Page 1

Page 2

A. Introduction

1

Heat Controller, Inc., Air Handlers come in a variety of models and

sizes for upow or horizontal use and when combined with cool-

ing coils, are ready for air conditioning and heat pump applications.

These instructions are primarily to assist qualied individuals trained

and experienced in the proper installation of this type of equipment.

B. Rules for Safe Installation and Operation

1. Read these rules and the instructions carefully. Failure

to follow the rules and the instructions could cause a

malfunction of the unit, and a possible safety hazard.

Keep these instructions nearby the unit for future

reference.

2. This unit has been designed and manufactured to comply

with National Codes; however, it is the installer’s

responsibility to install this unit to comply with

prevailing codes and regulations. Heat Controller, Inc.,

assumes no responsibility for units installed in violation

of any code or regulation.

3. Before servicing, ALWAYS SHUT OFF

ELECTRICITY TO THE UNIT. This will prevent any

electrical shocks.

4. Ground the unit to prevent electric shock. All electrical

wiring should be in accordance with the National

Electrical Code.

5. Duct work must be installed in accordance with the

standards of the National Fire Protection Association

(NFPA) for the installation of Air Conditioning, Warm

Air Heating and Ventilating Systems (NFPA 90A and

90B). The air distribution duct system should be sized for

0.2 inches of static pressure. See National Environmental

Systems Contractors Association Manual K for duct

sizing recommendations. Ductwork in non-conditioned

spaces must be insulated to prevent formation of

condensate and for maximum operating efciency.

6. The safety testing agency label appearing on the unit

covers the unit and factory installed coil(s) only. It does

not cover any other equipment.

7. Exterior surface of cabinet may sweat when unit is installed

in non-conditioned space such as attic or garage. Installer

must provide protection such as full size auxiliary drain

pan on all units installed in non-conditioned space such as

attic or garage type installations to prevent damage from

condensation. It is recommended that units installed in

non-conditioned space be insulated on the outside with 1”

thick berglass with the vapor barrier on the outside.

8. While designed to operate quietly when properly installed,

several steps should be taken to insure this. Use of

isolation pads when mounting unit, exible duct collars

for discharge, and use of acoustical duct liners are all

good installation practices that promote quiet operation.

9. Cabinet insulation is rated for R=4.2 (standard). Some

jurisdictions require R=6.0 on installations in nonconditioned space. Add insulation 1” thick to exterior of

air handler to comply in these jurisdictions, putting the

vapor barrier on the outside.

C. Unpacking the Unit

The unit should be unpacked on receipt and if damage is found,

a claim should be made immediately to the shipping carrier. This

is the responsibility of the entity receiving the equipment. The air

handler is completely assembled, as received. Electric power, ther-

mostat wiring, refrigerant piping and duct connections are needed

to complete an installation. Additionally, a drain connection will

be needed.

Check the rating plate for unit size, voltage, phase etc. to make

sure unit meets your requirements.

D. Physical Installation

MINIMUM CLEARANCES

These units have a 0” minimum clearance to combustible materi-

als rating from all cabinet surfaces. The unit should be installed

with serviceability clearance of 30” from the front of the unit. The

unit can be serviced entirely from the front, including replacing the

lter. Be sure and route primary and secondary drain connections

so as not to obstruct lter replacement.

ARRANGEMENT

Unit is shipped from the factory arranged to be installed in a verti-

cal upow or horizontal right to left airow position (standard) or

eld convertible to a horizontal left to right airow position.

Upow Application

In an upow installation the discharge outlet is at the top. Care

should be taken to ensure unit is level to permit proper condensate

drainage. Normal upow installation will be in a basement or clos-

et. If installed in a closet, the closet should have a platform framed

in, with an opening on top of the platform centered in the closet.

Connect the supply air outlet to a discharge air plenum. Install re-

turn air grilles from outside the closet to space below the platform.

Platform must be at least 10” above the oor. Run all supply and

return ductwork in accordance with local codes.

Horizontal application

Horizontal application will normally be used in an attic or crawl

space. This type installation requires a return air duct be attached

to the air handler inlet. The opposite end of the return air duct

is attached to a return air lter grille through the ceiling or wall.

Remove lter from unit if lter grill is used. The unit is shipped in

right to left conguration.

CAUTION

A “P” trap must be installed in the coil

drain line! Cap unused drain ttings.

