Page 1

1260 E. VanDeinse, Greenville, MI 48838

Phone (800) 223-3900 Fax (616) 754-9690

The Oval and Sweetheart

cookstoves are listed t o

CS A St andard B3 66.2M

ULC Standard S-627 & UL

1482 by Warnock Hersey

Professional Services Ltd.

NOTE: Warnock Hersey NBR

is 219.

INSTALLATION

AND OPERATING

INSTRUCTIONS

SAVE THESE

INSTRUCTIONS

FOR FUTURE USE

Note: Please read these instructions

thoroughly before attempting to install

this unit.

Oval

With Towel Rack

#1902

Oval

With Reservoir

#1903

SAFETY NOTICE: IF THIS STOVE IS NOT PROPERLY

INSTALLED, A HOUSE FIRE MAY RESULT. FOR YOUR

SAFETY, FOLLOW THE INSTALLATION DIRECTIONS.

CONTACT LOCAL BUILDING OR FIRE OFFICIALS

AB OUT RESTRICTIONS AND IN STALLATION

INSPECTION REQUIREMENTS IN YOUR AREA.

IMPORTANT: Check around oven chamber on a weekly

basis for soot and creosote accumulation. Clean the

chamber thoroughly from the top, side and bottom with

the rake (part #1425) provided. Burn the stove hot daily

to reduce creosote accumulation. Use only dry wood

aged for one year. Failure to do so could result in

OVERFIRING CAUTION:

will void warranty on this appliance.

See page 31 for details.

The temperature registered by the oven door

thermometer may not necessarily correspond with

the reading taken with the thermometer inside the

oven. For accurate oven temperatures, refer to the

interior oven thermometer.

SweetHeart

SweetHeart

With Towel Rack

#2602

© 2010 AGA Marvel

SweetHeart

With Reservoir

#2603

W O O D C O O K S T O V E S

ATTENTION INSTALLER: Leave this manual with appliance

Manual #1705 110512

1

Page 2

— FOR YOUR SAFETY—

DO NOT STORE OR USE GASOLINE OR OTHER

FLAMMABLE VAPOURS OR LIQUIDS IN THE

VICINITY OF THIS STOVE.

Stove Location - If the range must be located

near a window, avoid using long curtains which

could blow over the stove top, causing a re

hazard.

Any openings in the wall behind the stove or

in the oor under the range must be sealed.

Do not set unopened glass or metal containers

in the oven, or in the warming cabinet, or on

the cooking surface.

Grease accumulation is the cause of many

cooking res. Clean the oven compartment

regularly.

Do not attempt to extinguish a grease re

with water. Cover grease res with a pot lid

or baking soda.

Avoid the use of aerosol containers near the

range.

Never place pans, cookie sheets or roasters

directly on the oven bottom but use the oven

rack in its lowest position.

2

Page 3

Oval & Sweetheart Models

CONSUMER WARRANTY

ENTIRE PRODUCT – LIMITED ONE YEAR WARRANTY

AGA Marvel warrants the replacement or repair of all parts of this Wood Cookstove which prove to be defective in

material or workmanship, with the exception of the painted or porcelain enamel nish or plated surfaces, for one year

from the date of original purchase. Such parts will be repaired or replaced at the option of Heartland without charge,

subject to the terms and conditions set out below.

The warranty period against defects in the painted or porcelain enamel nish, or plated surfaces, is 90 days from date

of original purchase. The warranty does not include normal wear of rebox parts or gaskets.

TERMS AND CONDITIONS

1 This warranty applies only for single family domestic use when the Wood Cookstove has been properly in-

stalled according to the instructions supplied by Heartland and is connected to an adequate and proper chimney and chimney connections. Damage due to faulty installation, improper usage and care, abuse, accident,

re, ood, acts of God, commercial, business or rental use, and alteration, or the removal or defacing of the

serial plate, cancels all obligations of this warranty. Service during this warranty must be performed by a factory Authorized Service Person.

2 Warranty applies to product only in the country in which it was purchased.

3 Heartland is not liable for any claims or damages resulting from any failure of the Wood Cookstove or from

service delays beyond their reasonable control.

4 To obtain warranty service, the original purchaser must present the original Bill of Sale, Model and Serial

number. Components repaired or replaced are warranted through the remainder of the original warranty period

only.

5 The warranty does not cover expense involved in making this appliance readily accessible for servicing.

6 This warranty gives you specic legal rights. Additional warranty rights may be provided by law in some areas.

7 Adjustments such as calibrations, levelling, tightening of fasteners, or chimney and chimney connections

normally associated with original installation are the responsibility of the dealer or installer and not that of the

Company.

8 Overring of this appliance will void warranty.

9. If the product is installed outside the normal service area, any cost of transportation expenses (tolls, ferry trip

charges, or mileage expenses, etc.) involved in the repair of the product, or the replacement of a defective part,

shall be borne by the customer (owner).

TO ENSURE PROMPT WARRANTY SERVICE, SEND IN YOUR WARRANTY CARD WITHIN 10 DAYS OF PURCHASE.

If further help is needed concerning this warranty, contact:

Customer Service

AGA Marvel

1260 E. VanDeinse

Greenville MI 48838

PLACE OF PURCHASE______________________________

DATE OF PURCHASE_______________________________

SERIAL NUMBER__________________________________

Phone (800) 223-3900

Fax (616)754-9690

MODEL NUMBER__________________________________

3

Page 4

Installation Instructions ............................ 5

Unpacking.................................................................... 5

Assembly .................................................................... 6

Cabinet Installation ...................................................... 7

Installation .......................................................... 9

Clearances ..................................................................9

Rough In for Oval Diagram ........................................ 10

Rough In for SweetHeart Diagram .............................11

Chart of Clearances................................................... 12

Clearance Reductions ............................................... 13

Floor Protection ......................................................... 13

Chimneys and Draft ................................... 13

Recommended Chimney Clearances ........................ 13

Chimney Connection Requirements .......................... 14

Optional Accessories ...................... 14

Heat Shield Kit ........................................................... 14

Fresh Air Kit ............................................................... 15

Water Jacket .............................................................. 15

Fuel ................................................... 16

Woodburning ............................................................. 16

Using the Oven and Cooking

Surface .............................................

Stove Top Cooking .................................................... 22

Oven Cooking ............................................................ 23

Water Reservoir ......................................................... 24

22

Trouble Shooting ............................. 25

Chimneys and Draft ................................................... 25

How Chimneys Work ................................................. 25

Factors that Affect Draft ............................................. 25

Checking an Existing Chimney .................................. 25

Safety Practices......................................................... 26

What To Do If You Have a Chimney Fire ................ 26

Maintenance ..................................... 27

Oven Flue Passage ................................................... 27

Flue Boot Inspection .................................................. 28

Oven Damper ............................................................ 28

Chimney Maintenance ............................................... 28

Cooking Surface ........................................................ 28

Nickel Trim ................................................................. 28

Porcelain.................................................................... 28

Door Gaskets............................................................. 29

Firebox....................................................................... 29

Oven Thermometer Adjustment ................................. 29

Formula for Equivalent Hearth Extension .................. 29

Understanding Combustion ........... 17

Getting Acquainted .................................................... 17

Starting the Stove ...................................................... 17

Break In Fire .............................................................. 18

Your First Fire ............................................................ 18

Summer Burning........................................................ 19

Coal Burning ....................................20

Sweetheart Coal Grate .............................................. 20

Oval Coal Grate ......................................................... 20

Oval and Sweetheart Fire Door Damper ................... 20

Starting Up a Coal Fire .............................................. 20

Recharging the Fire ................................................... 21

Disposal of Ashes (wood and coal) ........................... 21

Use Caution ............................................................... 21

Terms of Reference and

Function ...........................................

30

Over Firing-Caution! ........................31

Oval Parts Diagram ......................... 33

SweetHeart Parts Diagram............. 34

Replacement Parts Diagram .......... 35

Cookstove Parts List ....................... 36

4

Page 5

— Welcome —

our Heartland Cookstove is a time proven design of

Y

North American heritage. Our cookstoves were rst

made in 1906 and many originals are still in use today.

With proper operation and maintenance, your Heartland

cookstove will give your family generations of warmth, delightful

meals and untold pleasures.

Take the opportunity to read this manual thoroughly to become

familiar with all the installation, operation and maintenance

procedures for your stove. You will nd it offers valuable insight

into how a cookstove functions.

Save These Instructions

Keep the manual available for future reference. The manual

is an important part of your stove. If your stove is sold, deliver

the manual to the new owner along with the stove.

The quality of the installation (especially the chimney connector

and chimney), and the quality of the fuel being burned will

affect the performance of your stove, but the most important

factor is the way you operate the stove. With the help of this

manual, you will learn how to effectively heat and cook with

your stove. Be sure to read it entirely, including the terms of

reference and function.

In addition, your own experience will help you to learn the

role that the chimney plays in stove performance. The Oval &

Sweetheart have been tested and are listed by Underwriters’

Laboratories of Canada and Underwriters’ Laboratories in the

U.S. The test standards are ULC S-627 and UL 1482.

The Oval & Sweetheart are listed for burning wood or coal

(with the optional coal grate). Do not burn other fuels. The

Oval & Sweetheart are not listed for installation in mobile

homes. Do not install the stove in mobile homes.

Safety Notice: If your stove is not properly installed and

maintained, a house re may result. For your safety, follow

all installation, operation and maintenance directions.

Contact local building ofcials about restrictions and

installation inspection requirements in your area.

(“Makeshift” compromises in the installation may result

in hazardous conditions, including a house re.)

Installation Instructions

Preparing the installation site before moving the stove into it

will save you from having to move the stove more than once.

See page 9 for information on “Clearances” and “Floor

Protection” page 13.

Unpacking

The stove is packaged in two main boxes. The smaller box

contains the warming cabinet. The main stove body is strapped

to the skid. Smaller component parts are packaged as follows:

Flu Body - (Oval only)

Flu body for the oval is fastened to the skid and must be

assembled to the stove. Assembly instructions are on the

following pages.

In the rebox:(Sweetheart and Oval)

1 ash scraper

The ash pan contains the following parts:(Sweetheart and Oval)

1 poker

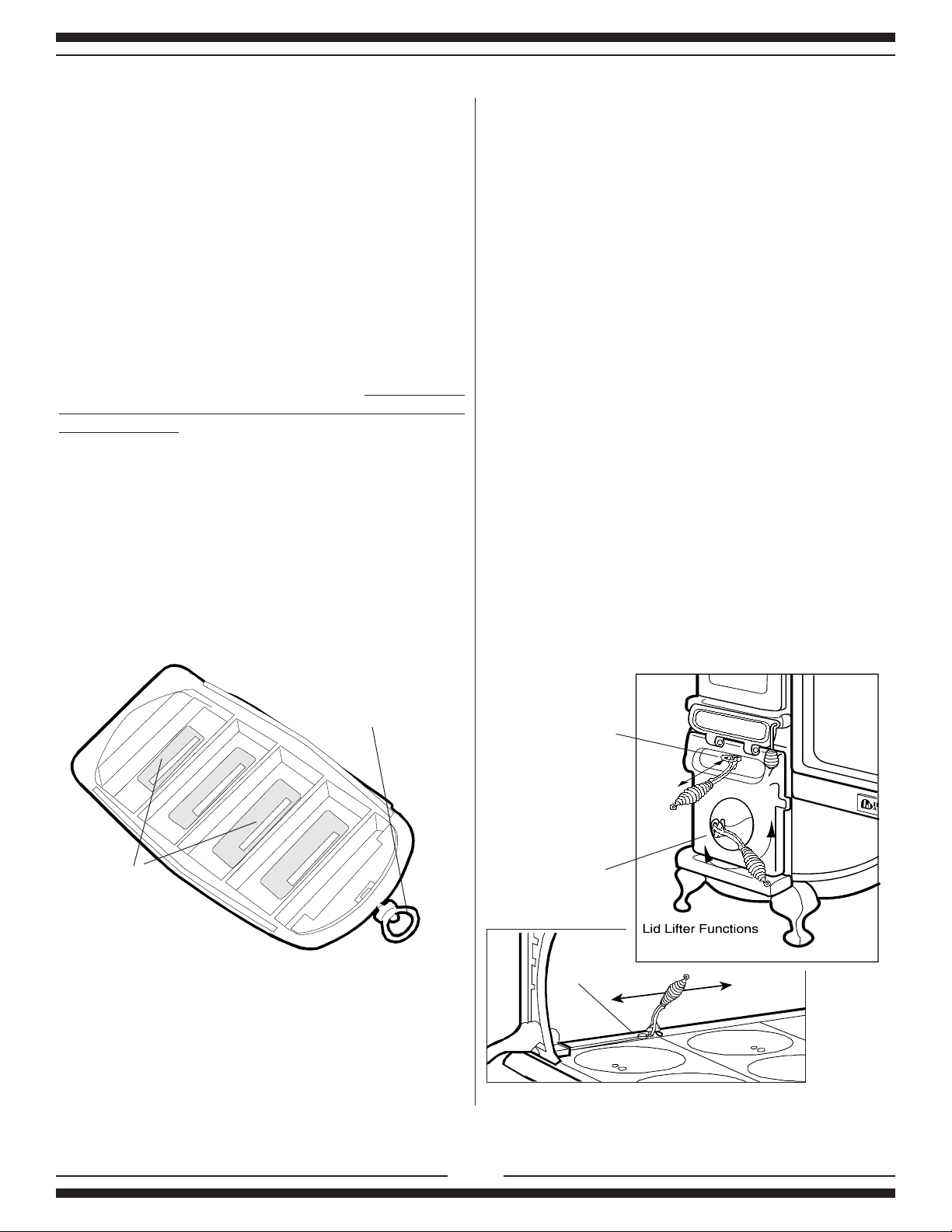

1 tool rack

1 lid lifter

1 cooking surface lift handle w/screw and nut

3 bell damper handles w/rod

3 bell dampers

1 Heartland oven cleanout door

1 bag of hardware

1 interior oven thermometer

Reservoir models only:(Sweetheart and Oval)

1 package containing:

water tap (tap thread wrapped with teon tape)

tap trim washer

Spend some time becoming familiar with the various parts by

operating them before you burn your stove.

After a few weeks of operating the stove re-read this manual.

Many of the procedures will become clearer after you have

had some experience with the stove.

