Page 1

Installation, Operation

& Maintenance Manual

Commercial Horizontal & Vertical

Packaged Water-Source Heat Pumps:

HBH/V Compact

Heat Controller, Inc. • 1900 Wellworth Ave. • Jackson, MI 49203 • (517)787-2100 • www.heatcontroller.com

Page 2

IOM Instructions HBH/V COMPACT Heat Controller, Inc.

TABLE OF CONTENTS

Model Nomenclature ..................................................2

Electrical - Power & Low Voltage Wiring .............22-24

General Information .................................................3-4

Physical Data..............................................................5

Horizontal Installation ...........................................6-7,9

Field Conversion of Air Discharge .............................. 8

Vertical Installation...............................................10-11

Piping Installation .....................................................12

Water Loop Applications ........................................... 13

Open Loop - Ground Water Systems ..................14-17

Water Quality Standards ..........................................18

Electrical - Line Voltage ............................................19

Electrical Data .....................................................20-21

Electrical - Thermostat Wiring ..................................25

CXM Controls ........................................................... 26

CXM Control - Safety Features ...........................27-28

Unit Starting & Operating Conditions........................29

Piping System Cleaning & Flushing .........................30

Unit & System Checkout...........................................31

Unit Start-Up Procedure ......................................32-33

Unit Operating Procedures & Temperatures ........34-37

Preventive Maintenance ........................................... 38

Functional Troubleshooting .................................39-42

Page 3

Heat Controller, Inc. HBH/V COMPACT IOM Instructions

HEAT CONTROLLER OEM PRICE LIST

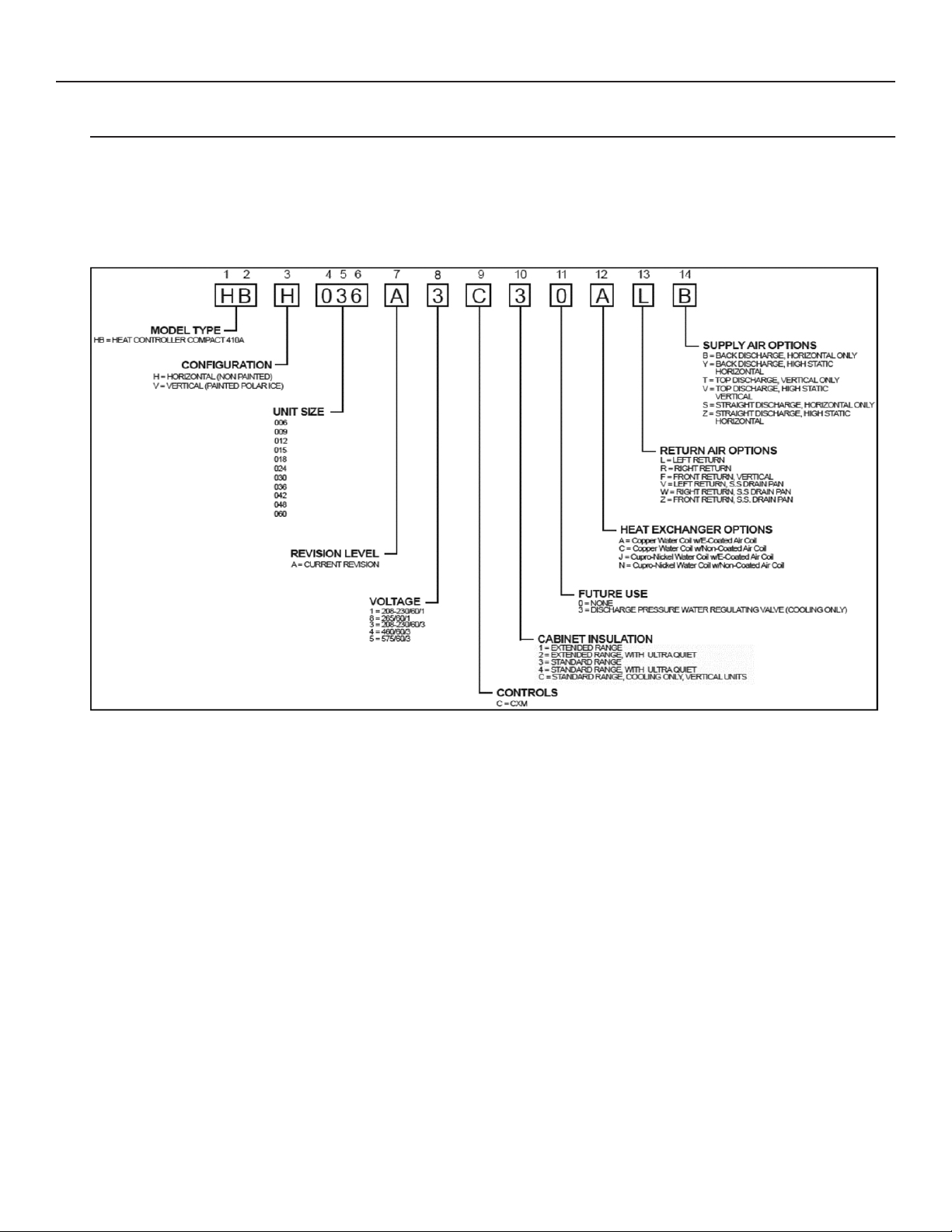

HBH & HBV COMPACT Horizontal & Vertical HFC-410a Units

H B H A0 3 6 C3 3 0 A L B

1 2 3 4 5 6 7

8

9 10 11 12 13 14

HB = HEAT CONTROLLER COMPACT 410A

MODEL TYPE

H = HORIZONTAL (NON PAINTED)

CONFIGURATION

V = VERTICAL (PAINTED POLAR ICE)

UNIT SIZE

018 - 1,8

024 - 1,3,4,8

030 - 1,3,4,8

036 - 1,3,4,8

042 - 1,3,4,5

048 - 1,3,4,5

060 - 1,3,4,5

REVISION LEVEL

A = CURRENT REVISION FOR SIZES 006 - 060

VOLTAGE

C = CXM

CONTROLS

3 = STANDARD RANGE

CABINET INSULATION

0 = NONE

FUTURE USE

A = Copper Water Coil w/E-Coated Air Coil

HEAT EXCHANGER OPTIONS

C = Copper Water Coil w/Non-Coated Air Coil

L = LEFT RETURN

RETURN AIR OPTIONS

R = RIGHT RETURN

F = FRONT RETURN, VERTICAL 009-030

B = BACK DISCHARGE, HORIZONTAL ONLY

SUPPLY AIR OPTIONS

Y = BACK DISCHARGE, HIGH STATIC

HORIZONTAL 018 - 060

T = TOP DISCHARGE, VERTICAL ONLY

V = TOP DISCHARGE, HIGH STATIC

VERTICAL 018 - 060

S = STRAIGHT DISCHARGE, HORIZONTAL ONLY

Z = STRAIGHT DISCHARGE, HIGH STATIC

HORIZONTAL 018 - 060

J = Cupro-Nickel Water Coil w/E-Coated Air Coil

N = Cupro-Nickel Water Coil w/Non-Coated Air Coil

4 = STANDARD RANGE, WITH ULTRA QUIET

015 - 1,8

1 = 208-230/60/1

8 = 265/60/1

3 = 208-230/60/3

4 = 460/60/3

5 = 575/60/3

C = STANDARD RANGE, COOLING ONLY, VERTICAL UNITS

3 = DISCHARGE PRESSURE WATER REGULATING VALVE (COOLING ONLY)

NOT AVAILABLE ON UNIT SIZES 006, 009 AND 012

V = LEFT RETURN, S.S DRAIN PAN

W = RIGHT RETURN, S.S DRAIN PAN

Z = FRONT RETURN, S.S. DRAIN PAN 009-030

}

Voltage Code

Entering Water Temperature Range: 20 - 120°F (-6.7 - 48.9°C)

Horizontal Water Source Heat Pump

Sizes 015-060

006-060

Vertical Water Source Heat Pump

Sizes 015-060

006-060

HBH & HBV Model Structure

Basic Unit Description:

The basic unit price includes sealed heat pump refrigerant circuit and

air handler within cabinetry, lter, and a factory installed hanger kit on

horizontal units.

• Cabinetry - Compact design - galvanized steel construction -

• Cabinetry – Compact design - galvanized steel construction - controls

powder coat nish on front access panels - controls access panel

access panel - compressor access panels - FPT water connections -

- com pres sor access panels - FPT water con nec tions - high and low

high and low voltage knockouts - 1” (25mm), air lter and lter rack. All

voltage knock outs - 1” (25mm), air lter and lter rack. All vertical

vertical units have a left or right return air option, sizes 006-030 have a

units have a left or right return air option, sizes 015 - 030 have a front

front return option. All horizontal units have eld convertible discharge air

return option. All hor i zon tal units have eld convertible dis charge air

patterns with extra parts required.

patterns with no extra parts required.

• Standard Controls - CXM Controller, loss of charge switch, high

pressure switch, water coil low temperature cutout, lockout safety

circuit resetable at ther mo stat or dis con nect, LED fault indication,

ve minute anti-short cycle protection, random start, high and low

voltage pro tec tion, con den sate over ow pro tec tion, dry contact for

alarm.

• Compressor - High ef ciency hermetic scroll or rotary, overload

pro tect ed - internally sprung & externally isolated using dual vibration

dampening system for extra quiet operation. Mounting system

incorporates rubber grommet isolation under the compressor and

rubber grommet isolation between the compressor mounting tray and

unit base.

006

• Reversing Valve - 4-way, pilot operated, solenoid activated in the

cool mode.

• Refrigerant Circuit - Utilizes expansion valve metering device -

copper tubing interconnecting all components - sealed & tested

non-ozone depleting, HFC-410A refrigerant circuit with high & low

side schraeder ports.

• Water to Refrigerant Coil - Tube-in-tube, convoluted copper inner

water tube.

• Refrigerant to Air Coil - Lanced aluminum ns on ri ed copper

tubes.

• Blower Motor - Three-speed PSC direct drive, permanently

lu bri cat ed (Two-speed on 575 volt applications).

• UltraQuiet Option - Compressor incorporates spring mounting

system, 015-060 include compressor discharge muf er, blower

housing is covered with high density noise suppression material.

• Application - Units can be applied in WLHP, GWHP, or GLHP

R-410A refrigerant circuit with high & low

applications.

Page 4

IOM Instructions HBH/V COMPACT Heat Controller, Inc.

General Information

Safety

Warnings, cautions and notices appear throughout this manual.

Read these items carefully before attempting any installation,

service or troubleshooting of the equipment.

DANGER: Indicates an immediate hazardous situation, which

if not avoided will result in death or serious injury. DANGER

labels on unit access panels must be observed.

WARNING: Indicates a potentially hazardous situation, which if

not avoided could result in death or serious injury.

WARNING! All refrigerant discharged from this unit must be

recovered WITHOUT EXCEPTION. Technicians must follow

industry accepted guidelines and all local, state, and federal

statutes for the recovery and disposal of refrigerants. If a

compressor is removed from this unit, refrigerant circuit oil will

remain in the compressor. To avoid leakage of compressor oil,

refrigerant lines of the compressor must be sealed after it is

removed.

WARNING!

CAUTION: Indicates a potentially hazardous situation or an

unsafe practice, which if not avoided could result in minor or

moderate injury or product or property damage.

NOTICE: Notication of installation, operation or maintenance

information, which is important, but which is not hazard-related.

WARNING!

WARNING! The Refrigerant Application and Service Manual

should be read and understood before attempting to service

refrigerant circuits with HFC-410A.

R-410A.

WARNING!

WARNING! To avoid the release of refrigerant into the

atmosphere, the refrigerant circuit of this unit must be

serviced only by technicians who meet local, state, and

federal prociency requirements.

CAUTION!

CAUTION!

these units as a source of heating or cooling during the

construction process. The mechanical components and

lters will quickly become clogged with construction dirt and

debris, which may cause system damage.

To avoid equipment damage, DO NOT use

Inspection

Upon receipt of the equipment, carefully check the shipment

against the bill of lading. Make sure all units have been received.

Inspect the packaging of each unit, and inspect each unit for

damage. Insure that the carrier makes proper notation of any

shortages or damage on all copies of the freight bill and completes

a common carrier inspection report. Concealed damage not

discovered during unloading must be reported to the carrier within

15 days of receipt of shipment. If not led within 15 days, the

freight company can deny the claim without recourse. Note: It is

the responsibility of the purchaser to le all necessary claims with

the carrier. Notify your equipment supplier of all damage within

fteen (15) days of shipment.

Storage

Equipment should be stored in its original packaging in a clean,

dry area. Store units in an upright position at all times. Stack

units a maximum of 3 units high.

Unit Protection

Cover units on the job site with either the original packaging or an

equivalent protective covering. Cap the open ends of pipes stored

on the job site. In areas where painting, plastering, and/or spraying

has not been completed, all due precautions must be taken to

avoid physical damage to the units and contamination by foreign

material. Physical damage and contamination may prevent proper

start-up and may result in costly equipment clean-up.

