Heartland 2612 User Instructions

Installation

Operation

and

Maintenance

Instructions

Woodburning Cookstove

Model

2612 Blackwood

CONTENTS

Safety Instructions ..............................................................3

Warranty Registration ........................................................4

Unpacking ...........................................................................5

Installation Instructions ........................................................6

Shelf Installation ..............................................................6

Cooking surface lift handle installation ............................7

Installation ...........................................................................7

Clearances .......................................................................7

Rough in Diagram for Blackwood ....................................8

Chart of Clearances .........................................................9

Clearance Reductions ....................................................10

Floor protection ..............................................................10

Chimneys and Draft ...........................................................10

Recommended Chimney Clearances .............................11

Chimney Connection Requirements ...............................11

Chimney Connector Systems .........................................12

Optioinal Accessories .......................................................13

Heat Shield Kit ................................................................13

Fresh Air kit .....................................................................13

Water Jacket ...................................................................14

Understanding Combustion .............................................15

Woodburning ..................................................................15

Getting Acquainted .........................................................15

Starting the Stove ..........................................................16

Break in Fire .................................................................17

Your First Fire ................................................................17

Summer Burning ...........................................................18

Coal Burning .....................................................................19

Blackwood Coal Grate ...................................................19

Fire Door Damper ..........................................................19

Starting Up a Coal Fire ..................................................19

Recharging a Fire ...........................................................20

Disposal of Ashes (Wood and Coal) ...............................20

Using the Oven and Cooking Surface .............................21

Stove Top Cooking .........................................................21

Oven Cooking ................................................................22

Troubleshooting .................................................................23

Chimneys and Draft .......................................................23

How Chimneys Work .....................................................23

Factors that Affect Draft ................................................23

Checking an Existing Chimney ......................................23

Safety Practices .............................................................24

Flue Pipes ......................................................................24

Maintenance ......................................................................25

Oven Flue passage .........................................................25

Flue Boot Inspection .......................................................26

Oven Damper ..................................................................26

Maintenance Continued ........................................................

Chimney Maintenance ...................................................26

Cooking Surface .............................................................26

Door Gaskets ..................................................................27

Firebox ...........................................................................27

Terms of Reference and Function ....................................28

Overring Caution .............................................................29

Obtaining Service ...............................................................30

Warranty ............................................................................31

CONTACT LOCAL BUILDING OR FIRE OFFICIALS BEFORE INSTALLATION ABOUT

RESTRICTIONS AND INSTALLATION INSPECTION REQUIREMENTS IN YOUR AREA AND

THE NEED FOR OBTAINING A PERMIT.

!

CAUTION

DO NOT USE CHEMICALS OR FLUIDS TO START THE

FIRE. DO NOT BURN GARBAGE OR FLAMMABLE

FLUIDS

!

CAUTION

Read this entire manual before you install and use your

new room heater. If this room heater is not properly in-

stalled, a house re may result. To reduce the risk of re,

follow the installation instructions. Failure to follow instruc-

tions may result in property damage, bodily injury, or even

death.

The Blackwood cookstove is listed to

CSA Standard B366.2MULC Standard

S-627 & UL 1482 by Warnock Hersey

Professional Services Ltd.

is committed to building a quality product

in an environmentally friendly manner. Our processes are

tightly controlled and closely monitored. We have achieved

certications in ISO 9001 for quality assurance, ISO 14001

for environmental management, and OHSAS 18001 for oc-

cupational health and safety from Lloyd’s Register Quality

Assurance.

2

SAFETY INSTRUCTIONS

Important Safety Instructions

Warnings and safety instructions appearing in this guide

are not meant to cover all possible conditions and situa-

tions that may occur. Common sense, caution, and care

must be exercised when installing, maintaining, or operat-

ing this appliance.

Recognize Safety Symbols,

Words, and Labels.

!

WARNING

WARNING-Hazards or unsafe practices with

high probability of personal injury or property / product damage.

!

WARNING

DO NOT STORE OR USE GASOLINE

OR OTHER FLAMMABLE VAPORS

OR LIQUIDS IN THE VICINITY OF

THIS STOVE.

Stove Location - If the range must be located near a

window, avoid using long curtains which could blow

over the stove top, causing a re hazard.

Any openings in the wall behind the stove or in the

oor under the range must be sealed.

Do not set unopened glass or metal containers in the

oven, on the warming shelf, or on the cooking surface.

!

CAUTION

CAUTION-Hazards or unsafe practices which could

result in personal injury or property or product damage.

NOTE

NOTE-Important information to help assure a problem

free installation and operation.

Grease accumulation is the cause of many cooking

res. Clean the oven compartment regularly.

Do not attempt to extinguish a grease re with water.

Cover grease res with a pot lid or baking soda.

Avoid the use of aerosol containers near the range.

Never place pans, cookie sheets or roasters directly

on the oven bottom but use the oven rack in its lowest

position.

3

WARRANTY REGISTRATION

Warranty Registration

It is important you send in your warranty registration card

immediately after taking delivery of your woodburning cookstove.

The following information will be required when registering

your unit.

Serial Number

Date of Manufacture

Date of Purchase

Dealer’s name and address

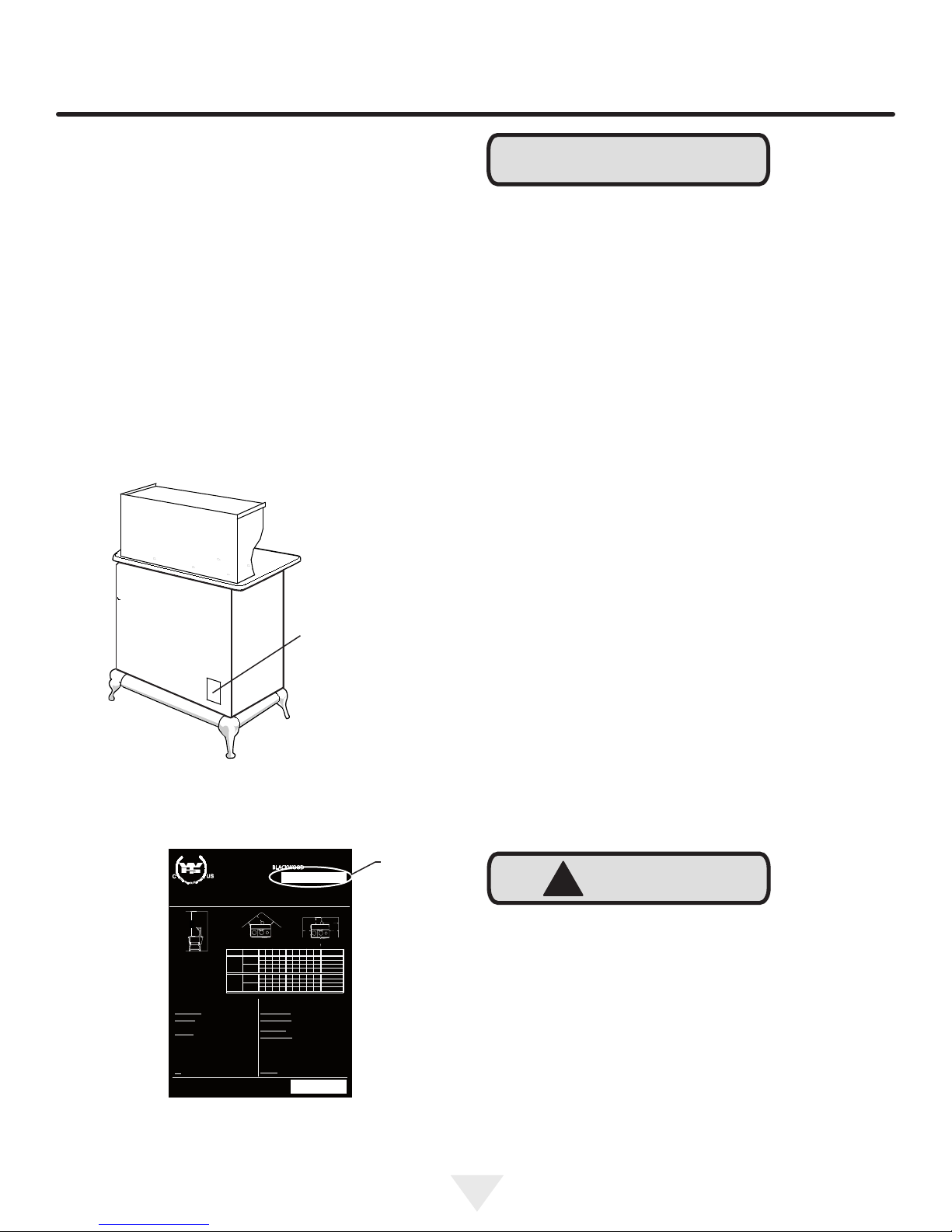

The serial number and date of manufacture can be found

on the serial plate located on the back of the stove. See

Figure 1 and 2.

NOTE

Please read these instructions thoroughly before attempting

to install this stove.

Your woodburning cookstove is a time proven design of

North American heritage. Our cookstoves were rst made

in 1906 and many originals are still in use today. With proper operation and maintenance, your woodburning cookstove will give your family generations of warmth, delightful

meals and untold pleasures.

Take the opportunity to read this manual thoroughly to be-

come familiar with all the installation, operation and maintenance procedures for your stove. You will nd it offers valu-

able insight into how a cookstove functions.

Save These Instructions

Keep the manual available for future reference. The manual

is an important part of your stove. If your stove is sold, de-

liver the manual to the new owner along with the stove.

-Serial plate,

see Figure 2

Figure 1

R

T

E

E

T

K

N

I

LISTED SOLID FUEL BURNING COOKSTOVES

POELE A AIR RADIANT

MODELS/MODELES -

TESTED TO: / MIS A L'EPREUVE SELON:

Contact local building officials about restrictions and installation inspection in your area.

Renseignez-vous aupres des autorites locales de la construciton et de la prevention

des incendies au sujet des restrictions et inspections d’installation dans votresecteur.

ceiling

plafond

G

Minimum clearance

to combustible

materials/

Degagements

minimaux des

materiaux combus-

tibles.Rear flue - mur

de tete

When a heatshield is installed clearances are taken from the

heatshield.

Prevent house fires: Install and use only in accordance with

the manufacturer’s instructions and local building codes.

Floor protection: Unit must be placed on a continuous non combustible pad (floor tile with grouting or sheet metal pad) extending 18" (457mm) in front and 8" (203mm) to the sides and back

of the unit.

Chimney type: Minimum 6" or 7" (153 or 178mm) diameter approved residential type.

Chimney connector: 6" or 7" (153 or178mm) diameter minimum 24 gauge steel.

Do not obstruct space under cookstove. Special methods are

required when passing through a wall or ceiling. See instructions and building codes. Do not connect this unit to a chimney

flue serving another appliance.

For safe operation, install in accordance with manufacturers

instructions.Keep doors closed while in operation, operate only

with firebox lining in place. Inspect and clean chimney frequently.

Fuel: For use with wood or anthracite coal only.

Made in USA by:

AGA Marvel

1260 E. Van Deinse St.,

Greenville, Michigan

Part No.

