilizes expansion valve metering device -

copper tubing interconnecting all components - sealed & tested

non-ozone depleting, HFC-410A refrigerant circuit with high & low

side schraeder ports.

• Water to Refrigerant Coil - Tube-in-tube, convoluted copper inner

water tube.

• Refrigerant to Air Coil - Lanced aluminum ns on ri ed copper

tubes.

• Blower Motor - Three-speed PSC direct drive, permanently

lu bri cat ed (Two-speed on 575 volt applications).

• UltraQuiet Option - Compressor incorporates spring mounting

system, 015-060 include compressor discharge muf er, blower

housing is covered with high density noise suppression material.

• Application - Units can be applied in WLHP, GWHP, or GLHP

R-410A refrigerant circuit with high & low

applications.

Page 7

Heat Controller, Inc. HBH/V SERIES Engineering Design Guide

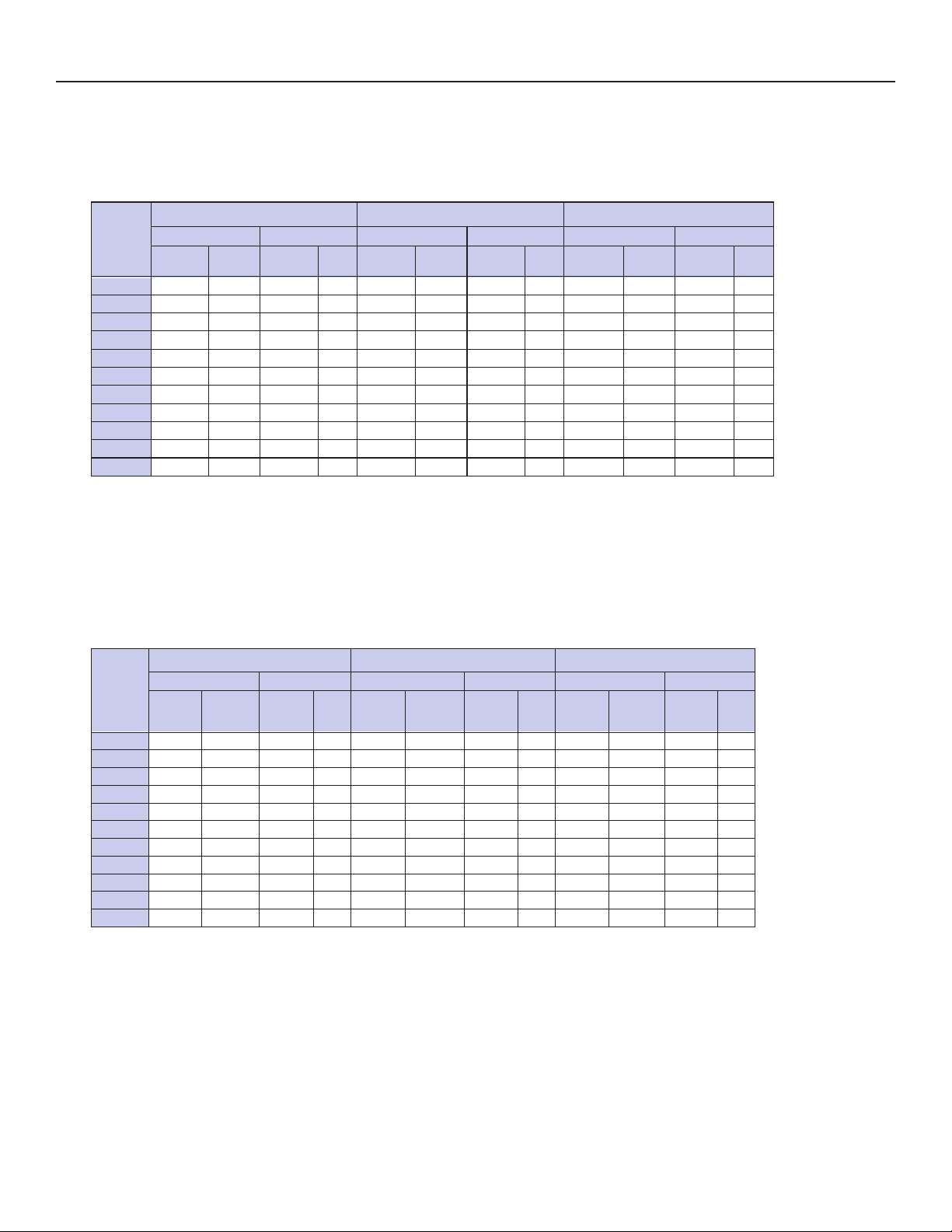

Performance Data

ARI/ASHRAE/ISO 13256-1

ASHRAE/ARI/ISO 13256-1. English (IP) Units

Water Loop Heat Pump Ground Water Heat Pump Ground Loop Heat Pump

Model

HB-006

HB-009

HB-012

HB-015

HB-018

HB-024

HB-030

HB-036

HB-042

HB-048

HB-060

Cooling capacities based upon 80.6°F DB, 66.2°F WB entering air temperature

Heating capacities based upon 68°F DB, 59°F WB entering air temperature

All ratings based upon operation at lower voltage of dual voltage rated models

Cooling 86°F Heating 68°F Cooling 59°F Heating 50°F Cooling 77°F Heating 32°F

Capacity

Btuh

5,800 13.2 7,500 4.7 6,900 21.1 6,200 4.0 6,200 15.4 4,900 3.4

8,800 13.4 11,600 4.2 10,100 21.0 9,800 3.9 9,300 15.7 7,900 3.4

11,700 13.5 15,200 4.3 13,700 20.8 12,500 3.8 12,000 14.9 9,900 3.2

14,500 15.4 17,300 5.0 16,800 24.5 14,400 4.4 15,000 17.2 11,100 3.6

17,300 14.3 21,500 5.0 20,600 24.2 17,200 4.4 18,400 16.3 13,900 3.4

23,700 13.4 28,500 4.7 26,700 20.9 24,000 4.1 24,900 15.4 18,500 3.3

28,100 13.4 35,100 4.6 31,700 20.1 29,600 4.1 28,900 15.1 23,400 3.4

34,500 13.5 45,200 4.4 38,700 20.7 37,500 4.0 35,300 14.9 29,600 3.3

40,100 13.1 52,700 4.3 45,900 19.6 44,000 3.8 40,500 14.4 34,300 3.2

47,700 13.3 55,900 4.7 54,300 20.5 46,500 4.1 49,000 14.7 36,400 3.4

59,400 13.4 77,000 4.3 66,600 19.9 64,000 3.8 60,100 14.8 50,500 3.1

EER

Btuh/W

Capacity

Btuh

COP

Capacity

Btuh

EER

Btuh/W

Capacity

Btuh

COP

Capacity

Btuh6

EER

Btuh/W

Capacity

Btuh

COP

ASHRAE/ARI/ISO 13256-1. Metric (SI) Units

Water Loop Heat Pump Ground Water Heat Pump Ground Loop Heat Pump

Model

HB-006

HB-009

HB-012

HB-015

HB-018

HB-024

HB-030

HB-036

HB-042

HB-048

HB-060

Cooling capacities based upon 27°C DB, 19°C WB entering air temperature

Heating capacities based upon 20°C DB, 15°C WB entering air temperature

All ratings based upon operation at lower voltage of dual voltage rated models

Cooling 30°C Heating 20°C Cooling 15°C Heating 10°C Cooling 25°C Heating 0°C

Capacity

Watts

10.11 4.0 13.24 4.4 11.34 6.1 10.99 4.0 10.34 4.4 8.67 3.3

11.75 3.8 15.44 4.3 13.45 5.7 12.89 3.8 11.87 4.2 10.05 3.2

13.98 3.9 16.38 4.7 15.91 6.0 13.62 4.1 14.36 4.3 10.67 3.4

17.40 3.9 22.56 4.3 19.51 5.8 18.75 3.8 17.61 4.3 14.80 3.1

Cooling

COP W/W

1.70 3.9 2.20 4.7 2.02 6.2 1.82 4.0 1.82 4.5 1.44 3.4

2.58 3.9 3.40 4.2 2.96 6.2 2.87 3.9 2.72 4.6 2.31 3.4

3.43 4.0 4.45 4.3 4.01 6.1 3.66 3.8 3.52 4.4 2.90 3.2

4.25 4.5 5.07 5.0 4.92 7.2 4.22 4.4 4.39 5.0 3.25 3.6

5.07 4.2 6.30 5.0 6.04 7.1 5.04 4.4 5.39 4.8 4.07 3.4

6.94 3.9 8.35 4.7 7.82 6.1 7.03 4.1 7.30 4.5 5.42 3.3

8.23 3.9 10.28 4.6 9.29 5.9 8.67 4.1 8.47 4.4 6.86 3.4

Capacity

Watts

COP

Capacity

Watts

Cooling

COP W/W

Capacity

Watts

COP

Capacity

Watts

Cooling

COP

W/W

Capacity

Watts

COP

6

Page 8

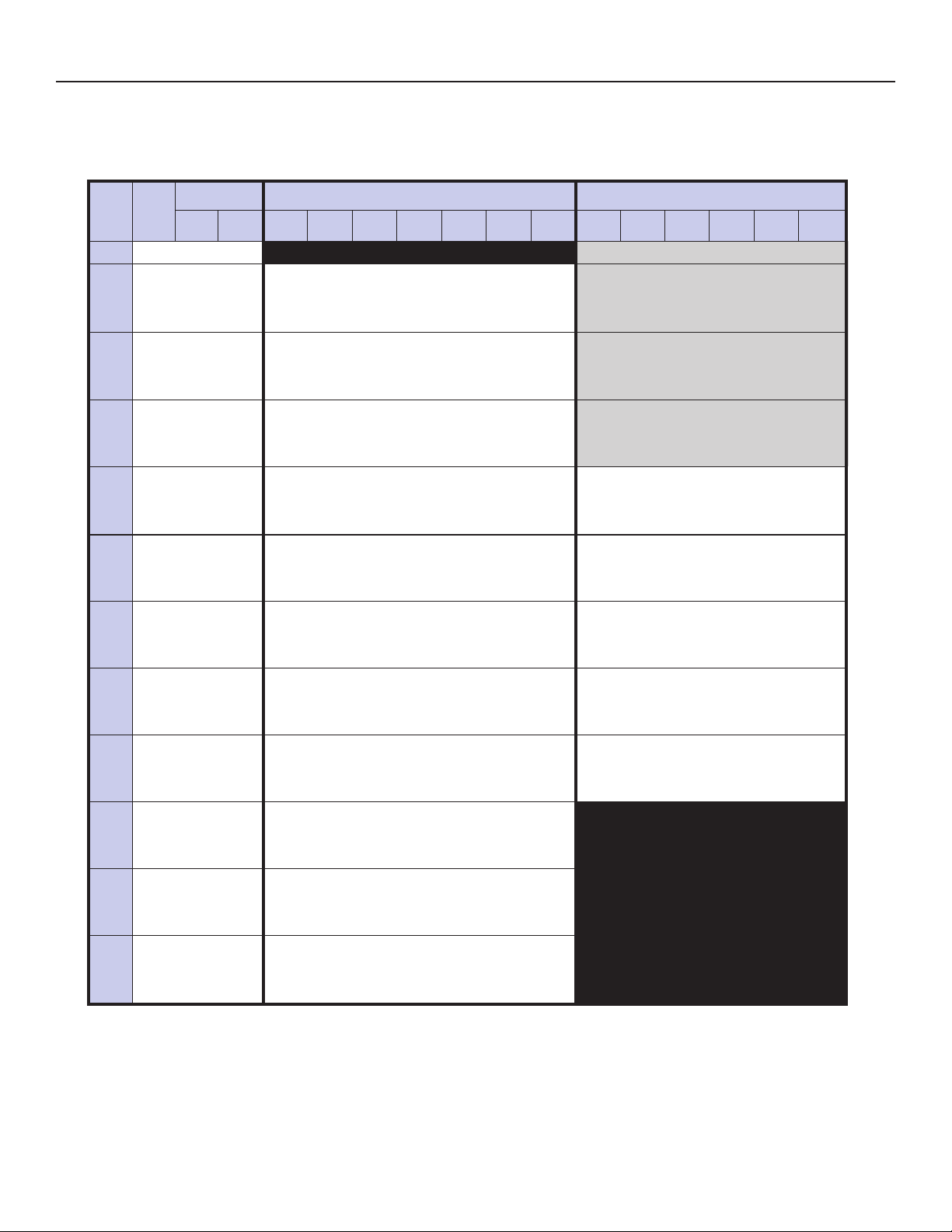

kW HR EER

Airow

CFM

HC kW HE LAT COP

Engineering Design Guide HBH/V SERIES Heat Controller, Inc.

