Page 1

1050 Fountain St N. Cambridge, Ontario, Canada N3H-4R7

Business (519) 650-5501 Fax (519) 650-3773 Toll Free Phone: 1-800-361-1517 Toll Free Fax: 1-800-327-5609

The Oval and Sweetheart

cookstoves are listed to CSA

Standard B366.2M ULC

Standard S-627 & UL 1482 by

Warnock Hersey Professional

Services Ltd.

NOTE: Warnock Hersey NBR

is 219.

INSTALLATION

AND OPERATING

INSTRUCTIONS

SAVE THESE

INSTRUCTIONS

FOR FUTURE USE

Note: Please read these instructions

thoroughly before attempting to install

this unit.

SAFETY NOTICE: IF THIS STOVE IS NOT PROPERLY

INSTALLED, A HOUSE FIRE MAY RESULT. FOR YOUR

SAFETY, FOLLOW THE INSTALLATION DIRECTIONS.

CONTACT LOCAL BUILDING OR FIRE OFFICIALS

ABOUT RESTRICTIONS AND INSTALLATION

INSPECTION REQUIREMENTS IN YOUR AREA.

IMPORTANT: Check around oven chamber on a weekly

basis for soot and creosote accumulation. Clean the

chamber thoroughly from the top, side and bottom with

the rake (part #1425) provided. Burn the stove hot daily to

reduce creosote accumulation. Use only dry wood aged

for one year. Failure to do so could result in chimney fire

and void the warranty.

OVERFIRING CAUTION:

Repeated or extended overfiring

will void warranty on this

appliance. See page 28 for details.

The temperature registered by the oven door

thermometer may not necessarily correspond with

the reading taken with the thermometer inside the

oven. For accurate oven temperatures, refer to the

interior oven thermometer.

PLEASE NOTE: Specifications contained in this manual are subject to change with out notice

Oval

With Towel Rack

#1902

SweetHeart

SweetHeart

With Towel Rack

#2602

© 2002 HEARTLAND APPLIANCES INC.

Oval

With Reservoir

#1903

SweetHeart

With Reservoir

#2603

WOODCOOKSTOVES

Manual #1705 051502

ATTENTION INSTALLER: Leave this manual with appliance

Page 2

— FOR YOUR SAFETY—

DO NOT STORE OR USE GASOLINE OR OTHER

FLAMMABLE VAPOURS OR LIQUIDS IN THE

VICINITY OF THIS STOVE.

Stove Location - If the range must be located

near a window, avoid using long curtains which

could blow over the stove top, causing a fire

hazard.

Any openings in the wall behind the stove or in

the floor under the range must be sealed.

Do not set unopened glass or metal containers

in the oven, or in the warming cabinet, or on the

cooking surface.

Grease accumulation is the cause of many

cooking fires. Clean the oven compartment

regularly.

Do not attempt to extinguish a grease fire with

water. Cover grease fires with a pot lid or

baking soda.

Avoid the use of aerosol containers near the

range.

Never place pans, cookie sheets or roasters

directly on the oven bottom but use the oven

rack in its lowest position.

Page 3

Oval & Sweetheart Models

CONSUMER WARRANTY

ENTIRE PRODUCT – LIMITED ONE YEAR WARRANTY

HEARTLAND warrants the replacement or repair of all parts of this Wood Cookstove which prove to be defective

in material or workmanship, with the exception of the painted or porcelain enamel finish or plated surfaces, for one

year from the date of original purchase. Such parts will be repaired or replaced at the option of Heartland without

charge, subject to the terms and conditions set out below.

The warranty period against defects in the painted or porcelain enamel finish, or plated surfaces, is 90 days from

date of original purchase. The warranty does not include normal wear of firebox parts or gaskets.

TERMS AND CONDITIONS

1. This warranty applies only for single family domestic use when the Wood Cookstove has been properly installed

according to the instructions supplied by Heartland and is connected to an adequate and proper chimney and

and chimney connections. Damage due to faulty installation, improper usage and care, abuse, accident, fire,

flood, acts of God, commercial, business or rental use, and alteration, or the removal or defacing of the serial

plate, cancels all obligations of this warranty. Service during this warranty must be performed by a factory

Authorized Service Person.

2. Warranty applies to product only in the country in which it was purchased.

3. Heartland is not liable for any claims or damages resulting from any failure of the Wood Cookstove or from

service delays beyond their reasonable control.

4. To obtain warranty service, the original purchaser must present the original Bill of Sale, Model and Serial

number. Components repaired or replaced are warranted through the remainder of the original warranty

period only.

5. The warranty does not cover expense involved in making this appliance readily accessible for servicing.

6. This warranty gives you specific legal rights. Additional warranty rights may be provided by law in some areas.

7. Adjustments such as calibrations, levelling, tightening of fasteners, or chimney and and chimney connections

normally associated with original installation are the responsibility of the dealer or installer and not that of the

Company.

8. Overfiring of this appliance will void warranty.

TO ENSURE PROMPT WARRANTY SERVICE, SEND IN YOUR WARRANTY CARD WITHIN 10 DAYS OF PURCHASE.

If further help is needed concerning this warranty, contact:

Customer Service

Heartland Appliances Inc.

1050 Fountain St N.

Cambridge, Ontario, N3H-4R7

PLACE OF PURCHASE______________________________

DATE OF PURCHASE_______________________________

SERIAL NUMBER__________________________________

MODEL NUMBER__________________________________

Business (519) 650-5775

Fax (519)650-3773

Toll Free Telephone 1-800-3611517

Toll Free Fax 1-800-327-5609

Page 4

TABLE OF CONTENTS

Installation Instructions.......................2

Unpacking ............................................................... 2

Assembly............................................................... 3

Cabinet Installation .................................................. 5

Installation .............................................6

Clearances .............................................................. 6

Rough In for Oval Diagram ....................................... 7

Rough In for SweetHeart Diagram ............................ 8

Chart of Clearances ................................................. 9

Clearance Reductions ............................................ 10

Floor Protection ...................................................... 10

Chimneys and Draft ........................... 10

Recommended Chimney Clearances ..................... 10

Chimney Connection Requirements ....................... 11

Optional Accessories ........................ 11

Heat Shield Kit .......................................................11

Fresh Air Kit ........................................................... 12

Water Jacket.......................................................... 13

Fuel....................................................... 13

Woodburning ..........................................................13

Using the Oven and Cooking Surface19

Stove Top Cooking ................................................. 19

Oven Cooking .........................................................20

Water Reservoir ...................................................... 20

Trouble Shooting ............................... 22

Chimneys and Draft ................................................ 22

How Chimneys Work.............................................. 22

Factors that Affect Draft .........................................22

Checking an Existing Chimney ..............................22

Saftey Practices.....................................................23

What To Do If You Have a Chimney Fire...........23

Maintenance ........................................ 24

Oven Flue Chamber ................................................ 24

Flue Boot Inspection .............................................. 24

Oven Damper ......................................................... 25

Chimney Maintenance ............................................ 25

Cooking Surface ..................................................... 25

Nickel Trim ............................................................. 25

Porcelain ................................................................25

Door Gaskets .........................................................26

Firebox ...................................................................26

Oven Thermometer Adjustment .............................. 26

Formula for Equivalent Hearth Extension ................ 26

Understanding Combustion ............. 14

Getting Acquainted ................................................ 14

Starting the Stove ...................................................15

Break In Fire .......................................................... 15

Summer Burning .................................................... 15

Your First Fire ........................................................16

Coal Burning ....................................... 17

Sweetheart Coal Grate ........................................... 17

Oval Coal Grate ...................................................... 17

Oval and Sweetheart Fire Door Damper .................. 17

Starting Up a Coal Fire ...........................................17

Recharging the Fire ................................................ 18

Disposal of Ashes (wood and coal) ........................ 18

Use Caution ........................................................... 18

Terms of Reference and Function ... 27

Over Firing-Caution! .......................... 28

Kitchen Appliances ............................ 29

Oval Parts Diagram ............................ 30

SweetHeart Parts Diagram ............... 31

Replacement Parts Diagram ............ 32

Cookstove Parts List ......................... 33

1

Page 5

— Welcome —

our Heartland Cookstove is a time proven design of

Y

North American heritage. Our cookstoves were first

made in 1906 and many originals are still in use today.

With proper operation and maintenance, your Heartland

cookstove will give your family generations of warmth, delightful

meals and untold pleasures.

Take the opportunity to read this manual throughly to become

familiar with all the installation, operation and maintenance

procedures for your stove. You will find it offers valuable insight

into how a cookstove functions.

Save These Instructions

Keep the manual available for future reference. The manual is

an important part of your stove. If your stove is sold, deliver the

manual to the new owner along with the stove.

The quality of the installation (especially the chimney connector

and chimney), and the quality of the fuel being burned will affect

the performance of your stove, but the most important factor

is the way you operate the stove. With the help of this manual,

you will learn how to effectively heat and cook with your stove.

Be sure to read it entirely, including the terms of reference and

function.

In addition, your own experience will help you to learn the role

that the chimney plays in stove performance. The Oval &

Sweetheart have been tested and are listed by Underwriters’

Laboratories of Canada and Underwriters’ Laboratories in the

U.S. The test standards are ULC S-627 and UL 1482.

The Oval & Sweetheart are listed for burning wood or coal (with

the optional coal grate). Do not burn other fuels. The Oval &

Sweetheart are not listed for installation in mobile homes. Do

not install the stove in mobile homes.

Safety Notice:

maintained, a house fire may result. For your safety,

follow all installation, operation and maintenance

directions. Contact local building officials about restrictions

and installation inspection requirements in your area.

(“Makeshift” compromises in the installation may result

in hazardous conditions, including a house fire.)

If your stove is not properly installed and

After a few weeks of operating the stove re-read this manual.

Many of the procedures will become clearer after you have had

some experience with the stove.

Installation Instructions

Preparing the installation site before moving the stove into it

will save you from having to move the stove more than once.

See page 6 for information on "Clearances" and "Floor

Protection" page 10.

Unpacking

The stove is packaged in two main boxes. The smaller box

contains the warming cabinet. The main stove body is strapped

to the skid. Smaller component parts are packaged as follows:

Base Assembly—(Sweetheart only)

Box stapled to skid includes:

4 legs

2 long rails

2 short rails

1 pkg. hardware

Flu Body - (Oval only)

Flu body for the oval is fastened to the skid and must be

assembled to the stove. Assembly instructions are on the

following pages.