48838

BLACKWOOD

UL 1482/ULCS627/CSAB366.2M

s/w (m/a)

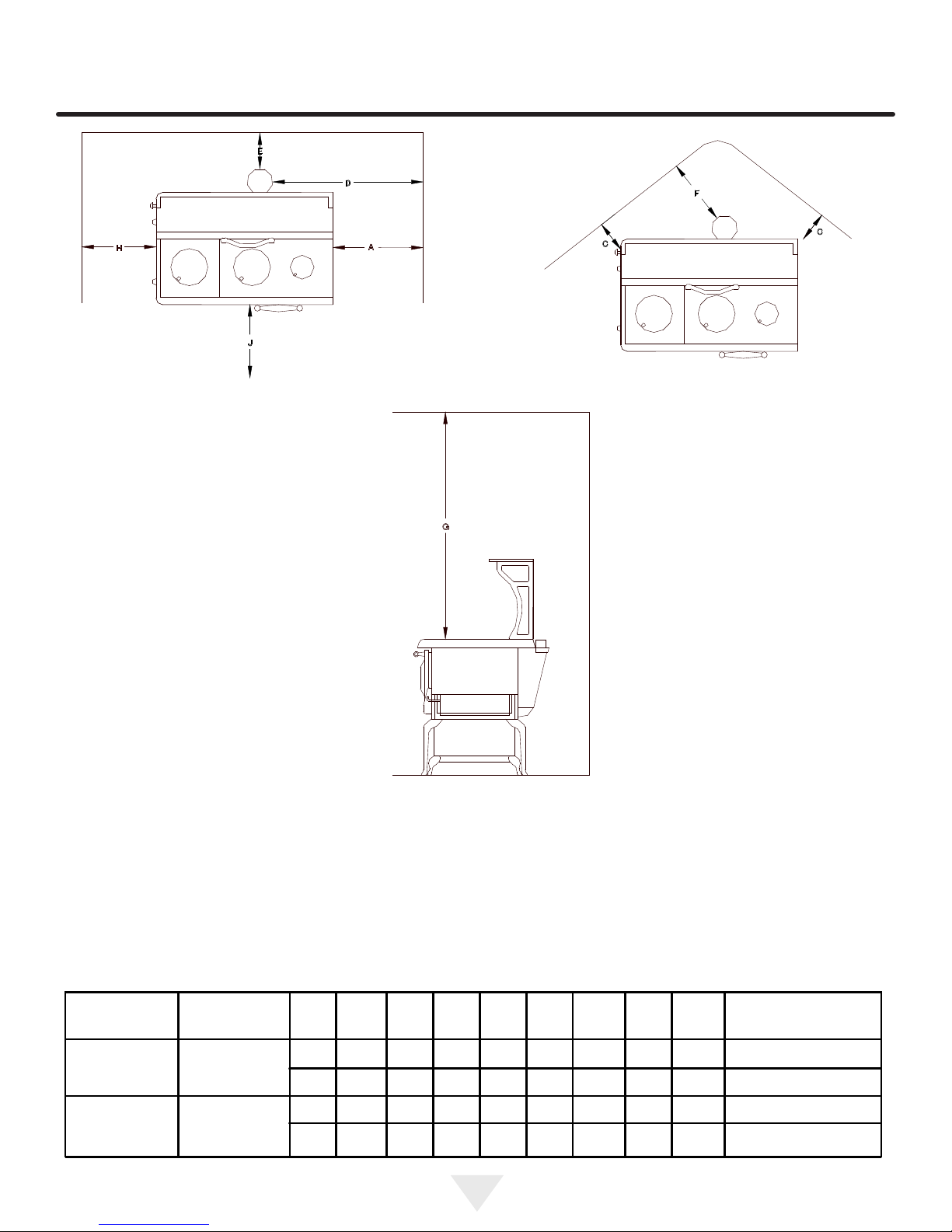

Status Model A B C D E F G H J Measure

NO HEAT

SHIELD

WITH HEAT

SHIELD

WH -

JULY 1993

s/w (m/a)

F

C C

25 69 66 66 50 58 132 61 121 Centimeters

BLACKWOOD

10 27 26 26 20 23 52 24 48 Inches

25 8 61 61531 132 61 121 Centimeters

BLACKWOOD

10 3 24 24 2 12½ 52 24 48 Inches

Lorsque vous installez un pare-chaleur les clairances se mesurent

a partir du pare-chaleur.

Prevenez les incendies: purt installation et utilisation conformement

aux instruciton du fabricant et aux codes locaux du batiment.

Protection du plancher: l’unite devras etre placer sur une planche

isolante continuelle devacant l"unite, de 18 po (457mm) a l’avant et

8 po (203mm) a l’arriere et sur les cotes.

Type de cheminee: diametre minimal 6 ou 7 po (153 ou 178mm)

approuvee pour usage residentiel

Raccord de cheminee: diametre 6 ou 7 po (153 ou 178mm)

d’eppaisseur calibre 24 acier.

Ne rien entreposer sous l’appareil.

Des methodes speciales sont requires lors du percage d’un mur ou

d’un plafond. Verifier les instrcitions et les codes du batiment. Ne

pas raccorder a la chminee d’un autre appareil pour une utilisation

de securite, installer l’appareil selon les instructions du fabricant.

Tenir les portes fermees lorsque le poele fonctionne.

Ne pas utiliser si la tole du foyer n’est pas en place. Inspecter la

cheminee et la ramover frequemment.

Combustible: Pour usage avec bois ou de l’anthracite seulement.

Date of Manufacture:

Date de Fabrication:

b/w (m/a)

E

B

H

J

D

Figure 2

The quality of the installation (especially the chimney connector and chimney), and the quality of the fuel being

burned will affect the performance of your stove, but the

most important factor is the way you operate the stove.

With the help of this manual, you will learn how to effectively heat and cook with your stove. Be sure to read it entirely,

including the terms of reference and function.

In addition, your own experience will help you to learn the

role that the chimney plays in stove performance. The

cookstove has been tested and is listed by Underwriters’

Laboratories of Canada and Underwriters’ Laboratories in

the U.S. The test standards are ULC S-627 and UL 1482.

Serial

number

A

The cookstove is listed for burning wood or coal (with the

!

CAUTION

optional coal grate). Do not burn other fuels. The cookstove

is not listed for installation in mobile homes. Do not install

the stove in mobile homes.

Preparing the installation site before moving the stove into

it will save you from having to move the stove more than

once. See page 9 for information on "Clearances" and

"Floor Protection" page 10.

4

UNPACKING

!

WARNING

WARNING- Safety Notice: If your stove is not

properly installed and maintained, a house re may

result. For your safety, follow all installation, operation

and maintenance directions. Contact local building

ofcials about restrictions and installation inspection

requirements in your area. ("Makeshift" compromises

in the installation may result in hazardous conditions,

including a house re.)

Spend some time becoming familiar with the various parts

by operating them before you burn your stove.

After a few weeks of operating the stove re-read this manual. Many of the procedures will become clearer after you

have had some experience with the stove.

!

WARNING

EXCESSIVE WEIGHT HAZARD

Use three or more people to move product.

Failure to do so can result in back or other injury.

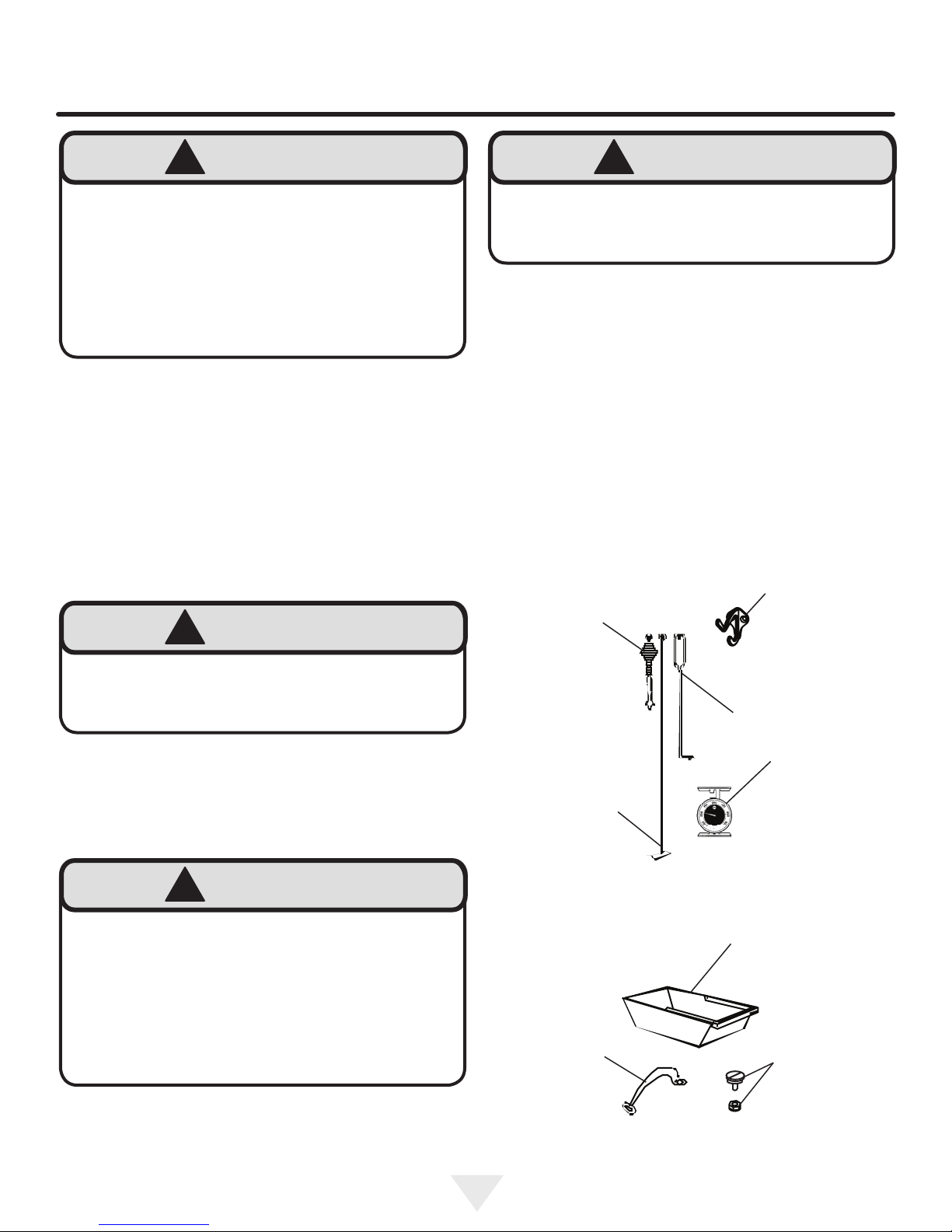

Unpacking

The warming shelf is secured to the skid with 2 screws and

a banding strap. The main stove body is strapped to the

skid. Smaller component parts are packaged as follows:

In the rebox:

1 ash scraper

The ash pan contains the following parts:

1 poker

1 tool rack

1 lid lifter

1 cooking surface lift handle w/screw and nut

1 interior oven thermometer

-Tool rack

!

WARNING

OVERFIRING CAUTION

Repeated or extended overring will void warranty on

this appliance. See page 29 for details.

!

WARNING

IMPORTANT:

Check around oven chamber on a weekly basis for

soot and creosote accumulation. Clean the chamber

thoroughly from the top, side and bottom with the ash

scraper provided. Burn the stove hot daily to reduce

creosote accumulation. Use only dry wood aged for

one year. Failure to do so could result in a chim-

ney re and void warranty.

Lid lifter-

Ash scraper-

Cooking surface

lift handle-

-Poker

-Interior oven

thermometer

Figure 3

-Ash pan

-Screw and nut

Figure 4

5

INSTALLATION INSTRUCTIONS

!

WARNING

WARNING- The stove is very heavy. Since

the legs may dig into a soft oor, do not locate the

stove, or even set it to rest, on a surface that could

be imprinted. We recommend that 3 or 4 persons be

available to assist in the lifting of the stove, and that

gloves should be worn to protect hands from cuts.