Performance Data

Selection Notes

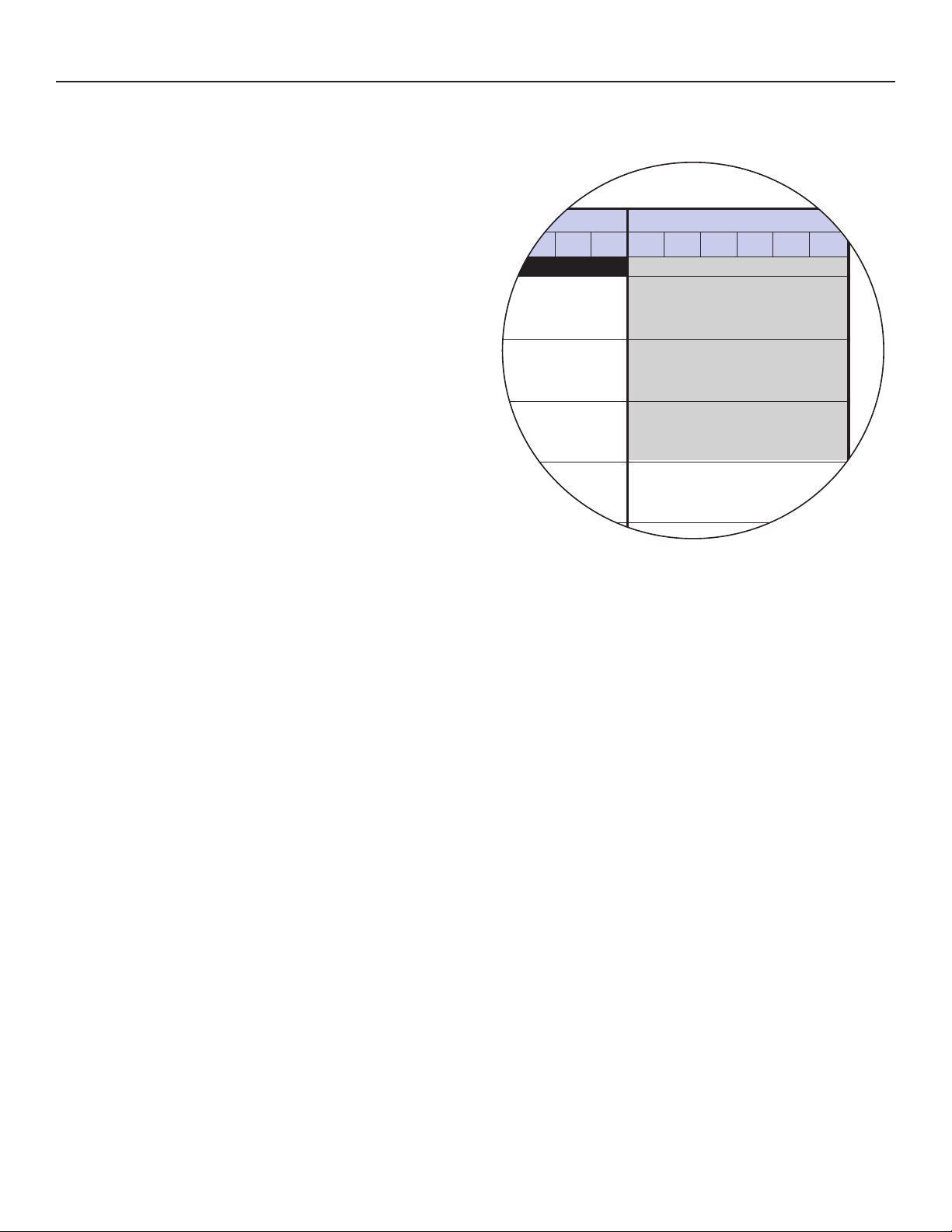

For operation in the shaded area when water is used

in lieu of an anti-freeze solution, the LWT (Leaving

Water Temperature) must be calculated. Flow must be

maintained to a level such that the LWT is maintained

above 40°F [4.4*C] when the JW3 jumper is not clipped

(see example below). This is due to the potential of the

refrigerant temperature being as low as 32°F [0°C] with

40°F [4.4°C] LWT, which may lead to a nuisance cutout

due to the activation of the Low Temperature Protection.

JW3 should never be clipped for standard range

equipment or systems without antifreeze.

Example:

At 50°F EWT (Entering Water Temperature) and 2.25

gpm/ton, a 3 ton unit has a HE of 27,300 Btuh. To

calculate LWT, rearrange the formula for HE as follows:

HE = TD x GPM x 500, where HE = Heat of Extraction

(Btuh); TD = temperature difference (EWT - LWT) and

GPM = U.S. Gallons per Minute.

TD = HE / (GPM x 500)

TD = 27,300 / (6.75 x 500)

TD = 8°F

LWT = EWT - TD

LWT = 50 - 8 = 42°F

In this example, as long as the EWT does not fall below 50°F, the system will operate as designed. For EWTs below

50°F, higher ow rates will be required (open loop systems, for example, require at least 2 gpm/ton when EWT is

below 50°F).

7

Page 9

Heat Controller, Inc. HBH/V SERIES Engineering Design Guide

Performance Data

HBH/V 006

Performance capacities shown in thousands of Btuh220 CFM Nominal (Rated) Airow

EWT

GPM

°F

1.5 1.7 4.0 395 170 4.3 0.49 2.7 93.3 2.6

20 Operation not recommended

1.5 1.7 4.0 525 225 4.4 0.44 2.9 88.0 2.9

0.8 0.5 1.2 170 7.4 4.2 0.57 0.28 8.4 26.4 170 4.6 0.50 3.0 95.2 2.7

0.8 0.5 1.2 225 7.7 4.8 0.62 0.29 8.7 26.4 225 4.7 0.45 3.2 89.5 3.1

1.1 0.8 1.8 170 7.4 4.1 0.55 0.26 8.3 28.5 170 4.8 0.51 3.2 96.2 2.8

30

1.1 0.8 1.8 225 7.7 4.6 0.60 0.27 8.6 28.5 225 4.9 0.46 3.4 90.3 3.2

1.5 1.3 2.9 170 7.3 4.0 0.54 0.25 8.2 29.2 170 4.9 0.51 3.2 96.8 2.8

1.5 1.3 2.9 225 7.6 4.5 0.59 0.26 8.5 29.2 225 5.0 0.46 3.5 90.7 3.2

0.8 0.4 0.9 170 7.3 4.3 0.59 0.31 8.3 23.2 170 5.3 0.52 3.6 98.8 3.0

0.8 0.4 0.9 225 7.6 4.8 0.64 0.33 8.7 23.2 225 5.4 0.47 3.8 92.3 3.4

1.1 0.6 1.4 170 7.4 4.2 0.57 0.29 8.4 25.8 170 5.5 0.53 3.8 100.2 3.1

40

1.1 0.6 1.4 225 7.7 4.8 0.62 0.30 8.7 25.8 225 5.7 0.47 4.1 93.3 3.5

1.5 1.0 2.4 170 7.4 4.2 0.56 0.28 8.4 26.9 170 5.7 0.53 3.9 100.9 3.1

1.5 1.0 2.4 225 7.7 4.7 0.61 0.29 8.7 26.9 225 5.8 0.48 4.2 93.9 3.6

0.8 0.3 0.8 170 6.9 4.2 0.61 0.35 8.1 19.9 170 6.0 0.54 4.2 102.7 3.3

0.8 0.3 0.8 225 7.2 4.8 0.66 0.36 8.5 19.9 225 6.1 0.48 4.5 95.3 3.7

1.1 0.5 1.2 170 7.2 4.3 0.59 0.32 8.3 22.5 170 6.3 0.55 4.5 104.4 3.4

50

1.1 0.5 1.2 225 7.5 4.8 0.64 0.33 8.6 22.5 225 6.5 0.49 4.8 96.6 3.9

1.5 0.9 2.0 170 7.3 4.3 0.58 0.31 8.3 23.8 170 6.5 0.55 4.6 105.4 3.4

1.5 0.9 2.0 225 7.6 4.8 0.63 0.32 8.7 23.8 225 6.7 0.50 5.0 97.4 3.9

0.8 0.3 0.6 170 6.5 4.1 0.63 0.39 7.9 16.8 170 6.7 0.56 4.9 106.7 3.5

0.8 0.3 0.6 225 6.8 4.7 0.69 0.40 8.2 16.8 225 6.9 0.50 5.2 98.4 4.0

1.1 0.5 1.0 170 6.9 4.2 0.61 0.36 8.1 19.1 170 7.1 0.57 5.2 108.6 3.7

60

1.1 0.5 1.0 225 7.1 4.8 0.67 0.37 8.4 19.1 225 7.3 0.51 5.5 99.9 4.2

1.5 0.8 1.8 170 7.0 4.2 0.61 0.34 8.2 20.4 170 7.3 0.57 5.3 109.7 3.7

1.5 0.8 1.8 225 7.3 4.8 0.66 0.36 8.5 20.4 225 7.5 0.51 5.7 100.7 4.3

0.8 0.2 0.5 170 6.0 4.0 0.66 0.43 7.5 14.0 170 7.4 0.58 5.5 110.5 3.8

0.8 0.2 0.5 225 6.3 4.5 0.72 0.45 7.8 14.0 225 7.6 0.52 5.9 101.4 4.3

1.1 0.4 0.9 170 6.4 4.1 0.64 0.40 7.8 16.0 170 7.8 0.58 5.8 112.4 3.9

70

1.1 0.4 0.9 225 6.7 4.6 0.70 0.42 8.1 16.0 225 8.0 0.53 6.2 102.8 4.5

1.5 0.7 1.6 170 6.6 4.1 0.63 0.38 7.9 17.1 170 8.0 0.59 5.9 113.4 4.0

1.5 0.7 1.6 225 6.8 4.7 0.69 0.40 8.2 17.1 225 8.2 0.53 6.4 103.6 4.5

0.8 0.2 0.5 170 5.6 3.8 0.68 0.47 7.2 12.0 170 7.9 0.59 5.9 113.2 4.0

0.8 0.2 0.5 225 5.8 4.3 0.74 0.49 7.5 12.0 225 8.1 0.53 6.3 103.5 4.5

1.1 0.4 0.8 170 5.9 3.9 0.67 0.45 7.4 13.2 170 8.3 0.60 6.3 115.4 4.1

80

1.1 0.4 0.8 225 6.1 4.4 0.73 0.46 7.7 13.2 225 8.5 0.54 6.7 105.1 4.6

1.5 0.6 1.5 170 6.2 4.0 0.65 0.42 7.6 14.7 170 8.4 0.60 6.3 115.7 4.1

1.5 0.6 1.5 225 6.4 4.6 0.71 0.44 7.9 14.7 225 8.6 0.54 6.7 105.3 4.6

0.8 0.2 0.5 170 5.3 3.7 0.70 0.5 7.0 10.7 170 8.2 0.60 6.2 114.7 4.0

0.8 0.2 0.5 225 5.5 4.2 0.76 0.52 7.3 10.7 225 8.4 0.5 6.6 104.6 4.6

1.1 0.3 0.8 170 5.6 3.8 0.68 0.47 7.2 11.9 170 8.5 0.6 6.4 116.2 4.1

85

1.1 0.3 0.8 225 5.8 4.3 0.74 0.49 7.5 11.9 225 8.7 0.5 6.8 105.8 4.7

1.5 0.6 1.4 170 5.8 3.9 0.67 0.45 7.4 13.1 170 8.5 0.6 6.4 116.4 4.1

1.5 0.6 1.4 225 6.1 4.4 0.73 0.47 7.7 13.1 225 8.7 0.5 6.8 105.9 4.7

0.8 0.2 0.4 170 5.0 3.6 0.72 0.53 6.7 9.4 170 8.5 0.61 6.4 116.3 4.1

0.8 0.2 0.4 225 5.2 4.1 0.79 0.55 7.0 9.4 225 8.7 0.55 6.8 105.8 4.7

1.1 0.3 0.7 170 5.3 3.7 0.70 0.49 7.0 10.7 170 8.6 0.62 6.5 117.0 4.1

90

1.1 0.3 0.7 225 5.5 4.2 0.76 0.52 7.3 10.7 225 8.8 0.55 7.0 106.4 4.7

1.5 0.6 1.3 170 5.5 3.8 0.69 0.48 7.1 11.5 170 8.7 0.62 6.5 117.1 4.1

1.5 0.6 1.3 225 5.7 4.3 0.75 0.50 7.4 11.5 225 8.9 0.56 7.0 106.5 4.7

0.8 0.2 0.4 170 4.4 3.4 0.76 0.58 6.4 7.6 395

0.8 0.2 0.4 225 4.6 3.8 0.83 0.60 6.6 7.6 525

1.1 0.3 0.7 170 4.7 3.5 0.74 0.55 6.6 8.7 395

100

1.1 0.3 0.7 225 4.9 4.0 0.80 0.57 6.9 8.7 525

1.5 0.5 1.2 170 4.9 3.6 0.73 0.53 6.7 9.3 395

1.5 0.5 1.2 225 5.1 4.0 0.79 0.55 7.0 9.3 525

0.8 0.2 0.3 170 3.9 3.1 0.81 0.63 6.0 6.2 395

0.8 0.2 0.3 225 4.1 3.6 0.87 0.66 6.3 6.2 525

1.1 0.3 0.6 170 4.2 3.3 0.78 0.60 6.2 7.0 395

110

1.1 0.3 0.6 225 4.4 3.7 0.85 0.62 6.5 7.0 525

1.5 0.5 1.2 170 4.3 3.3 0.77 0.58 6.3 7.4 395

1.5 0.5 1.2 225 4.5 3.8 0.83 0.61 6.6 7.4 525

0.8 0.1 0.3 170 3.5 3.0 0.85 0.68 5.8 5.0 395

0.8 0.1 0.3 225 3.6 3.3 0.93 0.71 6.0 5.0 525

1.1 0.3 0.6 170 3.7 3.0 0.83 0.65 5.9 5.6 395

120

1.1 0.3 0.6 225 3.8 3.4 0.90 0.68 6.2 5.6 525

1.5 0.5 1.1 170 3.8 3.1 0.81 0.64 6.0 6.0 395

1.5 0.5 1.1 225 4.0 3.5 0.88 0.67 6.2 6.0 525

Interpolation is permissible; extrapolation is not.

All entering air conditions are 80°F DB and 67°F WB in cooling, and 70°F DB in heating.

ARI/ISO certied conditions are 80.6°F DB and 66.2°F WB in cooling and 68°F DB in heating.

Table does not reect fan or pump power corrections for ARI/ISO conditions.

All performance is based upon the lower voltage of dual voltage rated units.

Performance stated is at the rated power supply; performance may vary as the power supply varies from the rated.

Operation below 40°F EWT is based upon a 15% antifreeze solution.

Operation below 60°F EWT requires optional insulated water/refrigerant circuit.

See performance correction tables for operating conditions other than those listed above.

See Performance Data Selection Notes for operation in the shaded areas.

