Page 1

RCT-MLT-II Remote Control Kits

- Installation and Operating Instructions -

INTRODUCTION

The remote control system can be operated thermostatically or manually from the transmitter. The system operates on radio frequencies (RF) within a 20 foot range. Can

be used with DSI, IPI or Standing Pilot systems.

This remote control kit has a hand held transmitter that

can be used as a remote on/off or as a thermostat. The

transmitter display shows the current room temperature,

target temperature, timer setting, on/off status, low battery indicator, current time, burner/valve operation and

fan operation. Electrical ratings for the receiver are: 1 10

VAC, 60 Hz, 6 W.

If pertinent, see additional fi replace wiring diagrams on

pages 9 to 11.

INSTALLATION PRECAUTIONS

This remote control kit is tested and safe when installed

in accordance with this installation manual.

Installation of this kit MUST be done by a qualifi ed

service technician.

NOTE: A manometer MUST be used to set the

manifold pressure on the gas valve.

It is the responsibility of the installer to read all instructions before starting installation and to follow these

instructions carefully during installation. Modifi cation of

the remote control system or any of its components will

void the warranty and may cause a fi re hazard.

NOTE: The factory installed junction box in the gas

fi replace must be wired with 110 VAC before installing this kit. See Installation Instructions section.

CAUTION: All wiring should be done by a qualifi ed

electrician and shall be in compliance with local codes

and with the National Electric Code ANSI/NFPA No. 70current (in the United States), or with the current CSA

C22.1 Canadian Electric Code (in Canada).

WARNING: DO NOT CONNECT 110-120 VAC

WIRING TO THE GAS CONTROL VAL VE OF THIS

APPLIANCE.

FCC REQUIREMENTS

WARNING: CHANGES OR MODIFICATIONS TO

THIS UNIT NOT EXPRESSLY APPROVED BY

THE PARTY RESPONSIBLE FOR COMPLIANCE

COULD VOID THE USER’S AUTHORITY T O OPERATE THE EQUIPMENT.

NOTE: This equipment has been tested and found

to comply with the limits for a Class B digital device,

pursuant to Part 15 of the FCC Rules. These limits are

designed to provide reasonable protection against harmful interference in a residential installation. This equipment generates, uses, and can radiate radio frequency

energy and, if not installed and used in accordance with

the instructions, may cause harmful interference to radio

communications. However, there is no guarantee that

interference will not occur in a particular installation. If

this equipment does cause harmful interference to radio

or television reception, which can be determined by turning the equipment off and on, the user is encouraged

to try to correct the interference by one or more of the

following measures:

- Reorient or relocate the receiving antenna.

- Increase the separation between the equipment and

receiver.

- Connect the equipment into an outlet on a circuit different from that to which the receiver is connected.

- Consult the dealer or an experienced radio TV technician for help.

Canadian Equipment Requirements

This digital apparatus does not exceed the (Class A/Class

B)* limits for radio noise emissions from digital apparatus set out in the Radio Interference Regulations of the

Canadian Department of Communications. Le present

appareil numerique n’emet pas de bruits radioelectriques

depassant les limites applicables aux appareils numeriques (de la class A/de la class B)* prescrites dans le

Reglement sur le brouillage radioelectrique edicte par le

ministere des Communications du Canada.

This device complies with RSS-210 of Industry and Science Canada. Operation is subject to the following two

conditions: (1) this device may not cause interference,

and (2) this device must accept any interference, including interference that may cause undesired operation of

the device.

Printed in U.S.A. Copyright 2008,

Hearth & Home Technologies Inc.

20802 Kensington Boulevard, Lakeville, MN 55044

100-907F 4/08

1

Page 2

INSTALLATION INSTRUCTIONS

Installing Electrical Service to the Junction Box

WARNING: TURN ELECTRICAL POWER OFF AT

THE CIRCUIT BREAKER BEFORE BEGINNING

THIS INSTALLATION.

Wire Colors

• Gas Valve - Millivolt or

Electronic Ignition ..............................................Red

• Fan/Blower - 110 VAC .........................Plug from Fan

• Flame Controller - HI/LO solenoid ..................Orange

NOTE: Some appliances do not have a cover plate.

Instead, there is a hole through which the Romex clamp

is attached to the outer wrap.