Unpacking:

1) Cut the banding holding the stove to the skid.

2) Remove the 3 screws at each corner which hold the

crate to the skid. (See crate diagram fastened to crate).

Lighten the stove by removing the keyplate and lids.

3) With 2 persons minimum on the heavier, rebox side

(left), and one person on the other side, lift the stove up,

off of the skid and onto its new location.

4) If possible, have a fourth person remove the skid while

the others lift.

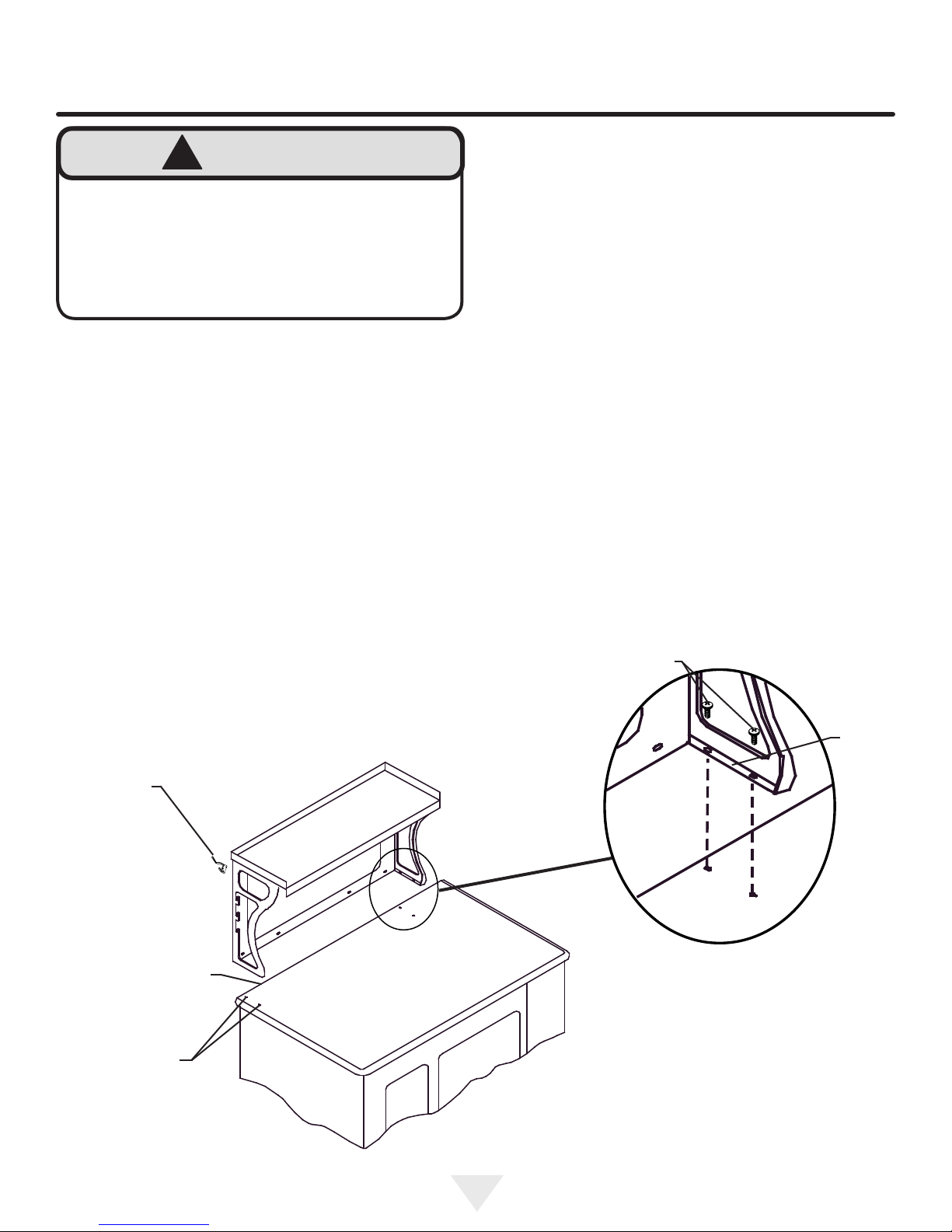

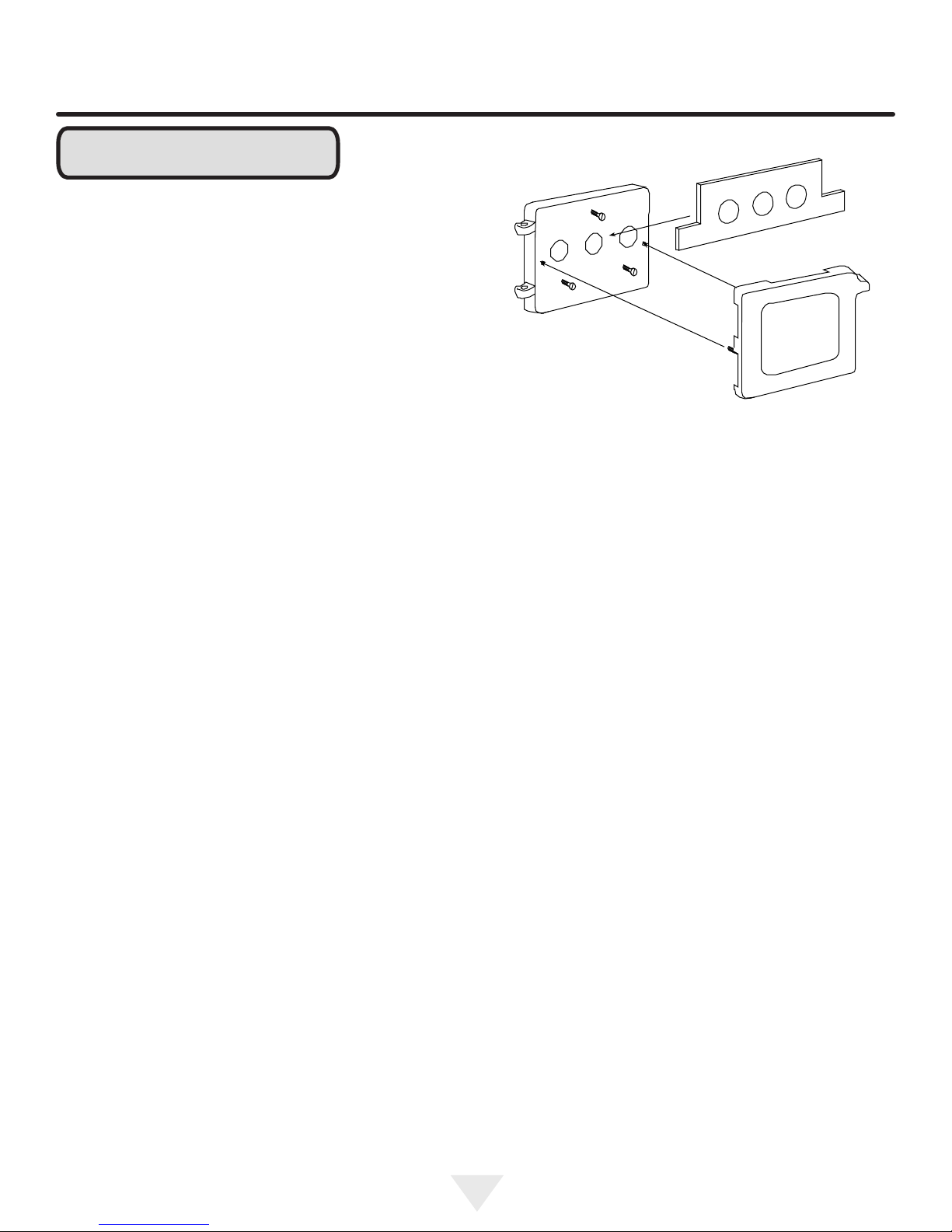

Shelf assembly to stove top:

Remember when working with the shelf it is top heavy.

Use your hand to support it during installation. Remove the

shelf assembly from the skid by removing the 2 screws and

cutting the banding strap. Lift the shelf assembly by the

bracket area that is circled and set on the oor or a table

top. Unwrap the shelf assembly.

Remove the washers and screws from the rear edge of the

stove top. (2 places). Also remove the 4 machine screws

from the top of the stove top.

With a helper lift the shelf assembly (by the circled bracket

area and supporting the top of the shelf) and place the shelf

into position on the stove top (see diagram above). Line up

the bracket holes with the 4 holes in the stove top while a

helper supports the shelf.

Secure the shelf to the stove top with the 4 machine screws

and the 2 screws and washers. To prevent chipping do not

overtighten screws or use power tools.

Tool Rack- fasten

to rear of shelf

using screws and

nuts provided.

Remove screws and

washers from top

back ange of top,

2 places

Remove machine

screws from the

top (2 each side)

Machine

Screw

Shelf

Bracket

Figure 5

6

INSTALLATION

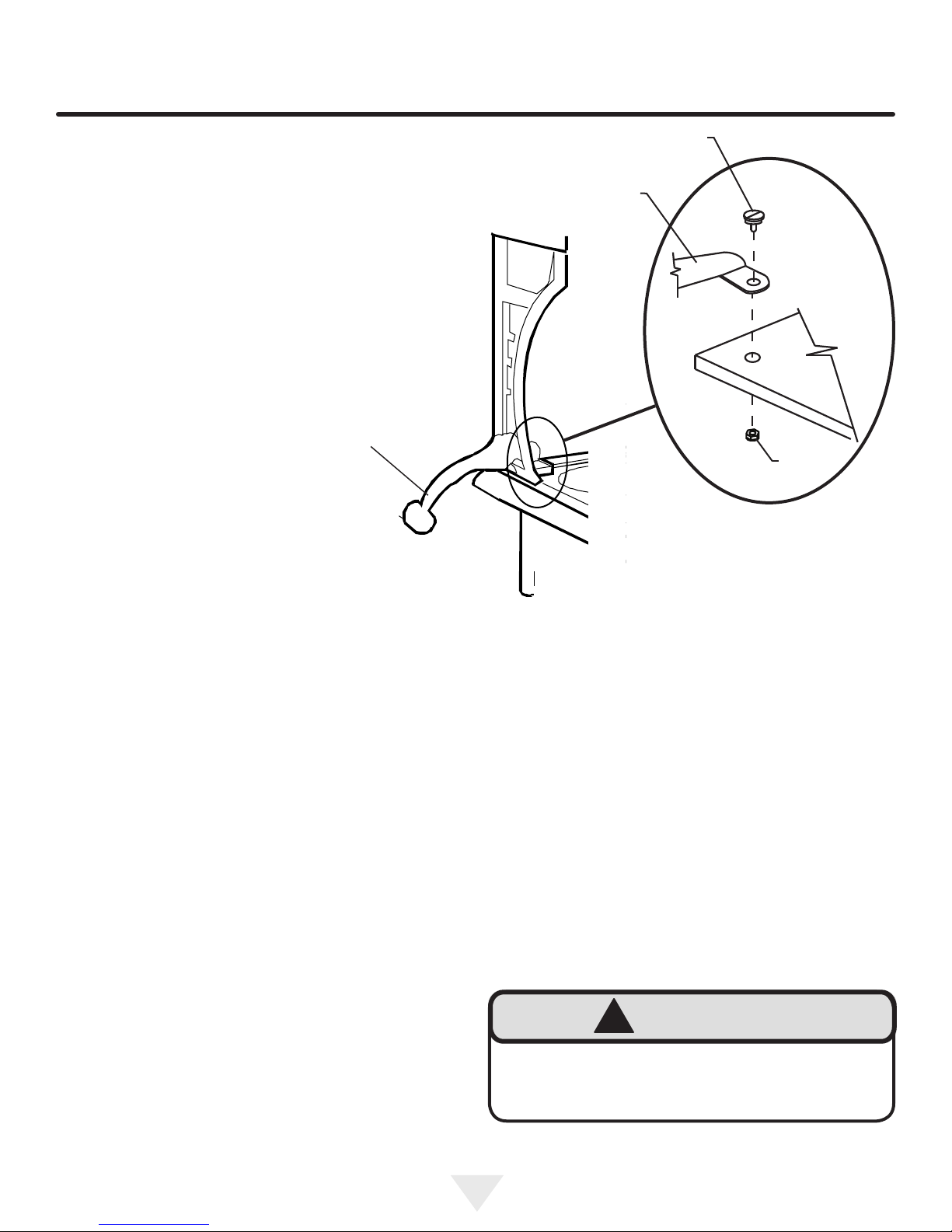

Cooking Surface Lift handle installation:

Insert the lift handle through the left side shelf bracket and

secure it to the cooking surface with the screw and locknut

provided. (See gure 6).