WPD Cooling - EAT 80/67°F Heating - EAT 70°F

PSI FT

Airow

CFM

TC SC

Sens/Tot

Ratio

kW HR EER

Airow

CFM

HC kW HE LAT COP

Operation not recommended

8

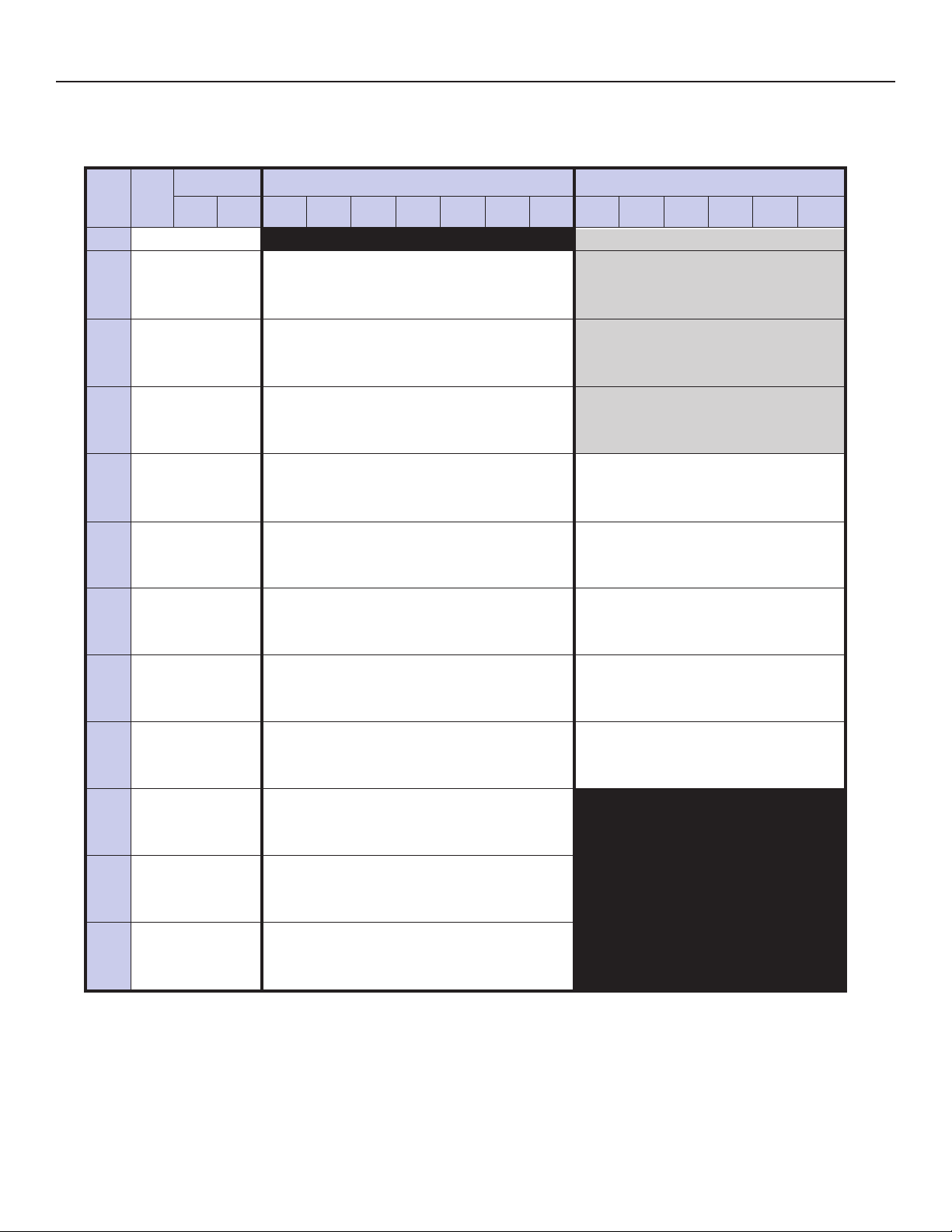

Page 10

Engineering Design Guide HBH/V SERIES Heat Controller, Inc.

Performance Data

HBH/V 009

Performance capacities shown in thousands of Btuh325 CFM Nominal (Rated) Airow

EWT

GPM

°F

2.3 4.5 10.5 395 250 6.5 0.73 4.2 94.2 2.6

20 Operation not recommended

2.3 4.5 10.5 525 330 6.7 0.66 4.4 88.8 3.0

1.1 1.3 3.0 250 10.2 6.0 0.59 0.39 11.6 26.6 250 7.1 0.74 4.7 96.3 2.8

1.1 1.3 3.0 330 10.7 6.8 0.64 0.40 12.0 26.6 330 7.3 0.67 5.0 90.4 3.2

1.7 1.9 4.4 250 10.5 6.0 0.57 0.36 11.7 29.5 250 7.4 0.75 4.9 97.4 2.9

30

1.7 1.9 4.4 330 10.9 6.8 0.62 0.37 12.2 29.5 330 7.6 0.67 5.3 91.2 3.3

2.3 3.5 8.1 250 10.6 6.0 0.56 0.34 11.8 31.1 250 7.5 0.75 5.1 97.9 2.9

2.3 3.5 8.1 330 11.0 6.8 0.61 0.36 12.3 31.1 330 7.7 0.68 5.4 91.7 3.4

1.1 0.9 2.0 250 9.9 6.0 0.61 0.43 11.3 22.8 250 8.0 0.76 5.5 99.8 3.1

1.1 0.9 2.0 330 10.3 6.8 0.66 0.45 11.8 22.8 330 8.2 0.69 5.9 93.1 3.5

1.7 1.5 3.5 250 10.1 6.0 0.59 0.40 11.5 25.4 250 8.4 0.77 5.8 101.1 3.2

40

1.7 1.5 3.5 330 10.5 6.8 0.64 0.41 12.0 25.4 330 8.6 0.69 6.2 94.1 3.6

2.3 3.0 6.8 250 10.3 6.0 0.59 0.38 11.6 26.8 250 8.6 0.78 6.0 101.8 3.2

2.3 3.0 6.8 330 10.7 6.8 0.64 0.40 12.0 26.9 330 8.8 0.70 6.4 94.7 3.7

1.1 0.6 1.5 250 9.4 6.0 0.63 0.48 11.1 19.5 250 9.0 0.79 6.4 103.3 3.4

1.1 0.6 1.5 330 9.8 6.7 0.69 0.50 11.6 19.5 330 9.2 0.71 6.8 95.8 3.8

1.7 1.3 2.9 250 9.7 6.0 0.62 0.45 11.3 21.7 250 9.4 0.80 6.7 104.8 3.5

50

1.7 1.3 2.9 330 10.1 6.8 0.67 0.47 11.7 21.7 330 9.6 0.72 7.2 97.0 3.9

2.3 2.6 6.0 250 9.9 6.0 0.61 0.43 11.3 23.0 250 9.6 0.80 6.9 105.6 3.5

2.3 2.6 6.0 330 10.3 6.8 0.66 0.45 11.8 23.0 330 9.8 0.72 7.4 97.6 4.0

1.1 0.5 1.2 250 9.0 5.9 0.65 0.54 10.8 16.5 250 9.9 0.81 7.2 106.8 3.6

1.1 0.5 1.2 330 9.4 6.7 0.71 0.57 11.3 16.5 330 10.2 0.73 7.7 98.5 4.1

1.7 1.1 2.5 250 9.3 5.9 0.64 0.50 11.0 18.5 250 10.4 0.82 7.6 108.4 3.7

60

1.7 1.1 2.5 330 9.7 6.7 0.69 0.52 11.5 18.5 330 10.6 0.74 8.1 99.8 4.2

2.3 2.3 5.4 250 9.5 6.0 0.63 0.48 11.1 19.6 250 10.6 0.83 7.8 109.3 3.7

2.3 2.3 5.4 330 9.8 6.7 0.69 0.50 11.6 19.6 330 10.9 0.75 8.3 100.5 4.3

1.1 0.4 0.9 250 8.5 5.8 0.68 0.61 10.6 14.0 250 10.8 0.84 8.0 110.1 3.8

1.1 0.4 0.9 330 8.8 6.5 0.74 0.63 11.0 14.0 330 11.1 0.75 8.5 101.1 4.3

1.7 1.0 2.3 250 8.8 5.8 0.66 0.56 10.7 15.6 250 11.3 0.85 8.4 111.9 3.9

70

1.7 1.0 2.3 330 9.2 6.6 0.72 0.59 11.2 15.6 330 11.6 0.77 9.0 102.5 4.4

2.3 2.1 4.9 250 9.1 5.9 0.65 0.53 10.9 17.1 250 11.4 0.85 8.5 112.1 3.9

2.3 2.1 4.9 330 9.5 6.7 0.71 0.55 11.3 17.1 330 11.6 0.77 9.0 102.7 4.4

1.1 0.3 0.8 250 8.0 5.6 0.70 0.67 10.3 11.8 250 11.7 0.87 8.7 113.3 4.0

1.1 0.3 0.8 330 8.3 6.3 0.77 0.70 10.7 11.8 330 12.0 0.78 9.3 103.6 4.5

1.7 0.9 2.1 250 8.3 5.7 0.69 0.63 10.5 13.2 250 12.2 0.88 9.1 115.1 4.0

80

1.7 0.9 2.1 330 8.6 6.5 0.75 0.66 10.9 13.2 330 12.5 0.79 9.8 105.0 4.6

2.3 2.0 4.6 250 8.6 5.8 0.67 0.59 10.6 14.4 250 12.2 0.88 9.2 115.4 4.1

2.3 2.0 4.6 330 8.9 6.5 0.73 0.62 11.1 14.4 330 12.5 0.79 9.8 105.2 4.6

1.1 0.3 0.7 250 7.7 5.5 0.71 0.7 10.1 11.0 250 12.0 0.88 9.0 114.5 4.0

1.1 0.3 0.7 330 8.0 6.2 0.78 0.73 10.5 11.0 330 12.3 0.8 9.6 104.6 4.6

1.7 0.9 2.0 250 8.0 5.6 0.70 0.67 10.3 12.1 250 12.6 0.9 9.5 116.5 4.1

85

1.7 0.9 2.0 330 8.4 6.4 0.76 0.69 10.7 12.1 330 12.9 0.8 10.1 106.1 4.7

2.3 1.9 4.4 250 8.3 5.7 0.69 0.63 10.5 13.3 250 12.6 0.9 9.5 116.8 4.1

2.3 1.9 4.4 330 8.7 6.5 0.75 0.65 10.9 13.3 330 12.9 0.8 10.2 106.3 4.7

1.1 0.3 0.6 250 7.5 5.4 0.72 0.73 10.0 10.2 250 12.3 0.89 9.3 115.7 4.1

1.1 0.3 0.6 330 7.8 6.2 0.79 0.76 10.4 10.2 330 12.6 0.80 9.9 105.5 4.6

1.7 0.8 1.9 250 7.7 5.5 0.71 0.70 10.1 11.1 250 12.9 0.91 9.8 117.9 4.2

90

1.7 0.8 1.9 330 8.1 6.3 0.78 0.73 10.6 11.1 330 13.3 0.82 10.5 107.2 4.8

2.3 1.8 4.3 250 8.0 5.6 0.70 0.66 10.3 12.1 250 13.0 0.91 9.9 118.2 4.2

2.3 1.8 4.3 330 8.4 6.4 0.76 0.69 10.7 12.1 330 13.3 0.82 10.5 107.4 4.8

1.1 0.2 0.6 250 6.8 5.1 0.76 0.82 9.6 8.2 395

1.1 0.2 0.6 330 7.0 5.8 0.82 0.86 10.0 8.2 525

1.7 0.8 1.7 250 7.1 5.3 0.74 0.78 9.8 9.2 395

100

1.7 0.8 1.7 330 7.4 6.0 0.81 0.81 10.2 9.2 525

2.3 1.7 4.0 250 7.3 5.4 0.73 0.75 9.9 9.7 395

2.3 1.7 4.0 330 7.6 6.1 0.80 0.78 10.3 9.7 525

1.1 0.2 0.5 250 6.1 4.8 0.79 0.90 9.2 6.8 395

1.1 0.2 0.5 330 6.3 5.4 0.85 0.94 9.5 6.8 525

1.7 0.7 1.6 250 6.5 5.0 0.77 0.86 9.4 7.6 395

110

1.7 0.7 1.6 330 6.8 5.6 0.84 0.89 9.8 7.6 525

2.3 1.6 3.8 250 6.7 5.1 0.76 0.83 9.5 8.0 395

2.3 1.6 3.8 330 7.0 5.8 0.83 0.87 9.9 8.0 525

1.1 0.2 0.4 250 5.4 4.4 0.82 0.98 8.7 5.5 395

1.1 0.2 0.4 330 5.6 5.0 0.89 1.02 9.1 5.5 525

1.7 0.7 1.6 250 5.8 4.6 0.80 0.94 9.0 6.2 395

120

1.7 0.7 1.6 330 6.0 5.2 0.87 0.98 9.4 6.2 525

2.3 1.6 3.6 250 6.0 4.7 0.79 0.91 9.1 6.5 395

2.3 1.6 3.6 330 6.2 5.4 0.86 0.95 9.5 6.5 525

Interpolation is permissible; extrapolation is not.

All entering air conditions are 80°F DB and 67°F WB in cooling, and 70°F DB in heating.

ARI/ISO certied conditions are 80.6°F DB and 66.2°F WB in cooling and 68°F DB in heating.

Table does not reect fan or pump power corrections for ARI/ISO conditions.

All performance is based upon the lower voltage of dual voltage rated units.

Performance stated is at the rated power supply; performance may vary as the power supply varies from the rated.

Operation below 40°F EWT is based upon a 15% antifreeze solution.

Operation below 60°F EWT requires optional insulated water/refrigerant circuit.

See performance correction tables for operating conditions other than those listed above.

See Performance Data Selection Notes for operation in the shaded areas.

