Page 1

AGA Marvel

1260 E. VanDeinse St.

Greenville MI 48838

THANK YOU for purchasing this high-quality product. If you should experience a problem not covered

in TROUBLESHOOTING, please visit our website at www.agamarvel.com for additional information. If

you still need assistance, call us at 1-800-223-3900.

You will need your model and serial number, located on the inside wall of the refrigerator compartment.

Toll free phone: 800-223-3900

Fax: 616-754-9690

www.agamarvel.com

Classic Model HCFDR23C Refrigerator User Instructions

Page 2

FINDING INFORMATION AND SAFETY

Table of Contents

Table of contents ................................................................2

Safety .................................................................................2

Unpacking your appliance ..................................................3

Electrical information ..........................................................4

Feature overview ................................................................5

Product dimensions ............................................................6

Installation ..........................................................................7

Removing the doors ..........................................................11

Connecting the water supply .............................................13

Controls ............................................................................14

Ice maker ..........................................................................16

Storage features ...............................................................17

Storing food and saving energy .......................................21

Normal operating sounds .................................................22

Changing water and air lters............................................23

Care and cleaning ............................................................25

Replacing LED lights ........................................................27

Solutions to common problems ........................................28

Warranty ...........................................................................31

Important Safety Instructions

Warnings and safety instructions appearing in this guide

are not meant to cover all possible conditions and situations that may occur. Common sense, caution, and care

must be exercised when installing, maintaining, or operating this appliance.

Recognize Safety Symbols,

Words, and Labels.

!

WARNING

WARNING-You can be killed or seriously injured if

you do not follow these instructions.

!

CAUTION

CAUTION-Hazards or unsafe practices which could re-

sult in personal injury or property / product damage.

NOTE

CFC/HCFC DISPOSAL

Your old refrigerator may have a cooling system that used

CFCs or HCFCs (chlorouorocarbons or hydrochlorouorocarbons). CFCs and HCFCs are believed to harm stratospheric ozone if released to the atmosphere. Other refrigerants may also cause harm to the environment if released to

the atmosphere.

If you are throwing away your old refrigerator, make sure

the refrigerant is removed for proper disposal by a qualied

technician. If you intentionally release refrigerant, you may

be subject to nes and imprisonment under provisions of

environmental legislation.

!

CAUTION

• Do not store or use gasoline or other ammable liquids

near this or any other appliance. Read product labels

for warnings regarding ammability and other hazards.

• Do not operate the refrigerator in the presence of explosive fumes.

• Avoid contact with any moving parts of the automatic

ice maker.

NOTE

NOTE-Important information to help assure a problem

free installation and operation.

State of California Proposition 65 Warnings:

WARNING: This product contains one or more chemicals

known to the State of California to cause cancer.

WARNING: This product contains one or more chemicals

known to the State of California to cause birth defects or

other reproductive harm..

2

Page 3

UNPACKING YOUR APPLIANCE

!

WARNING

EXCESSIVE WEIGHT HAZARD

Use two or more people to move product.

Failure to do so can result in personal injury.

Remove Interior Packaging

Your appliance has been packed for shipment with all parts

that could be damaged by movement securely fastened.

Remove internal packing materials and any tape holding internal components in place. The owners manual is shipped

inside the product in a plastic bag along with the warranty

registration card, and other accessory items.

Important

Keep your carton and packaging until your appliance has

been thoroughly inspected and found to be in good condition. If there is damage, the packaging will be needed as

proof of damage in transit. Afterwards please dispose of all

items responsibly.

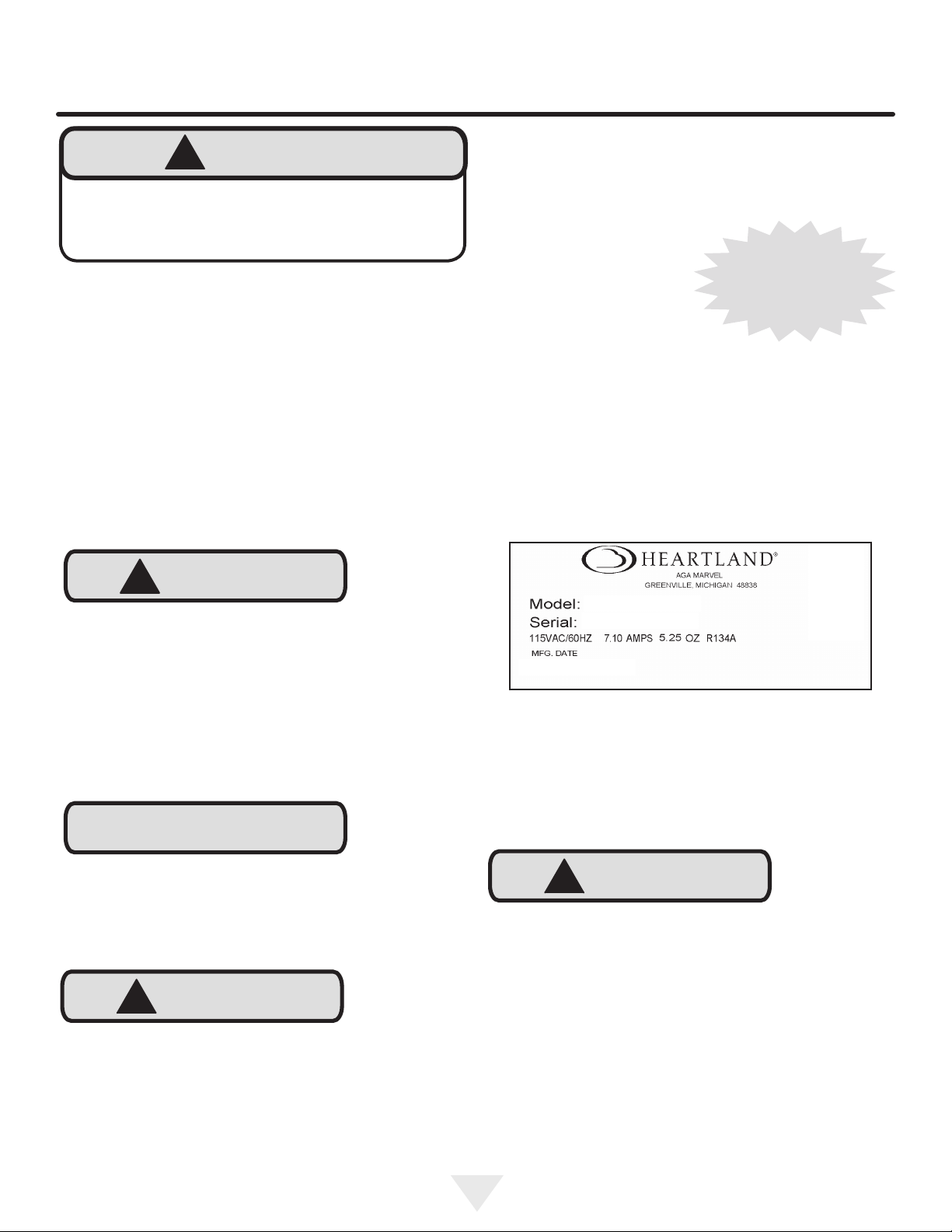

Warranty Registration

It is important you send in your warranty registration card

immediately after taking delivery of your appliance or you

can register online at www.agamarvel.com.

The following information will

be required when registering

your appliance.

Model Number

Serial Number

Date of Purchase

Dealer’s name and address

The service number and serial number can be found on the

serial plate which is located inside the right side refrigerator

cabinet on the right side of the cabinet liner. (See gure 1).

Online registration

available at

www.agamarvel.com

!

CAUTION

Dispose of the plastic bags which can be a suffocation

hazard.

Note to Customer

This merchandise was carefully packed and thoroughly

inspected before leaving our plant. Responsibility for its

safe delivery was assumed by the retailer upon acceptance

of the shipment. Claims for loss or damage sustained in

transit must be made to the retailer.

NOTE

DO NOT RETURN DAMAGED MERCHANDISE TO THE

MANUFACTURER - FILE THE CLAIM WITH THE

RETAILER.

!

CAUTION

If the appliance was shipped, handled, or stored in other

than an upright position for any period of time, allow the appliance to sit upright for a period of at least 24 hours before

plugging in. This will assure oil returns to the compressor.

Plugging the appliance in immediately may cause damage

to internal parts.

Figure 1

!

CAUTION

Help Prevent Tragedies

Child entrapment and suffocation are not problems of the

past. Junked or abandoned refrigerators are still dangerous

- even if they sit out for "just a few hours".

If you are getting rid of your old refrigerator, please follow

the instructions below to help prevent accidents.

Before you throw away your old refrigerator or freezer:

• Take off the doors or remove the drawers.

• Leave the shelves in place so children may not easily

climb inside.

3

Page 4

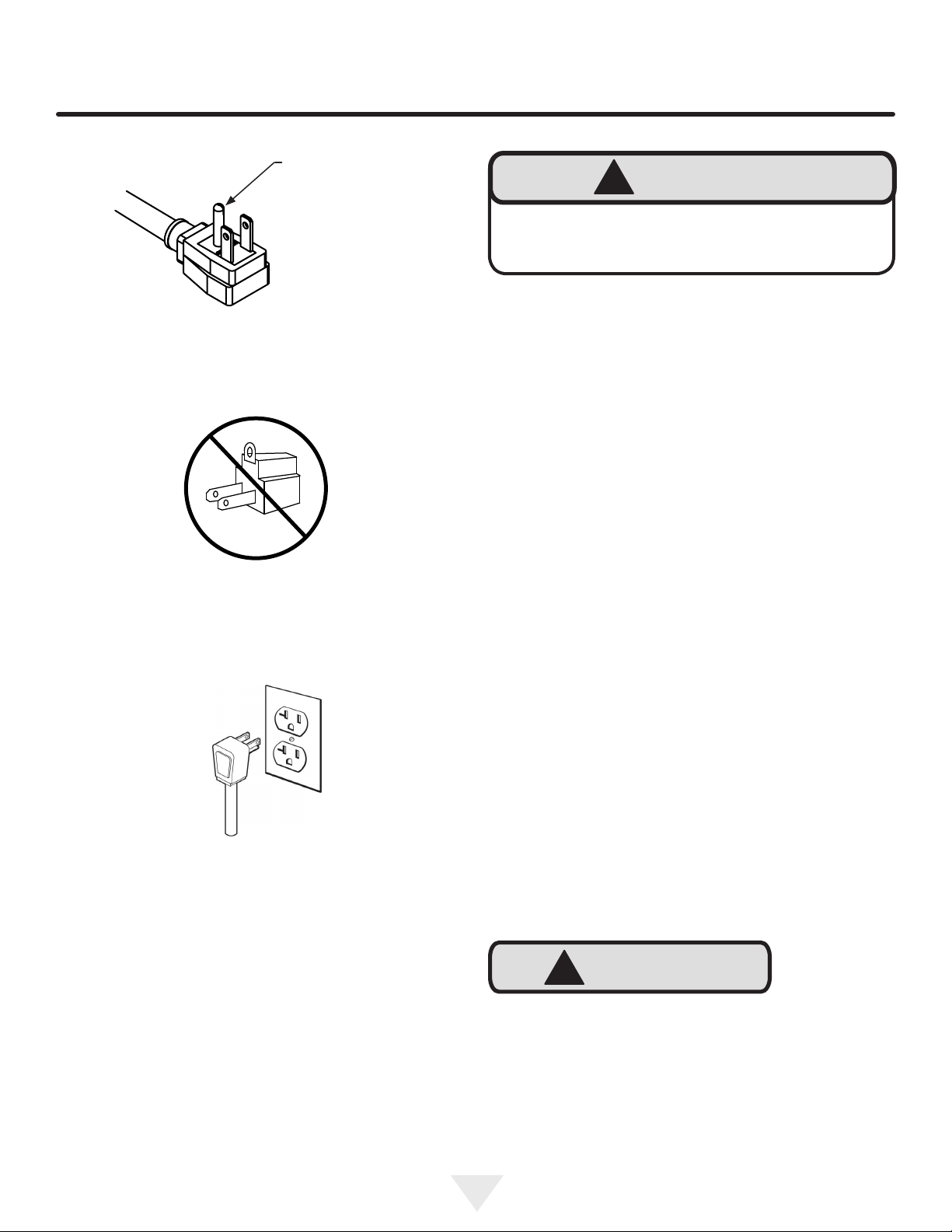

Figure 2

ELECTRICAL INFORMATION

Electrical information

Do not remove

ground prong

that your refrigerator’s safety mechanisms are

• The refrigerator must be plugged into its own dedicated 115 Volt, 60 Hz, AC-only non-GFCI electric outlet.

The power cord of the appliance is equipped with a

three-prong grounding plug for your protection against

electrical shock hazards. It must be plugged directly

into a properly grounded three-prong receptacle. The

receptacle must be installed in accordance with local

codes and ordinances. Consult a qualied electrician.

Do not use an extension cord or adapter plug.

• If the power cord is damaged, it should be replaced

by the manufacturer, service technician, or a qualied

person.

!

WARNING

You must follow these guidelines to ensure

operating correctly.

Figure 3

Figure 4

Grounding type

wall receptacle

• Never unplug the refrigerator by pulling on the power

cord. Always grip the plug rmly and pull straight out

from the receptacle to prevent damaging the power

cord.

• To avoid electrical shock, unplug the refrigerator before

cleaning and before replacing a light bulb or LED light.

• Performance may be affected if the voltage varies by

10% or more. Operating the refrigerator with insufcient

power can damage the compressor. Such damage is

not covered under your warranty.

• Do not plug the unit into an outlet controlled by a wall

switch or pull cord to prevent the refrigerator from being

turned off accidentally.

!

CAUTION

To turn off power to your refrigerator, unplug the

power cord from the wall outlet.

4

Page 5

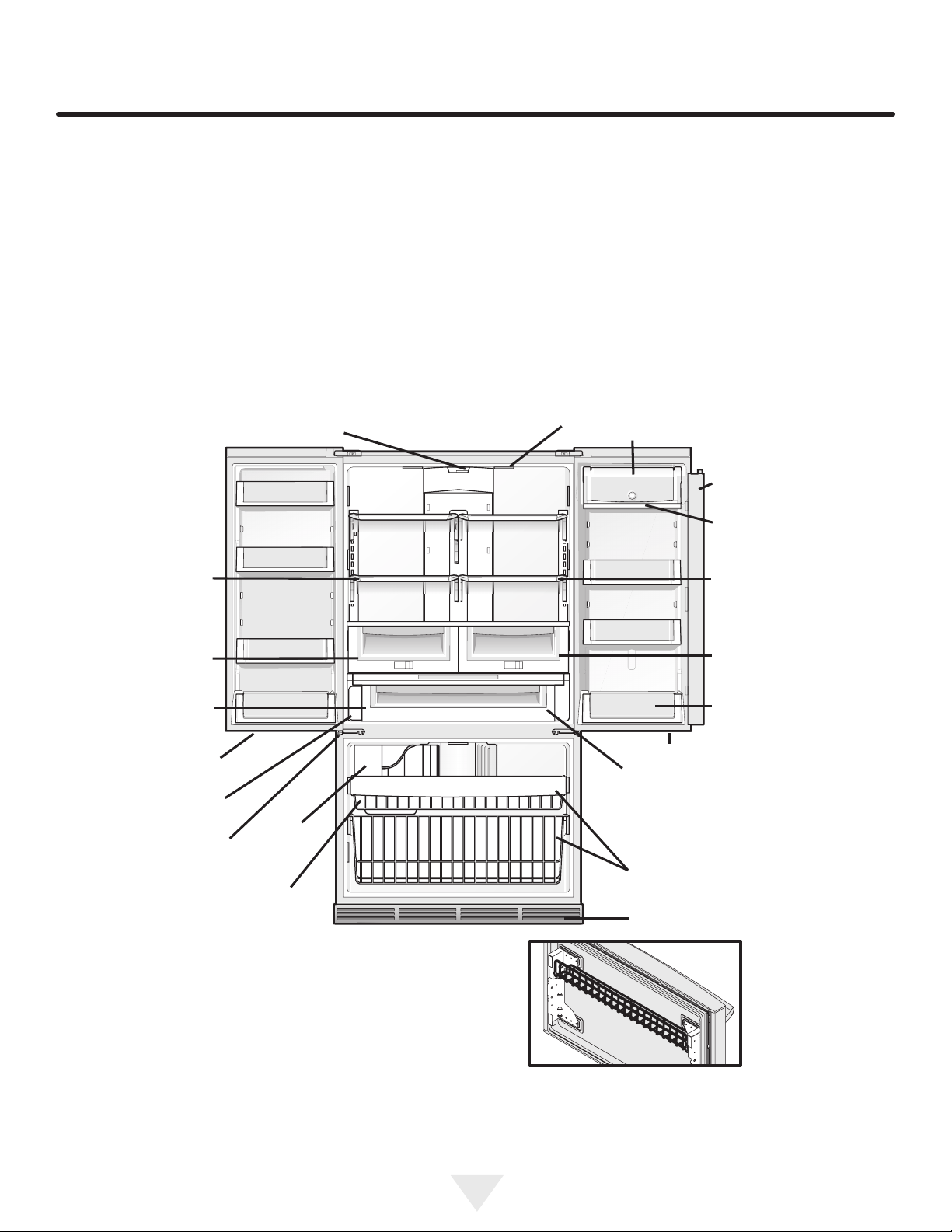

FEATURE OVERVIEW

Understanding features and terms

Your refrigerator is designed for optimal convenience and

storage exibility. The illustration below is provided to assist

you with familiarizing yourself with product features and

terminology.