5

Page 6

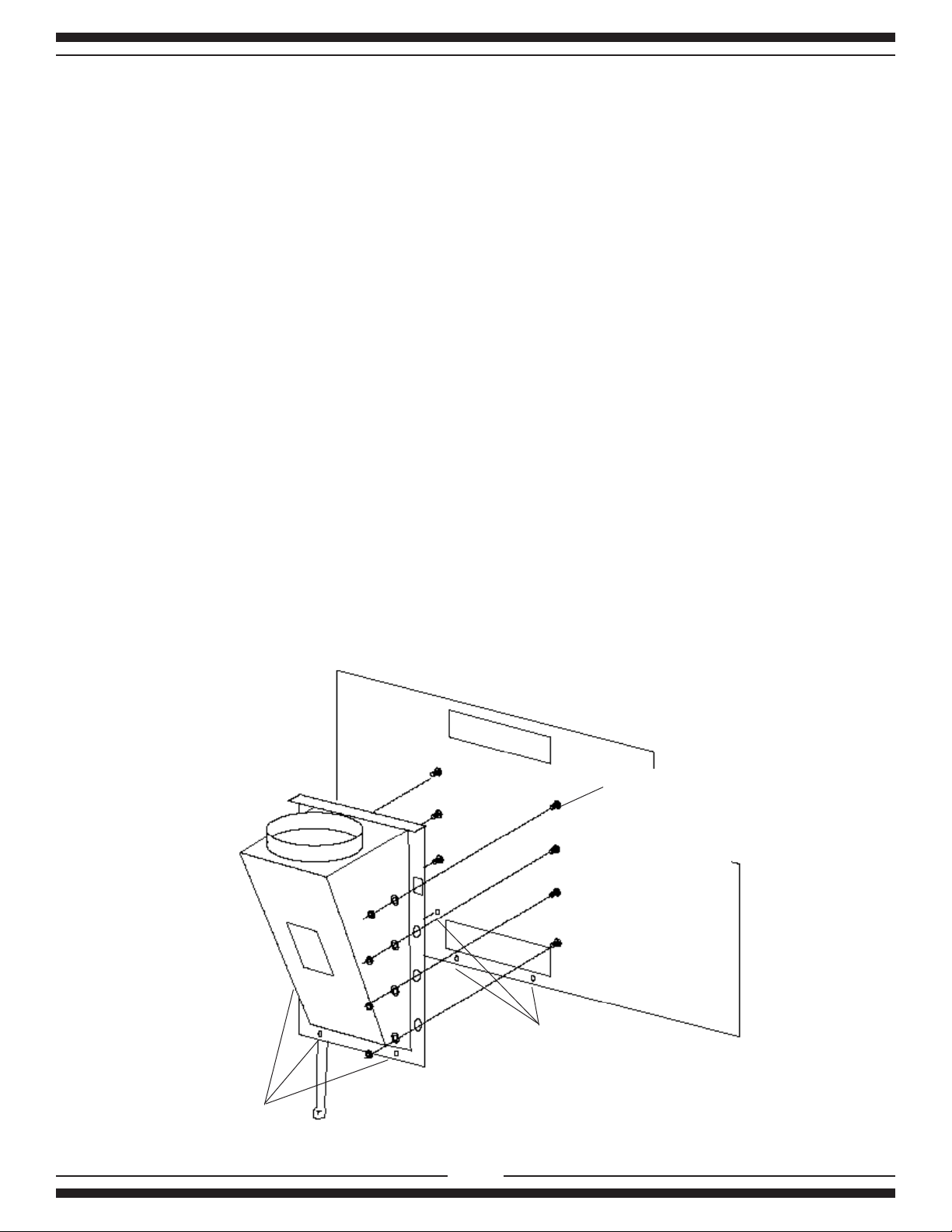

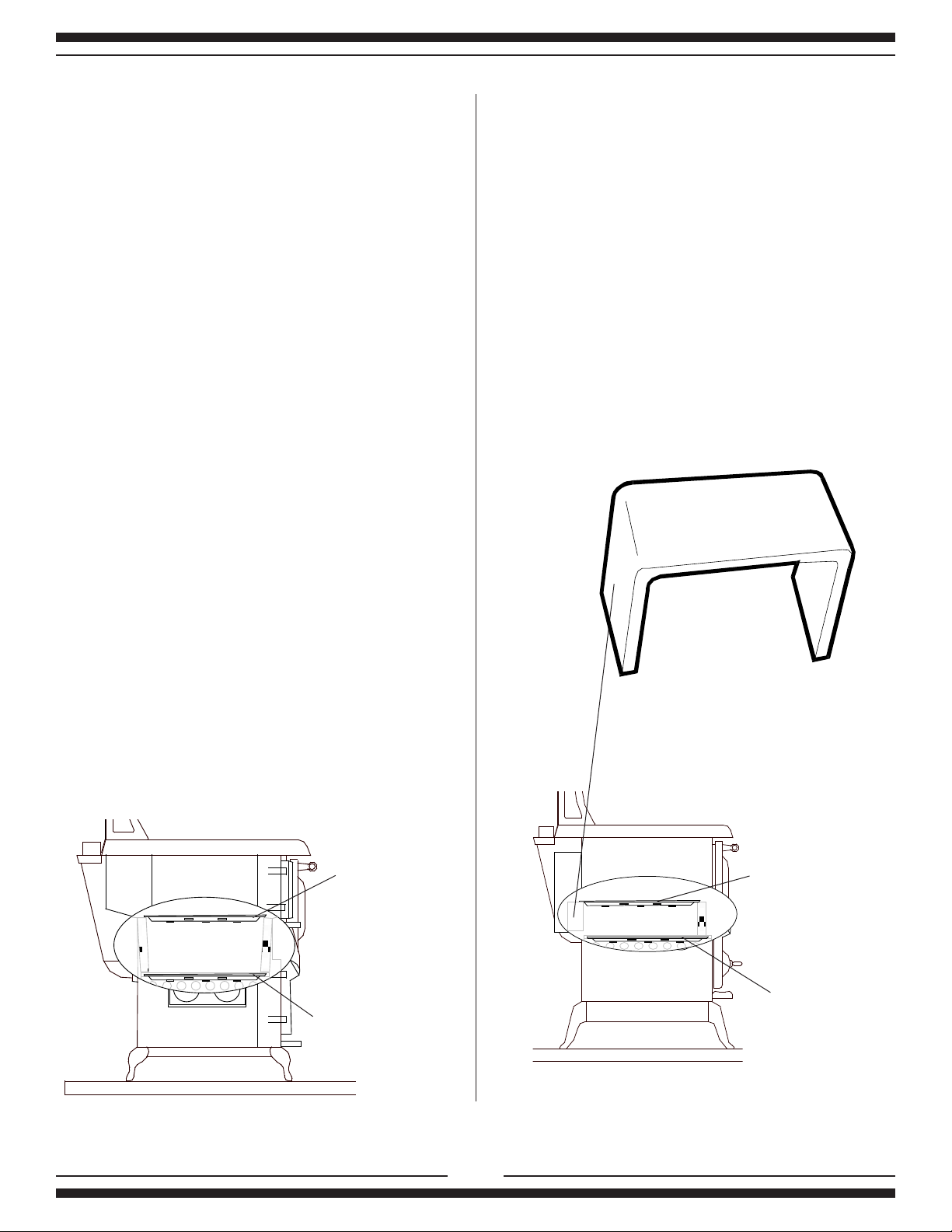

Assembly

Oval / Sweetheart

Before removing the oval stove from the skid, the u body

must rst be attached to the stove back. Follow the instructions

below.

1) Unscrew the u body from the skid and set aside.

2) Unscrew 3 sheet metal screws (2 along the bottom of the

oven at the bottom and 1 along left side - see illustration)

3) Remove the rst level only of nuts and washers from the

screws extending out the back of the stove (7pcs)

4) Place u body on back of stove so that the nuts on the

screws t inside the holes in the ange on each side of the

u body.

5) While holding the u body in place, attach the u to the

stove by putting on a washer and nut on each screw, hand

tight only.

6) Install the sheet metal screws along the bottom and side

of the u body, and tighten up.(3 places)

Warning: The stove is very heavy. Since the legs may dig

into a soft oor, do not locate the stove, or even set it to rest,

on a surface that could be imprinted.

We recommend that 3 or 4 persons be available to assist

in the lifting of the stove, and that gloves should be worn to

protect hands from cuts.

1) First, remove the screws that are holding the u body to

the skid and remove the u body.

2) Next, unscrew the two lag bolts which are securing the

front and back of the rebox base. Lighten the stove

by removing the keyplate and lids.

3) Look under the oven and note that the stove must be

lifted up, over the wooden brace located there.

4) With 2 persons on the heavier, rebox side (left), and one

person on the other side, lift the stove up, off of the skid

and onto its new location.

5) If possible, have a fourth person remove the skid while

the others lift.

7) Tighten up the remaining nuts (7 places)

Back of stove

Do not remove these nuts

from the screws, nuts t

through holes in u body.

Only remove the first

level of nuts and washers

Remove 3 sheet

metal screws before

installing u body

Reinstall 3 sheet metal

screws after installing

u body

6

Page 7

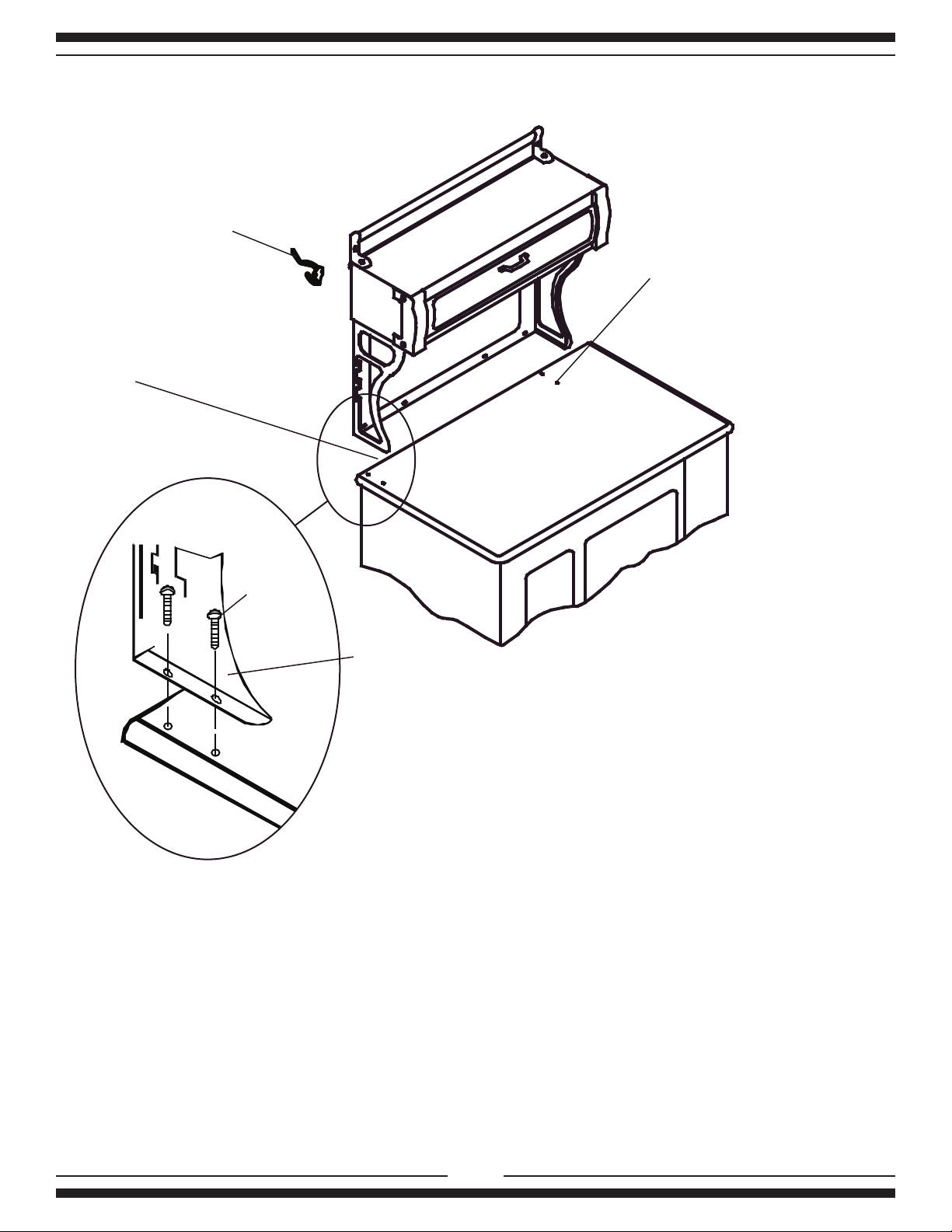

Cabinet Assembly to Stove Top

Tool Rack- fasten

to rear of cabinet

using screws and

nuts provided.

Remove screws and washers

from top back flange of top, 2

places on Sweetheart and 3

on Oval

Remove machine screws

from the top (2 each side).

Machine

Screw

Cabinet Bracket

Remember when working with the cabinet it is top heavy. Use your hand to support it during installation. Remove the cabinet

assembly from the top of the stove. Lift the cabinet assembly by the bracket area that is circled and set on the floor or a table top.

Unwrap the cabinet assembly.

Remove the washers and screws from the rear edge of the stove top. (2 places on sweetheart or 3 places on Oval. Also remove the

4 machine screws from the top of the stove top.

With a helper lift the cabinet assembly (by the circled bracket area and supporting the top of the cabinet) and place the cabinet into

position on the stove top (see diagram above). Line up the bracket holes with the 4 holes in the stove top while a helper supports

the cabinet.

Secure the cabinet to the stove top with the 4 machine screws and the 2 or 3 screws and washers. To prevent chipping do not

overtighten screws or use power tools.