Lift handle-

Screw

Lift

handle

Nut

Installation:

Be sure to read the sections on clearances, oor protection,

and chimneys before actively starting the installation.

Contact local building or re ofcials about restrictions and

installation in your area.

Clearances:

A woodburning stove radiates heat in all directions. Heat

directed toward living areas in front of the stove is usually

very welcome. However, heat radiating in other directions

will not be as welcome if it results in overheating nearby

walls, ceilings and oors.

An important part of planning a safe installation is to be

sure that combustible material located near your stove

does not overheat. Clearance is the distance between your

stove and stovepipe and nearby walls, ceilings, and oors.

If there is adequate clearance, then the nearby surfaces will

not overheat.

The clearance distance should be empty except for non-

combustible heat shields. Air owing between the stove and

stovepipe and nearby surfaces carries away heat. Do not

ll the empty space with any insulating material.

Figure 6

Be aware that as wood is exposed to continuous heat it

dries out, eventually lowering the temperature at which it

will start on re. Maintain the clearances outlined in this

manual, particularly with respect to nearby combustible

surfaces.

Your Heartland cookstove has been tested for safe operation providing that these guidelines are followed.

An optional heat shield kit is available for our woodstoves

for reduced clearances. See page 13 on "Heat Shield Kit"

!

WARNING

CLEARANCES must be maintained to all com-

bustible material. These include doors, trim, furniture,

drapes, newspapers, clothes, coal, and wood.

7

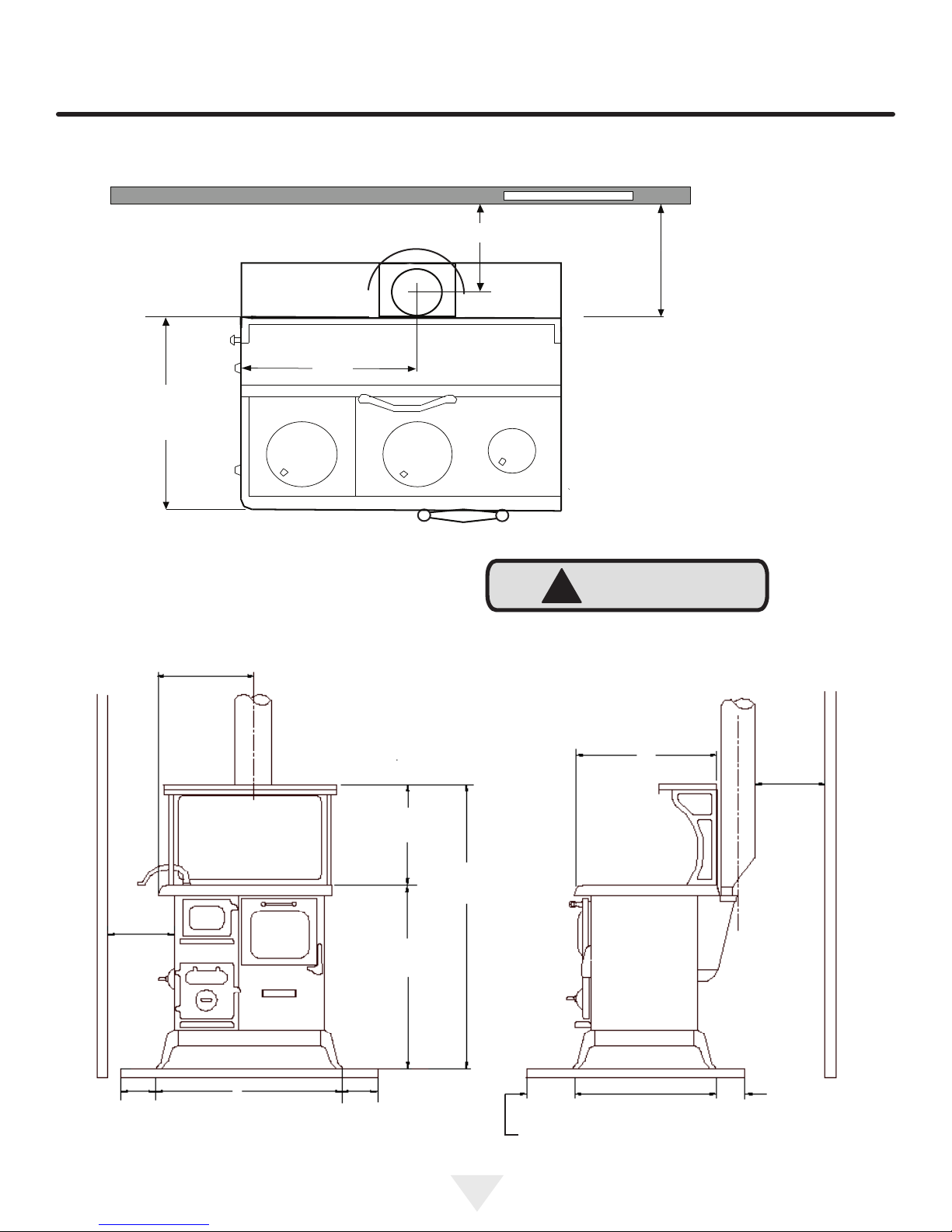

ROUGH IN AND DIMENSION DIAGRAMS

101⁄4" (26 cm) with heat shield kit #4241 (from wall to center of pipe)

23" (58.4cm) without heat shield (from wall to center of pipe)

181⁄4"

(46.4cm)

221⁄2" (57.2cm)

Combustible Wall

141⁄4" (36.2 cm) with heat

shield. 27" (68.6cm)

without heat shield to the

back of the stove top.

COMBUSTIBE WALL

(61cm)

24"

181⁄4"

(46.4cm)

Figure 7

(48.3cm)

(81.0cm)

19"

317⁄8"

These drawings are for reference only, showing approxi-

mate dimensions for rough in purposes. Make sure that no

oor or ceiling supports will be cut due to chimney installation.

507⁄8"

(129.2cm)

!

CAUTION

235⁄8"

(60.0cm)

20"

(51.0cm)

COMBUSTIBE WALL

HEARTH HEARTH

8"

(20.3cm)

30"

(76.2cm)

8"

(20.3cm)

Figure 8

21"

(53.3cm)

8"

(20.3cm)

16" (40.6cm) in U.S.

18" (45.7cm) in Canada

8

CHART OF CLEARANCES

When a heat shield is installed dimensions D, E and F are

taken from the heat shield. Dimensions A, C, G and H re-

main the same with or without a heat shield.

When two or more clearances to combustible walls

contradict each other, the clearance with the greater

numerical value must be maintained.

Status Model A C D E F G H J Measure

NO HEAT

SHIELD

WITH HEAT

SHIELD

BLACKWOOD

BLACKWOOD

25 66 66 51 58 132 61 121 Centimeters

10 26 26 20 23 52 24 48 Inches

25 66 132 61 121 Centimeters

10 26 52 24 48 Inches

Figure 9

61 5 31

24

2

9

12½

INSTALLATION

Clearance Reductions

There are many alternate decorative methods to reduce

clearances to combustible materials. See your dealer,

or local re or building ofcial to assure the appropriate

standards are being met with these alternatives. In Canada,

refer to the Installation Code for Solid Fuel Appliances

and Equipment. CAN3-B365-M84. In the U.S., refer to the

National Fire Protection Association Standard 211.

Floor Protection

When installing your woodstove on a combustible oor, a

non-combustible oor protector is required under the stove

to protect the oor from hot embers that may fall when

reloading. The oor pad must be a continuous, non-combustible pad (oor tile with grouting or a sheet metal pad). A

oor pad should not be placed on top of a carpet. Pad must

extend 18" (458mm) in front of the stove in Canada and

16" (407mm) in front of stove in U.S. Pad must extend 8"

(203mm) to the sides and back of the stove.

Pad must extend fully to the wall if using side and back

clearances less than these dimensions. Pad extension

must be fabricated from non-combustible materials:

1/2" (13mm) thick minimum with thermal conductivity factor

"K" of 0.43 or lower (units of K = btu/h/F/in).

To determine thickness of equivalent material required

use formula ("K" x 0.5) / 0.43 = thickness required ("K" value can be obtained from manufacturer of oor material).

Chimneys and Draft

The chimney is the most important element of successful

stove operation. (See also page 24 "Flue Pipes")

Performance of your woodburning system depends

more on the chimney than on any other single

component.

The chimney 'drives' the system by producing the draft that

draws in combustion air and exhausts smoke and gases to

the outdoors.

When installing a new woodburning system or upgrading

an existing one, give as much attention to the chimney as

you do to the appliance that it serves.

DO NOT CONNECT THIS UNIT TO A CHIMNEY FLUE

SERVING ANOTHER APPLIANCE.

This room heater must be connected to:

(1) a listed Type HT (2100°F) chimney per UL 103 or ULC

S629, or

(2) a code-approved masonry chimney with a ue liner.

The chimney size should not be less than or more than

three times greater than the cross-sectional area of the ue

collar.

Follow the chimney manufacturer’s directions for installation. We recommend that prior to installing your stove into a

masonry chimney, you have the chimney inspected by a

qualied mason. An unlined masonry chimney should not

be used without the installation of a liner.

The chimney and installation will have to be inspected by

your local building inspector.