WPD Cooling - EAT 80/67°F Heating - EAT 70°F

PSI FT

Airow

CFM

TC SC

Sens/Tot

Ratio

kW HR EER

Airow

CFM

HC kW HE LAT COP

Operation not recommended

9

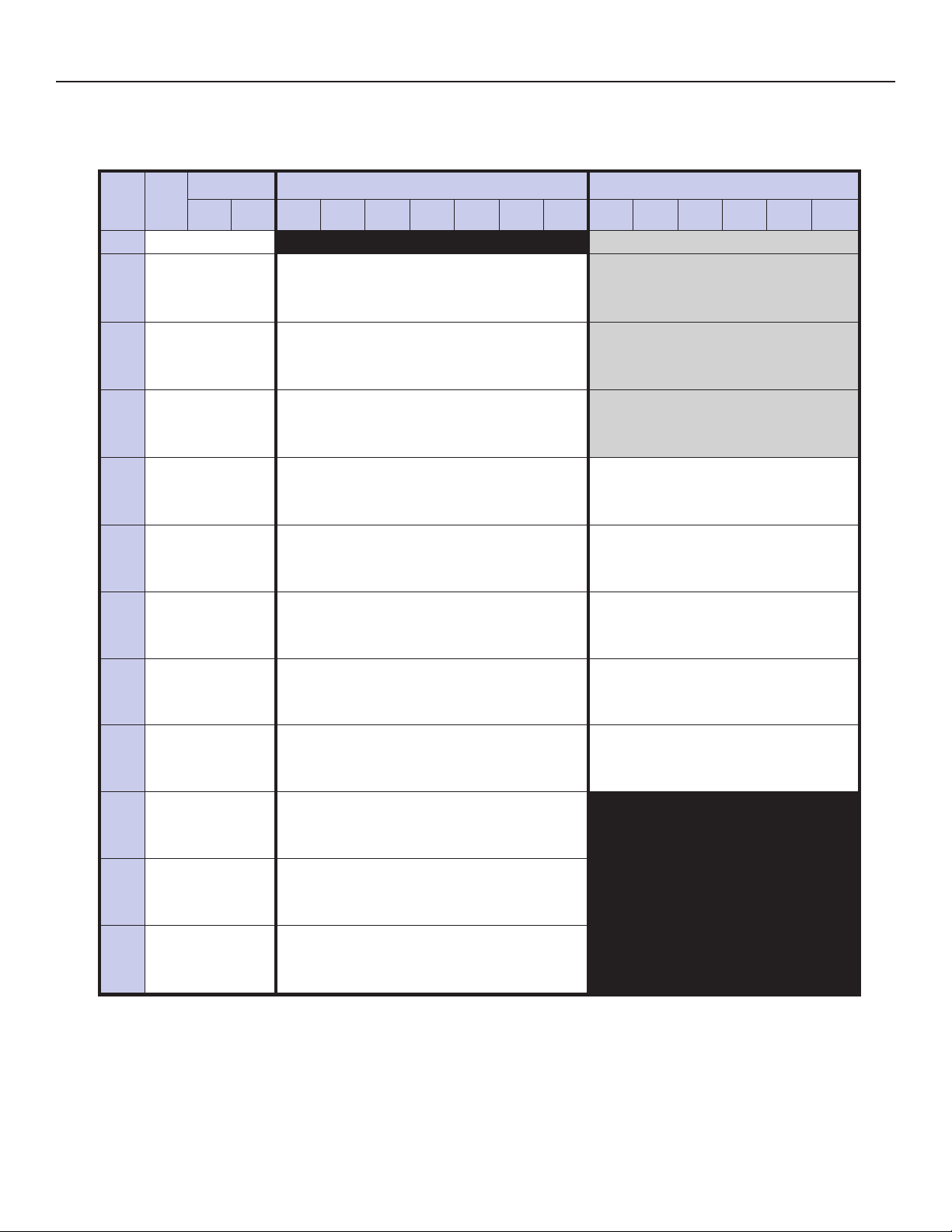

Page 11

Heat Controller, Inc. HBH/V SERIES Engineering Design Guide

Performance Data

HBH/V 012

Performance capacities shown in thousands of Btuh400 CFM Nominal (Rated) Airow

EWT

GPM

°F

3.0 8.5 19.6 300 300 8.5 0.98 5.3 96.2 2.5

20 Operation not recommended

3.0 8.5 19.6 400 400 8.7 0.88 5.7 90.2 2.9

1.5 1.9 4.3 300 14.2 8.2 0.58 0.55 16.1 25.8 300 9.3 1.00 6.0 98.6 2.7

1.5 1.9 4.3 400 14.8 9.3 0.63 0.57 16.8 25.8 400 9.5 0.90 6.4 91.9 3.1

2.3 3.6 8.4 300 14.3 8.2 0.58 0.51 16.1 27.9 300 9.6 1.01 6.3 99.7 2.8

30

2.3 3.6 8.4 400 14.9 9.3 0.63 0.53 16.7 27.9 400 9.9 0.91 6.8 92.8 3.2

3.0 6.7 15.5 300 14.3 8.2 0.58 0.50 16.0 28.8 300 9.8 1.02 6.5 100.4 2.8

3.0 6.7 15.5 400 14.9 9.3 0.63 0.52 16.6 28.8 400 10.1 0.92 7.0 93.3 3.2

1.5 1.4 3.2 300 14.0 8.1 0.58 0.61 16.0 22.9 300 10.6 1.04 7.1 102.6 3.0

1.5 1.4 3.2 400 14.5 9.2 0.63 0.63 16.7 22.9 400 10.8 0.93 7.6 95.0 3.4

2.3 3.0 6.9 300 14.2 8.2 0.58 0.57 16.1 25.1 300 11.0 1.05 7.6 104.1 3.1

40

2.3 3.0 6.9 400 14.8 9.3 0.63 0.59 16.8 25.1 400 11.3 0.94 8.1 96.2 3.5

3.0 5.7 13.1 300 14.3 8.2 0.58 0.54 16.1 26.2 300 11.3 1.06 7.8 104.9 3.1

3.0 5.7 13.1 400 14.8 9.3 0.63 0.57 16.8 26.2 400 11.6 0.95 8.3 96.8 3.6

1.5 1.1 2.5 300 13.5 7.9 0.58 0.67 15.8 20.1 300 11.9 1.08 8.3 106.8 3.2

1.5 1.1 2.5 400 14.1 8.9 0.63 0.70 16.5 20.1 400 12.2 0.97 8.9 98.2 3.7

2.3 2.6 6.0 300 13.9 8.0 0.58 0.62 16.0 22.2 300 12.5 1.09 8.9 108.6 3.4

50

2.3 2.6 6.0 400 14.4 9.1 0.63 0.65 16.7 22.2 400 12.8 0.98 9.5 99.6 3.8

3.0 5.0 11.5 300 14.0 8.1 0.58 0.60 16.1 23.3 300 12.8 1.10 9.1 109.6 3.4

3.0 5.0 11.5 400 14.6 9.2 0.63 0.63 16.7 23.3 400 13.1 0.99 9.8 100.4 3.9

1.5 0.9 2.1 300 12.9 7.6 0.59 0.74 15.5 17.4 300 13.3 1.11 9.6 111.1 3.5

1.5 0.9 2.1 400 13.5 8.6 0.64 0.77 16.1 17.4 400 13.6 1.00 10.2 101.5 4.0

2.3 2.3 5.3 300 13.4 7.8 0.58 0.69 15.7 19.3 300 14.0 1.13 10.2 113.1 3.6

60

2.3 2.3 5.3 400 13.9 8.8 0.63 0.72 16.4 19.3 400 14.3 1.02 10.8 103.1 4.1

3.0 4.5 10.3 300 13.6 7.9 0.58 0.67 15.8 20.4 300 14.3 1.14 10.5 114.2 3.7

3.0 4.5 10.3 400 14.1 8.9 0.63 0.69 16.5 20.4 400 14.7 1.03 11.2 104.0 4.2

1.5 0.8 1.8 300 12.2 7.3 0.60 0.82 15.0 14.9 300 14.7 1.15 10.8 115.3 3.7

1.5 0.8 1.8 400 12.7 8.3 0.65 0.85 15.6 14.9 400 15.0 1.04 11.5 104.8 4.2

2.3 2.1 4.8 300 12.5 7.4 0.59 0.77 15.2 16.3 300 15.4 1.18 11.4 117.6 3.8

70

2.3 2.1 4.8 400 13.1 8.4 0.64 0.80 15.8 16.3 400 15.8 1.06 12.2 106.5 4.4

3.0 4.1 9.5 300 12.7 7.5 0.59 0.75 15.3 17.0 300 15.8 1.19 11.7 118.8 3.9

3.0 4.1 9.5 400 13.3 8.5 0.64 0.78 15.9 17.0 400 16.2 1.07 12.5 107.5 4.4

1.5 0.7 1.5 300 11.4 7.0 0.61 0.90 14.5 12.7 300 16.0 1.20 11.9 119.4 3.9

1.5 0.7 1.5 400 11.9 7.9 0.67 0.94 15.1 12.7 400 16.4 1.08 12.7 108.0 4.5

2.3 1.9 4.4 300 11.8 7.1 0.60 0.85 14.7 13.9 300 16.8 1.22 12.6 121.7 4.0

80

2.3 1.9 4.4 400 12.3 8.0 0.65 0.88 15.3 13.9 400 17.2 1.10 13.4 109.8 4.6

3.0 3.8 8.8 300 12.0 7.2 0.60 0.83 14.8 14.5 300 17.2 1.24 12.9 123.0 4.1

3.0 3.8 8.8 400 12.5 8.1 0.65 0.86 15.4 14.5 400 17.6 1.11 13.8 110.7 4.6

1.5 0.6 1.5 300 10.9 6.8 0.62 0.9 14.2 11.7 300 16.6 1.22 12.5 121.3 4.0

1.5 0.6 1.5 400 11.4 7.7 0.68 0.98 14.7 11.7 400 17.0 1.1 13.3 109.4 4.6

2.3 1.8 4.2 300 11.4 6.9 0.61 0.89 14.4 12.8 300 17.4 1.3 13.1 123.6 4.1

85

2.3 1.8 4.2 400 11.9 7.9 0.66 0.93 15.0 12.8 400 17.8 1.1 14.0 111.2 4.6

3.0 3.7 8.5 300 11.6 7.0 0.60 0.87 14.5 13.4 300 17.7 1.3 13.4 124.8 4.1

3.0 3.7 8.5 400 12.1 7.9 0.66 0.90 15.1 13.4 400 18.2 1.1 14.3 112.1 4.7

1.5 0.6 1.4 300 10.5 6.7 0.63 0.99 13.9 10.7 300 17.3 1.24 13.0 123.3 4.1

1.5 0.6 1.4 400 10.9 7.5 0.69 1.03 14.4 10.7 400 17.7 1.12 13.9 110.9 4.6

2.3 1.8 4.1 300 11.0 6.8 0.62 0.93 14.1 11.7 300 18.0 1.28 13.6 125.5 4.1

90

2.3 1.8 4.1 400 11.4 7.7 0.67 0.97 14.7 11.7 400 18.4 1.15 14.5 112.6 4.7

3.0 3.6 8.2 300 11.2 6.8 0.61 0.91 14.3 12.3 300 18.3 1.29 13.9 126.6 4.2

3.0 3.6 8.2 400 11.6 7.7 0.67 0.95 14.8 12.3 400 18.8 1.16 14.8 113.5 4.7

1.5 0.5 1.2 300 9.5 6.4 0.67 1.07 13.2 8.9 300

1.5 0.5 1.2 400 9.9 7.2 0.72 1.12 13.8 8.9 400

2.3 1.7 3.8 300 10.1 6.5 0.65 1.02 13.5 9.8 300

100

2.3 1.7 3.8 400 10.5 7.3 0.70 1.06 14.1 9.8 400

3.0 3.3 7.7 300 10.4 6.6 0.64 1.00 13.8 10.4 300

3.0 3.3 7.7 400 10.8 7.5 0.69 1.04 14.3 10.4 400

1.5 0.5 1.1 300 8.5 6.0 0.71 1.17 12.5 7.3 300

1.5 0.5 1.1 400 8.9 6.8 0.77 1.22 13.1 7.3 400

2.3 1.6 3.6 300 9.1 6.2 0.68 1.12 12.9 8.1 300

110

2.3 1.6 3.6 400 9.4 7.0 0.74 1.16 13.4 8.1 400

3.0 3.2 7.3 300 9.4 6.3 0.67 1.09 13.1 8.6 300

3.0 3.2 7.3 400 9.8 7.1 0.73 1.14 13.7 8.6 400

1.5 0.4 1.0 300 7.5 5.7 0.76 1.27 11.8 5.9 300

1.5 0.4 1.0 400 7.8 6.4 0.82 1.32 12.3 5.9 400

2.3 1.5 3.4 300 8.0 5.8 0.73 1.22 12.2 6.6 300

120

2.3 1.5 3.4 400 8.3 6.6 0.79 1.27 12.7 6.6 400

3.0 3.0 7.0 300 8.3 5.9 0.71 1.19 12.4 7.0 300

Interpolation is permissible; extrapolation is not.

All entering air conditions are 80°F DB and 67°F WB in cooling, and 70°F DB in heating.

ARI/ISO certied conditions are 80.6°F DB and 66.2°F WB in cooling and 68°F DB in heating.

Table does not reect fan or pump power corrections for ARI/ISO conditions.

All performance is based upon the lower voltage of dual voltage rated units.

Performance stated is at the rated power supply; performance may vary as the power supply varies from the rated.

Operation below 40°F EWT is based upon a 15% antifreeze solution.

Operation below 60°F EWT requires optional insulated water/refrigerant circuit.

See performance correction tables for operating conditions other than those listed above.

See Performance Data Selection Notes for operation in the shaded areas.

3.0 3.0 7.0 400 8.7 6.7 0.77 1.24 12.9 7.0 400

WPD Cooling - EAT 80/67°F Heating - EAT 70°F

PSI FT

Airow

CFM

TC SC

Sens/Tot

Ratio

kW HR EER

Airow

CFM

HC kW HE LAT COP

Operation not recommended

10

Page 12

Engineering Design Guide HBH/V SERIES Heat Controller, Inc.