7

Page 8

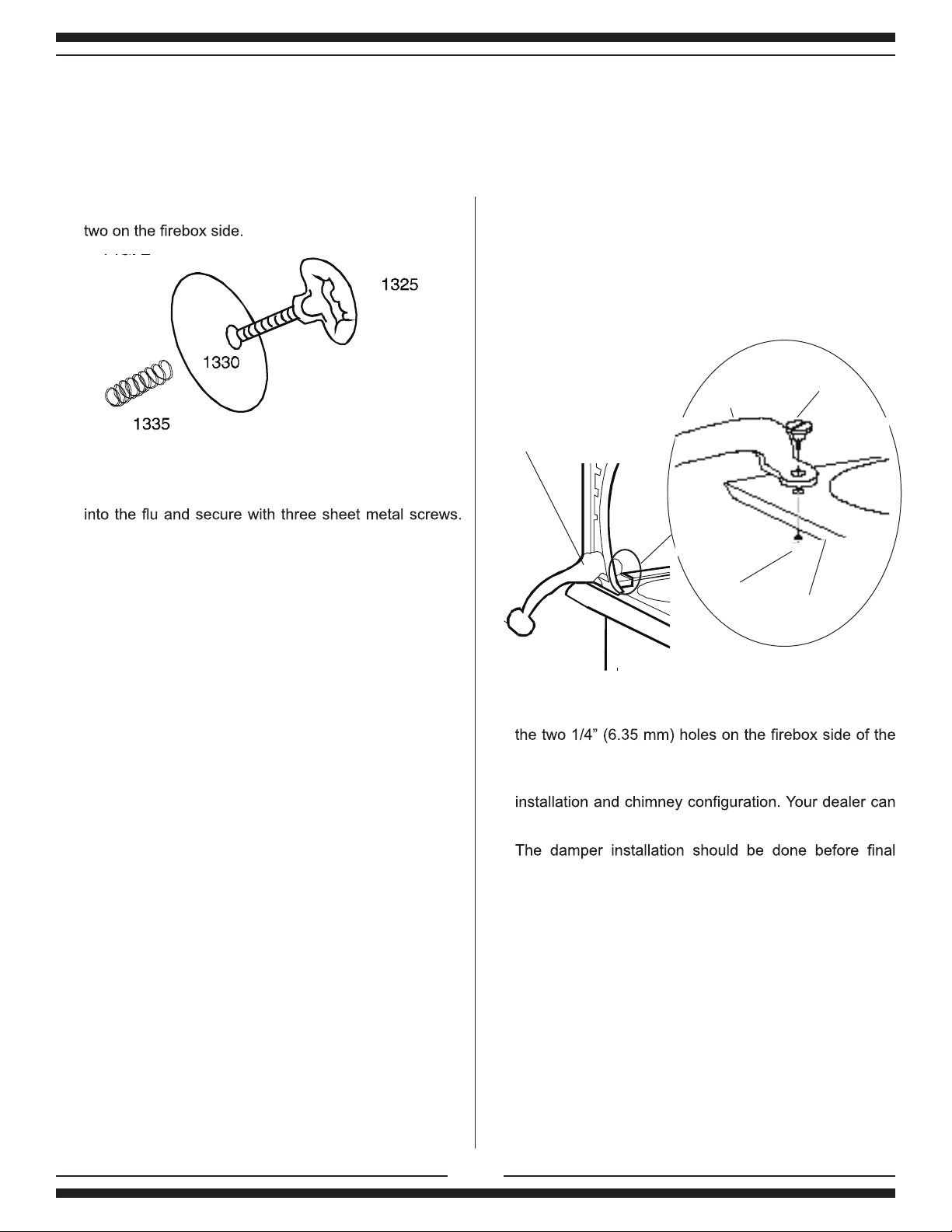

Oval and SweetHeart:

1. Assemble the bell dampers (Fig. 2) and thread into the

three locations, one at the front in the ash pan door, and

Figure 2

Bell Damper

2. Insert a piece of 6” (15 cm) diameter black smoke pipe

Once the cabinet has been assembled and installed, follow

these few remaining steps:

1. Insert the lift handle( #1361) through the bracket and bolt

it through the hole in the cooking surface with the screw

and locknut.

The handle should be able to pivot freely from this point.

Tighten the nut securely, so it can’t work loose under

normal use.

Lift handle

#1361 lift handle installed

on cooking surface

(See page 14, “Stovepipe Chimney Connection

Requirements”)

lockwasher

Nut

Cooking surface

2. The tool holder (#1440) is used to hang the

lid lifter, poker and scraper. To mount the holder, locate

warming cabinet back. Fasten with the bolts supplied.

3. A pipe damper installation is optional depending on your

supply you with a damper.

assembly of the chimney.

a) Open the front cabinet door.

b) Mark the spot for drilling in the back of the pipe by pushing

the sharp end of the damper rod into the back wall of the

pipe before drilling.

c) Drill a 1/4” (6.35 mm) hole in the middle of the smoke pipe

through the centre of the hole in the back of the cabinet.

d) Follow the instructions that came with the damper and

install the damper inside the cabinet with the handle of

the damper also inside the cabinet.

e) Make sure the damper disc rotates freely inside the pipe.

8

Page 9

Installation

Be sure to read the sections on clearances, oor protection,

and chimneys before actively starting the installation. Contact

local building or re ofcials about restrictions and

installation in your area.

Clearances

A woodburning stove radiates heat in all directions. Heat

directed toward living areas in front of the stove is usually

very welcome.

However, heat radiating in other directions will not be as

welcome if it results in overheating nearby walls, ceilings

and oors.

An important part of planning a safe installation is to be sure

that combustible material located near your stove does not

overheat.

Clearance is the distance between your stove and stovepipe

and nearby walls, ceilings, and oors.

If there is adequate clearance, then the nearby surfaces will

not overheat.

The clearance distance should be empty except for noncombustible heat shields.

Air owing between the stove and stovepipe and nearby

surfaces carries away heat.

Do not ll the empty space with any insulating material.

Be aware that as wood is exposed to continuous heat it dries

out, eventually lowering the temperature at which it will start

on re.

Maintain the clearances outlined in this manual, particularly

with respect to nearby combustible surfaces.

Your Heartland cookstove has been tested for safe operation

providing that these guidelines are followed.

Clearances must be maintained to all

combustible material. These include

doors, trim, furniture, drapes, newspapers

and clothes.

An optional heat shield kit is available for our woodstoves

for reduced clearances. See page 14 on “Heat Shield Kit”

(Continued on page 10)

9

Page 10

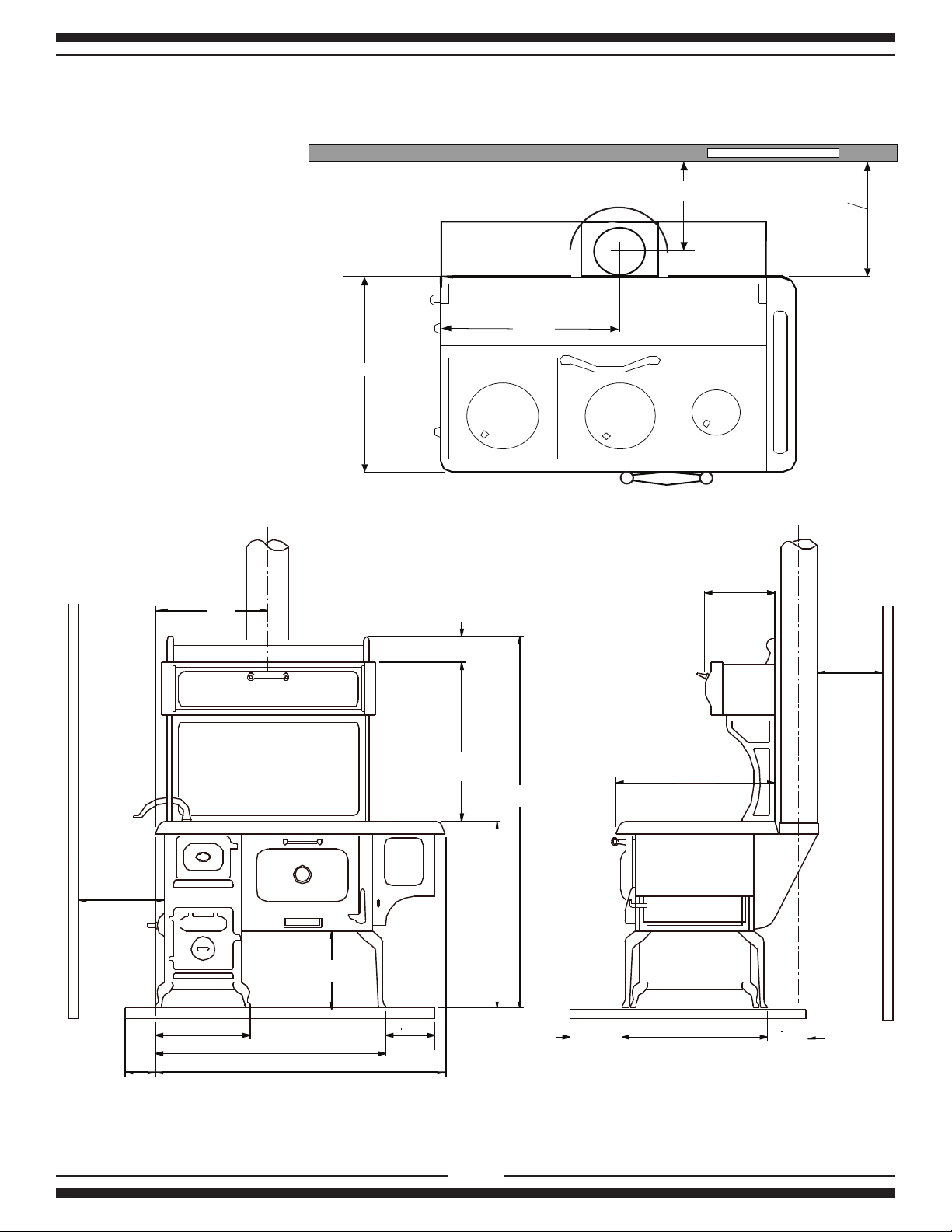

Oval Rough in and Dimension Diagrams

27 1/8 (69 cm)

8 5/8" (22 cm) with heat shield kit (from wall to center of pipe)

23" (59 cm) with out heat shield (from wall to center of pipe)

12 ½ " (32 cm) with

heat shield

27" (69 cm) with out

heat shield to the

back of the stove

top

Combustible Wall

Oval Coo kstove

(Top View)

20 1/4"

(51.44 cm)

3 3/4

(9.5)

26 1/4

(66.6)

62

(157.5)

32

(81.3)

14 1/2

(36.83)

35 1/2

(90.2)

8

(20.3)

47 3/24 (120.7)

8

(20.3)

18

(45.7)

22 1/2

(57.15)

27 1/8

(69.0)

Note: Dimensions in brackets are metric (cm)

HearthHearth

Hearth

8

(20.3)

C omb ust ib le Wa l l

24

(61.0)

C om bu st ib ie W a ll

11 13/16

(30.0)

20

(50)

13 1/4

(33.7)

20 1/4

(51.5)

These drawings are

for reference only,

showing approximate

dimensions for rough

in purposes. Make

sure that no oor or

ceiling supports will

be cut due to chimney

installation.

10

Page 11

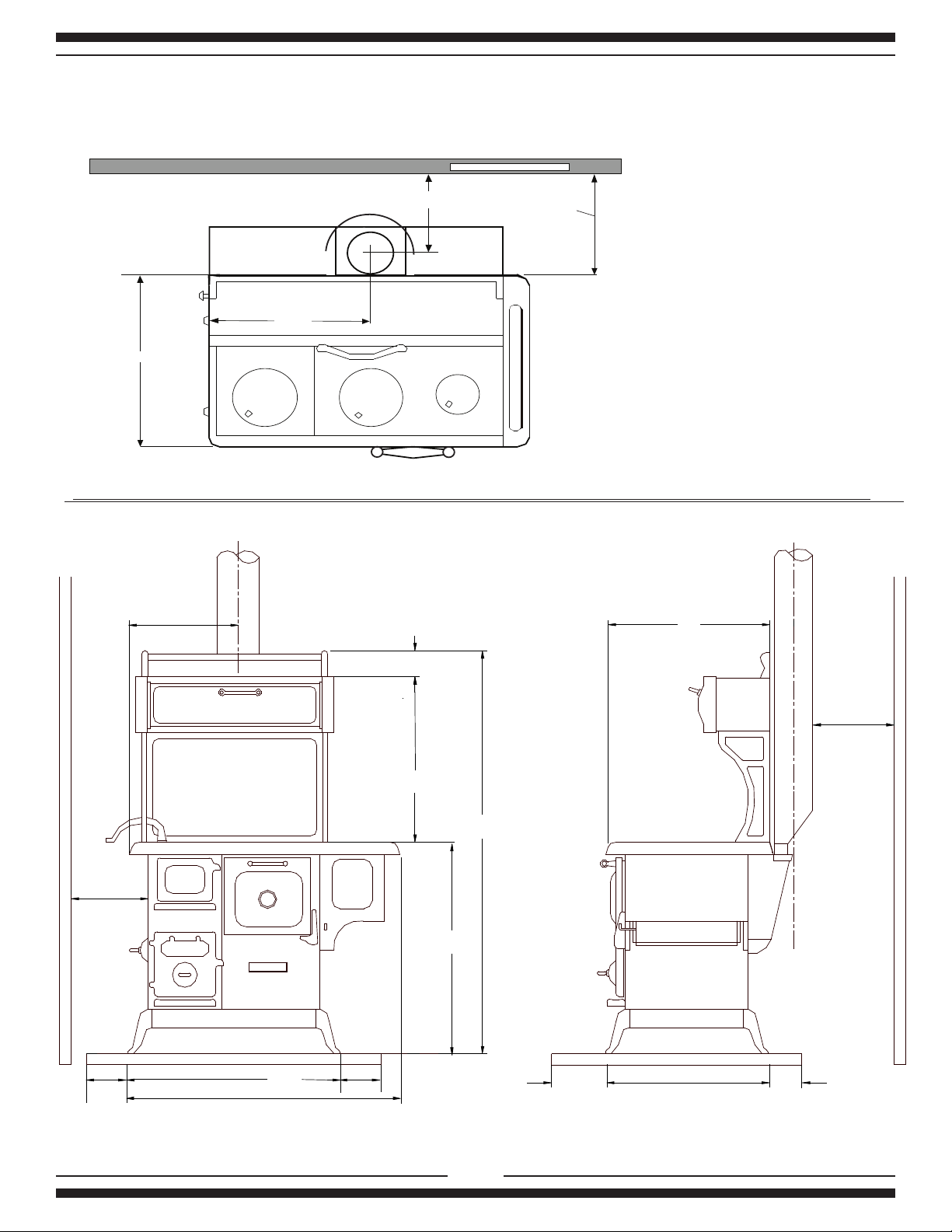

SweetHeart Rough in and Dimension Diagrams

22 1/2 (57.2)

9 1/2" (24 cm) with heat shield kit (from wall to center of pipe)

23" (59 cm) with out heat shield (from wall to center of pipe)

13" (33 cm) with

heat shield

27" (69 cm) with

out heat shield

to the back

of the stove top

Combustible Wall

(Top View)

18 1/4"

(46.4)

4

(10.0)

26.1/4

(66.5)

62

(157.5)

31 7/8

(81.0)

8

(20.3)

30

(76.0)

8

(20.3)

42 1/2

Hearth

24

(61.0)

Combustible Wall

18

(45.7)

21

(53.0)

Hearth

23 5/8

(60.0)

20

(51)

Combustible Wall

Note: dimensions in brackets are metric

8

(20.3)

18 1/4

(46.0)

These drawings are for

reference only, showing

approximate dimensions

for rough in purposes.

Make sure that no oor

or ceiling supports will

be cut due to chimney

installation.