WARNING

To ensure unit will not interfere with drains and

refrigerant lines, modication must be made

prior to installing these lines..

FOR LEFT TO RIGHT APPLICATIONS.

1. Remove and set aside front panels.

2. Remove the coil support bracket (4-screws).

Page 3

3. Remove horizontal drain pan retaining clip (1-screw).

2

4. Carefully remove coil assembly and bottom drain pan.

5. Move horizontal drain pan from left hand side of coil to

right side.

6. Install modied coil assembly back into unit.

7. Reinstall coil support bracket and horizontal drain pan

retaining clip.

8. Determine drain holes being used and reposition knockout

caps.

9. Reinstall doors.

CAUTION

IT IS MANDATORY TO USE AN

EMERGENCY AUXILIARY DRAIN PAN

WITH ANY COIL OR AIR HANDLER

INSTALLED IN AN ATTIC OR ABOVE A

FINISHED CEIING!

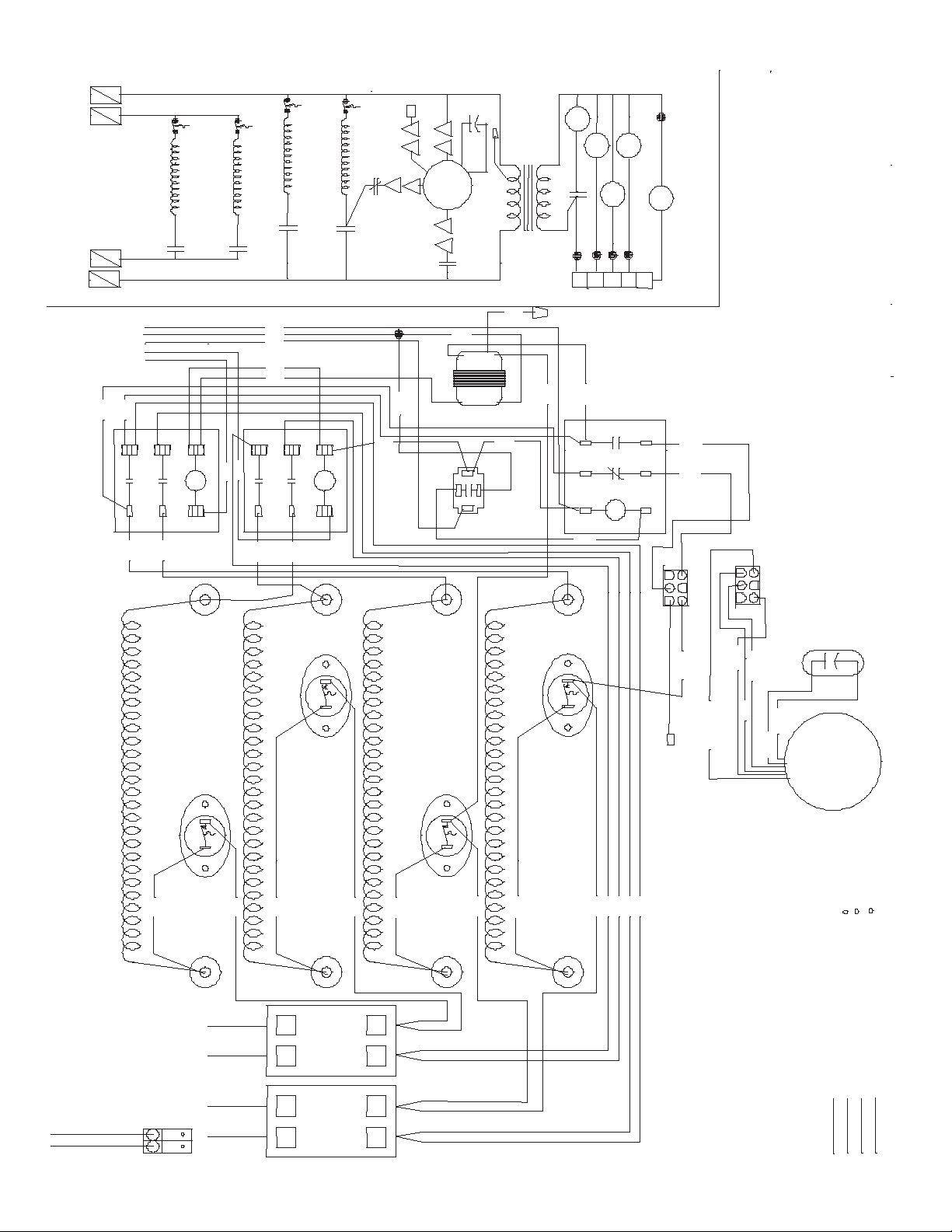

E. Electric Furnace

Optional electric heating packages are available, see the unit label

for various sizes.

