Page 1

THE GBi25 SERIES

B-VENT GAS FIRED FIREPLACE INSERT ROOM HEATER

INSTALLATION & OPERATING

INSTRUCTIONS

This manual must be used for installation of the GBi25 series B-Vent Gas Fired Fireplace Insert and

retained by the homeowner for operation and maintenance instructions.

WARNING: If the information in this manual

is not followed exactly, a fire or explosion may

result causing property damage, personal injury or loss of life.

Do not store or use gasoline or other flammable

vapors and liquids in the vicinity of this or any

other appliance.

What to do if you smell gas

Do not try to light any appliance.

Do not touch any electrical switch; do not use

any phone in your building.

Immediately call your gas supplier from a

neighbors phone. Follow the gas suppliers

instructions.

If you cannot reach your gas supplier, call the

fire department.

Installation and service must be performed by a

qualified installer, service agency or the gas

supplier.

WARNING!

Improper installation, adjustment, alteration, service or maintenance can cause injury or property damage. Refer to this

manual. For assistance or additional information, consult a qualified installer, service agency or the gas supplier.

02-02 1 26678 Rev H

Page 2

GBI25 SERIES B-VENT GAS FIRED FIREPLACE INSERT

Content s

A. Listings and Code Aprovals ..................................................................................................... 3

B. Description of the System .......................................................................................................3

C. System components ...............................................................................................................4

D. Dimensions and Clearances ................................................................................................... 4

E. Pre-Installation Preparation ..................................................................................................... 5

F. Step-by-Step Installation of the System ................................................................................... 6

G. Operating Instructions ...........................................................................................................14

H. Maintenance Instructions....................................................................................................... 16

I. Troubleshooting .....................................................................................................................17

J. Replacement Parts ............................................................................................................... 18

K. Optional Components ...........................................................................................................19

Index ...................................................................................................................................... 23

Warranty ................................................................................................................................ 24

CAUTION:

Do not expose the appliance to the elements (such as rain, etc.)

SAFETY PRECAUTIONS

1. Please read these installation instructions completely

before beginning installation procedures. Failure to

follow them could cause a malfunction resulting in

serious injury and/or property damage.

2. Installation and repair should be done by a qualified

service person. This appliance should also be

inspected annually by a qualified service person. More

frequent inspections/cleaning may be required due

to excessive lint from carpeting, bedding material, etc.

It is imperative that the control compartment and

burners of the appliance be kept clean.

3. The GBi25is a vented gas appliance. Do not burn

wood or other material in this appliance.

4. NEVER leave children unattended when there is a

fire burning in the fireplace.

5. This appliance must be vented with a minimum 4 B-

Vent system and must terminate above the roof line.

Venting must not be connected to a chimney flue

servicing a solid fuel burning appliance.

6. Use only the fuel gas specified on the rating label of

this gas appliance.

7. The appliance area shall be kept clear and free from

combustible materials, gasoline and other flammable

vapors and liquids.

8. While servicing this appliance, always shut off all

electricity and gas to the appliance. This will prevent

possible electrical shock or burns. Also, make sure

the fireplace is completely cooled before servicing.

9. Do not use this appliance if any part has been under

water. Immediately call a qualified service technician

to inspect the appliance and to replace any part of the

control system and any gas control which has been

under water.

10. Be sure to provide adequate clearances around the

air openings into the combustion chamber and

adequate accessibility clearances for servicing and

proper operation.

11. Provisions shall be made to provide adequate

combustion and ventilation air. The flow of combustion

and ventilation air should not be obstructed.

26678 Rev H 2 02-02

Page 3

GBI25 SERIES B-VENT GAS FIRED FIREPLACE INSERT

A. LISTINGS AND CODE APROVALS

U.S. AND CANADA CERTIFICATION

This appliance has been tested in accordance with ANSI

Z21.11.1-1991, CAN/CGA 1-2.1-MB6 and applicable

sections of ANSI Z21.50-1996 CAN/CGA 2.22-M96 and

has been LISTED by Underwriters Laboratories Inc. for

installation and operation as described in these

Installation and Operating Instructions. All components

are UL. AGA, CGA or CSA safety certified.