In the firebox:(Sweetheart and Oval)

1 ash scraper

The ash pan contains the following parts:(Sweetheart and

Oval)

1 poker

1 tool rack

1 lid lifter

1 cooking surface lift handle w/screw and nut

3 bell damper handles w/rod

3 bell dampers

1 Heartland oven cleanout door

1 bag of hardware

1 interior oven thermometer

Spend some time becoming familiar with the various parts by

operating them before you burn your stove.

Reservoir models only:(Sweetheart and Oval)

1 package containing:

water tap (tap thread wrapped with teflon tape)

tap trim washer

2

Page 6

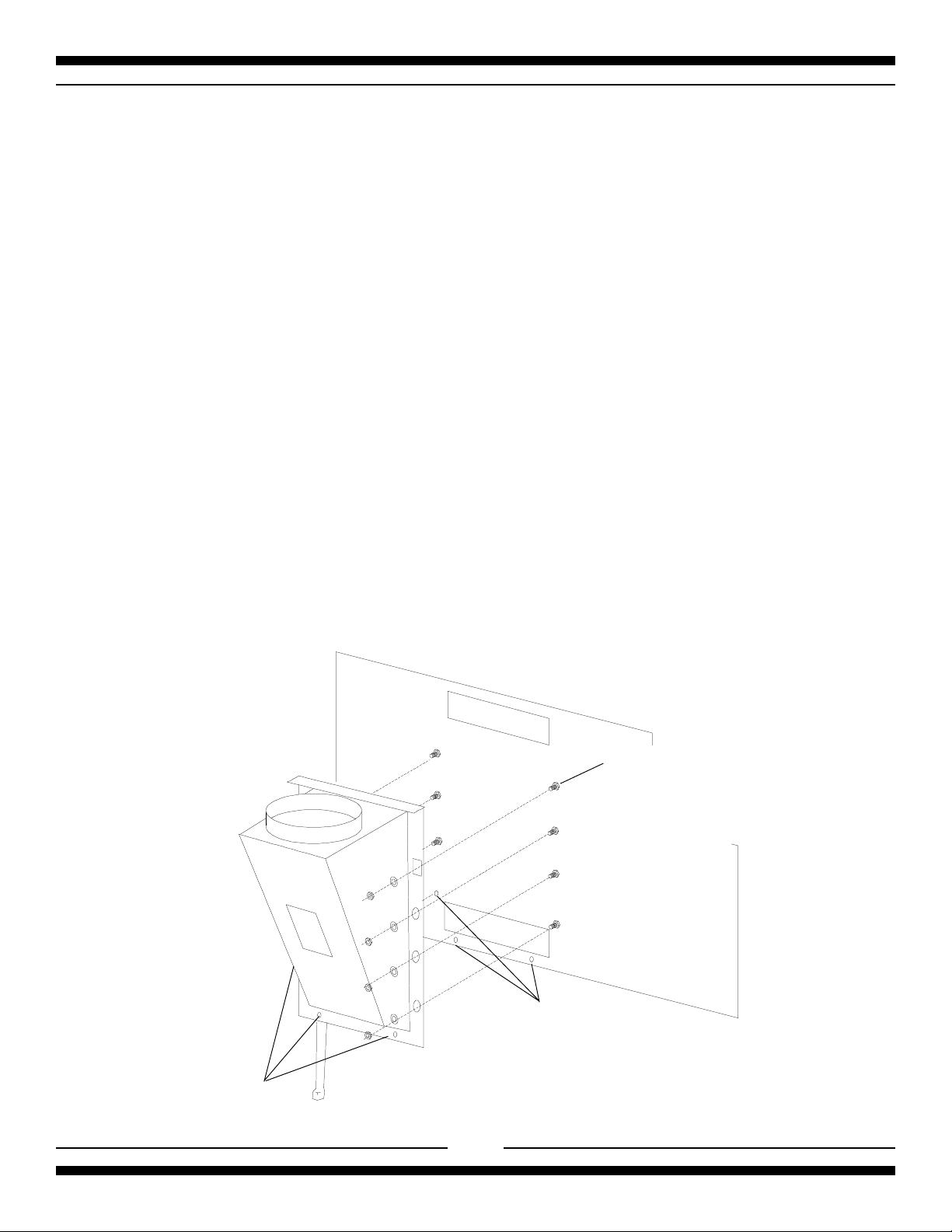

Oval

Assembly

Before removing the oval stove from the skid, the flu body must

first be attached tothe stove back. Follow the instructions

below.

1) unscrew the flu body from the skid and set aside.

Warning: The stove is very heavy. Since the legs may dig into

a soft floor, do not locate the stove, or even set it to rest, on a

surface that could be imprinted.

We recommend that 3 or 4 persons be available to assist in the

lifting of the stove, and that gloves should be worn to protect

hands from cuts.

2) unscrew 3 sheet metal screws (2 along the bottom of the

oven at the bottom and 1 along left side - see illustration)

3)Remove the first level only of nuts and washers from the

screws extending out the back of the stove (7pcs)

4) place flu body on back of stove so that the nuts on the

screws fit inside the holes in the flange on each side of the flu

body.

5) while holding the flu body in place, attach the flu to the stove

by putting on a washer and nut on each screw, hand tight only.

6) install the sheet metal screws along the bottom and side of

the flu body, and tighten up.(3)

7) tighten up the remaining nuts (7)

back of stove

1) First, remove the screws that are holding the flu body to

the skid and remove the flu body.

2) Next, unscrew the two lag bolts which are securing the

front and back of the firebox base. Lighten the stove by

removing the keyplate and lids.

3) Look under the oven and note that the stove must be lifted

up, over the wooden brace located there.

4) With 2 persons on the heavier, firebox side (left), and one

person on the other side, lift the stove up, off of the skid and

onto its new location.

5) If possible, have a fourth person remove the skid while the

others lift.

do not remove

from the screws,

fit thru holes

only remove the first

level of nuts and

washers

these nuts

nuts

in flu body

reinstall 3 sheet metal

screw after installing flu

body

remove 3 sheet metal

screw before

installing flu body

3

Page 7

SweetHeart

Warning: The stove is very heavy. Since the body frame may

dig into a soft floor, do not locate the stove, or even set it to rest,

on a surface that could be imprinted.

The Sweetheart is resting on a pad of styrofoam on the skid.

It consists of the range and a base assembly package.

The base assembly should be assembled and in position prior

to lifting the stove off of the skid; the base assembly instructions

follow below.

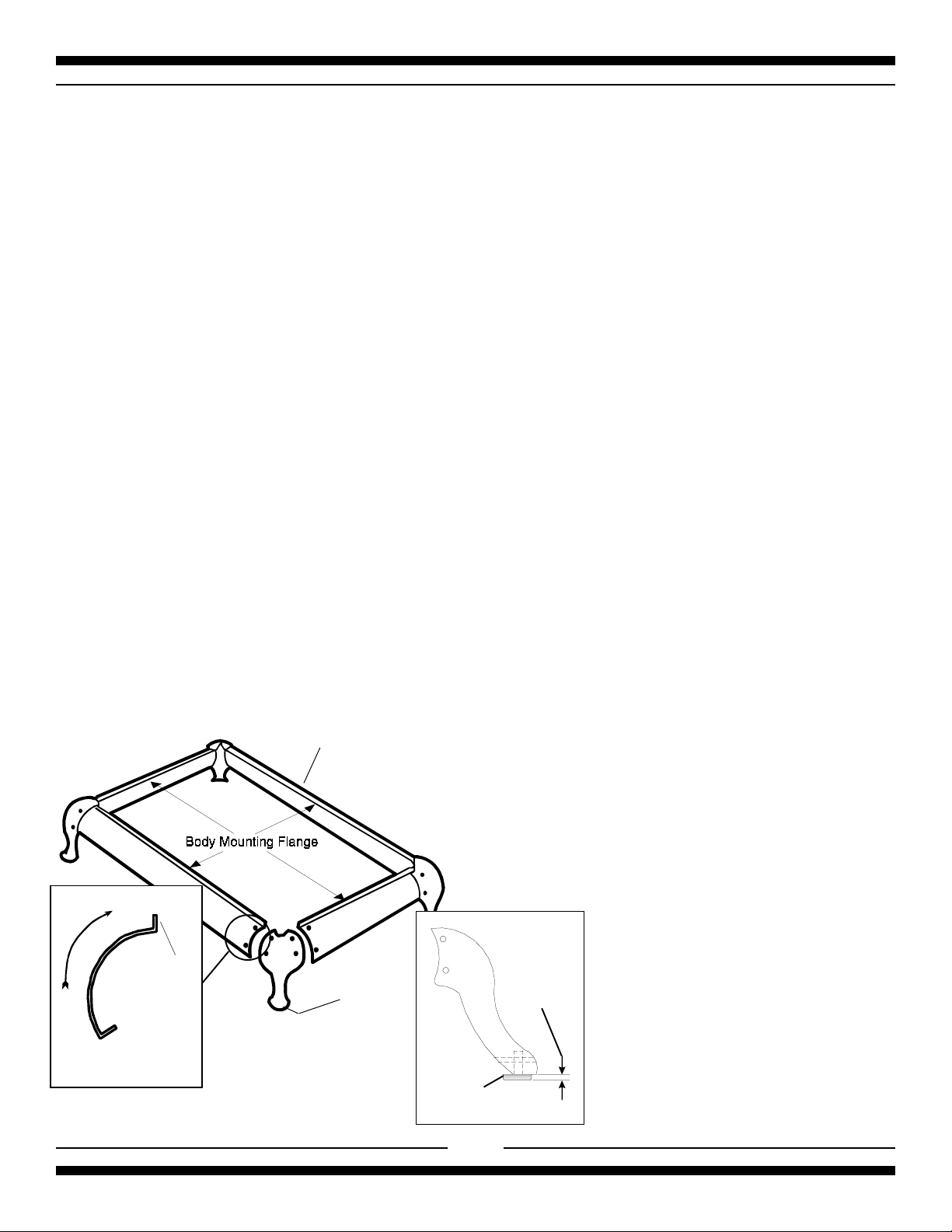

Base Assembly (Sweetheart only)

1. Unpackage the base sections, legs and hardware package

which are are located in a carton fastened to the skid at

rear of the range(it would be a good idea to check for any

damage that may have occured during shipping).