Examine all pipes, ttings, and valves before installing any of

the system components. Remove any dirt or debris found in or

on these components.

Pre-Installation

Installation, Operation, and Maintenance instructions are

provided with each unit. Horizontal equipment is designed for

installation above false ceiling or in a ceiling plenum. Other

unit congurations are typically installed in a mechanical room.

The installation site chosen should include adequate service

clearance around the unit. Before unit start-up, read all manuals

and become familiar with the unit and its operation. Thoroughly

check the system before operation.

Page 5

Heat Controller, Inc. HBH/V COMPACT IOM Instructions

General Information

Prepare units for installation as follows:

1. Compare the electrical data on the unit nameplate with

ordering and shipping information to verify that the correct

unit has been shipped.

2. Keep the cabinet covered with the original packaging until

installation is complete and all plastering, painting, etc. is

nished.

3. Verify refrigerant tubing is free of kinks or dents and that it

does not touch other unit components.

4. Inspect all electrical connections. Connections must be

clean and tight at the terminals.

5. Remove any blower support packaging (water-to-air units

only).

6. Loosen compressor bolts on units equipped with

compressor spring vibration isolation until the compressor

rides freely on the springs. Remove shipping restraints.

7. Some airow patterns are eld convertible (horizontal units

only). Locate the airow conversion section of this IOM.

8. Locate and verify any hot water generator (HWG), hanger,

or other accessory kit located in the compressor section or

blower section.

CAUTION!

CAUTION!

direction of rotation veried at start-up. Verication is achieved by

checking compressor Amp draw. Amp draw will be substantially

lower compared to nameplate values. Additionally, reverse rotation

results in an elevated sound level compared to correct rotation.

Reverse rotation will result in compressor internal overload trip

within several minutes. Verify compressor type before proceeding.

All three phase scroll compressors must have

CAUTION!

CAUTION! DO NOT store or install units in corrosive

environments or in locations subject to temperature or

humidity extremes (e.g., attics, garages, rooftops, etc.).

Corrosive conditions and high temperature or humidity can

signicantly reduce performance, reliability, and service life.

Always move and store units in an upright position. Tilting

units on their sides may cause equipment damage.

CAUTION!

CAUTION! CUT HAZARD - Failure to follow this caution

may result in personal injury. Sheet metal parts may have

sharp edges or burrs. Use care and wear appropriate

protective clothing, safety glasses and gloves when

handling parts and servicing heat pumps.

NOTICE! Failure to remove shipping brackets from springmounted compressors will cause excessive noise, and

could cause component failure due to added vibration.

Page 6

IOM Instructions HBH/V COMPACT Heat Controller, Inc.

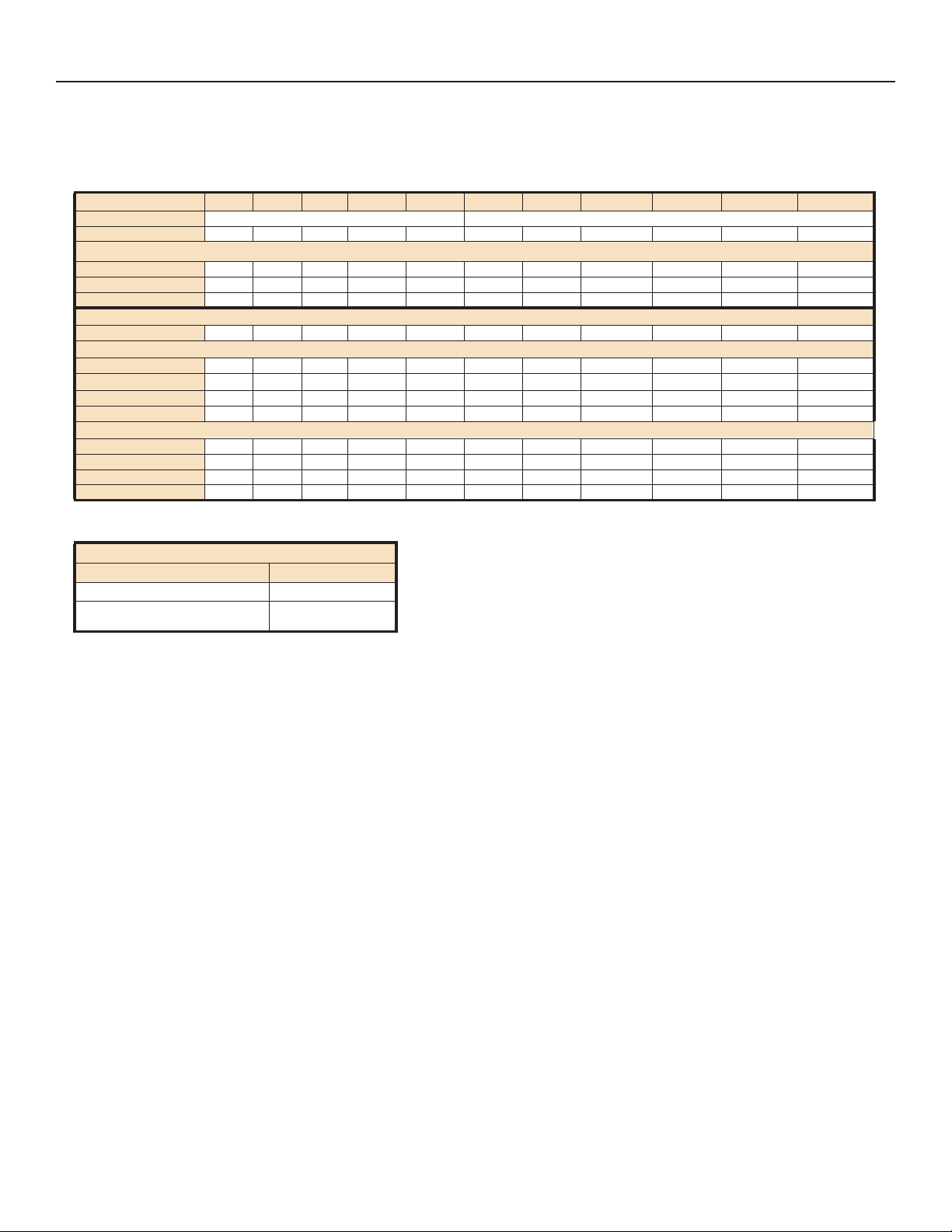

Unit Physical Data

HBH/V Series

HB Series

Compressor (1 Each) Rotary Scroll

Factory Charge R410A (oz) 17 18.5 23 32 43 43 47 50 70 74 82

PSC Fan Motor & Blower

Fan Motor Type/Speeds PSC/3 PSC/3 PSC-3 PSC/3 PSC/3 PSC/3 PSC/3 PSC/3 PSC/3 PSC/3 PSC/3

Fan Motor (hp) 1/25 1/10 1/10 1/6 1/6 1/4 3/4 1/2 3/4 3/4 1

Blower Wheel Size (Dia x w) 5x5 5x5 6x5 8x7 8x7 9x7 9x7 9x8 9x8 10x10 11x10

Water Connection Size

IPT 1/2” 1/2” 1/2” 1/2" 1/2" 3/4" 3/4" 3/4" 3/4" 1" 1"

Vertical

Air Coil Dimensions (H x W) 10x15 10x15 10x15 20x17.25 20x17.25 20x17.25 20x17.25 24x21.75 24x21.76 24x28.25 24x28.25

Filter Standard - 1" Throwaway 10x18 10x18 10x18 20x20 20x20 20x20 20x20 24x24 24x24 1-14x24, 1-18x24 1-14x24, 1-18x24

Weight - Operating (lbs.) 103 105 114 153 158 189 197 203 218 263 278

Weight - Packaged (lbs.) 113 115 124 158 163 194 202 209 224 270

Horizontal

Air Coil Dimensions (H x W) 10x15 10x15 10x15 16x22 16x22 16x22 16x22 20x25 20x25 20x35 20x35

Filter Standard - 1" Throwaway 10x18 10x18 10x18 16x25 16x25 18x25

Weight - Operating (lbs.) 103 105 114 153 158 174 182 203 218 263 278

Weight - Packaged (lbs.) 113 115 124 158 163 179 187 209 224 270 285

Notes:

Models 006-012 have spring compressor mounts, all others have grommets,TXV expansion device, and 1/2” & 3/4” electrical knockouts.

006 009 012 015 018 024 030 036 042 048 060

285

18x25 20x28 or 2-20x14 20x28 or 2-20x14

1-20x24, 1-20x14

1-20x24, 1-20x14

Unit Maximum Water Working Pressure

Options

Base Unit

Discharge Pressure

Water Regulating Valve

Use the lowest maximum pressure rating when multiple options are combined.

Max Pressure PSIG [kPa]

500 [3,445]

140 [965]

Page 7

Heat Controller, Inc. HBH/V COMPACT IOM Instructions

Horizontal Installation

Horizontal Unit Location

Units are not designed for outdoor installation. Locate

the unit in an INDOOR area that allows enough space

for service personnel to perform typical maintenance or

repairs without removing unit from the ceiling. Horizontal

units are typically installed above a false ceiling or in a

ceiling plenum. Never install units in areas subject to

freezing or where humidity levels could cause cabinet

condensation (such as unconditioned spaces subject

to 100% outside air). Consideration should be given to

access for easy removal of the lter and access panels.

Provide sufcient room to make water, electrical, and

duct connection(s).

If the unit is located in a conned space, such as a closet,

provisions must be made for return air to freely enter the

space by means of a louvered door, etc. Any access panel

screws that would be difcult to remove after the unit is

installed should be removed prior to setting the unit. Refer

to Figure 3 for an illustration of a typical installation. Refer

to unit engineering design guide for dimensional data.

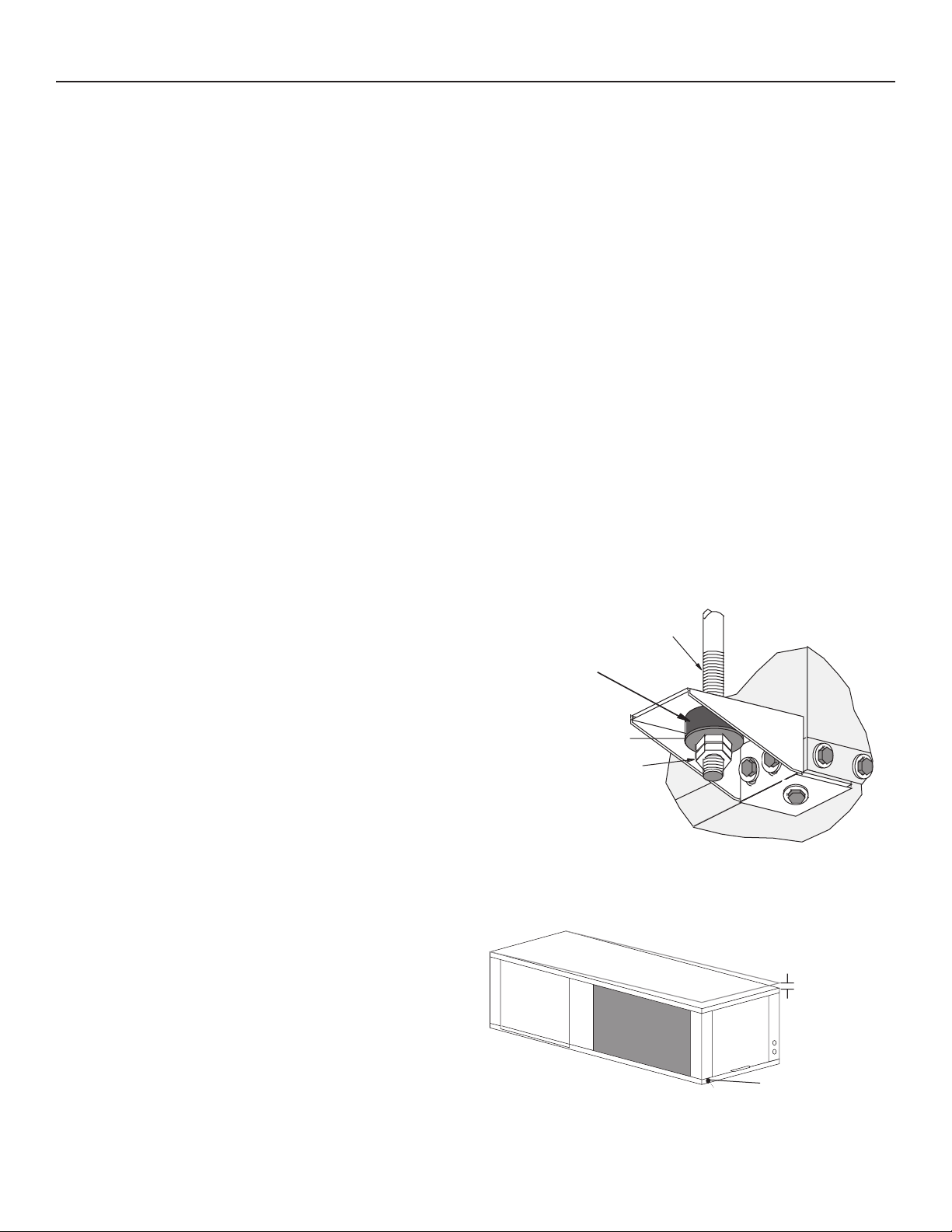

Mounting Horizontal Units

Horizontal units have hanger kits pre-installed from the factory

as shown in Figure 1. Figure 3 shows a typical horizontal unit

installation.