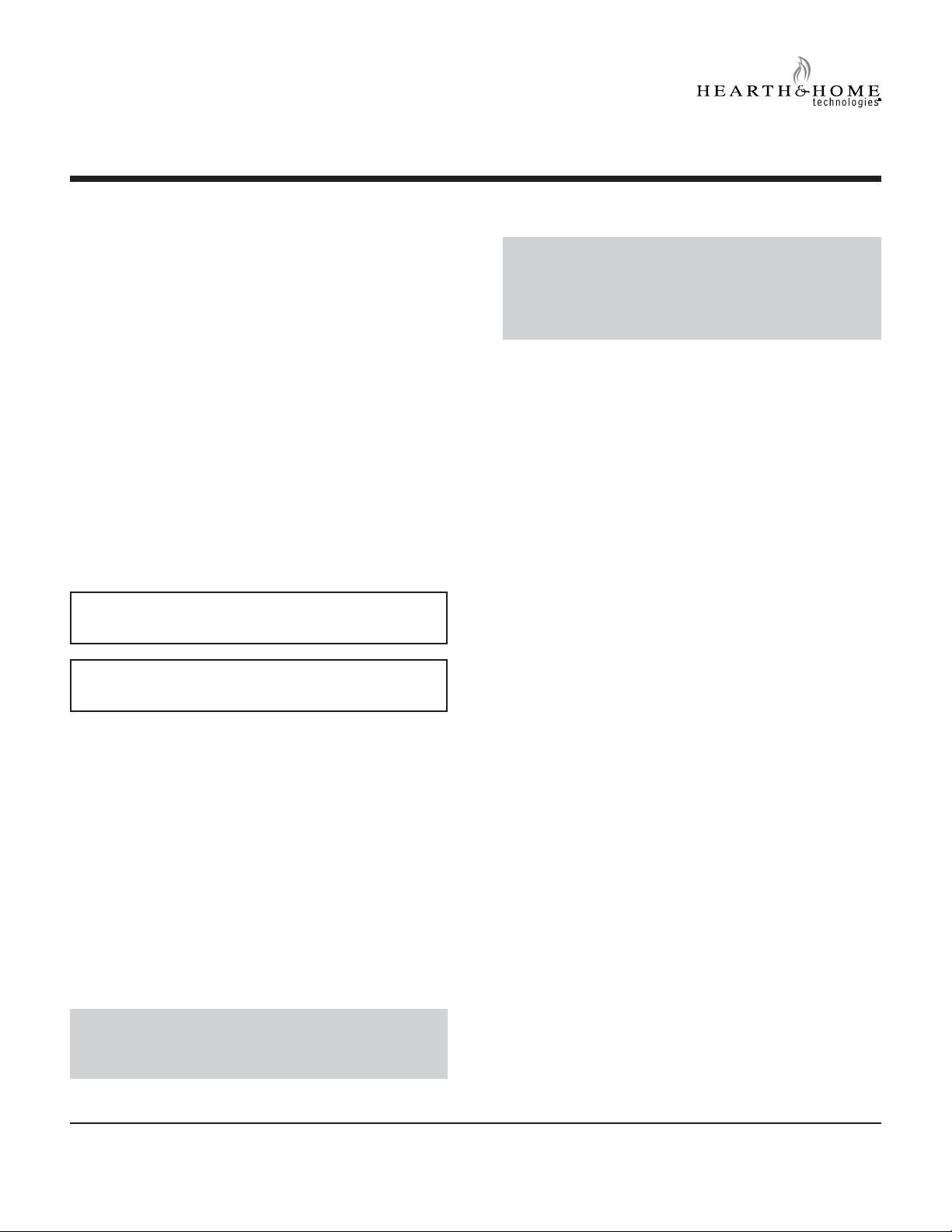

1. Remove the electrical cover plate from the lower side

of the fi replace. Remove the knock-out from the plate

and attach the Romex clamp (screws to the outside)

(see Figure 1).

ACCESS HOLE

110 VAC

SERVICE

COVER

PLATE

Figure 1

2. Feed the electrical service wires through the Romex

clamp and secure the wires to the clamp.

3. Using the wire nuts provided, connect the service

wires to the junction box. The black wires to the black

service wire, the white wires to the white service wire,

and the service ground wire to the ground stud of the

junction box.

4. Re-attach the cover plate to the outside of the fi re-

place.

RECEIVER WIRING INSTRUCTIONS

Incorrect wiring connections WILL cause damage to the

gas valve or electronic module operating the gas appliance and may also damage the remote receiver.