Crisper

drawer

Specialty items rack,

inside drawer

Water

lter

Door

hinges

Flipper Guide

Ice

bucket

Ice

maker

LED lights

Covered

door bin

Flipper

mullion

Air lter

ShelvesShelves

Crisper

drawer

Tilt-out

bin

LED lightLED light

Select

temperature

drawer

Freezer baskets

Toe grille

Model is shown

without freezer

door cover

Figure 5

Wire tilt-out shelf

(inside freezer drawer)

5

Page 6

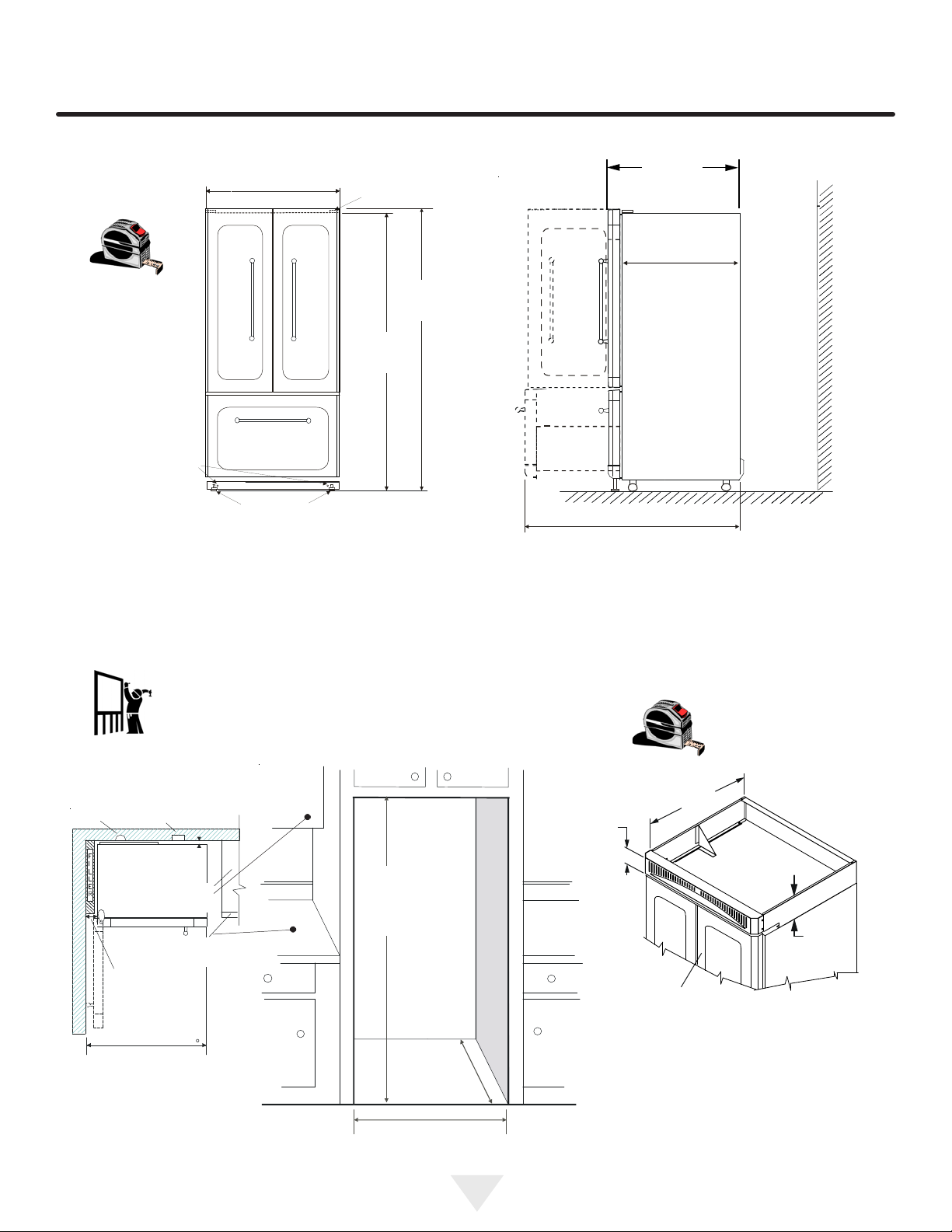

PRODUCT DIMENSIONS

Dimensions

front leg

adjusters

3/8”

Body Width

35 5/8”

(90.5 cm)

front

stabilizers

Hinge

(177.8 cm)

68 3/16”

(173.2 cm)

70”

Figure 6

26 7/8”

(68.3 cm)

23 5/8”

(60.0 cm)

44 1/2”

(113.0 cm)

with freezer drawer open

Rough In

Measurements

Water

Electrical

1” (2.5 cm)

air gap

24” (61 cm)

cabinet depth

25” (63.5 cm)

41-1

/4”

(105 cm)

counter depth

4” (10.2 cm)

for door swing

w/ door open 90

Figure 7

gap

4/1-07

no cowl

76-1/4””

6” cowl

Figure 8

(

)mc 4.871

(

193.7 cm)

25”

(63.5 cm)

36-1/2”

(92.7 cm)

4 1/4”

(10.8 cm)

OPTIONAL COWL

Dimensions

24”

(61 cm)

6 1/8”

(15.6 cm)

Refrigerator

•

Optional 6” (15 cm) high cowl - part

number 30059 - color.

Note: Color to be specified at time

of order.

• Cut-out height of opening will dependant on installation of cowl option. See adjacent Figure.

Figure 9

6

Page 7

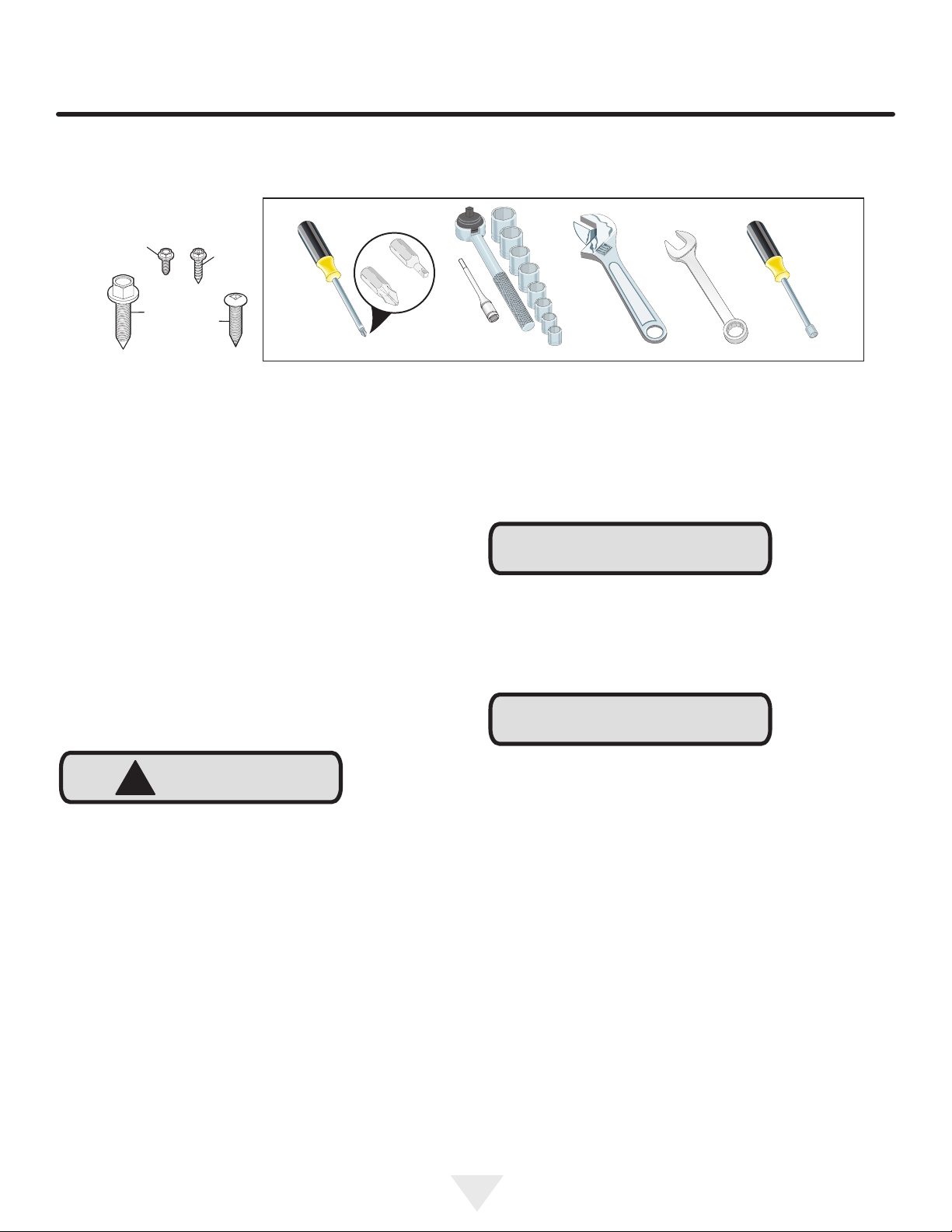

INSTALLATION

Required tools

You will need the following tools:

Components

provided:

Top hinge cover

front screw

Top

hinge

screw

Lower

hinge

screw

Top hinge

cover

rear screw

This Use & Care Guide provides general installation and

operating instructions for your model. We recommend

using a service or kitchen contracting professional to install

your refrigerator. Use the refrigerator only as instructed in

this Use & Care Guide. Before starting the refrigerator,

follow these important rst steps.

Tools necessary:

Phillips™ Head

or #2 square

drive head

(or)

And

Figure 10

Socket wrench set

(or)

Adjustable

wrench

(or) (or)

3/8" Fixed

wrench

1/4" Nut

driver

Installation

• Allow the following clearances for ease of installation,

proper air circulation, and plumbing and electrical connections:

Sides & Top ⅜ inch (9.5 mm)

Back 1 inch (25.4 mm)

Location

• Choose a place that is near a grounded, non-GFCI,

electrical outlet. Do Not use an extension cord or an

adapter plug.

• If possible, place the refrigerator out of direct sunlight

and away from the range, dishwasher, or other heat

sources.

• The refrigerator must be installed on a oor that is level

and strong enough to support a fully loaded refrigerator.

• Consider water supply availability for models equipped

with an automatic ice maker.

!

CAUTION

DO NOT install the refrigerator where the temperature will

drop below 55°F (13°C) or rise above 110°F (43°C). The

compressor will not be able to maintain proper temperatures inside the refrigerator.

DO NOT block the toe grille on the lower front of your re-

frigerator. Sufcient air circulation is essential for the proper

operation of your refrigerator.

NOTE

If your refrigerator is placed with the door hinge against a

wall, you may have to allow additional space so the door

can be opened wider.

Door opening

NOTE

The refrigerator doors are designed to shut by themselves

within a 20 degree opening.

Your refrigerator should be positioned to allow easy access

to a counter when removing food. For best use of refrigerator drawers and freezer baskets, the refrigerator should be

in a position where both can be fully opened.

Guidelines for nal positioning of your refrigerator

• All four corners of the cabinet must rest rmly on the

oor.

• The cabinet should be level at the front and rear.

• The sides should tilt ¼ inch (6 mm) from front to back

(to ensure that doors close and seal properly).

• Doors should align with each other and be level.

Most of these conditions can be met by raising or

lowering the adjustable front rollers.

7

Page 8

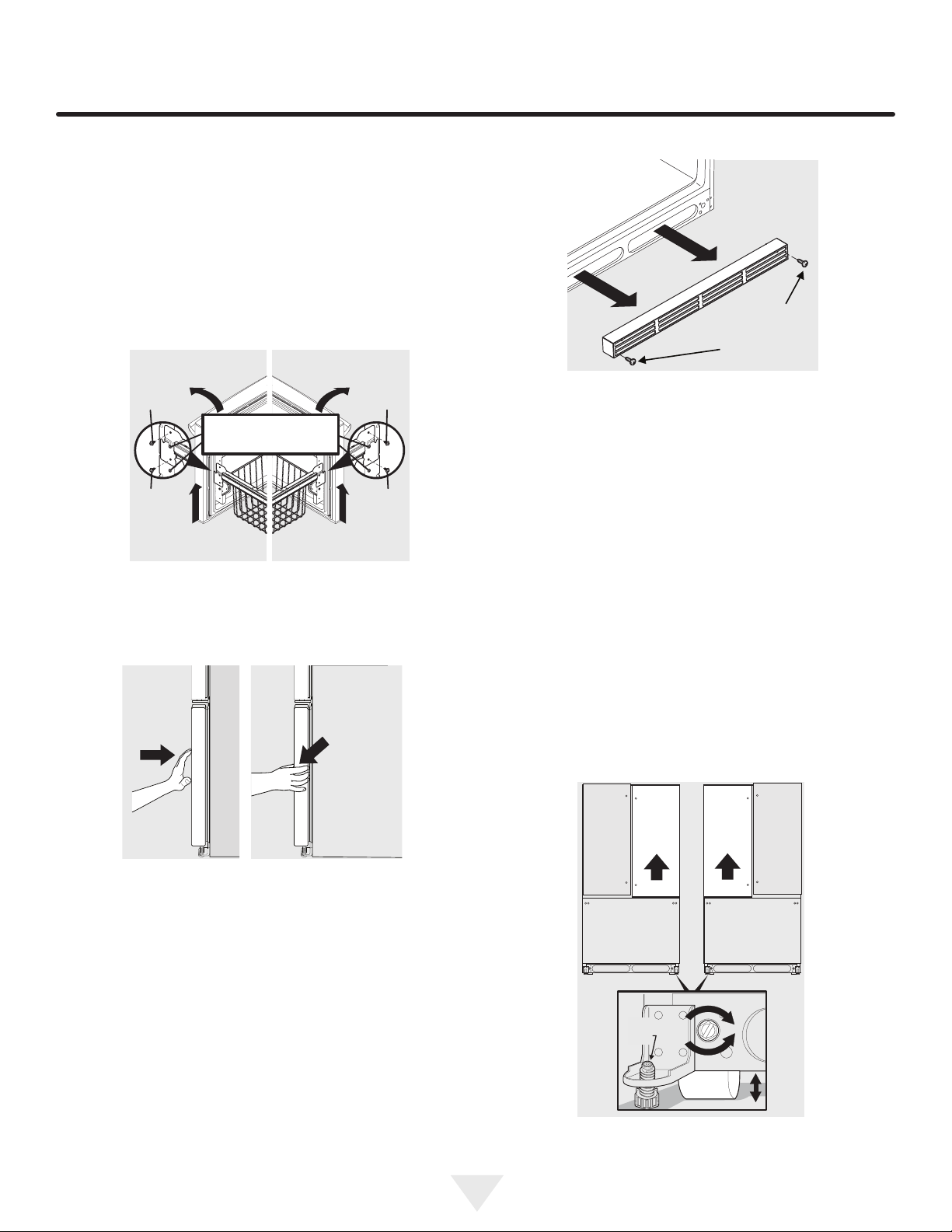

INSTALLATION

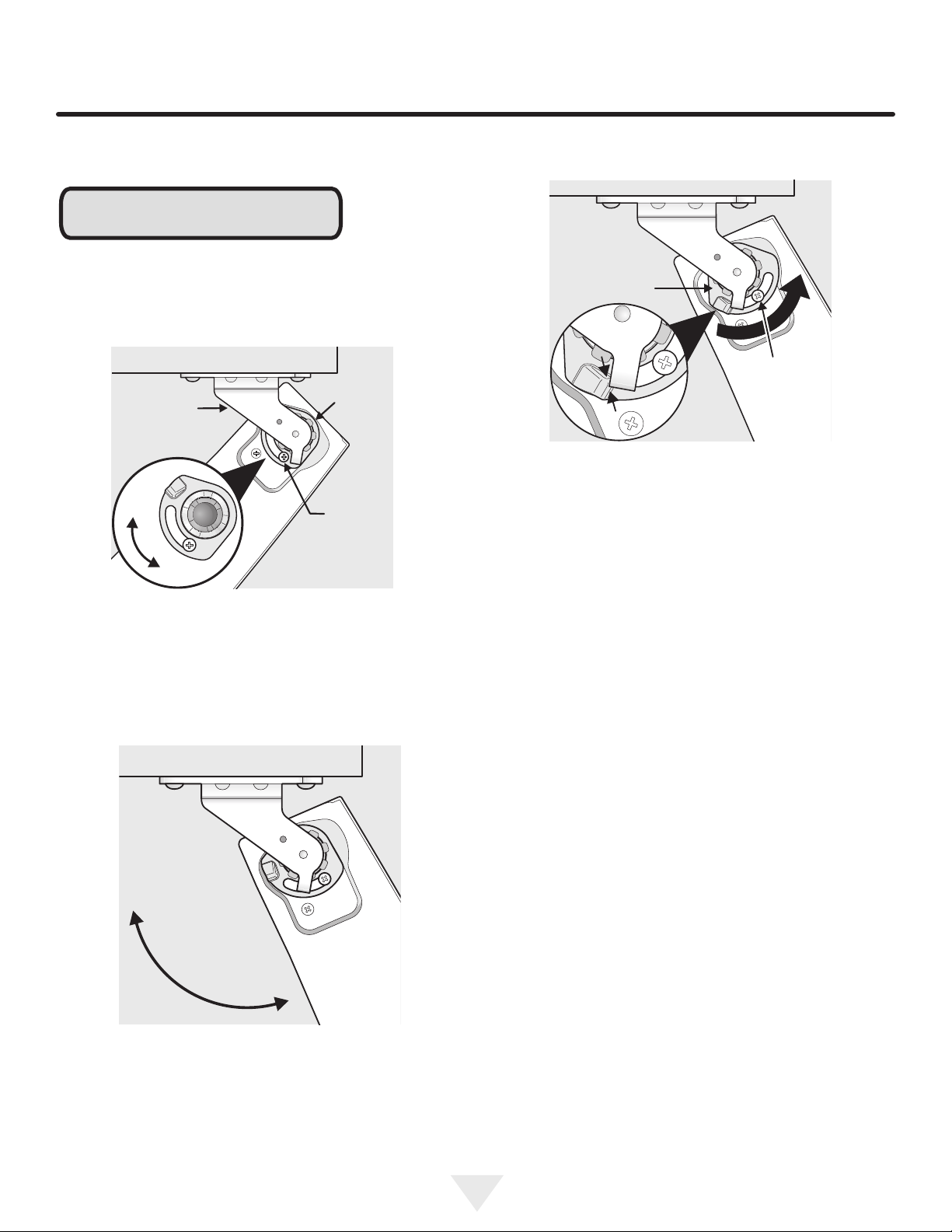

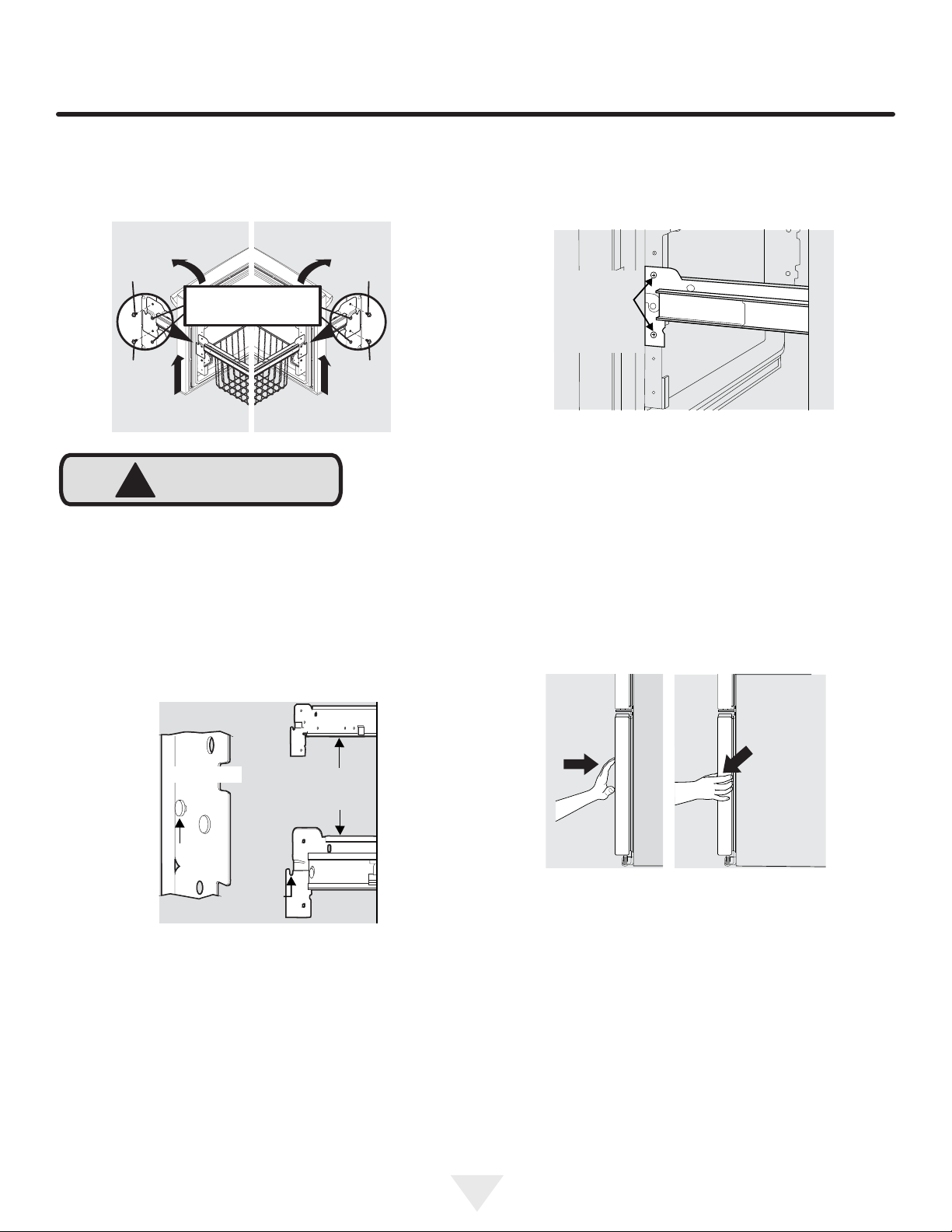

Leveling Freezer Drawer (if necessary)

1. Check gasket seal around top, bottom, and sides of

freezer drawer.