2. Screw the base levelling bolts (with teflon glider attached)

into each of the four legs. The levelling bolts are located in

the hardware package. When installing the levelling bolts,

the teflon glider should

extend

beyond the bottom of the

leg by approximately 1/8"-1/4". Adjusting levelling bolts

in too far will cause the leg to drag on the floor potentially

causing damage to flooring. (see figure 1 ) . Check that

gliders and floor are free of any debris, this will ensure you

do not scratch your floor.

Painted section goes to the rear

3. Assemble base to legs using the nuts and bolts provided.

The shorter base sections are the sides. The longer

sections are front and rear.(the black painted section goes

to the rear, see fig. 1).

4. Hand tighten the nuts and bolts until the base is completely

assembled. Ensure that all base sections are installed

with the body mounting flange up.

5. Adjust base sections to the most upper position and

tighten up the nuts and bolts.

Assemble Stove to Base

1. The range body rests directly on the base - no bolts are

required. We recommend that 3 or 4 persons be available

to assist in the lifting of the stove, and that gloves should

be worn to protect hands from cuts.

2. Do not lift the stove by the nickel trim. With 2 persons

on the heavier, firebox side (left), and one person on the

other side, lift the stove up, off of the skid and onto the base

assembly. If possible, have a fourth person remove the

skid while the others lift.

3. In order not to damage the nickel trim lift the range from the

front and the rear . The person at the front can first open

the oven door and use the oven opening for a hand hold.

The rear of the oven body at the bottom can be used to lift

from the back.

adjust up

flange

side view of skirt showing

position of body mounting

flange

Figure 1

SweetHeart

Base

Assembly

Teflon

Glider

4. Lift the range off the pallet and onto base, making sure the

range is sitting square and level on base. The stove sits

over the lip of the base assembly. Helpful hint: Instead of

trying to square the entire stove over the base, put one side

or back on first then slowly lower the other side into

position.

5. To level the stove, simply adjust the

levelling screws with teflon pads located

at the bottom of each leg (the ones you

assembled in step 2). Using a 5/16 (8

mm) open end wrench turn the adjusting

1/8"- 1/4"

screw clockwise to raise up the corner,

and counter-clockwise to lower the

corner. (Don't forget the teflon glider

should

extend

beyond the bottom of the

leg by approximately 1/8"-1/4")

4

Page 8

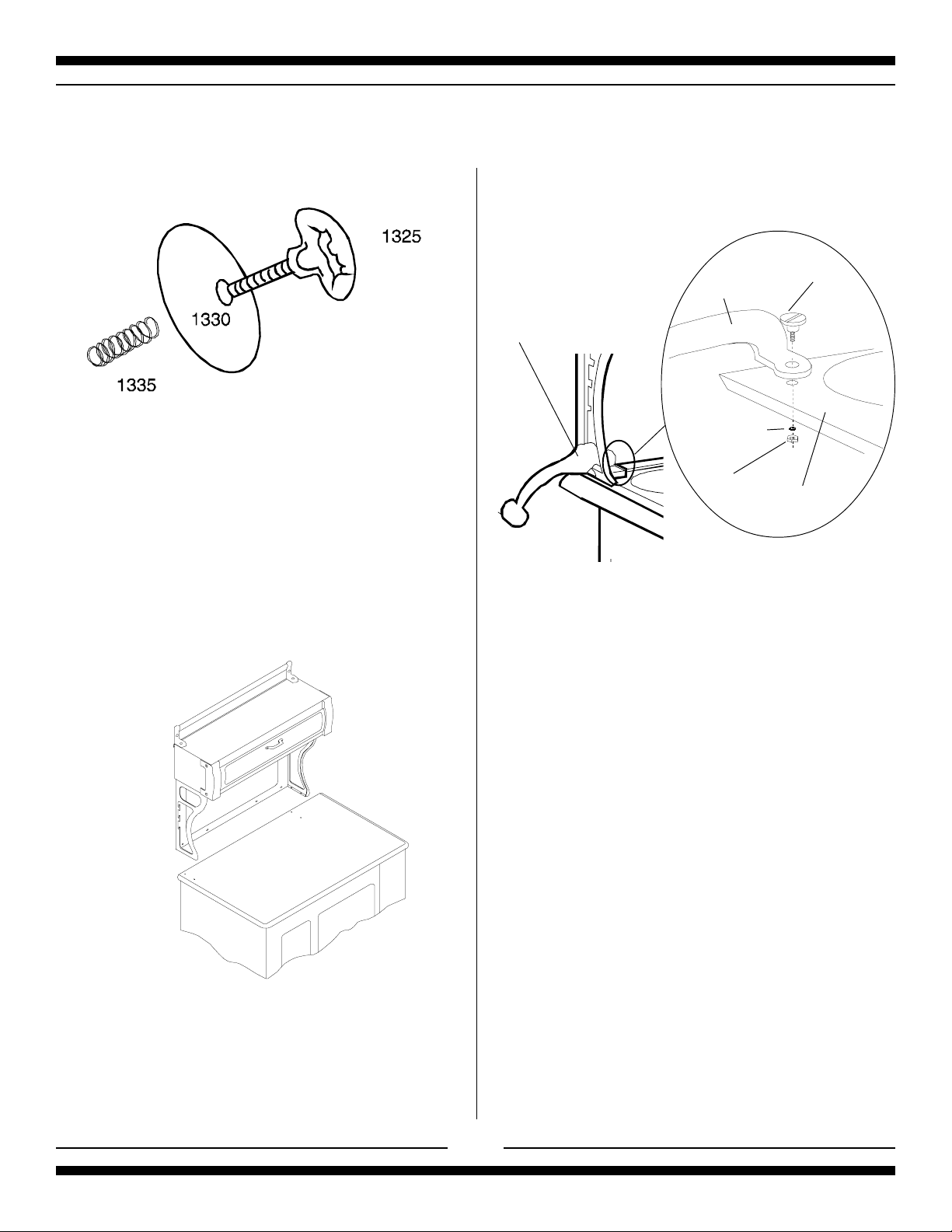

Oval and SweetHeart:

1. Assemble the bell dampers (Fig. 2).and thread into the

three locations, one at the front in the ash pan door, and

two on the firebox side.

Figure 2

Bell Damper

Once the cabinet has been assembled and installed, follow

these few remaining steps:

1. Insert the lift handle( #1361) through the bracket and bolt

it through the hole in the cooking surface with the screw

and locknut.

lift handle

#1361 lift handle installed

on cooking surface

lockwasher

2. Insert a piece of 6” diameter black smoke pipe into the flu

and secure with three sheet metal screws.(see page 10,

"Stovepipe Chimney Connection Reqiurements")

nut

cooking surface

The handle should be able to pivot freely from this point.

Tighten the nut securely, so it can't work loose under

normal use.

2. The three pronged tool holder (#1440) is used to hang the

lid lifter, poker and scraper.

To mount the holder, locate the two 1/4” holes on the

firebox side of the warming cabinet back. Fasten with the

bolts supplied.

3. A pipe damper installation is optional depending on your

installation and chimney configuration. Your dealer can

supply you with a damper.

The damper installation should be done before final assembly

of the chimney.

a) Open the front cabinet door.

b) Mark the spot for drilling in the back of the pipe by

pushing the sharp end of the damper rod into the back wall

of the pipe before drilling.

Cabinet Assembly

See the manual entitled "Cabinet Assembly Instructions for

Gas,Electric,Combination and Wood Stoves" which is

included in the cabinet box.

(Oval and SweetHeart)

c) Drill a 1/4” hole in the middle of the smoke pipe

through the centre of the hole in the back of the cabinet.

:

d) Follow the instructions that came with the damper and

install the damper inside the cabinet with the handle of the

damper also inside the cabinet.

e) Make sure the damper disc rotates freely inside the

pipe.

5

Page 9

Installation

Be sure to read the sections on clearances, floor protection

and chimneys before actively starting the installation. Contact

local building or fire officials about restrictions and

installation in your area.

Clearances

A woodburning stove radiates heat in all directions. Heat

directed toward living areas in front of the stove is usually very

welcome.

However, heat radiating in other directions will not be as

welcome if it results in overheating nearby walls, ceilings and

floors.

An important part of planning a safe installation is to be sure

that combustible material located near your stove does not

overheat.

Clearance is the distance between your stove and stovepipe

and nearby walls, ceilings and floors.

If there is adequate clearance, then the nearby surfaces will

not overheat.

The clearance distance should be empty except for noncombustible heat shields.

Do not fill the empty space with any insulating material.

If you plan to install a Fresh air Kit with your stove, be aware

of the greater clearances required. See page 9 "Chart of

Clearances" and page 12 "Fresh Air Kit" for more information

Be aware that as wood is exposed to continuous heat it dries

out, eventually lowering the temperature at which it will start on

fire.

Maintain the clearances outlined in this manual, particularly

with respect to nearby combustable surfaces.

Your Heartland cookstove has been tested for safe operation

providing that these guidelines are followed.

Clearances must be maintained to

all combustible material. These

include doors, trim, furniture, drapes,

newspapers and clothes.

Air flowing between the stove and stovepipe and nearby

surfaces carries away heat.