* See Electric Heater Kit Specications Table

F. Power Wiring

Refer to the unit’s nameplate for specic electrical data.

CAUTION

DISCONNECT POWER AT MAIN FUSE OR CIRCUIT

BREAKER DISTRIBUTION PANEL BEFORE WIRING

UNIT TO PREVENT SHOCK OR FIRE HAZARD.

Use copper conductors only. Tighten all wire connectors.

Refer to unit nameplate for minimum circuit ampacity. For correct

wire size, refer to the National Electrical Code. Use 75˚C minimum

wire in unit wiring compartment.

NOTE: SEE UNIT FOR COMPLETE WIRING DIAGRAM

LOCATED ON BLOWER HOUSING.

G. Control Wiring

Field connections are made to the low voltage terminal strip.

Consult installation instructions provided with accessory items

for specic information on control wiring. Use 18 AWG minimum

copper control conductors for control wiring up to 50 feet between

units. 16 AWG control conductors are recommended for lengths up

to 100 feet. Class 2 wiring is acceptable. Do not short control leads.

Transformer burn-out will result. Set thermostat heat anticipator at

0.15 amps for air handler.

Terminal number 4 on the (FR) fan relay is the cooling blower

speed and terminal number 6 on the (FR) is the heating blower

speed.

I. Refrigerant Piping

All air handlers have DX refrigerant cooling coils installed, liquid

and suction piping should be sized in accordance with condensing

unit manufacturer’s recommendations. An adapter (by others) may

be required to make the transition between the line set and the

coil connector. The evaporator coil has sweat copper connections.

The suction line is a swaged solder cup connection. The liquid line

connection is made to a tail piece portion of the TXV. Remove the

nut on the inlet to the expansion valve and place it on the tail piece

prior to brazing the liquid line. DO NOT connect the tail piece

to the TXV until the liquid line has been brazed to the tail piece.

Refrigerant lines should be soldered with silver solder or other

high temperature brazing alloy. Dry nitrogen must ow through the

refrigerant lines during the brazing operation to prevent oxidation.

J. Refrigerant Flow Control

As shipped, the TXV installed on the A-coil is for the nominal

capacity of a 13 SEER matched with Heat Controller, Inc.,

condensing units. The TXV is for use on an R-410A system. For

other refrigerants, contact the factory. TXV has a built-in check

valve for reverse ow and is suitable for heat pump operation. All

are externally equalized with non-adjustable superheat and have

15% bleed. Hard start capability for outdoor units is not normally

required when a 15% bleed valve is used. The external equalizer

line attached to the TXV has a female are nut and is attached to

the suction line at the coil. Install the TXV bulb to the suction line

using the bulb clamp furnished with the kit. The bulb should be

installed on a horizontal run of the suction line if possible. On a

line less than 7/8” OD, the bulb may be installed on top of the line.

With 7/8” OD or over, the bulb should be installed in a position of

about 4 or 8 o’clock. If the bulb installation is made on a vertical

run, the bulb should be located at least 6 inches from any bend

and on the tubing side opposite the plane of the bend. On vertical

bulb installations, the bulbs should be positioned with the bulb

capillary tube at the top. The bulb must be insulated using thermal

insulation to protect it from the effects of the surrounding ambient

temperature.

H. Blower Motor

Units are equipped with a three-speed blower motor. Two factoryselected motor speed leads are connected to the fan relay (FR) to

provide automatic speed change for heating and cooling airow

volumes. The pre-selected motor speeds would normally not have

to be changed in the eld. All HAH models contain a post purge

timer (TDR) that delays the blower turning off at the end of the

cooling cycle, this improves energy efciency.