LOCAL CODES

Check with your local building code agency prior to

installing this appliance to ensure compliance with local

codes, including the need for permits and follow-up

inspections. This installation must conform with local

codes or, in the absence of local codes, with the National

Fuel Gas Code, ANSI Z223.1-latest edition in the U.S.A.

and the CANI-B149-latest edition in Canada. The

appliance, when installed, must be electrically grounded

in accordance with local codes; in the absence of local

codes, with the current National Electric Code ANSI/FNPA

No. 70 (in the U.S.A.) or with the current CSA C2.1 Canadian

Electric Code in Canada.

FUEL

Any additions, changes or conversions required in order

for the appliance to satisfactorily meet the application

needs, must be made by a qualified service technician

using factory specified and approved parts.

If you require assistance during installation, please contact

your local dealer or the Heatilator Technical Services

Department, Hearth Technologies Inc., 1915 W. Saunders

Street, Mt. Pleasant, Iowa 52641 (1-800-843-2848).

HEATILATOR® is a registered trademark of Hearth

Technologies Inc. (HTI), a division of HON INDUSTRIES.

B. DESCRIPTION OF THE SYSTEM

The GBi25 Series is a B-vent gas-fired room heater.

Combustion air is supplied from inside the house.

This HEATILATOR system must consist of the following:

1. Appliance

2. B-Vent Venting System

3. Termination

4. Surround

Tools and building supplies normally required for

installation:

Saw Wall-finishing materials

Pliers Framing material

Hammer Surround

Phillips screwdriver Caulking material

Tape measure Safety gloves

Plumb line Electric drill/bits

Level Framing Square

HIGH TEMPERATURE SEALANT MATERIAL

Sealants that will withstand high temperatures: General

Electric RTV103 (Black), or equivalent. Rutland, Inc.

Fireplace Mortar #63 or equivalent; Dow Corning 732 or

equivalent.

We strongly recommend that you DO NOT install B-Vent

Gas Appliances in strong negative air locations, such

as a basement or a public facility. Living rooms with

cathedral ceilings could be susceptible to a negative

air situation, but such installations can be overcome

through raising the termination, depending on specific

installations. This fireplace uses room air for normal

operation and could have problems establishing a

positive draft in negative air locations. In lieu, we

recommend a direct vent appliance.

Note: Illustrations throughout these instructions reflect

typical installations and are for design purposes only.

Actual installation may vary slightly due to individual

design preferences. However, minimum and maximum

clearances must be maintained at all times.

The illustrations and diagrams used throughout these

installation instructions are not drawn to scale.

02-02 3 26678 Rev H

Page 4

GBI25 SERIES B-VENT GAS FIRED FIREPLACE INSERT

C. SYSTEM COMPONENTS

The table below is a list of only those components which may be safely used with this gas-fired fireplace insert.