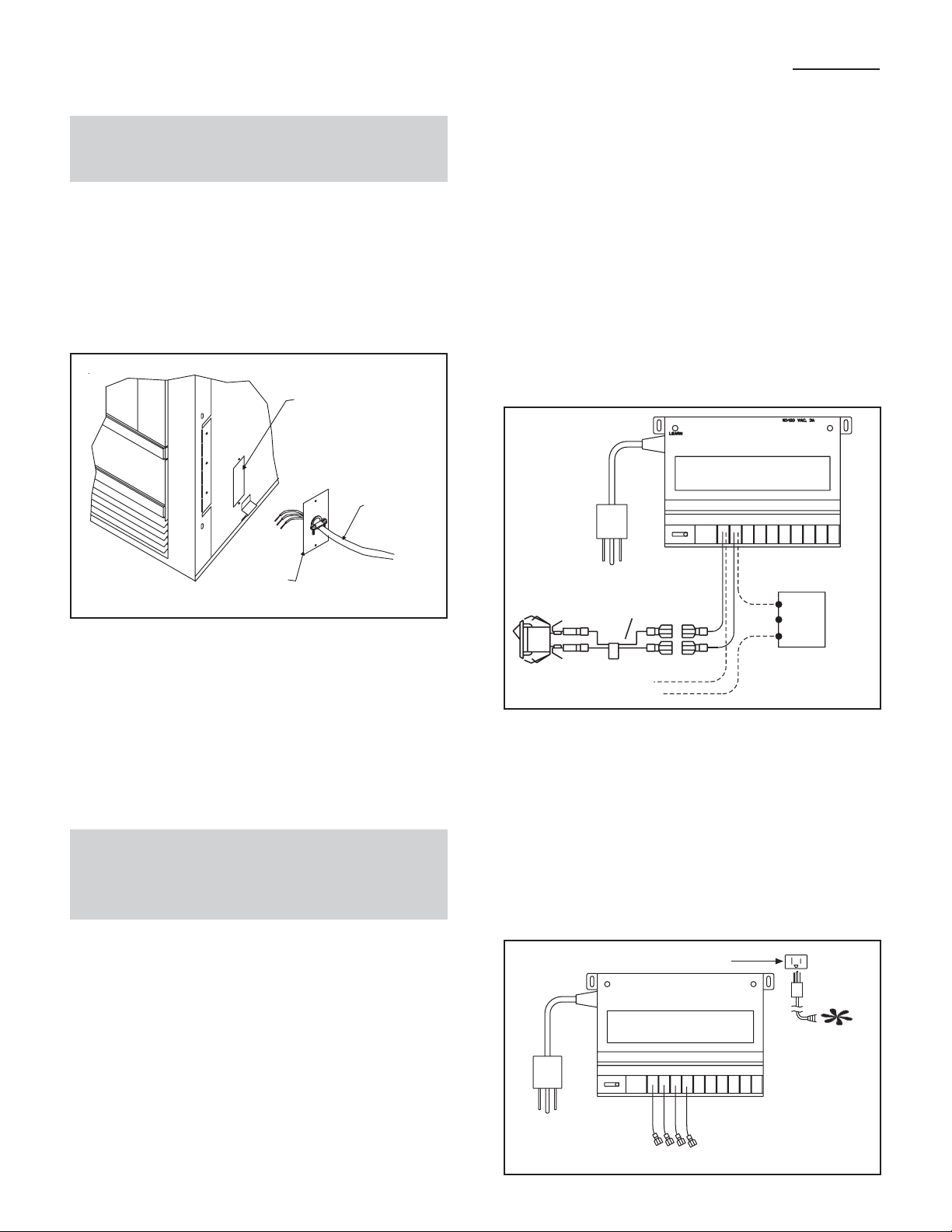

Wiring Flame Function (Standing Pilot, DSI, IPI)

Connect the remote receiver by connecting the two red

wires leading from the remote receiver to the red and

brown remote wires labeled “FOR USE WITH REMOTE

OR WALL SWITCH ONLY”. See Figure 2.

REMOTE

RECEIVER

RED

VALVE

TH

TP

TH

TP

ON/OFF

SWITCH REMOTE SWITCH

Figure 2.

BROWN

RED

PIGTAIL

WALL

SWITCH

RED

Alternative Wiring for units with a wall switch

Disconnect the wall switch wire from the TH terminal on

the valve and connect this wire to male connector supplied on the receiver. Connect remaining female connector from receiver to the TH terminal on the valve.

WARNING: LEAVE ELECTRICAL POWER OFF

AT THIS TIME. DO NOT RESTORE POWER UNTIL THE REMOTE CONTROL SYSTEM IS COMPLETELY INSTALLED.

REMOTE RECEIVER

Important: The remote receiver should be positioned

close to front in right or left corner where ambient

temperatures do not exceed 170º F.

The remote receiver is powered by 1 10-120V AC. It plugs

into a standard polarized duplex receptacle.

Locating Receiver and Operating Functions

This remote receiver can be positioned under the fi rebox

in the control compartment of the fi replace if ambient

temperatures do not exceed 170º F. This system is designed to control the following components:

Adding Optional Fan/Blower

Plug 2-prong fan cord directly into the 3 prong polarized

plug on the back of the receiver (see Figure 3). This

receptacle output is 110/120 VAC, 3 AMP.

(Receptacle on back)

Figure 3. Adding Fan/Blower

2

LEARN

REMOTE

RECEIVER

110/120 VAC, 3A

Line cord

from fan

Page 3

GAS CONTROL

D

VALVE

KNOB

SCREW

NUT

WASHER

VARIABLE

REGULATOR

FLAME CONTROL

SOLENOI

Figure 4.

NOTE: All steps required for installation of the

fl ame controller MUST be done by a qualifi ed gas

service technician.