2. If gasket is not sealed, open drawer and slightly loosen

four drawer screws (two on each side) to allow drawer

to rotate (see illustration).

3. Close drawer and recheck the seal on the gasket (A).

Open the drawer grabbing by the sides in the center

(B). Be careful not to rotate the drawer.

Remove hex

head drawer

screw

Remove hex

head drawer

screw

Figure 11

Remove hex

head drawer

screw

Do not remove

other screws

Remove hex

head drawer

screw

Figure 13: Remove screws and then gently pull forward.

Remove

mounting

screws

Figure 13

4. Tighten four drawer screws.

5. Recheck gasket seal.

Figure 12

Push

against

freezer

drawer

A

B

Grab

drawer

at center

from both

sides

then

pull

drawer

out

Level Refrigerator & Adjust Doors (if necessary)

Guidelines for nal positioning of your refrigerator:

• All four corners of the cabinet must rest rmly on the

oor.

• The sides should tilt ¼ inch (6 mm) from front to back

(to ensure that doors close and seal properly).

• Doors should align with each other and be level.

Most of these conditions can be met by raising or lowering the adjustable front rollers.

3. You can raise or lower each door. Use a ⅜ inch socket

wrench to turn the adjustment screws (one per side).

To raise: turn adjustment screw clockwise.

To lower: turn adjustment screw counterclockwise.

4. Ensure both doors are bind-free with their seals touching the cabinet on all four sides and that cabinet is

stable.

5. After unit is leveled, lower anti-tip leg until it contacts

the oor.

Door Door

Figure 14

Raise

Anti-tip

leg

Lower

To level the cabinet using the front rollers:

1. Slightly open freezer drawer.

2. Remove the toe grille. See Figure 13.

6. Install the toe grille by tting into place (replacing

screws on some models).

8

Page 9

INSTALLATION

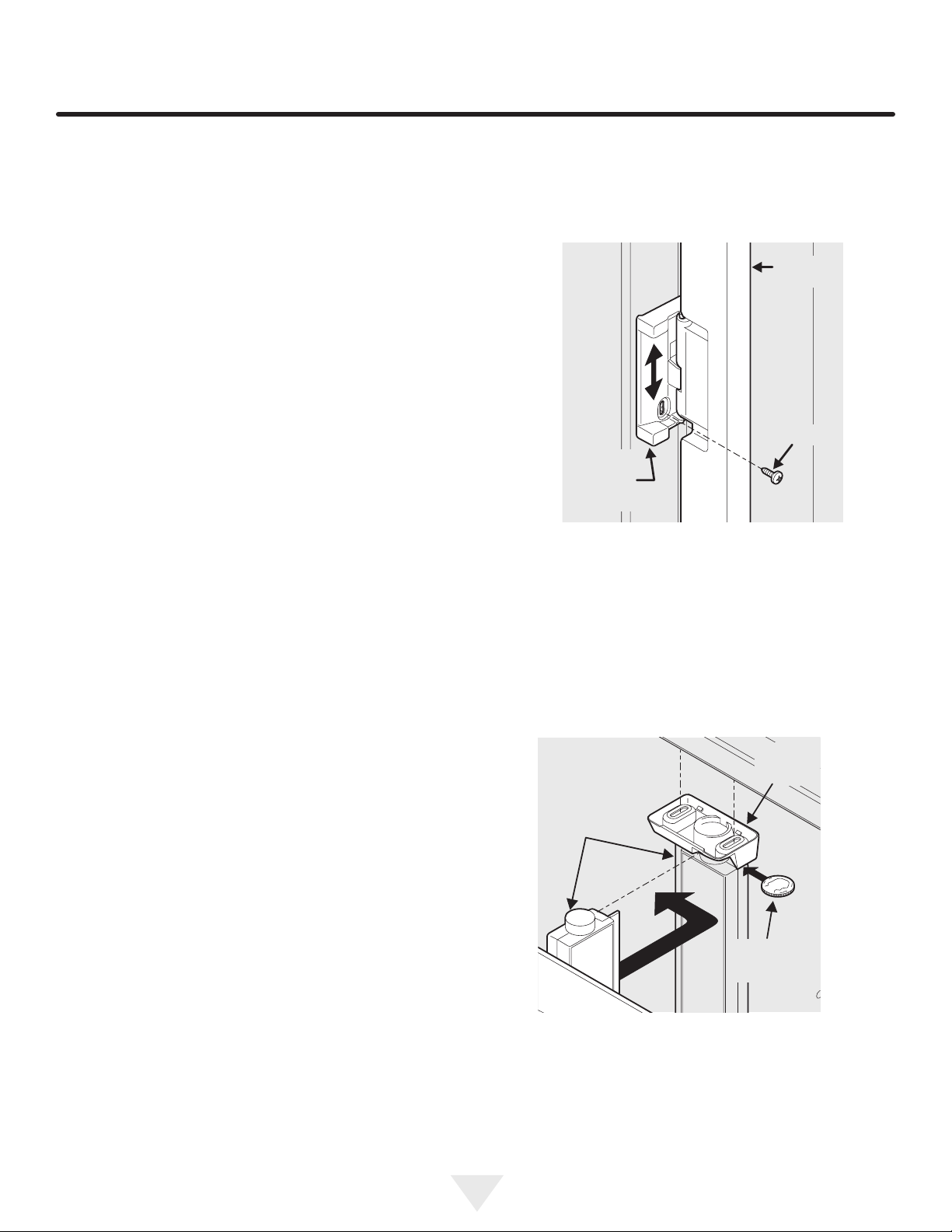

To adjust the door stop:

Door stop is adjustable between 85 to 145 degrees.

NOTE

View shown is looking up at the bottom of the refrigerator

door.

Lower

hinge

Door

stop

Screw

5. Re-tighten screw.

Rotate

door

stop

Re-tighten

screw

Re-tighten screw

Figure 17

6. Ensure door stops in desired location before resuming

normal use.

Adjustable door stop

Figure 15

1. Open door to provide access to screw.

2. Loosen screw.

3. Adjust door to desired location.

Rotate door

to desired

location

Adjusting door

Figure 16

4. Rotate door stop until it makes contact with the lower

hinge.

9

Page 10

INSTALLATION

To adjust the ipper mullion:

1. Loosen the screw located on the ipper mullion hinge.

Flipper

mullion

Screw

Flipper

mullion

hinge

Figure 18

Adjusting ipper mullion screw

2. Adjust ipper mullion height. For proper connection with

the ipper mullion guide, there should be a separation

about the thickness of a coin (0.060 inches, or 1.5 mm)

between the guide and ipper mullion.

Mullion

guide

Flipper

mullion

Thickness

of a coin

Adjusting ipper mullion height

3. Re-tighten screw.

10

Figure 19

Page 11

REMOVING THE DOORS

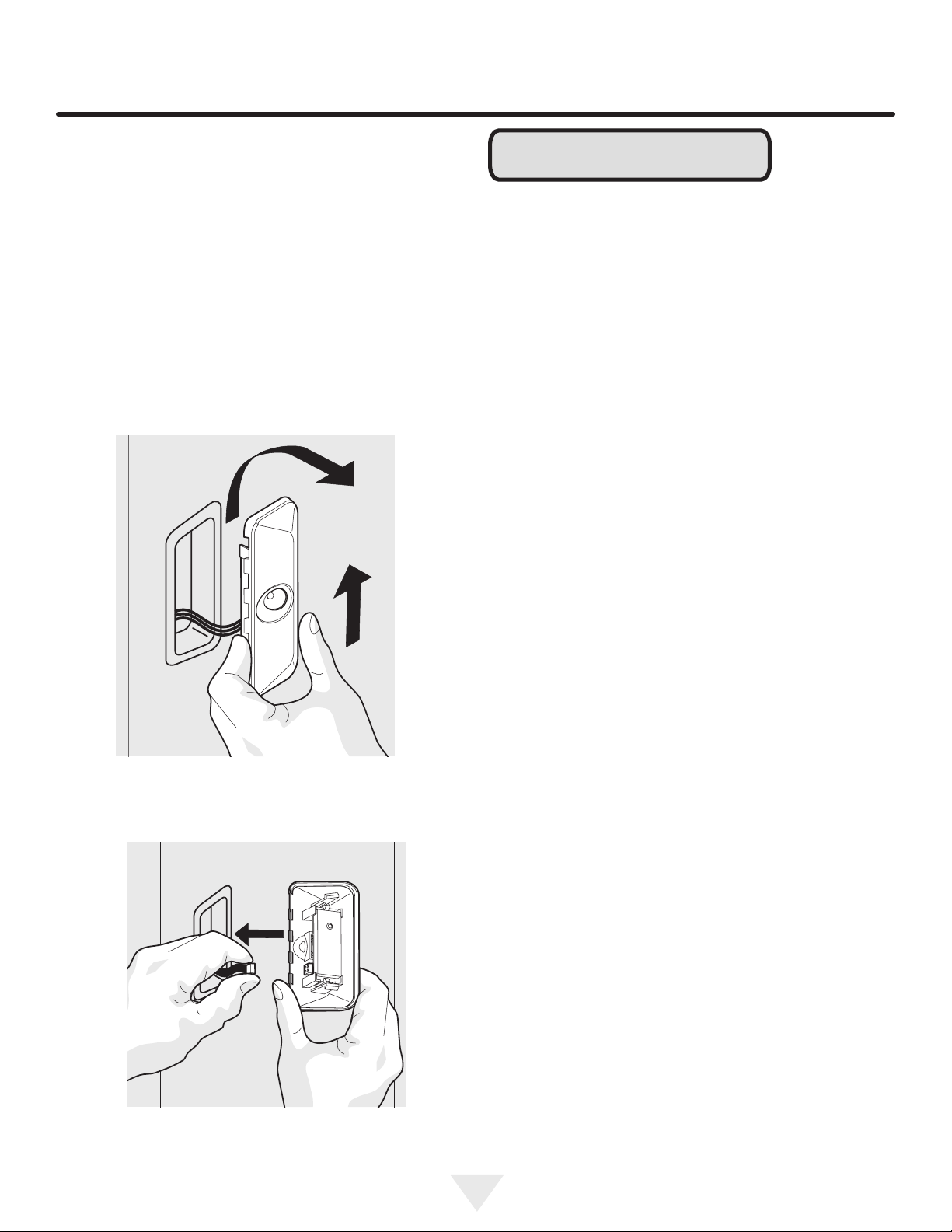

Getting through narrow spaces

If your refrigerator will not t through an entrance area,

you can remove the doors. Check rst by measuring the

entrance.

To prepare for removing the doors:

1. Make sure the electrical power cord is unplugged from

the wall outlet.

2. Open the freezer drawer and remove the toe grille (see

“Installation” section).

3. Remove any food from the door shelves and close the

doors.

To remove the top hinge covers:

1. Remove the two screws from each cover over the top

door hinges.

2. Lift inside edge of hinge cover and tilt back.

Front

cover screw

Top hinge

cover

Rear

cover

screw

2. Disconnect the harness by grasping both sides of the

connector rmly, depress the latch, and pull apart. Remove the two screws from the top hinge. Lift the door

off of the bottom hinge and set it aside.

Figure 22

3. Unscrew the three lower hinge screws and hinge if

necessary.

To reinstall the right door, reverse the above steps.

Hinge

screws

Multi-wire

cables

Leave

hinge

with

door

Ground

screw

Top

hinge

Figure 20

NOTE

DO NOT remove the ground screw from hinge.

To remove the refrigerator doors:

1. Trace lightly around the door’s top hinges with a pencil.

This makes reinstallation easier.

lower hinge removal

Figure 23

Once both doors are in place, ensure they are aligned with

each other and level (please see the “Installation” section

for more details), and replace the top hinge cover.

!

CAUTION

Be sure doors are set aside in a secure position where they

cannot fall and cause personal injury, or damage to the

doors or handles.

Figure 21

11

Page 12

REMOVING THE DOORS

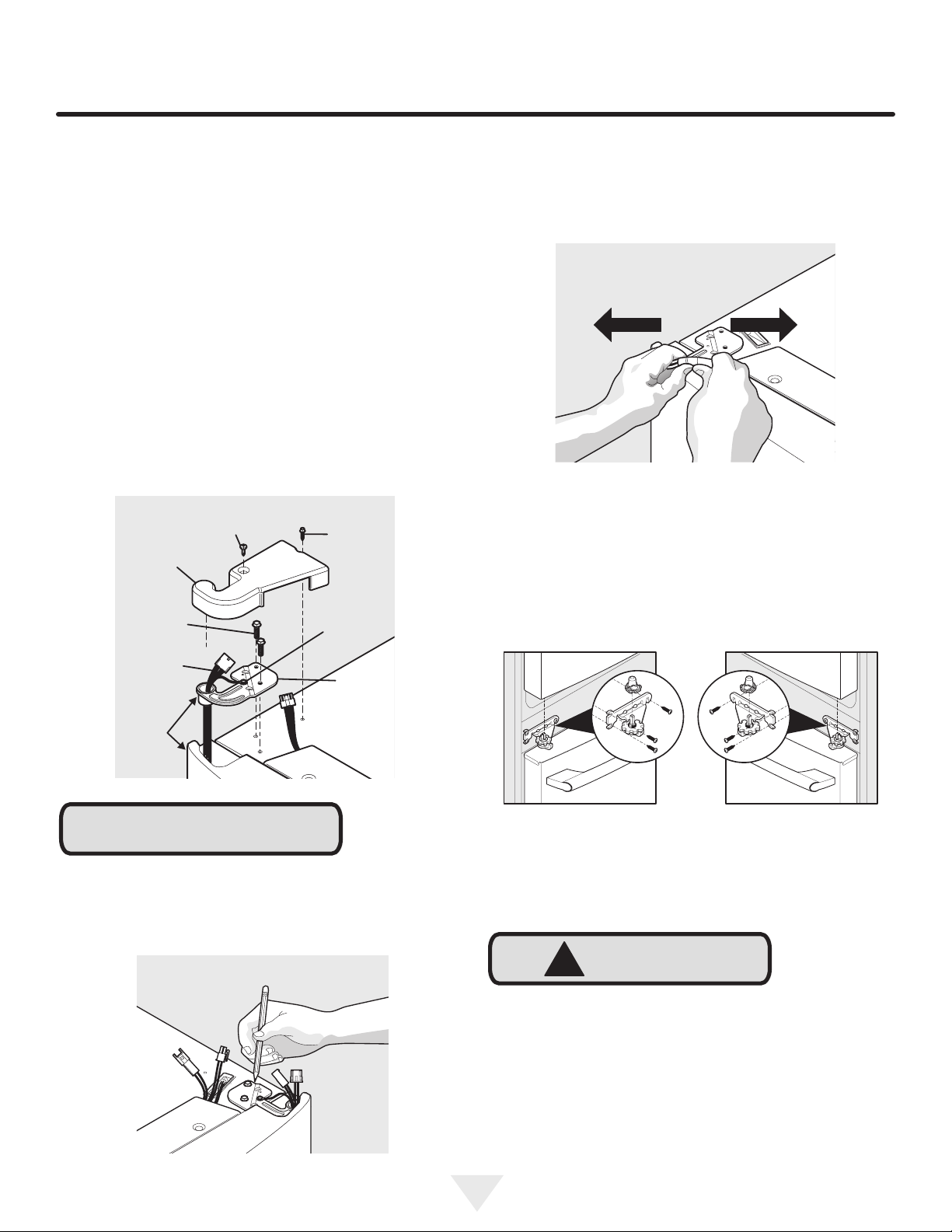

Removing Freezer Drawer

1. Open freezer drawer.

2. Remove drawer screws on right and left sides (two

screws on each side).

Remove hex

head drawer

screw

Do not remove

other screws

Remove

hex

head drawer

screw

Remove hex

head drawer

screw

Remove

hex

head drawer

screw

Figure 24

!

CAUTION

Drawer is heavy. Use caution when lifting.