rebmuNgolataCnoitpircseD

52iBGtoliPgnidnatS,saGlarutaN-tresnIderiF-saGtneV-B

L52iBGtoliPgnidnatS,saGenaporP-tresnIderiF-saGtneV-B

42DSGmirThtiW)W"2/1-04xH"42(dnuorruSllamS

04DSGmirThtiW)W"2/1-04xH"2/1-82(dnuorruSmuideM

64DSGmirThtiW)W"64xH"33(dnuorruSegraL

PVKCsaGenaporPottiKnoisrevnoC

NVKCsaGlarutaNottiKnoisrevnoC

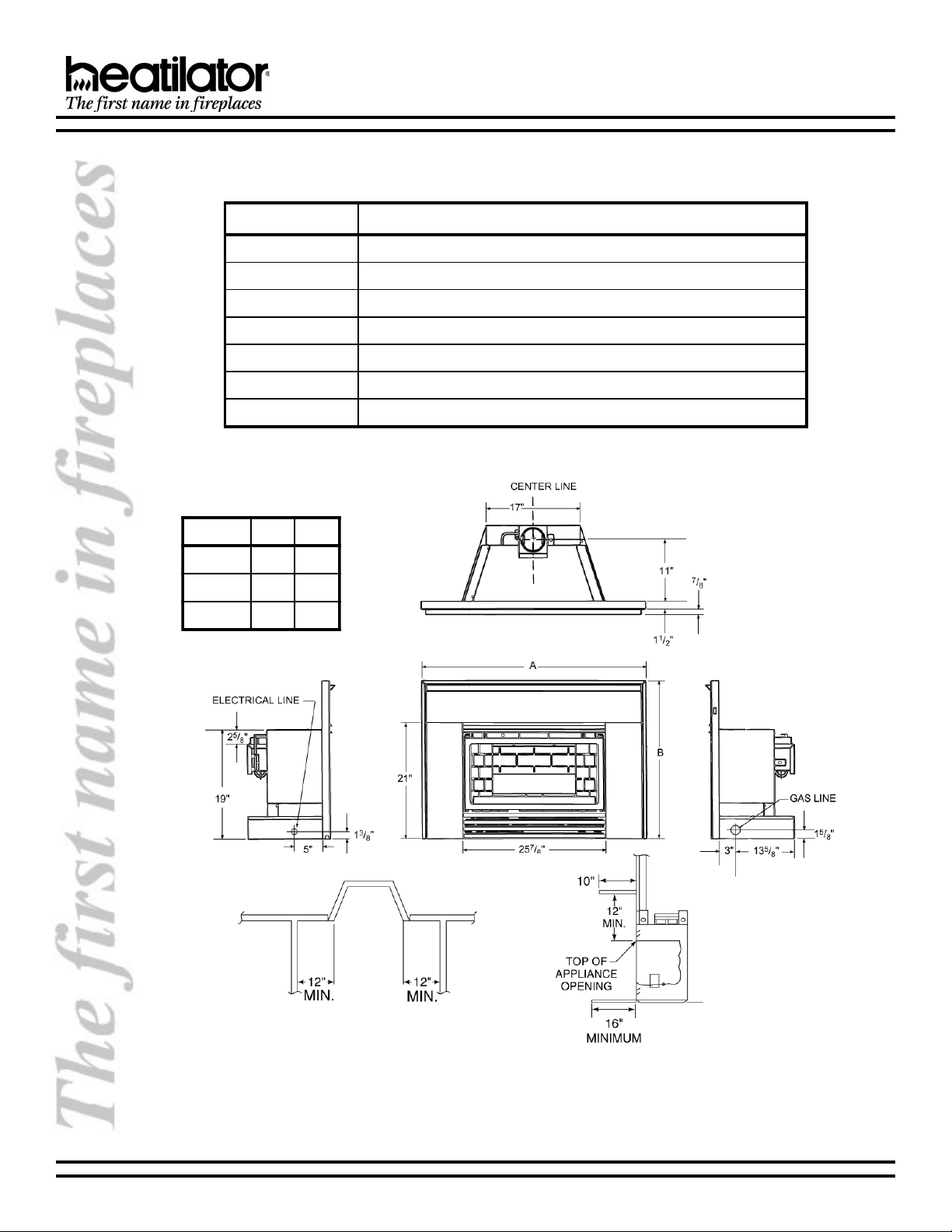

D. DIMENSIONS AND CLEARANCES

LEDOMAB

42DSG"5.04"42

04DSG"5.04"5.82

64DSG"64"33

MANTEL

A combustible mantel may be positioned no lower than 12 above the top of the appliance opening of the existing

fireplace. The combustible mantel may have a maximum depth of 10. Combustible trim materials, such as a surround

or mantel support brackets, protruding no more than 1-1/2 from the face of the existing fireplace, can be placed no

closer than 6 from any edge of the surround.

26678 Rev H 4 02-02

Page 5

GBI25 SERIES B-VENT GAS FIRED FIREPLACE INSERT

E. PRE-INSTALLATION PREPARATION

Installation and repair should be done by a qualified service technician. The appliance should be inspected before

use and at least annually by a qualified service technician. More frequent cleaning may be required due to excessive

lint from carpeting, bedding material, etc. It is imperative that control compartments, burners and circulating air

passageways of the appliance be kept clean.

Due to high temperatures, the appliance should be located out of traffic and away from furniture and draperies.

WARNING!

This appliance may use the B-vent chimney system only and must not be connected to a chimney flue servicing

a separate solid fuel buring appliance.

This appliance must be installed on a noncombustible, flat, solid, continuous surface (i.e. fireplace hearth.)

WARNING!

To prevent contact with sagging or loose insulation, the appliance must not be installed against vapor barriers

or exposed insulation.

1. GAS PRESSURE

For natural gas, the minimum inlet gas supply

pressure is 4.5 inches water column (w.c.), and the

maximum inlet gas supply pressure is 7.0 inches

w.c. Input rate is 17,000 to 22,000 Btu/hr. For propane

gas, the minimum inlet gas supply pressure is 11.0

inches w.c. and a maximum 14.0 inches w.c. Input

rate is 15,000 to 22,000 Btu/hr.