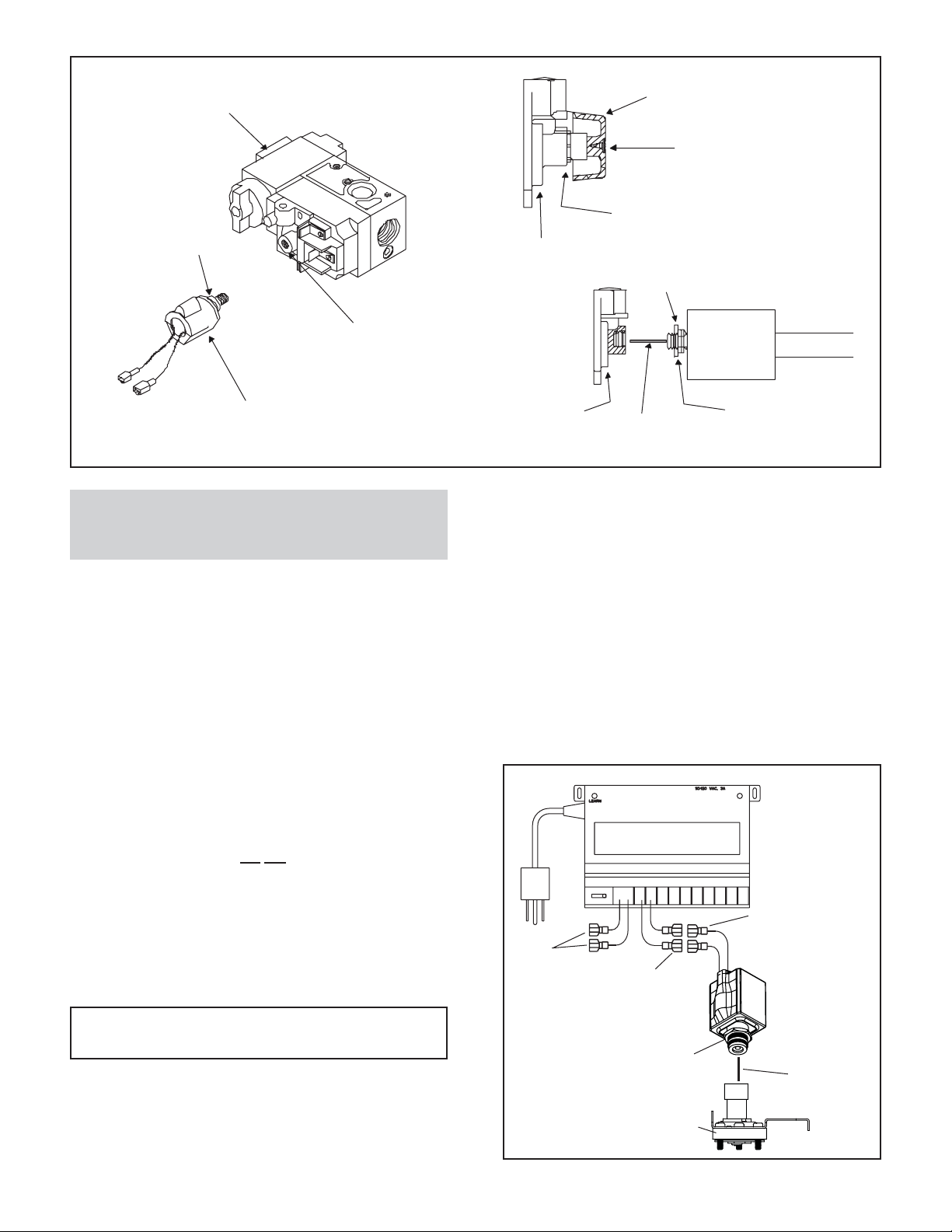

Installing Flame Control Solenoid

1. Remove the screw and knob from the variable regulator and discard.

2. Unscrew the nut from the regulator and discard.

3. Remove the bag containing a washer and blue and

red plungers from the side of the fl ame control sole-

noid.

4. Place washer on fl ame control solenoid (see Figure 4).

5. Insert the correct plunger (blue - natural gas, red propane) into the fl ame control solenoid (see Figure 4).

6. Thread the fl ame control solenoid with correct plunger

into the thread hole in the variable regulator. Turn

one to two turns only . Do not tighten or damage may

occur.

VARIABLE REGULATOR

WASHER

SOLENOID

VARIABLE

REGULATOR

PLUNGER

JAM NUT

3. Plug the remote receiver into the 110/120 V AC power

supply.

4. Light the fi replace as directed in the Owner’s Manual.

5. Set the manifold pressure on the gas valve by rotating

the fl ame control solenoid. Adjust until the reading on

the manometer is 3.5 inches w.c. for natural gas, or

10.0 inches w.c. for LP.

6. Tighten the jam nut (see Figure 4) to the face of the

variable regulator body.

7. Turn the main gas knob on the gas valve OFF.

8. Remove the manometer from the pressure tap and

screw the tap closed.

REMOTE

RECEIVER

Wiring the Flame Controller

1. Connect the two leads from the fl ame control solenoid

to the orange leads from the receiver.

2. Install a manometer into the pressure tap.

NOTE: A manometer MUST be used to set the

manifold pressure on the gas valve.

BLUE

RED

ORANGE

JAM NUT

PLUNGER

REGULATOR

TOWER

Figure 5.

