Page 1

Installation &

Owner’s Manual

AIR HANDLERS:

Variable Speed

AHGV Hydronic

Air Handler

HAGV Electric

Air Handler with

Optional Heat

Heat Controller, Inc. • 1900 Wellworth Ave. • Jackson, MI 49203 • (517)787-2100 • www.heatcontroller.com

Page 2

1 Variable Speed Air Handlers Installation & Owners Manual

Table of Contents

Unit Nomenclature .................................2

General Information ...............................3

Inspection ...............................................3

Reference ...............................................3

Limitations .............................................3

Location .................................................3

Installation/Operation Safety Rules .......4

Unpacking ..............................................4

Clearances ..............................................4

Arrangement ..........................................4

Upow....................................................5

Horizontal ..............................................5

Control Wiring .......................................5

ECM Blower Motor ...............................5

Hot Water Piping ....................................6

Condensate Piping .................................6

Check / Test / Start Up ...........................7

Unit Shutdown .......................................7

Maintenance ...........................................7

Electrical Data ........................................8

AHGV Hydronic Performance Data ......9

Blower Performance ECM 2.3 .............10

HAVG Dimensional Data ....................11

AHGV Dimensional Data ....................12

Power Wiring .........................................5

Heat Controller, Inc. • 1900 Wellworth Ave. • Jackson, MI 49203 • (517)787-2100 • www.heatcontroller.com