Manifold pressure for this appliance is 1.7 - 3.5 inches

w.c. for natural gas and 5.4 - 11.0 inches w.c. for

propane gas. This appliance has a variable adjust

manifold.

Input (line) and output (manifold) pressure taps are

located at the front of the gas control valve near the

variable regulator for test gauge connection with a

3/8 diameter hose.

A 1/8 NPT plugged tapping is provided on the gas

control valve, near the outlet to the main burner

immediately upstream of the gas supply connection

to the appliance, accessible for a test gauge

connection.

2. HIGH ALTITUDE INSTALLATION

U.S. Installation: Appliances are tested and approved

for elevations from 0-2000 feet (0-610m).

When installing this appliance at an elevation above

2000 feet, it may be necessary to decrease the input

rating by changing the existing burner orifice to a

smaller size. Input should be reduced 4% for each

1000 feet above sea level. Check with the local gas

utility for proper orifice size identification and to see if

the gas in your area has been deregulated. This

appliance is shipped with a .093 in./2.36 mm. orifice

size on natural gas versions and a .056 in./1.42 mm.

orifice size on propane gas versions.

Canadian Installation: Appliances are certified for

elevations from 0-4500 feet. When installing this

appliance at an elevation between 0-4500 feet in

Canada, the input rating does not need to be reduced.

When installing this appliance at an elevation above

4500 feet in Canada, check with local authorities.

Consult your local gas company for assistance in

determining the proper orifice for your location or refer

to ANSI Z23.1-latest edition, Appendix F.

3. COMPONENTS

Before installing this appliance, it may be necessary

to remove the smoke shield, ash lip, refractory,

damper blade, etc. If removed, the label referenced

on page 7 MUST be affixed to the existing fireplace

prior to installation.

02-02 5 26678 Rev H

Page 6

GBI25 SERIES B-VENT GAS FIRED FIREPLACE INSERT

F. STEP-BY-STEP INSTALLATION OF THE SYSTEM

WARNING!

Before starting, do the following:

1. Wear gloves and safety glasses for protection.

2. Keep hand tools in good contition. Sharpen cutting edges and make sure tool handles are secure.

3. Always maintain the minimum air space required to the enclosure to prevent fire.

WARNING!

This appliance is equipped with a safety control system designed to protect against improper venting of combustion products. Operation of this appliance when not connected to a properly installed and maintained venting

system, or tampering with a vent safety shut-off system can result in carbon monoxide (CO) poisoning and

possible death.

1. VENTING REQUIREMENTS

A flue liner from the outlet of the draft hood to the roof

termination is required. This appliance is required to

be connected to a listed 4 diameter, stainless steel

or aluminum flexible gas vent liner with a top

termination. A 4 B-Vent or listed 4 rigid single wall

gas vent may also be used.

Before attempting to run your flue liner, you must make

sure that it will pass through the existing damper area;

this is best done with a flexible liner. In a zero clearance

(factory built) fireplace, the existing damper must be

removed or locked out of the way in the open position.

For masonry fireplaces, if the damper will not allow

the passage or a 4 flex, do not proceed without

consulting a local mason on how to remove or alter

the damper without risk of structural damage or

leakage.

A minimum vertical venting height of 9 feet above the

base of the appliance must be maintined. The

horizontal run must not exceed 50% of the vertical

height. Maximum vertical venting height is 40 above

the base of the appliance. The vent termination must

be in accordance with its respective listing and

manufacturers instructions.

Install 4 flue liner down through the chimney. When

using flexible liner, use caution around the offsets so

as not to rupture the liner. Measure up 16 from the

existing fireplace bottom and leave hanging in

fireplace.

brought into the fireplace through the gas knockouts

provided.

Note: The appliance and its manual shutoff valve must

be disconnected from the gas supply piping system

during any pressure testing of that system at test pressures in excess of 1/2 psi (3.5 kPa). The appliance must

be isolated from the gas supply piping system by closing the manual shutoff valve during any pressure testing of the gas supply piping system at test pressures

equal to or less than 1/2 psi (3.5 kPa).