3

Page 4

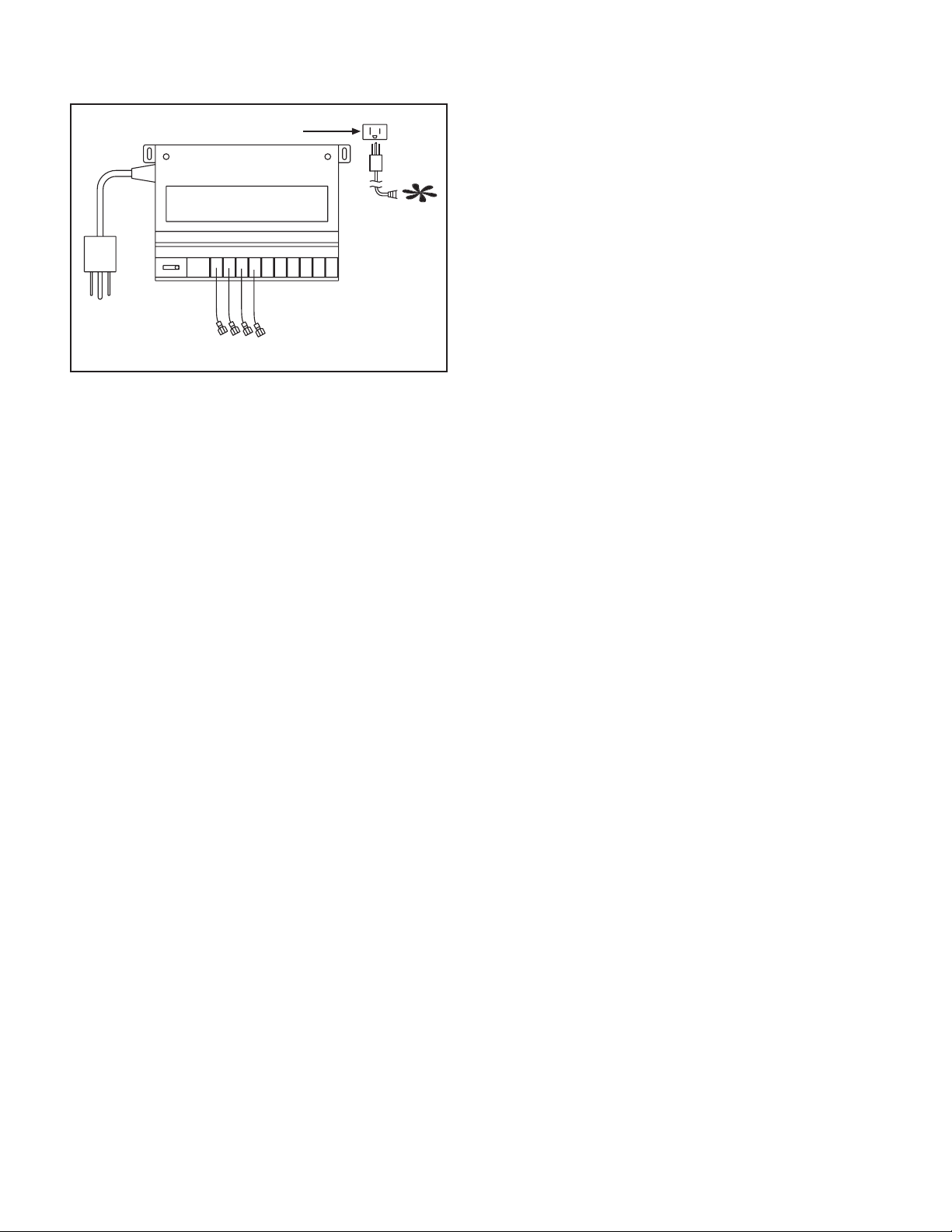

The remote receiver has a 3-position slide switch: OFF/

REMOTE/ON (see Figure 6).

(Receptacle on back)

LEARN

REMOTE

RECEIVER

Figure 6. Remote Receiver

110/120 VAC, 3A

Line cord

from fan

NOTE: The remote receiver will only respond to the

transmitter when the 3-position slide button on the

remote receiver is in the Remote position. If the

system does not respond to the transmitter on initial

use, see section Matching Security Codes.

1. With the slide switch in the ON position, the system

is on.

2. With the slide switch in the REMOTE position, the

system only operates if the remote receiver receives

commands from the transmitter.

3. With the slide switch in the OFF position, the system

is off.

NOTE: The slide switch should be placed in the OFF position if you will be away from your home for an extended

period of time. Placing the switch in the OFF position also

functions as a safety “lock out” by turning the system off

and rendering the remote receiver inoperative.

TRANSMITTER

Important: Before operating remote control, transmitter and receiver must have matching security codes.

See section ‘Matching Security Codes’.

Important: Review ‘Thermo-Updating/Communication-

Safety Features’ under ‘Transmitter Safety Features’

section. Communication Safety features shut down the

fi replace system when a potentially unsafe condition

exists.

Important: Review ‘Auto Shutdown’ section. This safety

feature shuts down the fi replace after 9 hours of continu-

ous operation, in ON mode only.

Important: New or fully charged batteries are essential

for proper operation of the multi-function transmitter. The

transmitter operates on 2 AAA-size 1.5V batteries. Use

Alkaline batteries for longer battery life and maximum

operational performance.

Insert 2 AAA-size 1.5V batteries into the battery compartment on the back of the transmitter. When the batteries

are correctly inserted, the screen will display numbers

(see Figure 7 for LCD Display Screen).

NOTE: If the transmitter is activated from a very cold

condition it may be necessary to allow the transmitter to

stabilize to room temperature (could take up to 15 minutes) before accurate room temperatures are displayed

on the screen.

NOTE: LCD screen is equipped with a “backlite” for

easier viewing of LCD screen. Backlite illuminates when

a function button is depressed. After 5 seconds elapses,

LCD screen will return to its normal state.

4

Page 5

1. LOW - Battery power low. Replace batteries within two weeks.

2. TIMER - Indicates time remaining before system shuts off, when timer-programmed, 9

- hour maximum setting.

3. MODE - Indicates operation MODE of system. ON indicates the system is on, either

manually or thermostatically. THERMO indicates the system will automatically cycle

ON/OFF , depending on programmed SET temperature. OFF indicates the entire system

is turned off.

4. SET - Indicates desired SET room temperature for THERMO operation.

5. FLAME - Single or double Flame/Hi icon indicates

burner/valve operational.

6. CLOCK - Indicates the current time in AM/PM.

7. ROOM - Indicates CURRENT room temperature.

8. ºF - Indicates degrees Fahrenheit (ºC indicates degrees

Celsius).

9. FAN - Indicates fan is on or programmed to come on.

Three speed settings are available.

Figure 7. Transmitter LCD Display Screen

MATCHING SECURITY CODES

It may be necessary to program the remote receiver to

the security code of the transmitter upon initial use, if

batteries are replaced, or if a replacement transmitter

is purchased from your dealer. To program the remote

receiver:

1. Set the slide button on the receiver to the REMOTE

position.

2. Push the LEARN button (one beep will be heard) on

the top of the remote receiver.

3. Then press the MODE button on the transmitter.

Several beeps indicate the transmitter’s code has

been programmed into the receiver. When an existing receiver is matched to a new transmitter, the new

security code will overwrite the old one. NOTE: When

the LEARN button is depressed, “beeping” sounds

should be heard. If no “beeping” is heard check to

see that the receiver has 110-120VAC power to it.

If you are unsuccessful in matching the security code on

the fi rst attempt, wait 1-2 minutes before trying again.

OPERATING INSTRUCTIONS

To operate the system, press the MODE button (Figure

7) on the transmitter to select the operational MODE

desired.

• ON indicates the system is on, either manually, timed

or thermostatically.

• THERMO indicates the system will automatically cycle

ON/OFF, depending on programmed set temperature.

• OFF indicates the entire system is turned off.