10

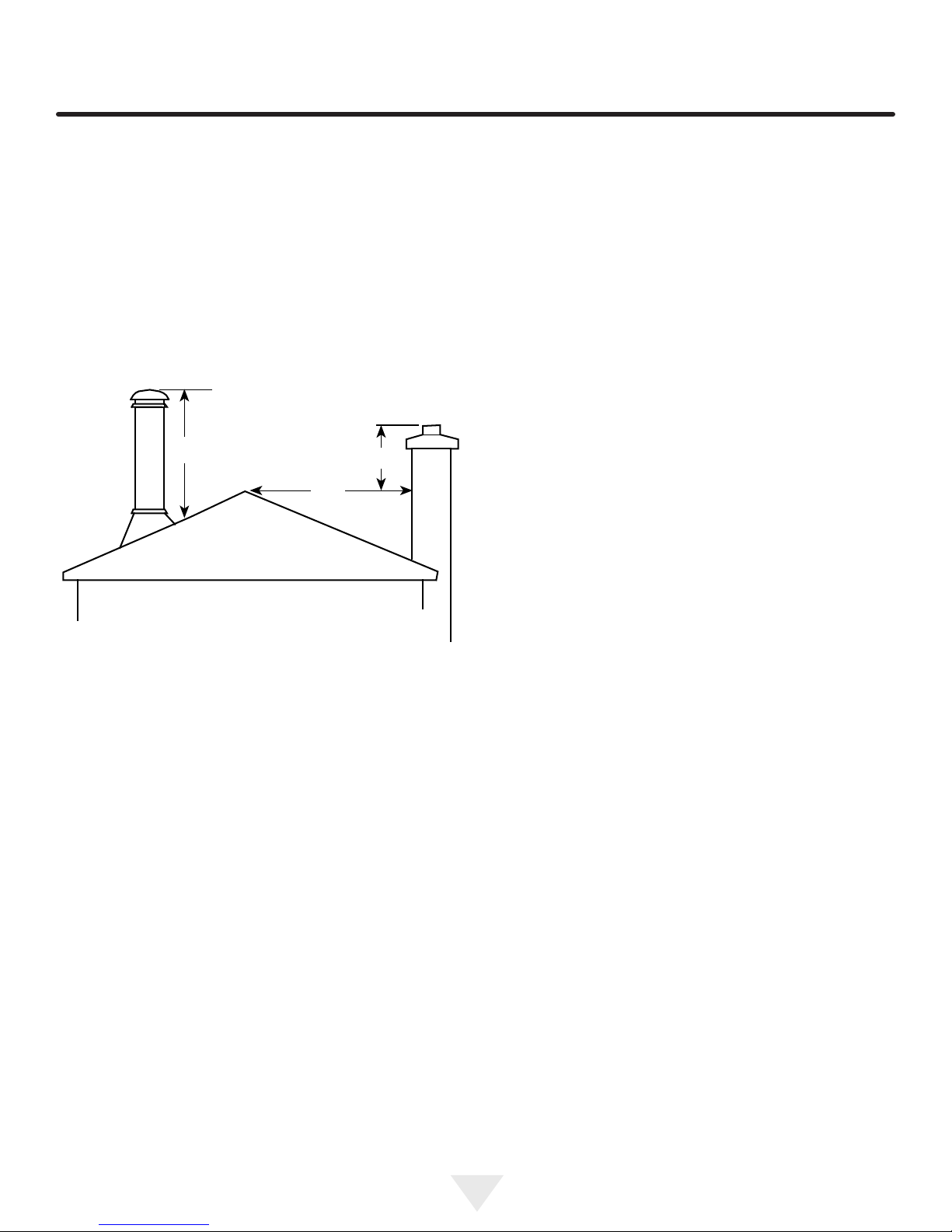

CHIMNEYS AND DRAFT

Recommended Chimney Clearances

The chimney must:

• extend at least 14 ft. (4.27m) above the collar of the

stove;

• extend at least 3 ft. (92 cm) above the point where it

passes through the roof;

• be at least 2 ft. above anything within a 10 ft. (3.048m)

radius of the top of the pipe.

Good draft in a cold chimney should be between

0.01" and 0.15" "water column" (your dealer may be

able to check this for you).

36" (900mm)

Figure 10

Illustration showing minimum heights required,

depending on the chimneys location.

24" (600mm)

10 Feet

(3 meters)

Stovepipe Chimney

Connection Requirements

1) The stovepipe chimney connector should be made of 24

gauge or thicker sheet metal and should be 6" in

(15.24cm) diameter.

2) The last section of the chimney connector starting from

the stove should be screwed to the ue collar of the

stove. Individual sections of the chimney connector must

be screwed together with at least three sheet metal

screws. The last section should be securely attached to

the chimney. Be sure there are no "weak links" in the

system.

3) The crimped ends of pipe sections should point down-

ward toward the stove so that any soot or creosote that

falls from the inside of the pipe will be funnelled into a

clean out or fall into the stove.

4) The chimney connector should be at least the height of

the warming shelf before a 90 degree turn is installed,

with no more than two 90 degree turns.

5) A horizontal run of stovepipe should be no longer than 4

ft (1.22m). A vertical run of stovepipe to a prefabricated

metal chimney should be no longer than 8 ft (2.44m).

6) Do not pass the stovepipe chimney connector through

a combustible wall if it can be avoided. If this cannot

be avoided, follow the recommended in CSA B365 in

Canada and NFPA 211 in the U.S., recommendation on

Wall Pass-Throughs.

7) Do not use single wall smokepipe as an outside chim-

ney.

8) Never pass stovepipe chimney connector through a

combustible ceiling.

9) The whole chimney connector should be exposed and

accessible for inspection and cleaning.

10) Galvanized stovepipe should not be used. When ex-

posed to the temperatures reached by smoke and

exhaust gases, galvanized pipe may release toxic

fumes.

11) Horizontal runs of chimney connector should slope

upward 1⁄4" (6.35 mm) per foot going from the stove

toward the chimney.

12) During a chimney re, the chimney connector may

vibrate violently. The connector must be securely

attached to the pipe and chimney, and individual

sections must be securely attached together.

13) This stove is not to be connected to an air distribution

duct.

11

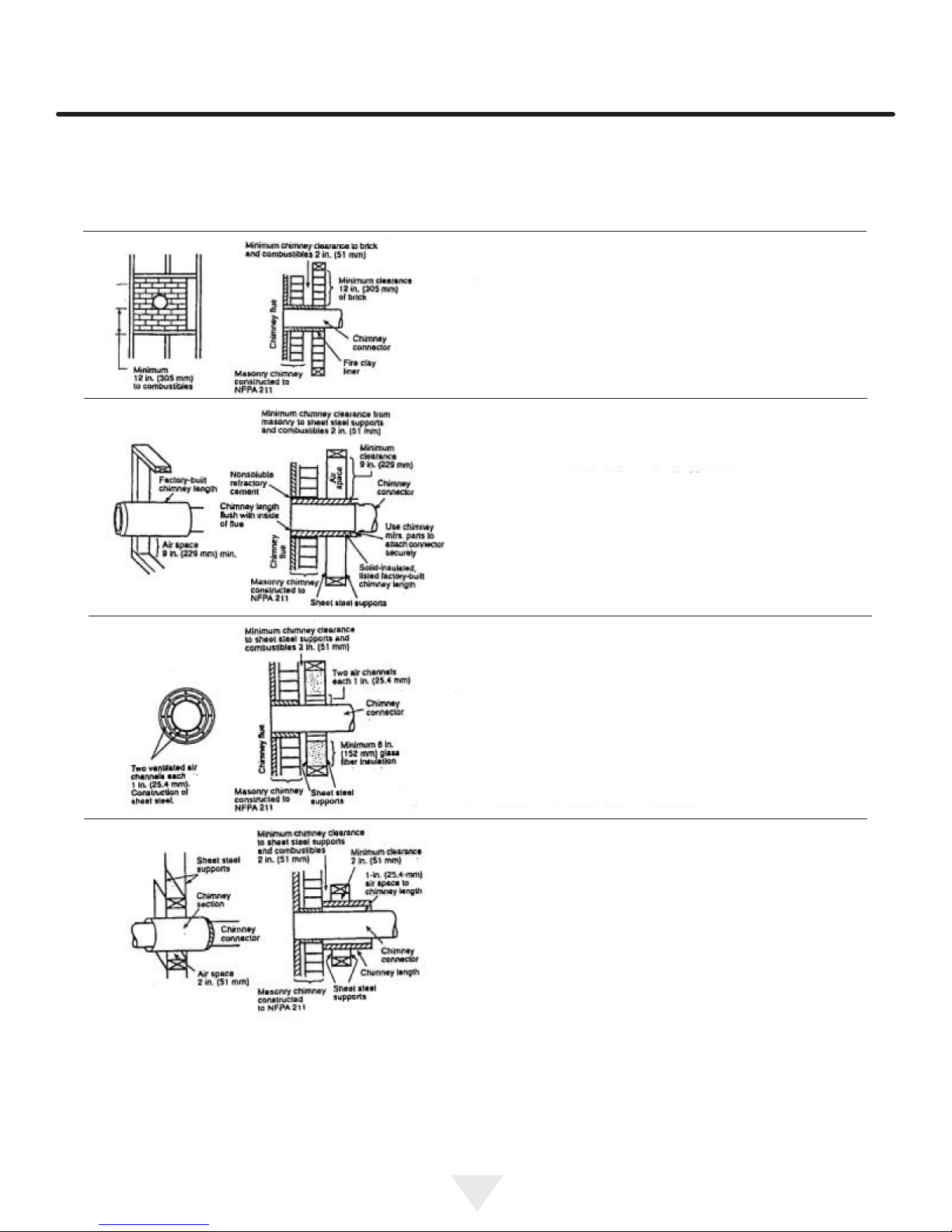

CHIMNEYS AND DRAFT

Chimney Connector Systems and Clearances

from Combustible Walls for Residential

Heating Appliances:

Figure 11

Minimum 31⁄2" thick brick masonry all framed into combustible wall with a minimum of 12" brick separation from clay

liner to combustibles. The reclay liner shall run from outer

surface of brick wall to, but not beyond, the inner surface of

chimney ue liner and shall be rmly cemented in place.

Figure 12

Solid-insulated, listed factory-built chimney length of the

same inside diameter as the chimney connector and hav-

ing 1" or more of insulation with a minimum 9" air space

between the outer wall of the chimney length and combustibles.

Figure 13

Sheet steel chimney connector, minimum 24 gauge in thick-

ness, with a ventilated thimble, minimum 24 gauge in thickness, having two 1" air channels, separated from combustibles by a minimum of 6" of glass ber insulation. Opening

shall be covered, and thimble supported with a sheet steel

support, minimum 24 gauge in thickness.

Figure 14

Solid insulated, listed factory-built chimney length with an

inside diameter 2" larger than the chimney connector and

having 1" or more of insulation, serving as a pass-through

for a single wall sheet steel chimney connector of minimum

24 gauge thickness, with a minimum 2" air space between

the outer wall of chimney section and combustibles. Mini-

mum length of chimney section shall be 12" chimney section spaced 1" away from connector using sheet steel sup-

port plates on both ends of chimney section. Opening shall

be covered, and chimney section supported on both sides

with sheet steel supports securely fastened to wall surfaces

of minimum 24 gauge thickness. Fasteners used to secure

chimney section shall not penetrate chimney ue liner.