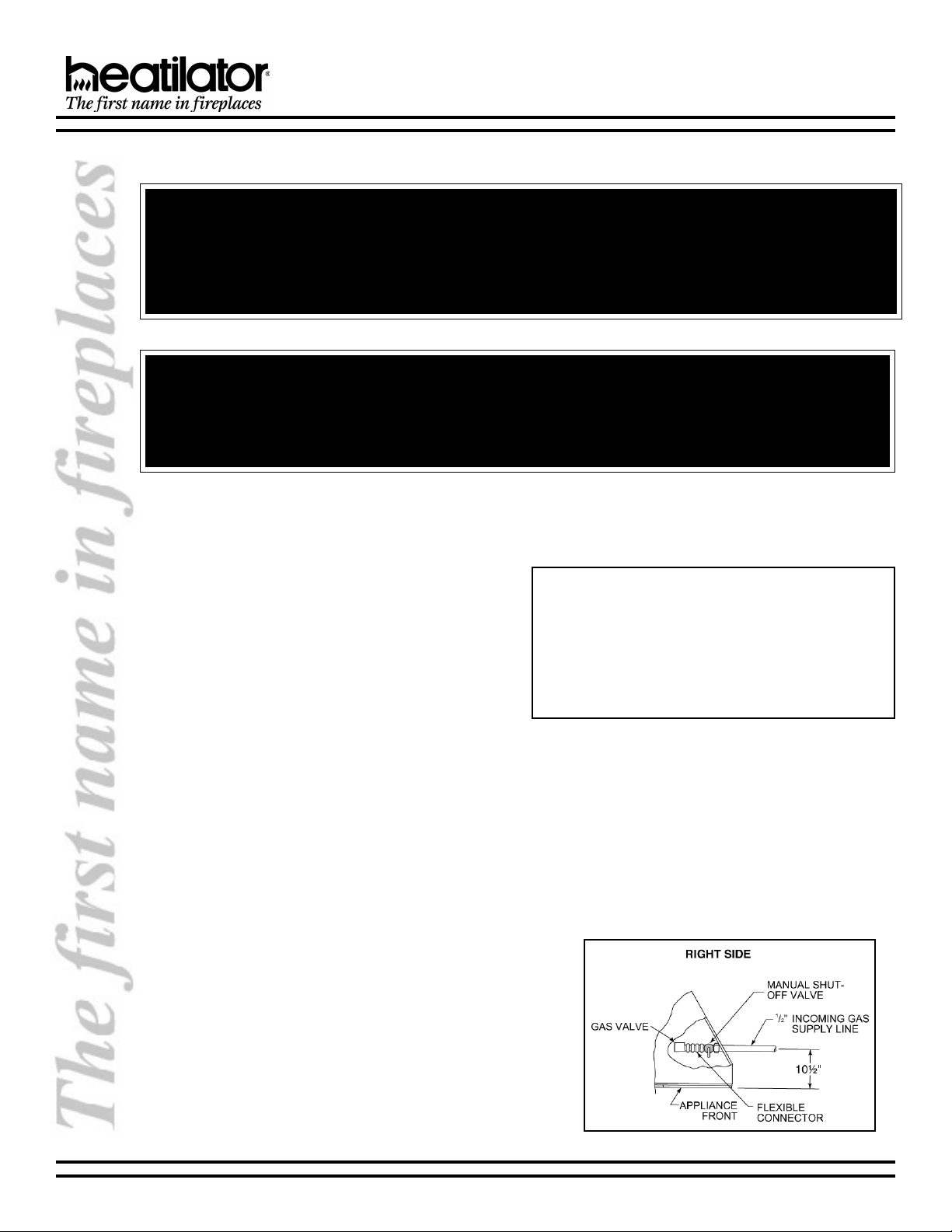

It is recommended that 1/2 inside diameter black

pipe be run into the fireplace through the right side. If

the existing fireplace already has gas run to it, but

through the left side, it is recommended that the gas

be rerouted to the right side. See Figure 1.

Place an elbow at the end of the black pipe so that it

runs perpendicular to the face. A 1/3 flare adapter

(not supplied) is necessary to connect the flex line

(supplied) to the black pipe.

Check for leaks using a soap and water solution or a

leak detector.

2. GAS LINE INSTALLATION

A gas line must run into the existing woodburning

fireplace, for either a factory built or masonry fireplace.

If it is a factory built fireplace, the gas line should be

Figure 1 - Gas Line Installation

26678 Rev H 6 02-02

Page 7

GBI25 SERIES B-VENT GAS FIRED FIREPLACE INSERT

Seal with high temperature silicone at the point where

the gas line enters the existing fireplace to prevent

cold air infiltration.

This fireplace has been altered to

accommodate an insert and should be

inspected by a qualified service technician

prior to re-use as a conventional fireplace.