LCDDISPLA YSCREEN

THERMO

3

7

ROOM

6

ON

OFF

F

F

SET

AM

TIMER

1

4

8

2

MODE

SET

TIMER

TIME

FAN

5

FLAME

Transmitter Settings

Flip open the plastic cover on the front of the transmitter

to expose the “SET” buttons.

NOTE: Flashing numbers on the display indicate the

system is waiting for input, such as using the UP and

DOWN buttons to program a new setting. If no change

is made to fl ashing digits within 15 seconds, the system

will complete the procedure last programmed and reset

the display to its normal state.

Setting the Clock

1. Press and hold the TIMER/TIME button on the transmitter for more than two seconds. The hour digit(s)

will begin fl ashing (see Figure 7, Location #6).

2. Press the UP or DOWN button until the desired hour

is displayed in AM or PM.

3. After setting the desired hour, press and release the

TIMER/TIME button again to set the minutes; the

minute digits will begin fl ashing.

4. Press the UP or DOWN button until the desired minutes are displayed.

5. Press and hold the TIMER/TIME button again for more

than two seconds. The time digits will cease fl ashing,

indicating the clock has been successfully set. You

may also press the SET button on the transmitter to

stop the time digits from fl ashing and set the time.

5

UP

DOWN

FLAME

Page 6

Figure 8. Setting Button/Child Proof Lockout

Setting ºF/ºC Scale

The factory setting for temperature is degrees Fahrenheit

(ºF). To change this setting to degrees Centigrade (ºC):

1. Remove the battery cover on the back of the transmitter and locate the “setting button” at the top center of

battery compartment (see Figure 8).

2. Push setting button and ºF will begin fl ashing on the

LCD screen (see Figure 7, Location #4).

3. Push the DOWN button on the transmitter to change

ºF to ºC.

4. Push “setting button” on transmitter and Centigrade

(ºC) degree readings will display on LCD screen.

5. Repeat this process to change back to Fahrenheit (ºF)

reading, this time pushing the UP button. NOTE: LCD

screen will return to normal state if setting button is

not pushed within 15 seconds.

Setting Desired Room Temperature Thermo Operations

This remote control system can be thermostatically

controlled when the transmitter is in the THERMO

mode. (THERMO must be displayed on the screen). The

transmitter will “sense” the room temperature every two

minutes automatically turning the fi replace ON or OFF

thermostatically. To set the desired room temperature:

1. Press the MODE button to place the transmitter into

THERMO mode. THERMO ON or OFF will display.

2. Press the UP or DOWN button to select the desired room

temperature. The highest SET temperature is 99º F (32º

C). The lowest SET temperature is 45º F (6º C).

NOTE: To prevent repeated thermo-cycling of the gas

appliance, the sensing unit in the transmitter will only activate the remote receiver when the temperature change

exceeds 2º F (1º C) above or below the SET (desired)

temperature.

When the transmitter is in the THERMO mode, it should

be kept away from direct sources of heat such as fi re-

places, incandescent lighting and direct sunlight. Leaving

the transmitter in direct sunlight, for example, will cause it

to read the room temperature higher than it actually is.

Setting the Countdown Timer

This remote control system can operate with a built-in

countdown timer when the transmitter is in the ON or

THERMO modes (THERMO or ON must be displayed

on the LCD screen).

1. Press and release the TIMER/TIME button on the

transmitter. The word TIMER and 0:15 fl ash on the

screen (see Figure 7, Location #2).

2. Press the UP and DOWN button to begin advancing

through each of the countdown time options. A vailable

countdown times are 15 min, 30 min, 45 min, 1 hour,

1 hr 30 min, and each additional half hour up to nine

hours.

3. T o set the TIMER, press the SET button on the transmitter. If the system is ON, it will remain on until the

“time” has expired. If the system is in the THERMO

mode, it will cycle on and off as the room temperature

requires until the “time” has expired.

NOTE: When the timer is used in the THERMO mode,

the THERMO operation will discontinue when the “time”

has expired.

Operating the Fan Operates in ON or THERMO mode

This remote control system has the capability of operating

a 110 VAC fan or blower system that may be included

with your gas fi replace. The fan will only operate when

the transmitter is in the ON or THERMO mode. (THERMO

or ON must be displayed on LCD screen).

1. To turn fan ON, press and release the FAN button

on the transmitter (see Figure 7, Location #9). The

fan will operate at HI speed, and fan blade icon will

appear on LCD screen.

2. T o change fan speed to MED, press and release F AN

button again. To change fan speed to LO, press and

release FAN button again.

3. T o turn fan OFF , press and release F AN button again.

Fan blade icon will disappear from LCD screen.

6

Page 7

Adjusting the Flame Height Operates in ON or THERMO mode

This remote control system allows the user to control

the height of the FLAME when the gas valve is factory

equipped with a FLAME CONTROLLER.

1. Press and release FLAME button to change fl ame

height to HI (see Figure 7, Location #5), (a second

fl ame icon appears).

2. Press again to return fl ame to normal state.

Low/Battery Indicator

An “X” outlined by a battery on the right side of the LCD

screen will appear when battery power has dropped

signifi cantly. At this time, approximately two weeks of

battery power remains.

Child Proof Lockout (CP)

The transmitter contains a “Child Proof” lockout feature

that prevents unauthorized use of the remote control. To

access the “Child Proof” activation button, remove cover

on BACK of transmitter. To activate LOCKOUT:

1. Press and hold in the “setting button” for 5 seconds.

The letters CP will display on the LCD screen (see

Figure 8). This prevents the activation of fi replace.

When any function button is pressed ON/OFF etc.

the letter CP will display on the LCD screen.