Page 3

Installation & Owners Manual Variable Speed Air Handlers 2

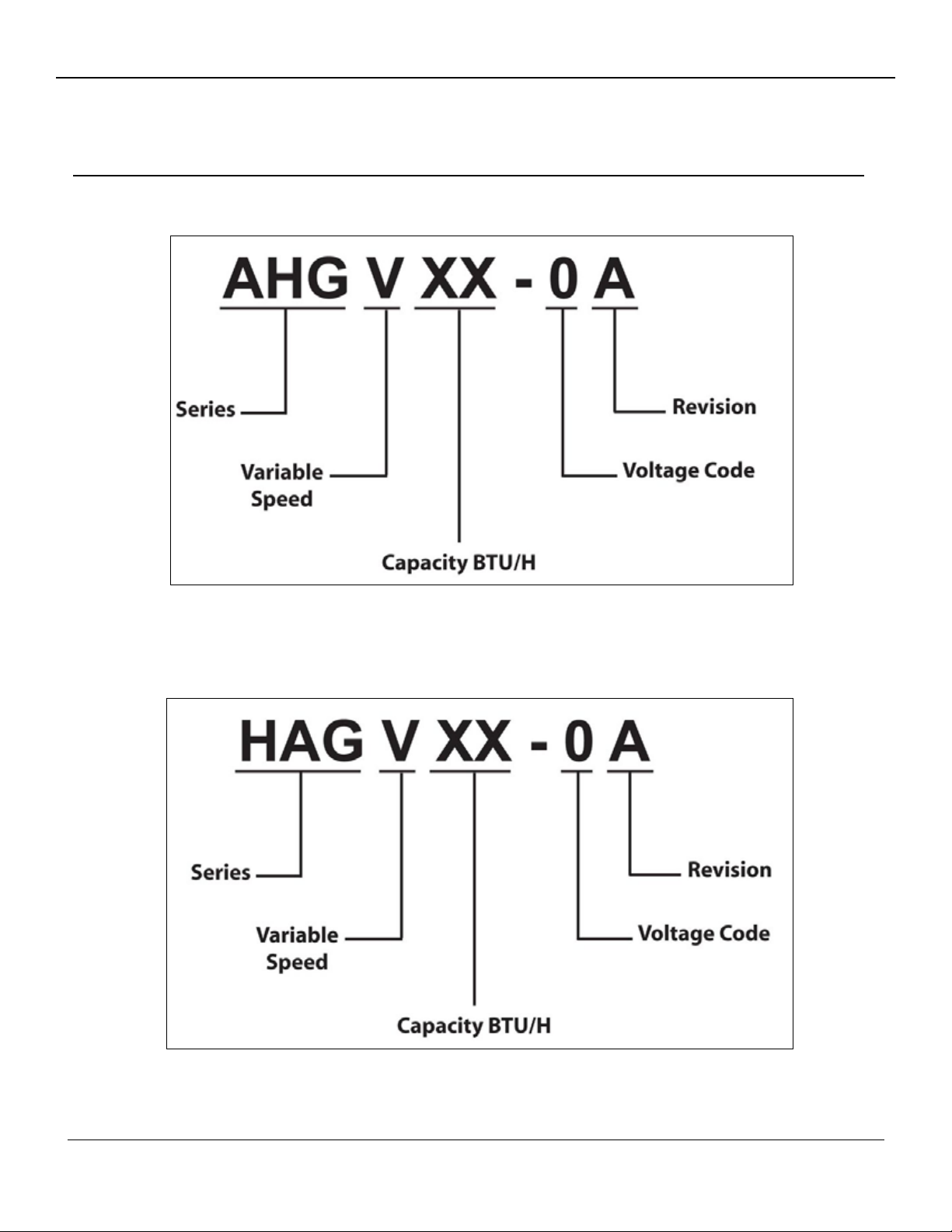

Unit Nomenclatures

AHGV:

HAGV:

Heat Controller, Inc. • 1900 Wellworth Ave. • Jackson, MI 49203 • (517)787-2100 • www.heatcontroller.com

Page 4

3 Variable Speed Air Handlers Installation & Owners Manual

Air Handler Installation Instructions

Electric and Hydronic

Heat Controller, Inc. • 1900 Wellworth Ave. • Jackson, MI 49203 • (517)787-2100 • www.heatcontroller.com

Page 5

Installation & Owners Manual Variable Speed Air Handlers 4

Air Handler Installation Instructions

Electric and Hydronic

INSTALLATION/OPERATION SAFETY RULES:

1. Read these rules and instructions carefully.

Failure to follow these rules and the installation

instructions could cause a malfunction of the unit,

and a possible safety hazard. Keep these

instructions nearby the unit for future reference.

2. While this unit has been designed and

manufactured to comply with National codes, it is

the installer’s responsibility to install this unit to

comply with Nationa

local codes and regulations. HCI assumes no

responsibility for units installed in violation of

any code or regulation.

3. Before servicing, allow unit to cool.

WARNING

ELECTRICITY WHEN WORKING ON UNIT.

This will prevent any electrical shocks or burns.

4. Ground the unit to prevent electric shock. All

electrical wiring should be in accordance with the

National Electric Code.

5. Duct work must be installed in accordance with

the standards of the National Fire Protection

Association (NFPA) for the installation of Air

Conditioning, Warm Air Heating and Ventilating

Systems (NFPA 90A

non-conditioned spaces must be insulated to

prevent formation of condensate and for

maximum efficiency.

6. The safety testing agency labels appear on the

unit’s cover and t h e factory installed coil (if

provided) only. It does not cover any other

equipment. Exterior surface of cabinet may sweat

when units is installed in a non-conditioned space

such as an attic or garage. Installer must provide

protection such

all units installed in a non-conditioned space to

prevent damage from condensation runoff. It is

recommended that units installed in nonconditioned spaces be insulated with 1” thick

fiberglass with the vapor barrier on the outside.

7. While designed to operate quietly when properly

installed, several steps should be taken insure this.

Use of isolation pads when mounting unit,

flexible d

acoustical duct liners are all good installation

practices that promote quite operation.

: ALWAYS SHUT OFF

uct collars for discharge, and use of

l codes and/or prevailing

and 90B). Duct work in

as full size auxiliary drain pan on

8. Cabinet insulation is rated for R-4.2 (standard).

Some jurisdictions require R-6.0 on installations

in a non-conditioned space. To achieve R-6.0,

add insulation 1” thick to exterior of the unit

to comply in these jurisdictions, putting the

vapor barrier on the outside.