Page 4

K. CONDENSATE DRAIN

3

The air handler drain pan has ¾” FPT primary and

secondary connections whether used in an upflow or

horizontal configuration. Piping from each stub is to

have a 1½” minimum trap and each run pitched so as

to provide for adequate drainage and secondary

fittings together into a common drain. When an air

handler is installed above a finished ceiling, an

auxiliary drain pan must be provided under the unit

as required by most local building codes. The

secondary drain must be piped to a location that

would provide the occupant a warning if the primary

drain is blocked.

L. AIR FILTER

Air handlers are factory equipped with an air filter.

If the return grille has its own filter, the filter

installed in the air handler should be removed. Air

filter should be inspected and cleaned or replaced as

often as is necessary to prevent restriction of air flow

(minimum every three months for normal

installations). Always replace the filter with the

same type originally furnished.

M. CHECK TEST AND START UP

TURN OFF POWER AT BREAKER PANEL

Electric heaters are high current devices. Verify that

all electrical connectors, whether push-on or

compression-type are tight. Loose connections will

cause the wire and/or terminal to fail.

The unit should be tested after the system has been

completely installed to determine proper operation.

Energize the unit by switching on the line voltage

source and the thermostat.

N. PERIODIC MAINTENANCE

Inspect and clean or replace filters at least every three

months to ensure good airflow and optimum system

capacity, efficiency and life. This equipment should

NEVER BE OPERATED WITHOUT AN AIR FILTER

in place (see Section AIR FILTER). The blower motor

is permanently lubricated. ALWAYS disconnect

power before removing access doors!