Performance Data

HBH/V 015

Performance capacities shown in thousands of Btuh525 CFM Nominal (Rated) Airow

EWT

GPM

°F

3.8 4.1 9.5 395 395 9.5 1.07 6.1 92 2.62

20 Operation not recommended

3.8 4.1 9.5 525 525 9.8 0.96 6.5 87 2.98

1.9 1.0 2.3 395 17.3 10.8 0.62 0.61 19.4 28.4 395 10.6 1.09 7.1 95 2.84

1.9 1.0 2.3 525 18.1 12.2 0.67 0.64 20.2 28.4 525 10.9 0.98 7.5 89 3.24

2.8 1.8 4.3 395 17.5 10.8 0.62 0.56 19.4 31.1 395 11.1 1.11 7.5 96 2.94

30

2.8 1.8 4.3 525 18.2 12.2 0.67 0.59 20.2 31.1 525 11.4 0.99 8.0 90 3.35

3.8 3.3 7.7 395 17.5 10.8 0.62 0.54 19.4 32.2 395 11.3 1.11 7.7 97 2.99

3.8 3.3 7.7 525 18.3 12.2 0.67 0.57 20.2 32.2 525 11.6 1.00 8.2 90 3.41

1.9 0.8 1.8 395 17.0 10.6 0.63 0.68 19.3 24.8 395 12.3 1.13 8.5 99 3.18

1.9 0.8 1.8 525 17.7 12.0 0.68 0.71 20.1 24.8 525 12.6 1.02 9.1 92 3.62

2.8 1.6 3.6 395 17.2 10.7 0.62 0.63 19.4 27.3 395 12.8 1.14 9.0 100 3.29

40

2.8 1.6 3.6 525 18.0 12.1 0.68 0.66 20.2 27.3 525 13.1 1.03 9.7 93 3.75

3.8 2.9 6.6 395 17.4 10.8 0.62 0.60 19.4 28.8 395 13.1 1.15 9.3 101 3.35

3.8 2.9 6.6 525 18.1 12.2 0.67 0.63 20.2 28.8 525 13.5 1.03 10.0 94 3.82

1.9 0.6 1.5 395 16.4 10.4 0.63 0.76 19.0 21.6 395 13.9 1.16 10.0 103 3.50

1.9 0.6 1.5 525 17.1 11.8 0.69 0.79 19.8 21.6 525 14.2 1.05 10.7 95 3.99

2.8 1.4 3.1 395 16.8 10.6 0.63 0.71 19.2 23.8 395 14.6 1.18 10.6 104 3.63

50

2.8 1.4 3.1 525 17.5 12.0 0.68 0.74 20.0 23.8 525 14.9 1.06 11.3 96 4.13

3.8 2.5 5.8 395 17.0 10.6 0.63 0.68 19.3 25.0 395 14.9 1.18 10.9 105 3.69

3.8 2.5 5.8 525 17.7 12.0 0.68 0.71 20.1 25.0 525 15.3 1.06 11.7 97 4.21

1.9 0.6 1.3 395 15.7 10.2 0.65 0.84 18.6 18.7 395 15.5 1.20 11.5 106 3.81

1.9 0.6 1.3 525 16.4 11.5 0.70 0.88 19.4 18.7 525 15.9 1.07 12.2 98 4.34

2.8 1.2 2.8 395 16.2 10.4 0.64 0.79 18.9 20.5 395 16.3 1.21 12.1 108 3.94

60

2.8 1.2 2.8 525 16.9 11.7 0.69 0.82 19.7 20.5 525 16.7 1.09 13.0 99 4.50

3.8 2.3 5.3 395 16.4 10.4 0.63 0.76 19.0 21.6 395 16.7 1.22 12.5 109 4.02

3.8 2.3 5.3 525 17.1 11.8 0.69 0.79 19.8 21.6 525 17.1 1.09 13.3 100 4.58

1.9 0.5 1.1 395 15.2 10.1 0.66 0.93 18.3 16.2 395 17.1 1.22 12.9 110 4.10

1.9 0.5 1.1 525 15.8 11.4 0.72 0.97 19.1 16.3 525 17.5 1.10 13.8 101 4.68

2.8 1.1 2.5 395 15.5 10.1 0.65 0.88 18.5 17.6 395 18.0 1.24 13.7 112 4.25

70

2.8 1.1 2.5 525 16.1 11.4 0.71 0.91 19.2 17.6 525 18.4 1.11 14.6 102 4.85

3.8 2.1 4.9 395 15.8 10.2 0.65 0.85 18.6 18.6 395 18.4 1.25 14.1 113 4.33

3.8 2.1 4.9 525 16.4 11.5 0.70 0.88 19.4 18.6 525 18.8 1.12 15.0 103 4.94

1.9 0.4 1.0 395 14.3 9.8 0.68 1.03 17.8 13.9 395 18.7 1.25 14.3 114 4.38

1.9 0.4 1.0 525 14.9 11.1 0.74 1.07 18.5 13.9 525 19.2 1.12 15.3 104 5.00

2.8 1.0 2.4 395 14.7 9.8 0.67 0.97 18.0 15.1 395 19.6 1.27 15.1 116 4.54

80

2.8 1.0 2.4 525 15.3 11.1 0.73 1.01 18.7 15.1 525 20.1 1.14 16.2 105 5.18

3.8 2.0 4.6 395 14.9 9.9 0.66 0.94 18.2 15.9 395 20.1 1.27 15.6 117 4.62

3.8 2.0 4.6 525 15.6 11.2 0.72 0.98 18.9 15.9 525 20.6 1.14 16.6 106 5.27

1.9 0.4 0.9 395 13.8 9.6 0.70 1.1 17.5 12.8 395 19.5 1.26 15.0 116 4.52

1.9 0.4 0.9 525 14.4 10.9 0.76 1.13 18.2 12.8 525 19.9 1.13 16.0 105 5.15

2.8 1.0 2.3 395 14.2 9.7 0.68 1.02 17.7 13.9 395 20.4 1.28 15.9 118 4.68

85

2.8 1.0 2.3 525 14.8 11.0 0.74 1.07 18.4 13.9 525 20.9 1.15 16.9 107 5.34

3.8 1.9 4.4 395 14.5 9.8 0.67 0.99 17.9 14.7 395 20.9 1.29 16.3 119 4.77

3.8 1.9 4.4 525 15.1 11.1 0.73 1.03 18.6 14.7 525 21.4 1.15 17.4 108 5.43

1.9 0.4 0.9 395 13.3 9.5 0.71 1.14 17.2 11.7 395 20.2 1.28 15.7 117 4.65

1.9 0.4 0.9 525 13.9 10.7 0.77 1.19 18.0 11.7 525 20.7 1.15 16.8 107 5.30

2.8 1.0 2.2 395 13.7 9.5 0.69 1.08 17.4 12.8 395 21.2 1.29 16.6 120 4.82

90

2.8 1.0 2.2 525 14.3 10.8 0.75 1.12 18.1 12.8 525 21.7 1.16 17.7 108 5.49

3.8 1.9 4.3 395 14.1 9.6 0.69 1.04 17.6 13.5 395 21.7 1.30 17.1 121 4.90

3.8 1.9 4.3 525 14.6 10.9 0.74 1.08 18.3 13.5 525 22.2 1.17 18.2 109 5.59

1.9 0.4 0.8 395 12.4 9.2 0.74 1.25 16.6 9.9 395

1.9 0.4 0.8 525 12.9 10.4 0.80 1.31 17.3 9.9 525

2.8 0.9 2.1 395 12.8 9.2 0.72 1.19 16.8 10.8 395

100

2.8 0.9 2.1 525 13.3 10.4 0.78 1.23 17.5 10.8 525

3.8 1.8 4.1 395 13.1 9.3 0.71 1.15 17.0 11.4 395

3.8 1.8 4.1 525 13.6 10.5 0.77 1.20 17.7 11.4 525

1.9 0.3 0.7 395 11.3 8.8 0.78 1.37 16.0 8.3 395

1.9 0.3 0.7 525 11.8 10.0 0.84 1.43 16.7 8.3 525

2.8 0.8 1.9 395 11.8 8.9 0.75 1.30 16.2 9.0 395

110

2.8 0.8 1.9 525 12.2 10.0 0.82 1.36 16.9 9.0 525

3.8 1.7 3.9 395 12.1 9.0 0.74 1.27 16.4 9.5 395

3.8 1.7 3.9 525 12.6 10.2 0.81 1.32 17.1 9.5 525

1.9 0.3 0.7 395 10.3 8.5 0.82 1.50 15.5 6.9 395

1.9 0.3 0.7 525 10.8 9.6 0.89 1.56 16.1 6.9 525

2.8 0.8 1.8 395 10.7 8.5 0.79 1.43 15.6 7.5 395

120

2.8 0.8 1.8 525 11.2 9.6 0.86 1.48 16.2 7.5 525

3.8 1.6 3.7 395 11.0 8.6 0.78 1.39 15.8 7.9 395

3.8 1.6 3.7 525 11.5 9.8 0.85 1.45 16.4 7.9 525

Interpolation is permissible; extrapolation is not.

All entering air conditions are 80°F DB and 67°F WB in cooling, and 70°F DB in heating.

ARI/ISO certied conditions are 80.6°F DB and 66.2°F WB in cooling and 68°F DB in heating.

Table does not reect fan or pump power corrections for ARI/ISO conditions.

All performance is based upon the lower voltage of dual voltage rated units.

Performance stated is at the rated power supply; performance may vary as the power supply varies from the rated.

Operation below 40°F EWT is based upon a 15% antifreeze solution.

Operation below 60°F EWT requires optional insulated water/refrigerant circuit.

See performance correction tables for operating conditions other than those listed above.

See Performance Data Selection Notes for operation in the shaded areas.