WARNING:

Hot water can scald. Water heated to a temperature

which will satisfy space heating can scald and

permanently injure a person upon contact. Some people

are more likely to be permanently injured by hot water

than others. These include the elderly, children, the

infirm, physically or mentally handicapped.

Check local, State, and National codes requiring a

certain temperature water at the hot water tap. Special

precautions must be used in addition to us

possible temperature setting that satisfies your hot water

needs. A Tempering device such as a mixing valve,

should be used at the hot water taps, or water heater.

UNPACKING THE UNIT:

The unit should be unpacked on receipt and if any damage

is found, follow the instructions under the “INSPECTION”

section of this manual.

This air handler is completely assembled. (NOTE: Electric

heat can be ordered as field installed, if field

installed, refer to the sep

provided with the heater kit.) Only electrical power,

thermostat wiring, hot water piping (if applicable) and

duct connections are needed for installation. DX coils will

also require refrigerant and condensate drain connections.

Some units may have motor supports over the motor shaft.

Remove these supports as necessary.

MINIMUM CLEARENCES:

These units have a 0” minimum clearance to combustible

als rating from all cabinet surfaces. The unit should

materi

be installed with serviceability clearance of 30” from the

front of the unit. The unit can be serviced entirely from the

front, including replacing the filter. Be sure to route

primary and secondary condensate drain piping so that it

does not obstruct replacement of the filter.

ARRANGEMENT:

Unit is shipped from the factory for installation in a vertical

upflow or horizontal right to left air flow position

(standard) or field convertibl

to right air flow position.

arate installation instructions

e to a horizontal left

ing the lowest

Heat Controller, Inc. • 1900 Wellworth Ave. • Jackson, MI 49203 • (517)787-2100 • www.heatcontroller.com

Page 6

5 Variable Speed Air Handlers Installation & Owners Manual

Air Handler Installation Instructions

Electric and Hydronic

UPFLOW APPLICATION:

In an upflow installation the discharge outlet is at the top.

Care should be taken to insure unit is level to permit

proper condensate drainage. Normal upflow installation

will be in a closet or basement. If installed in a closet, the

closet should have a platform framed in, with an opening

at the top of the platform centered in the closet. Connect

the supply air outlet to a plenum. Install

from outside the closet to space below the platform.

Platform must be at least 12” above the floor. If installed

in a basement, run supply and return duct work in

accordance with local codes.

HORIZONTAL APPLICATION:

Horizontal applications will normally be used in an attic or

crawl space. This type of installation requires a return air

duct be attached to the unit inlet. The opposite end of the

return air d

the ceiling or wall. Remove air filter from unit if filter

grille is used. The unit is shipped in right to left

configuration. For left to right applications (before

connecting drains, refrigerant or water piping) remove coil

and doors and move horizontal pan to right side. Reinstall

coil and doors.

CAUTION:

It is mandatory to use an emergency auxiliary drain

with any coil or air

a finished ceiling.

ELECTRICAL WIRING:

Refer to the unit nameplate for specific electrical data.

uct is attached to a return air filter grille through

handler installed in an attic or above

return air grilles

pan

NOTE: See unit for complete wiring diagram located on

blower housing.

CONTROL WIRING:

Field connections to the low voltage leads are made using

appropriate field supplied wiring connectors. Consult

installatio

specific information on control wiring. Use 18 AWG

minimum copper conductors for control wiring up to 50’

between units. 16 AWG control conductors are

recommended for lengths between 50’ and 100’. Class 2

wiring is acceptable.

transformer burnout could result. Some manufacturer’s

outdoor units are equipped with a 24 volt control

transformer. If this type of outdoor unit is used with this

air handler, use a thermostat with isolating contacts to

prevent inter-connection of two separate Class 2 circuits.

Set thermostat heat anticipator at 0.15 amps for units

12KW or smaller, set at .30 amps for 15 KW and larger.

VARIABLE SPEED MOTORS:

Electronic commutated and constant torque motor

factory programmed and cannot be re-programmed in the

field. ECM motors have (4) jumper settings.