Horizontal heat pumps are typically suspended above a ceiling

or within a soft using eld supplied, threaded rods sized to

support the weight of the unit.

Use four (4) eld supplied threaded rods and factory provided

vibration isolators to suspend the unit. Hang the unit clear of the

oor slab above and support the unit by the mounting bracket

assemblies only. DO NOT attach the unit ush with the oor

slab above.

Pitch the unit toward the drain as shown in Figure 2 to improve

the condensate drainage. On small units (less than 2.5

tons/8.8kW) ensure that unit pitch does not cause condensate

leaks inside the cabinet.

In limited side access installations, pre-removal of the

control box side mounting screws will allow control box

removal for future servicing (HB units only).

Conform to the following guidelines when selecting

unit location:

1. Provide a hinged access door in concealed-spline

or plaster ceilings. Provide removable ceiling

tiles in T-bar or lay-in ceilings. Refer to horizontal

unit dimensions for specic series and model in

unit submittal data. Size the access opening to

accommodate the service technician during the

removal or replacement of the compressor and the

removal or installation of the unit itself.

2.

Provide access to hanger brackets, water valves

and ttings. Provide screwdriver clearance to access

panels, discharge collars and all electrical connections.

3. DO NOT obstruct the space beneath the unit with

piping, electrical cables and other items that prohibit

future removal of components or the unit itself.

4. Use a manual portable jack/lift to lift and support the

weight of the unit during installation and servicing.

The installation of water source heat pump units and all

associated components, parts and accessories which

make up the installation shall be in accordance with

the regulations of ALL authorities having jurisdiction

and MUST conform to all applicable codes. It is the

responsibility of the installing contractor to determine and

comply with ALL applicable codes and regulations.

Figure 1: Hanger Bracket

3/8" [10mm] Threaded

Rod (by others)

Vibration Isolator

(factory supplied)

Washer

(by others)

Double Hex Nuts

(by others)

Figure 2: Horizontal Unit Pitch

1/4" [6.4mm] pitch

for drainage

Drain

Connection

Page 8

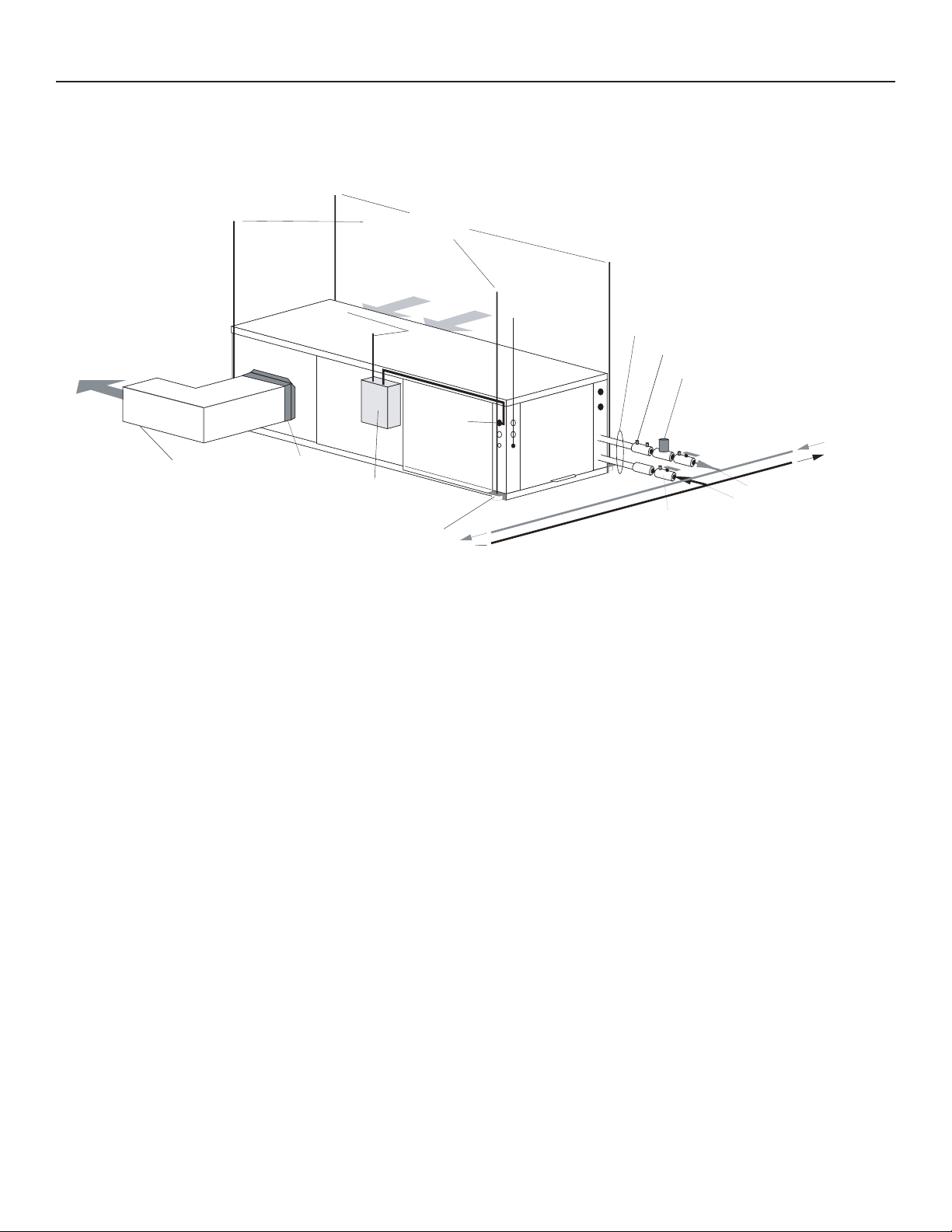

IOM Instructions HBH/V COMPACT Heat Controller, Inc.

HORIZONTAL INSTALLATION

Figure 3: Typical Horizontal Unit Installation

Horizontal Installation

Figure 3: Typical Horizontal Unit Installation

3/8" [10mm] threaded rods

(by others)

Return Air

Power Wiring

Supply Air

Unit Power

Insulated supply duct with

at least one 90 deg elbow

to reduce air noise

Flexible Duct

Connector

Unit Power

Disconnect

(by others)

Unit Hanger

Air Coil

To obtain maximum performance, the air coil should be cleaned

before start-up. A 10% solution of dishwasher detergent and

water is recommended for both sides of the coil. A thorough

water rinse should follow. UV based anti-bacterial systems

may damage e-coated air coils.

Thermostat

Wiring

Stainless steel braided hoses with

Stainless steel braid hose

threaded connections

with integral "J" swivel

and one swivel end

Optional Balancing Valve

Optional Low Pressure Drop Water

Ball Valve with optional

integral P/T plug

Control Valve

(can be internally mounted

on some models)

Water Out

Water In

Building

Loop

NOTICE! Installation Note - Ducted Return: Many horizontal

WSHPs are installed in a return air ceiling plenum application

(above ceiling). Vertical WSHPs are commonly installed in a

mechanical room with free return (e.g. louvered door). Therefore,

lter rails are the industry standard and are included on Heat

Controller, Inc., commercial heat pumps for the purposes of

holding the lter only. For ducted return applications, the lter rail

must be removed and replaced with a duct ange or lter rack.

Canvas or exible connectors should also be used to minimize

vibration between the unit and ductwork.

Page 9

Heat Controller, Inc. HBH/V COMPACT IOM Instructions

Water

Connection End

Return Air

Remove Screws

Water

Connection End

Return Air

Rotate

Move to Side

Side Discharge

Return Air

Water

Connection End

Discharge Air

Drain

Back Discharge

Replace Screws

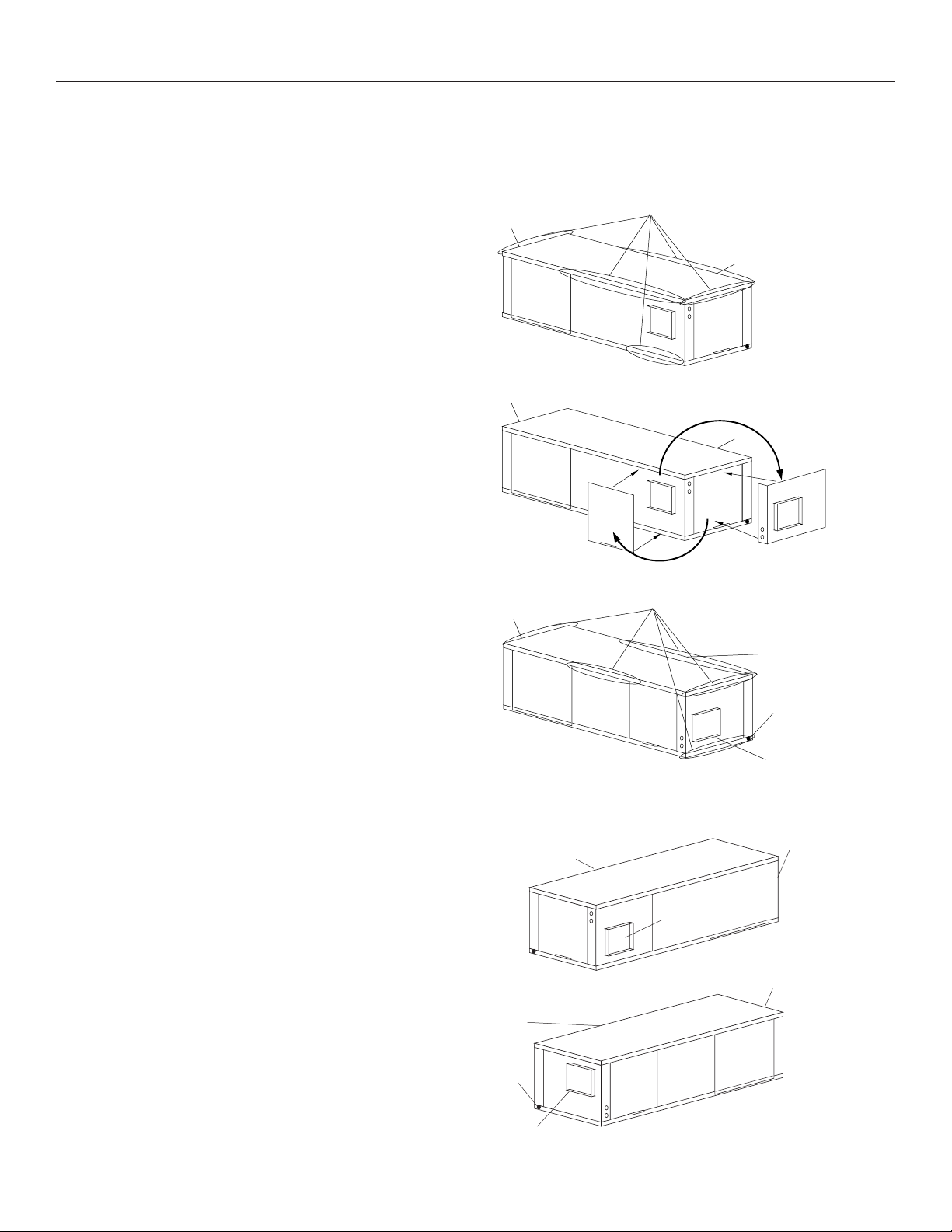

Field Conversion of Air Discharge

Overview

Horizontal units can be eld converted between side (straight)

and back (end) discharge using the instructions below.

Note: It is not possible to eld convert return air between

left or right return models due to the necessity of

refrigeration copper piping changes.

Preparation

It is best to eld convert the unit on the ground before hanging.

If the unit is already hung it should be taken down for the eld

conversion.

Side to Back Discharge Conversion

1.

Place unit in well lit area. Remove the screws as shown in

Figure 4 to free top panel and discharge panel.

2. Lift out the access panel and set aside. Lift and rotate

the discharge panel to the other position as shown, being

careful with the blower wiring.

3.

Check blower wire routing and connections for tension or

contact with sheet metal edges. Reroute if necessary.

4. Check refrigerant tubing for contact with

other components.

5. Reinstall top panel and screws noting that the location for

some screws will have changed.

6. Manually spin the fan wheel to insure that the wheel is not

rubbing or obstructed.

7. Replace access panels.

Figure 4: Left Return Side to Back

Back to Side Discharge Conversion

If the discharge is changed from back to side, use above

instruction noting that illustrations will be reversed.

Left vs. Right Return

It is not possible to eld convert return air between left or right

return models due to the necessity of refrigeration copper

piping changes. However, the conversion process of side to

back or back to side discharge for either right or left return

conguration is the same. In some cases, it may be possible

to rotate the entire unit 180 degrees if the return air connection

needs to be on the opposite side. Note that rotating the unit will

move the piping to the other end of the unit.