12

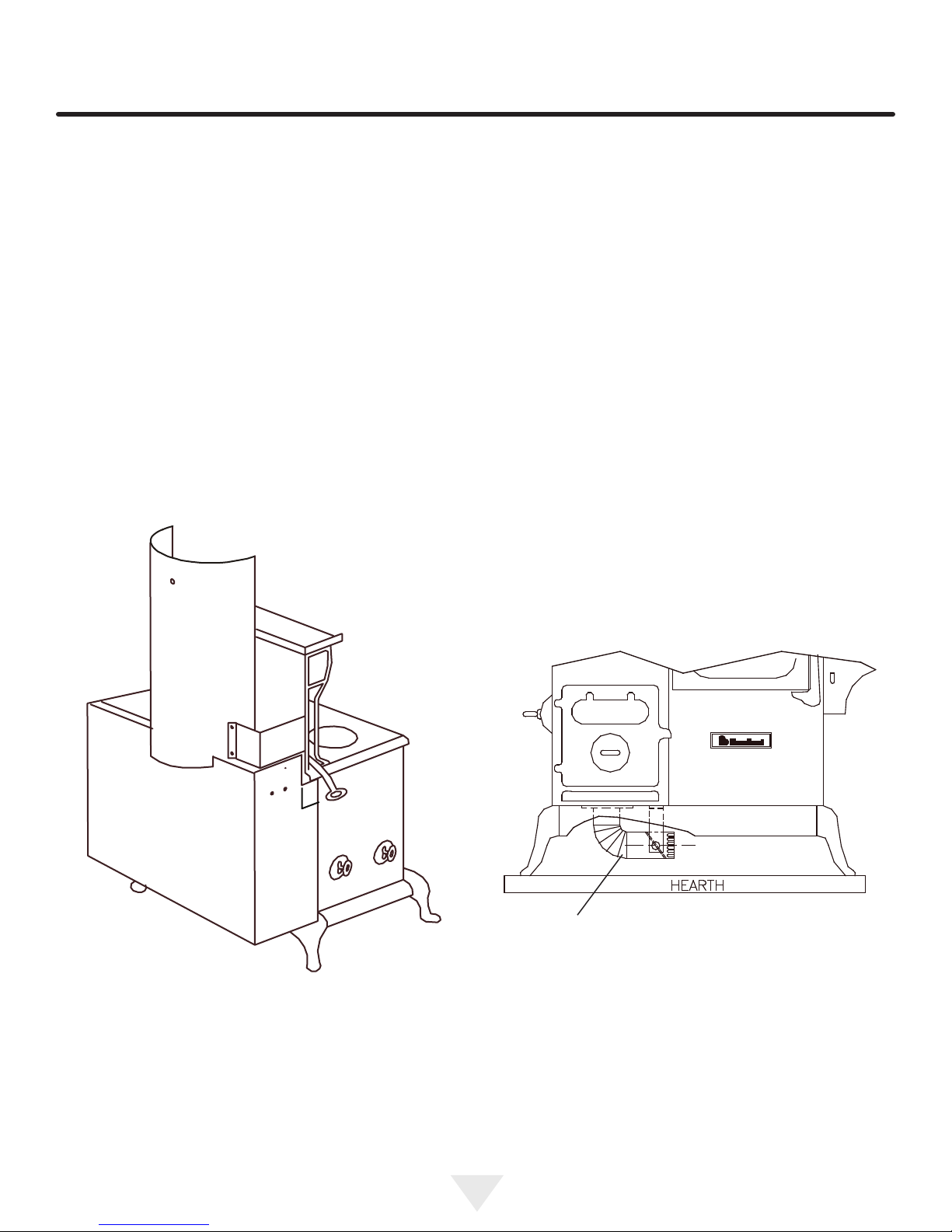

OPTIONAL ACCESSORIES

Accessories may be obtained from your dealer or call us

direct at 800-223-3900. Our ofce hours are from 8:00 a.m.

to 5:00 p.m. est.

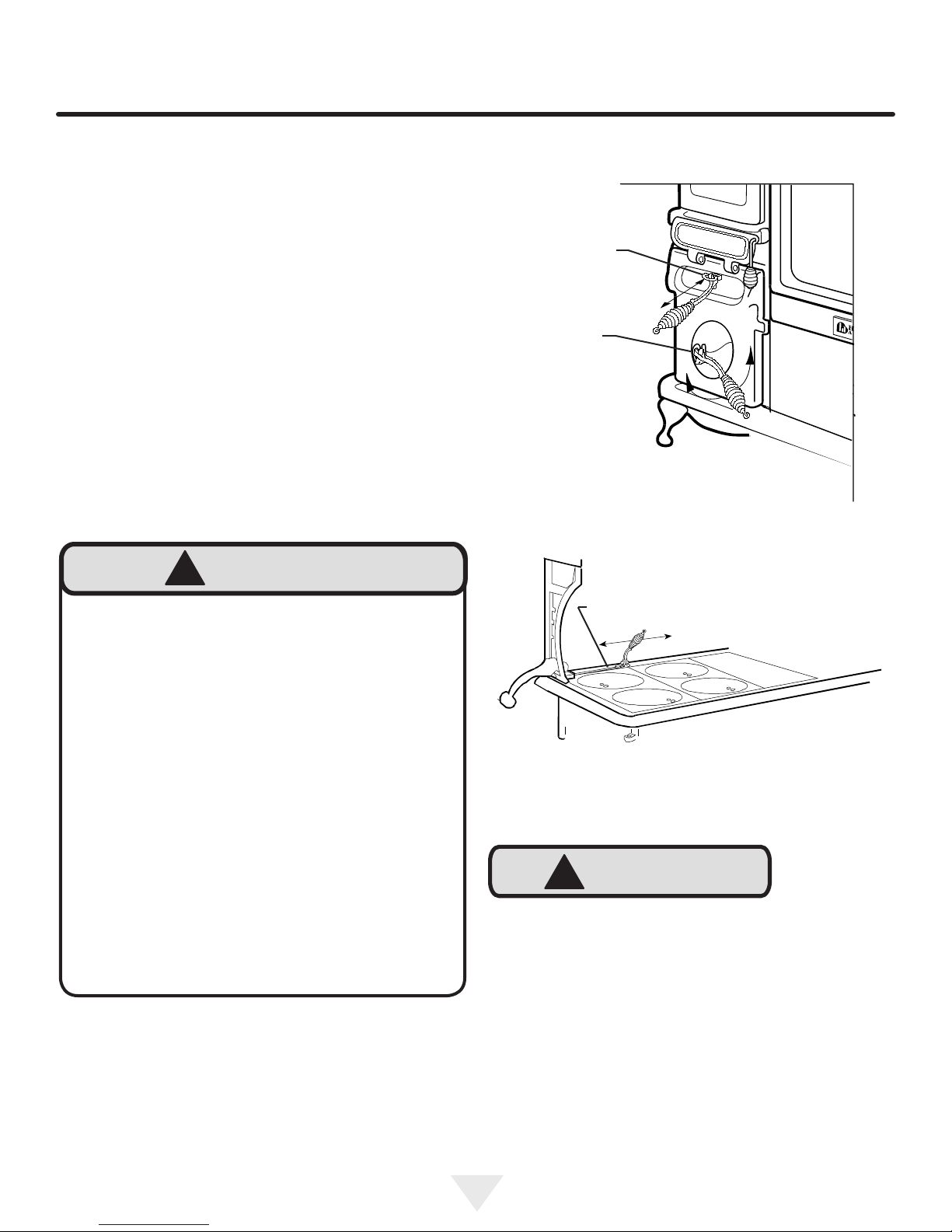

Heat Shield Kit #4241

A space saving heat shield kit enables you to install your

cookstove as close as 2" (5.1cm) to a combustible wall!

Installation is Easy

The heat shield kit is available for the cookstove and

mounts directly on the rear of the stove. The main section

of the shield covers the rebox and oven of the cookstove,

while the upper section covers the u pipe to a height

above the warming shelf.(See illustration, Figure 15.) An

installation and operating manual is packed with every heat

shield kit. Extra copies may be obtained from your dealer or

by contacting AGA Marvel.

Fresh Air Kit #1017

A fresh air kit enables you to use outside air, instead of

room air to fuel the re. Using an outside source for com-

bustion air has its advantages. If your home is tight and

well insulated, then the re in the stove may be "starved" of

combustible air, it will be difcult maintaining a re, and you

may have back drafting problems.

During the heating season, cold air, (which is more dense

than warm air), will cause the re to burn a little hotter, resulting in more BTU’s from your wood, and less creosote

build-up.

Installation is Easy

Mounting holes and airways are all pre-punched on the

cookstove.(See gure 16). Simply remove the cover plates

on the bottom of the rebox. Now you are ready for installation. A complete set of diagrams and instructions are included with each fresh air kit. Please note that some States

require a fresh air source to be installed with wood burning

appliances. Please check your local, and state, building

codes.

Figure 15

Illustration of heat

shield kit

s

Fresh air kit-

Figure 16

Illustration of Fresh air kit

13

OPTIONAL ACCESSORIES

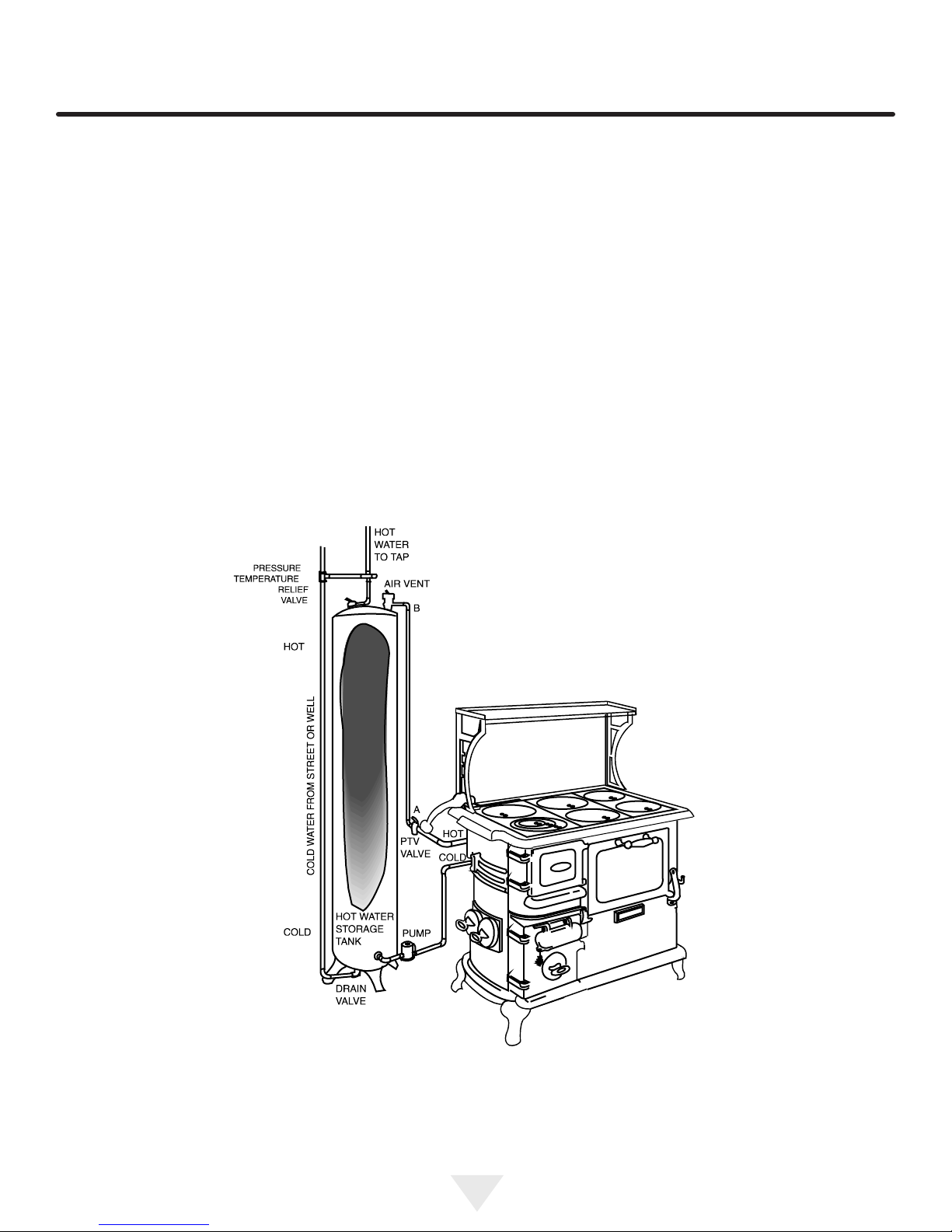

Water Jacket Kit #4506

The average family spent about one quarter of their utility

bill to heat water last year. By installing the water jacket in

your cookstove, you can reduce or virtually eliminate your

hot water utility bill.