11

Page 12

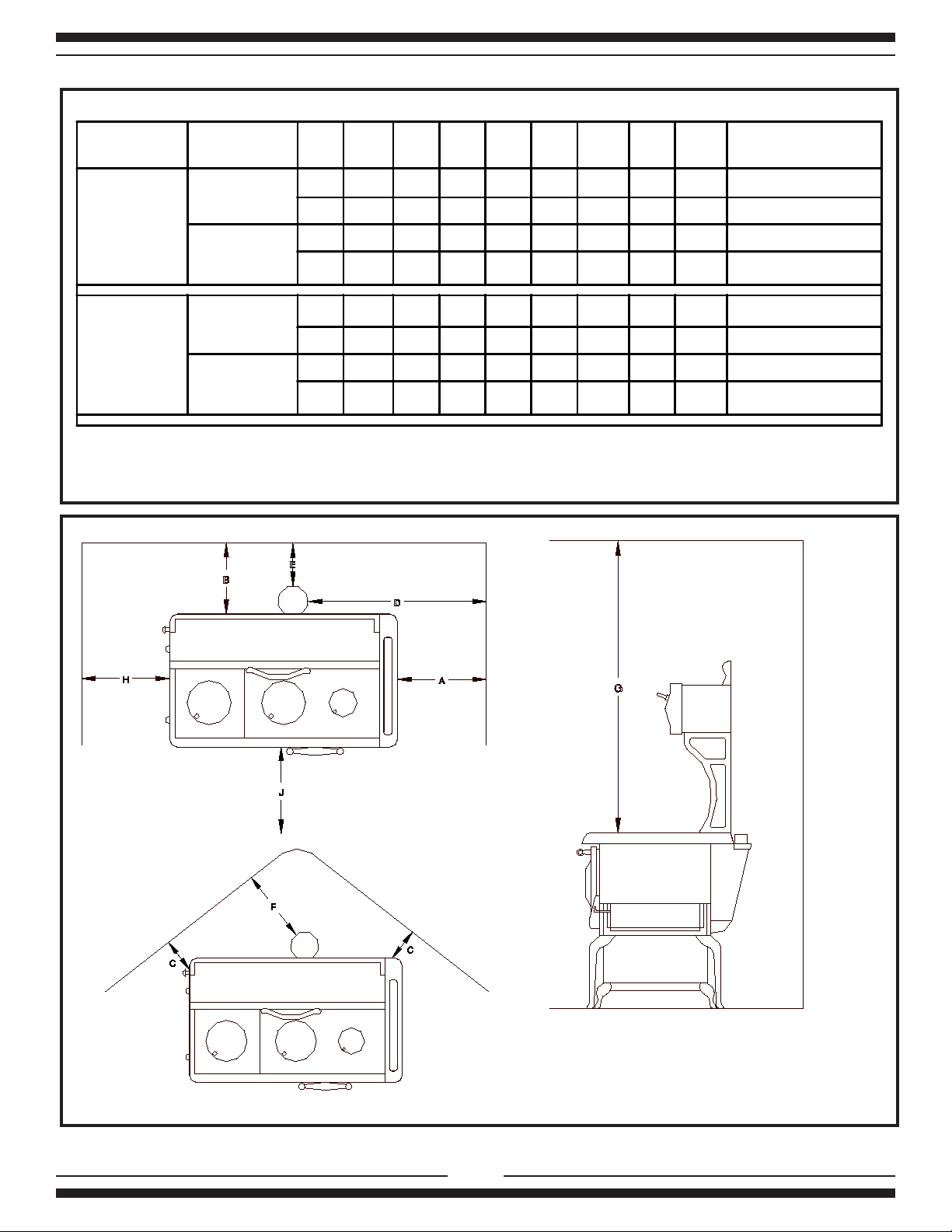

Chart of Clearances

Status Model A B C D E F G H J Measure

NO HEAT

SHIELD

SweetHeart

25 69 66 66 50 58 132 61 121 Centimeters

10 27 26 26 20 23 52 24 48 Inches

Oval

25 68 66 91 50 86 132 61 121 Centimeters

10 27 26 36 20 34 52 24 48 Inches

WITH HEAT

SHIELD

SweetHeart

25 8 66 61 5 31 132 61 121 Centimeters

10 3 26 24 2 12½ 52 24 48 Inches

Oval

25 8 66 91 5 44 132 61 121 Centimeters

10 3 26 36 2 17½ 52 24 48 Inches

*Note: A chimney approved to ULC standard S629 in Canada or UL 103HT in the U.S. must be used to connect the smokepipe at

the top of the cabinet to maintain the 2” (5.08cm) clearance to combustibles. The approved chimney must extend 1” (2.54cm) below

the heatshield. PLEASE NOTE: That these are factory recommended clearances only, and are subject to local, provincial or state

building and re codes. These clearances may change without notice

When a heat shield is installed dimensions B, D, E and F are taken from

the heat shield.

Dimensions A, C, G, and H remain the same with or with-out a heat

shield.

Dimensions A and C are taken from the reservoir on reservoir models.

When two or more clearances to combustible walls contradict each other,

the clearance with the greater numerical value must be maintained.

12

Page 13

Clearance Reductions

There are many alternate decorative methods to reduce

clearances to combustible materials. See your dealer,

standards are being met with these alternatives. In Canada,

refer to the Installation Code for Solid Fuel Appliances

and Equipment. CAN3-B365-M84. In the U.S., refer to the

National Fire Protection Association Standard 211,

Floor Protection

Chimneys and Draft

The chimney is the most important element of successful

stove operation. (See also page 26 “Flue Pipes”)

Performance of your woodburning system depends more

on the chimney than on any other single component.

The chimney ‘drives’ the system by producing the draft that

draws in combustion air and exhausts smoke and gases to

outdoors.

When installing a new woodburning system or upgrading an

existing one, give as much attention to the chimney as you

do to the appliance that it serves.

The Oval and Sweetheart can be installed in a masonry

chimney which is in compliance with the appropriate standard

-

or a prefabricated chimney approved to ULC Standard S629

in Canada and UL 103HT in the U.S.

Pad must extend 21” (534mm) in front of the stove in

Canada and 18” (458mm) in front of stove in U.S.

Pad must extend 8” (203mm) to the sides and back of the

stove.

Pad must extend fully to the wall if using side and back

clearances less than these dimensions.

materials: 1/2” (13mm) thick minimum with thermal

btu/h/F/in).

To determine thickness of equivalent material required

use formula (“K” x 0.5) / 0.43 = thickness required (“K”

material).

Follow the chimney manufacturer’s directions for installation.

We recommend that prior to installing your stove into a

masonry chimney, you have the chimney inspected by a

be used without the installation of a liner.

The chimney and installation will have to be inspected by

your local building inspector.

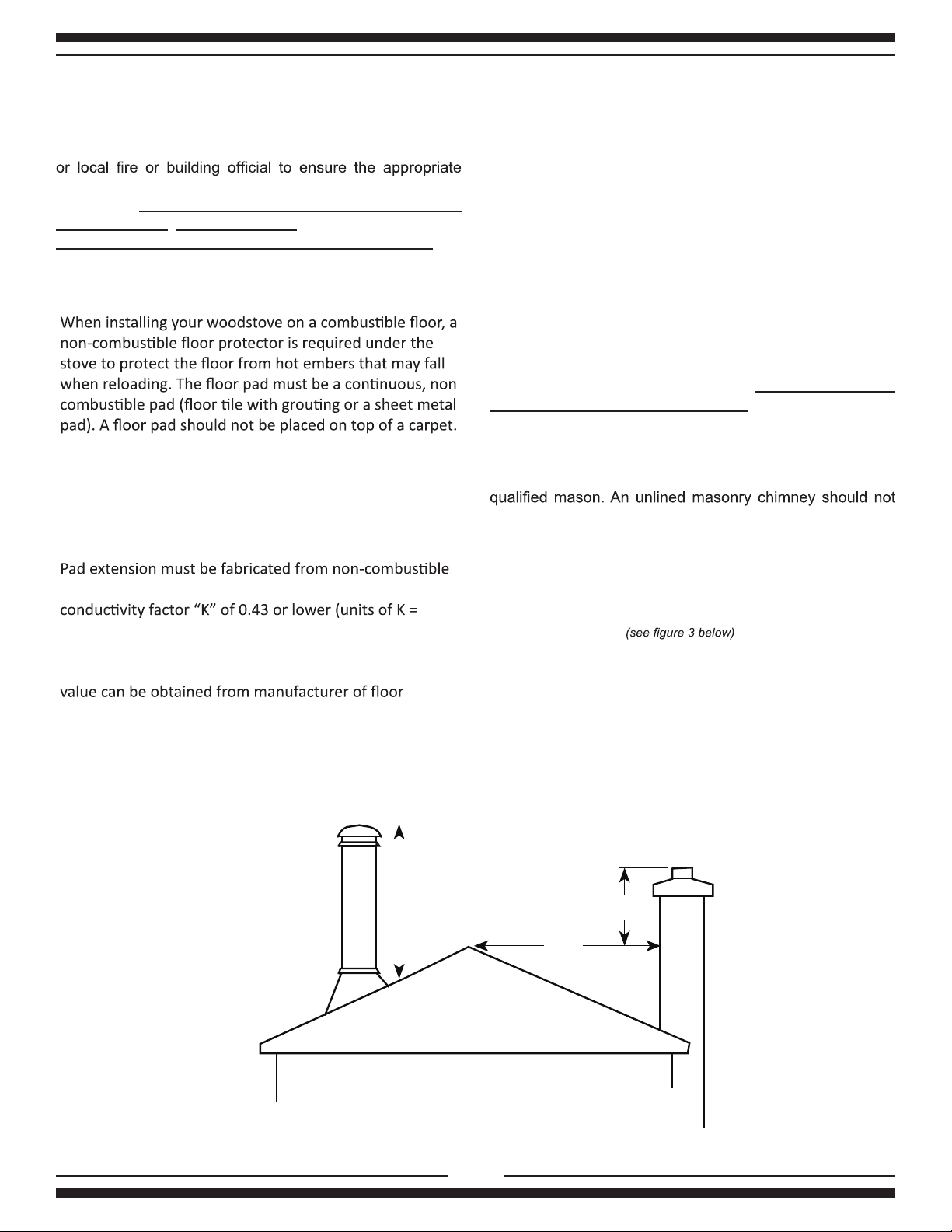

Recommended Chimney Clearances

The chimney must:

• extend at least 14 ft. (4.27m) above the collar of the

stove;

• extend at least 3 ft. (92 cm) above the point where it

passes through the roof;

• be at least 2 ft. above anything within a 10 ft. (3.048m)

radius of the top of the pipe.

Good draft in a cold chimney should be between 0.01” and

0.15” “water column” (your dealer may be able to check

this for you).

36" (900 mm)

24" (600mm)

10'

(3 metres)

Illustration showing minimum heights required,

depending on the location of chimney

Figure 3

13

Page 14

Stovepipe Chimney

Connection Requirements

1. The stovepipe chimney connector should be made of 24

gauge or thicker sheet metal and should be 6” in (15.24

cm) diameter.

2. The last section of the chimney connector starting from

the stove should be screwed to the ue collar of the stove.

Individual sections of the chimney connector must be

screwed together with at least three sheet metal screws.

The last section should be securely attached to the

chimney. Be sure there are no “weak links” in the system.

3. The crimped ends of pipe sections should point downward

toward the stove so that any soot or creosote that falls

from the inside of the pipe will be funnelled into a clean

out or fall into the stove.

4. The chimney connector should be at least the height of

the warming cabinet before a 90 degree turn is installed,

with no more than two 90 degree turns.

5. A horizontal run of stovepipe should be no longer than 4

ft (1.22m). A vertical run of stovepipe to a prefabricated

metal chimney should be no longer than 8 ft (2.44m).

Optional Accessories

Accessories may be obtained from your dealer or call us

direct at 800-223-3900. Our ofce hours are from 8:30 a.m.

to 5:00 p.m. est

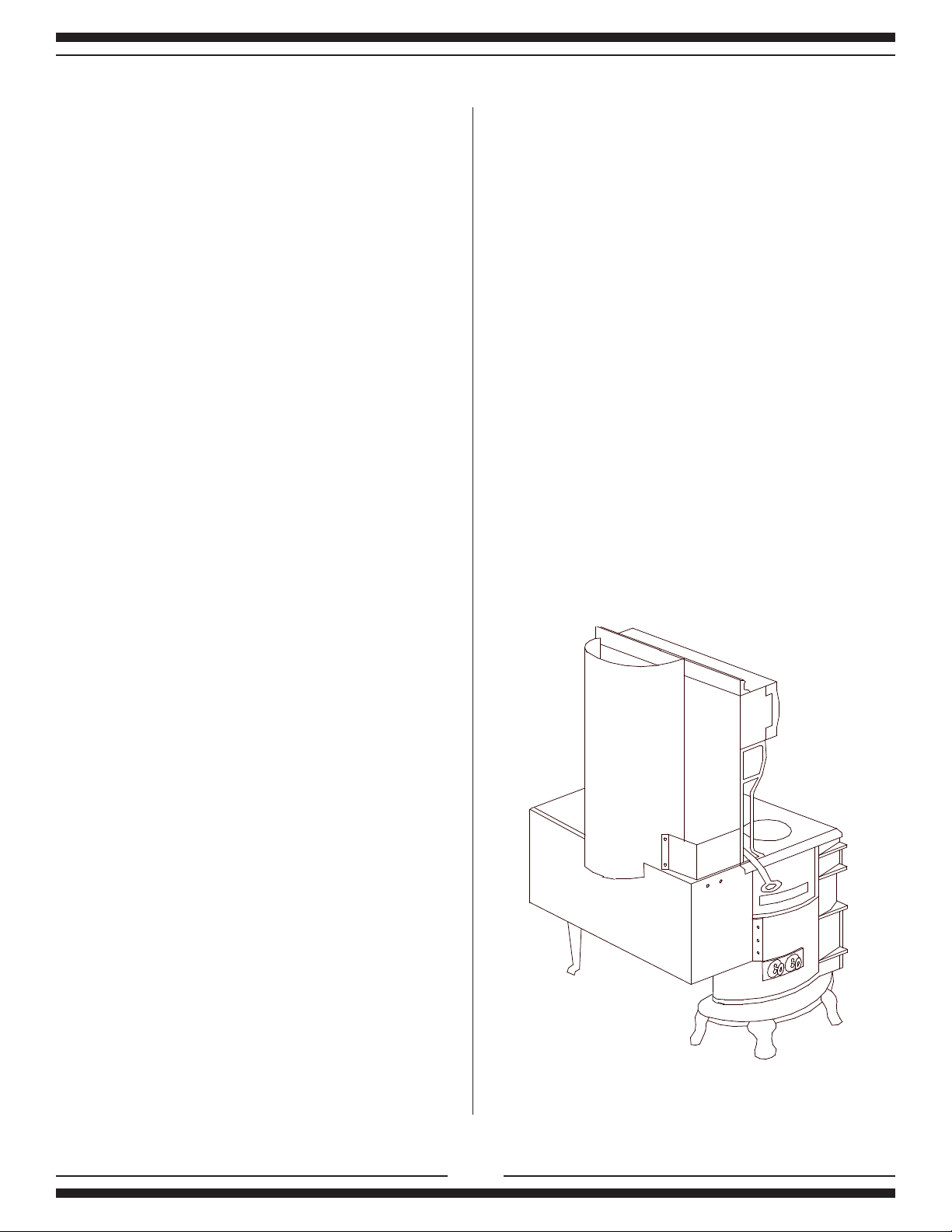

Heat Shield Kit

A space saving heat shield kit enables you to install your

cookstove as close as 2” (51mm) to a combustible wall!