Label

Note: The above label, located in the instruction

package, must be affixed to the existing fireplace prior

to installation of the GBi25 Gas Fired Fireplace Insert.

3. APPLIANCE INSTALLATION

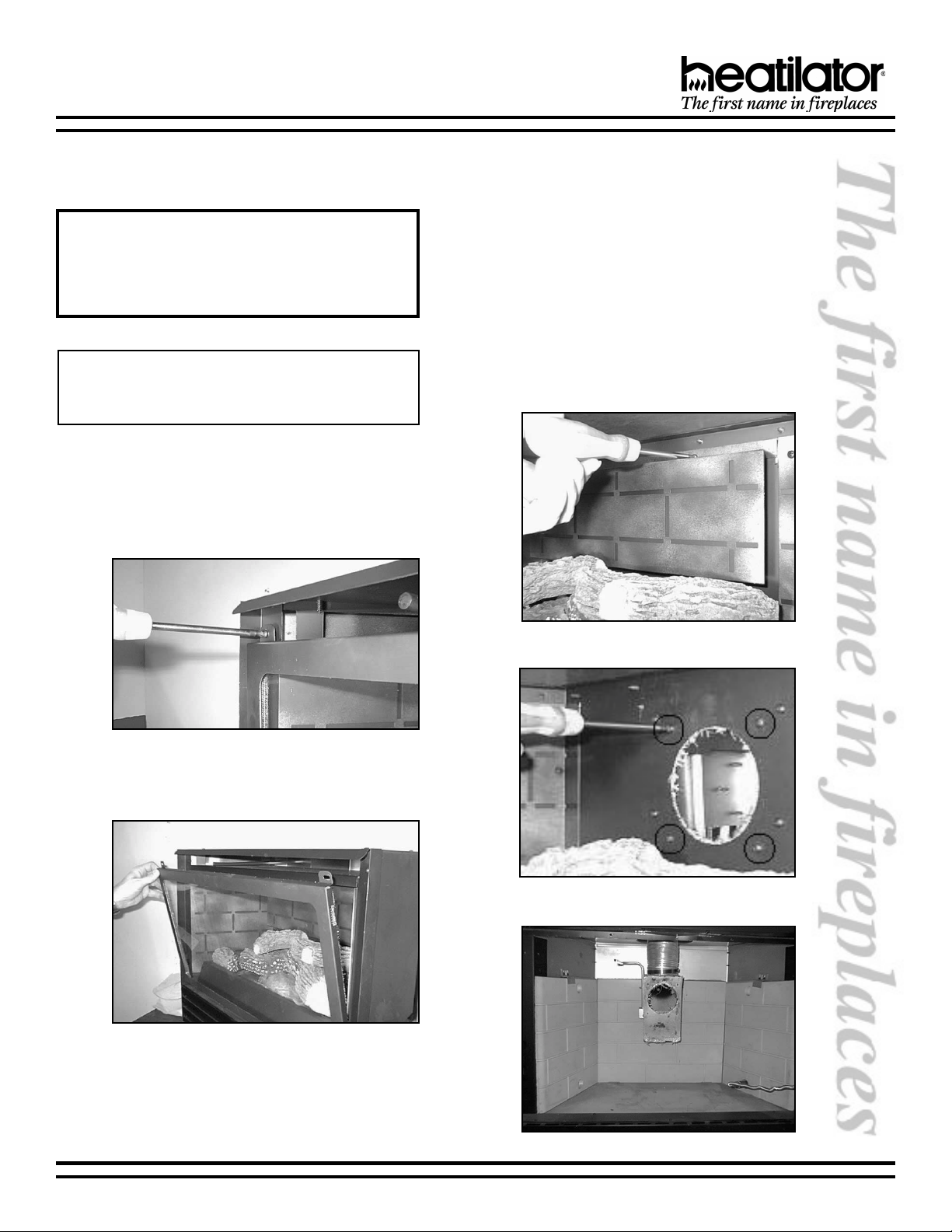

a. Firebox Entry

To gain access to the draft hood, remove the two

screws located in the upper corners of the glass

frame. See Figure 2.

the four screws located around the exhaust

opening. See Figure 5. Slide the draft hood out of

the appliance and attach draft hood to flex liner in

appliance with a minimum of three sheet metal

screws. A 4 diameter hose clamp may also be

used. See Figure 6.

The draft hood must be installed so as to be in

the same atmospheric pressure zone as the

combustion air inlet to the appliance and shall

be located so that the relief opening is accessible

for checking vent operation.