An optional heat shield kit is available

for our woodstoves for reduced

clearances. See page 11 on "Heat

Shield Kit"

(continued on page 10)

6

Page 10

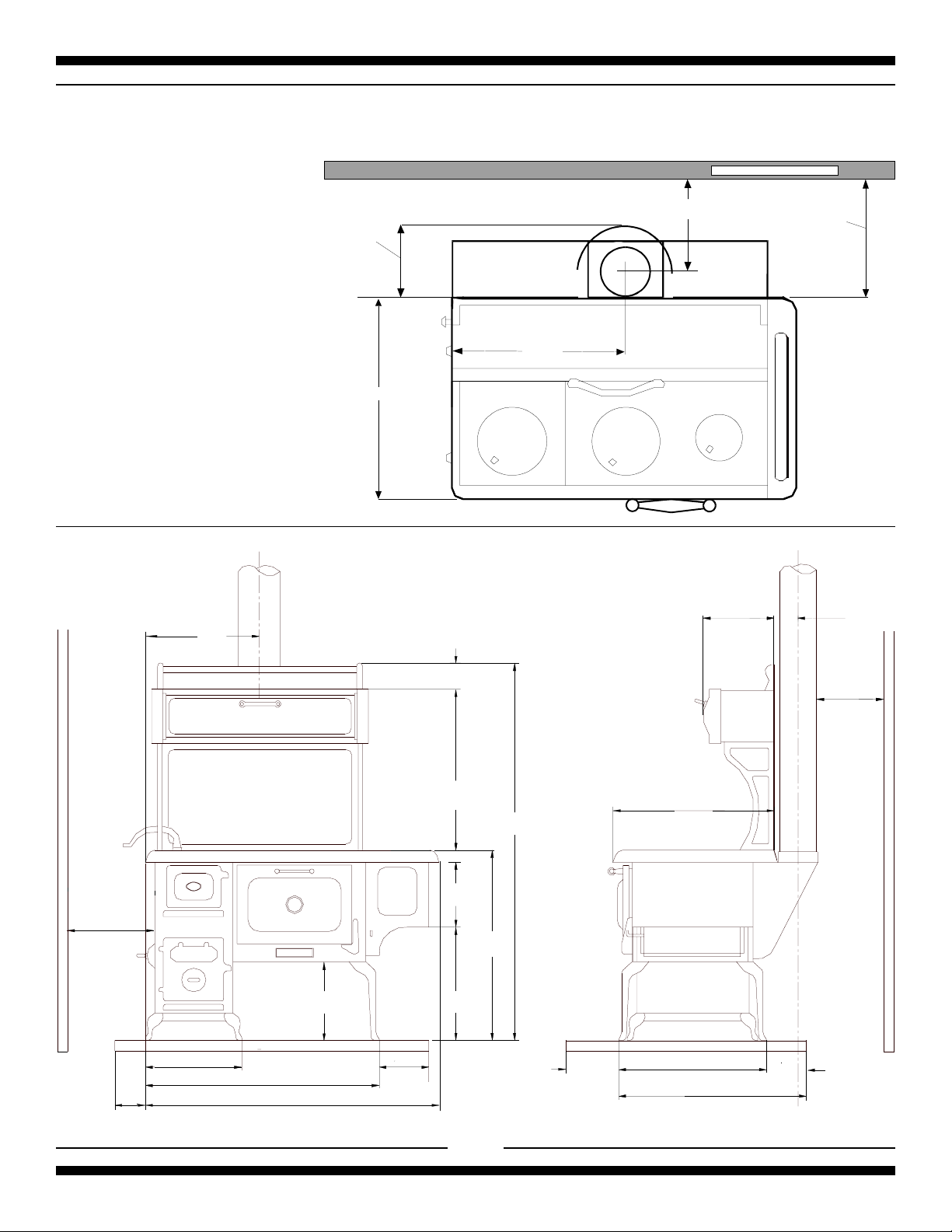

Oval Rough in and Dimension Diagrams

These drawings are

for reference only,

showing

approximate

dimensions for

rough in purposes.

Make sure that no

floor or ceiling

supports will be cut

due to chimney

installation.

Heat shield

extends 10 "

from back of

the stove top

¾

27 1/8

¾

8 " with heat shield kit (from wall to center of pipe)

21“ with out heat shield (from wall to center of pipe)

Oval Coo kstov e

20 1/4"

(Top Vi ew )

Combustible Wall

¾

12 " with

heat shield

25" with out

heat shield

to the back

of the stove

top

Note: Dimensions in brackets are metric (cm)

11 13/16

20 1/4

(51.5)

3 3/4

(9.5)

26 1/4

(66.6)

62

(157.5)

1 3/16

Com busti ble Wall

24

(61.0)

13 1/4

(33.7)

12

(30.5)

18 7/8

(47.9)

32

(81.3)

27 1/8

(69.0)

(30.0)

3 ½

( 9 )

18

(46)

Com bustibie W all

8

(20.3)

14 1/2

(36.83)

HearthHearth

47 3/24 (120.7)

35 1/2

(90.2)

8

(20.3)

Hearth

18

(45.7)

22 1/2

(57.15)

30 1/2

(77.47)

8

(20.3)

7

Page 11

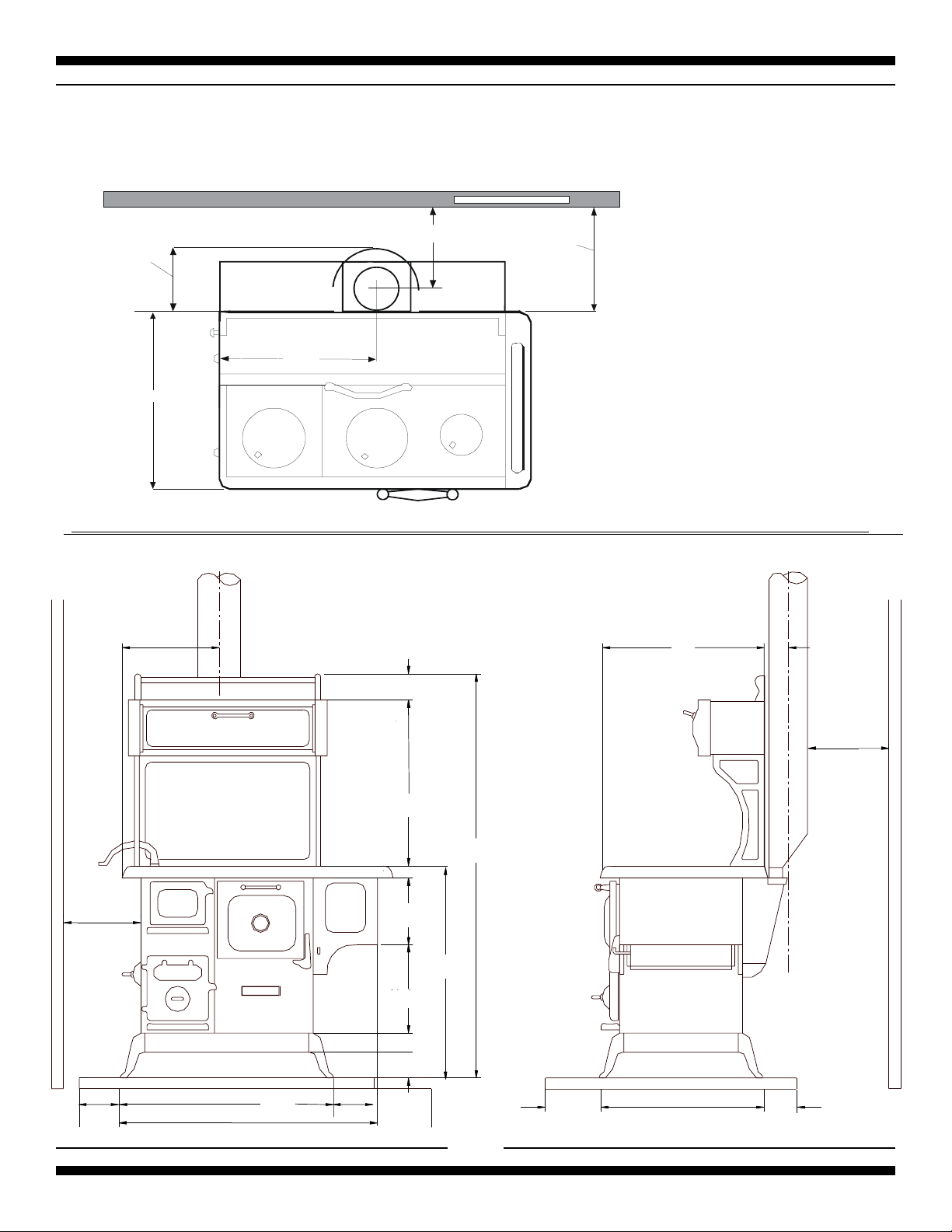

SweetHeart Rough in and Dimension Diagrams

Heat shield

extends 14 "

from back of

the stove top

22 ¼ "

12 " with heat shield kit (from wall to center of pipe)

21“ with out heat shield (from wall to center of pipe)

18 ¼ "

18 1/4

(46.0)

Combustible Wall

16

heat shield

25

heat shield

from the wa ll

to the back

of the stove

top

(To p Vi ew )

Note: dimensions in brackets are metric

4

(10.0)

" with

" With out

These drawings are for

reference only, showing

approximate

dimensions for rough in

purposes. Make sure

that no floor or ceiling

supports will be cut due

to chimney installation.

23 5/8

(60.0)

4 5/16

(11.0)

18

(45.7)

26.1/4

(66.5)

62

(157.5

1 3/16(3.0)

Combustable Wall

24

(61.0)

8

(20.3)

Hearth

42 1/2

(123.1)

33

(83.8)

(20.3)

11 1/4

(28.6)

31 7/8

(81.0)

11 /4

28.6

3

(7.5)

5 1/4

(13.3)

8

18

(45.7)

Hearth

24

(60.9)

8

(20.3)