Installation is Easy

The water jacket can be installed in the stove using only a

slot screwdriver. The water jacket is a hollow bafed chamber that ts in the rebox. Two pipes and a pump installed

from the water jacket to the electric or gas water heater,

circulate heated water from the stove to the storage tank.

(See illustration, Figure 17.)

You can expect from 6 to 8 gallons (22.7 to 30.3L) or more

hot water per hour (about 8,000 BTUs) from your water

jacket.

Because cold water cools the water jacket in the rebox,

creosote will be attracted to its cool surface, like humidity

being attracted to a cold window.

These deposits will quickly burn off thus reducing creosote

formation in the stove and chimney.

An installation and operating manual is packed with every

water jacket. Extra copies may be obtained from your dealer or by contacting AGA Marvel. (See page 30).

This is an illustration of an active or pumped

Figure 17

A Sample Water Jacket Installation

circulating hot water system.

14

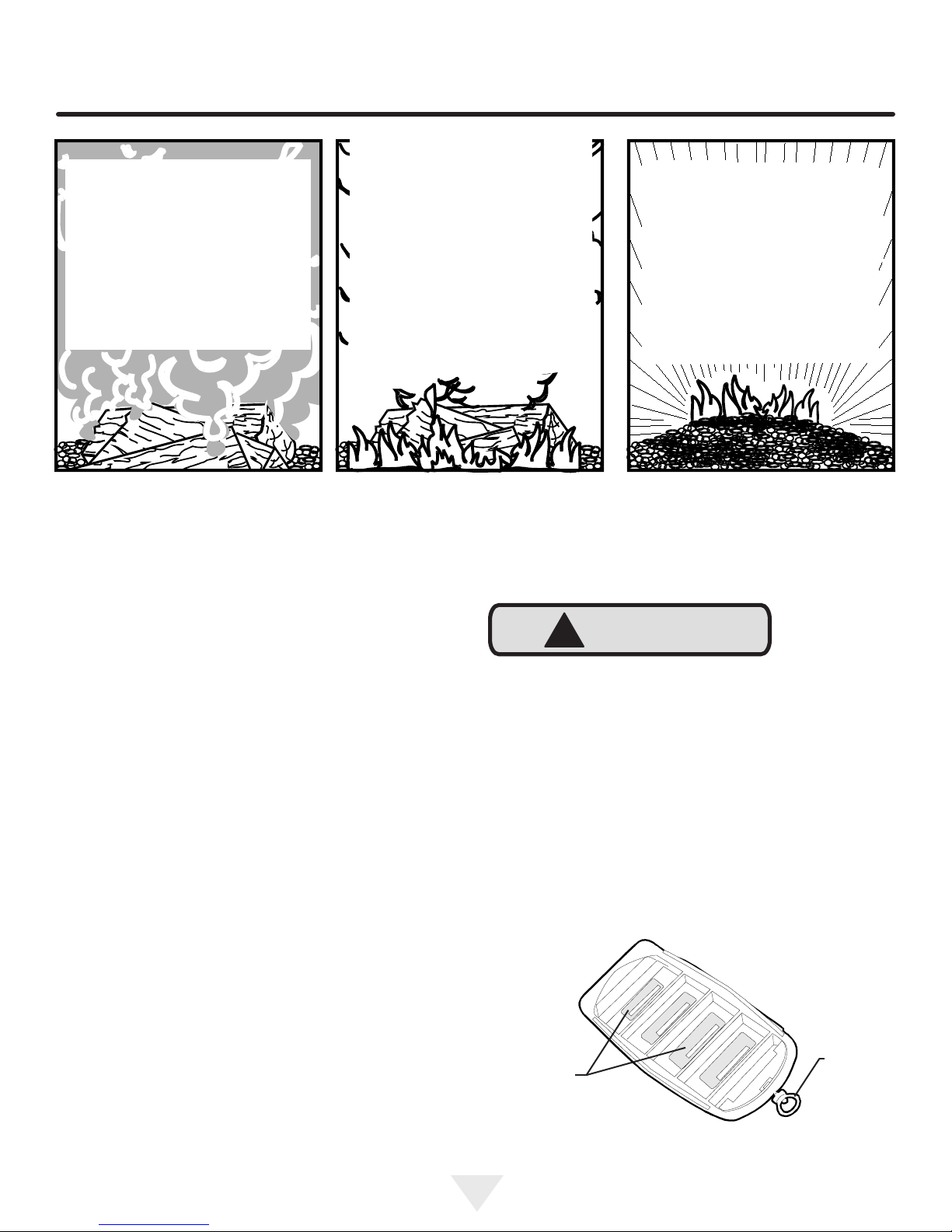

Water: Up to half the weight of

freshly cut logs is water. After

proper seasoning only about 20%

of the weight is water. As the wood

is heated in the rebox, this water

boils off, consuming heat energy in

the wood, the more heat energy is

consumed. That is why wet wood

hisses and sizzles while dry wood

ignites and burns easily.

UNDERSTANDING COMBUSTION

Smoke (or ame): As the wood

heats up above the boiling point

of water, it starts to smoke. The

hydrocarbon gases and tars that

make up the smoke are combustible if the temperature is high

enough and oxygen is present.

When the smoke burns, it makes

the bright ames that are characteristic of a wood re. If the smoke

does not burn, it will condense in

the chimney forming creosote or

exit the chimney as air pollution.

Figure 18

Charcoal: As the re progresses

most of the gases have vapor-

ized, charcoal remains. Charcoal

is almost 100% carbon and burns

with very little ame or smoke.

Charcoal is a good fuel that burns

easily and cleanly when enough

oxygen is present. Of the total

energy content of the wood you

burn, about half is in the form of

smoke, and half is charcoal.

Break In Fires for New Stoves:

If this is your rst re, OR you have installed a replacement

set of brick, read the procedure for break-in res. Proper

seasoning ensures longer stove life.

Woodburning:

The rewood you use will make an important contribution

to successful operation. You will achieve the best perfor-

mance and overall efciency by burning rewood that has

been split, stacked and air-dried undercover from rain for

at least one year. Burning improperly seasoned or "green"

wood can be a frustrating experience leading to poor per-

formance, smoky res and a build-up of creosote. Do not

burn saltwater driftwood refuse, rubber tires, etc. Use of

improper fuels can cause a re hazard and lead to a premature deterioration of the stove components, voiding the

warranty. (See Figure 18, Understanding Combustion.)

Burn dry wood because:

• It gives up to 25% higher efciency;

• It produces less creosote;

• It ignites faster and smokes less;

• Valuable heat is lost in the re as it dries out wet wood.

Before starting the stove, lift the key plate handle and rest

the arm in the top hook of the shelf bracket. Open both

the top loading and ash pan doors. The doors open by lifting slightly over the hook and pulling towards you.

!

CAUTION

Always use the lid lifter to open doors and bell dampers and when adjusting the oven damper.

In the cookstove, looking into the rebox through the top

you will see rebrick liners on the left and right side of the

rebox.

At the bottom of the rebox is the wood grate, looking in

through the ash pan door, you will see the wood grate

pull—slide it back and forth and looking down into the re-

box you will see the slots open and close.

Getting Acquainted:

This cookstove is a time proven heating and cooking appliance. Take your time to acquaint yourself with the principles

on which your new stove operates as a heater and cooking

stove.

Understanding the primary principles of the air intake

controls, the oven damper, the ame path for the re and

the relationship to the chimney will give you a very comprehensive understanding of what you are trying to accomplish

with the stove.

15

Slots, open

and close

Wood

grate pull

Figure 19

UNDERSTANDING COMBUSTION

The stove is burned with the slots open which allows the

combustion air to enter underneath the re. As ash and

coals build up on the grate these slots ll and will require

the occasional "shaking".

It is a good policy to shake the grate or stir the coals with

the poker before loading a new charge of wood.

You will notice that with the ash door closed the ash ap

may be lifted to access the wood grate pull without having

to open the door.

Burning skid wood or construction materials with nails is not

recommended as anything in the rebox that will not burn

has the potential to get caught in the grate.

The ash pan is directly below the grate.

Starting the Stove:

Good safety practices:

Wood grate pull

Bell damper

Lid Lifter Functions

Figure 20

!

WARNING

Educate your family members:

• Before burning the stove, have each family member

read this manual and be aware of safety practices.

• Keep children, clothing and furniture away from the

stove.

• The stove is HOT while in operation – DO NOT

TOUCH the stove, contact may cause burns.

• Open the redoor, ash pan door, woodgrate pull,

bell dampers and oven damper with the 1415 lid lifter

only—these surfaces get hot; (see gure 20 and 21).

• Keep a class A re extinguisher nearby and have a

clearly understood plan on how to extinguish a re.

• Make sure you have a high quality smoke detec-

tor in your home. Check with your local building

code authority for more information.

Oven damper slide

Figure 21

!

CAUTION

Never use gasoline, gasoline-type lantern fuel, kerosene,

charcoal lighter uid, or similar liquids to start or 'freshen

up' a re in this heater. Keep all such liquids well away

from the heater while it is in use.

16

UNDERSTANDING COMBUSTION

Break-In Fire

(Refer to page 15 gure 18)

The rebox of your stove is made of superior materials—

cast iron and rebrick lining.

Both materials could be broken by a sharp blow or thermal

shock. A little extra care and thoughtfulness during the

breakin period will help promote a long life for your stove.

The cast iron and rebrick will have picked up moisture during shipping and storage.

During the break-in period it is important to let the cast iron

and rebrick slowly dry out and avoid thermal shock,

caused by strong hot res.

• Build a small kindling re (following the instructions

below for the rst re) and add small pieces of

kindling. Let the stove burn for approximately one

hour on the rst ring.

• Let the stove cool keeping the doors closed.

• Repeat the process for a few days or until you have

had six break-in res. You may notice some smoke

or "burnoff" during your initial ring. This is normal

and is caused by the curing of the paint nish.

Your First Fire

It is advisable to read and understand this section thor-

oughly before starting the re (Refer to page 15 gure 18).

1. Open the oven damper (see Figure 22) and air intake

controls (bell dampers). On damp cold days, it may help

to open the ash door slightly until a good draw develops

in the chimney.

Light the paper at the bottom of the load and then light

the paper at the top, shut the key plate immediately. You

may nd it helps to hold the key plate open just slightly

for a few seconds to give some extra air and establish

the re.

3. To Fuel the Fire. After a couple of minutes open the front

loading door slowly. When the kindling is established add

larger pieces, perhaps 2"x2"x10" (5cm by 5 cm by

25.4 cm) long.

Continue this process until the re is established when

split logs can be added.

Dampering the stove. Tighten the bell dampers to

approximately 1⁄4" (6.35 mm) opening. This will slow

the re down. Wait momentarily and close the oven

damper.

The smoke and heat is now being routed around the

oven. Remember, by closing the oven damper resistance

has been put on the system.

If the stove/chimney is not yet heated enough or there

is too much volume of re going through, this additional

resistance will cause backpufng.

Close the oven damper slowly (Fig. 18) to allow the oven

ue chamber to absorb the smoke and heat.

4. Reloading the stove—Stove tending time will be greatly

reduced if you reload your stove while the system is still

hot and there is plenty of hot embers to rekindle the re

quickly. Including some smaller pieces of wood in the

new fuel load will help the stove regain temperatures

quickly.

2. To kindle a re. Lift the key plate lift handle and rest it

in the top slot of the closet bracket. Crumple six to eight

single sheets of newspaper into loose balls and place

them on the wood grate. Cut 10-15 pieces of kindling into

strips approximately 1/2" by 1/2" by 10" long (1.27 cm by

1.27 cm by 25.4 cm).