Installation is Easy

The heat shield kit is available for both Oval and Sweetheart

cookstoves and mounts directly on the rear of the stove. The

main section of the shield covers the rebox and oven of the

cookstove, while the upper section covers the u pipe to the

height of the warming cabinet.(See illustration, Fig. 4.)

An installation and operating manual is packed with every Oval

and Sweetheart heat shield kit. Extra copies may be obtained

from your dealer or by contacting AGA Marvel.

6. Do not pass the stovepipe chimney connector through

a combustible wall if it can be avoided. If this cannot

be avoided, follow the recommended in CSA B365 in

Canada and NFPA 211 in the U.S., recommendation on

Wall Pass-Throughs.

7. Do not use single wall smokepipe as an outside chimney.

8. Never pass stovepipe chimney connector through a

combustible ceiling.

9. The whole chimney connector should be exposed and

accessible for inspection and cleaning.

10. Galvanized stovepipe should not be used. When exposed

to the temperatures reached by smoke and exhaust gases,

galvanized pipe may release toxic fumes.

11. Horizontal runs of chimney connector should slope upward

1/4” (6.35 mm) per foot going from the stove toward the

chimney.

12. During a chimney re, the chimney connector may vibrate

violently. The connector must be securely attached to

the pipe and chimney, and individual sections must be

securely attached together.

13. This stove is not to be connected to an air distribution

duct.

Figure 4

Illustration of Oval with

heat shield kit

14

Page 15

Fresh Air Kit

®

A fresh air kit enables you to use outside air, instead of room

air to fuel the re. Using an outside source for combustion air

has its advantages. If your home is tight and well insulated,

then the re in the stove may be “starved” of combustible air,

it will be difcult maintaining a re, and you may have back

drafting problems.

During the heating season, cold air, (which is more dense than

warm air), will cause the re to burn a little hotter, resulting

in more BTU’s from your wood, and less creosote build-up.

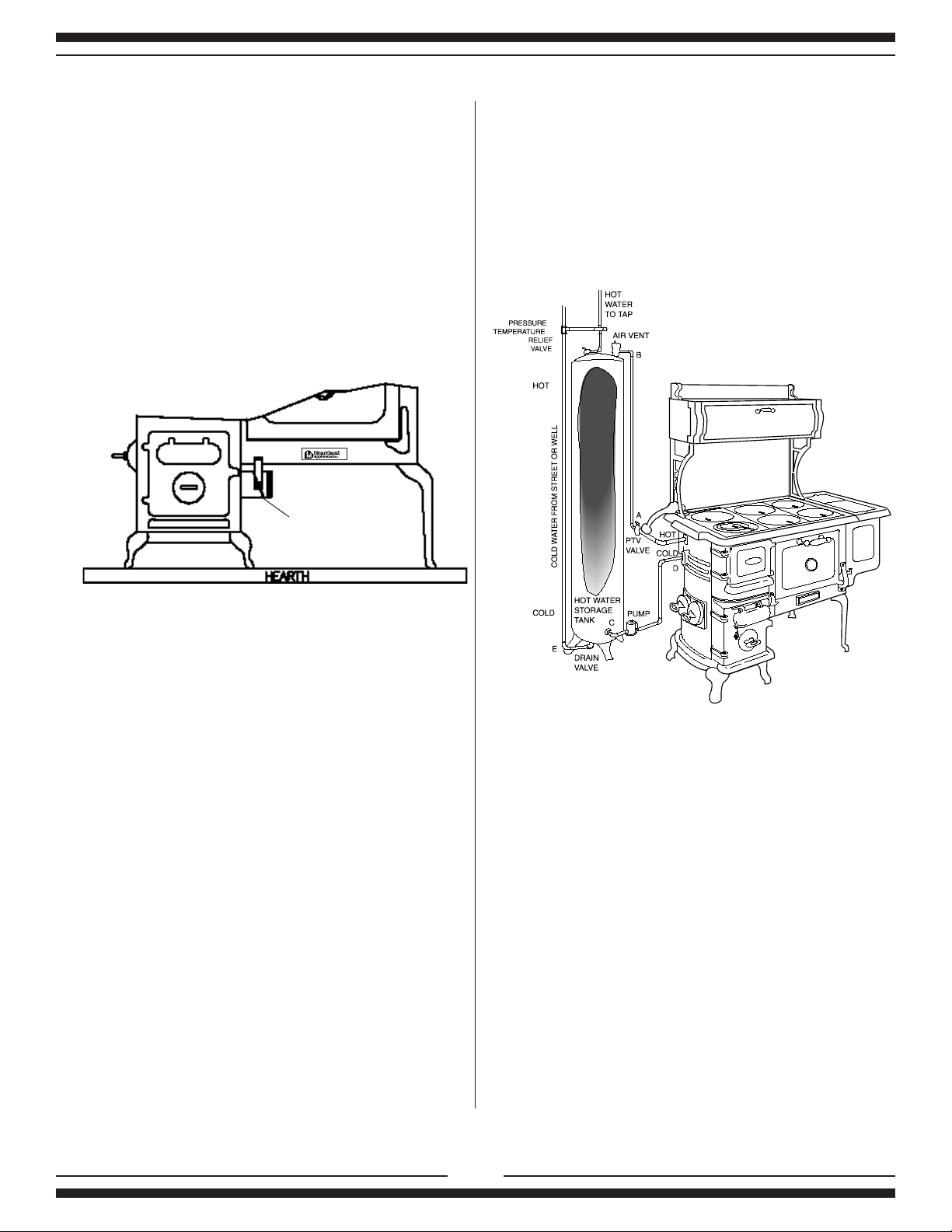

Figure 5

Illustration of Oval with

fresh air kit

Fresh air kit

Installation is Easy

The water jacket can be installed in the stove in less than a

minute using only a slot screwdriver. The water jacket is a

hollow bafed chamber that ts in the rebox. Two pipes and

a pump installed from the water jacket to the electric or gas

water heater, circulate heated water from the stove to the

storage tank. (See illustration, Fig. 6.)

Installation is Easy

Mounting holes and airways are all pre-punched on all new

Oval and Sweetheart cookstoves.(See gure 5)

Simply remove the cover plates (right side of rebox on the

Oval and, bottom of the rebox on Sweetheart). Now you

are ready for installation. A complete set of diagrams and

instructions are included with each fresh air kit.

Please note that some States require a fresh air source to be

installed with wood burning appliances. Please check your

local, and state, building codes.

Water Jacket

The average family spent about one quarter of their utility

bill to heat water last year. By installing the water jacket in

your cookstove, you can reduce or virtually eliminate your

hot water utility bill.

Figure 6

A Sample Oval Water Jacket Installation

This is an illustration of an active or pumped

circulating hot water system.

You can expect from 8 to 10 gallons (30.3 to 37.9L) or more

hot water per hour (about 10,000 BTUs) from your oval water

jacket, OR 6 to 8 gallons (22.7 to 30.3L) (about 8,000 BTUs)

from your Sweetheart water jacket.

Because cold water cools the water jacket in the rebox,

creosote will be attracted to its cool surface, like humidity being

attracted to a cold window. These deposits will quickly burn off

thus reducing creosote formation in the stove and chimney.

An installation and operating manual is packed with every Oval

and Sweetheart water jacket. Extra copies may be obtained

from your dealer or by contacting AGA Marvel.

15

Page 16

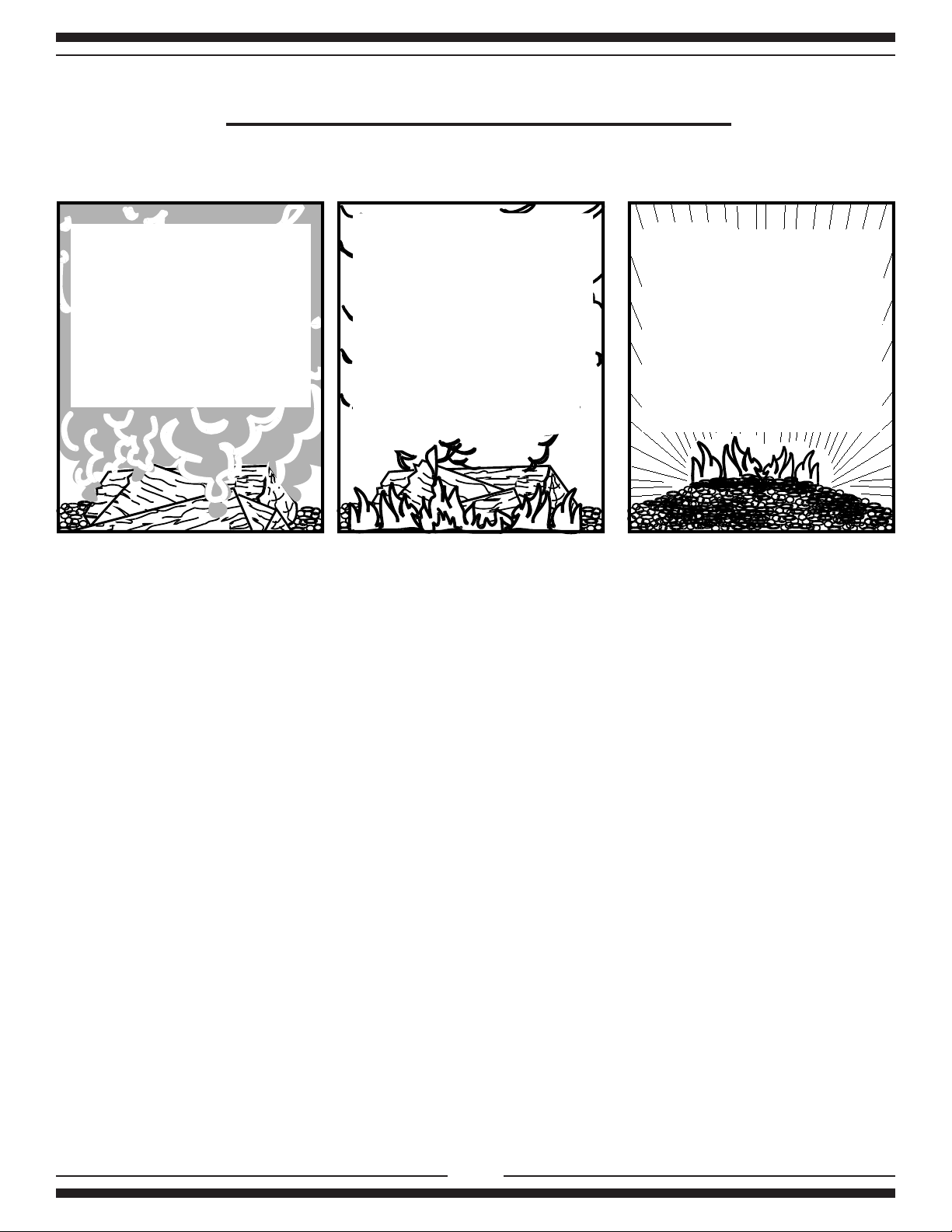

Understanding Combustion

Water: Up to half the weight of

freshly cut logs is water. After

proper seasoning only about 20%

of the weight is water. As the wood

is heated in the rebox, this water

boils off, consuming heat energy in

the wood, the more heat energy is

consumed. That is why wet wood

hisses and sizzles while dry wood

ignites and burns easily.

Smoke (or ame): As the wood

heats up above the boiling point

of water, it starts to smoke. The

hydrocarbon gases and tars that

make up the smoke are combustible

if the temperature is high enough and

oxygen is present. When the smoke

burns, it makes the bright ames that

are characteristic of a wood re. If the

smoke does not burn, it will condense

in the chimney forming creosote or

exit the chimney as air pollution.

Figure 7

Charcoal: As the re progresses and

most of the gases have vaporized,

charcoal remains. Charcoal is

almost 100% carbon and burns with

very little ame or smoke. Charcoal

is a good fuel that burns easily and

cleanly when enough oxygen is

present. Of the total energy content

of the wood you burn, about half is

in the form of smoke, and half is

charcoal.

Break-in Fires for New Stoves

If this is your rst re, OR you have installed a replacement set of brick, read the procedure for break-in res.

Proper seasoning ensures longer stove life.

Fuel

Woodburning

The rewood you use will make an important contribution to successful operation. You will achieve the best performance

and overall efciency by burning rewood that has been split, stacked and air-dried undercover from rain for at least one

year. Burning improperly seasoned or “green” wood can be a frustrating experience leading to poor performance, smoky

res and a build-up of creosote. Do not burn saltwater driftwood refuse, rubber tires, etc. Use of improper fuels can cause a

re hazard and lead to a premature deterioration of the stove components, voiding the warranty. (See Fig. 7 Understanding

Combustion.)

Burn dry wood because:

• it gives up to 25% higher efciency;

• it produces less creosote;

• it ignites faster and smokes less;

• valuable heat is lost in the re as it dries out wet wood.

16

Page 17

Getting Acquainted

may be lifted to access the wood grate pull without having

to open the door.

The Sweetheart and Oval cookstove are time proven heating

and cooking appliances. Take your time to acquaint yourself

with the principles on which your new stove operates as a

heater and cooking stove.

Understanding the primary principles of the air intake

controls, the oven damper, the ame path for the re and the

relationship to the chimney will give you a very comprehensive

understanding of what you are trying to accomplish with the

stove.

Before starting the stove, lift the key plate handle and rest

the arm in the top hook of the cabinet bracket. Open both

the top loading and ash pan doors. The doors open by lifting

slightly over the hook and pulling towards you. Always use the

lid lifter to open doors and bell dampers and when adjusting

the oven damper.

In the Oval, looking into the rebox through the top you

see cast iron liners, these liners rest on an oval refractory

rebrick.

In the Sweetheart, looking into the rebox through the top

you will see rebrick liners on the left and right side of the

rebox.

Burning skid wood or construction materials with nails is not

recommended as anything in the rebox that will not burn

has the potential to get caught in the grate.

The ash pan is directly below the grate.

Starting the Stove

Good safety practices:

Educate your family members:

• before burning the stove, have each family member read

this manual and be aware of safety practices;

• keep children, clothing and furniture away from the

stove;

• the stove is HOT while in operation – DO NOT TOUCH

the stove, contact may cause burns;

• open the redoor, ash pan door, woodgrate pull, bell

dampers and oven damper with the 1415 lid lifter

only—these surfaces get hot; (see gure 8)

At the bottom of the rebox is the wood grate, looking in through

the ash pan door, you will see the wood grate pull—slide it

back and forth and looking down into the rebox you will see

the slots open and close.

Wood grate pull

Slots open and close

The stove is burned with the slots open which allows the

combustion air to enter underneath the re. As ash and

coals build up on the grate these slots ll and will require the

occasional “shaking”.

• keep a re extinguisher nearby and have a clearly

understood plan on how to extinguish a re.

Wood Grate Pull

Bell Damper

Oven Damper Slide

Figure 8

It is a good policy to shake the grate or stir the coals with the

poker before loading a new charge of wood.