Figure 5: Right Return Side to Back

Water

Connection End

Water

Connection End

Return Air

Drain

Discharge Air

Return Air

Supply Duct

Side Discharge

Back Discharge

Page 10

IOM Instructions HBH/V COMPACT Heat Controller, Inc.

*3/4" IPT

Trap Depth

1.5" [38mm]

Min 1.5"

[38mm]

1/4" per foot

(21mm per m)

drain slope

3/4" PVC or

Copper by others

Rev.: 6/26/09S

Vent

* Some units include a painted drain

connection. Using a threaded pipe or

similar device to clear any excess paint

accumulated inside this fitting may

ease final drain line installation.

Horizontal Installation

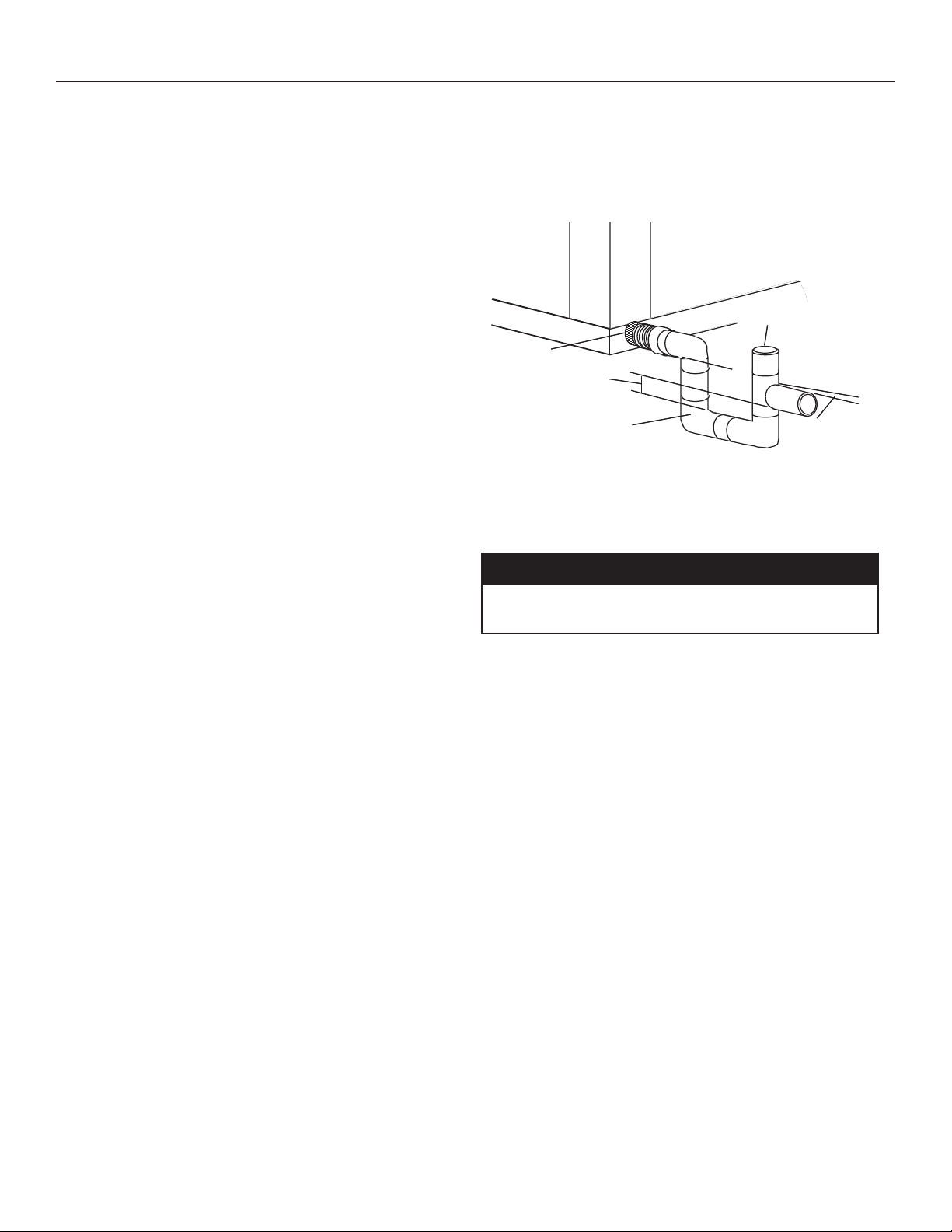

Condensate Piping – Horizontal Units

Pitch the unit toward the drain as shown in Figure 2 to

improve the condensate drainage. On small units (less

than 2.5 tons/8.8 kW), insure that unit pitch does not

cause condensate leaks inside the cabinet.

Install condensate trap at each unit with the top of the trap

positioned below the unit condensate drain connection as

shown in Figure 6.

Each unit must be installed with its own individual trap

and connection to the condensate line (main) or riser.

Provide a means to ush or blow out the condensate line.

DO NOT install units with a common trap and/or vent.

Always vent the condensate line when dirt or air can

collect in the line or a long horizontal drain line is

required. Also vent when large units are working against

higher external static pressure than other units connected

to the same condensate main since this may cause

poor drainage for all units on the line. WHEN A VENT

IS INSTALLED IN THE DRAIN LINE, IT MUST BE

LOCATED AFTER THE TRAP IN THE DIRECTION OF

THE CONDENSATE FLOW.

Figure 6: Horizontal Condensate Connection

CAUTION!

CAUTION! Ensure condensate line is pitched toward drain

1/4” per foot [21mm per m] of run.

Duct System Installation

Proper duct sizing and design is critical to the

performance of the unit. The duct system should be

designed to allow adequate and even airow through

the unit during operation. Air ow through the unit MUST

be at or above the minimum stated airow for the unit

to avoid equipment damage. Duct systems should

be designed for quiet operation. Refer to Figure 3 for

horizontal duct system details or gure 8 for vertical duct

system details. A exible connector is recommended

for both discharge and return air duct connections on

metal duct systems to eliminate the transfer of vibration

to the duct system. To maximize sound attenuation of

the unit blower, the supply and return plenums should

include internal berglass duct liner or be constructed

from ductboard for the rst few feet. Application of the

unit to uninsulated ductwork in an unconditioned space

DUCT SYSTEM INSTALLATION

is not recommended, as the unit’s performance will be

adversely affected.

At least one 90° elbow should be included in the supply

duct to reduce air noise. If air noise or excessive air ow

is a problem, the blower speed can be changed. For

airow charts, consult submittal data for the series and

model of the specic unit.

If the unit is connected to existing ductwork, a previous

check should have been made to insure that the

ductwork has the capacity to handle the airow required

for the unit. If ducting is too small, as in the replacement

of a heating only system, larger ductwork should be

installed. All existing ductwork should be checked for

leaks and repaired as necessary.

Page 11

Heat Controller, Inc. HBH/V COMPACT IOM Instructions

noise

Flexible canvas duct

connector to reduce

noise and vibration

Use turning vanes in

supply transition

Internally insulate supply

duct for first 4’ [1.2m] each

way to reduce noise

Internally insulate return

transition duct to reduce

noise

Rounded return

transition

Rev.: 6/2/09S

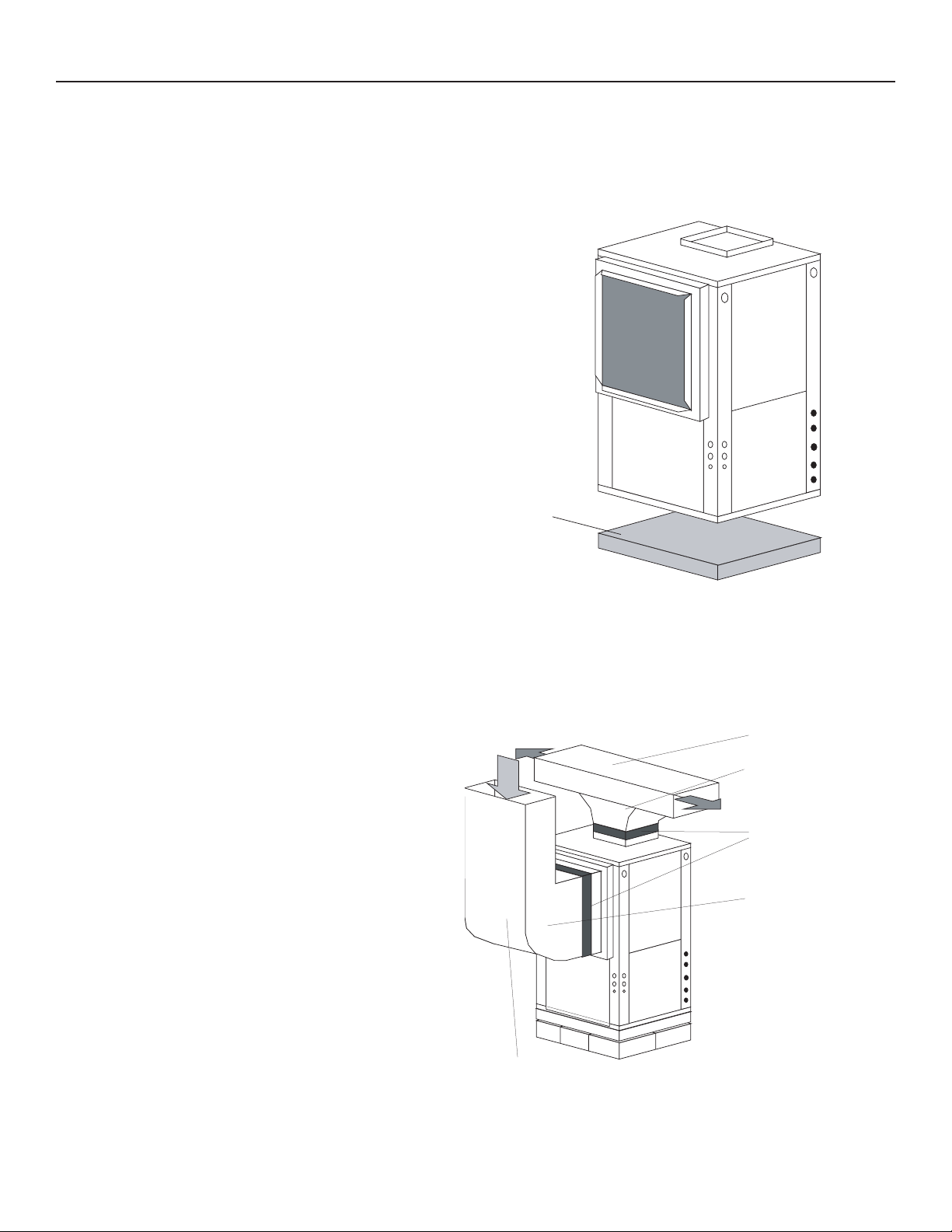

Vertical Installation

Vertical Unit Location

Units are not designed for outdoor installation. Locate

the unit in an INDOOR area that allows enough space

for service personnel to perform typical maintenance

or repairs without removing unit from the mechanical

room/closet. Vertical units are typically installed in a

mechanical room or closet. Never install units in areas

subject to freezing or where humidity levels could cause

cabinet condensation (such as unconditioned spaces

subject to 100% outside air). Consideration should be

given to access for easy removal of the lter and access

panels. Provide sufcient room to make water, electrical,

and duct connection(s).

If the unit is located in a conned space, such as a closet,

provisions must be made for return air to freely enter

the space by means of a louvered door, etc. Any access

panel screws that would be difcult to remove after the

unit is installed should be removed prior to setting the

unit. Refer to Figures 7 and 8 for typical installation

illustrations. Refer to unit submittal data or engineering

design guide for dimensional data.

1. Install the unit on a piece of rubber, neoprene or

other mounting pad material for sound isolation. The

pad should be at least 3/8” [10mm] to 1/2” [13mm] in

thickness. Extend the pad beyond all four edges of

the unit.

2. Provide adequate clearance for lter replacement

and drain pan cleaning. Do not block lter access

with piping, conduit or other materials. Refer to

unit submittal data or engineering design guide for

dimensional data.

3. Provide access for fan and fan motor maintenance

and for servicing the compressor and coils without

removing the unit.

4. Provide an unobstructed path to the unit within the

closet or mechanical room. Space should be sufcient

to allow removal of the unit, if necessary.

5.

In limited side access installations, pre-removal of the

control box side mounting screws will allow control box

removal for future servicing (TC units only).

6. Provide access to water valves and ttings and

screwdriver access to the unit side panels, discharge

collar and all electrical connections.

HB

Figure 7: Vertical Unit Mounting

Air Pad or Extruded

polystyrene insulation board

Figure 8: Typical Vertical Unit Installation Using

Ducted Return Air

Internally insulate supply

duct for first 4’ [1.2 m] each way

to reduce noise

Use turning vanes in

supply transition

Flexible canvas duct

connector to reduce

noise and vibration

Rounded return

transition

Internally insulate return

transition duct to reduce

Rev.: 6/2/09S

Page 12

IOM Instructions HBH/V COMPACT Heat Controller, Inc.