WPD Cooling - EAT 80/67°F Heating - EAT 70°F

PSI FT

Airow

CFM

TC SC

Sens/Tot

Ratio

kW HR EER

Airow

CFM

HC kW HE LAT COP

Operation not recommended

11

Page 13

Heat Controller, Inc. HBH/V SERIES Engineering Design Guide

Performance Data

HBH/V 018

Performance capacities shown in thousands of Btuh600 CFM Nominal (Rated) Airow

EWT

GPM

°F

4.5 7.2 16.7 450 450 11.2 1.25 7.2 93 2.61

20 Operation not recommended

4.5 7.2 16.7 600 600 11.4 1.13 7.6 88 2.98

2.3 2.1 4.9 450 22.1 14.2 0.64 0.72 24.5 30.7 450 12.4 1.29 8.2 96 2.83

2.3 2.1 4.9 600 23.0 16.1 0.70 0.75 25.5 30.8 600 12.7 1.16 8.8 90 3.22

3.4 3.4 7.9 450 22.9 14.4 0.63 0.64 25.1 35.8 450 12.9 1.30 8.7 97 2.92

30

3.4 3.4 7.9 600 23.9 16.3 0.68 0.67 26.1 35.8 600 13.3 1.17 9.3 90 3.33

4.5 5.9 13.7 450 23.3 14.4 0.62 0.60 25.3 39.0 450 13.2 1.31 9.0 97 2.97

4.5 5.9 13.7 600 24.3 16.3 0.67 0.62 26.4 39.0 600 13.5 1.17 9.6 91 3.38

2.3 1.7 3.9 450 21.1 13.9 0.66 0.82 23.9 25.6 450 14.3 1.33 9.9 99 3.15

2.3 1.7 3.9 600 22.0 15.7 0.72 0.86 24.9 25.6 600 14.7 1.20 10.6 93 3.59

3.4 2.9 6.7 450 21.9 14.2 0.65 0.75 24.4 29.3 450 15.0 1.35 10.5 101 3.26

40

3.4 2.9 6.7 600 22.8 16.0 0.70 0.78 25.4 29.3 600 15.3 1.21 11.2 94 3.72

4.5 5.1 11.8 450 22.5 14.5 0.64 0.71 24.9 31.9 450 15.3 1.35 10.8 102 3.32

4.5 5.1 11.8 600 23.5 16.4 0.70 0.74 25.9 31.9 600 15.7 1.22 11.6 94 3.78

2.3 1.4 3.3 450 20.4 13.7 0.67 0.93 23.5 21.9 450 16.3 1.37 11.7 103 3.47

2.3 1.4 3.3 600 21.2 15.5 0.73 0.97 24.5 22.0 600 16.6 1.23 12.5 96 3.96

3.4 2.6 5.9 450 20.8 13.8 0.66 0.85 23.7 24.4 450 17.0 1.39 12.4 105 3.60

50

3.4 2.6 5.9 600 21.7 15.6 0.72 0.89 24.7 24.4 600 17.4 1.25 13.2 97 4.10

4.5 4.6 10.6 450 21.2 13.9 0.66 0.81 23.9 26.1 450 17.4 1.39 12.7 106 3.67

4.5 4.6 10.6 600 22.1 15.8 0.72 0.85 24.9 26.1 600 17.9 1.25 13.6 98 4.18

2.3 1.3 2.9 450 19.3 13.2 0.68 1.04 22.8 18.6 450 18.2 1.41 13.4 107 3.79

2.3 1.3 2.9 600 20.1 14.9 0.74 1.08 23.8 18.6 600 18.6 1.26 14.3 99 4.32

3.4 2.3 5.3 450 19.8 13.4 0.68 0.96 23.0 20.6 450 19.1 1.42 14.2 109 3.93

60

3.4 2.3 5.3 600 20.6 15.1 0.73 1.00 24.0 20.6 600 19.6 1.28 15.2 100 4.49

4.5 4.2 9.6 450 20.1 13.5 0.67 0.92 23.3 21.9 450 19.6 1.43 14.7 110 4.01

4.5 4.2 9.6 600 21.0 15.3 0.73 0.96 24.2 21.9 600 20.1 1.29 15.7 101 4.58

2.3 1.1 2.6 450 18.2 12.7 0.69 1.15 22.1 15.8 450 20.2 1.44 15.2 112 4.11

2.3 1.1 2.6 600 19.0 14.3 0.76 1.20 23.1 15.8 600 20.7 1.29 16.2 102 4.68

3.4 2.1 4.9 450 18.7 12.8 0.69 1.07 22.3 17.4 450 21.2 1.46 16.1 114 4.27

70

3.4 2.1 4.9 600 19.4 14.5 0.75 1.12 23.2 17.4 600 21.7 1.31 17.2 103 4.86

4.5 3.9 8.9 450 19.1 13.0 0.68 1.03 22.6 18.4 450 21.7 1.46 16.6 115 4.35

4.5 3.9 8.9 600 19.8 14.7 0.74 1.08 23.5 18.4 600 22.3 1.32 17.8 104 4.96

2.3 1.0 2.3 450 17.0 12.1 0.71 1.28 21.4 13.3 450 22.1 1.47 17.0 116 4.41

2.3 1.0 2.3 600 17.7 13.7 0.77 1.33 22.3 13.3 600 22.7 1.32 18.2 105 5.03

3.4 2.0 4.5 450 17.5 12.3 0.70 1.20 21.6 14.7 450 23.3 1.49 18.0 118 4.59

80

3.4 2.0 4.5 600 18.3 13.9 0.76 1.25 22.5 14.7 600 23.9 1.34 19.3 107 5.23

4.5 3.6 8.3 450 17.9 12.5 0.69 1.15 21.9 15.5 450 23.9 1.50 18.6 119 4.68

4.5 3.6 8.3 600 18.7 14.1 0.76 1.20 22.8 15.5 600 24.5 1.35 19.9 108 5.34

2.3 1.0 2.2 450 16.4 11.8 0.72 1.35 21.0 12.2 450 23.1 1.49 17.9 118 4.56

2.3 1.0 2.2 600 17.1 13.3 0.78 1.40 21.9 12.2 600 23.7 1.33 19.1 107 5.20

3.4 1.9 4.4 450 16.9 12.0 0.71 1.26 21.2 13.5 450 24.3 1.50 19.0 120 4.74

85

3.4 1.9 4.4 600 17.6 13.5 0.77 1.31 22.1 13.5 600 24.9 1.35 20.3 108 5.41

4.5 3.5 8.1 450 17.3 12.2 0.70 1.22 21.5 14.3 450 25.0 1.51 19.6 121 4.84

4.5 3.5 8.1 600 18.0 13.8 0.76 1.27 22.4 14.3 600 25.6 1.36 20.9 110 5.51

2.3 0.9 2.1 450 15.8 11.5 0.73 1.42 20.6 11.1 450 24.1 1.50 18.8 120 4.71

2.3 0.9 2.1 600 16.4 13.0 0.79 1.48 21.5 11.1 600 24.7 1.35 20.1 108 5.37

3.4 1.8 4.2 450 16.3 11.7 0.71 1.33 20.8 12.3 450 25.4 1.52 20.0 122 4.89

90

3.4 1.8 4.2 600 17.0 13.2 0.78 1.38 21.7 12.3 600 26.0 1.37 21.3 110 5.58

4.5 3.4 7.9 450 16.7 11.9 0.71 1.28 21.1 13.0 450 26.1 1.53 20.6 124 4.99

4.5 3.4 7.9 600 17.4 13.4 0.77 1.34 22.0 13.0 600 26.7 1.38 22.0 111 5.69

2.3 0.9 2.0 450 14.4 10.8 0.75 1.57 19.8 9.2 450

2.3 0.9 2.0 600 15.0 12.2 0.82 1.63 20.6 9.2 600

3.4 1.7 4.0 450 15.0 11.0 0.74 1.48 20.0 10.1 450

100

3.4 1.7 4.0 600 15.6 12.5 0.80 1.54 20.8 10.1 600

4.5 3.2 7.4 450 15.4 11.2 0.73 1.43 20.3 10.8 450

4.5 3.2 7.4 600 16.0 12.7 0.79 1.49 21.1 10.8 600

2.3 0.8 1.8 450 12.9 10.1 0.78 1.74 18.8 7.4 450

2.3 0.8 1.8 600 13.4 11.4 0.85 1.81 19.6 7.4 600

3.4 1.6 3.8 450 13.5 10.3 0.76 1.64 19.1 8.2 450

110

3.4 1.6 3.8 600 14.0 11.6 0.83 1.71 19.9 8.2 600

4.5 3.1 7.1 450 13.9 10.5 0.75 1.59 19.4 8.8 450

4.5 3.1 7.1 600 14.5 11.9 0.82 1.65 20.2 8.8 600

2.3 0.7 1.7 450 11.2 9.2 0.82 1.92 17.8 5.8 450

2.3 0.7 1.7 600 11.6 10.4 0.89 2.00 18.5 5.8 600

3.4 1.6 3.6 450 11.8 9.5 0.80 1.82 18.1 6.5 450

120

3.4 1.6 3.6 600 12.3 10.7 0.87 1.89 18.8 6.5 600

4.5 2.9 6.8 450 12.3 9.7 0.79 1.77 18.4 7.0 450

4.5 2.9 6.8 600 12.8 11.0 0.86 1.84 19.1 7.0 600

Interpolation is permissible; extrapolation is not.

All entering air conditions are 80°F DB and 67°F WB in cooling, and 70°F DB in heating.

ARI/ISO certied conditions are 80.6°F DB and 66.2°F WB in cooling and 68°F DB in heating.

Table does not reect fan or pump power corrections for ARI/ISO conditions.

All performance is based upon the lower voltage of dual voltage rated units.

Performance stated is at the rated power supply; performance may vary as the power supply varies from the rated.

Operation below 40°F EWT is based upon a 15% antifreeze solution.

Operation below 60°F EWT requires optional insulated water/refrigerant circuit.

See performance correction tables for operating conditions other than those listed above.

See Performance Data Selection Notes for operation in the shaded areas.

WPD Cooling - EAT 80/67°F Heating - EAT 70°F

PSI FT

Airow

CFM

TC SC

Sens/Tot

Ratio

kW HR EER

Airow

CFM

HC kW HE LAT COP

Operation not recommended

12

Page 14

Engineering Design Guide HBH/V SERIES Heat Controller, Inc.

Performance Data

HBH/V 024

800 CFM Nominal (Rated) Airow

EWT

GPM

°F

6.0 8.5 19.6 640 640 15.5 1.91 9.5 92 2.39

20 Operation not recommended

6.0 8.5 19.6 850 850 15.9 1.71 10.1 87 2.72

3.0 2.2 5.2 640 27.7 17.4 0.63 1.12 31.5 24.8 640 17.2 1.93 11.0 95 2.61

3.0 2.2 5.2 850 28.9 19.7 0.68 1.16 32.8 24.8 850 17.6 1.74 11.8 89 2.98

4.5 4.0 9.3 640 28.2 17.5 0.62 1.05 31.8 26.9 640 18.0 1.95 11.7 96 2.70

30

4.5 4.0 9.3 850 29.4 19.8 0.67 1.09 33.1 26.9 850 18.4 1.75 12.5 90 3.08

6.0 7.2 16.7 640 28.5 17.5 0.62 1.02 31.9 28.0 640 18.4 1.95 12.1 97 2.76

6.0 7.2 16.7 850 29.6 19.8 0.67 1.06 33.2 28.0 850 18.8 1.76 12.9 91 3.14

3.0 1.9 4.4 640 26.9 17.1 0.64 1.23 31.1 21.9 640 19.9 1.98 13.4 99 2.94

3.0 1.9 4.4 850 28.0 19.4 0.69 1.28 32.4 21.9 850 20.4 1.78 14.4 92 3.36

4.5 3.6 8.2 640 27.5 17.3 0.63 1.15 31.4 24.0 640 20.8 2.00 14.3 100 3.06

40

4.5 3.6 8.2 850 28.7 19.6 0.68 1.19 32.7 24.0 850 21.3 1.79 15.3 93 3.49

6.0 6.4 14.9 640 27.8 17.4 0.63 1.11 31.5 25.1 640 21.3 2.01 14.7 101 3.12

6.0 6.4 14.9 850 28.9 19.7 0.68 1.16 32.8 25.1 850 21.9 1.80 15.7 94 3.55

3.0 1.7 3.9 640 26.2 16.9 0.65 1.36 30.8 19.3 640 22.6 2.03 15.9 103 3.27

3.0 1.7 3.9 850 27.3 19.1 0.70 1.42 32.1 19.3 850 23.2 1.82 17.0 95 3.72

4.5 3.2 7.4 640 26.7 17.0 0.64 1.26 31.0 21.1 640 23.7 2.05 16.9 104 3.39

50

4.5 3.2 7.4 850 27.8 19.3 0.69 1.32 32.2 21.1 850 24.3 1.84 18.0 96 3.87

6.0 5.9 13.6 640 27.0 17.1 0.64 1.22 31.1 22.1 640 24.3 2.06 17.4 105 3.46

6.0 5.9 13.6 850 28.1 19.4 0.69 1.27 32.4 22.1 850 24.9 1.85 18.6 97 3.94

3.0 1.5 3.5 640 25.3 16.6 0.66 1.52 30.4 16.7 640 25.3 2.08 18.3 107 3.57

3.0 1.5 3.5 850 26.3 18.8 0.71 1.58 31.7 16.7 850 25.9 1.87 19.6 98 4.07

4.5 3.0 6.9 640 25.7 16.7 0.65 1.40 30.5 18.3 640 26.6 2.10 19.4 108 3.70

60

4.5 3.0 6.9 850 26.8 18.9 0.70 1.46 31.7 18.3 850 27.2 1.89 20.7 100 4.22

6.0 5.5 12.6 640 26.1 16.8 0.64 1.35 30.6 19.3 640 27.2 2.12 20.0 109 3.77

6.0 5.5 12.6 850 27.1 19.0 0.70 1.41 31.9 19.3 850 27.9 1.90 21.4 100 4.30

3.0 1.4 3.2 640 24.1 16.2 0.67 1.70 29.9 14.2 640 27.9 2.13 20.7 110 3.84

3.0 1.4 3.2 850 25.1 18.3 0.73 1.77 31.1 14.2 850 28.6 1.91 22.1 101 4.38

4.5 2.8 6.4 640 24.6 16.3 0.66 1.57 30.0 15.7 640 29.2 2.16 21.8 112 3.97

70

4.5 2.8 6.4 850 25.6 18.4 0.72 1.63 31.2 15.7 850 29.9 1.94 23.3 103 4.53

6.0 5.2 11.9 640 25.0 16.4 0.66 1.51 30.1 16.6 640 29.9 2.17 22.5 113 4.04

6.0 5.2 11.9 850 26.0 18.6 0.71 1.57 31.4 16.6 850 30.6 1.95 24.0 103 4.60

3.0 1.3 3.0 640 22.9 15.7 0.69 1.91 29.4 12.0 640 30.4 2.18 22.9 114 4.08

3.0 1.3 3.0 850 23.8 17.8 0.75 1.99 30.6 12.0 850 31.1 1.96 24.4 104 4.65

4.5 2.6 6.1 640 23.4 15.8 0.67 1.76 29.4 13.3 640 31.7 2.21 24.0 116 4.20

80

4.5 2.6 6.1 850 24.4 17.9 0.73 1.84 30.7 13.3 850 32.5 1.99 25.7 105 4.79

6.0 4.9 11.3 640 23.8 16.0 0.67 1.70 29.6 14.1 640 32.4 2.23 24.6 117 4.26

6.0 4.9 11.3 850 24.8 18.1 0.73 1.77 30.8 14.1 850 33.1 2.00 26.3 106 4.85

3.0 1.3 2.9 640 22.2 15.5 0.70 2.03 29.2 11.0 640 31.5 2.21 23.8 116 4.18

3.0 1.3 2.9 850 23.1 17.5 0.76 2.12 30.4 11.0 850 32.3 1.98 25.5 105 4.77

4.5 2.6 5.9 640 22.8 15.6 0.68 1.88 29.2 12.2 640 32.7 2.24 25.0 117 4.29

85

4.5 2.6 5.9 850 23.7 17.6 0.74 1.95 30.4 12.2 850 33.5 2.01 26.7 107 4.89

6.0 4.8 11.0 640 23.2 15.7 0.68 1.80 29.3 12.9 640 33.4 2.25 25.5 118 4.34

6.0 4.8 11.0 850 24.1 17.8 0.74 1.88 30.5 12.9 850 34.2 2.02 27.2 107 4.95

3.0 1.2 2.8 640 21.6 15.3 0.71 2.16 28.9 10.0 640 32.6 2.23 24.8 117 4.28

3.0 1.2 2.8 850 22.4 17.3 0.77 2.25 30.1 10.0 850 33.4 2.01 26.5 106 4.88

4.5 2.5 5.8 640 22.2 15.4 0.69 1.99 29.0 11.1 640 33.8 2.26 25.9 119 4.38

90

4.5 2.5 5.8 850 23.1 17.4 0.75 2.07 30.1 11.1 850 34.6 2.03 27.6 108 4.99

6.0 4.7 10.7 640 22.5 15.4 0.69 1.91 29.0 11.8 640 34.4 2.28 26.4 120 4.42

6.0 4.7 10.7 850 23.4 17.5 0.75 1.99 30.2 11.8 850 35.2 2.05 28.2 108 5.04

3.0 1.2 2.7 640 20.2 14.8 0.74 2.44 28.5 8.3 640

3.0 1.2 2.7 850 21.0 16.8 0.80 2.54 29.7 8.3 850

4.5 2.4 5.5 640 20.8 14.9 0.72 2.25 28.5 9.2 640

100

4.5 2.4 5.5 850 21.6 16.9 0.78 2.34 29.7 9.2 850

6.0 4.5 10.3 640 21.1 15.0 0.71 2.16 28.5 9.8 640

6.0 4.5 10.3 850 22.0 17.0 0.77 2.25 29.7 9.8 850

3.0 1.1 2.5 640 18.8 14.4 0.77 2.77 28.3 6.8 640

3.0 1.1 2.5 850 19.5 16.3 0.84 2.88 29.4 6.8 850

4.5 2.3 5.3 640 19.3 14.4 0.75 2.55 28.1 7.6 640

110

4.5 2.3 5.3 850 20.1 16.3 0.81 2.66 29.2 7.6 850

6.0 4.3 9.9 640 19.7 14.5 0.74 2.45 28.1 8.0 640

6.0 4.3 9.9 850 20.5 16.4 0.80 2.55 29.3 8.0 850

3.0 1.0 2.4 640 17.1 13.9 0.81 3.13 27.9 5.5 640

3.0 1.0 2.4 850 17.8 15.7 0.88 3.26 29.0 5.5 850

4.5 2.2 5.1 640 17.8 14.0 0.78 2.89 27.8 6.2 640

120

4.5 2.2 5.1 850 18.6 15.8 0.85 3.01 28.9 6.2 850

6.0 4.2 9.6 640 18.3 14.1 0.77 2.78 27.9 6.6 640

6.0 4.2 9.6 850 19.1 16.0 0.84 2.89 29.0 6.6 850

Interpolation is permissible; extrapolation is not.

All entering air conditions are 80°F DB and 67°F WB in cooling, and 70°F DB in heating.

ARI/ISO certied conditions are 80.6°F DB and 66.2°F WB in cooling and 68°F DB in heating.

Table does not reect fan or pump power corrections for ARI/ISO conditions.

All performance is based upon the lower voltage of dual voltage rated units. * Performance Data is for 208-230/60/1, 208-230/60/3 and 460/60/3. Consult factory for 265/60/1 performance.

Performance stated is at the rated power supply; performance may vary as the power supply varies from the rated.

Operation below 40°F EWT is based upon a 15% antifreeze solution.