You will notice that with the ash door closed the ash ap

17

Page 18

Break-In Fire

(Refer to page 16 gure 7)

The rebox of your stove is made of superior materials—cast

iron and rebrick lining.

Both materials could be broken by a sharp blow or thermal

shock. A little extra care and thoughtfulness during the breakin period will help promote a long life for your stove.

The cast iron and rebrick will have picked up moisture during

shipping and storage.

During the break-in period it is important to let the cast iron

and rebrick slowly dry out and avoid thermal shock, caused

by strong hot res.

• Build a small kindling re (following the instructions below

for the rst re) and add small pieces of kindling. Let the

stove burn for approximately one hour on the rst ring.

• Let the stove cool keeping the doors closed.

• Repeat the process for a few days or until you have had

six break-in res. You may notice some smoke or “burnoff”

during your initial ring. This is normal and is caused by

the curing of the paint nish.

Your First Fire

Flu Gases

Oven Damper

Figure 9 - shows oven damper open

Lighting the ‘charge’ is of your personal preference. One

method is to roll a piece of newspaper into a torch, lighting

one end and using it to start the paper.

Light the paper at the bottom of the load and then light

the paper at the top, shut the key plate immediately. You

may nd it helps to hold the key plate open just slightly

for a few seconds to give some extra air and establish

the re.

It is advisable to read and understand this section thoroughly

before starting the re (Refer to page 16 gure 7)

1. Open the oven damper (see Fig. 8 and 9) and air intake

controls (bell dampers). On damp cold days, it may help

to open the ash door slightly until a good draw develops

in the chimney.

2. To kindle a re. Lift the key plate lift handle and rest it

in the top slot of the closet bracket. Crumple six to eight

single sheets of newspaper into loose balls and place

them on the wood grate. Cut 10-15 pieces of kindling into

strips approximately 1/2” by 1/2” by 10” long (1.27 cm by

1.27 cm by 25.4 cm).

Place the kindling on the newspaper. Place 2 or 3 more

pieces of crumpled newspaper on top of the kindling.

Ensure that the wood grate slides are open.

3. To Fuel the Fire. After a couple of minutes lift the key plate

or open the front loading door slowly. When the kindling

is established add larger pieces, perhaps 2”x2”x10” (5

cm by 5 cm by 25.4 cm) long.

Continue this process until the re is established when

split logs can be added.

Dampering the stove. Tighten the bell dampers to

approximately 1/4” (6.35 mm) opening. This will slow

the re down. Wait momentarily and close the oven

damper.

The smoke and heat is now being routed around the oven.

Remember, by closing the oven damper resistance has

been put on the system.

If the stove/chimney is not yet heated enough or there

is too much volume of re going through, this additional

resistance will cause backpufng.

Close the oven damper slowly (Fig. 9) to allow the oven

ue chamber to absorb the smoke and heat.

18

Page 19

4. Reloading the stove—Stove tending time will be greatly

reduced if you reload your stove while the system is still

hot and there is plenty of hot embers to rekindle the re

quickly. Including some smaller pieces of wood in the new

fuel load will help the stove regain temperatures quickly.

When reloading, open the oven damper and wait

momentarily—if loading from the top—slowly lift the key

plate or if loading from the front, open the door slowly.

Load wood—smaller, split pieces rst.

Close the door or key plate.

Open the bell dampers slightly.

Sweetheart:

To use the summer position in the SweetHeart you will need

to purchase the optional #4271 summer grate support. Call

your dealer to order, or call direct to AGA Marvel.

1. Remove the wood grate from the lower rebox position by

pulling the grate up, back end rst, and out of the rebox.

2. Remove the wood grate slide from the wood grate. Place

the “summer position wood grate stand” at the back of

the rebox on the rebox extension.

3. Place the re grate so the back of the re grate rests on

the stand, and the front rests on the top of the front brick.

The stove must rebuild its thermal momentum before

closing the oven damper.

As you become more experienced you will gain knowledge

on what settings of bell dampers and oven dampers can

be used at the different stages of the woodburning cycle

(see Combustion Process, page 16 gure 7).

Summer Burning

Both Oval and Sweetheart stoves feature a utility which allows

you to use your stove during the summer months with less

heat radiating from the rebox.

Oval:

1. Slide the wood grate from the lower rebox position and

remove the wood grate slide.

2. Set the wood grate on top of the rebrick. You are now

ready for summer cooking.

You are now ready for summer cooking.

sweetheart summer grate stand

wood grate positions for oval stove

upper “summer position”

lower “standard position”

upper “summer position”

lower “standard position”

wood grate positions for Sweetheart stove

19

Page 20

Coal Burning

C

O

Do not burn coal on the wood grate. An optional coal grate kit

is available for the Oval (#1500) and the SweetHeart (#4500)

to burn coal. An installation and operating manual is packed

with every Oval and Sweetheart Coal Kit. Extra copies may

be obtained from your dealer or by contacting AGA Marvel.

Below is a brief description of the coal kit installation

Sweetheart Coal Grate Installation

To install the optional coal grates, remove the lift handle, the

key plate and lids. Lift the wood grate out through the top of

the rebox and replace it with the coal grate. Remove small

front brick in rebox by unscrewing bolt & nut that holds brick

in place. (Please note that older models require front re brick

to be installed with the groove facing away from the rebox

and towards the front of the stove). Replace with large brick

in coal kit. Gently tap the coal grate down until it ts snugly

into the steel track. Replace the key plate, lift handle and lids.

Then proceed with redoor damper installation.

Oval Coal Grate Installation

Illustration showing

Oval redoor

damper installation

Starting Up a Coal Fire

A chimney 6” (15.25 cm) in diameter is imperative for the

Coal Burning process. On chimney larger than 6” (15.25

cm) in diameter will cause poor ignition of the coal due to

inadequate draft.

To install the optional coal grate package, remove the wood

grate through the ash pan door and replace with the coal

grate. Remove the key plate over the rebox and slide the coal

liners #1470 in the front and #1475 in the back of the rebox.

Replace the key plate, lift handle and lids. Then proceed with

redoor damper installation.

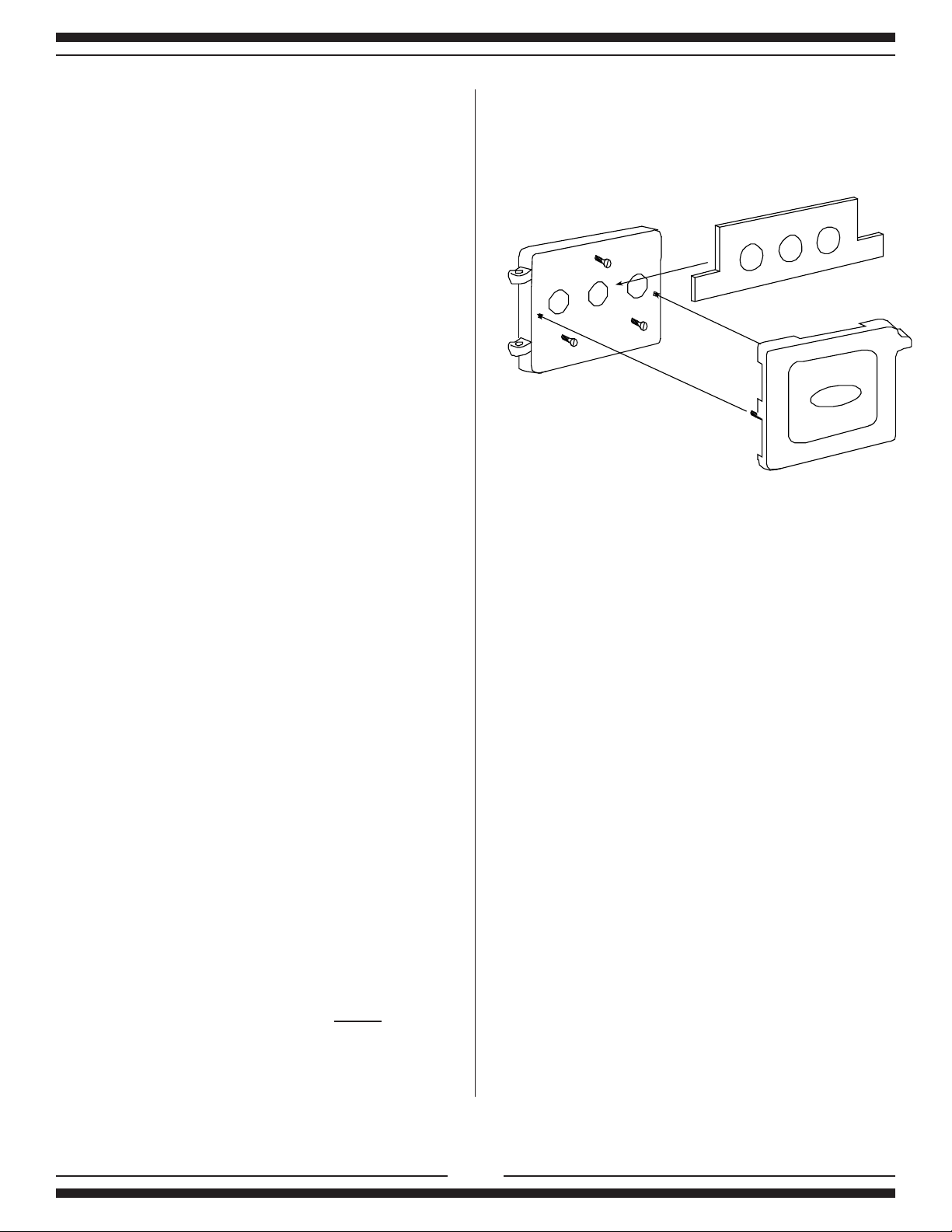

Oval and Sweetheart Firedoor Damper

(Coal burning only, see illustration on next column)

The redoor damper comes with each coal kit and must be

installed. Remove the nickel redoor frame from the redoor.

Loosen the three screws that hold the cover plate over the

damper holes. Replace the cover plate with the coal damper,

lettered side out. Tighten screws just enough to hold the damper

plate on but also allow it to slide freely back and forth. Lock

screws in position with a nut on each screw thread.

A wood “break in” re should be done before attempting

to burn coal (see page 16).

It is possible to burn coal with a large diameter chimney, but

banking a new bed of coals will require a greater mix of wood

to create and maintain an adequate draft.

The minimum draft required to maintain an oven temperature

of 350 ºF (175⁰C) is around .04” (1.016 mm) on a water

column. For drafts under .04” (1.016 mm) on a water column,

closing the oven draft damper more than half way, will cause

back pufng.

During the recharge phase of a new bank, a draft of .08” (2.03

mm) should be maintained for at least 10-15 minutes or until

a substantial bed of red embers is built up.

We recommend burning anthracite coal, which is relatively

clean to handle, burns evenly with a low ame, has a low

sulphur content and produces relatively little smoke.

Use a “chess nut” or “nut” size of coal, which is 1 3/16 to 1

5/8 in (3 cm to 4.13 cm) diameter. However, other coal, such

as bituminous, can be burned, but is inferior to anthracite.

20

Page 21

To Start a Coal Fire:

1. Use paper and dry wood kindling to start the re.

2. Add small, compact pieces of hardwood when the kindling

is burning hot. Keep the primary damper controls fully

open to establish a hot re quickly. The ash door also

may be opened during start-up to accelerate the initial

burn.

3. When a substantial bed of red embers is built up, start

adding coal – small amounts at a time. Keep the draft

control open.

4. Continue adding small amounts of coal until there is a

solid bed of burning coal. Do not add too much at one

time. Allow sufcient time between each small loading (at

least ve to ten minutes), so that each loading has time

to ignite thoroughly before the next load is put in.

When a substantial bed of burning coals has been

established, ll the stove to the highest possible level,

no higher than the bottom of the redoor – be careful not

to overload! A deep bed of coal will always burn more

satisfactorily than a shallow bed.

5. When most of the wood is burned and the coal is completely

ignited (usually ve to ten minutes or less after lling the

stove), the draft control should be turned down to the

proper operating level. (If the ash door has been opened,

it must be closed to prevent overring, which can severely

damage the stove.)

NOTE: When burning coal, the redoor damper must

be kept open. The secondary air is required to aid in

burning off coal gases. The coal damper is not required

when burning wood and should be kept closed when

burning wood.

Coal grates are not to be used in upper (summer)

position. Do NOT ll rebox with coal higher than the

bottom of the redoor opening.

Disposal of Ashes (wood and coal)

Do not remove the ash pan when the stove is hot. Carry

the ash pan with one hand on the handle in the upright

position and the other on the front handle to balance the pan.

Improper disposal of ashes is the most common cause of

wood stove related res.

Empty the ash pan before ashes build up over the top.

Use Caution:

• don’t carry hot ashes through the house;

• even though the stove may be cool, the

ashes in the pan may still be hot;

Recharging the Fire

If the re is burning hot and there is a deep bed of coals, add

coal a hand full at a time.

Allow enough time between each addition for the combustion

process to start. As the bank becomes larger, the amount of

coal added at a time can be increased.

If the coal bed is under 5” (12.7cm) before a recharge is

started, it may be necessary to add kindling wood to increase

the combustion level so that more coal can be added.

1. Coal never should be added unless there is a reasonably

hot re. The coal bed should be bright and vigorous.

2. If the re is burning hot and there is a deep bed of coals,

full loads of coal can be added at any time. However, if

there is not a deep bed of coals, it is best to add small

amounts of coal at rst.

• never place the ash pan on a combustible

oor;

• never leave the ashes near combustible

material or combustible liquids;

• always dispose of ashes in a closed metal

container with a tight tting lid—if an

unexpected gust of wind fan the ashes, a

re could result.