3. Lift drawer up and out to remove.

Installing Freezer Drawer

1. With lower slides pulled out, hang drawer onto slide

brackets ensuring pins on each side are fully inserted

into slots on each side.

2. Reinstall four drawer screws (two per side), tighten

down, and close drawer (C).

Install

screws

(2) each

side

Figure 26

3. Check gasket seal around top, bottom, and sides of

freezer drawer.

4. If gasket is not sealed, open drawer and slightly loosen

four drawer screws (two on each side) to allow drawer

to rotate.

5. Close drawer and recheck the seal on the gasket (A).

Open the drawer grabbing by the sides in the center

(B). Be careful not to rotate the drawer.

Assembly

Pin

Slot

Figure 25

Fully extend

drawer slides

Cabinet

Push

against

freezer

drawer

A

B

Grab drawer

at center

from both

sides, then

pull drawer out

Figure 27

6. Tighten four drawer screws.

7. Recheck gasket seal.

8. Install the toe grille by tting into place.

12

Page 13

CONNECTING THE WATER SUPPLY

!

WARNING

To avoid electric shock, which can cause death or severe

personal injury, disconnect the refrigerator from electrical

power before connecting a water supply line to the refrigerator.

!

CAUTION

To Avoid Property Damage:

• Copper or Stainless Steel braided tubing is recommended

for the water supply line. Water supply tubing made of ¼ inch

plastic is not recommended to be used. Plastic tubing greatly

increases the potential for water leaks, and the manufacturer will not be responsible for any damage if plastic tubing is

used for the supply line.

• DO NOT install water supply tubing in areas where temperatures fall below freezing.

• Chemicals from a malfunctioning softener can damage the

ice maker. If the ice maker is connected to soft water, ensure

that the softener is maintained and working properly.

NOTE

Ensure that your water supply line connections comply with all

local plumbing codes.

Before Installing The Water Supply Line, You Will Need:

• Basic Tools: adjustable wrench, at-blade screwdriver, and

Phillips™ screwdriver

• Access to a household cold water line with water pressure

between 30 and 100 psi.

• A water supply line made of ¼ inch (6.4 mm) OD, copper

or stainless steel tubing. To determine the length of tubing

needed, measure the distance from the ice maker inlet valve

at the back of the refrigerator to your cold water pipe. Then

add approximately 7 feet (2.1 meters), so the refrigerator can

be moved out for cleaning (as shown).

• A shutoff valve to connect the water supply line to your

household water system. DO NOT use a self-piercing type

shutoff valve.

• Do not reuse compression tting or use thread seal tape.

• A compression nut and ferrule (sleeve) for connecting a copper water supply line to the ice maker inlet valve.

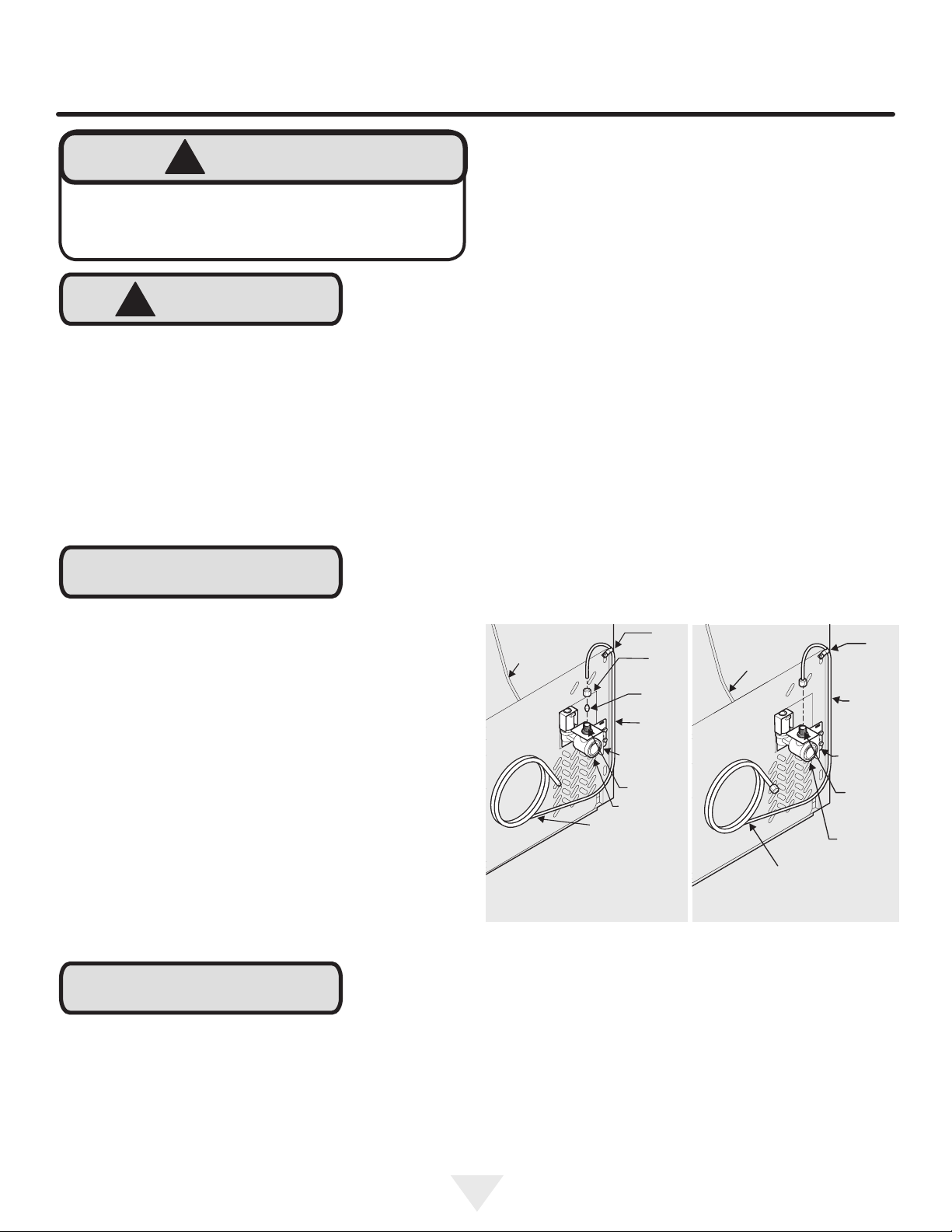

To Connect Water Supply Line To Ice Maker Inlet Valve

1. Disconnect refrigerator from electric power source.

2. Place end of water supply line into sink or bucket. Turn ON

water supply and ush supply line until water is clear. Turn

OFF water supply at shutoff valve.

3. Remove plastic cap from water valve inlet and discard cap.

4. If you use copper tubing - Slide brass compression nut,

then ferrule (sleeve) onto water supply line. Push water supply line into water valve inlet as far as it will go (¼ inch / 6.4

mm). Slide ferrule (sleeve) into valve inlet and nger tighten

compression nut onto valve. Tighten another half turn with a

wrench; DO NOT over tighten. See Figure 28.

If you use stainless steel tubing - The nut and ferrule are

already assembled on the tubing. Slide compression nut onto

valve inlet and nger tighten compression nut onto valve.

Tighten another half turn with a wrench; DO NOT over

tighten. See Figure 29.

5. With steel clamp and screw, secure water supply line (copper

tubing only) to rear panel of refrigerator as shown.

6. Coil excess water supply line (copper tubing only), about 2½

turns, behind refrigerator as shown and arrange coils so they

do not vibrate or wear against any other surface.

7. Turn ON water supply at shutoff valve and tighten any connections that leak.

8. Reconnect refrigerator to electrical power source.

9. To turn ice maker on, lower wire signal arm (freezer ice

maker) or set the ice maker’s On/Off power switch to the “On”

position (fresh food ice maker).

Plastic water tubing

to ice maker

ll tube

Copper water line

from household

water supply

Figure 28 Figure 29

Steel

clamp

Brass

compression

Ferrule

(sleeve)

Copper

water

line

Water valve

bracket

Valve inlet

Water valve

nut

Plastic water tubing

to ice maker

ll tube

6 ft. stainless steel water

line from household water

supply

Steel

clamp

Stainless

steel

water line

Water valve

bracket

Valve inlet

Water valve

NOTE

Check with your local building authority for recommendations on

water lines and associated materials prior to installing your new

refrigerator.

13

Page 14

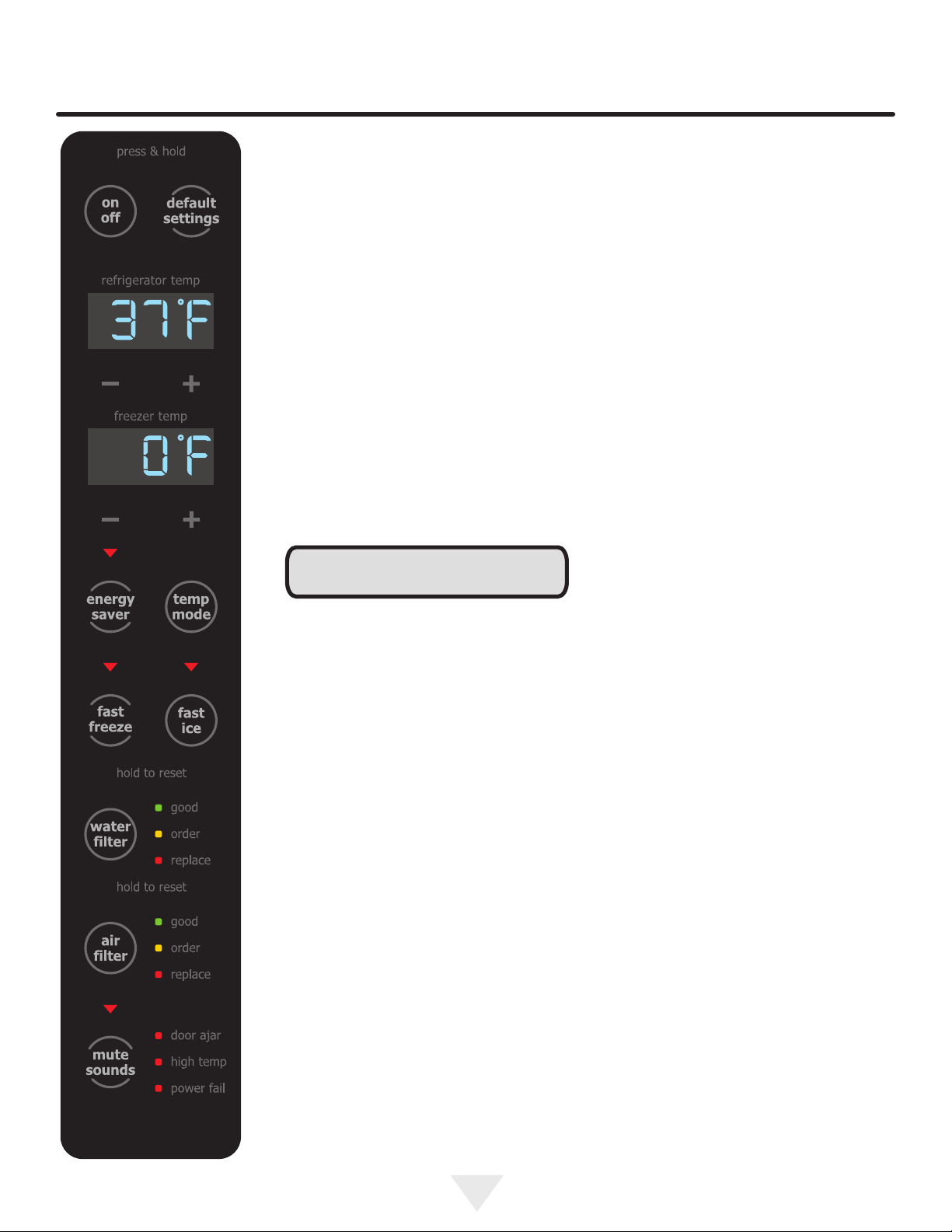

ELECTRONIC CONTROL

A red indicator light will be illuminated above most active features.

Touch the icon to activate the options below.

fast freeze Activates a faster rate for freezing food.

fast ice Increases the production of ice

energy saver Keep this switch set on energy saver (light on) for lowest energy us

age. If moisture appears on the cabinet between the doors, pressing

this button will turn the light off and enable an electric heater used to

reduce moisture on the cabinet between the doors.

water lter Press and hold for three seconds to reset after lter change.

air lter Filter condition status is always displayed when door is open. Press

and hold for three seconds to reset after lter change.

temp mode Touch to toggle display from Fahrenheit to Celsius.

mute sounds Tones emitted by each key press can be turned off based on user

preference. The sounds are muted when the red indicator is lit. Warn-

ing signals will stay active.

default settings Resets all refrigerator settings such as temp, temp display and tones

to their factory default settings.

on off Press and hold for three seconds to turn off the cooling system to

clean the refrigerator. It also turns off the ice maker. The temperature

displays will read OFF.

Pressing the system on/off icon does not

NOTE

turn off power to your refrigerator. You must

unplug the power cord from the wall outlet.

Setting cooling temperatures

Press the + or – indicator to adjust the temperature to the desired setting.

The temperature display will begin to blink with the rst touch. The display will time out

after 10 seconds and return to the basic display.

Alarms

Door Ajar If the door has been left open for an extended period of time, an alarm

will sound and the door ajar indicator will display on the bottom display

of the control panel. The alarm is turned off by closing the door. The

mute sounds key will blink to prompt the reset of any active alarms.

Press this key to reset any system alarms.

High Temp In the event of a high temperature condition, the temperature display

will blink and display “HI”. After 20 minutes, the alarm will sound and

the high temp indicator will be red on the bottom of the control panel.

The mute sounds icon will illuminate until pressed, acknowledging the

alarm, at which time the highest temperature reached will be displayed

and the refrigerator will resume normal operation. In case the high temp

alarm is not acknowledged at the rst alarm sound time out, when the

door is rst opened, the alarm sound will be repeated.

Power fail In the event of a power failure, the power fail alert will be displayed and

the temperature display will blink until the mute sounds icon is pressed,

acknowledging the alarm. Other modes may be turned off until the alarm

is acknowledged. The power fail alert is turned off and the refrigerator

will resume normal operation. The high temp alarm may also be illumi

nated until a safe operating range temperature has been reached.

Figure 30

14

Page 15

ELECTRONIC CONTROL

Sabbath mode

The Sabbath Mode is a feature that disables portions

of the refrigerator and its controls for, in accordance with

observance of the weekly Sabbath and religious holidays

within the Orthodox Jewish community.

Sabbath Mode is turned ON and OFF by pressing and

holding the freezer temp “-” and the refrigerator temp “+”

indicators for ve seconds. The display shows “Sb” while in

Sabbath mode.

In the Sabbath Mode, the High Temp alarm is active for

health reasons. If a high temperature alarm is activated

during this time, for example due to a door left ajar, the

alarm will sound intermittently for about two minutes. The

alarm will then silence on its own and a red high temperature icon will display. The high temp icon will continue to

display, even if the door is closed, until the Sabbath mode

is exited and the icon reset. The refrigerator will function

normally once the door is closed, without any violation of

the Sabbath/Holidays.

Sabbath Mode and the Select Temp

Drawer

The Select Temp Drawer should be turned off for the

Sabbath/Holidays. Before putting the refrigerator into the

Sabbath mode, turn the Select Temp Drawer off by pressing the drawer on/off button. The display will show “OFF”

and the drawer will turn off. Then enter the Sabbath mode

function on the main refrigerator display. See the electronic

control “Sabbath Mode” section. When in Sabbath mode,

the display will not illuminate and the drawer will remain

off. The drawer can still be used as a non-temp controlled

drawer in this mode. When the refrigerator is taken out of

Sabbath mode, the Select Temp Drawer will have to be

turned back on.

NOTE

If the Select Temp Drawer is not turned off prior to putting

the unit into Sabbath Mode, it will continue to adjust itself to

maintain the set point even if the display does not illuminate

to show that it is still on.

NOTE

While in Sabbath Mode, neither the lights nor the control

panel will work until Sabbath Mode is deactivated. Refrigerator stays in Sabbath Mode after power failure recovery.

It must be deactivated with the buttons on the control panel.

NOTE

During Sabbath Mode, the ice maker is turned off by main

control board.

15

Page 16

AUTOMATIC ICE MAKER

Ice maker operation & care

After the refrigerator is installed properly, the ice maker can

produce ice within 24 hours. It can completely ll an ice bin

in about three days.

When using the ice maker for the rst time and in order

for the ice maker to work properly, it is necessary to clear

air from water lter tubing. Once ice maker begins making

ice, allow the bucket to ll completely, then discard the rst

TWO FULL buckets of ice. It will take at least two days to

completely ll the bucket on regular ice making mode or 1½

days on fast ice mode.

The ice maker produces approximately four pounds of ice

every 24 hours depending on usage conditions.

NOTE

Your ice maker is turned on at the factory so it can work as

soon as you install your refrigerator. If you cannot connect

a water supply, lift the ice maker’s wire signal arm to turn it

off. Otherwise, the ice maker’s ll valve may make a loud

chattering noise when it attempts to operate without water.