Refer to blower perform ance data located in the spec sheet

for the particular product to select the tap setting that best

fits the application

NOTE: All 208/230 volt motors are factory programmed

for “0” second fan “ON” delay for use with electric heat.

Motor must energize with electric heat. All 115 volt

motors are factory programmed for “30” second fan “ON”

delay for use with hydronic heat.

n instructions provided with accessory items for

Take care not to short control leads as,

s are

CAUTION:

Disconnect power at main fuse or circuit breaker

distribution panel before wiring unit to prevent shock or

fire hazard.

POWER WIRING:

Unit is suitable for use with copper conductors. Tighten all

wire connectors. Take care not to damage heater ceramic

insulators on electric heat models. For correct

size see unit nameplate and field wiring table inside

electrical compartment door. Use 75°C minimum wire in

unit wiring compartment. Units larger than 10 KW will

require multiple sets of power conductors.

field wire

Heat Controller, Inc. • 1900 Wellworth Ave. • Jackson, MI 49203 • (517)787-2100 • www.heatcontroller.com

Page 7

Installation & Owners Manual Variable Speed Air Handlers 6

Air Handler Installation Instructions

Electric and Hydronic

PIPING:

HOT WATER PIPING FOR HYDRONIC AHGV UNITS:

HOT WATER PIPING:

If a residential water heater is used for space heating water,

do not exceed a distance of 70’ between the air handler and

the water heater. The water heater should be the quick

recovery type. Air handler and water heater must be

located indoors and not subject to freezing temperatures.

WARNING:

Air handler must be located so that if any connections

should leak, water will not cause damage to the adjacent

area. When such locations can’t be avoided, a suitable

drain pan should be installed under the air handler, not

over 1-1/2” deep, with minimum length and width at least

2” greater than the air handler dimensions and

connected to an adequate drain. Under no circumstances

is the manufacturer to be held libel for any water damage

in connection with this air handler.

Total piping should not exceed 140’. All piping should be

¾” copper or approved PVC. It is recommended that the

water shut-off valve for the water heater be located close

to the water heater. Isolation valves are also

recommended.

It is recommended that any devices installed, which could

create a closed system, have a by-pass and/or the system

have an expansion tank to relieve the pr

thermal expansion in the water system.

essure built up by

CONDENSATE DRAIN PIPING:

The air handler “

female primary and two secondary connections (left or

right hand). Horizontal pan has two ¾” NPT female, one

primary and one secondary. Piping from each fitting used

is to have 1-1/2 minimum trap and each run in such a

manner as to provide enough slope for adequate drainage

to a visible area. Do not pipe these two fittings together

into a common drain. Cap unused connection.

AIR FILTER:

A clean, appropriately sized filter must be used or system

damage will occur. Filters are not supplied with this air

handler, a field installed filter accessory is available.

A” coil drain pan has two ¾” NPT

PVC PIPE

Typical Condensate Traps

WARNING:

Toxic chemicals such as used for treatment of boilers or

non-potable water heating appliances shall never be

introduced into a potable water space heating system.

WARNING:

When the system required water at temperatures higher

than required for other uses, a means such as a mixing

valve shall be installed to temper the water for those uses

in order to reduce the scald hazard potential.

After piping has been installed, allow the system to fill

with water and check connections for leaks. To insure

complete filling of the system, follow start-up procedure.

Heat Controller, Inc. • 1900 Wellworth Ave. • Jackson, MI 49203 • (517)787-2100 • www.heatcontroller.com

Page 8

7 Variable Speed Air Handlers Installation & Owners Manual

Single Piece Air Handler Installation Instructions

Electric and Hydronic

CHECK TEST AND START UP:

HAGV UNITS: Air handler with optional electric heat

The unit should be tested after the system has been

completely installed to determine proper operation. Unit is

equipped with heater time delay controls. If electric

heater is field installed, all heating elements should turn on

within one minute.

NOTE:

Circuit breakers are equipped with a visual “visi-trip” red

flag indicator. If red indicator shows that circuit breaker

has tripped, this indicated that a problem exists in your

system which should be corrected before re

breaker.