Pack the area at the damper with noncombustible

insulation to prevent cold air infiltration into the

fireplace cavity.

Figure 2 - Firebox Entry

Rotate glass frame forward and lift out. See

Figure3.

Figure 3 - Glass Frame Removal

Handle the glass frame with care to avoid striking

or scratching it on hard objects or slamming it

shut.

Remove the two screws on the baffle, as shown

in Figure 4. To remove the draft hood, unscrew

Figure 4 - Baffle Removal

Figure 5 - Draft Hood Removal

Figure 6 - Draft Hood Attachment

02-02 7 26678 Rev H

Page 8

GBI25 SERIES B-VENT GAS FIRED FIREPLACE INSERT

b. Installation of Appliance

1) The appliance should be set on a level

surface. Located on the bottom pan of the

appliance are two 5/16-18 nuts. Bolts

(provided) may be used for leveling purposes.

2) Place appliance on hearth and slide the

appliance into the fireplace. Position the draft

tube in the hold located on the back. Reach

through the exhaust hole and grab the draft

hood. See Figure 7. Continue to slide

appliance back until draft hood is in position.

Reinstall four screws around the exhaust

hole.

GSD24, the bend tab is located on the top of

the right surround side. For Models GSD40

and GSD46 the bend tab is located on the

right side of the top surround. Use a pair of

pliers to bend the tab forward. See Figure 8.

Figure 9 - Installation of Surround Hood

Figure 7

3) Place the flex line through the gas line access

hole on the right side and connect it to the

manual shutoff valve. Turn on the gas and

check for leaks with a soap and water

solution or a gas leak detector. If a leak is

detected, tighten the fitting and recheck all

joints.

Reinstall the baffle with two screws.

c. Surround Installation

1) Carefully remove the surround parts from the

shipping carton. Attach the surround top to

each side with two screws provided. See

Figure 8. Located on the surrounds is a bend

tab used to cover the switch leads. For Model

Figure 8 - Attach Surround Top

Figure 10 - Installation of Surround Hood

2) For zero clearance fireplaces or fireplaces

with combustible material within 12 inches

of the firebox opening, it is required to use

the surround hood (black). This hood is not

required for masonry fireplaces. To install

the surround hood, bend the tabs down, as

shown in Figure 9. Place the tab through the

slots in the surround top and bend the small

tab over. See Figure 10.

3) Place three screws in the surround top and

slide the brass hood over the screws.

Remove the plastic coating on brass before

securing. See Figure 11.

4) Assemble the brass trim with brackets

provided, as shown in Figure 12. Slide the

brass trim on the surround (Figure 13).

5) To install the surround, place hooks on the

surround side into slots located on the

column (Figure 14).

6) Locate the electrical cord on the left side of

the appliance and route it through the

surround and trim. Make sure that the

electircal cord is routed away from the

appliance.

26678 Rev H 8 02-02

Page 9

GBI25 SERIES B-VENT GAS FIRED FIREPLACE INSERT

WARNING!

ELECTRICAL GROUNDING INSTRUCTIONS

This appliance is equipped with a three-prong

(grounding) plug for your protection against shock

hazard and should be plugged directly into a properly grounded three-prong receptacle. Do not cut or

remove the grounding prong from this plug.

Figure 14 - Installation of Surround Hood

7) DO NOT PACK INSULATION INSIDE THE

SURROUND.

8) Remove the switch from wire assembly and

feed wire through the brass trim. See

Figure15. Re-install the switch to the wires

and push into place. See Figure 16.

Important: Remove all shipping material, fingerprints

and smudges from the brass trim prior to burning the

appliance. If this is not done, they will be burned into

Figure 11 - Installation of Hood

the trim.

Figure 12 - Assemble Brass Trim

Figure 13 - Installation of Surround Hood

02-02 9 26678 Rev H

Figure 15 - Installation of ON/OFF Switch

Figure 16 - ON/OFF Switch in Surround Installed

Page 10

GBI25 SERIES B-VENT GAS FIRED FIREPLACE INSERT

d. Rock Wool Placement

The log set is shipped in place. Tear the rock

wool into pieces no larger than 1/2 diameter.

Place the rock wool in front of the flange located

in the middle of the burner. Do not place the rock

wool behind or above the 3/8 flange. This will

block the air slot and cause carbon desposits on

the log. Place the rock wool on both the left and

right sides to complete the burning ember look. It

is not necessary to use the entire bag. See

Figure17.