Combustable Wall

8

Page 12

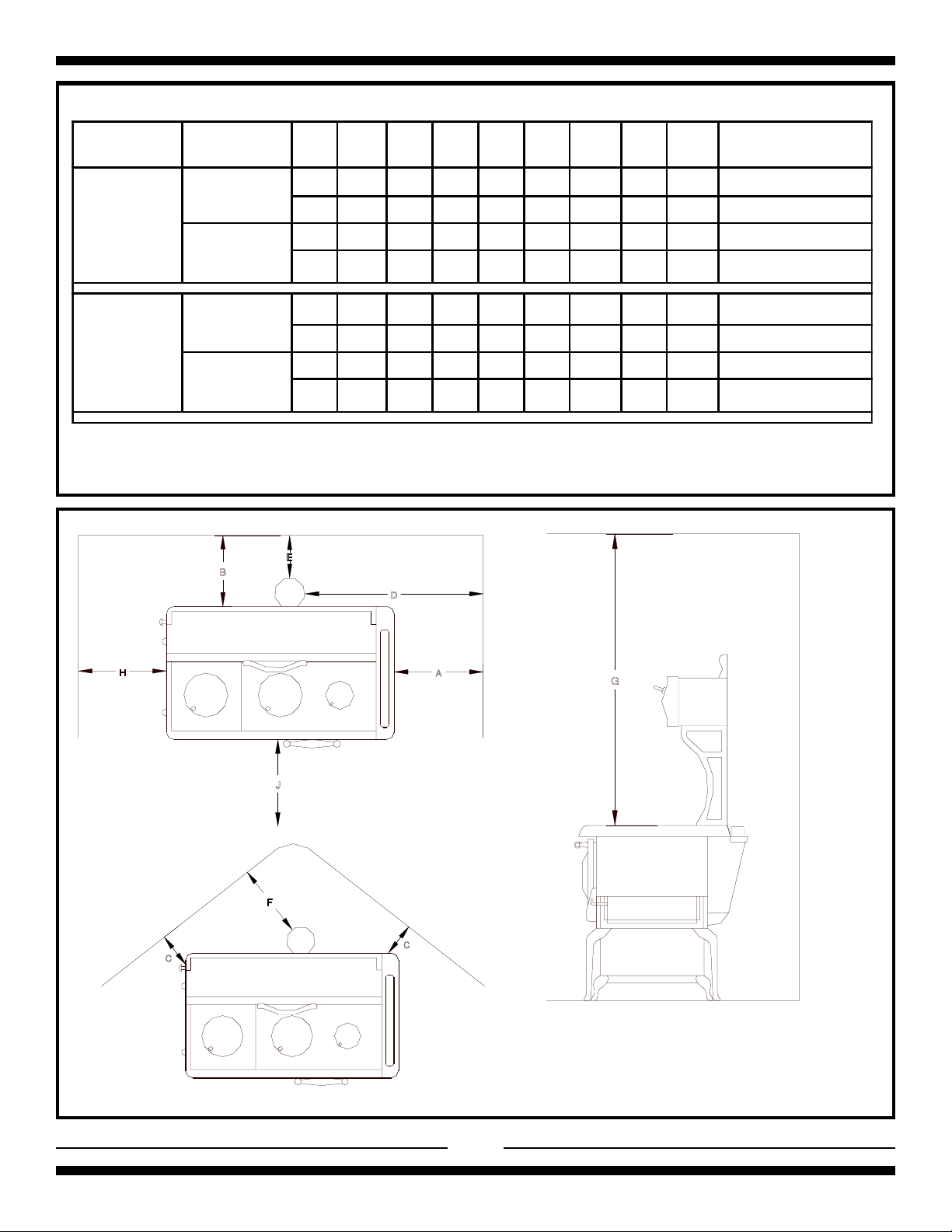

Chart of Clearances

Status Model A B C D E F G H J Measure

SweetHeart

25 69 66 66 50 58 132 61 121 Centimeters

NO HEAT

SHIELD

10 27 26 26 20 23 52 24 48 Inches

25 68 66 91 50 86 132 61 121 Centimeters

Oval

10 27 26 36 20 34 52 24 48 Inches

25 8 61 61 5 31 132 61 121 Centimeters

SweetHeart

WITH HE AT

SHIELD

10 3 24 24 2 12½ 52 24 48 Inches

25 8 61 91 5 44 132 61 121 Centimeters

Oval

10 3 24 36 2 17½ 52 24 48 Inches

*Note:

A chimney approved to ULC standard S629 in Canada or UL 103HT in the U.S. must be used to connect the smokepipe

at the top of the cabinet to maintain the 2" clearance to combustibles. The approved chimney must extend 1" below the heatshield.

PLEASE NOTE: That these are factory recommended clearances only, and are subject to local, provincial or state building and

fire codes. These clearances may change without notice

When a heat shield is installed dimensions B, D, E and F are taken from the

heat shield.

Dimensions A, C, G, and H remain the same with or with-out a heat shield.

Dimensions A and C are taken from the

When two or more clerances to combustible walls contradict each other,

the clearance with the greater numerical value must be maintained.

reservoir

on reservoir models.

9

Page 13

Clearance Reductions

There are many alternate decorative methods to reduce

clearances to combustible materials. See your dealer, or local

fire or building official to ensure the appropriate standards are

being met with these alternatives. In Canada, refer to the

Installation Code for Solid Fuel Appliances and

Equipment. CAN3-B365-M84. In the U.S., refer to the National

Fire Protection Association Standard 211,

Floor Protection

The chimney ‘drives’ the system by producing the draft that

draws in combustion air and exhausts smoke and gases to

outdoors.

When installing a new woodburning system or upgrading an

existing one, give as much attention to the chimney as you do

to the appliance that it serves.

The Oval and Sweetheart can be installed in a masonry

chimney which is in compliance with the appropriate standard

or a prefabricated chimney approved to

in Canada and UL 103HT in the U.S.

ULC Standard S629

When installing this cookstove on a combustible floor, a

noncombustible floor protector is required under the stove. The

floor pad is to protect the floor from hot embers that may fall

from the loading door. The floor pad must be continous

noncombustible surface. Floor tiles with grouting between

them or sheet metal pads are acceptable. The pad must

extend 450 mm (18") beyond any side with a loading door and

200 mm (8") beyond the other sides and rear. (See page 7

"Oval Rough-in Dimension Diagram" or page 8 "SweetHeart

Rough-in Dimension Diagram".) Floor pads may be fabricated

from non-combustible materials. (see page 26 "Formula for

Equivalent Hearth Extension")

Chimneys and Draft

The chimney is the most important element of successful

stove operation. (see also page 23 "Flue Pipes")

Performance of your woodburning system depends more

on the chimney than on any other single component.

Follow the chimney manufacturer’s directions for installation.

We recommend that prior to installing your stove into a

masonry chimney, you have the chimney inspected by a

qualified mason. An unlined masonry chimney should not be

used without the installation of a liner.

The chimney and installation will have to be inspected by your

local building inspector.

Recommended Chimney Clearances

The chimney must:

• extend at least 14 ft. above the collar of the stove;

• extend at least 3 ft. above the point where it passes

through the roof;

• be at least 2 ft. above anything within a 10 ft. radius of the

top of the pipe.

Good draft in a cold chimney should be between 0.01" and

0.15" “water column” (your dealer may be able to check this

for you).

(see figure 3 below)

36"

(900 mm)

24"

(600mm)

10'

(3 metres)

Illustration showing minimum heights required,

depending on the locaton of chimney

Figure 3

10

Page 14

Stovepipe Chimney

Connection Requirements

1. The stovepipe chimney connector should be made of 24

gauge or thicker sheet metal and should be 6” in diameter.

2. The last section of the chimney connector starting from

the stove should be screwed to the flue collar of the stove.

Individual sections of the chimney connector must be

screwed together with at least three sheet metal screws.

The last section should be securely attached to the

chimney. Be sure there are no “weak links” in the system.

3. The crimped ends of pipe sections should point downward

toward the stove so that any soot or creosote that falls

from the inside of the pipe will be funnelled into a clean out

or fall into the stove.

4. The chimney connector should be at least the height of the

warming cabinet before a 90 degree turn is installed, with

no more than two 90 degree turns.

5. A horizontal run of stovepipe should be no longer than 4 ft.

A vertical run of stovepipe to a prefabricated metal chimney

should be no longer than 8 ft.

Optional Accessories

Accessories may be obtained from your dealer or call us direct

at 519-650-5501. Our office hours are from 8:30 a.m. to 5:00

p.m. est

Heat Shield Kit

A space saving heat shield kit enables you to install your

cookstove as close as 2" (51mm) to a combustible wall!

Installation is Easy

The heat shield kit is available for both Oval and Sweetheart

cookstoves and mounts directly on the rear of the stove. The

main section of the shield covers the firebox and oven of the

cookstove, while the upper section covers the flu pipe to the

height of the warming cabinet.(See illustration, Fig. 4.)

An installation and operating manual is packed with every Oval

and Sweetheart heat shield kit. Extra copies may be obtained

from your dealer or by contacting Heartland Appliances Inc.

6. Do not pass the stovepipe chimney connector through a

combustible wall if it can be avoided. If this cannot be

avoided, follow the recommended in CSA B365 in Canada

and NFPA 211 in the U.S., recommendation on Wall

Pass-Throughs.

7. Do not use single wall smokepipe as an outside chimney.

8. Never pass stovepipe chimney connector through a

combustible ceiling.

9. The whole chimney connector should be exposed and

accessible for inspection and cleaning.

10. Galvanized stovepipe should not be used. When exposed

to the temperatures reached by smoke and exhaust

gases, galvanized pipe may release toxic fumes.

11. Horizontal runs of chimney connector should slope upward

1/4” per foot going from the stove toward the chimney.

12. During a chimney fire, the chimney connector may vibrate

violently. The connector must be securely attached to the

pipe and chimney, and individual sections must be securely

attached together.

13. This stove is not to be connected to an air distribution duct.

Figure 4

Illustration of Oval with

heat shield kit

11

Page 15

Fresh Air Kit

Installation is Easy

A fresh air kit enables you to use outside air, instead of room

air to fuel the fire. Using an outside source for combustion air

has its advantages. If your home is tight and well insulated,

then the fire in the stove may be “starved” of combustible air,

it will be difficult maintaining a fire, and you may have back

drafting problems.

During the heating season, cold air, (which is more dense than

warm air), will cause the fire to burn a little hotter, resulting in

more BTU’s from your wood, and less creosote build-up.

Figure 5

Illustration of Oval with

fresh air kit

Fresh air kit

The water jacket can be installed in the stove in less than a

minute using only a slot screwdriver. The water jacket is a

hollow baffled chamber that fits in the firebox. Two pipes and

a pump installed from the water jacket to the electric or gas

water heater, circulate heated water from the stove to the

storage tank. (See illustration, Fig. 6.)

Installation is Easy

Mounting holes and airways are all pre-punched on all new

Oval and Sweetheart cookstoves.(see figure 5)

Simply remove the cover plates (right side of firebox on the Oval

and, bottom of the firebox on Sweetheart). Now you are ready

for installation. A complete set of diagrams and instructions

are included with each fresh air kit.

Please note that some States require a fresh air source to be

installed with wood burning appliances. Please check your

local, and state, building codes.

Water Jacket

The average family spent about one quarter of their utility bill

to heat water last year. By installing the water jacket in your

cookstove, you can reduce or virtually eliminate your hot water

utility bill.

Figure 6

A Sample Oval Water Jacket Installation

This is an illustration of an active or pumped

circulating hot water system.

You can expect from 8 to 10 gallons or more hot water per hour

(about 10,000 BTUs) from your oval water jacket, OR 6 to 8

gallons (about 8,000 BTUs) from your Sweetheart water

jacket.

Because cold water cools the water jacket in the firebox,

creosote will be attracted to its cool surface, like humidity

being attracted to a cold window. These deposits will quickly

burn off thus reducing creosote formation in the stove and

chimney.