Vertical Installation

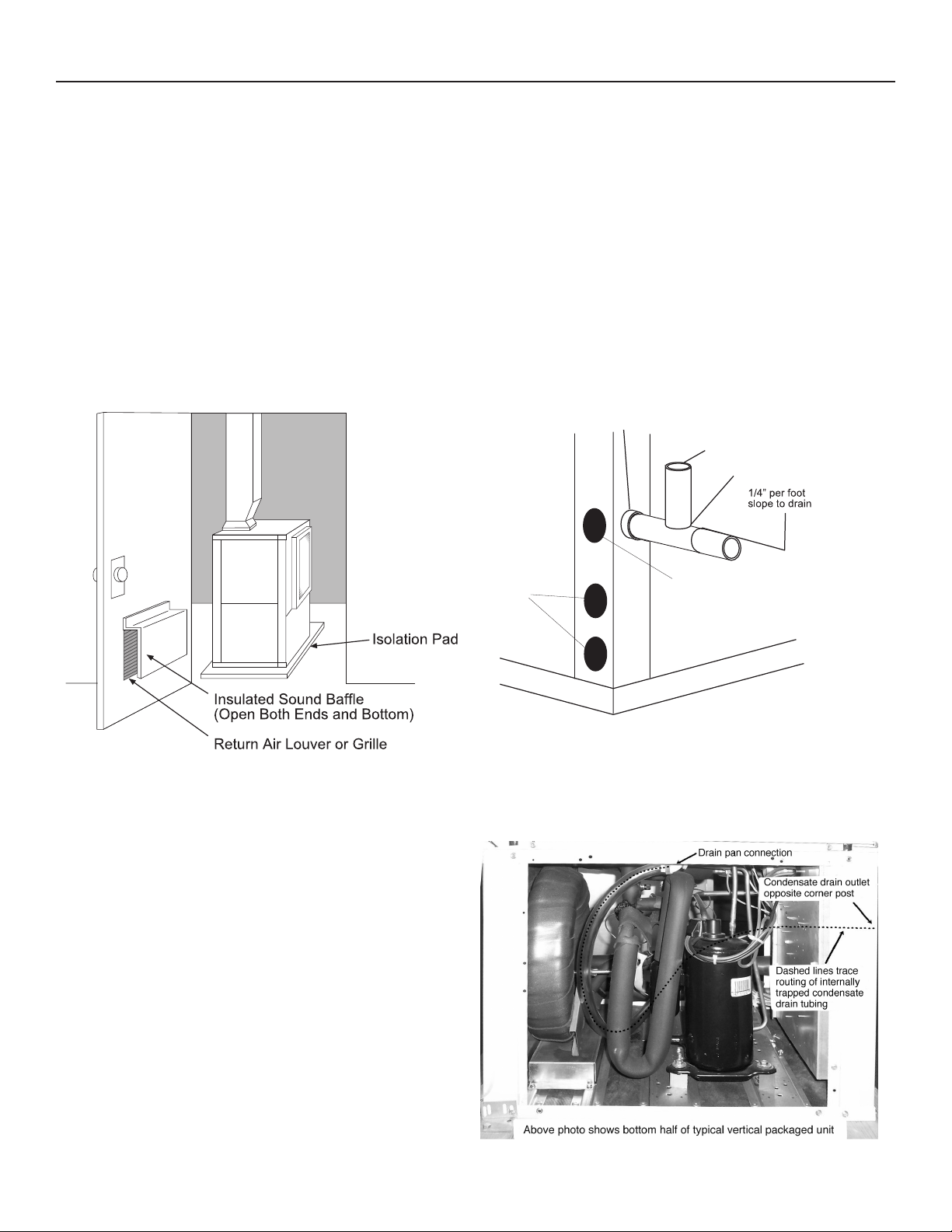

Sound Attenuation for Vertical Units

Sound attenuation is achieved by enclosing the unit within a

small mechanical room or a closet. Additional measures for

sound control include the following:

1. Mount the unit so that the return air inlet is 90° to the

return air grille. Refer to Figure 9. Install a sound bafe as

illustrated to reduce line-of sight sound transmitted through

return air grilles.

2.

Mount the unit on a rubber or neoprene isolation pad to minimize vibration transmission to the building structure.

Figure 9: Vertical Sound Attenuation

Condensate Piping – Vertical Units

Vertical units utilize a condensate hose inside the cabinet as

a trapping loop; therefore an external trap is not necessary.

Figure 10a shows typical condensate connections. Figure 10b

illustrates the internal trap for a typical vertical heat pump.

Each unit must be installed with its own individual vent (where

necessary) and a means to ush or blow out the condensate

drain line. Do not install units with a common trap and/or vent.

Figure 10a: Vertical Condensate Drain

*3/4" IPT

Vent

3/4" PVC

(21mm per m)

Water

Connections

Alternate

Condensate

Location

NOTICE! Units with clear plastic drain lines should have

regular maintenance (as required) to avoid buildup of debris,

especially in new construction.

* Some units include a painted drain connection. Using a

threaded pipe or similar device to clear any excess paint

accumulated inside this fitting may ease final drain line installation.

Figure 10b: Vertical Internal Condensate Trap

Page 13

Heat Controller, Inc. HBH/V COMPACT IOM Instructions

Swivel

EPT

Piping Installation

Installation of Supply and Return Piping

Follow these piping guidelines.

1. Install a drain valve at the base of each supply and

return riser to facilitate system ushing.

2. Install shut-off / balancing valves and unions at each

unit to permit unit removal for servicing.

3. Place strainers at the inlet of each system

circulating pump.

4. Select the proper hose length to allow slack between

connection points. Hoses may vary in length by +2%

to -4% under pressure.

5. Refer to Table 1. Do not exceed the minimum bend

radius for the hose selected. Exceeding the minimum

bend radius may cause the hose to collapse, which

reduces water ow rate. Install an angle adapter to

avoid sharp bends in the hose when the radius falls

below the required minimum.

Insulation is not required on loop water piping except

where the piping runs through unheated areas, outside

the building or when the loop water temperature is

below the minimum expected dew point of the pipe

ambient conditions. Insulation is required if loop water

temperature drops below the dew point (insulation is

required for ground loop applications in most climates).

A backup wrench is required when tightening water

connections on HB series to prevent water line damage.

CAUTION!

CAUTION! Corrosive system water requires corrosion resis-

tant ttings and hoses, and may require water treatment.

CAUTION!

CAUTION! Do not bend or kink supply lines or hoses.

CAUTION!

CAUTION! Piping must comply with all applicable codes.

Table 1: Metal Hose Minimum Bend Radii

Hose Diameter Minimum Bend Radii

1/2" [12.7mm] 2-1/2" [6.4cm]

3/4" [19.1mm] 4" [10.2cm]

1" [25.4mm] 5-1/2" [14cm]

1-1/4" [31.8mm] 6-3/4" [17.1cm]

Pipe joint compound is not necessary when Teon®

thread tape is pre-applied to hose assemblies or when

ared-end connections are used. If pipe joint compound

is preferred, use compound only in small amounts on

the external pipe threads of the tting adapters. Prevent

sealant from reaching the ared surfaces of the joint.

Note: When anti-freeze is used in the loop, insure that it

is compatible with the Teon tape or pipe joint compound

that is applied.

Maximum allowable torque for brass ttings is 30 ft-lbs

[41 N-m]. If a torque wrench is not available, tighten

nger-tight plus one quarter turn. Tighten steel ttings

as necessary.

Optional pressure-rated hose assemblies designed

specically for use with Heat Controller units are available.

Similar hoses can be obtained from alternate suppliers.

Supply and return hoses are tted with swivel-joint ttings

at one end to prevent kinking during installation.

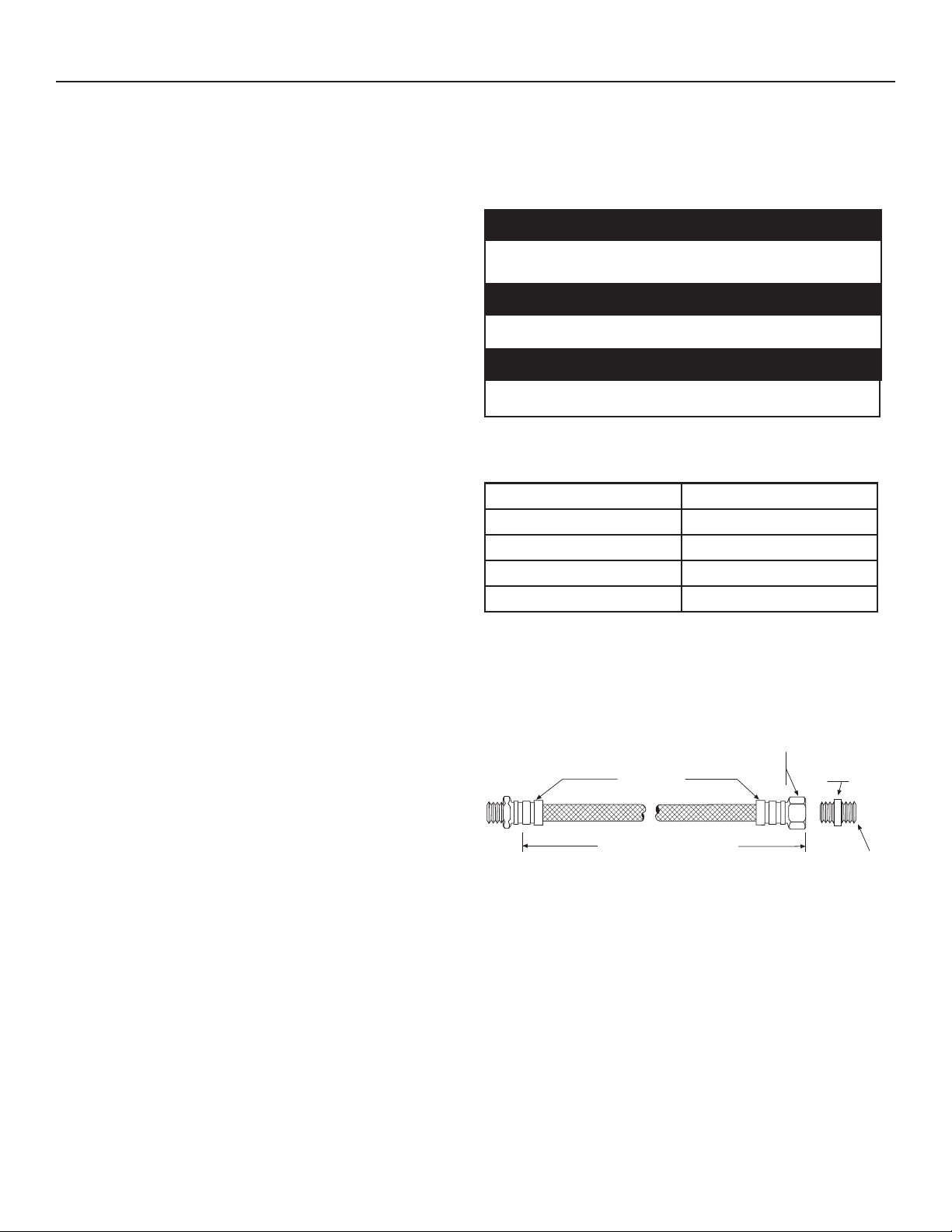

Refer to Figure 11 for an illustration of a typical supply/

return hose kit. Adapters secure hose assemblies to the

unit and risers. Install hose assemblies properly and

check regularly to avoid system failure and reduced

service life.

NOTICE! Do not allow hoses to rest against structural

building components. Compressor vibration may be

transmitted through the hoses to the structure, causing

unnecessary noise complaints.

Figure 11: Supply/Return Hose Kit

Rib Crimped

Length

(2 ft [0.6m] Length Standard)

Brass

Fitting

Brass

Fitting

Page 14

IOM Instructions HBH/V COMPACT Heat Controller, Inc.

Water-Loop Heat Pump Applications

Commercial Water Loop Applications

Commercial systems typically include a number of

units connected to a common piping system. Any unit

plumbing maintenance work can introduce air into the

piping system; therefore air elimination equipment is

a major portion of the mechanical room plumbing. In

piping systems expected to utilize water temperatures

below 60°F [16°C], 1/2” (13mm) closed cell insulation is

required on all piping surfaces to eliminate condensation

(extended range units required). Metal to plastic threaded

joints should never be used due to their tendency to leak

over time. A backup wrench must be used for HB series

equipment ttings.

Teon tape thread sealant is recommended to minimize

internal fouling of the heat exchanger. Do not over tighten

connections and route piping so as not to interfere with

service or maintenance access. Hose kits are available

from Heat Controller in different congurations as shown

in Figure 12 for connection between the unit and the

piping system.