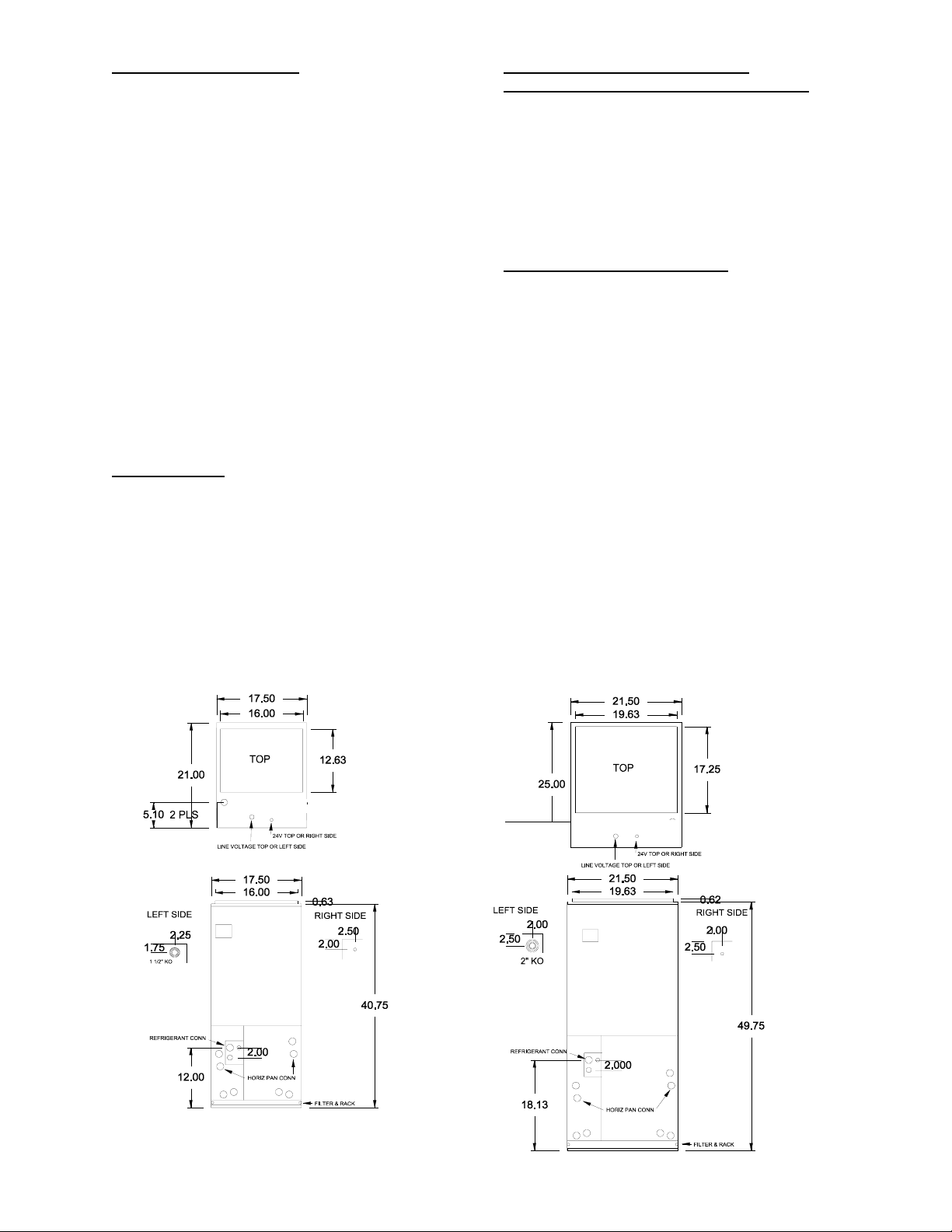

AHB 24, 30, 36

HAG 1324,1336

AHB Dimensions 24-60

Dimensions

AHB 42, 48, 60

HAG 1348,1360

Page 5

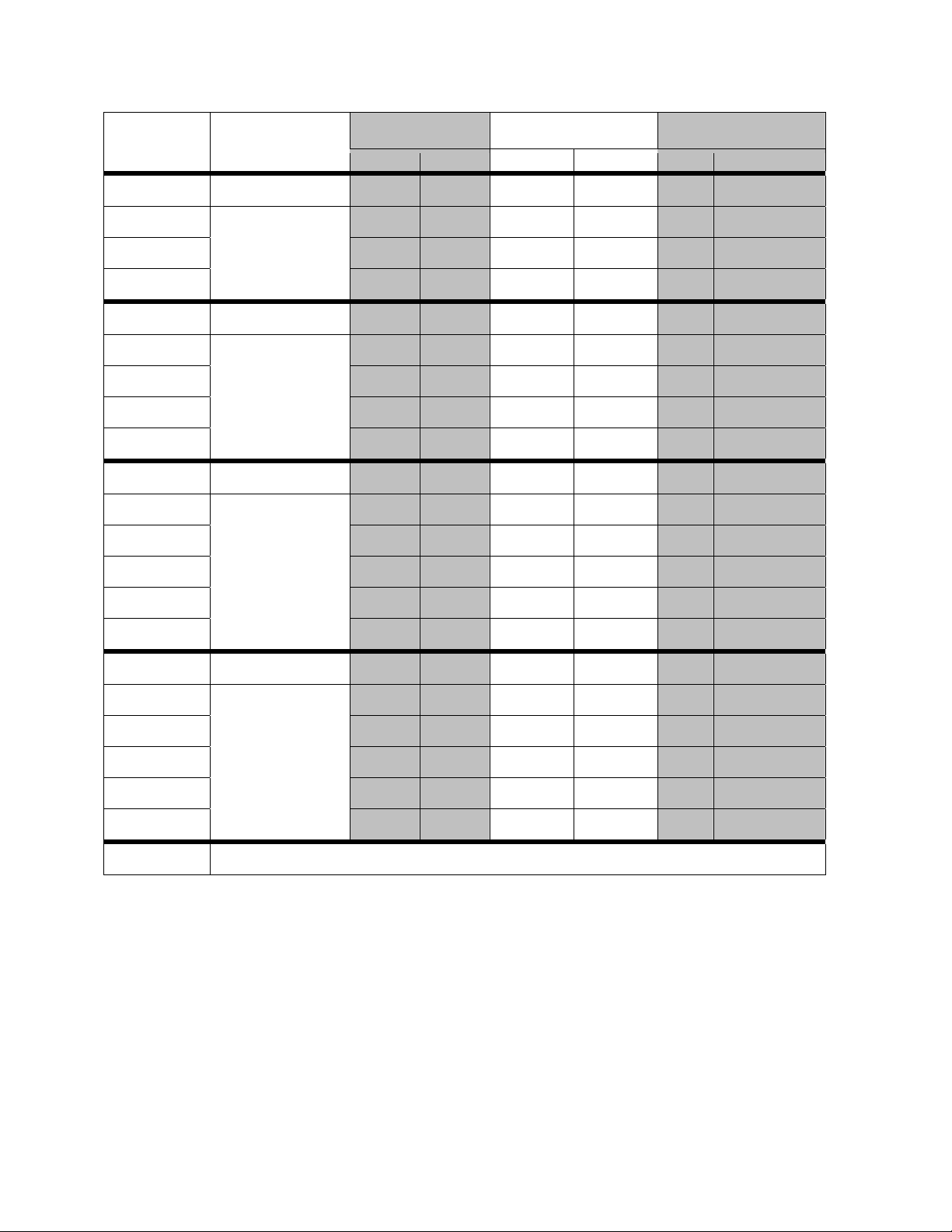

ELECTRIC HEATER KIT SPECIFICATIONS

4

MODEL

USED WITH

MINIMUM CIRCUIT

kW@

AMPACITY

240V 208V 240V 208V 240V 208V

MAX. FUSE OR

BREAKER (HACR)