To deactivate LOCKOUT:

1. Press and hold in the “setting button” for 5 seconds. The

LCD will display CP until 5 seconds have elapsed, and

then the LCD screen will return to its normal state.

TRANSMITTER SAFETY FEATURES

It is recommended that the TRANSMITTERS always be

located within a 20 foot operating range of the fi replace,

preferably in the same room in which the fi replace system

is located. The TRANSMITTER features several safety

features that alert the user when the TRANSMITTER is

placed outside the 20 foot normal operating range.

Thermo-Updating and Communication-Safety Features

This remote control has a COMMUNICATION-SAFETY

function built into its software. It provides an extra margin

of safety when the TRANSMITTER is out of the normal

20 foot operating range of the receiver. It is also activated

when the batteries become weak or are removed from

the transmitter.

In the THERMO-UPDATING feature (only in the THERMO or TIMER modes) the transmitter normally reads

the ROOM temperature every 2 minutes. In addition to

checking the temperature, the transmitter sends a signal

to the receiver indicating that the transmitter and its batteries are still active.

In the COMMUNICATION-SAFETY feature, at all times

and in all OPERATING MODES the transmitter sends a

signal every fi fteen (15) minutes to the receiver, indicat-

ing that the transmitter is within the normal operating

range of 20 feet.

Should the receiver NOT receive a transmitter signal

every 15 minutes (COMMUNICATION-SAFETY feature), the RECEIVER will begin a 2 HOUR (120 minute)

countdown timing function. If during this 2 hour period,

the receiver does not receive a signal from the transmitter, the RECEIVER will shut down the fi replace being

controlled by the receiver. The RECEIVER will then emit

a series of rapid “beeps”. Then, after 10 rapid “beeps”,

the RECEIVER will continue to emit a single “beep” every

4 seconds until a transmitter signal is again received.

The intermittent 4 second beeping will go on indefi nitely

until reset.

To “reset” the RECEIVER and operate the fi replace

system:

1. Press the MODE button on the transmitter. The word

ON must display on the LCD screen. The COMMUNICATION -SAFETY operation is overridden and the

system will return to normal operation depending on

the MODE selected at the transmitter.

We recommend the user check the batteries in the

TRANSMITTER to make sure the voltage is no less

than 2.7 volts.

Auto Shutdown

This remote control has an Auto Shutdown feature incorporated into its system. When the transmitter MODE is

in the ON position the fi replace will continuously operate

for 9 hours. After 9 hours, the fi replace will shut down.

To relight the fi replace:

1. Press the MODE button. The fi replace will operate

continuously for up to 9 hours before Auto Shutdown

repeats cycle. The Auto Shutdown signal comes from

the transmitter. The transmitter must be positioned

within a 20 foot operating range for the Auto Shutdown

feature to operate.

SYSTEM CHECK

Millivolt Valves

Light the appliance following the lighting instructions

that came with the fi replace. Confi rm that the pilot fl ame

is on. It must be in operation for the main gas valve to

operate.

1. Slide the 3-position button on the remote receiver to

the ON position. The main gas fl ame (i.e., the fi re)

should ignite.

2. Slide the button to OFF. The fl ame should extinguish

(the pilot fl ame will remain on).

3. Slide the button to REMOTE (the center position),

then press the MODE button on the transmitter to

change the system to ON. The main gas fl ame should

ignite.

4. Press the MODE button on the transmitter to change

the system to OFF. The fl ame should extinguish (the

pilot fl ame will remain on).

5. Press the MODE button on the transmitter to change

the system to THERMO.

7

Page 8

6. Advance the SET temperature on the transmitter to a

temperature of at least 2º F (1º C) above the ROOM

temperature displayed on the LCD screen and the

system fl ame will ignite.

7. Set the SET temperature to at least 2º F (1º C) below

the room temperature and the system fl ame will extin-

guish. Thereafter, it should continue to cycle on and

off thermostatically approximately every two minutes

as the ROOM temperature changes, but only when

the temperature differential between ROOM and SET

temperatures differs at least 2º F (1º C). The 2º F differential is the factory setting.

Electronic Ignition System

1. Slide the 3-position button on the remote receiver to

the ON position. The spark electrode should begin

sparking to ignite the pilot (the pilot may ignite after

only one spark). After the pilot fl ame is lit, the main

gas valve should open and the main gas fl ame should

ignite.

2. Slide the button to OFF. The main gas fl ame and pilot

fl ame should BOTH extinguish.

3. Slide the button to REMOTE (the center position).

4. Then press the MODE button on the transmitter to

change the system to ON. The spark electrode should

begin sparking to ignite the pilot. After the pilot is lit,

the main gas valve should open and the main gas

fl ame should ignite.

5. Press the MODE button on the transmitter to OFF.

The main gas fl ame and pilot fl ame should BOTH

extinguish.

6. Press the MODE button on the transmitter to change

the system to THERMO.

7. Advance the SET temperature on the transmitter to

temperature of at least 2º F (1º C) above the room

temperature displayed on the LCD screen and the

system fl ame will ignite.

8. Set the SET temperature to at least 2º F (1º C) below

the room temperature and the system will extinguish.

Thereafter, it should continue to cycle on and off

thermostatically approximately every two minutes as

the ROOM temperature changes, but only when the

temperature differential between ROOM and SET

temperatures differ at least 2º F (1º C). The 2º F differential is the factory setting.

Timer Operation

The countdown timer will operate in either the manual ON

or THERMO mode. Once the fi replace system is in an

operating mode, set the countdown timer to turn off in 15

minutes. The timer function will allow operation to continue

until the “countdown time” on the LCD screen expires. After

15 min. elapses, the system should turn off.