21

Page 22

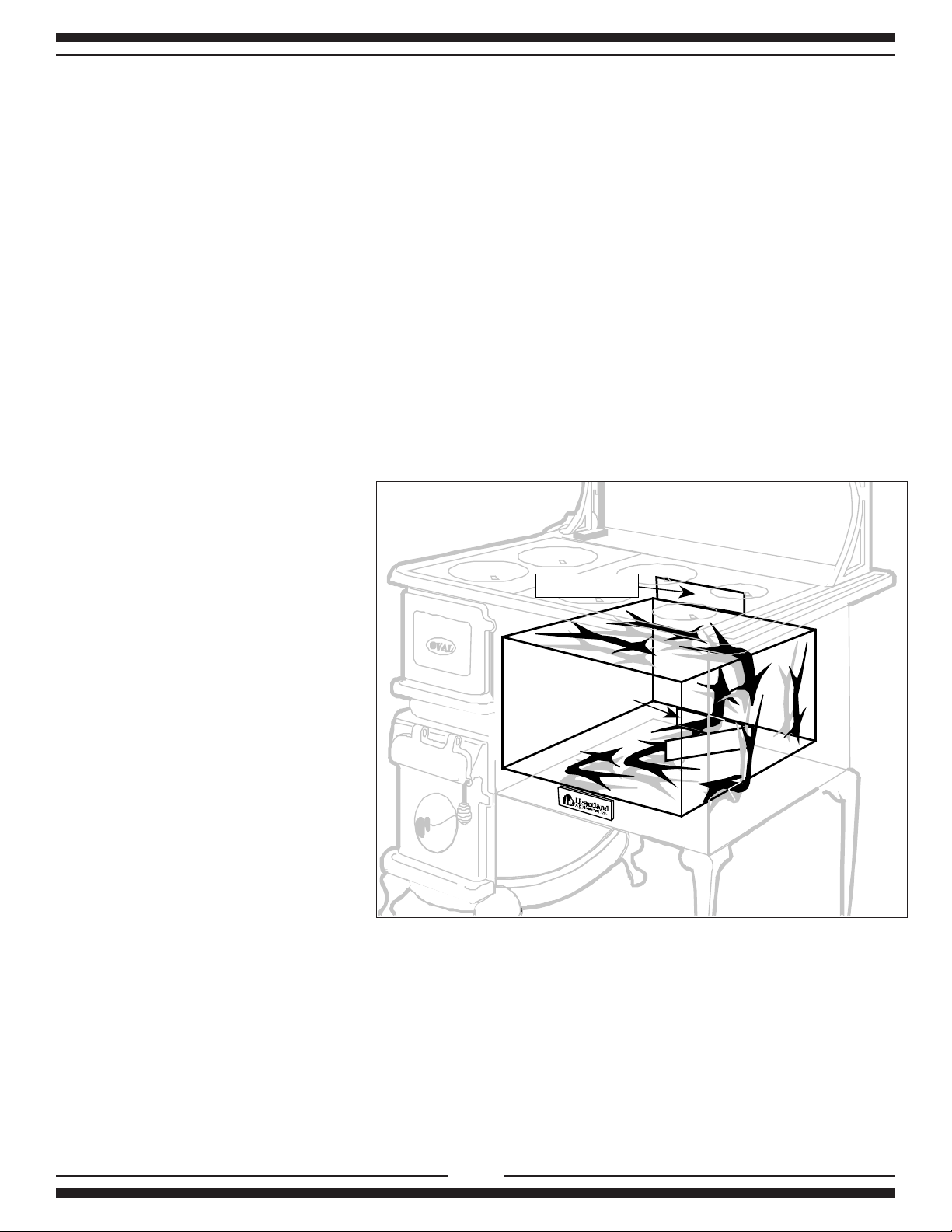

Using the Oven and Cooking Surface

Under Oven E

xhaust

Damper Closed

Stove top cooking

The cast iron top provides an excellent large cooking area

for griddling, frying, basting and simmering.

Some users report griddling directly on the cooking surface,

although this is not recommended, as it usually creates

quite a mess. A cast iron cooking vessel with a at bottom is

recommended. As you inspect your new oval, you may nd

the edges of your keyplate sitting slightly above the cooking

surface. This is caused by the stiff new gasket under the

keyplate. As the gasket compresses over time, the keyplate

will drop to a position even with the rest of the cooktop.

To allow for normal settling, we have purposely created a

slight upward warp at the middle of

your oval keyplate. As the keyplate

heats and cools it will eventually settle

to a at position. The time period for

settling will be different for each stove

depending on usage. Please allow a full

season of use as a minimum.

When getting used to cooking on the

stove top remember that the surface is

cast iron and like cast iron cookware,

once heated retains the heat for a long

time.

The temperatures established on both the cooking surface

and in the oven are determined by three primary things:

1. The amount of draft the chimney has. As the bell dampers

are opened more air gets in the rebox and is drawn

through the stove and chimney, resulting in a faster,

hotter re.

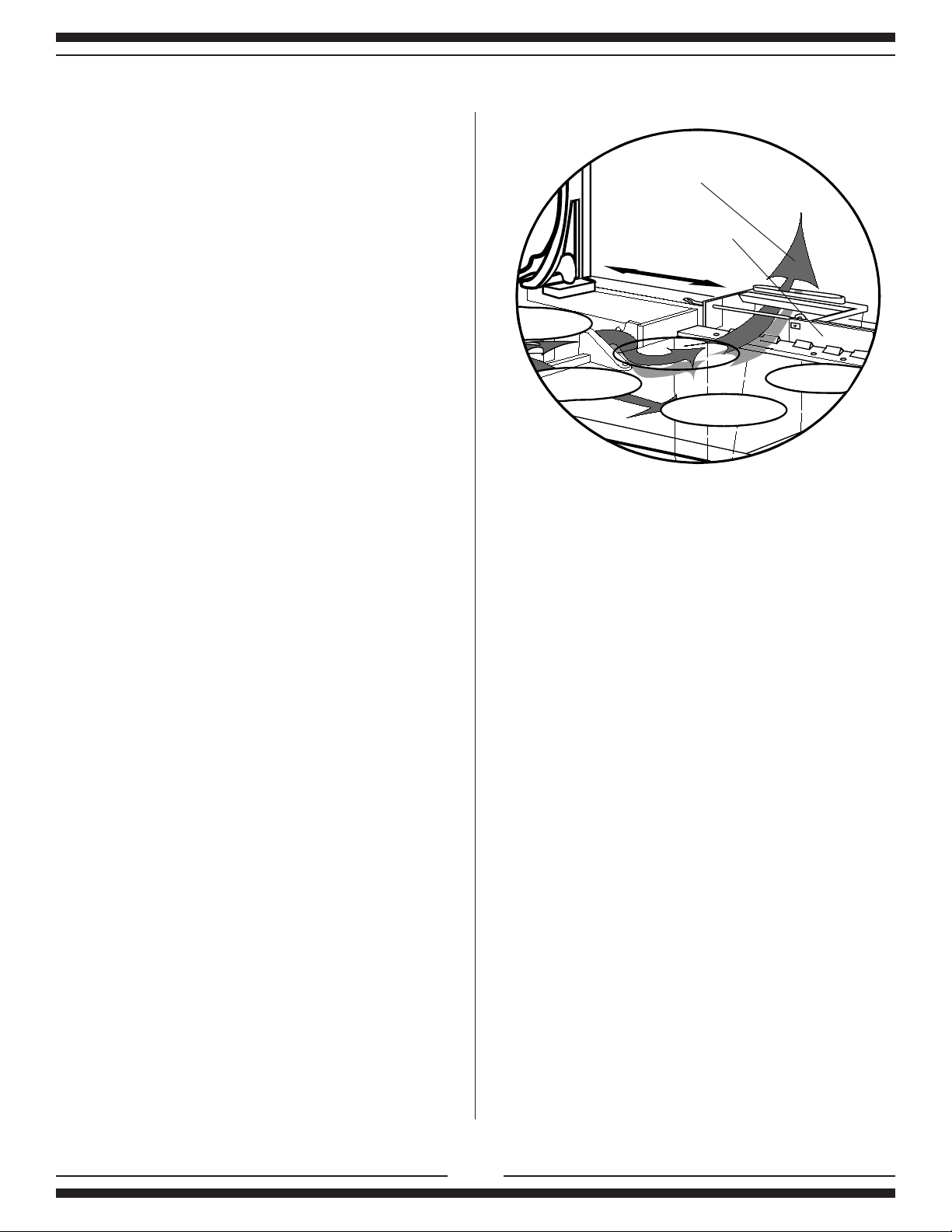

2. The position of the oven damper. With the oven damper

closed, the heat is channelled under the entire cooking

surface (heating it up) and around the oven (heating it

up). When the oven damper is open, the heat will be

routed directly up the chimney.

3. How much wood/coal is in the rebox and what stage of

the combustion process it is at.

Successful stove top and oven cooking

will not result from trying to re the stove

up immediately but by having a heated

stove and ‘banking’ the re to retain the

temperature required.

The left hand side of the cookstove

top will be the hottest as the re burns

directly beneath it. The surface will get

cooler the further you go to the right.

The oven damper can be used to help

control the heat on the cooking surface.

To have the entire cooking surface

warm, the damper will need to be in

the closed position. This funnels the heat under the entire

cooking surface, therefore heating it (see gure 10).

Figure 10

22

Page 23

Oven Cooking

Learning how to most effectively control the oven temperature

takes some time and experience. As a general rule, the stove

should be at the charcoal stage of the combustion process

before the oven is ready for cooking.

6. Ideally your stove will perform best if it is left running

constantly, keeping the entire system warm. Depending

on your wood and chimney conditions it would typically

take three or four charges of cord wood to establish a

good base for oven cooking, meaning 1 1/2 to 2 hours

before cooking from a cold start.

Important Note: The oven door thermometer registers the

temperature at the door only. For accurate oven temperatures,

refer to this interior oven thermometer.

Ovens vary in temperature from top to bottom and side to

Rotate base for use as

a hanger.

side. The only accurate check on oven temperature is an oven

thermometer placed along side food being roasted or baked.

See page 29 if your door thermometer needs adjustment.

1. You will nd that once the stove has about 4” (10.16cm) of

red hot coals in the rebox, it will have reached ‘equilibrium’.

2. Equilibrium means that the entire stove and chimney

system is heated and running at a fairly constant

temperature.

3. At this point, you may load a new charge of wood following

the procedure for ‘reloading’. Allow the stove to regain its

momentum—igniting the new charge. Keep bell dampers

dampered down to allow a steady slow ame.

7. Always load a new charge of wood to a glowing hot coal

bed about 4” (10.16 cm) deep. Waiting too long to load

a new charge means that the dampers will have to be

opened, to get the new charge burning well. This results

in extreme temperature swings and will make cooking

difcult. Your objective is to maintain the coal bed and a

constant heat.

8. Occasional ‘tending’ or stirring may be required. Keeping

these principals in mind and with a little experience, you

will nd cooking to be easy and trouble-free.

9. Woodstove cooking methods are as diverse as their

owners—there is no right or wrong way, only, in time,

your way.

10. Remember by opening the oven damper there is less

resistance on the ue and a hotter faster re will result.

The cooking surface directly over the rebox will typically

get hotter in this conguration.

11. Always open the oven damper before opening any rebox

doors or lifting the key plate. Wait momentarily before

opening the doors to allow the smoke in the oven chamber

to be drawn up the chimney to avoid backpufng.

Maintain your stove properly. The benets in superior

performance and safety are well worth the time.

4. The oven temperature can be controlled by moving the

oven damper slide. In the closed position, the oven will

get warmer, and cooler when you open it.

5. Remember the effects of the changes in the damper

position are not instantaneous on the oven temperature.

23

Page 24

Water Reservoir

Helpful Hint: When lighting your stove from cold or when

the stove is relatively cool remember the water in the reservoir

will be at the same temperature.

This section pertains to the water holding tank on the side of

the stove and applies only to reservoir models.

The reservoir has a porcelain enamel top and lid. The lid lifts

open and will rest at an open position, or can be removed

entirely.

The tank in the reservoir is made of copper, for easy cleaning

and the seams are soldered with lead free solder. The tank

has a 5 gallon (18.9L) capacity with a spigot mounted on the

side, for easy access to the water.

Water must be added manually, the tank is not connected

to your plumbing.

To route heat around the reservoir, open the reservoir damper

(turn handle to the right). Vertical position of the handle means

that the reservoir damper is closed, and no heat is passing

under the copper tank. Horizontal position of the handle

means that the reservoir damper is open and more heat is

circulating under the copper tank.

The water in the reservoir can be heated from luke warm to

boiling hot depending on how you are burning the stove, the

position of the water reservoir and the oven dampers.

The reservoir damper is ‘downstream’ from the oven damper

which means that if the oven damper is open, the u gases

are not circulating around the oven and therefore not past

the reservoir either, so the water in the reservoir will not get

as hot as when the oven damper is closed.

The cold water will tend to absorb the heat that you are

attempting to use to heat the chimney to start the stove. Close

the reservoir damper during this period.

The same theory applies when heating the oven. If the water

reservoir damper is open, the valuable heat you are trying

to heat the oven with will be absorbed by the mass of cool

water in the reservoir. Close the water reservoir damper

during this period.

Woodstove heat is very dry and the water in the reservoir will

add much needed moisture to your home. The warm water

can be used for bathing, dishes or other clean up needs.

Always ensure water is in the tank when the stove is in

operation. If the reservoir runs dry the soldering may melt

away from the joints, resulting in leakage.

Copper water tank

Reservoir damper arm

vertical-closed (shown)

horizontal-open

Reservoir Lid

Water Tap

24

Page 25

Trouble Shooting

Chimneys and Draft

The performance of your woodburning system depends

more on the chimney than on any other single component.

The chimney ‘drives’ the system by producing the draft that

draws in combustion air and exhausts smoke and gases to

outdoors. Give as much attention to the chimney as you do

to the appliance that it serves.

How Chimneys Work

It is well known that hot air rises. This principle is at work

inside chimneys and is the key to understanding how chimneys

function.

The hot exhaust gases from the appliance are lighter than

the outside air. This buoyancy causes the gases to rise in the

chimney. As they rise, a slight negative pressure is created

inside the appliance. Air rushes into the appliance through

any available openings to balance this negative pressure.

The force caused by the rising gases is called draft. Draft is

created by the difference in temperature between the gases

in the chimney and the outside air. Greater temperature

differences produce stronger draft.

Factors That Affect Draft

There are several factors that interfere with draft and most

woodburning systems have one or more of these features. It

is usually a combination of conditions that make a chimney

fail to function properly.

Here are the main factors that inuence draft:

Cold Chimney Liner

An uninsulated chimney that runs up the outside of a house

and is exposed on three sides is chilled by outside cold. This

means that the ue gases give up their heat rapidly to the liner.

As they cool, they lose their buoyancy and draft is reduced.

Insulation between the liner and the chimney shell can help

to reduce the heat loss, but a chimney that is enclosed within

the house is preferable.

Large Liner

Chimney liners that are much larger than the ue collar of

the appliance allow ue gases to move too slowly. This slow

movement gives the gases more time to cool and lose their

buoyancy. Oversized liners are the reason that many replace

inserts vented through replace chimneys tend to perform

poorly. Ideally, the liner should have the same internal area

as the ue collar of the appliance.

Chimney Height

Taller chimneys tend to produce stronger draft. We recommend

that the top of the chimney should be at least 36” (900 mm)

higher than the highest point at which it contacts the roof and

24” (600 mm) higher than any rooine or obstacle within a

horizontal distance of ten feet (three metres). These gures

produce the minimum allowable chimney height. Chimneys

higher than this are often needed for performance reasons.

A chimney serving a cookstove located on the main oor of

a single-storey house or cottage may not be tall enough to

perform well, even though the minimum heights in the building

code have been followed. A good rule of thumb to use states

that the top of the chimney should be at least 16 feet (4.9

metres) higher than the oor on which the cookstove sits.