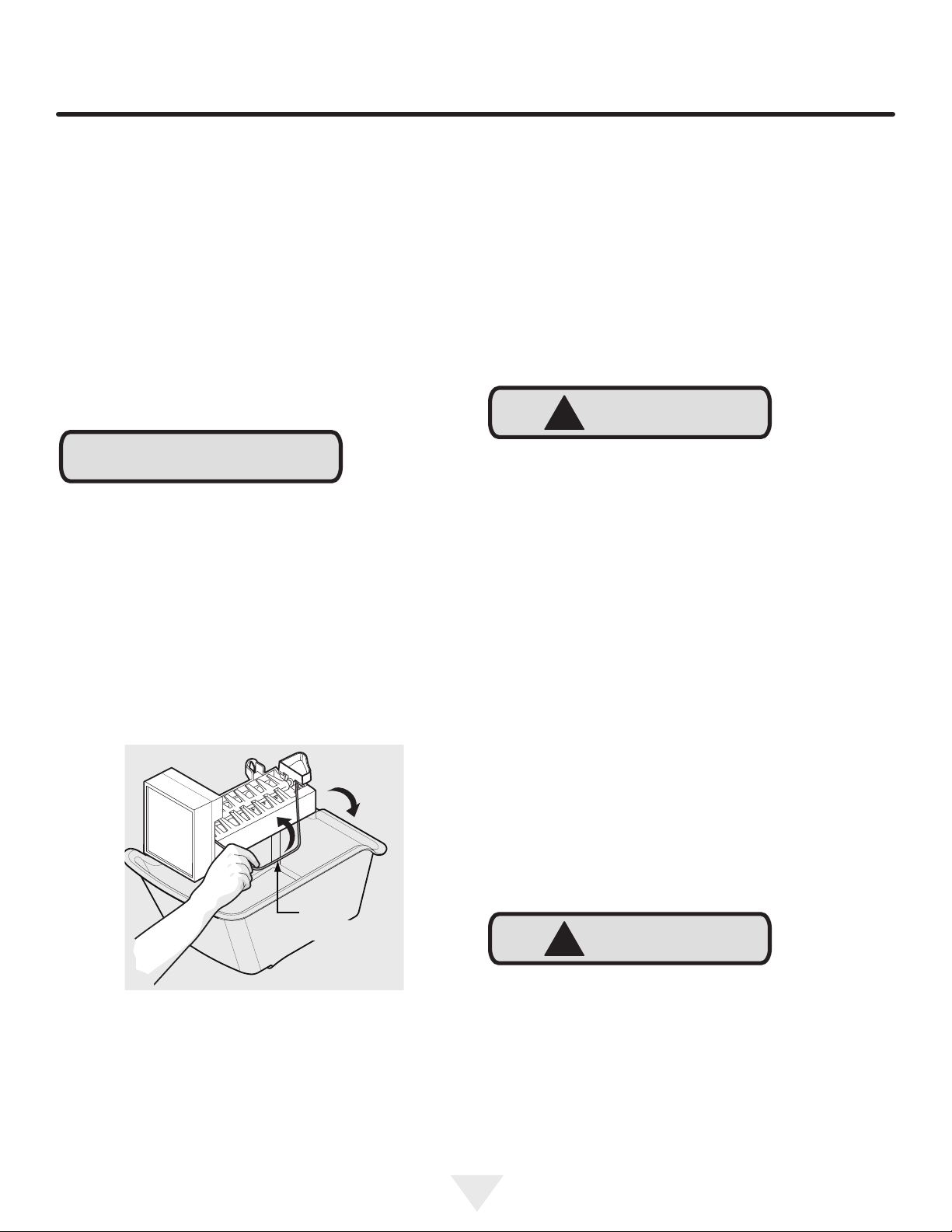

Turning the ice maker on and off

Ice production is controlled by lifting/lowering the ice maker’s wire signal arm. To gain access to the ice maker, pull

the freezer drawer out. Lift the wire signal arm to turn the

ice maker OFF and lower the wire signal arm to turn it ON.

• The following sounds are normal when the ice maker is

operating:

- Motor running

- Ice dropping into ice bin

- Water valve opening or closing

- Running water

Fast Ice Function

Your refrigerator is equipped with a Fast Ice Function, that

will, if activated at your user interface, allow an increase in

ice production. You do not need to deactivate it, if not needed, your refrigerator will operate on normal conditions.

!

CAUTION

If the water supply to your refrigerator is softened, be sure

the softener is properly maintained. Chemicals from a water

softener can damage the ice maker.

Cleaning the ice maker

Clean the ice maker and ice bin at regular intervals, especially prior to vacation or moving.

1. Turn off the ice maker.

2. Remove the ice bin.

3. Empty and carefully clean the ice bin with mild deter-

gent. Do not use harsh or abrasive cleaners. Rinse with

clean water.

4. Allow the ice bin to dry completely before replacing in

the freezer.

5. Replace the ice bin. Turn the ice maker on.

On

Off

Wire

signal arm

Figure 31

Ice maker tips

• If your refrigerator is not connected to a water supply or

the water supply is turned off, turn off the ice maker by

lifting wire signal arm.

• Ice cubes stored too long may develop an odd avor.

Empty the ice bin as explained below.

Remove and empty the ice bin if:

• An extended power failure (one hour or longe)

causes ice cubes in the ice bin to melt and freeze

together.

Remove the ice bin and shake to loosen the cubes or clean

as explained above.

!

CAUTION

NEVER use an ice pick or similar sharp instrument to break

up the ice. This could damage the ice bin. To loosen stuck

ice, use warm water. Before replacing the ice bin, make

sure it is completely dry.

16

Page 17

STORAGE FEATURES

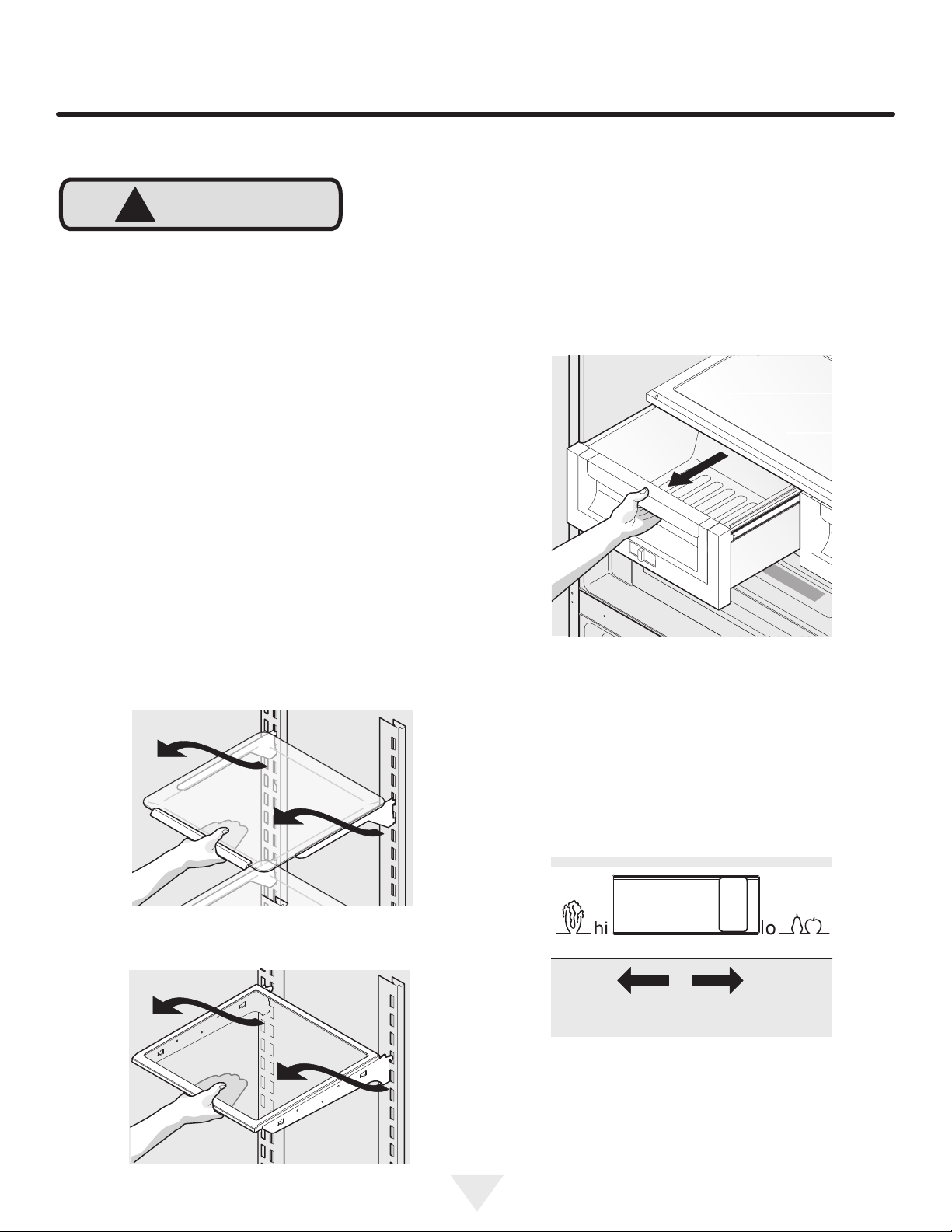

Shelf features Drawers

Your refrigerator includes a variety of storage drawers.

These drawers are located in xed positions at the bottom

of the fresh food compartment.

!

CAUTION

To avoid injury from breakage, handle tempered glass

shelves carefully.

Your refrigerator includes glass shelves that are designed

to catch and hold accidental spills.

You can easily adjust shelf positions in the fresh food compartments to suit your needs. The shelves have mounting

brackets that attach to slotted supports at the rear of each

compartment.

Crispers

Crisper drawers are designed for storing fruits, vegetables,

and other fresh produce.

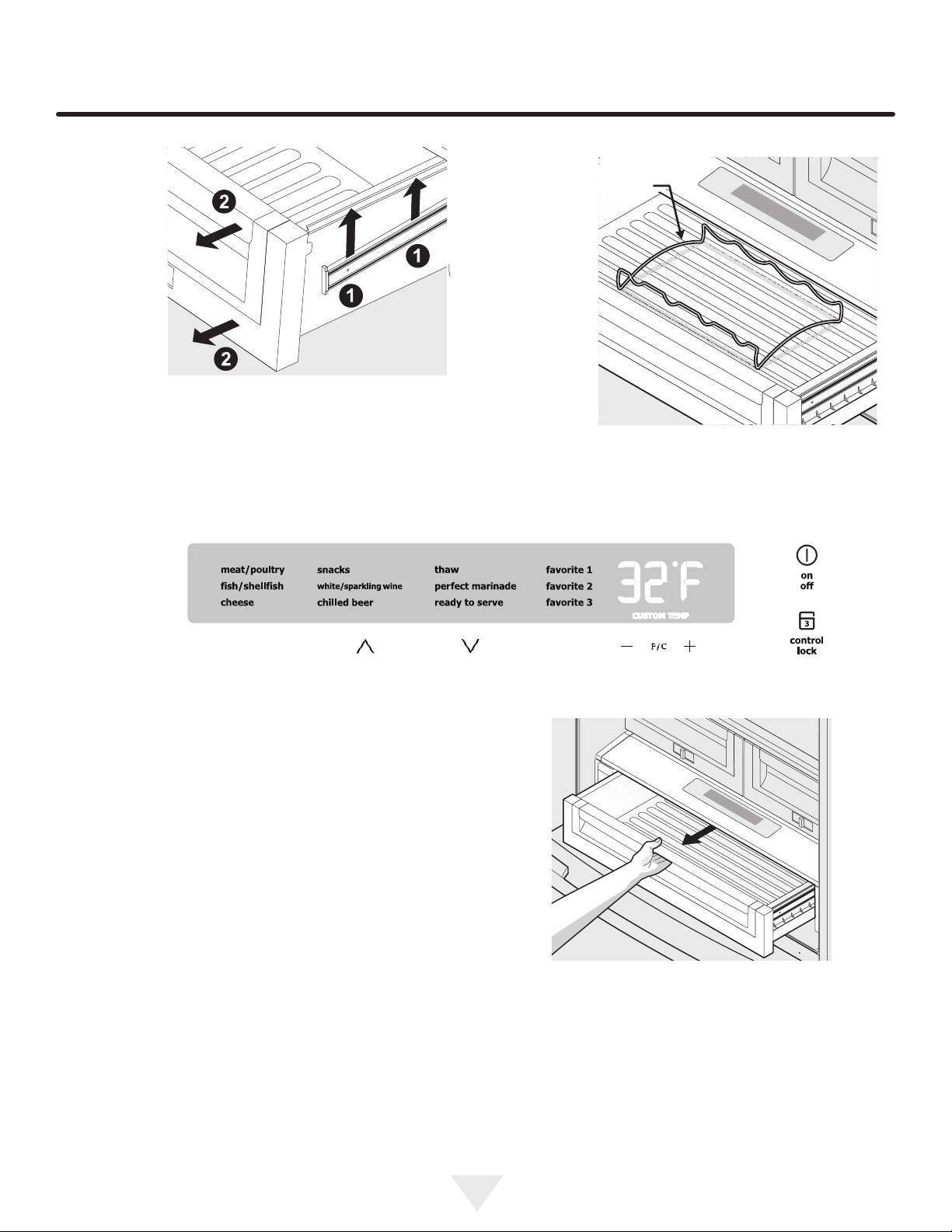

To change the position of a shelf:

1. Before adjusting a shelf, remove all food.

2. Lift the front edge up and pull the shelf out.

3. Replace by inserting the mounting bracket hooks into

the desired support slots.

4. Lower the shelf and lock into position.

Figure 32

or

Opening crisper drawer

Crisper humidity control

Crisper drawers include a sliding control for adjusting the

humidity inside the crisper. Leafy vegetables keep best

when stored with the Humidity Control set on Higher Humidity. Fresh fruits keep best when stored with the Humidity

Control set on Lower Humidity.

Humidity control

Higher

humidity

Adjusting crisper humidity

Lower

humidity

Figure 34

Figure 35

Figure 33

17

Page 18

STORAGE FEATURES

To remove

the crisper

drawer for

cleaning:

1. Pull the

drawer out

until it stops.

2. Lift the

front slightly

and remove

the drawer.

Cool zone

Some models are equipped with a meat keeper drawer for

short-term storage of bulk meat items. This drawer includes

sliding controls for adjusting the humidity inside. Any meat

to be kept longer than two days should be frozen. If you

store fruits or vegetables in this drawer, set it to a higher

humidity.

Figure 36

Removing crisper

drawer

Special

items rack

The innovative design of

the special

items rack

allows you to

store 4 bottles of wine

or soft drink

bottles.

Special items

rack

Figure 38

Figure 37

To operate:

1. To turn on and off, press the drawer’s On/Off button.

The numeric display will show a temperature between

“28°F and 42°F” when on and “OFF” when off.

2. Press F/C if you prefer to display Fahrenheit “F,” or

Celsius “C”.

3. Press either the up or down scroll buttons to illuminate the desired item.

4. Once an option is selected, the drawer will adjust and

maintain the temperature for the setting selected.

5. When turned off, the Select Temp Drawer functions

as a standard meat pan. The Select Temp Drawer is

best used for packaged food products. Leafy vegetables and unpackaged fruits are best kept in one of the

crisper drawers.

6. The three favorite selections provide exibility to set

and store personal temperature selections. The temperature is adjusted up by pressing the + or – buttons.

The drawer will store the selected temperature setting

until it is changed.

7. 7 The control buttons can be locked to prevent accidental changes by pressing the control lock button for three

seconds. Deactivate by pressing for three seconds

again.

<

<

Opening the drawer

Figure 39

18

Page 19

STORAGE FEATURES

NOTE

DO NOT clean the display area of the Select Temp

Drawer with abrasive or caustic cleaners. Wipe clean

with a moist sponge.

!

CAUTION

The Select Temp Drawer and cover can be removed for

cleaning but the control unit, attached to the right side of

the fridge, cannot be removed. Do not immerse the Select

Temp Drawer cover in water or put it in a dishwasher.

Clean with a damp cloth or sponge.

To remove the Select Temp Drawer for cleaning:

1. Pull the drawer out until it stops.

2. Lift the front slightly and remove the drawer.

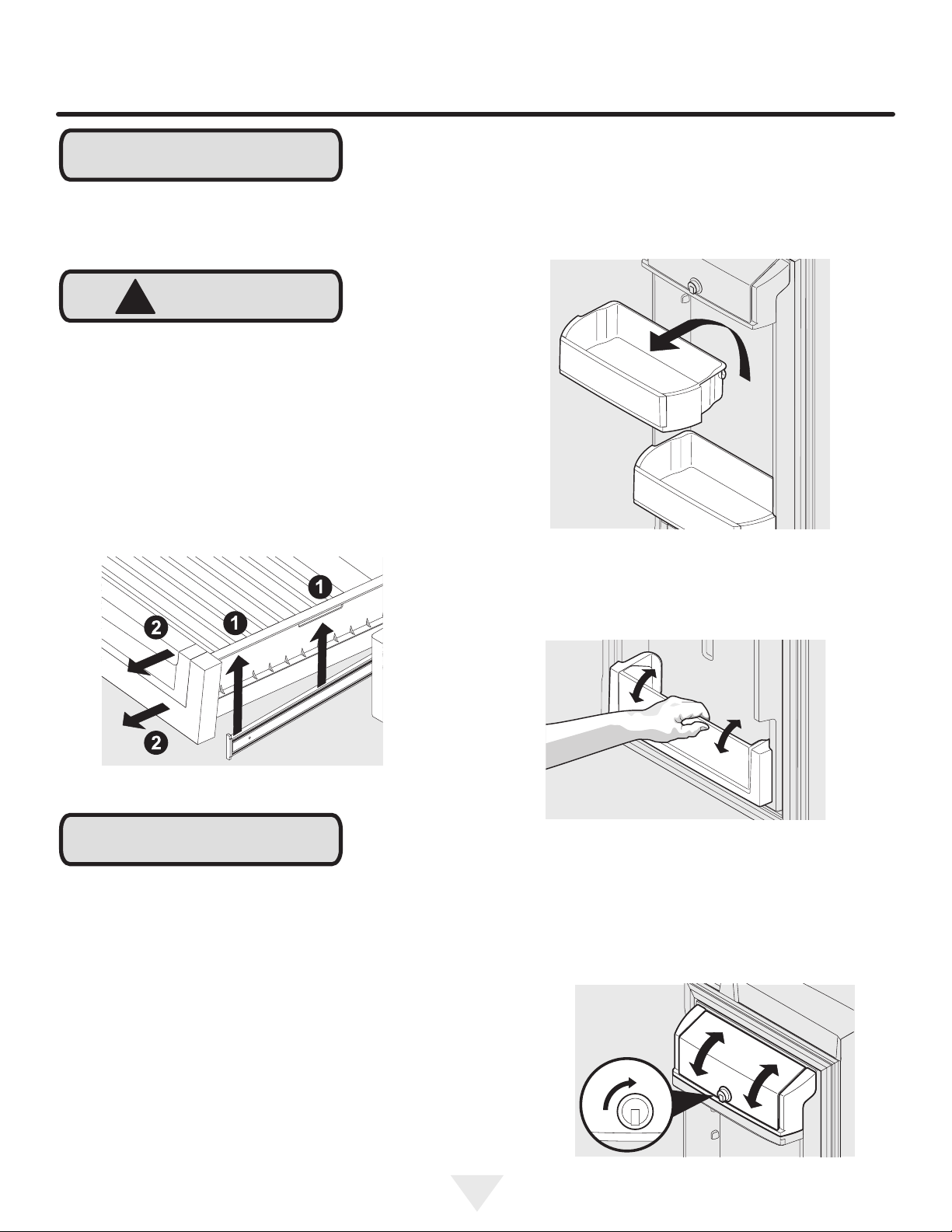

To change the position of an adjustable door bin:

1. Before adjusting a bin, remove all food.

2. Grip the bin rmly with both hands and lift it upward.

3. Remove the bin.

4. Place the bin just above desired position.

5. Lower the bin onto supports until locked in place.

Adjustable Door Bin

Removing the drawer

Figure 40

NOTE

When the refrigerator is turned off by pressing the main

electronic control on/off button, the Select Temp Drawer will

also be turned off. When the refrigerator is turned back on,

the Select Temp Drawer will resume operations at the temp

setting that was set before the refrigerator was turned off.