An installation and operating manual is packed with every Oval

and Sweetheart water jacket. Extra copies may be obtained

from your dealer or by contacting Heartland Appliances Inc.

12

Page 16

Understanding Combustion

Water: Up to half the weight of

freshly cut logs is water. After proper

seasoning only about 20% of the

weight is water. As the wood is

heated in the firebox, this water

boils off, consuming heat energy in

the wood, the more heat energy is

consumed. That is why wet wood

hisses and sizzles while dry wood

ignites and burns easily.

Smoke (or flame): As the wood heats

up above the boiling point of water, it

starts to smoke. The hydrocarbon

gases and tars that make up the

smoke are combustible if the

temperature is high enough and

oxygen is present. When the smoke

burns, it makes the bright flames that

are characteristic of a wood fire. If the

smoke does not burn, it will condense

in the chimney forming creosote or

exit the chimney as air pollution.

figure 7

Charcoal: As the fire progresses

and most of the gases have vaporized,

charcoal remains. Charcoal is almost

100% carbon and burns with very

little flame or smoke. Charcoal is a

good fuel that burns easily and

cleanly when enough oxygen is

present. Of the total energy content

of the wood you burn, about half is in

the form of smoke, and half is

charcoal.

Break-in Fires for New Stoves

If this is your first fire, OR you have installed a replacement set of brick, read the procedure for break-in fires.

Proper seasoning ensures longer stove life.

Fuel

Woodburning

The firewood you use will make an important contribution to successful operation. You will achieve the best performance and

overall efficiency by burning firewood that has been split, stacked and air-dried undercover from rain for at least one year. Burning

improperly seasoned or “green” wood can be a frustrating experience leading to poor performance, smoky fires and a build-up

of creosote. Do not burn saltwater driftwood refuse, rubber tires, etc. Use of improper fuels can cause a fire hazard and lead to

a premature deterioration of the stove components, voiding the warranty. (See Fig. 7 Understanding Combustion.)

Burn dry wood because:

• it gives up to 25% higher efficiency;

• it produces less creosote;

• it ignites faster and smokes less;

• valuable heat is lost in the fire as it dries out wet wood.

13

Page 17

Getting Acquainted

The Sweetheart and Oval cookstove are time proven heating

and cooking appliances. Take your time to acquaint yourself

with the principles on which your new stove operates as a

heater and cooking stove.

Understanding the primary principles of the air intake controls,

the oven damper, the flame path for the fire and the relationship

to the chimney will give you a very comprehensive understanding

of what you are trying to accomplish with the stove.

Before starting the stove, lift the key plate handle and rest the

arm in the top hook of the cabinet bracket. Open both the top

loading and ash pan doors. The doors open by lifting slightly

over the hook and pulling towards you. Always use the lid lifter

to open doors and bell dampers and when adjusting the oven

damper.

In the Oval, looking into the firebox through the top you see

cast iron liners, these liners rest on an oval refractory firebrick.

In the Sweetheart, looking into the firebox through the top you

will see firebrick liners on the left and right side of the firebox.

At the bottom of the firebox is the wood grate, looking in

through the ash pan door, you will see the wood grate pull—

slide it back and forth and looking down into the firebox you will

see the slots open and close.

You will notice that with the ash door closed the ash flap may

be lifted to access the wood grate pull without having to open

the door.

Burning skid wood or construction materials with nails is not

recommended as anything in the firebox that will not burn has

the potential to get caught in the grate.

The ash pan is directly below the grate.

Starting the Stove

Good safety practices:

Educate your family members:

• before burning the stove, have each family member read

this manual and be aware of safety practices;

• keep children, clothing and furniture away from the stove;

• the stove is HOT while in operation – DO NOT TOUCH the

stove, contact may cause burns;

• open the firedoor, ash pan door, woodgrate pull, bell

dampers and oven damper with the 1415 lid lifter only—

these surfaces get hot; (see figure 8)

The stove is burned with the slots open which allows the

wood grate pull

slots open and close

combustion air to enter underneath the fire. As ash and coals

build up on the grate these slots fill and will require the

occasional “shaking”.

It is a good policy to shake the grate or stir the coals with the

poker before loading a new charge of wood.

Wood Grate Pull

Bell Damper

Oven Damper Slide

figure 8

• keep a fire extinguisher nearby and have a clearly

understood plan on how to extinguish a fire.

14

Page 18

Break-In Fire

(Refer to page 13 figure 7)

Flu Gases

The firebox of your stove is made of superior materials—cast

iron and firebrick lining.

Both materials could be broken by a sharp blow or thermal

shock. A little extra care and thoughtfulness during the breakin period will help promote a long life for your stove.

The cast iron and firebrick will have picked up moisture during

shipping and storage.

During the break-in period it is important to let the cast iron and

firebrick slowly dry out and avoid thermal shock, caused by

strong hot fires.

• Build a small kindling fire (following the instructions below

for the first fire) and add small pieces of kindling. Let the

stove burn for approximately one hour on the first firing.

• Let the stove cool keeping the doors closed.

• Repeat the process for a few days or until you have had six

break-in fires. You may notice some smoke or “burnoff”

during your initial firing. This is normal and is caused by

the curing of the paint finish.

Oven Damper

Figure 9 - shows oven damper open

Lighting the ‘charge’ is of your personal preference. One

method is to roll a piece of newspaper into a torch, lighting

one end and using it to start the paper.

Light the paper at the bottom of the load and then light the

paper at the top, shut the key plate immediately. You may

find it helps to hold the key plate open just slightly for a few

seconds to give some extra air and establish the fire.

Your First Fire

It is advisable to read and understand this section thoroughly

before starting the fire (Refer to page 12 figure 7)

1. Open the oven damper (see Fig. 8 and 9) and air intake

controls (bell dampers). On damp cold days, it may help

to open the ash door slightly until a good draw develops in

the chimney.

2. To kindle a fire. Lift the key plate lift handle and rest it in

the top slot of the closet bracket. Crumple six to eight

single sheets of newspaper into loose balls and place

them on the wood grate. Cut 10-15 pieces of kindling into

strips approximately 1/2” by 1/2” by 10” long.

Place the kindling on the newspaper. Place 2 or 3 more

pieces of crumpled newspaper on top of the kindling.

Ensure that the wood grate slides are open.

3. To Fuel the Fire. After a couple of minutes lift the key plate

or open the front loading door slowly. When the kindling is

established add larger pieces, perhaps 2”x2”x10” long.

Continue this process until the fire is established when

split logs can be added.

Dampering the stove. Tighten the bell dampers to

approximately 1/4” opening. This will slow the fire down.

Wait momentarily and close the oven damper.

The smoke and heat is now being routed around the oven.

Remember, by closing the oven damper resistance has

been put on the system.

If the stove/chimney is not yet heated enough or there is

too much volume of fire going through, this additional

resistance will cause backpuffing.

Close the oven damper slowly (Fig. 9) to allow the oven flue

chamber to absorb the smoke and heat.

15

Page 19

4. Reloading the stove—Stove tending time will be greatly

reduced if you reload your stove while the system is still

hot and there is plenty of hot embersl to rekindle the fire

quickly. Including some smaller pieces of wood in the new

fuel load will help the stove regain temperatures quickly.

When reloading, open the oven damper and wait

momentarily—if loading from the top—slowly lift the key

plate or if loading from the front, open the door slowly.

Load wood—smaller, split pieces first.

Close the door or key plate.

Open the bell dampers slightly.

Sweetheart:

To use the summer position in the SweetHeart you will need

to purchase the optional #4271 summer grate support. Call

your dealer to order, or call direct to Heartland

1. Remove the wood grate from the lower firebox position by

pulling the grate up, back end first, and out of the firebox.

2. Remove the wood grate slide from the wood grate. Place

the "summer position wood grate stand" at the back of the

firebox on the firebox extension.

3. Place the fire grate so the back of the fire grate rests on

the stand, and the front rests on the top of the front brick.

The stove must rebuild its thermal momentum before

closing the oven damper.

As you become more experienced you will gain knowledge

on what settings of bell dampers and oven dampers can be

used at the different stages of the woodburning cycle (see

Combustion Process, page 13 figure 7).

Summer Burning

Both Oval and Sweetheart stoves feature a utility which allows

you to use your stove during the summer months with less

heat radiating from the firebox.

Oval:

1. Slide the wood grate from the lower firebox position and

remove the wood grate slide.

2. Set the wood grate on top of the firebrick. You are now

ready for summer cooking.

You are now ready for summer cooking.

sweetheart summer grate stand

upper "summer position"

lower "standard position"

wood grate positions for oval stove

upper "summer position"

lower "standard position"

wood grate positions for Sweetheart stove

16

Page 20

Coal Burning

Do not burn coal on the wood grate. An optional coal grate kit

is available for the Oval (#1500) and the SweetHeart (#4500) to

burn coal. An installation and operating manual is packed with

every Oval and Sweetheart Coal Kit. Extra copies may be

obtained from your dealer or by contacting Heartland Appliances

Inc. Below is a brief description of the coal kit installation

Sweetheart Coal Grate Installation

To install the optional coal grates, remove the lift handle, the

key plate and lids. Lift the wood grate out through the top of the

firebox and replace it with the coal grate. Remove small front

brick in firebox by unscrewing bolt & nut that holds brick in

place. (Please note that older models require front fire brick to

be installed with the groove facing away from the firebox and

towards the front of the stove).Replace with large brick in coal

kit. Gently tap the coal grate down until it fits snugly into the

steel track. Replace the key plate, lift handle and lids. Then

proceed with firedoor damper installation.

O

C

Illustration

showing Oval

firedoor damper

installation

Starting Up a Coal Fire

A chimney 6" in diameters is imperative for the Coal Burning

process. On chimney larger than 6" in diameters will cause

poor ignition of the coal due to inadequate draft.

It is possible to burn coal with a large diameter chimney , but

banking a new bed of coals will require a greater mix of wood

to create and maintain an adequate draft.

Oval Coal Grate Installation

To install the optional coal grate package, remove the wood

grate through the ash pan door and replace with the coal grate.

Remove the key plate over the firebox and slide the coal liners

#1470 in the front and #1475 in the back of the firebox.Replace

the key plate, lift handle and lids. Then proceed with firedoor

damper installation.