AHGV UNITS: Hydronic air handler

NOTE:

Heating system should not be switched on until system is

filled and hot water coil vented.

1. Fill and pressurize the water heater and air

handler.

2. The water heater should be started.

3. Vent air from the water tank by opening a hot

water spigot.

4. Vent and flush the supply and return lines by

attaching a hose to the volume purge valve and

running purge water to a safe location. Run

approximately 5 gallon

rate to purge.

5. Energize the unit by switching on the line voltage

source and the thermostat. The fan and pump

should start simultaneously. The water coil should

become warm after a few minutes of operation.

6. Units are rated at temperatures of 130° -180° F.

Set water source temperature at design

temperature and take proper safeguards for water

usage at supply points as per local codes and

safety considerations.

s of water at a high flow

:

setting

SYSTEM SHUT-DOWN:

For short periods of time during freezing temperatures if

:

the system is to be left unused, to prevent freezing of the

air handler and piping, do the following: Do not turn the

system off and leave the air handler’s thermostat on in heat

mode. If the water heater and air handler must be shut

down for extended periods, a qualified service technician

should insure that the air handler and co

drained of water.

PERIODIC MAINTENANCE:

The filter must be changed monthly to permit proper

airflow for safe and efficient operation. All other

maintenance should be performed by a licensed

technician.

il are completely

Heat Controller, Inc. • 1900 Wellworth Ave. • Jackson, MI 49203 • (517)787-2100 • www.heatcontroller.com

Page 9

Installation & Owners Manual Variable Speed Air Handlers 8

ELECTRICAL DATA

Heat Controller, Inc. • 1900 Wellworth Ave. • Jackson, MI 49203 • (517)787-2100 • www.heatcontroller.com

Page 10

9 Variable Speed Air Handlers Installation & Owners Manual

HYDRONIC PERFORMANCE DATA

Heat Controller, Inc. • 1900 Wellworth Ave. • Jackson, MI 49203 • (517)787-2100 • www.heatcontroller.com

Page 11

Installation & Owners Manual Variable Speed Air Handlers 10

BLOWER PERFORMANCE DATA

Heat Controller, Inc. • 1900 Wellworth Ave. • Jackson, MI 49203 • (517)787-2100 • www.heatcontroller.com

Page 12

11 Variable Speed Air Handlers Installation & Owners Manual

HAGV Dimensioal Data

Air Handler with Optional Electric Heat

DIMENSIONS (inches)

MODELS A B C D E F G H J K L M N P R

HAGV24-00-1A

HAGV36-00-1A

HAGV48-00-1A

HAGV60-00-1A

* All dimensions are approximate

21.00 48.00 21.00 19.00 12.50 14.50 13.00 6.75 20.00 17.00 12.75 10.30 2.30 4.35 5.00

24.50 58.75 21.75 23.35 21.25 19.75 17.25 6.75 26.00 23.00 16.75 14.35 2.30 4.35 4.50

*

Heat Controller, Inc. • 1900 Wellworth Ave. • Jackson, MI 49203 • (517)787-2100 • www.heatcontroller.com

Page 13

Installation & Owners Manual Variable Speed Air Handlers 12

AHGV Dimensioal Data

Hydronic Air Handler

DIMENSIONS (inches)

MODELS A B C D E F G H J K L M N P R S T U

AHGV24/36

AHGV48/60

* All dimensions are approximate

Heat Controller, Inc. • 1900 Wellworth Ave. • Jackson, MI 49203 • (517)787-2100 • www.heatcontroller.com

21.00 48.00 21.00 19.00 15.00 14.50 13.00 6.75 20.00 17.00 13.00 10.30 2.30 4.35 3.75 1.75 2.50 1.50

24.50 58.75 21.75 23.50 15.75 19.75 17.25 6.75 26.00 23.00 16.75 14.35 2.30 4.35 3.50 1.50 2.25 1.25

*

Page 14

6/2009

Loading...

Loading...