Figure 12: Typical Water-Loop Application

3/8" [10mm] threaded rods

(by others)

The piping system should be ushed to remove dirt,

piping chips, and other foreign material prior to operation

(see “Piping System Cleaning and Flushing Procedures”

in this manual). The ow rate is usually set between 2.25

and 3.5 gpm per ton [2.9 and 4.5 l/m per kW] of cooling

capacity. Heat Controller recommends 3 gpm per ton

[3.9 l/m per kW] for most applications of water loop heat

pumps. To insure proper maintenance and servicing, P/T

ports are imperative for temperature and ow verication,

as well as performance checks.

Water loop heat pump (cooling tower/boiler) systems

typically utilize a common loop, maintained between 60 90°F [16 - 32°C]. The use of a closed circuit evaporative

cooling tower with a secondary heat exchanger between

the tower and the water loop is recommended. If an

open type cooling tower is used continuously, chemical

treatment and ltering will be necessary.

Low Water Temperature Cutout Setting - CXM Control

When antifreeze is selected, the FP1 jumper (JW3) should

be clipped to select the low temperature (antifreeze 13°F

[-10.6°C]) set point and avoid nuisance faults (see “Low

Water Temperature Cutout Selection” in this manual). NOTE:

Low water temperature operation requires extended range

equipment.

Stainless steel braided hoses

with threaded connections

and one swivel end

Page 15

Heat Controller, Inc. HBH/V COMPACT IOM Instructions

Ground-Loop Heat Pump Applications

Test individual horizontal loop circuits before backlling.

Test vertical U-bends and pond loop assemblies prior to

CAUTION!

CAUTION! The following instructions represent industry

accepted installation practices for closed loop earth coupled

heat pump systems. Instructions are provided to assist the

contractor in installing trouble free ground loops. These

instructions are recommendations only. State/provincial

and local codes MUST be followed and installation MUST

conform to ALL applicable codes. It is the responsibility of

the installing contractor to determine and comply with ALL

applicable codes and regulations.

CAUTION!

CAUTION! Ground loop applications require extended range

equipment and optional refrigerant/water circuit insulation.

Pre-Installation

Prior to installation, locate and mark all existing

underground utilities, piping, etc. Install loops for new

construction before sidewalks, patios, driveways, and other

construction has begun. During construction, accurately

mark all ground loop piping on the plot plan as an aid in

avoiding potential future damage to the installation.

Piping Installation

The typical closed loop ground source system is shown

in Figure 13. All earth loop piping materials should be

limited to polyethylene fusion only for in-ground sections

of the loop. Galvanized or steel ttings should not be

used at any time due to their tendency to corrode. All

plastic to metal threaded ttings should be avoided due

to their potential to leak in earth coupled applications. A

anged tting should be substituted. P/T plugs should be

used so that ow can be measured using the pressure

drop of the unit heat exchanger.

Earth loop temperatures can range between 25 and

110°F [-4 to 43°C]. Flow rates between 2.25 and 3 gpm

per ton [2.41 to 3.23 l/m per kW] of cooling capacity is

recommended in these applications.

installation. Pressures of at least 100 psi [689 kPa] should

be used when testing. Do not exceed the pipe pressure

rating. Test entire system when all loops are assembled.

Flushing the Earth Loop

Upon completion of system installation and testing, ush

the system to remove all foreign objects and purge to

remove all air.

Antifreeze

In areas where minimum entering loop temperatures drop

below 40°F [5°C] or where piping will be routed through

areas subject to freezing, antifreeze is required. Alcohols

and glycols are commonly used as antifreeze. Freeze

protection should be maintained to 15°F [9°C] below the

lowest expected entering loop temperature. For example,

if 30°F [-1°C] is the minimum expected entering loop

temperature, the leaving loop temperature would be 25 to

22°F [-4 to -6°C] and freeze protection should be at 15°F

[-10°C]. Calculation is as follows:

30°F - 15°F = 15°F [-1°C - 9°C = -10°C].

All alcohols should be premixed and pumped from

a reservoir outside of the building when possible or

introduced under the water level to prevent fumes.

Calculate the total volume of uid in the piping system.

Then use the percentage by volume shown in table

2 for the amount of antifreeze needed. Antifreeze

concentration should be checked from a well mixed

sample using a hydrometer to measure specic gravity.

Low Water Temperature Cutout Setting - CXM Control

When antifreeze is selected, the FP1 jumper (JW3) should

be clipped to select the low temperature (antifreeze 13°F

[-10.6°C]) set point and avoid nuisance faults (see “Low

Water Temperature Cutout Selection” in this manual). NOTE:

Low water temperature operation requires extended range

equipment.

Table 2: Antifreeze Percentages by Volume

Type

Methanol

100% USP food grade Propylene Glycol

Ethanol*

* Must not be denatured with any petroleum based product

10°F [-12.2°C] 15°F [-9.4°C] 20°F [-6.7°C] 25°F [-3.9°C]

Minimum Temperature for Low Temperature Protection

25%

38%

29%

21%

25%

25%

16%

22%

20%

10%

15%

14%

Page 16

IOM Instructions HBH/V COMPACT Heat Controller, Inc.

Ground-Loop Heat Pump Applications

Figure 13: Typical Ground-Loop Application

Page 17

Page 18

IOM Instructions HBH/V COMPACT Heat Controller, Inc.

Ground-Water Heat Pump Applications

Water Coil Low Temperature Limit Setting

For all open loop systems the 30°F [-1.1°C] FP1 setting

(factory setting-water) should be used to avoid freeze

damage to the unit. See “Low Water Temperature Cutout

Selection” in this manual for details on the low limit setting.

Figure 14: Typical Open Loop/Well Application

Water

Control

Valve

P/T Plugs

Flow

Regulator

Boiler

Drains

Pressure

Tank

Water Out

Water In

Shut-Off

Valve

Optional

Filter

Page 19

Heat Controller, Inc. HBH/V COMPACT IOM Instructions

Water Quality Standards

Table 3: Water Quality Standards

WaterÊQuality

Parameter

HX

Material

Closed

Recirculating

OpenÊLoopÊandÊRecirculatingÊWell

ScalingÊPotentialÊ-ÊPrimaryÊMeasurement

AboveÊtheÊgivenÊlimits,ÊscalingÊisÊlikelyÊtoÊoccur.ÊÊScalingÊindexesÊshouldÊbeÊcalculatedÊusingÊtheÊlimitsÊbelow

pH/CalciumÊHardness

Method

All

pHÊ<Ê7.5ÊandÊCaÊHardnessÊ<100ppm

IndexÊLimitsÊforÊProbableÊScalingÊSituationsÊ-Ê(OperationÊoutsideÊtheseÊlimitsÊisÊnotÊrecommended)

ScalingÊindexesÊshouldÊbeÊcalculatedÊatÊ150¡FÊ[66¡C]ÊforÊdirectÊuseÊandÊHWGÊapplications,ÊandÊatÊ90¡FÊ[32¡C]ÊforÊindirectÊHXÊuse.Ê

AÊmonitoringÊplanÊshouldÊbeÊimplemented.

Ryznar

StabilityÊIndex IfÊ>7.5ÊminimizeÊsteelÊpipeÊuse.

Langelier

SaturationÊIndex

All

All

- 6.0Ê-Ê7.5

-

IfÊ<-0.5ÊminimizeÊsteelÊpipeÊuse.ÊBasedÊuponÊ150¡FÊ[66¡C]ÊHWGÊand

-0.5ÊtoÊ+0.5

DirectÊwell,Ê85¡FÊ[29¡C]ÊIndirectÊWellÊHX

IronÊFouling

IronÊFe2+(Ferrous)

(BacterialÊIronÊpotential)

IronÊFouling

All

All

-

2+

Ê(ferrous)>0.2ÊppmÊwithÊpHÊ6Ê-Ê8,ÊO2<5ÊppmÊcheckÊforÊironÊbacteria

IfÊFe

-

AboveÊthisÊlevelÊdepositionÊwillÊoccur.

<0.2ÊppmÊ(Ferrous)

<0.5ÊppmÊofÊOxygen

CorrosionÊPrevention

pH

HydrogenÊSulfideÊ(H

AmmoniaÊionÊasÊhydroxide,Êchloride,Ê

nitrateÊandÊsulfateÊcompounds

Maximum

ChlorideÊLevels

S)

2

6Ê-Ê8.5

All

All

All

Copper - <20ppm NR NR

CuproNickel - <150Êppm NR NR

304ÊSS - <400Êppm <250Êppm <150 ppm

316ÊSS - <1000Êppm <550Êppm < 375 ppm

Titanium - >1000Êppm >550Êppm >375 ppm

Monitor/treatÊas

needed

- <0.5Êppm

-

MinimizeÊsteelÊpipeÊbelowÊ7ÊandÊnoÊopenÊtanksÊwithÊpHÊ<8

AtÊH

S>0.2Êppm,ÊavoidÊuseÊofÊcopperÊandÊcopperÊnickelÊpipingÊorÊHX's.

2

CopperÊalloyÊ(bronzeÊorÊbrass)ÊcastÊcomponentsÊareÊOKÊtoÊ<0.5Êppm.

50¡FÊ(10¡C) 75¡FÊ(24¡C) 100ϒF (38ϒC)

RottenÊeggÊsmellÊappearsÊatÊ0.5ÊppmÊlevel.

MaximumÊAllowableÊatÊmaximumÊwaterÊtemperature.

6Ê-Ê8.5

<0.5Êppm

ErosionÊandÊClogging

<10ÊppmÊofÊparticles

andÊaÊmaximum

velocityÊofÊ6ÊfpsÊ[1.8Êm/s].

ParticulateÊSizeÊand

Erosion

Notes:

• Closed Recirculating system is identified by a

• Recirculating open wells should observe the open recirculating design considerations.

• NR - Application not recommended.

• "-" No design Maximum.

All

FilteredÊforÊmaximum

800ÊmicronÊ[800mm,

20Êmesh]Êsize.

closed pressurized piping system.

<10ÊppmÊ(<1ÊppmÊ"sandfree"ÊforÊreinjection)ÊofÊparticlesandÊaÊmaximum

velocityÊofÊ6ÊfpsÊ[1.8Êm/s].ÊFilteredÊforÊmaximumÊ800ÊmicronÊ[800mm,

20Êmesh]Êsize.AnyÊparticulateÊthatÊisÊnotÊremovedÊcanÊpotentially

clogÊcomponents.

Rev.: 01/21/09B

Page 20

IOM Instructions HBH/V COMPACT Heat Controller, Inc.

Electrical - Line Voltage

Electrical - Line Voltage

All eld installed wiring, including electrical ground, must

comply with the National Electrical Code as well as all

applicable local codes. Refer to the unit electrical data for

fuse sizes. Consult wiring diagram for eld connections

that must be made by the installing (or electrical)

contractor. All nal electrical connections must be made

with a length of exible conduit to minimize vibration and

sound transmission to the building.

General Line Voltage Wiring

Be sure the available power is the same voltage and

phase shown on the unit serial plate. Line and low voltage

wiring must be done in accordance with local codes or the

National Electric Code, whichever is applicable.

Transformer

All 208/230 voltage units are factory wired for 208

volt. If supply voltage is 230 volt, installer must rewire

transformer. See wire diagram for connections.

WARNING!

WARNING! To avoid possible injury or death due to

electrical shock, open the power supply disconnect switch

and secure it in an open position during installation.

CAUTION!

CAUTION!

wiring. Unit terminals are not designed to accept other types of

conductors.

Use only copper conductors for eld installed electrical

Page 21

Heat Controller, Inc. HBH/V COMPACT IOM Instructions

Electrical - Line Voltage

Table 4a: HB Series Electrical Data - (Standard 60Hz Units)

HB

Voltage

Model

006 1

009 1

012 1

015

018

024

030

036

042

048

060

Code

1

8

1

8

1

8

1

8

3

4

1

8

3

4

1

3

4

5

1

3

4

5

1

3

4

5

Rated

Voltage

208-230/60/1 197/254 1 3.3 17.7 0.40 3.7 4.5 15

208-230/60/1 197/254 1 5.6 22.2 0.80 6.4 7.8 15

208-230/60/1 197/254 1 5.1 32.5 0.80 5.9 7.2 15

208-230/60/1 197/254 1 6.0 29.0 1.00 7.0 8.5 15

265/60/1 239/292 1 5.4 28.0 0.86 6.3 7.6 15

208-230/60/1 197/254 1 7.2 33.0 1.00 8.2 10.0 15

265/60/1 239/292 1 5.9 28.0 0.86 6.8 8.2 15

208-230/60/1 197/254 1 12.8 58.3 1.50 14.3 17.5 30

265/60/1 239/292 1 9.6 54.0 1.30 10.9 13.3 20

208-230/60/1 197/254 1 14.1 73.0 3.00 17.1 20.6 30

265/60/1 239/292 1 11.2 60.0 2.70 13.9 16.7 25

208-230/60/3 197/254 1 8.9 58.0 3.00 11.9 14.1 20

460/60/3 414/506 1 4.2 28.0 1.70 5.9 7.0 15

208-230/60/1 197/254 1 16.7 79.0 1.80 18.5 22.7 35

265/60/1 239/292 1 13.5 72.0 2.00 15.5 18.9 30

208-230/60/3 197/254 1 10.4 73.0 1.80 12.2 14.8 25

460/60/3 414/506 1 5.8 38.0 1.24 7.0 8.5 15

208-230/60/1 197/254 1 17.9 112.0 3.00 20.9 25.4 40

208-230/60/3 197/254 1 13.5 88.0 3.00 16.5 19.9 30

460/60/3 414/506 1 6.0 44.0 1.70 7.7 9.2 15

575/60/3 518/633 1 4.9 34.0 1.40 6.3 7.5 15

208-230/60/1 197/254 1 21.8 117.0 3.40 25.2 30.7 50

208-230/60/3 197/254 1 13.7 83.1 3.40 17.1 20.5 30

460/60/3 414/506 1 6.2 41.0 1.80 8.0 9.6 15

575/60/3 518/633 1 4.8 33.0 1.40 6.2 7.4 15

208-230/60/1 197/254 1 26.3 134.0 4.90 31.2 37.8 60

208-230/60/3 197/254 1 15.6 110.0 4.90 20.5 24.4 40

460/60/3 414/506 1 7.8 52.0 2.50 10.3 12.3 20

575/60/3 518/633 1 5.8 38.9 1.90 7.7 9.2 15

Voltage

Min/

Max

Compressor

QTY RLA LRA

Fan

Motor

FLA

Total

Unit

FLA

Min

Circuit

Amp

Max

Fuse/

HACR

HACR circuit breaker in USA only

All fuses Class RK-5

Page 22

IOM Instructions HBH/V COMPACT Heat Controller, Inc.