Oval and Sweetheart Firedoor Damper

(Coal burning only, see illustration on next column)

The firedoor damper comes with each coal kit and must be

installed. Remove the nickel firedoor frame from the firedoor.

Loosen the three screws that hold the cover plate over the

damper holes. Replace the cover plate with the coal damper,

lettered side out. Tighten screws just enough to hold the

damper plate on but also allow it to slide freely back and forth.

Lock screws in position with a nut on each screw thread.

A wood “break in” fire should be done before attempting

to burn coal (see page 13).

The minimum draft required to maintain an oven temperature

of 350 ºf is around .04" on a water column. For drafts under .04"

on a water column, closing the oven draft damper more than

half way, will cause back puffing.

During the recharge phase of a new bank, a draft of .08" should

be maintained for at least 10-15 minutes or until a substantial

bed of red embers is built up.

We recommend burning anthracite coal, which is relatively

clean to handle, burns evenly with a low flame, has a low

sulphur content and produces relatively little smoke.

Use a “chess nut” or “nut” size of coal, which is 1 3/16 to 1 5/

8 in diameter. However, other coal, such as bitumious, can be

burned, but is inferior to anthracite.

To Start a Coal Fire:

1. Use paper and dry wood kindling to start the fire.

2. Add small, compact pieces of hardwood when the kindling

is burning hot. Keep the primary damper controls fully

open to establish a hot fire quickly.

17

Page 21

The ash door also may be opened during start-up to

accelerate the initial burn.

3. When a substantial bed of red embers is built up, start

adding coal – small amounts at a time. Keep the draft control

open.

4. Continue adding small amounts of coal until there is a

solid bed of

time. Allow sufficient time between each small loading (at

least five to ten minutes), so that each loading has time

to ignite thoroughly before the next load is put in.

When a substantial bed of burning coals has been

established, fill the stove to the highest possible level, no

higher than the bottom of the firedoor – be careful not to

overload!

A deep bed of coal will always burn more satisfactorily

than a shallow bed.

5. When most of the wood is burned and the coal is

completely ignited (usually five to ten minutes or less

after filling the stove), the draft control should be turned

down to the proper operating level.

(If the ash door has been opened, it

prevent overfiring, which can severely damage the stove.)

burning

coal. Do not add too much at one

must

be closed to

NOTE: When burning coal, the firedoor damper must be

kept open. The secondary air is required to aid in

burning off coal gases. The coal damper is not required

when burning wood and should be kept closed when

burning wood.

Coal grates are not to be used in upper (summer)

position. Do NOT fill firebox with coal higher than the

bottom of the firedoor opening.

Disposal of Ashes (wood and coal)

Do not remove the ash pan when the stove is hot. Carry

the ash pan with one hand on the handle in the upright position

and the other on the front handle to balance the pan.

Improper disposal of ashes is the most common cause of

wood stove related fires.

Empty the ash pan before ashes build up over the top.

Recharging the Fire

If the fire is burning hot and there is a deep bed of coals, add

coal a hand full at a time.

Allow enough time between each addition for the combustion

process to start. As the bank becomes larger, the amount of

coal added at a time can be increased.

If the coal bed is under 5" before a recharge is started, it may

be necessary to add kindling wood to increase the combustion

level so that more coal can be added.

1. Coal never should be added unless there is a reasonably

hot fire. The coal bed should be bright and vigorous.

2. If the fire is burning hot and there is a deep bed of coals,

full loads of coal can be added at any time. However, if

there is not a deep bed of coals, it is best to add small

amounts of coal at first.

Use Caution:

• don’t carry hot ashes through the

house;

• even though the stove may be cool,

the ashes in the pan may still be hot;

• never place the ash pan on a

combustible floor;

• never leave the ashes near

combustible material or

combustible liquids;

• always disposeof ashes in a closed

metal container with a tight fitting

lid—if an unexpected gust of wind

fan the the ashes, a fire could result.

18

Page 22

Using the Oven and Cooking Surface

Stove top cooking

The cast iron top provides an excellent large cooking area for

griddling, frying, basting and simmering.

Some users report griddling directly on the cooking surface,

although this is not recommended, as it usually creates quite

a mess. A cast iron cooking vessel with a flat bottom is

recommended. As you inspect your new oval, you may find the

edges of your keyplate sitting slightly above the cooking

surface. This is caused by the stiff new gasket under the

keyplate. As the gasket compresses over time, the keyplate

will drop to a position even with the rest of the cooktop.

To allow for normal settling, we have purposely created a slight

upward warp at the middle of your oval

keyplate. As the keyplate heats and

cools it will eventually settle to a flat

position. The time period for settling

will be different for each stove

depending on usage. Please allow a

full season of use as a minimum.

When getting used to cooking on the

stove top remember that the surface is

cast iron and like cast iron cookware,

once heated retains the heat for a long

time.

Successful stove top and oven cooking

will not result from trying to fire the

stove up immediately but by having a

heated stove and ‘banking’ the fire to

retain the temperature required.

The temperatures established on both the cooking surface and

in the oven are determined by three primary things:

1. The amount of draft the chimney has. As the bell dampers

are opened more air gets in the firebox and is drawn

through the stove and chimney, resulting in a faster, hotter

fire.

2. The position of the oven damper. With the oven damper

closed, the heat is channeled under the entire cooking

surface (heating it up) and around the oven (heating it up).

When the oven damper is open, the heat will be routed

directly up the chimney.

Damper Closed

Under Oven E

xhaust

The left hand side of the cookstove top

will be the hottest as the fire burns

directly beneath it. The surface will get

cooler the further you go to the right.

The oven damper can be used to help

control the heat on the cooking surface.

To have the entire cooking surface

warm, the damper will need to be in the closed position. This

funnels the heat under the entire cooking surface, therefore

heating it (see figure 10).

Figure 10

3. How much wood/coal is in the firebox and what stage of

the combustion process it is at.

19

Page 23

Oven Cooking

Learning how to most effectively control the oven temperature

takes some time and experience. As a general rule, the stove

should be at the charcoal stage of the combustion process

before the oven is ready for cooking.

Important Note: The oven door thermometer registers the

temperature at the door only. For accurate oven temperatures,

refer to this interior oven thermometer.

Rotate base for use as

a hanger.

cooking from a cold start.

7. Always load a new charge of wood to a glowing hot coal

bed about 4” deep. Waiting too long to load a new charge

means that the dampers will have to opened, to get the

new charge burning well. This results in extreme

temperature swings and will make cooking difficult. Your

objective is to maintain the coal bed and a constant heat.

8. Occasional ‘tending’ or stirring may be required. Keeping

these principals in mind and with a little experience, you

will find cooking to be easy and trouble-free.

9. Woodstove cooking methods are as diverse as their

owners—there is no right or wrong way, only, in time, your

way.

Ovens vary in temperature from top to bottom and side to side.

The only accurate check on oven temperature is an oven

thermometer placed alonside food being roasted or baked.

See page 26 if your door thermometer needs adjustment.

1. You will find that once the stove has about 4” of red hot

coals in the firebox, it will have reached ‘equilibrium’.

2. Equilibrium means that the entire stove and chimney

system is heated and running at a fairly constant

temperature.

3. At this point, you may load a new charge of wood following

the procedure for ‘reloading’. Allow the stove to regain its

momentum—igniting the new charge. Keep bell dampers

dampered down to allow a steady slow flame.

4. The oven temperature can be controlled by moving the

oven damper slide. In the closed position, the oven will get

warmer, and cooler when you open it.

10. Remember by opening the oven damper there is less

resistance on the flue and a hotter faster fire will result. The

cooking surface directly over the firebox will typically get

hotter in this configuration.

11. Always open the oven damper before opening any firebox

doors or lifting the key plate. Wait momentarily before

opening the doors to allow the smoke in the oven chamber

to be drawn up the chimney to avoid backpuffing.

Maintain your stove properly. The benefits in superior

performance and safety are well worth the time.

Water Reservoir

This section pertains to the water holding tank on the side of

the stove and applies only to reservoir models .

5. Remember the effects of the changes in the damper

position are not instantaneous on the oven temperature.

6. Ideally your stove will perform best if it is left running

constantly, keeping the entire system warm. Depending

on your wood and chimney conditions it would typically

take three or four charges of cord wood to establish a good

base for oven cooking, meaning 1 1/2 to 2 hours before

The reservoir has a porcelain enamel top and lid. The lid lifts

open and will rest at an open position, or can be removed

entirely.

20

Page 24

The tank in the reservoir is made of copper, for easy cleaning

and the seams are soldered with lead free solder.The tank has

a 5 gallon capacity with a spigot mounted on the side, for easy

access to the water.

Water must be added manually, the tank is not connected to

your plumbing.

To route heat around the reservoir, open the reservoir damper

(turn handle to the right). Vertical position of the handle means

that the reservoir damper is closed, and no heat is passing

under the copper tank. Horizontal position of the handle means

that the reservoir damper is open and more heat is circulating

under the copper tank.

The water in the reservoir can be heated from luke warm to

boiling hot depending on how you are burning the stove, the

position of the water reservoir and the oven dampers.

The reservoir damper is ‘downstream’ from the oven damper

which means that if the oven damper is open, the flu gases are

not circulating around the oven and therefore not past the

reservoir either, so the water in the reservoir will not get as hot

as when the oven damper closed.

The cold water will tend to absorb the heat that you are

attempting to use to heat the chimney to start the stove. Close

the reservoir damper during this period.

The same theory applies when heating the oven. If the water

reservoir damper is open, the valuable heat you are trying to

heat the oven with will be absorbed by the mass of cool water

in the reservoir. Close the water reservoir damper during this

period.

Woodstove heat is very dry and the water in the reservoir will

add much needed moisture to your home. The warm water can

be used for bathing, dishes or other clean up needs.

Always ensure water is in the tank when the stove is in

operation.

If the reservoir runs dry the soldering may melt

away from the joints, resulting in leakage.

Caution: The water reservoir is a naturally cooler area of your

stove, so creosote and fly ash will tend to build up on and

around that side of the stove. Because of the potential for

blockage and or ignition of the creosote,

frequent inspection

of this area is very critical and clean out must be performed

more often.

Helpful Hint: When lighting your stove from cold or when the

stove is relatively cool remember the water in the reservoir will

be at the same temperature.