GENERAL INFORMATION

Transmitter Wall Bracket

The transmitter can be hung on a wall using the bracket

provided. Locate the bracket on an inside wall suffi -

ciently far away from direct sources of heat such as a

fi replace, incandescent lighting, or sunlight so it detects

ambient room temperatures, not a single heat source.

If the bracket is installed on a solid wood wall, drill 1/8”

pilot holes and install with the screws provided. If it is

installed on a plaster/wallboard wall, fi rst drill two 1/4”

holes into the wall, then use a hammer to tap in the two

plastic wall anchors fl ush with the wall, then install the

screws provided.

Battery Life

Life expectancy of the batteries in the transmitter should

be at least 12 months. Check batteries annually . When the

transmitter no longer operates the remote receiver from

a distance it did previously (i.e., the transmitter’s range

has decreased) the batteries should be checked.

Specifi cations

Batteries: Transmitter - 3V 2 ea.; AAA 1.5V, Alkaline

Remote - 110-120 VAC; 60Hz

Operating Frequency: 303.8 MHZ

FCC ID No.’s: Transmitter - K9L300ITX

Receiver - K9L3003RX

Canadian ISC ID No.’s: Transmitter - 2439 102 760

Receiver - 2439 102 760A

Service Parts List

DESCRIPTION SERVICE PART NO.

3-PRONG ADAPTER HTI-18-006

SOLENOID-110 VOLT HI/LO HTI-17-006

TRANSMITTER WALL HOLDER HTI-16-006

BATTERIES-TRANSMITTER HTI-14-006

RECEIVER HTI-13-006

TRANSMITTER (RCT-MLT-HNG) HTI-12-006-HNG

TRANSMITTER (RCT-MLT-HTL) HTI-12-006-HTL

HARDWARE PACKAGE HTI-11-006

Limited Warranty

This REMOTE CONTROL SYSTEM is warranted for 12

months from the date of purchase or installation to the

original purchaser to be free from defects in materials

and workmanship. Damage to the SYSTEM caused by

accident, misuse, abuse, or installation error whether

performed by a contractor, service company, or owner, is

not covered by this warranty . Seller will not be responsible

for labor charges and/or damage incurred in installation,

repair, replacement or for incidental or consequential

damages. Batteries and any damage caused by them

are not covered by this warranty.

Some states, provinces, and nations do not allow exclusion or limitations of incidental or consequential damages,

so the above limitations or exclusions may not apply . This

warranty gives you specifi c legal rights. You may have

other rights that vary by state, province or nation.

8

Page 9

IGNITION MODULE 3 VAC INTERMITTENT PILOT IGNITOR

I

S

BATTERY PACK

THERMOSTAT

WIREASSEMBLY

TRANSFORMER

3VAC

HOT

NEUTRAL

PLUG IN

D

E

R

JUMPER WIRE

(TO BROWN)

WHITE

ORANGE

GROUND TO

FIREPLACE

CHASSIS

ORANGE

VALVE

GREEN

Figure 9. Intermittent Pilot Ignition (IPI) Wiring Diagram

PIEZO

PILOT

THERMOCOUPLE

WHITE

VALVE

RED

Figure 10. Standing Pilot Ignition Wiring Diagram

THERMOSTAT

WIRE ASSEMBLY

9

Page 10

3V TRANSFORMER

V

ON/OFF

WALL

SWITCH

VALVE

NEUTRAL

PLUG-IN

IGNITION

MODULE

(3V)

LOW VOLTAGE

GROUND

FLAME SPARKER/

SENSOR

SEE NOTE 1

REMOTE

CONTROL

HOT

IGNITION MODULE

3VAC

I

S

WHT

ORG

GROUNDTO

FIREPLACE

CHASSIS

INTERMITTENT

PILOT

IGNITOR

WHITE WIRE

CAN BE

PLUGGED

INTOANY

BLACK WIRE CAN BE

PLUGGED INTO ANY OF

#1 - #5 LOCATIONS

ON THE HOT SIDE

OF #1-#5

LOCATIONS

ON THE

NEUTRAL SIDE

TRANSFORMER

PLUG IN

Figure 11. Intermittent Pilot Ignition (IPI) Wiring Diagram

3/16” PIGGYBACK CONNECTOR

3VAC

BLACK S2

BRN

PIGGYBACK

ON/OFF SWITCH

BRN

ORG

GRN

ALVE

REMOTE SWITCH

PIGTAIL

ON

OFF

ON/OFF

SWITCH

OPTIONALWALL SWITCH,

THERMOSTAT OR REMOTE

THERMOCOUPLE

GAS VALUE

WHITE T2

RED T1

THERMOPILE

BLACK S1

Figure 12. Standing Pilot Ignition Wiring Diagram

10

Page 11

Remote Control Wiring Diagrams

V

BATTERY PACK

REMOTE RECEIVER

TRANSFORMER

3 VAC

PLUG IN

IGNITION MODULE 3 VAC

K

C

A

L

B

D

E

R

JUMPER WIRE

(TO BROWN)

INTERMITTENT PILOT IGNITOR

I

S

WHITE

ORANGE

GROUND TO

FIREPLACE

CHASSIS

ORANGE

GREEN

Figure 13. Remote Control Intermittent Pilot Ignition (IPI) Wiring Diagram

PILOT

THERMOCOUPLE

VALVE

WHITE

RED

ALVE

PIEZO

REMOTE RECEIVER

Figure 14. Remote Control Standing Pilot Ignition Wiring Diagram

11

Loading...

Loading...