Operation below 60°F EWT requires optional insulated water/refrigerant circuit.

See performance correction tables for operating conditions other than those listed above.

See Performance Data Selection Notes for operation in the shaded areas.

WPD Cooling - EAT 80/67°F Heating - EAT 70°F

PSI FT

Airow

CFM

TC SC

Sens/Tot

Ratio

kW HR EER

Performance capacities shown in thousands of Btuh

Airow

HC kW HE LAT COP

CFM

Operation not recommended

13

Page 15

Heat Controller, Inc. HBH/V SERIES Engineering Design Guide

Performance Data

HBH/V 030

1000 CFM Nominal (Rated) Airow

EWT

GPM

°F

7.5 5.0 11.6 750 750 20.0 2.31 12.6 95 2.53

20 Operation not recommended

7.5 5.0 11.6 1000 1000 20.4 2.08 13.4 89 2.89

3.8 1.3 2.9 750 33.3 20.3 0.61 1.38 38.0 24.0 750 21.6 2.37 14.0 97 2.67

3.8 1.3 2.9 1000 34.7 22.9 0.66 1.44 39.5 24.0 1000 22.1 2.13 14.9 90 3.04

5.6 2.3 5.4 750 33.5 20.2 0.60 1.31 37.9 25.7 750 22.5 2.40 14.7 98 2.75

30

5.6 2.3 5.4 1000 34.9 22.8 0.65 1.36 39.5 25.7 1000 23.0 2.15 15.7 91 3.13

7.5 4.2 9.7 750 33.6 20.0 0.60 1.27 37.9 26.5 750 22.9 2.41 15.1 98 2.79

7.5 4.2 9.7 1000 35.0 22.7 0.65 1.32 39.4 26.5 1000 23.5 2.16 16.2 92 3.18

3.8 1.0 2.4 750 32.6 20.2 0.62 1.51 37.7 21.6 750 24.7 2.45 16.7 100 2.95

3.8 1.0 2.4 1000 34.0 22.8 0.67 1.57 39.3 21.6 1000 25.3 2.20 17.8 93 3.36

5.6 2.0 4.7 750 33.1 20.3 0.61 1.42 37.9 23.3 750 25.7 2.48 17.6 102 3.04

40

5.6 2.0 4.7 1000 34.5 22.9 0.67 1.48 39.5 23.3 1000 26.4 2.23 18.8 94 3.47

7.5 3.7 8.6 750 33.7 20.5 0.61 1.38 38.3 24.4 750 26.3 2.49 18.1 102 3.10

7.5 3.7 8.6 1000 35.1 23.2 0.66 1.44 39.9 24.4 1000 26.9 2.24 19.4 95 3.53

3.8 0.9 2.1 750 31.6 19.9 0.63 1.65 37.2 19.2 750 27.8 2.52 19.5 104 3.24

3.8 0.9 2.1 1000 32.9 22.5 0.68 1.72 38.8 19.2 1000 28.5 2.26 20.8 96 3.69

5.6 1.8 4.2 750 32.3 20.1 0.62 1.55 37.6 20.9 750 29.1 2.55 20.6 106 3.35

50

5.6 1.8 4.2 1000 33.7 22.8 0.68 1.61 39.1 20.9 1000 29.8 2.29 22.0 98 3.82

7.5 3.4 7.8 750 32.6 20.2 0.62 1.50 37.7 21.7 750 29.8 2.56 21.3 107 3.41

7.5 3.4 7.8 1000 34.0 22.9 0.67 1.57 39.3 21.7 1000 30.5 2.30 22.7 98 3.89

3.8 0.8 1.8 750 30.4 19.4 0.64 1.81 36.6 16.8 750 31.0 2.58 22.4 108 3.52

3.8 0.8 1.8 1000 31.7 21.9 0.69 1.89 38.1 16.8 1000 31.8 2.32 23.9 99 4.02

5.6 1.7 3.8 750 31.1 19.6 0.63 1.70 36.9 18.3 750 32.5 2.61 23.7 110 3.65

60

5.6 1.7 3.8 1000 32.4 22.2 0.69 1.77 38.4 18.3 1000 33.3 2.34 25.3 101 4.16

7.5 3.1 7.2 750 31.4 19.7 0.63 1.65 37.0 19.0 750 33.3 2.63 24.4 111 3.71

7.5 3.1 7.2 1000 32.7 22.3 0.68 1.71 38.5 19.1 1000 34.1 2.36 26.0 102 4.24

3.8 0.7 1.6 750 29.0 18.8 0.65 2.00 35.8 14.5 750 34.2 2.64 25.2 112 3.79

3.8 0.7 1.6 1000 30.2 21.2 0.70 2.08 37.3 14.5 1000 35.1 2.37 26.9 102 4.33

5.6 1.5 3.6 750 30.0 19.2 0.64 1.87 36.3 16.0 750 35.8 2.68 26.7 114 3.92

70

5.6 1.5 3.6 1000 31.2 21.7 0.70 1.95 37.8 16.0 1000 36.7 2.40 28.5 104 4.47

7.5 2.9 6.7 750 30.4 19.4 0.64 1.81 36.6 16.8 750 36.7 2.70 27.4 115 3.99

7.5 2.9 6.7 1000 31.7 21.9 0.69 1.89 38.1 16.8 1000 37.6 2.42 29.3 105 4.55

3.8 0.7 1.5 750 27.7 18.3 0.66 2.21 35.3 12.5 750 37.3 2.71 28.0 116 4.04

3.8 0.7 1.5 1000 28.8 20.7 0.72 2.30 36.7 12.5 1000 38.2 2.43 29.9 105 4.60

5.6 1.4 3.3 750 28.5 18.5 0.65 2.07 35.5 13.7 750 39.0 2.75 29.5 118 4.15

80

5.6 1.4 3.3 1000 29.6 21.0 0.71 2.16 37.0 13.7 1000 40.0 2.47 31.5 107 4.74

7.5 2.7 6.3 750 29.0 18.7 0.65 2.00 35.8 14.5 750 40.2 2.78 30.6 120 4.24

7.5 2.7 6.3 1000 30.2 21.2 0.70 2.08 37.3 14.5 1000 41.2 2.50 32.6 108 4.84

3.8 0.6 1.4 750 26.7 17.8 0.67 2.34 34.7 11.5 750 38.8 2.75 29.3 118 4.14

3.8 0.6 1.4 1000 27.8 20.1 0.72 2.43 36.1 11.5 1000 39.8 2.5 31.3 107 4.72

5.6 1.4 3.2 750 27.6 18.2 0.66 2.18 35.1 12.7 750 40.5 2.8 30.8 120 4.24

85

5.6 1.4 3.2 1000 28.8 20.6 0.71 2.27 36.5 12.7 1000 41.5 2.5 32.9 108 4.84

7.5 2.7 6.2 750 28.2 18.4 0.65 2.11 35.4 13.4 750 41.6 2.8 31.7 121 4.30

7.5 2.7 6.2 1000 29.3 20.8 0.71 2.20 36.8 13.4 1000 42.6 2.5 33.9 109 4.91

3.8 0.6 1.4 750 25.7 17.3 0.67 2.46 34.1 10.5 750 40.3 2.79 30.6 120 4.23

3.8 0.6 1.4 1000 26.8 19.6 0.73 2.56 35.5 10.5 1000 41.3 2.51 32.7 108 4.83

5.6 1.4 3.1 750 26.8 17.8 0.66 2.30 34.7 11.7 750 42.0 2.85 32.1 122 4.33

90

5.6 1.4 3.1 1000 27.9 20.1 0.72 2.39 36.1 11.7 1000 43.0 2.56 34.3 110 4.93

7.5 2.6 6.0 750 27.3 18.0 0.66 2.22 34.9 12.3 750 42.9 2.88 32.9 123 4.36

7.5 2.6 6.0 1000 28.5 20.4 0.72 2.31 36.4 12.3 1000 44.0 2.59 35.1 111 4.98

3.8 0.6 1.3 750 24.0 16.6 0.69 2.74 33.3 8.7 750

3.8 0.6 1.3 1000 24.9 18.8 0.75 2.85 34.7 8.7 1000

5.6 1.3 3.0 750 25.1 17.0 0.68 2.56 33.8 9.8 750

100

5.6 1.3 3.0 1000 26.1 19.3 0.74 2.67 35.2 9.8 1000

7.5 2.5 5.7 750 25.6 17.3 0.67 2.48 34.1 10.3 750

7.5 2.5 5.7 1000 26.7 19.6 0.73 2.58 35.5 10.3 1000

3.8 0.5 1.2 750 22.5 16.1 0.72 3.07 33.0 7.4 750

3.8 0.5 1.2 1000 23.5 18.2 0.78 3.19 34.4 7.4 1000

5.6 1.2 2.8 750 23.2 16.3 0.70 2.86 33.1 8.1 750

110

5.6 1.2 2.8 1000 24.2 18.4 0.76 2.98 34.4 8.1 1000

7.5 2.4 5.5 750 23.8 16.5 0.69 2.77 33.3 8.6 750

7.5 2.4 5.5 1000 24.8 18.7 0.75 2.88 34.6 8.6 1000

3.8 0.5 1.1 750 20.4 15.2 0.74 3.44 32.2 5.9 750

3.8 0.5 1.1 1000 21.2 17.2 0.81 3.58 33.5 5.9 1000

5.6 1.2 2.7 750 21.4 15.6 0.73 3.21 32.4 6.7 750

120

5.6 1.2 2.7 1000 22.3 17.6 0.79 3.34 33.8 6.7 1000

7.5 2.3 5.3 750 22.0 15.8 0.72 3.10 32.6 7.1 750

7.5 2.3 5.3 1000 22.9 17.8 0.78 3.23 33.9 7.1 1000

Interpolation is permissible; extrapolation is not.

All entering air conditions are 80°F DB and 67°F WB in cooling, and 70°F DB in heating.

ARI/ISO certied conditions are 80.6°F DB and 66.2°F WB in cooling and 68°F DB in heating.

Table does not reect fan or pump power corrections for ARI/ISO conditions.

All performance is based upon the lower voltage of dual voltage rated units.

Performance stated is at the rated power supply; performance may vary as the power supply varies from the rated.

Operation below 40°F EWT is based upon a 15% antifreeze solution.

Operation below 60°F EWT requires optional insulated water/refrigerant circuit.

See performance correction tables for operating conditions other than those listed above.

See Performance Data Selection Notes for operation in the shaded areas.

WPD Cooling - EAT 80/67°F Heating - EAT 70°F

PSI FT

Airow

CFM

TC SC

Sens/Tot

Ratio

kW HR EER

Performance capacities shown in thousands of Btuh

Airow

HC kW HE LAT COP

CFM

Operation not recommended

14

Page 16

Engineering Design Guide HBH/V SERIES Heat Controller, Inc.