N/A Without heat 0 0 2.1 1.9 15 15

7800-305B 5.0 3.8 29 25 30 25

7800-306B 8.0 6.0 44 39 45 40

7800-308B

HAG24-00-1A

10 7.5 55 48 60 50

N/A Without heat 0 0 3.5 3.4 15 15

7800-305B 5.0 3.8 30 27 30 30

7800-306B 8.0 6.0 46 40 50 40

HAG36-00-1A

7800-308B 10 7.5 56 49 60 50

7800-312B

15 11.3 56/26 49/23 60/30 50/30

N/A Without heat 0 0 4.0 3.9 15 15

7800-313B 5.0 3.8 30 27 30 25

7800-314B 8.0 6.0 46 41 50 45

7800-315B 10 7.5 57 50 60 50

HAG48-00-1A

7800-316B 15 11.3 53/30 46/27 60/30 50/30

7800-317B

20 15 57/63 50/46 60/60 50/50

N/A Without heat 0 0 6.0 5.9 15 15

7800-313B 5.0 3.8 32 29 35 30

7800-314B 8.0 6.0 48 42 50 45

7800-315B 10 7.5 59 52 60 60

HAG60-00-1A

HAG61-00-1A

7800-316B 15 11.3 5 3/32 46/29 60/35 50/30

7800-317B

20 15 59/53 52/46 60/60 60/50

7800-400 4-Pole Jumper Bar Assembly 15 and 20 kW only

Page 6

1

5

CB

2

2

L

CB

2

CB

1

1

L

CB

S-4L

AT H TE IS 4R P -

2-SH

LS-3

T RI HE AT 3S P-

H 2S-

S-2L

EAT TH IS 2R P-

S-H 1

LS-1

6

3

P2

6

3

P3

EAT IH STR 1-P

H S-1

P24P3

LO

4

FR

BLOWER

2

FR

08 C2 VA

P2

P3

RMOTO

XFMR

R F

S-2H

TD R

1H S-

TDR

C

P3

2

P2

HI

R

G

Y

W1

W2

ORG

YEL

C O N D

AN D

W2

T-STAT

W1

RED

BLK

RED

GRN

YEL

BLU

RED

YEL

13

4

WHT

H S-2

5

BLU

BLU

BLU

13

4

WHT

H S-1

5

BLU

RED

208/240240VAC

XFMR

24VAC

H

TD R

H

WHT

BLK

YEL

2 4

5 6

FR

1 3

GRN

BLK

RED

4, 5 KW RESISTIVE HEAT STRIP

RED

GROUND LUG

FEMALE P2

WHT

LS-3

LS-1

WH T/YEL

LS-4

4, 5 KW RESISTIVE HEAT STRIP

RED

RED

1 2

L L

1 2

L L

RED

2

T

1

T

2

T

1

T

CB 1 CB 2

LS-2

5 KW RESISTIVE HEAT STR IP

RED

5 KW RESISTIVE HEAT STR IP

RED

RED

RED

BLK

BLK

BLK

BLK

LEGEND

C B C I R C U IT BREAKER

C O U TD O O R U N IT C O N TAC TOR

MALE P3

RED

BLK

BLU

BRN

BRN

MOTOR

BLOWER

18 GA T YPE 1015 600V T EW 105 C 24V

12 GA TYPE 1015 600V TEW 105 C

18 GA TYPE 1015 600V TEW 105 C

FIELD WIRING PER LOCAL CODE

TD R TIM E D EL AY R EL AY

H S H EAT SEQ U EN C ER

FR F AN R ELAY

XFMR TR AN SFO R M ER

LS LI MIT SWITC H

HAG - TO 20 KW WITH TDR

Page 7

06/2009

Loading...

Loading...