Negative Pressure in the House

The draft produced by chimneys is a weak force that can be

inuenced by pressures inside the house. A woodburning

cookstove acts as an exhaust ventilator by removing air for

combustion from the house. A typical house may have several

other exhausts, clothes dryer, gas or oil furnace, replace,

or central vacuum system. When one or more of these other

exhaust ventilators is running, it may compete for the same

air that the woodburning appliance needs for combustion. This

competition for air supply can make a re slow to kindle or

cause a stove to smoke when its door is opened. Chimneys

are often blamed for this type of performance.

Stack Effect in houses

In winter, the air in houses is much warmer and, therefore, more

buoyant than the outside air. The warm air in the house tends

to rise, creating slightly negative pressure in the basement

and slightly positive pressure at higher levels. This negative

pressure in the basement can compete with chimney draft to

a stove or furnace located there.

CHECKING AN EXISTING CHIMNEY

Before an existing chimney is used to vent your new

cookstove, a thorough inspection should be done to determine

its suitability. The inspection should be performed by an

experienced professional because of the many factors that

must be considered. A reputable chimney sweep or retailer can

give you good advice on the suitability of an existing chimney.

25

Page 26

Masonry chimneys should be checked for deterioration

including damaged bricks, crumbling and missing mortar,

cracks in the drip cap at the top of the chimney, and loose

ashings at the roof line. The liner should be checked for

cracks and misalignment, and its size should be 6” (15.24 cm).

An existing factory-built metal chimney needs a careful

inspection. Your new cookstove should be connected only

to factory-built chimneys approved to ULC Standard S629 in

Canada and UL 103HT in the U.S. Possible problems with

an older metal chimney can include a warped or buckled

liner caused by the heat of a chimney re, corrosion of the

outer shell, a loose ashing, and a lack of proper support.

Any discolouration of the metal shell near a joint indicates

that the insulation has settled. A damaged metal chimney

should be replaced with a new approved chimney which will

be safer and will perform better.

Safety Practices

Here is a checklist to follow when installing or checking a ue

pipe assembly. It is based on the requirements found in the

Canadian Standards Association’s Installation Code for Solid

Fuel Burning Appliances and Equipment (Standard B365).

1) Single-wall flue pipe assemblies must not exceed

3 metres (10’ ) in overall length.

2) The assembly should be as short and direct as possible.

3) A single-wall ue pipe assembly must have no more than

two 90 degree elbows; use 45 degree elbow, wherever

possible.

4) Do not use galvanized ue pipe because the coating can

vaporize at high temperatures, emitting poisonous gases

and leaving the pipe thin and weak.

5) Flue pipes for woodburning appliances need to be thicker

than those used for other re-burning appliances; 24

gauge for 150 mm (6”) .

6) Joints between pipes should overlap at least 30mm (1

1/4”).

What To Do If You Have a Chimney Fire

1) Close all the combustion air dampers on the appliance.

2) Call the re department immediately.

3) Be prepared to get everyone out of the house in case

the re spreads.

4) Go outside and check to see that hot ashes do not ignite

shingles.

5) Watch anything near the chimney that could catch re

and burn.

6) After the re has run its course and the chimney has

cooled, have the chimney thoroughly inspected to

determine if it sustained any damage.

7) Resolve to inspect and clean the chimney more often to

prevent another chimney re.

Flue Pipes

Flue pipes carry the exhaust gases from the appliance ue

collar to the chimney. The ue pipe assembly is an extremely

important part of a woodburning systems and should be

carefully planned and installed.

7) Each joint should be secured with three sheet metal

screws.

8) The assembly should be constructed to allow for

expansion. Elbows in an assembly allow it to expand;

straight ue pipe assemblies should have one section left

unscrewed and secured with an inspection wrap clamped

around the joint.

9) The pipes should slope up towards the chimney at least

20 mm/metre (1/4 in/ft).

10) One end of the ue pipe assembly must be securely

fastened to the ue collar of the appliance and the other

end fastened to the chimney.

11) There must be provision for the cleaning and inspection

of the pipes by removal of the pipe. The removal of the

pipes should not require moving the appliance.

12) The crimped ends of the pipes should point towards the

appliance so that condensation drains to the appliance

and does not leak out.

13) A ue pipe must never pass through a combustible oor

or ceiling, or through a concealed attic, roof space, or

closet.

Flue pipe assemblies should be stable and secure. To check

the stability of a ue pipe assembly, grasp it at its mid-point

and give it a good shake. If it is properly constructed, it will

have little or no movement.

26

Page 27

Maintenance

Oven Flue Passage

As heat, smoke and gases travel around the oven, y ash and often creosote are left behind. The frequency of cleaning of the

oven ue will depend on your use, burning habits and the wood you burn. If a ‘y ash’ which is very ne and light in colour,

is what is left behind in the oven ue chamber, it is a good indication you are burning your stove well.

If a sticky black ash is what you observe, you are burning wood which is too wet or the stove is not burning hot enough as

a result of a poor chimney. Your dealer can help you correct this.

Follow this procedure when cleaning around the ue passage:

1) Clean the oven ue chamber by removing the top lids and scraping the ash to the sides.

2) Then scrape the sides so the ash falls to the bottom.

3) All the ash may then be scraped into a metal container through the ash cleanout door with the ash scraper.

4) Follow the procedure for ash disposal when cleaning the oven ue chamber, and chimney connector system.

Creosote buildup in the oven ue chamber can lead to rusting, a bad odour, and chimney res. Check for creosote regularly

and clean it out upon discovery. Caution: The water reservoir is a naturally cooler area of your stove, so creosote and y

ash will tend to build up on and around that side of the stove. Because of the potential for blockage and or ignition of the

creosote, frequent inspection of this area is very critical and clean out must be performed more often.

Creosote is a tell tale condition of burning wet wood, a practice which should immediately be discontinued.

Remove keyplate and lids to scrape

upper ue passage

Remove lids to gain access

to ue passage

Oven damper track should be cleaned periodically

Oven damper

Scrape down the sides of ue passage

to the bottom ue passage

Caution: Models with water reservoir

frequent inspection of this area is

very critical and clean out must be

performed more often.

Scrape ash in the bottom u passage and remove through the clean

out door opening

Ash clean out door-lift slightly to remove

27

Page 28

Flue Boot Inspection

Remove the cover plate on the ue boot, located at the back

of the range. Inspect for soot or creosote buildup, scrape and

clean as much as possible, and remove debris through the

clean out door with the ash scraper.

on the condition of the chimney. Referrals are the best way

to select a chimney sweep. Check with your neighbours to

see if they are satised with the sweeping services they have

received.

Oven Damper

The oven damper may stick from time to time because

of a buildup of ashes or creosote in the damper track. To

free up the damper, scrape out the buildup or spray with a

creosote remover, let sit for about 1/2 hour and clean out

debris. (Caution: Never use any remover or cleaner on a

hot stove.)

Chimney Maintenance

Chimney serving woodburning appliances must be checked

regularly for creosote build-up. The rate of build-up depends

on cookstove and chimney characteristics, the type of fuel

used, and on how the system is operated.

Until you are familiar with the rate of creosote build-up in the

system, check it often - every couple of weeks. Well-designed

woodburning systems tend to have a slower rate of build-up

in the spring and fall when heat demand, and therefore ring

rate, is lower.

Creosote may be in the form of dry, aky deposits clinging

to the liner, or a shiny, glazed coating that looks like black

paint.

Cooking Surface

After the initial ring, your stove top will start to turn colour.

This is normal and eventually the stove top will have a uniform

blue nish.

The stove tops and lids are highly polished untreated cast

iron. To minimize the potential for permanent stains,

always maintain the top with cooking oil. During periods

of heavy use, a light coating is sufcient. When you will

not be using the stove for a week or more, give the top

a heavier coat and re-apply as needed. Always remove

food, water or rust stains as quickly as possible. If such

stains are left unattended, a permanent mark can result.

To help remove stains, use a medium/ne aluminium oxide

abrasive sanding block, available at most hardware stores,

or a metal cleaner such as Flitz, in conjunction with ne

(000) steel wool. Do not be afraid to use elbow grease.

Stove top and/or keyplate may expand during heating and

use - this is normal and slight gaps may appear around

key plate. The natural expansion and contraction of the

keyplate during heating is not unusual.

At the end of the heating season, especially in a seasonal

location, apply a coat of cooking oil to keep the top from rusting.

Glazed creosote is the most dangerous kind and indicates

that one or a combination of conditions exist in the system

that can cause the deposits;

1) a cold liner

2) smouldering res

3) wet wood

Glazed creosote should never be allowed to exceed 1/8”(3

mm ) in thickness, Dry, aky creosote should be removed

when it reaches 6 mm (1/4”) in thickness.

Chimney Cleaning Equipment

Brushes and rods are the most common chimney cleaning

equipment. Plastic brushes are normally used in metal

chimneys and steel brushes are used for masonry chimney.

The brush should t snugly in the chimney so that enough

friction is produced to remove deposits. Most chimney cleaning

rods are made from breglass with threaded couplings at

each end. Several passes with the brush are needed for a

thorough cleaning.

Many homeowners prefer to contact the services of a chimney

sweep rather than climbing on their roofs to clean the chimney.

An experienced chimney sweep can complete the job quickly

and will leave no mess behind. The sweep will also report

Please note - Owners of SweetHeart Cookstove: There

is an expansion joint at the rear of the cooking surface

on the rebox side. The purpose of this joint is to allow

the top to expand and contract as required.

Nickel Trim

Nickel trim must be cleaned with warm soapy water and a

micro cloth

Porcelain

Never clean porcelain while the stove is hot. Porcelain is glass

and sudden changes in temperature may cause cracking.

Clean porcelain surfaces with glass cleaner or polish and

a soft cloth. Oven stains may be removed with household

oven cleaner.

Please Note: The spilling of acids like vinegar or lemon juice

on the porcelained reservoir could leave a permanent stain.

28

Page 29

Door Gaskets

a good seal.

If the gasket comes loose but is still usable, it can be

reseated using a good high temperature silicon. Replacement

gasketing and adhesive can be ordered from Heartland or

your dealer.

Gasketing is sold by the foot. Refer to the gasket listing

below.

SweetHeart:

oven door - 4 ft #6387 rope gasket

ash door - 3 ft #1710 rope gasket

key plate gasket - 5 ft #1711 rope gasket

Oval:

Oven Thermometer Adjustment

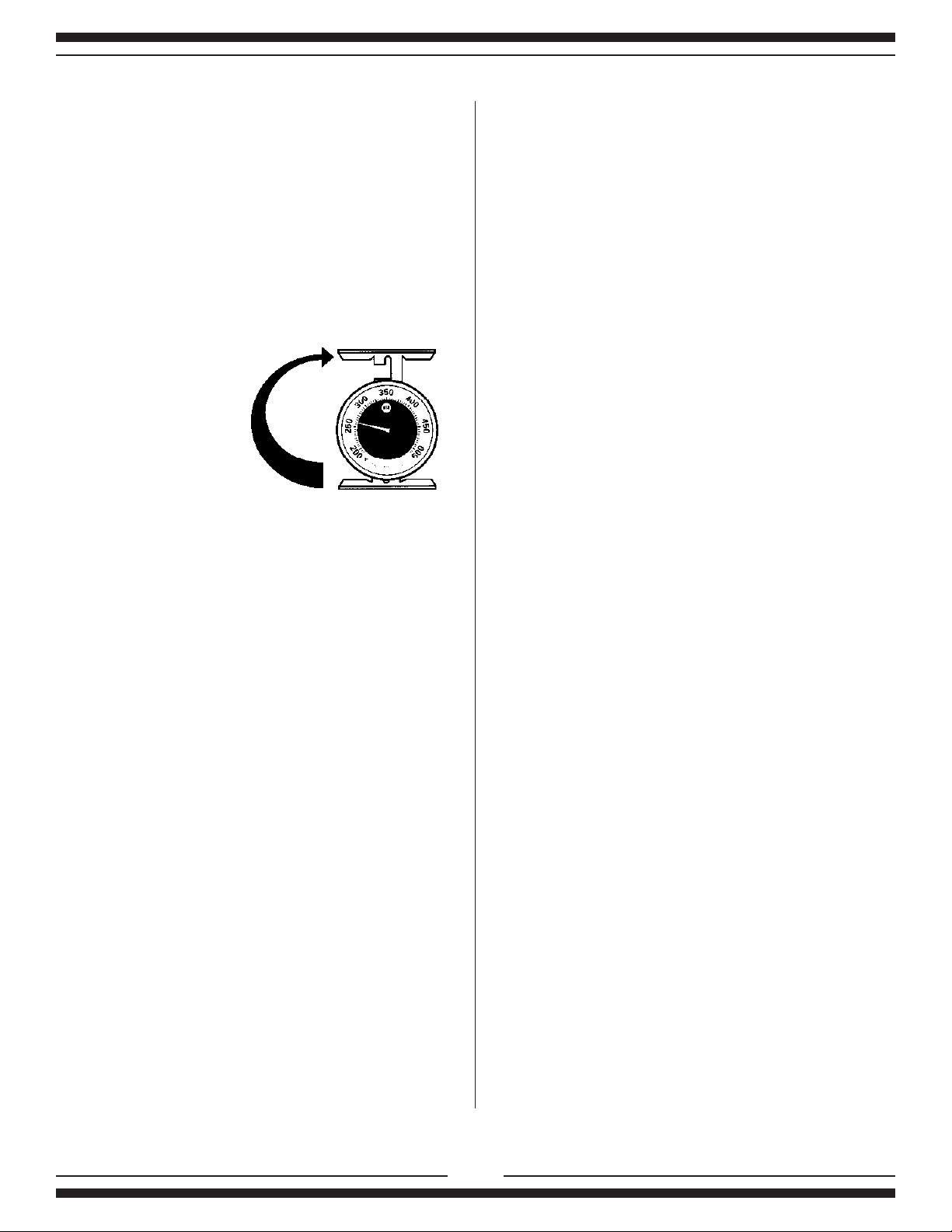

The temperature registered by the oven door thermometer

may not necessarily correspond with the reading taken

with the thermometer inside the oven. For accurate oven

temperatures, refer to the interior oven thermometer.

An adjustment* can be made to the oven door thermometer

to allow a more representative temperature reading

(most thermometers are adjusted to provide accurate

readings in the 300F to 400F (150C to 205C) temperature

range). After the adjustment, the low and high end of

the temperature spectrum will not be accurate. To make

temperature adjustments please follow the instructions

below:

* This adjustment may not be available on your unit.

1) Begin by removing the screws on the inside oven door

panel. Remove panel.

oven door - 4 ft #6387 rope gasket

ash door - 4 ft #1710 rope gasket

key plate gasket - 6 ft #1711 rope gasket

Firebox

Periodic cleaning and inspection of the firebox is

recommended.

On the SweetHeart and Oval cookstove there is a gasket on

the top under the keyplate. This gasket should be inspected

and replaced if it fails to seal.

Check for condition of side castings (Oval only) and smooth

operation of wood grate.

and may be sealed

with stove cement.

will prolong the life of these parts by:

1.

Rear view of Thermometer Figure 11

2) The back of the thermometer is exposed ready for

3)

thermometer, moving indicator needle to desired position.