Copper water tank

Reservoir damper arm

vertical-closed (shown)

horizontal-open

Reservoir Lid

Water tap

21

Page 25

Chimneys and Draft

T rouble Shooting

The performance of your woodburning system depends more

on the chimney than on any other single component. The

chimney ‘drives’ the system by producing the draft that

draws in combustion air and exhausts smoke and gases to

outdoors. Give as much attention to the chimney as you do

to the appliance that it serves.

How Chimneys Work

It is well known that hot air rises. This principle is at work

inside chimneys and is the key to understanding how

chimneys function.

The hot exhaust gases from the appliance are lighter than the

outside air. This buoyancy causes the gases to rise in the

chimney. As they rise, a slight negative pressure is created

inside the appliance. Air rushes into the appliance through

any available openings to balance this negative pressure.

The force caused by the rising gases is called draft. Draft is

created by the difference in temperature between the gases

in the chimney and the outside air. Greater temperature

differences produce stronger draft.

Factors That Affect Draft

There are several factors that interfere with draft and most

woodburning systems have one or more of these features. It

is usually a combination of conditions that make a chimney

fail to function properly.

Here are the main factors that influence draft:

poorly. Ideally, the liner should have the same internal area as

the flue collar of the appliance.

Chimney Height

Taller chimneys tend to produce stronger draft. We recommend

that the top of the chimney should be at least 36" (900 mm)

higher than the highest point at which it contacts the roof and

24" (600 mm) higher than any roofline or obstacle within a

horizontal distance of ten feet (three metres). These figures

produce the minimum allowable chimney height. Chimneys

higher than this are often needed for performance reasons. A

chimney serving a cookstove located on the main floor of a

single-storey house or cottage may not be tall enough to

perform well, even though the minimum heights in the building

code have been followed. A good rule of thumb to use states

that the top of the chimney should be at least 16 feet (4.9

metres) higher than the floor on which the cookstove sits.

Negative Pressure in the House

The draft produced by chimneys is a weak force that can be

influenced by pressures inside the house. A woodburning

cookstove acts as an exhaust ventilator by removing air for

combustion from the house. A typical house may have several

other exhausts, clothes dryer, gas or oil furnace, fireplace, or

central vacuum system. When one or more of these other

exhaust ventilators is running, it may compete for the same air

that the woodburning appliance needs for combustion. This

competition for air supply can make a fire slow to kindle or

cause a stove to smoke when its door is opened. Chimneys

are often blamed for this type of performance.

Cold Chimney Liner

An uninsulated chimney that runs up the outside of a house

and is exposed on three sides is chilled by outside cold. This

means that the flue gases give up their heat rapidly to the

liner. As they cool, they lose their buoyancy and draft is

reduced. Insulation between the liner and the chimney shell

can help to reduce the heat loss, but a chimney that is

enclosed within the house is preferable.

Large Liner

Chimney liners that are much larger than the flue collar of the

appliance allow flue gases to move too slowly. This slow

movement gives the gases more time to cool and lose their

buoyancy. Oversized liners are the reason that many fireplace

inserts vented through fireplace chimneys tend to perform

Stack Effect in houses

In winter, the air in houses is much warmer and, therefore,

more buoyant than the outside air. The warm air in the house

tends to rise, creating slightly negative pressure in the

basement and slightly positive pressure at higher levels. This

negative pressure in the basement can compete with chimney

draft to a stove or furnace located there.

CHECKING AN EXISTING CHIMNEY

Before an existing chimney is used to vent your new cookstove,

a thorough inspection should be done to determine its suitability.

The inspection should be performed by an experienced

professional because of the many factors that must be

considered. A reputable chimney sweep or retailer can give

you good advice on the suitability of an existing chimney.

22

Page 26

Masonry chimneys should be checked for deterioration

including damaged bricks, crumbling and missing mortar,

cracks in the drip cap at the top of the chimney, and loose

flashings at the roof line. The liner should be checked for

cracks and mis-alignment, and its size should be 6".

An existing factory-built metal chimney needs a careful

inspection. Your new cookstove should be connected only to

factory-built chimneys approved to ULC Standard S629 in

Canada and UL 103HT in the U.S. Possible problems with an

older metal chimney can include a warped or buckled liner

caused by the heat of a chimney fire, corrosion of the outer

shell, a loose flashing, and a lack of proper support. Any

discolouration of the metal shell near a joint indicates that the

insulation has settled. A damaged metal chimney should be

replaced with a new approved chimney which will be safer and

will perform better.

Safety Practices

What To Do If You Have a Chimney Fire

Here is a checklist to follow when installing or checking a flue

pipe assembly. It is based on the requirements found in the

Canadian Standards Association’s Installation Code for Solid

Fuel Burning Appliances and Equipment (Standard B365).

1) Single-wall flue pipe assemblies must not exceed

3 metres (10' ) in overall length.

2) The assembly should be as short and direct as possible.

3) A single-wall flue pipe assembly must have no more than

two 90 degree elbows; use 45 degree elbow, wherever

possible.

4) Do not use galvanized flue pipe because the coating can

vaporize at high temperatures, emitting poisonous gases

and leaving the pipe thin and weak.

5) Flue pipes for woodburning appliances need to be thicker

than those used for other fire-burning appliances; 24

gauge for 150 mm (6") .

6) Joints between pipes should overlap at least 30mm

(1 1/4").

7) Each joint should be secured with three sheet metal

screws.

1) Close all the combustion air dampers on the appliance.

2)

Call the fire department immediately.

3) Be prepared to get everyone out of the house in case the

fire spreads

4) Go outside and check to see that hot ashes do not ignite

shingles.

5) Watch anything near the chimney that could catch fire and

burn.

6) After the fire has run its course and the chimney has

cooled,

have the chimney thoroughly inspected to

determine if it sustained any damage.

7) Resolve to inspect and clean the chimney more often to

prevent another chimney fire.

Flue Pipes

Flue pipes carry the exhaust gases from the appliance flue

collar to the chimney. The flue pipe assembly is an extremely

important part of a woodburning systems and should be

carefully planned and installed.

8) The assembly should be constructed to allow for expansion.

Elbows in an assembly allow it to expand; straight flue

pipe assemblies should have one section left unscrewed

and secured with an inspection wrap clamped around the

joint.

9) The pipes should slope up towards the chimney at least

20 mm/metre (1/4 in/ft).

10) One end of the flue pipe assembly must be securely

fastened to the flue collar of the appliance and the other

end fastened to the chimney.

11) There must be provision for the cleaning and inspection of

the pipes by removal of the pipe. The removal of the pipes

should not require moving the appliance.

12) The crimped ends of the pipes should point towards the

appliance so that condensation drains to the appliance

and does not leak out.

13) A flue pipe must never pass through a combustible floor or

ceiling, or through a concealed attic, roof space, or closet.

Flue pipe assemblies should be stable and secure. To check

the stability of a flue pipe assembly, grasp it at its mid-point

and give it a good shake. If it is properly constructed, it will have

little or no movement.

23

Page 27

Maintenance

Oven Flue Passage

As heat, smoke and gases travel around the oven, fly ash and often creosote are left behind. The frequency of cleaning of the

oven flue will depend on your use, burning habits and the wood you burn. If a ‘fly ash’ which is very fine and light in colour, is

what is left behind in the oven flue chamber, it is a good indication you are burning your stove well.

If a sticky black ash is what you observe, you are burning wood which is too wet or the stove is not burning hot enough as a

result of a poor chimney. Your dealer can help you correct this.

Follow this procedure when cleaning around the flue passage:

1) Clean the oven flue chamber by removing the top lids and scraping the ash to the sides.

2) Then scrape the sides so the ash falls to the bottom.

3) All the ash may then be scraped into a metal container through the ash cleanout door with the ash scraper.

4) Follow the procedure for ash disposal when cleaning the oven flue chamber, and chimney connector system.

Creosote buildup in the oven flue chamber can lead to rusting, a bad odour, and chimney fires. Check for creosote regularly and

clean it out upon discovery.Caution: The water reservoir is a naturally cooler area of your stove, so creosote and fly ash will

tend to build up on and around that side of the stove. Because of the potential for blockage and or ignition of the creosote,

inspection of this area is very critical and clean out must be performed more often.

Creosote is a tell tale condition of burning wet wood, a practice which should immediately be discontinued.

frequent

remove keyplate and lids to scrape

upper flue passage

remove lids to gain access

to flue passage

oven damper track should be cleaned periodically

oven damper

scrape down the sides of flue passage

to the bottom flue passage

Caution: Models with water reservoir

frequent inspection of this area is

very critical and clean out must

be performed more often.

scrape ash in the bottom flu passage and remove through

the clean out door opening

ash clean out door-lift slightly to remove

24

Page 28

Flue Boot Inspection

Remove the cover plate on the flue boot, located at the back

of the range. Inspect for soot or creosote buildup, scrape and

clean as much as possible, and remove debris through the

clean out door with the ash scraper.

Oven Damper

The oven damper may stick from time to time because of a

buildup of ashes or creosote in the damper track. To free up the

damper, scrape out the buildup or spray with a creosote

remover, let sit for about 1/2 hour and clean out debris.

(Caution: Never use any remover or cleaner on a hot stove.)

Chimney Maintenance

Chimney serving woodburning appliances must be checked

regularly for creosote build-up. The rate of build-up depends

cookstove and chimney characteristics, the type of fuel used,

and on how the system is operated.

Until you are familiar with the rate of creosote build-up in the

system, check it often - every couple of weeks. Well-designed

woodburning systems tend to have a slower rate of build-up in

the spring and fall when heat demand, and therefore firing rate,

is lower.

the condition of the chimney. Referrals are the best way to

select a chimney sweep. Check with your neighbours to see

if they are satisfied with the sweeping services they have

received.

Cooking Surface

After the initial firing, your stove top will start to turn colour. This

is normal and eventually the stove top will have a uniform blue

finish.

The stove tops and lids are highly polished untreated cast iron.

To minimize the potential for permanent stains, always

maintain the top with cooking oil. During periods of

heavy use, a light coating is sufficient. When you will not

be using the stove for a week or more, give the top a

heavier coat and re-apply as needed. Always remove

food, water or rust stains as quickly as possible. If such

stains are left unattended, a permanent mark can result.

To help remove stains, use a medium/fine aluminum

oxide abrasive sanding block, available at most

hardware stores, or a metal cleaner such as Flitz, in

conjunction with fine (000) steel wool. Do not be afraid

to use elbow grease.

Creosote may be in the form of dry, flaky deposits clinging to