Doors

Storage bins

The doors to your fresh food compartment use a system of

modular storage bins. All of these bins are removable for

easy cleaning. Some of them have xed positions, while

others can be adjusted to your needs.

Accesorries

Figure 41

Tilt can bins

The can bins allow you to efciently and securely store up

to eight 12-ounce canned beverages.

Tilt can bin

Covered Door Bin

Use the covered door bin, at the top of the fresh food compartment door, for short-term storage of cheese, spreads,

or butter. The covered door bin is designed to be warmer

than the open area and includes a lift-up cover that may be

locked and a dairy divider (select models).

Lock

Figure 42

Door bins are ideal for storing jars, bottles, cans, and large

drink containers. They also enable quick selection of frequently used items.

19

Covered door bin

Figure 43

Page 20

STORAGE FEATURES

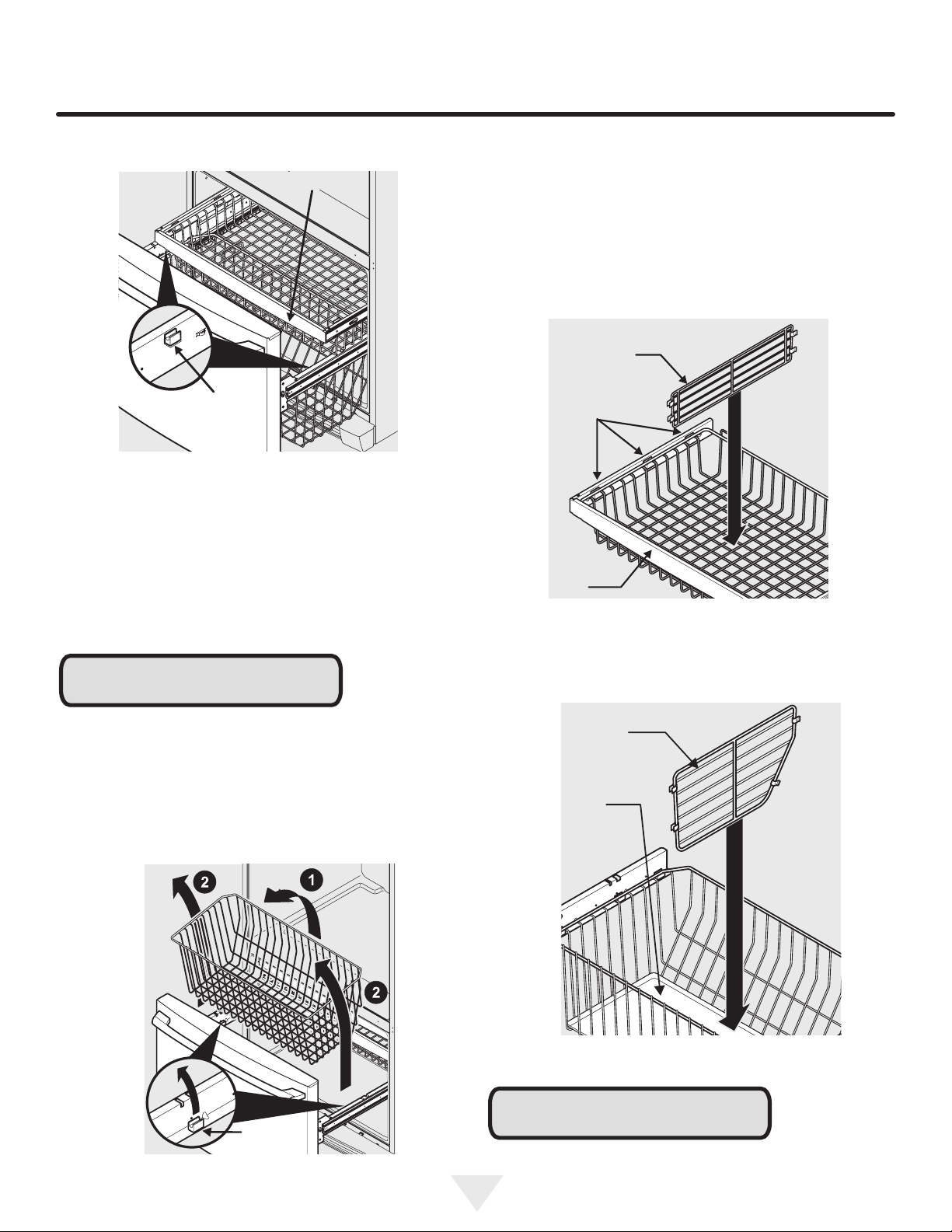

Freezer Features

Stabilizer bar

Basket

retainer

clips

Two freezer baskets

To Remove Upper Basket

1. Remove all items from basket.

2. Remove basket by pulling basket out to its full extension and lift out.

To reinstall upper basket, position basket onto the retainer

clips making sure the front of the basket rests in the retainer clips on the stabilizer bar.

Figure 44

Lift up on the rear of the lower divider and pull out.

Tilt Wire Shelf

The freezer tilt wire shelf (located on the inside of the freezer drawer) is not designed to be removed.

Dividers Removal

Lift up on the front of the upper divider and pull out.

Middle basket

divider

Retainers

Stabilizer

bar

Upper basket divider

Figure 46

NOTE

If basket is not resting on stabilizer bar retainer clips, the

drawer will not close properly.

To Remove Lower Basket

1. Remove all items from basket.

2. Remove the basket by tilting it forward and lifting it from

the retainer clips.

Figure 45

Removing lower basket

Basket

retainer

Lift up on the rear of the lower divider and pull out.

Lower basket

divider

Spill guard

tray

Lower basket divider and

spill guard tray

Figure 47

NOTE

Spill Guard Tray should be hand washed in warm water.

20

Page 21

STORING FOOD AND SAVING ENERGY

Ideas for storing foods

Fresh food storage

• Keep the fresh food compartment between 34°F and

40°F with an optimum temperature of 37°F.

• Avoid overcrowding the refrigerator shelves, which

reduces air circulation and causes uneven cooling.

Fruits and vegetables

• Store fruits and vegetables in crisper drawers, where

trapped moisture helps preserve food quality for longer

time periods.

• Wash items and remove excess water.

• Wrap any items that have strong odors or high moisture

content.

Meat

• Wrap raw meat and poultry separately and securely

to prevent leaks and contamination of other foods or

surfaces.

• Use the deli drawer or Select Temp drawer and set to

meat/poultry setting for short-term storage. Any meat to

be kept longer than two days should be frozen.

Frozen food storage

• Keep the freezer compartment at 0°F or lower.

• A freezer operates most efciently when it is at least ⅔

full.

Packaging foods for freezing

• To minimize food dehydration and quality deterioration, use aluminum foil, freezer wrap, freezer bags, or

airtight containers. Force as much air out of the packages as possible and seal them tightly. Trapped air can

cause food to dry out, change color, and develop an

off-avor (freezer burn).

• Wrap fresh meats and poultry with suitable freezer

wrap prior to freezing.

• Do not refreeze meat that has completely thawed.

Ideas for saving energy

Installation

• Locate the refrigerator in the coolest part of the room,

out of direct sunlight, and away from heating ducts or

registers.

• Do not place the refrigerator next to heat producing

appliances such as a range, oven, or dishwasher. If this

is not possible, a section of cabinetry or an added layer

of insulation between the two appliances will help the

refrigerator operate more efciently.

• Level the refrigerator so that the doors close tightly.

Temperature settings

• Refer to the “Controls” section for procedures on temperature settings.

Food storage

• Avoid overcrowding the refrigerator or blocking cold air

vents. Doing so causes the refrigerator to run longer

and use more energy.

• Cover foods and wipe containers dry before placing

them in the refrigerator. This cuts down on moisture

build-up inside the unit.

• Organize the refrigerator to reduce door openings. Remove as many items as needed at one time and close

the door as soon as possible.

• Do not place a hot container directly on a cold shelf.

Remember, such an extreme temperature change may

damage the glass

Loading the freezer

• Prior to grocery shopping, activate “fast freeze” so that

on your return you can ensure your newly purchased

food designated for the freezer will be preserved as

quickly as possible.

• Activating “fast freeze” also will help your freezer more

efciently maintain the selected temperature after placing new purchases with pre-existing frozen foods.

• Avoid adding too much warm food to the freezer at one

time. This overloads the freezer, slows the rate of freezing, and can raise the temperature of frozen foods.

• Leave a space between packages, so cold air can

circulate freely, allowing food to freeze as quickly as

possible.

21

Page 22

NORMAL OPERATING SOUNDS

Understanding the sounds you may hear

Your new, high-efciency refrigerator may introduce unfamiliar sounds. These sounds normally indicate your re-

frigerator is operating correctly. Some surfaces on oors,

walls, and kitchen cabinets may make these sounds more

noticeable.

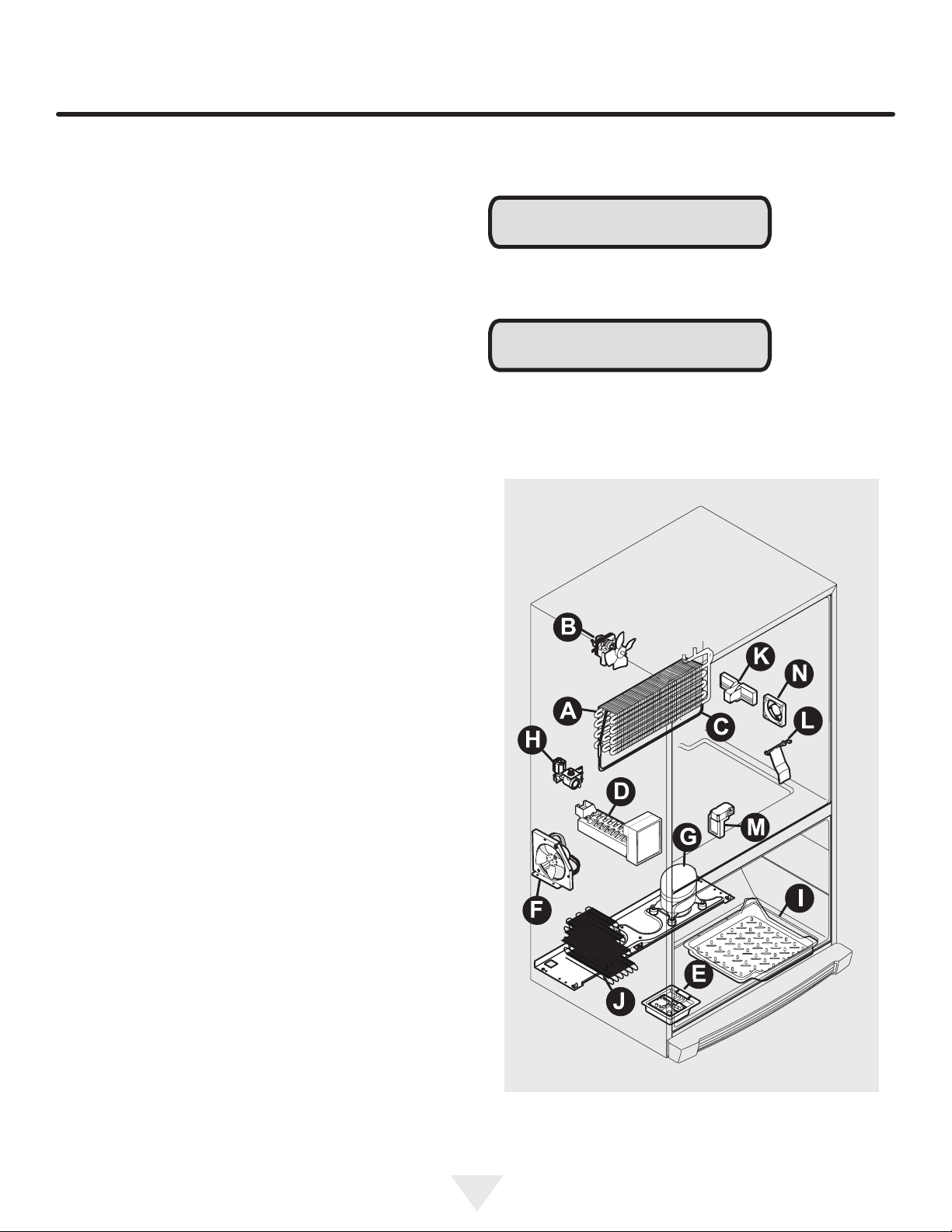

The following is a list of major components in your refrigerator and the sounds they can cause:

A. Evaporator Refrigerant through the evaporator may

create a boiling or gurgling sound.

B Evaporator fan You may hear air being forced through

the refrigerator by the evaporator fan.

C Defrost heater During defrost cycles, water dripping

onto the defrost heater may cause a hissing or sizzling

sound. After defrosting, a popping sound may occur.

D Automatic ice maker When ice has been produced, you

will hear ice cubes falling into the ice bin. Ice maker fan,

water valve activation, and refrigerant gas uid may create

sounds from its operation.

N Select Temp drawer fan Turns off when door opens or

Select Temp drawer is turned off.

NOTE

Energy efcient foam in your refrigerator is not a sound

insulator.

NOTE

During automatic defrost cycle, a red glow in the back wall

vents of your freezer compartment is normal.

E Electronic control & automatic defrost control These

parts can produce a snapping or clicking sound when turning the cooling system on and off.

F Condenser fan You may hear air being forced through

the condenser.

G Compressor Modern, high-efciency compressors run

much faster than older models. The compressor may have

a high-pitched hum or pulsating sound.

H Water valve Makes a buzzing sound each time it opens

to ll the ice maker.

I Drain pan (not removable) You may hear water dripping

into the drain pan during the defrost cycle.

J Condenser May create minimal sounds from forced air.

K Motorized Select Temp drawer damper May produce a

light humming during operation.

L Ice dispensing paddle When dispensing ice, you will

hear a snapping, clicking, or popping sound when the solenoid opens and closes the ice chute.

M Motorized damper May produce a light humming during

operation.

Figure 48

22

Page 23

CHANGING THE WATER AND AIR FILTERS

Your refrigerator is equipped with separate water and air

ltering systems. The water lter system lters all the water

used to produce ice. The air lter removes odors and impu-

rities from the refrigerator compartment.

NOTE

The control panel includes controls to monitor the

status of your water and air lters. See the Controls

section for more information.

About your advanced water lter

The lter system is tested and certied by NSF International to NSF/ANSI

Standards 42 and 53 for the reduction

of claims specied on the performance

data sheet.

Do not use with water that is microbiologically unsafe or of

unknown quality without adequate disinfection before or af-

ter the system. Systems certied for cyst reduction may be

used on disinfected waters that may contain lterable cysts.

• Rated Capacity - 240 gallons

• Rated service ow - .5 gallons per minute

• Maximum Rated Pressure - 100 pounds per square

inch

• Recommended Minimum Operating Pressure: 30

pounds per square inch

• Operating Temp.: Min. 33°F, Max. 100°F

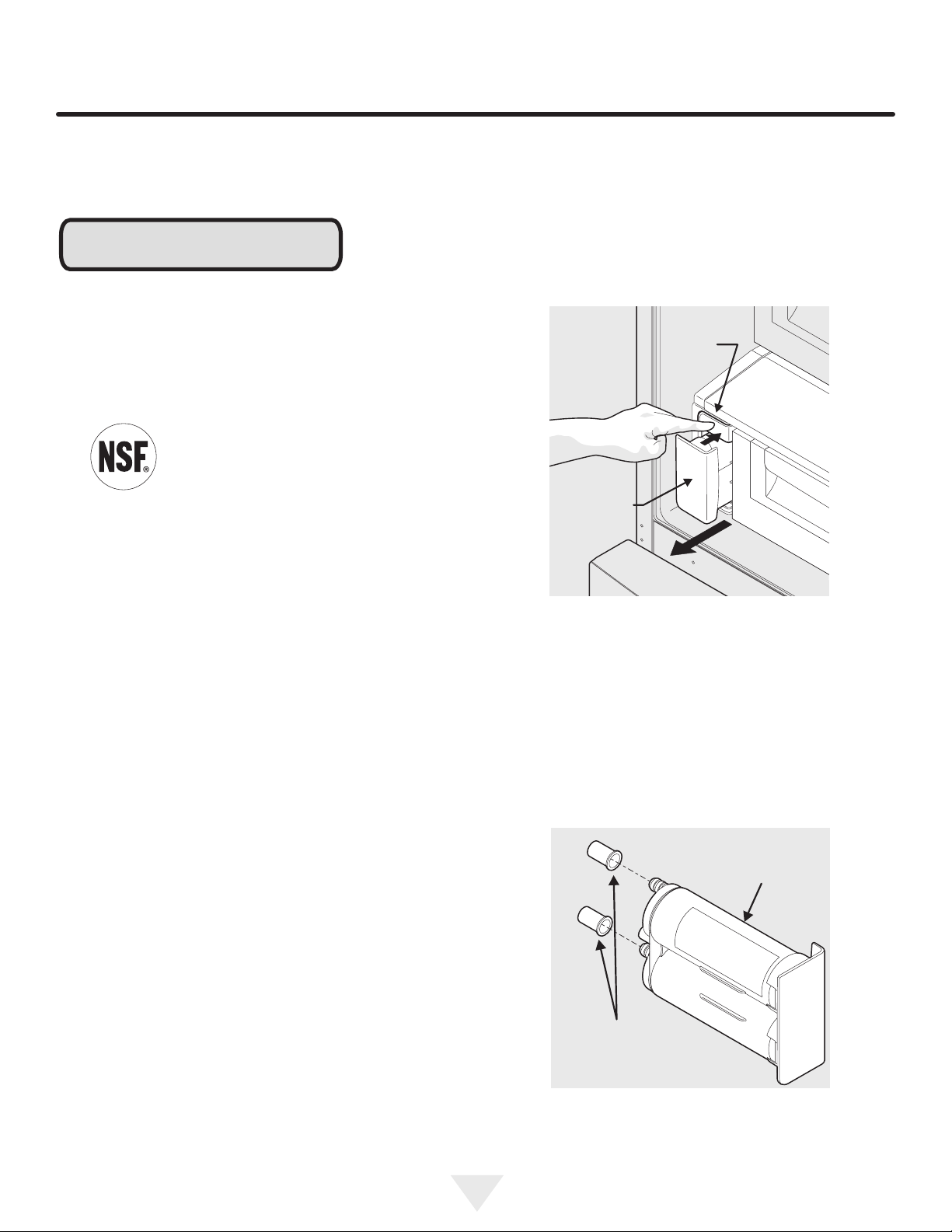

Water lter

The water lter is located at the lower left side of the

fresh food compartment.