Table 4b: HB Series Electrical Data - (Standard 60Hz Units High Static)

HB

Model

015

018

024

030

036

042

048

060

Voltage

Code

1

8

1

8

1

8

1

8

3

4

1

8

3

4

1

3

4

5

1

3

4

5

1

3

4

5

Rated

Voltage

208-230/60/1 197/254 1 6.0 29.0 1.00 7.0 8.5 15

265/60/1 239/292 1 5.4 28.0 0.86 6.3 7.6 15

208-230/60/1 197/254 1 7.2 33.0 1.50 8.7 10.5 15

265/60/1 239/292 1 5.9 28.0 1.30 7.2 8.7 15

208-230/60/1 197/254 1 12.8 58.3 3.00 15.8 19.0 30

265/60/1 239/292 1 9.6 54.0 2.70 12.3 14.7 20

208-230/60/1 197/254 1 14.1 73.0 3.00 17.1 20.6 30

265/60/1 239/292 1 11.2 60.0 2.70 13.9 16.7 25

208-230/60/3 197/254 1 8.9 58.0 3.00 11.9 14.1 20

460/60/3 414/506 1 4.2 28.0 1.70 5.9 7.0 15

208-230/60/1 197/254 1 16.7 79.0 3.00 19.7 23.9 40

265/60/1 239/292 1 13.5 72.0 2.70 16.2 19.6 30

208-230/60/3 197/254 1 10.4 73.0 3.00 13.4 16.0 25

460/60/3 414/506 1 5.8 38.0 1.70 7.5 9.0 15

208-230/60/1 197/254 1 17.9 112.0 3.00 20.9 25.4 40

208-230/60/3 197/254 1 13.5 88.0 3.00 16.5 19.9 30

460/60/3 414/506 1 6.0 44.0 1.70 7.7 9.2 15

575/60/3 518/633 1 4.9 34.0 1.40 6.3 7.5 15

208-230/60/1 197/254 1 21.8 117.0 4.90 26.7 32.2 50

208-230/60/3 197/254 1 13.7 83.1 4.90 18.6 22.0 35

460/60/3 414/506 1 6.2 41.0 2.50 8.7 10.3 15

575/60/3 518/633 1 4.8 33.0 1.90 6.7 7.9 15

208-230/60/1 197/254 1 26.3 134.0 5.80 32.1 38.7 60

208-230/60/3 197/254 1 15.6 110.0 5.80 21.4 25.3 40

460/60/3 414/506 1 7.8 52.0 2.60 10.4 12.4 20

575/60/3 518/633 1 5.8 38.9 2.30 8.1 9.6 15

Voltage

Min/

Max

Compressor

QTY RLA LRA

Fan

Motor

FLA

Total

Unit

FLA

Min

Circuit

Amp

Max

Fuse/

HACR

HACR circuit breaker in USA only

All fuses Class RK-5

Page 23

Heat Controller, Inc. HBH/V COMPACT IOM Instructions

Transformer

CXM

Control

Contactor -CC

BR

Low

Voltage

Connector

CB

L2

L1

Unit Power Supply

See electrical table for

breaker size

Grnd

Rev.: 5/17/01 B

Capacitor

Electrical - Power Wiring

Power Connection

WARNING!

WARNING! Disconnect electrical power source to prevent

injury or death from electrical shock.

Line voltage connection is made by connecting the

incoming line voltage wires to the “L” side of the

contractor as shown in Figure 15. Consult electrical data

tables for correct fuse size.

CAUTION!

CAUTION!

Use only copper conductors for eld installed electrical

wiring. Unit terminals are not designed to accept other types of

conductors.

Electrical - Line Voltage

All eld installed wiring, including electrical ground, must

comply with the National Electrical Code as well as all

applicable local codes. Refer to the unit electrical data for

fuse sizes. Consult wiring diagram for eld connections

that must be made by the installing (or electrical)

contractor. All nal electrical connections must be made

with a length of exible conduit to minimize vibration and

sound transmission to the building.

Transformer

All 208/230 voltage units are factory wired for 208

volt. If supply voltage is 230 volt, installer must rewire

transformer. See wire diagram for connections.

General Line Voltage Wiring

Be sure the available power is the same voltage and

phase shown on the unit serial plate. Line and low voltage

wiring must be done in accordance with local codes or the

National Electric Code, whichever is applicable.

Figure 15: HB Single Phase Line Voltage Field Wiring.

Three phase wiring is similar except that all three

power wires are directly connected to the contactor.

Page 24

IOM Instructions HBH/V COMPACT Heat Controller, Inc.

Electrical - Power & Low Voltage Wiring

Blower Speed Selection – Units with PSC Motor

PSC (Permanent Split Capacitor) blower fan speed

can be changed by moving the blue wire on the fan

motor terminal block to the desired speed as shown

in Figure 16. Most Heat Controller units are shipped

on the medium speed tap. Consult submittal data or

engineering design guide for specic unit airow tables.

Typical unit design delivers rated airow at nominal

static (0.15 in. w.g. [37Pa]) on medium speed and rated

airow at a higher static (0.4 to 0.5 in. w.g. [100 to 125

Pa]) on high speed for applications where higher static

is required. Low speed will deliver approximately 85%

of rated airow at 0.10 in. w.g. [25 Pa]. An optional high

static blower is available on some models.

Special Note for AHRI Testing: To achieve rated

airow for ARI testing purposes on all PSC products,

it is necessary to change the fan speed to “HI” speed.

When the heat pump has experienced less than 100

operational hours and the coil has not had sufcient time

to be “seasoned”, it is necessary to clean the coil with a

mild surfactant such as Calgon to remove the oils left by

manufacturing processes and enable the condensate to

properly “sheet” off of the coil.

Low Water Temperature Cutout Selection

The CXM control allows the eld selection of low water

(or water-antifreeze solution) temperature limit by clipping

jumper JW3, which changes the sensing temperature

associated with thermistor FP1. Note that the FP1

thermistor is located on the refrigerant line between the

coaxial heat exchanger and expansion device (TXV

or cap tube). Therefore, FP1 is sensing refrigerant

temperature, not water temperature, which is a better

indication of how water ow rate/temperature is affecting

the refrigeration circuit.

The factory setting for FP1 is for systems using water

(30°F [-1.1°C] refrigerant temperature). In low water

temperature (extended range) applications with

antifreeze (most ground loops), jumper JW3 should be

clipped as shown in Figure 18 to change the setting to

10°F [-12.2°C] refrigerant temperature, a more suitable

temperature when using an antifreeze solution. All

Heat Controller units operating with entering water

temperatures below 59°F [15°C] must include the

optional water/refrigerant circuit insulation package to

prevent internal condensation.

Figure 16: PSC Motor Speed Selection

Connect the blue wire to:

H for High speed fan

M for Medium speed fan

L for Low speed fan

Medium is factory setting

Fan Motor

ELECTRICAL - LOW VOLTAGE WIRING

Thermostat Connections

The thermostat should be wired directly to the

CXM board. Figure 17 shows wiring for HB units.

See “Electrical – Thermostat” for specic terminal

connections.

Figure 17: HB Low Voltage Field Wiring

Page 25

Heat Controller, Inc. HBH/V COMPACT IOM Instructions

Water Valve Wiring

Electrical - Low Voltage Wiring

Figure 18: FP1 Limit Setting

JW3-FP1

jumper should

be clipped for

low temperature

operation

CXM PCB

Accessory Connections

A terminal paralleling the compressor contactor coil

has been provided on the CXM control. Terminal “A”

is designed to control accessory devices, such as

water valves. Note: This terminal should be used only

with 24 Volt signals and not line voltage. Terminal

“A” is energized with the compressor contactor.

See Figure 19 or the specic unit wiring diagram for

details.

Low Voltage VA Ratings

Component VA

Typical Blower Relay 6 - 7

Typical Reversing Valve Solenoid 4 - 6

30A Compressor Contactor 6 - 9

Subtotal 16 - 22

+ CXM board (5 - 9 VA)* 21 - 31

Remaing VA for Accessories 19 - 29

*Standard transformer for CXM board is 50VA.

Figure 19: Accessory Wiring

Water Solenoid Valves

An external solenoid valve(s) should be used on ground

water installations to shut off ow to the unit when the

compressor is not operating. A slow closing valve may be

required to help reduce water hammer. Figure 19 shows

typical wiring for a 24VAC external solenoid valve. Figures

20 and 21 illustrate typical slow closing water control valve

wiring for Taco 500 series and Taco ESP series valves.

Slow closing valves take approximately 60 seconds to

open (very little water will ow before 45 seconds). Once

fully open, an end switch allows the compressor to be

energized. Only relay or triac based electronic thermostats

should be used with slow closing valves. When wired as

shown, the slow closing valve will operate properly with

the following notations:

1. The valve will remain open during a unit lockout.

2. The valve will draw approximately 25-35 VA through

the “Y” signal of the thermostat.

Note: This valve can overheat the anticipator of an

electromechanical thermostat. Therefore, only relay or

triac based thermostats should be used.

Figure 20: Taco 500 Series Valve Wiring

C

Y1

CAUTION!

CAUTION! Many units are installed with a factory or eld

supplied manual or electric shut-off valve. DAMAGE WILL

OCCUR if shut-off valve is closed during unit operation. A high

pressure switch must be installed on the heat pump side of

any eld provided shut-off valves and connected to the heat

pump controls in series with the built-in refrigerant circuit high

pressure switch to disable compressor operation if water

pressure exceeds pressure switch setting. The eld installed

high pressure switch shall have a cut-out pressure of 300 psig

and a cut-in pressure of 250 psig.

1

Heater Switch

C

Thermostat

2

Y1

3

Taco Valve

AVM

Figure 21: Taco SBV Valve Wiring

Page 26

IOM Instructions HBH/V COMPACT Heat Controller, Inc.

Electrical - Thermostat Wiring

Thermostat Installation

The thermostat should be located on an interior wall in

a larger room, away from supply duct drafts. DO NOT

locate the thermostat in areas subject to sunlight, drafts

or on external walls. The wire access hole behind the

thermostat may in certain cases need to be sealed to

prevent erroneous temperature measurement. Position

the thermostat back plate against the wall so that it

appears level and so the thermostat wires protrude

Figure 22: Units With PSC Fan And CXM

Connection to CXM Control

ATM11C01 Thermostat

Compressor

Reversing Valve

Fan

24Vac Hot

Y

W

O

G

R

CXM

Y

O

G

R

through the middle of the back plate. Mark the position of

the back plate mounting holes and drill holes with a 3/16”

(5mm) bit. Install supplied anchors and secure plate to

the wall. Thermostat wire must be 18 AWG wire. Wire the

appropriate thermostat as shown in Figures 22 through

25c to the low voltage terminal strip on the CXM control

board. Practically any heat pump thermostat will work

with Heat Controller units, provided it has the correct

number of heating and cooling stages.

Field Wiring

Factory Wiring

Page 27

Heat Controller, Inc. HBH/V COMPACT IOM Instructions

Description of Operation LED Alarm Relay

Normal Mode On Open

Normal Mode with UPS Warning On Cycle (closed 5 sec., Open 25 sec.)

CXM is non-functional Off Open

Fault Retry Slow Flash Open

Lockout Fast Flash Closed

Over/Under Voltage Shutdown Slow Flash Open (Closed after 15 minutes)

Test Mode - No fault in memory Flashing Code 1 Cycling Code 1

Test Mode - HP Fault in memory Flashing Code 2 Cycling Code 2

Test Mode - LP Fault in memory Flashing Code 3 Cycling Code 3

Test Mode - FP1 Fault in memory Flashing Code 4 Cycling Code 4

Test Mode - FP2 Fault in memory Flashing Code 5 Cycling Code 5

Test Mode - CO Fault in memory Flashing Code 6 Cycling Code 6

Test Mode - Over/Under

shutdown in memory

Flashing Code 7 Cycling Code 7

Test Mode - UPS in memory Flashing Code 8 Cycling Code 8

Test Mode - Swapped Thermistor Flashing Code 9 Cycling Code 9

CXM Controls

CXM Control

For detailed control information, see CXM Application,

Operation and Maintenance manual.