Performance Data

HBH/V 036

1,200 CFM Nominal (Rated) Airow

EWT

GPM

°F

9.0 6.4 14.8 860 860 22.6 2.67 14.1 94 2.49

20 Operation not recommended

9.0 6.4 14.8 1150 1150 23.2 2.39 15.1 89 2.84

4.5 1.8 4.3 860 39.9 24.2 0.61 1.67 45.6 23.8 860 25.6 2.80 16.6 98 2.68

4.5 1.8 4.3 1150 41.5 27.4 0.66 1.74 47.4 23.8 1150 26.2 2.51 17.7 91 3.06

6.8 3.1 7.1 860 40.1 24.3 0.61 1.62 45.5 24.7 860 26.8 2.85 17.6 99 2.76

30

6.8 3.1 7.1 1150 41.7 27.5 0.66 1.69 47.4 24.7 1150 27.5 2.56 18.8 92 3.15

9.0 5.4 12.5 860 40.0 24.3 0.61 1.60 45.5 25.0 860 27.5 2.88 18.2 100 2.80

9.0 5.4 12.5 1150 41.7 27.5 0.66 1.67 47.3 25.0 1150 28.2 2.59 19.4 93 3.19

4.5 1.6 3.6 860 39.2 24.0 0.61 1.80 45.3 21.8 860 30.1 2.98 20.3 102 2.95

4.5 1.6 3.6 1150 40.8 27.2 0.67 1.87 47.1 21.8 1150 30.8 2.68 21.7 95 3.37

6.8 2.7 6.2 860 39.7 24.2 0.61 1.71 45.5 23.3 860 31.6 3.05 21.6 104 3.04

40

6.8 2.7 6.2 1150 41.4 27.4 0.66 1.78 47.4 23.3 1150 32.4 2.74 23.1 96 3.47

9.0 4.8 11.1 860 39.9 24.3 0.61 1.67 45.6 23.9 860 32.4 3.08 22.3 105 3.09

9.0 4.8 11.1 1150 41.6 27.4 0.66 1.74 47.4 23.9 1150 33.2 2.77 23.8 97 3.52

4.5 1.4 3.2 860 38.0 23.6 0.62 1.98 44.7 19.2 860 34.5 3.16 24.1 107 3.20

4.5 1.4 3.2 1150 39.5 26.7 0.68 2.06 46.5 19.2 1150 35.4 2.84 25.7 98 3.65

6.8 2.4 5.6 860 38.8 23.9 0.62 1.85 45.1 21.0 860 36.3 3.23 25.6 109 3.30

50

6.8 2.4 5.6 1150 40.4 27.0 0.67 1.92 47.0 21.0 1150 37.2 2.90 27.3 100 3.76

9.0 4.4 10.1 860 39.2 24.0 0.61 1.79 45.3 21.9 860 37.3 3.27 26.4 110 3.35

9.0 4.4 10.1 1150 40.8 27.2 0.67 1.87 47.2 21.9 1150 38.2 2.93 28.2 101 3.82

4.5 1.3 2.9 860 36.1 22.9 0.63 2.20 43.6 16.4 860 38.9 3.32 27.8 112 3.43

4.5 1.3 2.9 1150 37.6 25.9 0.69 2.29 45.4 16.4 1150 39.8 2.99 29.7 102 3.91

6.8 2.3 5.2 860 37.5 23.5 0.63 2.04 44.4 18.4 860 40.9 3.40 29.5 114 3.53

60

6.8 2.3 5.2 1150 39.1 26.5 0.68 2.13 46.3 18.4 1150 41.9 3.05 31.5 104 4.02

9.0 4.0 9.3 860 38.0 23.6 0.62 1.97 44.7 19.3 860 42.0 3.44 30.4 115 3.58

9.0 4.0 9.3 1150 39.6 26.7 0.68 2.05 46.5 19.3 1150 43.0 3.09 32.5 105 4.08

4.5 1.2 2.7 860 34.6 22.5 0.65 2.46 42.9 14.0 860 43.1 3.47 31.4 116 3.64

4.5 1.2 2.7 1150 36.0 25.5 0.71 2.56 44.7 14.0 1150 44.1 3.12 33.5 106 4.15

6.8 2.1 4.9 860 35.8 22.9 0.64 2.28 43.6 15.7 860 45.2 3.55 33.2 119 3.74

70

6.8 2.1 4.9 1150 37.3 25.9 0.70 2.38 45.4 15.7 1150 46.3 3.19 35.4 107 4.26

9.0 3.8 8.7 860 36.4 23.1 0.63 2.20 43.9 16.6 860 46.4 3.59 34.2 120 3.79

9.0 3.8 8.7 1150 37.9 26.1 0.69 2.29 45.7 16.6 1150 47.5 3.22 36.5 108 4.32

4.5 1.1 2.5 860 32.5 21.8 0.67 2.76 41.9 11.8 860 47.0 3.61 34.8 121 3.82

4.5 1.1 2.5 1150 33.8 24.7 0.73 2.88 43.7 11.8 1150 48.2 3.24 37.1 109 4.36

6.8 2.0 4.6 860 33.9 22.3 0.66 2.56 42.6 13.2 860 49.2 3.68 36.6 123 3.92

80

6.8 2.0 4.6 1150 35.3 25.2 0.72 2.67 44.4 13.2 1150 50.4 3.30 39.1 111 4.47

9.0 3.6 8.3 860 34.5 22.5 0.65 2.47 42.9 14.0 860 50.3 3.71 37.6 124 3.97

9.0 3.6 8.3 1150 35.9 25.5 0.71 2.57 44.7 14.0 1150 51.5 3.34 40.1 111 4.53

4.5 1.0 2.4 860 31.5 21.5 0.68 2.9 41.5 10.8 860 48.8 3.67 36.3 123 3.90

4.5 1.0 2.4 1150 32.8 24.4 0.74 3.05 43.3 10.8 1150 50.0 3.29 38.8 110 4.45

6.8 1.9 4.4 860 32.8 21.9 0.67 2.72 42.1 12.1 860 50.9 3.73 38.1 125 4.00

85

6.8 1.9 4.4 1150 34.1 24.8 0.73 2.84 43.8 12.1 1150 52.2 3.35 40.7 112 4.56

9.0 3.5 8.1 860 33.4 22.1 0.66 2.62 42.3 12.8 860 52.0 3.76 39.0 126 4.05

9.0 3.5 8.1 1150 34.7 25.0 0.72 2.73 44.1 12.8 1150 53.2 3.38 41.7 113 4.62

4.5 1.0 2.3 860 30.5 21.2 0.70 3.10 41.1 9.8 860 50.6 3.72 37.9 125 3.99

4.5 1.0 2.3 1150 31.8 24.0 0.76 3.23 42.8 9.8 1150 51.9 3.34 40.4 112 4.54

6.8 1.9 4.3 860 31.7 21.6 0.68 2.88 41.6 11.0 860 52.7 3.79 39.6 127 4.08

90

6.8 1.9 4.3 1150 33.0 24.4 0.74 3.00 43.3 11.0 1150 54.0 3.40 42.3 113 4.65

9.0 3.4 7.9 860 32.2 21.7 0.67 2.78 41.7 11.6 860 53.7 3.82 40.5 128 4.12

9.0 3.4 7.9 1150 33.5 24.5 0.73 2.89 43.4 11.6 1150 55.0 3.43 43.2 114 4.70

4.5 0.9 2.2 860 28.3 20.5 0.72 3.47 40.2 8.1 860

4.5 0.9 2.2 1150 29.5 23.1 0.79 3.62 41.9 8.2 1150

6.8 1.8 4.1 860 29.5 20.8 0.71 3.24 40.6 9.1 860

100

6.8 1.8 4.1 1150 30.7 23.5 0.77 3.37 42.2 9.1 1150

9.0 3.3 7.5 860 30.1 21.0 0.70 3.13 40.8 9.6 860

9.0 3.3 7.5 1150 31.3 23.7 0.76 3.25 42.5 9.6 1150

4.5 0.9 2.1 860 26.2 19.8 0.75 3.88 39.5 6.8 860

4.5 0.9 2.1 1150 27.3 22.4 0.82 4.04 41.1 6.8 1150

6.8 1.7 4.0 860 27.2 20.0 0.73 3.63 39.7 7.5 860

110

6.8 1.7 4.0 1150 28.4 22.6 0.80 3.78 41.3 7.5 1150

9.0 3.1 7.2 860 27.6 20.0 0.72 3.51 39.6 7.9 860

9.0 3.1 7.2 1150 28.8 22.7 0.79 3.65 41.3 7.9 1150

4.5 0.9 2.0 860 24.1 19.0 0.79 4.31 38.9 5.6 860

4.5 0.9 2.0 1150 25.1 21.4 0.86 4.49 40.4 5.6 1150

6.8 1.6 3.8 860 25.1 19.2 0.77 4.05 39.0 6.2 860

120

6.8 1.6 3.8 1150 26.1 21.8 0.83 4.21 40.6 6.2 1150

9.0 3.0 7.0 860 25.4 19.2 0.76 3.92 38.9 6.5 860

9.0 3.0 7.0 1150 26.5 21.8 0.82 4.08 40.5 6.5 1150

Interpolation is permissible; extrapolation is not.

All entering air conditions are 80°F DB and 67°F WB in cooling, and 70°F DB in heating.

ARI/ISO certied conditions are 80.6°F DB and 66.2°F WB in cooling and 68°F DB in heating.

Table does not reect fan or pump power corrections for ARI/ISO conditions.

All performance is based upon the lower voltage of dual voltage rated units.

Performance stated is at the rated power supply; performance may vary as the power supply varies from the rated.

Operation below 40°F EWT is based upon a 15% antifreeze solution.

Operation below 60°F EWT requires optional insulated water/refrigerant circuit.

See performance correction tables for operating conditions other than those listed above.

See Performance Data Selection Notes for operation in the shaded areas.

WPD Cooling - EAT 80/67°F Heating - EAT 70°F

PSI FT

Airow

CFM

TC SC

Sens/Tot

Ratio

kW HR EER

Performance capacities shown in thousands of Btuh

Airow

HC kW HE LAT COP

CFM

Operation not recommended

15

Page 17

Heat Controller, Inc. HBH/V SERIES Engineering Design Guide

Performance Data

HBH/V 042

1,350 CFM Nominal (Rated) Airow

EWT

GPM

°F

10.5 9.2 21.3 1050 1050 28.8 3.37 18.1 95 2.51

20 Operation not recommended

10.5 9.2 21.3 1400 1400 29.5 3.03 19.3 90 2.86

5.3 2.3 5.3 1050 47.4 30.6 0.65 1.87 53.7 25.4 1050 31.6 3.45 20.5 98 2.68

5.3 2.3 5.3 1400 49.3 34.7 0.70 1.95 55.9 25.4 1400 32.4 3.10 21.9 91 3.06

7.9 4.3 10.0 1050 48.4 31.1 0.64 1.76 54.4 27.5 1050 32.9 3.49 21.6 99 2.76

30

7.9 4.3 10.0 1400 50.4 35.2 0.70 1.83 56.6 27.5 1400 33.7 3.14 23.1 92 3.15

10.5 7.9 18.2 1050 48.9 31.3 0.64 1.71 54.7 28.6 1050 33.6 3.52 22.3 100 2.80

10.5 7.9 18.2 1400 50.9 35.5 0.70 1.78 57.0 28.6 1400 34.5 3.16 23.8 93 3.20

5.3 2.0 4.6 1050 45.9 29.9 0.65 2.05 52.8 22.4 1050 36.1 3.59 24.4 102 2.95

5.3 2.0 4.6 1400 47.8 33.9 0.71 2.13 55.0 22.4 1400 37.0 3.23 26.1 94 3.36

7.9 3.9 8.9 1050 47.0 30.4 0.65 1.92 53.4 24.5 1050 37.8 3.64 25.8 103 3.04

40

7.9 3.9 8.9 1400 48.9 34.4 0.70 2.00 55.6 24.5 1400 38.7 3.27 27.6 96 3.46

10.5 7.1 16.4 1050 47.5 30.7 0.65 1.86 53.8 25.5 1050 38.7 3.67 26.6 104 3.09

10.5 7.1 16.4 1400 49.4 34.7 0.70 1.94 56.0 25.5 1400 39.6 3.30 28.4 96 3.52

5.3 1.8 4.1 1050 44.4 29.2 0.66 2.26 52.0 19.6 1050 40.8 3.74 28.5 106 3.20

5.3 1.8 4.1 1400 46.2 33.1 0.72 2.35 54.2 19.6 1400 41.8 3.36 30.4 98 3.65

7.9 3.5 8.1 1050 45.4 29.7 0.65 2.11 52.6 21.5 1050 42.8 3.80 30.2 108 3.30

50

7.9 3.5 8.1 1400 47.3 33.6 0.71 2.20 54.8 21.5 1400 43.8 3.41 32.2 99 3.76

10.5 6.5 15.0 1050 46.0 30.0 0.65 2.04 52.9 22.5 1050 43.9 3.83 31.1 109 3.35

10.5 6.5 15.0 1400 47.9 33.9 0.71 2.12 55.1 22.5 1400 44.9 3.44 33.2 100 3.82

5.3 1.6 3.7 1050 43.1 28.8 0.67 2.51 51.7 17.2 1050 45.6 3.89 32.6 110 3.44

5.3 1.6 3.7 1400 44.9 32.6 0.73 2.61 53.8 17.2 1400 46.7 3.49 34.8 101 3.92

7.9 3.3 7.5 1050 43.9 29.0 0.66 2.34 51.8 18.8 1050 47.8 3.96 34.5 112 3.54

60

7.9 3.3 7.5 1400 45.7 32.8 0.72 2.43 53.9 18.8 1400 49.0 3.56 36.9 102 4.04

10.5 6.1 14.0 1050 44.4 29.2 0.66 2.25 52.1 19.7 1050 49.0 4.00 35.6 113 3.60

10.5 6.1 14.0 1400 46.2 33.1 0.72 2.35 54.2 19.7 1400 50.2 3.59 38.0 103 4.10

5.3 1.5 3.4 1050 41.3 28.1 0.68 2.80 50.9 14.8 1050 50.3 4.04 36.7 114 3.65

5.3 1.5 3.4 1400 43.0 31.8 0.74 2.91 52.9 14.8 1400 51.5 3.63 39.2 104 4.16

7.9 3.1 7.1 1050 42.2 28.3 0.67 2.60 51.0 16.2 1050 52.8 4.11 38.8 117 3.76

70

7.9 3.1 7.1 1400 43.9 32.0 0.73 2.71 53.1 16.2 1400 54.1 3.70 41.5 106 4.29

10.5 5.7 13.2 1050 42.8 28.5 0.67 2.51 51.3 17.1 1050 54.1 4.16 40.0 118 3.82

10.5 5.7 13.2 1400 44.5 32.3 0.73 2.61 53.4 17.1 1400 55.4 3.73 42.7 107 4.35

5.3 1.4 3.2 1050 39.5 27.4 0.70 3.13 50.1 12.6 1050 54.9 4.18 40.7 118 3.85

5.3 1.4 3.2 1400 41.1 31.0 0.76 3.26 52.2 12.6 1400 56.3 3.76 43.4 107 4.39

7.9 2.9 6.7 1050 40.4 27.6 0.68 2.91 50.3 13.9 1050 57.6 4.27 43.0 121 3.96

80

7.9 2.9 6.7 1400 42.1 31.3 0.74 3.03 52.4 13.9 1400 59.0 3.83 45.9 109 4.51

10.5 5.4 12.6 1050 41.0 27.9 0.68 2.80 50.6 14.6 1050 59.0 4.31 44.2 122 4.01

10.5 5.4 12.6 1400 42.7 31.5 0.74 2.92 52.6 14.6 1400 60.4 3.87 47.2 110 4.58

5.3 1.3 3.1 1050 38.4 27.1 0.71 3.32 49.8 11.6 1050 57.2 4.25 42.6 120 3.94

5.3 1.3 3.1 1400 40.0 30.7 0.77 3.46 51.8 11.6 1400 58.6 3.82 45.5 109 4.49

7.9 2.8 6.5 1050 39.4 27.3 0.69 3.08 50.0 12.8 1050 59.9 4.34 44.9 123 4.05

85

7.9 2.8 6.5 1400 41.1 30.9 0.75 3.21 52.0 12.9 1400 61.3 3.89 48.0 111 4.61

10.5 5.3 12.3 1050 40.1 27.5 0.69 2.97 50.2 13.5 1050 61.3 4.38 46.2 124 4.10

10.5 5.3 12.3 1400 41.7 31.2 0.75 3.09 52.3 13.6 1400 62.7 3.93 49.3 111 4.68

5.3 1.3 3.0 1050 37.4 26.8 0.72 3.51 49.4 10.7 1050 59.4 4.32 44.6 122 4.03

5.3 1.3 3.0 1400 39.0 30.3 0.78 3.65 51.5 10.7 1400 60.8 3.88 47.6 110 4.59

7.9 2.8 6.4 1050 38.5 27.0 0.70 3.26 49.6 11.8 1050 62.1 4.40 46.9 125 4.13

90

7.9 2.8 6.4 1400 40.1 30.6 0.76 3.39 51.6 11.8 1400 63.6 3.96 50.1 112 4.71

10.5 5.2 12.0 1050 39.1 27.2 0.70 3.14 49.8 12.5 1050 63.5 4.45 48.1 126 4.19

10.5 5.2 12.0 1400 40.7 30.8 0.76 3.27 51.9 12.5 1400 65.1 3.99 51.4 113 4.77

5.3 1.2 2.8 1050 35.2 26.2 0.74 3.94 48.7 8.9 1050

5.3 1.2 2.8 1400 36.7 29.6 0.81 4.10 50.7 8.9 1400