It is not necessary to turn the water supply off to change

the lter. Be ready to wipe up any small amounts of water

released during the lter replacement.

1. Push the lter release button above the cartridge to

disconnect it.

Water lter

button

Water lter

cartridge

Figure 49

2. Slide the old water lter cartridge straight out of the

housing and discard it.

3. Unpack the new lter cartridge and remove the two pro-

tective caps covering the inlet and exit of the lter. Slide

the lter gently into the housing until it stops against the

snap-in connector at the back of the housing.

Push water lter button

Replacing your water lter

In general, you should change the water lter every six

months to ensure the highest possible water quality. The

Water Filter Status light on the Touch Panel prompts you

to replace the lter after the six month time period has

elapsed. The water lter status light on this model is not

performance tested or certied by NSF.

If your refrigerator has not been used for a period of time

(during moving for example), change the lter before reinstalling the refrigerator.

Replacement

water lter

Remove two

protective caps

Figure 50

23

Page 24

CHANGING THE WATER AND AIR FILTERS

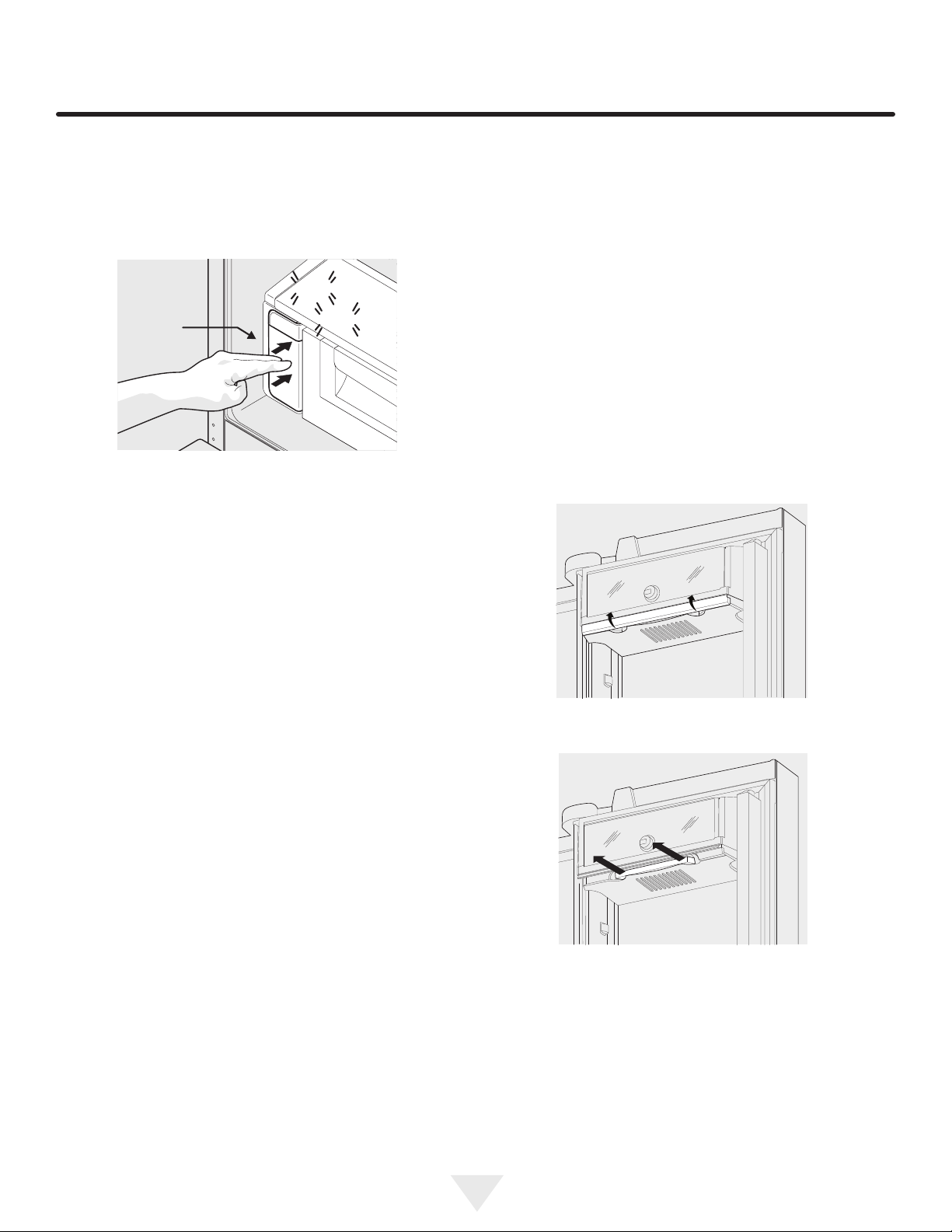

4. Push rmly until the cartridge snaps into place

(you should hear two clicks). When fully engaged,

the front of the lter cartridge should be ush with the

lter release button.

click

Push in

until

two clicks

Figure 51

5. Press and hold the Filter Status button on the control

panel for three seconds. When the display changes

from “Replace” to “Good,” the status has been reset.

6. After replacing the water lter and in order for the ice

maker to work properly, it is necessary to clear air from

water lter tubing. Once ice maker begins making ice,

allow the bucket to ll completely, then discard the rst

TWO FULL buckets of ice. It will take at least two days

to completely ll the bucket on regular ice making mode

or 1½ days on fast ice mode.

Reinstall water lter

click

Air lter

The air lter is located under the utility bin.

Replacing your air lter

To ensure optimal ltering of refrigerator odors, you should

change the air lter every six months (the lter status light

on the Touch Panel prompts you to replace the lter after

six months).

1. Open the air lter door.

2. Remove the old lter and discard it.

3. Unpack the new lter and slide it into the housing.

4. To close the air lter door, push the top and bottom to

lock the door closed.

5. Press and hold the Air Filter Reset button on the control

panel for three seconds. When the display changes

from “Replace” to “Good,” the status has been reset.

6. The Air Filter Reset will turn itself off after a few seconds.

Figure 52

Figure 53

Ordering replacement lters

Order new lters by calling 800-223-3900, online at or

through the dealer where you bought your refrigerator. You

may want to consider ordering extra lters when you rst

install your refrigerator.

24

Page 25

CARE AND CLEANING

Protecting your investment

Keeping your refrigerator clean maintains its appearance

and prevents odor build-up. Wipe up any spills immediately

and clean the freezer and fresh food compartments at least

twice a year.

NOTE

NOTE

If you store or move your refrigerator in freezing temper- atures, be sure to completely drain the water supply

system. Failure to do so could result in water leaks when

the refrigerator is put back into service. Contact a service

representative to perform this operation.

Do not use abrasive cleaners such as window sprays,

scouring cleansers, ammable uids, cleaning waxes,

concentrated detergents, bleaches, or cleansers containing

petroleum products on plastic parts, interior doors, gaskets,

or cabinet liners. Do not use paper towels, scouring pads,

or other abrasive cleaning materials.

• Never use metallic scouring pads, brushes, abrasive

cleaners, or strong alkaline solutions on any surface.

• Never use CHLORIDE or cleaners with bleach to clean

stainless steel.

• Do not wash any removable parts in a dishwasher.

• Always unplug the electrical power cord from the wall

outlet before cleaning.

NOTE

If you set your temperature controls to turn off cooling, power to lights and other electrical components will continue

until you unplug the power cord from the wall outlet.

Refer to the guide on the next page for details on caring

and cleaning specic areas of your refrigerator.

• Remove adhesive labels by hand. Do not use razor

blades or other sharp instruments which can scratch

the appliance surface.

• Do not remove the serial plate. Removal of your serial

plate voids your warranty.

• Before moving your refrigerator, raise the anti-tip brackets so the rollers will work correctly. This will prevent

the oor from being damaged.

!

CAUTION

• Pull the refrigerator straight out to move it. Shifting it

from side to side may damage ooring. Be careful not

to move the refrigerator beyond the plumbing connections.

• Damp objects stick to cold metal surfaces. Do not touch

refrigerated surfaces with wet or damp hands.

25

Page 26

CARE AND CLEANING

Care and cleaning tips

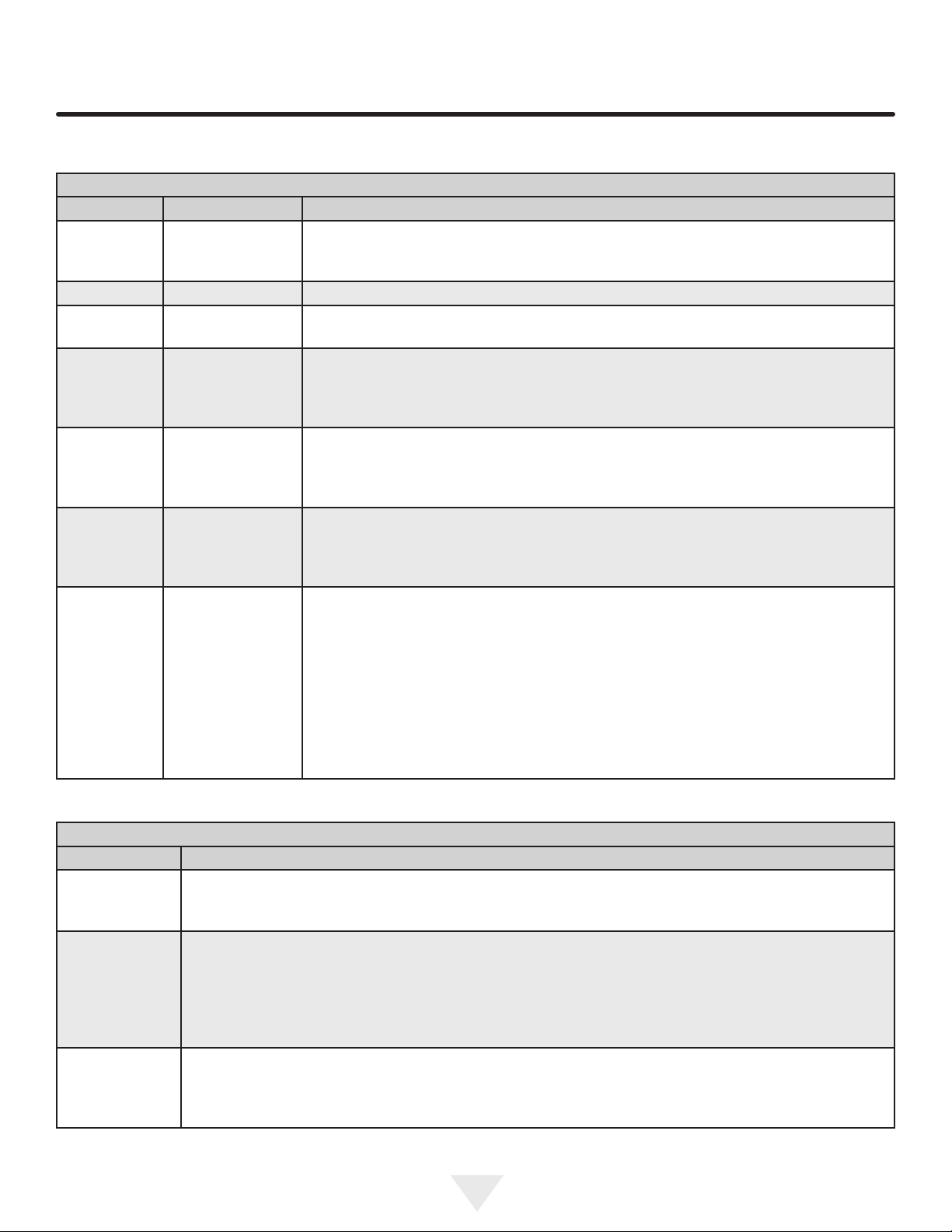

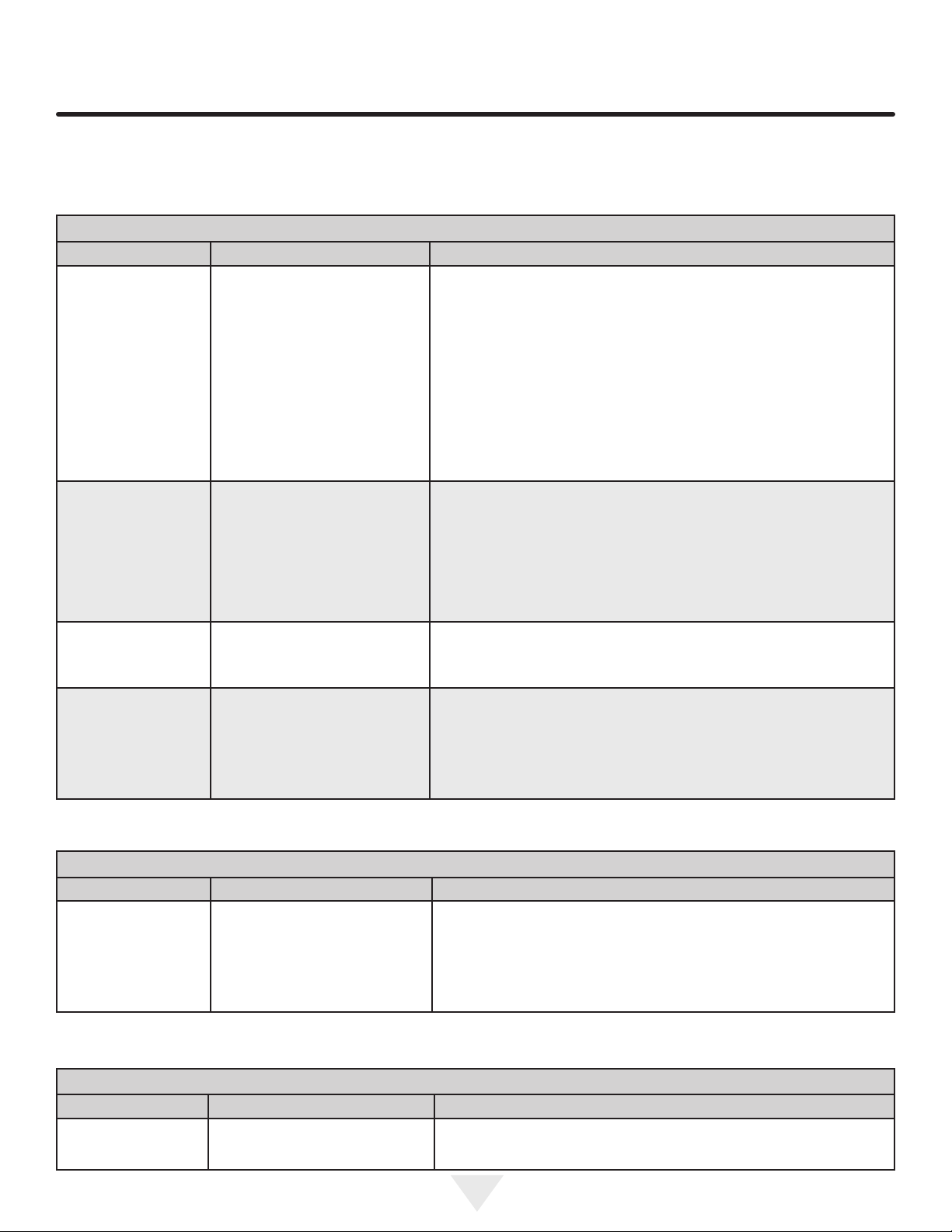

Part Cleaning agents Tips and Precautions

Interior and

door liners

Door gaskets ●Soap and water ●Wipe gaskets with a clean soft cloth.

Drawers and

bins

Glass

shelves

Toe grille ●Soap and water

Exterior &

handles

Exterior &

handles

(stainless

steel models

only)

●Soap and water

●Baking soda

and water

●Soap and water ● Use a soft cloth to clean drawer runners and tracks.

●Soap and water

●Glass cleaner

●Mild liquid

sprays

●Mild liquid

sprays

●Vacuum

●Soap and water

●Non abrasive

glass cleaner

●Soap and water

●Stainless steel

cleaners

● Use two tablespoons of baking soda in one quart of warm water.

● Be sure to wring excess water out of sponge or cloth before cleaning around

controls, light bulb or any electrical part.

● Do not wash any removable items (bins, drawers, etc.) in dishwasher.

● Allow glass to warm to room temperature before immersing in warm water.

● Remove toe grille (see Installation Instructions).

● Vacuum both sides and wipe with sudsy cloth or sponge. Rinse and dry.

● Do not use commercial household cleaners containing ammonia, bleach or alco-

hol to clean handles.

● Use a soft cloth to clean smooth handles.

● Do not use a dry cloth to clean smooth doors.

● Never use CHLORIDE or cleaners with bleach to clean stainless steel.

● Clean stainless steel front and handles with non-abrasive soapy water and a dish-

cloth. Rinse with clean water and a soft cloth.

● Use a non-abrasive stainless steel cleaner. These cleaners can be purchased at

most home improvement or major department stores. Always follow manufacturer’s

instruction. Do not use household cleaners containing ammonia or bleach.

● NOTE: Always clean, wipe and dry with grain to prevent scratching.

● Wash the rest of the cabinet with warm water and mild liquid detergent. Rinse well

and wipe dry with a clean soft cloth.

Vacation and moving tips

Occasion Tips

Short vacations ● Leave refrigerator operating during vacations of three weeks or less.

● Use all perishable items from refrigerator compartment.

● Turn automatic ice maker off and empty ice bucket, even if you will only be gone a few days.

Long vacations ● Remove all food and ice if you will be gone one month or more.

● Turn the cooling system off (see “Controls” section for location of On/Off button) and disconnect

power cord.

● Turn water supply valve to closed position.

● Clean interior thoroughly.

● Leave doors open to prevent odors and mold build-up. Block doors open if necessary.

Moving ● Remove all food and ice.

● If using a handcart, load from the side.

● Adjust rollers all the way up to protect them during sliding or moving.

● Pad cabinet to avoid scratching surface.

26

Page 27

CARE AND CLEANING

Replacing LED Lights

Both the freezer and fresh food compartments of your

refrigerator include LED lights.

To replace LED Lights:

1. Unplug your refrigerator’s power cord.

2. Remove light cover by pushing up and out.

3. Hold the LED cover with one hand and pull the connector with the other hand while pressing the connector

latch.

4. Replace LED light and snap in place assuring the light

is facing in toward the unit (inside fresh food and freezer) or facing outward on bottom of fresh food doors.

NOTE

LED lights are in series so if one is bad or unplugged, several lights may not light up.