Place the kindling on the newspaper. Place 2 or 3 more

pieces of crumpled newspaper on top of the kindling.

Ensure that the wood grate slides are open.

Lighting the ‘charge’ is of your personal preference. One

method is to roll a piece of newspaper into a torch, light-

ing one end and using it to start the paper.

When reloading, open the oven damper and wait

momentarily—if loading from the top—slowly lift the key

plate or if loading from the front, open the door slowly.

Load wood—smaller, split pieces rst.

Close the door or key plate.

Open the bell dampers slightly.

The stove must rebuild its thermal momentum before

closing the oven damper.

As you become more experienced you will gain knowl-

edge on what settings of bell dampers and oven damp ers can be used at the different stages of the woodburn-

ing cycle (see Combustion Process, page 15 gure 18).

17

UNDERSTANDING COMBUSTION

An "Airtight" House:

If your home is well insulated or especially well sealed, the

inltration air supply to the interior of the house may be in-

adequate. This phenomenon of air starvation can be exac-

erbated if exhaust fans (such as clothes dryers, bathroom

fans, or cook stove exhaust fans) are used in your home.

Outtting your stove with the optional fresh air kit adapter,

connected to an air duct leading to the outside of your

home, should correct this problem.

Flue Gases

Oven

Damper

Figure 22

Oven Damper Open

Summer Burning:

The cookstove features a utility which allows you to use

your stove during the summer months with less heat radiat-

ing from the rebox.

To use the summer position in the Blackwood you will need

to purchase the optional #4271 summer grate support. Call

your dealer to order, or call direct to AGA Marvel.

1. Remove the wood grate from the lower rebox position

by pulling the grate up, back end rst, and out of the

rebox.

2. Remove the wood grate slide from the wood grate. Place

the "summer position wood grate stand" at the back of

the rebox on the rebox extension.

3. Place the re grate so the back of the re grate rests on

the stand, and the front rests on the top of the front brick.

You are now ready for summer cooking.

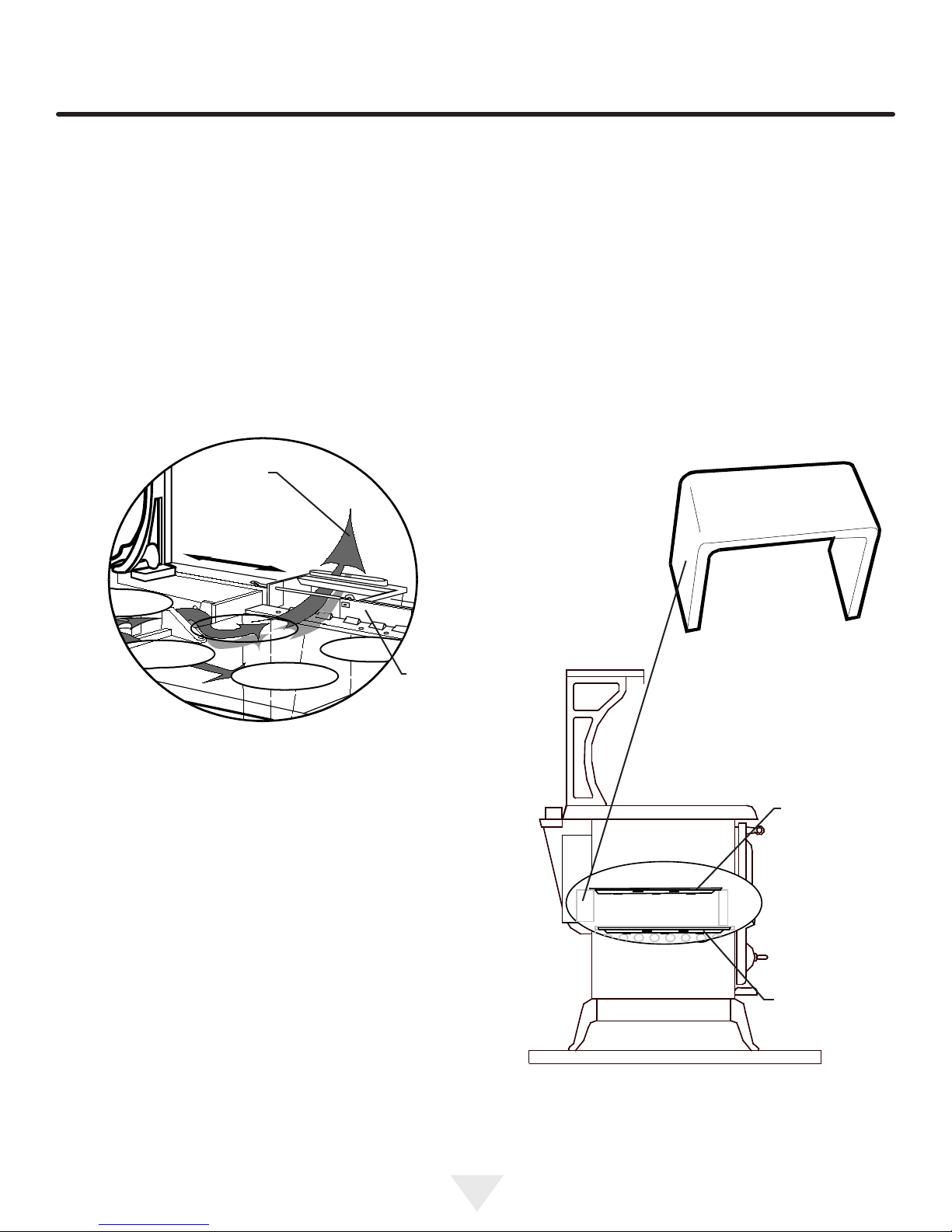

Blackwood

summer

grate stand

Upper "Summer

position".

Lower "Standard position".

Figure 23

Wood grate positions

for the blackwood stove

18

NOTE

COAL BURNING

NOTE-A series of wood "break in" res should be done

before attempting to burn coal (see page 17).

Coal Burning:

Do not burn coal on the wood grate. An optional coal grate

kit is available for the cookstove (#4500) to burn coal. An

installation and operating manual is packed with every

Blackwood Coal Kit. Extra copies may be obtained from

your dealer or by contacting AGA Marvel. Below is a brief

description of the coal kit installation.

Storage of Coal:

Store coal in a dry, well ventilated area.

Coal Grate Installation:

To install the optional coal grate, remove the lift handle, the

key plate and lids. Lift the wood grate out through the top

of the rebox and replace it with the coal grate. Remove

small front brick in rebox by unscrewing bolt & nut that

holds brick in place. Replace with large brick in coal kit.

Gently tap the coal grate down until it ts snugly into the

steel track. Replace the key plate, lift handle and lids. Then

proceed with redoor damper installation.

Firedoor Damper

(Coal burning only, see Figure 24.)

O

C

Figure 24

Illustration showing

redoor

damper installation

Starting Up a Coal Fire

A chimney 6" (15.25 cm) in diameter is imperative for the

Coal Burning process. A chimney larger than 6" (15.25

cm) in diameter will cause poor ignition of the coal due to

inadequate draft.

It is possible to burn coal with a large diameter chimney,

but banking a new bed of coals will require a greater mix of

wood to create and maintain an adequate draft.

The minimum draft required to maintain an oven tempera-

ture of 350º F (175C) is around .04" (1.016 mm) on a water

column. For drafts under .04" (1.016 mm) on a water column, closing the oven draft damper more than half way, will

cause back pufng.

The redoor damper comes with each coal kit and must be

installed. Remove the black redoor frame from the re-

door. Loosen the three screws that hold the cover plate

over the damper holes. Replace the cover plate with the

coal damper, lettered side out. Tighten screws just enough

to hold the damper plate on but also allow it to slide freely

back and forth. Lock screws in position with a nut on each

screw thread.

During the recharge phase of a new bank, a draft of .08"

(2.03mm) should be maintained for at least 10-15 minutes

or until a substantial bed of red embers is built up.

We recommend burning anthracite coal, which is relatively

clean to handle, burns evenly with a low ame, has a low

sulphur content and produces relatively little smoke.

Use a "chess nut" or "nut" size of coal, which is 13⁄16 to 15⁄8

in (3 cm to 4.13 cm) diameter. However, other coal, such as

bituminous, can be burned, but is inferior to anthracite.

To Start a Coal Fire:

1. Use paper and dry wood kindling to start the re.

2. Add small, compact pieces of hardwood when the kin dling is burning hot. Keep the primary damper controls

fully open to establish a hot re quickly. The ash door

also may be opened during start-up to accelerate the

initial burn.

3. When a substantial bed of red embers is built up, start

adding coal – small amounts at a time. Keep the draft

control open.

19

COAL BURNING

4. Continue adding small amounts of coal until there is a

solid bed of burning coal. Do not add too much at one

time. Allow sufcient time between each small loading (at

least ve to ten minutes), so that each loading has time

to ignite thoroughly before the next load is put in.

When a substantial bed of burning coals has been

established, ll the stove to the highest possible level,

no higher than the bottom of the redoor – be careful not

to overload! A deep bed of coal will always burn more

satisfactorily than a shallow bed.

5. When most of the wood is burned and the coal is com pletely ignited (usually ve to ten minutes or less after

lling the stove), the draft control should be turned down

to the proper operating level. (If the ash door has been

opened, it must be closed to prevent overring, which

can severely damage the stove.)

Recharging the Fire:

If the re is burning hot and there is a deep bed of coals,

add coal a hand full at a time.

Allow enough time between each addition for the combustion process to start. As the bank becomes larger, the

amount of coal added at a time can be increased.

Soot - Formation and Need for Removal:

When coal is burned, the products of combustion combine

with moisture to form a soot residue, which accumulates

on the ue lining. When ignited, this soot makes an extremely hot re. When burning coal, the chimney connector

and chimney should be inspected at least once every two

months during the heating season to determine if a soot

buildup has occurred.

Disposal of Ashes (wood and coal):

Do not remove the ash pan when the stove is hot. Carry

the ash pan with one hand on the handle in the upright

position and the other on the front edge of the pan to balance the pan.

Empty the ash pan before ashes build up over the top.

Improper disposal of ashes is the most common cause of

wood stove related res.

If the coal bed is under 5" (12.7cm) before a recharge is

started, it may be necessary to add kindling wood to in-

crease the combustion level so that more coal can be

added.

1. Coal never should be added unless there is a reasonably

hot re. The coal bed should be bright and vigorous.

2. If the re is burning hot and there is a deep bed of coals,

full loads of coal can be added at any time. However, if

there is not a deep bed of coals, it is best to add small

amounts of coal at rst.

NOTE

When burning coal, the redoor damper must be kept open.

The secondary air is required to aid in burning off coal

gases. The coal damper is not required when burning wood

and should be kept closed when burning wood.

Coal grates are not to be used in upper (summer) position.

Do NOT ll rebox with coal higher than the bottom of the

redoor opening.

Disposal of Ashes - Ashes should be placed in a metal

container with a tight tting lid. The closed container of

ashes should be placed on a noncombustible oor or on

the ground, well away from all combustible materials, pending nal disposal. If the ashes are disposed of by burial in

soil or otherwise locally dispersed, they should be retained

in the closed container until all cinders have thoroughly

cooled.

!

CAUTION

• Don’t carry hot ashes through the house.

• Even though the stove may be cool, the ashes in the pan

may still be hot.

• Never place the ash pan on a combustible oor.

• Never leave the ashes near combustible material or com-

bustible liquids.

• Always dispose of ashes in a closed metal container with

a tight tting lid—if an unexpected gust of wind fan the

ashes, a re could result.

20

Loading...

Loading...