Field Selectable Inputs

Test mode: Test mode allows the service technician to

check the operation of the control in a timely manner. By

momentarily shorting the test terminals, the CXM control

enters a 20 minute test mode period in which all time

delays are sped up 15 times. Upon entering test mode,

the status LED will ash a code representing the last fault.

For diagnostic ease at the thermostat, the alarm relay will

also cycle during test mode. The alarm relay will cycle

on and off similar to the status LED to indicate a code

representing the last fault, at the thermostat. Test mode

can be exited by shorting the test terminals for 3 seconds.

Retry Mode: If the control is attempting a retry of a fault,

the status LED will slow ash (slow ash = one ash

every 2 seconds) to indicate the control is in the process

of retrying.

Field Conguration Options

Note: In the following eld conguration options, jumper

wires should be clipped ONLY when power is removed

from the CXM control.

whether compressor has an “on” delay. If set to stage

2, the compressor will have a 3 second delay before

energizing. Also, if set for stage 2, the alarm relay will

NOT cycle during test mode.

On = Stage 1. Off = Stage 2

DIP switch 3: Not Used.

DIP switch 4: DDC Output at EH2 - provides selection for

DDC operation. If set to “DDC Output at EH2,” the EH2

terminal will continuously output the last fault code of

the controller. If set to “EH2 normal,” EH2 will operate as

standard electric heat output.

On = EH2 Normal. Off = DDC Output at EH2.

NOTE: Some CXM controls only have a 2 position DIP

switch package. If this is the case, this option can be

selected by clipping the jumper which is in position 4

of SW1.

Jumper not clipped = EH2 Normal. Jumper clipped =

DDC Output at EH2.

DIP switch 5: Factory Setting - Normal position is “On.”

Do not change selection unless instructed to do so by

the factory.

Table 5: CXM LED And Alarm Relay Operations

Water coil low temperature limit setting: Jumper 3 (JW3-

FP1 Low Temp) provides eld selection of temperature

limit setting for FP1 of 30°F or 10°F [-1°F or -12°C]

(refrigerant temperature).

Not Clipped = 30°F [-1°C]. Clipped = 10°F [-12°C].

Air coil low temperature limit setting: Jumper 2 (JW2-FP2

Low Temp) provides eld selection of temperature limit

setting for FP2 of 30°F or 10°F [-1°F or -12°C] (refrigerant

temperature). Note: This jumper should only be clipped

under extenuating circumstances, as recommended by

the factory.

Not Clipped = 30°F [-1°C]. Clipped = 10°F [-12°C].

Alarm relay setting: Jumper 1 (JW1-AL2 Dry) provides

eld selection of the alarm relay terminal AL2 to be

jumpered to 24VAC or to be a dry contact (no connection).

Not Clipped = AL2 connected to R. Clipped = AL2 dry

contact (no connection).

DIP Switches

Note: In the following eld conguration options, DIP

switches should only be changed when power is removed

from the CXM control.

DIP switch 1: Unit Performance Sentinel Disable -

provides eld selection to disable the UPS feature.

On = Enabled. Off = Disabled.

DIP switch 2: Stage 2 Selection - provides selection of

-Slow Flash = 1 ash every 2 seconds

-Fast Flash = 2 ashes every 1 second

-Flash code 2 = 2 quick ashes, 10 second pause, 2 quick

ashes, 10 second pause, etc.

-On pulse 1/3 second; off pulse 1/3 second

CAUTION!

CAUTION! Do not restart units without inspection and

remedy of faulting condition. Equipment damage may occur.

Page 28

IOM Instructions HBH/V COMPACT Heat Controller, Inc.

Safety Features

Safety Features – CXM Control

The safety features below are provided to protect

the compressor, heat exchangers, wiring and other

components from damage caused by operation outside

of design conditions.

Anti-short cycle protection: The control features a 5

minute anti-short cycle protection for the compressor.

Note: The 5 minute anti-short cycle also occurs at power up.

Random start: The control features a random start upon

power up of 5-80 seconds.

Fault Retry: In Fault Retry mode, the Status LED begins

slowly ashing to signal that the control is trying to

recover from a fault input. The control will stage off the

outputs and then “try again” to satisfy the thermostat

input call. Once the thermostat input call is satised,

the control will continue on as if no fault occurred. If 3

consecutive faults occur without satisfying the thermostat

input call, the control will go into “lockout” mode. The last

fault causing the lockout will be stored in memory and

can be viewed by going into test mode (CXM board).

Note: FP1/FP2 faults are factory set at only one try.

Lockout: In lockout mode, the status LED will begin fast

ashing. The compressor relay is turned off immediately.

Lockout mode can be “soft” reset by turning off the

thermostat (or satisfying the call). A “soft” reset keeps

the fault in memory but resets the control. A “hard” reset

(disconnecting power to the control) resets the control

and erases fault memory.

Lockout with emergency heat: While in lockout mode,

if W becomes active (CXM), emergency heat mode will

occur.

High pressure switch: When the high pressure switch opens

due to high refrigerant pressures, the compressor relay is

de-energized immediately since the high pressure switch

is in series with the compressor contactor coil. The high

pressure fault recognition is immediate (does not delay for 30

continuous seconds before de-energizing the compressor).

High pressure lockout code = 2

Example: 2 quick ashes, 10 sec pause, 2 quick ashes,

10 sec. pause, etc.

Low pressure switch: The low pressure switch must be open

and remain open for 30 continuous seconds during “on”

cycle to be recognized as a low pressure fault. If the low

pressure switch is open for 30 seconds prior to compressor

power up it will be considered a low pressure (loss of

charge) fault. The low pressure switch input is bypassed for

the initial 60 seconds of a compressor run cycle.

Low pressure lockout code = 3

Water coil low temperature (FP1): The FP1 thermistor

temperature must be below the selected low temperature

limit setting for 30 continuous seconds during a

compressor run cycle to be recognized as a FP1 fault.

The FP1 input is bypassed for the initial 60 seconds of

a compressor run cycle. FP1 is set at the factory for one

try. Therefore, the control will go into lockout mode once

the FP1 fault has occurred.

FP1 lockout code = 4

Air coil low temperature (FP2): The FP2 thermistor

temperature must be below the selected low temperature

limit setting for 30 continuous seconds during a

compressor run cycle to be recognized as a FP2 fault.

The FP2 input is bypassed for the initial 60 seconds of

a compressor run cycle. FP2 is set at the factory for one

try. Therefore, the control will go into lockout mode once

the FP2 fault has occurred.

FP2 lockout code = 5

Condensate overow: The condensate overow sensor

must sense overow level for 30 continuous seconds to

be recognized as a CO fault. Condensate overow will be

monitored at all times.

CO lockout code = 6

Over/under voltage shutdown: An over/under voltage

condition exists when the control voltage is outside the

range of 19VAC to 30VAC. Over/under voltage shut

down is a self-resetting safety. If the voltage comes back

within range for at least 0.5 seconds, normal operation is

restored. This is not considered a fault or lockout. If the

CXM is in over/under voltage shutdown for 15 minutes,

the alarm relay will close.

Over/under voltage shut down code = 7

Unit Performance Sentinel-UPS (patent pending): The

UPS feature indicates when the heat pump is operating

inefciently. A UPS condition exists when:

a) In heating mode with compressor energized, FP2 is

greater than 125°F [52°C] for 30 continuous seconds,

or:

Page 29

Heat Controller, Inc. HBH/V COMPACT IOM Instructions

CXM Controls

b) In cooling mode with compressor energized, FP1 is

greater than 125°F [52°C] for 30 continuous seconds,

or:

c) In cooling mode with compressor energized, FP2 is

less than 40°F [4.5°C] for 30 continuous seconds.

If a UPS condition occurs, the control will immediately

go to UPS warning. The status LED will remain on as

if the control is in normal mode. Outputs of the control,

excluding LED and alarm relay, will NOT be affected

by UPS. The UPS condition cannot occur during a

compressor off cycle. During UPS warning, the alarm

relay will cycle on and off. The cycle rate will be “on” for 5

seconds, “off” for 25 seconds, “on” for 5 seconds, “off” for

25 seconds, etc.

UPS warning code = 8

Swapped FP1/FP2 thermistors: During test mode, the

control monitors to see if the FP1 and FP2 thermistors

are in the appropriate places. If the control is in test

mode, the control will lockout with code 9 after 30

seconds if:

a) The compressor is on in the cooling mode and the

FP1 sensor is colder than the FP2 sensor, or:

b) The compressor is on in the heating mode and the

FP2 sensor is colder than the FP1 sensor.

CXM Control Start-up Operation

The control will not operate until all inputs and safety

controls are checked for normal conditions. The

compressor will have a 5 minute anti-short cycle delay

at power-up. The rst time after power-up that there is a

call for compressor, the compressor will follow a 5 to 80

second random start delay. After the random start delay

and anti-short cycle delay, the compressor relay will

be energized. On all subsequent compressor calls, the

random start delay is omitted.

Diagnostic Features

The LED on the CXM board advises the technician of the

current status of the CXM control. The LED can display

either the current CXM mode or the last fault in memory

if in test mode. If there is no fault in memory, the LED will

ash Code 1 (when in test mode).

Page 30

IOM Instructions HBH/V COMPACT Heat Controller, Inc.

Cooling Heating Cooling Heating Cooling Heating

45ºF [7ºC] 39ºF [4ºC] 45ºF [7ºC] 39ºF [4ºC] 45ºF [7ºC] 39ºF [4ºC]

0.6ºF [27ºC] 68ºF [20ºC] 80.6ºF [27ºC] 68ºF [20ºC] 80.6ºF [27ºC] 68ºF [20ºC]

10ºF [43ºC] 85ºF [29ºC] 110ºF [43ºC] 85ºF [29ºC] 110ºF [43ºC] 85ºF [29ºC]

60/45ºF [16/7ºC] 40ºF [4.4ºC]

60/50ºF [16/10ºC]

45ºF [7ºC] 65/50ºF [18/10ºC] 45ºF [7.2ºC]

80.6/66.2ºF [27/19ºC] 68ºF [20ºC] 80.6/66.2ºF [27/19ºC] 68ºF [20ºC] 80.6/66.2ºF [27/19ºC] 68ºF [20ºC]

100/75ºF [38/24ºC] 80ºF [27ºC] 95/75ºF [35/24ºC] 80ºF [27ºC]

95/75ºF [35/24ºC]

80ºF [27ºC]

30ºF [-1ºC] 20ºF [-6.7ºC] 30ºF [-1ºC] 20ºF [-6.7ºC] 30ºF [-1ºC]

20ºF [-6.7ºC]

50-110ºF [10-43ºC] 30-70ºF [-1 to 21ºC] 50-110ºF [10-43ºC] 30-70ºF [-1 to 21ºC] 50-110ºF [10-43ºC] 30-70ºF [-1 to 21ºC]

120ºF [49ºC] 90ºF [32ºC] 120ºF [49ºC] 90ºF [32ºC]

120ºF [49ºC]

90ºF [32ºC]

TCTSTT

[1.6 to 3.2 l/m per kW]

1.5 to 3.0 gpm / ton

[1.6 to 3.2 l/m per kW]

1.5 to 3.0 gpm / ton

[1.6 to 3.2 l/m per kW]

1.5 to 3.0 gpm / ton

UNIT STARTING AND OPERATING CONDITIONS

Operating Limits

Environment – Units are designed for indoor installation only. Never install units in areas subject to freezing or where

humidity levels could cause cabinet condensation (such as unconditioned spaces subject to 100% outside air).

Power Supply – A voltage variation of +/– 10% of nameplate utilization voltage is acceptable.

Determination of operating limits is dependent primarily upon three factors: 1) return air temperature. 2) water

temperature, and 3) ambient temperature. When any one of these factors is at minimum or maximum levels, the other

two factors should be at normal levels to insure proper unit operation. Extreme variations in temperature and humidity

and/or corrosive water or air will adversely affect unit performance, reliability, and service life. Consult Table 6a for

operating limits.

Table 6a: Operating Limits

TC

Operating

Starting Limits

Air Limits

Min. ambient air, DB

Rated ambient air, DB 8

Max. ambient air, DB 1

Min. entering air, DB/WB

Rated entering air, DB/WB

Max. entering air, DB/WB

Water Limits

Min. entering water

Normal entering water

Max. entering water

Normal Water Flow

65/50ºF [18/10ºC] 45ºF [7.2ºC]

0.6/66.2ºF [27/19ºC] 68ºF [20ºC]

95/75ºF [35/24ºC]

50-110ºF [10-43ºC] 30-70ºF [-1 to 21ºC]