Ordering Replacement LED Lights

Order new LEDs by calling 800-223-3900, or through the

dealer where you bought the refrigerator.

LED light removal

LED light harness removal

Figure 54

Figure 55

27

Page 28

SOLUTIONS TO COMMON PROBLEMS

Before you call

If you experience a concern with your refrigerator or notice a product behavior or condition that you do not understand,

you can usually avoid a call to your service representative by referring to this section for an answer. Beginning with the

following table, this information includes concerns, potential causes, and common solutions.

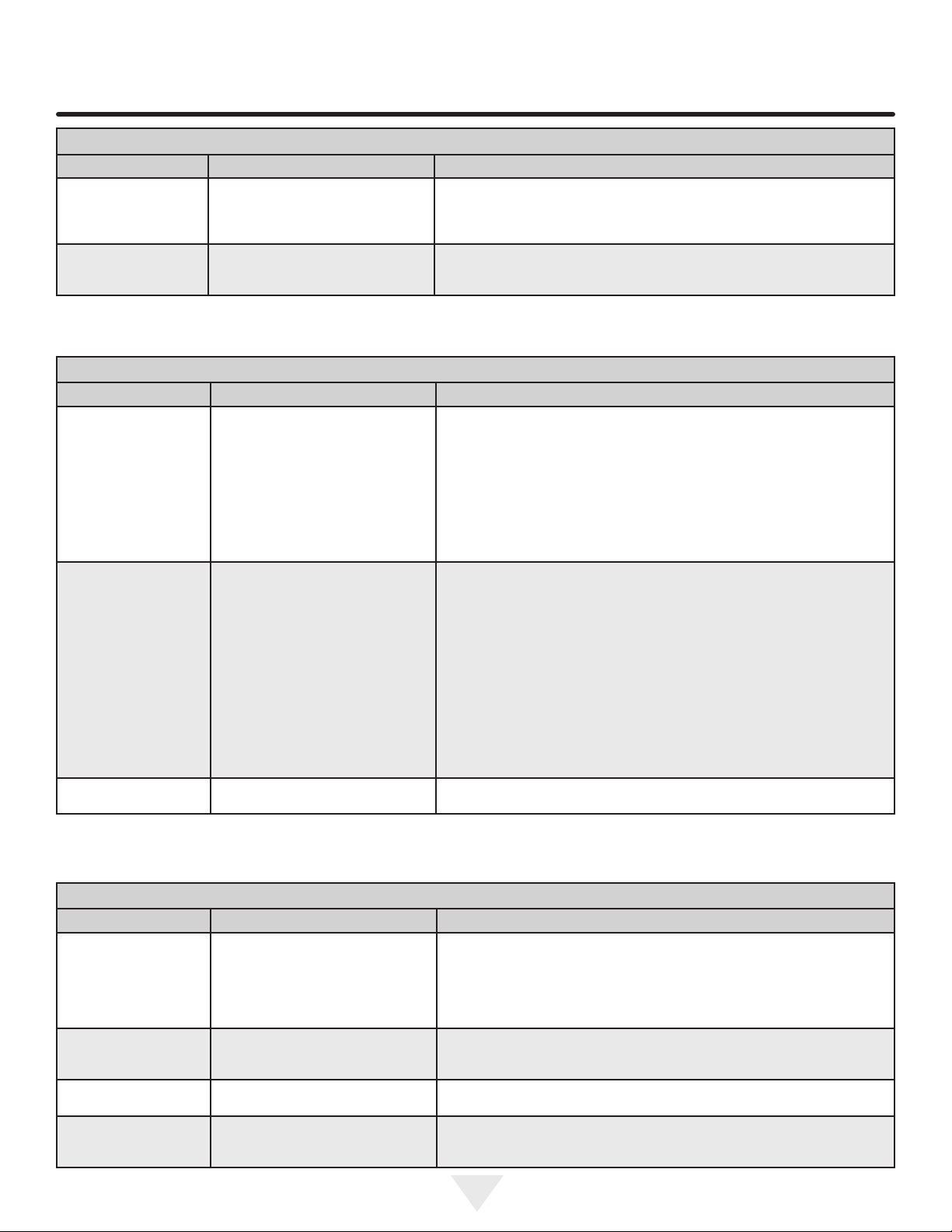

Automatic Ice Maker

Problem Cause Correction

Ice maker is not making

any ice

Ice maker is not making

enough ice.

Freezer ice maker will

not stop making ice.

Ice cubes are freezing

together.

● Ice maker is turned off.

●Refrigerator is not connected to

water line or water valve is not open.

● The water supply line is kinked.

● The water lter is not seated

properly.

● The water lter may be clogged

with foreign material.

● Saddle valve on cold water pipe

is clogged or restricted by foreign

material.

● Ice maker is producing less ice

than you expect.

● The water filter may be clogged

with foreign material.

● The water supply line is kinked.

● Saddle valve on cold water pipe

is clogged or restricted by foreign

material.

● Ice maker wire signal arm is being

held down by some package in the

freezer that has fallen against the ice

maker.

● Ice cubes are not being used

frequently enough.

● Ice cubes are hollow (shells of ice

with water inside). The hollow cubes

break open in the bin and leak their

water onto existing ice, which causes

it to freeze together.

● Turn on ice maker. For the fresh food ice maker, press and hold the “Ice Off”

button for four seconds until the indicator turns off. For the freezer ice maker,

lower the wire signal arm.

● Connect the unit to the household water supply and ensure the supply valve is

open.

● Ensure that the supply line does not kink when the refrigerator is pushed into

place against the wall.

● Remove and re-install the water filter. Be sure to push the filter firmly so that you

hear it lock solidly into position.

● If water dispenses slowly or not at all, or if the filter is six months old or older, it

should be replaced.

● Turn off household water line valve. Remove valve. Ensure that valve is not a

self-piercing saddle valve. Clean valve. Replace valve if necessary.

● The fresh food and freezer ice makers will each produce approximately 2.5

pounds of ice every 24 hours depending on usage conditions.

● If water dispenses slower than normal, or if the filter is six months old or older, it

should be replaced.

●Ensure that the supply line does not kink when the refrigerator is pushed into

place against the wall.

● Turn off household water line valve. Remove valve. Ensure that valve is not a

self-piercing saddle valve. Clean valve. Replace valve if necessary

● Move the item and release wire signal arm. Remove any ice cubes that may

have frozen together over the wire signal arm.

● Remove ice container and discard ice. The ice maker will produce fresh supply.

Ice should be used at least twice weekly to keep the cubes separated.

● This generally occurs when the ice maker does not get enough water. This is

usually the result of a clogged water lter. Replace the water lter.

Light is not on

Concern Potential cause Common solution

Light is not on ● Light bulb is burned out or LED light

is damaged.

● No electric current is reaching

refrigerator.

● Control system has disabled lights

because one or both doors were left

open too long.

● See Replacing Light Bulbs or LED lights in Care and Cleaning section.

● See “Concern” section, “Refrigerator Operations”.

●Close and reopen door(s) to enable lights.

Odors in refrigerator

Concern Potential cause Common solution

Interior is dirty. Odors ●Interior needs to be cleaned.

● Food with strong odors is stored in

refrigerator.

●See care & cleaning tips.

● Cover food tightly. Air lter may need to be changed more frequently if foods

with strong odors are routinely stored in refrigerator.

28

Page 29

SOLUTIONS TO COMMON PROBLEMS

Opening/Closing of Doors/Drawers

Concern Potential cause Common solution

Door(s) will not close. ●Refrigerator is not level. It rocks on

Drawers are difcult to

move.

the oor when moved slightly.

● An object has fallen from the bas-

kets blocking the door from closing.

●Food is touching shelf on top of

drawer.

●Drawer is overloaded.

Refrigerator Operations

Concern Potential cause Common solution

Compressor does not run ●Cooling system is turned off.

● Refrigerator is in defrost cycle.

● Plug at wall outlet is disconnected.

● House fuse is blown or a tripped

circuit breaker.

●Power outage

● Electronic control system keeps the

refrigerator at a constant temperature.

Refrigerator runs to much

or to long.

Digital temperature dis-

plays are ashing.

●Room or outside weather is hot.

●Refrigerator has recently been dis-

connected for a period of time.

●Automatic ice maker is operating.

●Doors are opened too frequently or

too long.

●Refrigerator/freezer door may be

slightly open.

●Freezer control is set too cold (control found on side of left hand door).

●Fresh food/freezer gasket is dirty,

worn, cracked, or poorly tted.

●This model is provided with a high-efciency, variable-speed compressor.

●Electronic control system has detect-

ed a performance problem.

● Ensure floor is level and solid, and can adequately support the refrigerator.

Contact a carpenter to correct a sagging or sloping floor.

● Check for ice or food items blocking drawer.

●Keep less food in drawer.

●Remove or redistribute food.

● Turn cooling system On. See Controls Section for location of cooling system

On/Off button.

● This is normal for a fully automatic defrost refrigerator. The defrost cycle occurs

periodically, lasting about 30 minutes.

● Ensure plug is tightly pushed into outlet.

● Check/replace fuse with a 15 amp time-delay fuse. Reset circuit breaker.

● Check house lights. Call local Electric Company.

● This is normal. Refrigerator goes on and off to keep temperature constant.

●It’s normal for the refrigerator to work longer under these conditions.

●It takes 8-12 hours for the refrigerator to cool down completely.

●Ice maker operation causes refrigerator to run slightly more.

●Warm air entering the refrigerator causes it to run more. Open doors less often.

●Ensure refrigerator is level. Keep food and containers from blocking door. See

Concern section, Opening/Closing of Doors/ Drawers.

●Set freezer control to warmer setting until refrigerator temperature is satisfactory. Allow 24 hours for temperature to stabilize.

●Clean or change gasket. Leaks in door seal will cause refrigerator to run longer

in order to maintain desired temperatures.

●It is normal for the compressor to run for long periods of time, instead of starting

and stopping frequently.

● Call your service representative, who can interpret any messages or number

codes ashing on the digital displays.

Temperatures are to Cold

Concern Potential cause Common solution

Freezer temperature too

cold. Refrigerator temperature is satisfactory.

Refrigerator temperature

too cold. Freezer temperature is satisfactory.

Food stored in drawers

freezes.

Food stored in Cool Zone

freezes

●Fast Freeze function is activated.

●Freezer control is set too cold.

●Ice maker is on.

●Fast Ice function is activated.

●Refrigerator control is set too cold. ●Set refrigerator control to a warmer setting. Allow 24 hours for temperature to

●Refrigerator control is set too cold. ●See solution above.

●Cool Zone temperature control is set

too cold.

●Deactivate Fast Freeze function.

●Set freezer control to a warmer setting. Allow 24 hours for temperature to

stabilize.

●It is normal for the freezer compartment to over cool while automatic ice maker

is on.

●Deactivate Fast Ice function.

stabilize.

●Adjust Cool Zone temperature control to a warmer setting. Meat should be

stored at a temperature just below the freezing point for maximum fresh storage

time. It is normal for ice crystals to form due to the moisture content of meat.

29

Page 30

SOLUTIONS TO COMMON PROBLEMS

Temperatures are to Warm

Concern Potential Cause Common Solution

Freezer/Refrigerator

temperature is too warm.

Freezer temperature is

too warm. Refrigerator

temperature is

satisfactory.

Refrigerator temperature

is too warm. Freezer

temperature is

satisfactory.

Temperature in the

Select

Temp Drawer is too

warm .

●Doors are opened too frequently or

too long.

●Door is slightly open.

●Freezer control is set too warm. ●Set freezer control to a colder setting. Allow 24 hours

●Refrigerator control is set too warm. ●Set refrigerator control to a colder setting. Allow 24

●Temperature control is set too warm. ●Adjust temperature control to a colder setting.

●Warm air enters the refrigerator whenever the door is

opened. Open the door less often.

●See Concern section, Opening/Closing of Doors/

Drawers.

for temperature to stabilize.

hours for temperature to stabilize.

Water/Moisture/Frost Inside Refrigerator

Concern Potential Cause Common Solution

Moisture collects on

inside of refrigerator

walls.

Water collects on bottom

side of drawer cover.

Moisture collects in

bottom of drawer.

Moisture collects on

outside of refrigerator or

between doors.

●Weather is hot and humid.

●Door is slightly open.

●Door is opened too often or too long.

●Open containers.

●Vegetables contain and give off

moisture.

●Washed vegetables and fruit drain

while in the drawer.

●Fruits and vegetables are kept past

their prime.

●Weather is humid.

●Door is slightly open, causing cold air

from inside refrigerator to meet warm

air from outside.

●The rate of frost buildup and internal sweating increases.

●See Concern section, Opening/Closing of Doors/ Drawers.

●Open door less often to allow internal temperature to stabilize.

●Keep containers covered.

●Moisture on the bottom side of the cover is not unusual.

●Move humidity control (select models) to lower setting.

●Dry items before putting them in the drawer. Water collecting in bottom of

drawer is normal.

●Routinely clean out old fruits and vegetables especially if they begin to break

down.

●This is normal in humid weather. When humidity is lower, the moisture should

disappear.

●See Concern section, Opening/Closing of Doors/ Drawers.

30

Page 31

WARRANTY

Entire Product – Limited One Year Warranty

AGA Marvel warrants the replacement or repair of all parts,

of this appliance which prove to be defective in material or

workmanship, with the exception of the painted or porcelain

enamel nish or plated surfaces, for one year from the date

of original purchase. Such parts will be repaired or replaced

at the option of Heartland without charge, subject to the

terms and conditions as set out below.

Limited Warranty - Major Refrigeration Components

Second Through Fifth Year - After the rst year from the

date of original purchase, through the fth year, the manufacturer will repair or replace, at its option, free of charge

for parts and labor only, any part of the sealed refrigeration

system (consisting of the compressor, evaporator, condenser, drier and connecting tubing) and the cabinet liner (exclusive of the door liner) which fail in normal home use. All

other costs, including mileage, transportation, trip charge

and diagnostic charge, if required, shall be the responsibility of the owner.

Limited Warranty - Water Filter-

30 days - From the original retail purchase date, any part of

the water lter cartridge which fails due to a defect in workmanship or materials will be replaced free of charge.

THE WARRANTIES, SET FORTH HEREIN ARE THE

ONLY WARRANTIES EXTENDED BY HEARTLAND. ANY

IMPLIED WARRANTIES, INCLUDING THE IMPLIED

WARRANTY OF MERCHANTABILITY, ARE LIMITED TO

THE DURATION OF THESE EXPRESS WARRANTIES.

IN NO EVENT SHALL HEARTLAND BE LIABLE FOR

ANY CONSEQUENTIAL OR INCIDENTAL DAMAGES OF

EXPENSES RESULTING FROM BREACH OF THESE OR

ANY OTHER WARRANTIES, WHETHER EXPRESSED

OR IMPLIED. Some states do not allow the exclusion or

limitation of consequential damages or limitations on how

long an implied warranty lasts, so the above exclusion or

limitation may not apply to you. Warranty applies to prod-

uct only in the country in which it was purchased.

No person, rm or corporation is authorized to make any

other warranty or assume any other obligation for HEARTLAND. To obtain performance of the warranty, report any

defects to: Your Dealer or Heartland Appliances Service

Representative.

AGA Marvel

1260 E. VanDeinse St.

Greenville MI 48838

What is not covered by this Warranty

1. Customer education or instructions on how to use the

refrigerator/freezer.

2. Any food loss due to product failure. (Warranter is not

be liable for any incidental or consequential damage

including food loss.

3. Any expenses involved in making this appliance readily

accessible for servicing.

4. Transportation, delivery, or subsequent damages.

5. Use commercially or rental use or use other than normal household.

6. Improper installation, misuse, abuse, accident or

alteration, use on wiring not conforming to electrical

codes, low voltage, failure to provide necessary maintenance or other unreasonable use.

7. Parts of service not supplied or designated by the

factory.

8. Accident, re, ood, acts of God.

9. Alteration, or the removal or defacing of the serial plate,

10. The original Bill of Sale, delivery date or serial number

cannot be veried.

11. The product is moved from place of original installation,

and reinstalled without reviewing installation procedures with dealer or manufacturer.

12. Light bulbs

13. If the product is installed outside the normal service

area, any cost of transportation expenses [tolls, ferry

trip charges, or mileage expenses, etc.] involved in the

repair of the product, or the replacement of a defective

part, shall be borne by the customer [owner].

phone: 800-223-3900

fax: 616-754-9690

PLACE OF PURCHASE

DATE OF PURCHASE

SERIAL NUMBER

MODEL NUMBER

31

Page 32

41014176-EN rev A

6/9/15

www.agamarvel.com

All specications and product designs subject to change without notice. Such revisions do not entitle

the buyer to corresponding changes, improvements, additions, replacements or compensation for

previously purchased products.

32

Page 33

AGA Marvel

1260 E. VanDeinse St.

Greenville MI 48838

Nous vous REMERCIONS d'avoir acheté ce produit de haute qualité. Si vous rencontrez un problème non mentionné

dans la section DÉPANNAGE, veuillez visiter notre site Web www.agamarvel.com pour des informations supplémentaires.

Si vous avez toujours besoin d'assistance, veuillez nous téléphoner au 1-800-223-3900.

Téléphone sans frais: 800-223-3900

Fax: 616-754-9690

www.agamarvel.com

Classic Modèle HCFDR23C Instructions D’Utilisation

Du Réfrigérateur

1

Page 34

TABLE DES MATIÈRES ET SÉCURITÉ

Table des matières

Renseignements.........................................................2

Sécurité...................................................................2

Déballage de votre appareil ............................................................3

Électriqué .......................................................................................4

Aperçu des caractéristiques..........................................................5

Dimensions du produit ..................................................................6

Installation..................................................................7

Dépose des portes...................................................................... 11

Raccorder l’alimentation en eau.................................................. 13

Commandes................................................................................. 14

Distributeur d’eau et de glaçons automatique............................ 16

Caractéristiques de rangement................................................... 17

Conservation des aliments et économie d’énergie..................... 21

Bruits et éléments visuels d’un fonctionnement normal.............. 22

Remplacement des ltres à eau et à air.................................... 23

Entretien et nettoyage................................................................ 25

Solutions aux problèmes courants.............................................. 28

Garantie....................................................................................... 31

REMARQUE

ÉLIMINATION DE CFC/HCFC

Votre vieux réfrigérateur peut avoir un système de refroidissement

qui utilise les CFC ou HCFC (chlorouorocarbures ou hydrochlorouorocarbures). Les CFC et les HCFC sont jugés nocifs pour la

couche d’ozone stratosphérique s’ils sont libérés dans l’atmosphère. D’autres réfrigérants peuvent également causer des