Figure 17 - Rock Wool Placement

f. Brass Trim Cleaning

All prints and smudges must be wiped clean from

the brass trim prior to initial burn. If this is not

done, these prints will be cured into the brass

finish and set for the life of the appliance. To keep

the finish looking its best, gently wipe with a soft

cloth after the appliance has had ample time to

cool down. If desired, use a non-abrasive cleaner

such as soap and water. Never use any solvent,

thinner or abrasive cleaner since these will

damage the finish.

g. Valve Access

The valve is located behind the control access

panel. Lift the panel up and rotate forward. See

Figure18. This will expose the gas valve, variable

regulator and fan control, as shown in Figure 19.

Note: Placement of the rock wool should be done

with care and time, as this will create the look of

the fire when burning.

e. Glass Frame Installation

1) When cleaning the glass, use only non-

caustic, non-abrasive cleaners. DO NOT

ATTEMPT TO CLEAN HOT GLASS. It is

dangerous, and the glass is more likely to

be stained by the cleaning agent. Stubborn

film can often be removed using Brasso® or

a non-abrasive cleaner.

2) After cleaning the glass, position the tabs on

the glass frame into the slots on the column

of the appliance. Hold door in place and

secure with screws removed earlier. Be

careful not to over-tighten.

WARNING!

Never operate this appliance with the glass removed

or not sealed.

Figure 18 - Valve Access

Figure 19 - Gas Valve, Variable Regulator & Fan Control

WARNING!

Do not operate appliance with the panel(s) removed,

cracked or broken. Replacement of the panel(s)

should be done by a licensed or qualified service

person.

26678 Rev H 10 02-02

Page 11

GBI25 SERIES B-VENT GAS FIRED FIREPLACE INSERT

h. Firebox Bottom Removal

1) Shut off the gas to the appliance before

removing. Remove the glass frame following

instructions found in Step 3a. on page 7.

2) Remove the two screws on the log assembly

(Figure 20). Pull out the log assembly (Figure

21) and place in a safe area. Remove the

four screws located around the firebox

bottom. See Figure 22.

3) To re-install the firebox bottom, reverse the

above steps.

Figure 22 - Firebox Bottom Removal

i. Fan Access

1) Disconnect the power cord or turn off the

circuit breaker before removing the fan.

Remove the firebox bottom following

directions in Step 3h.

2) Remove the four screws located on the fan

bracket (Figure 23). Remove two on the fan

control. Remove the bushing and unplug the

cord from the junction box. Slide the fan

bracket out.

Figure 20 - Log Assembly Removal

3) To re-install fan, reverse the above steps.

Figure 21 - Log Assembly Removal

Figure 23 - Fan Removal

WARNING!

Any safety screen or guard removed for servicing an appliance must be replaced prior to operating this appliance.

Clothing or other flammable material should not be placed on or near the appliance.

02-02 11 26678 Rev H

Page 12

GBI25 SERIES B-VENT GAS FIRED FIREPLACE INSERT

4. WIRING

a. A 110V AC outlet should be located close to the

lower left side of the appliance to allow the fan to

be plugged in. See Figure 24.

Note: This appliance must be electrically wired and

grounded in accordance with local codes or, in the absence of local codes, with National Electric Code ANSI/

NFPA 70-latest edition. This appliance can be used with

a thermostat.

Note: This appliance REQUIRES a 110V AC

supply for operation of the fan.

CAUTION:

Label all wires prior to disconnection when servicing controls. Wiring errors can cause improper and dangerous operation. Verify proper operation after servicing.

Figure 24 - Wiring Diagram

WARNING!

Do not use this appliance if any part has been under water. Immediately call a qualified

service technician to inspect the appliance and to replace any part of the control system and any gas control which has been under water.

26678 Rev H 12 02-02

Page 13

GBI25 SERIES B-VENT GAS FIRED FIREPLACE INSERT

b. Optional Wall Thermostat

The use of a millivolt thermostat is allowed. It

must be located within 20 feet of the appliance.

Figure 25 shows how to connect the thermostat.

Remove ON/OFF switch wires from valve. Place

thermostat wires to the posts marked TH and

TH/TP.

Note: The ON/OFF switch now becomes inoperable.

Figure 25 - Wiring Diagram

5. PRE-USE CHECKLIST

Use the following checklist as a guide to be sure your

installation is correct and complete

Operating instructions have been read and

understood.

All safety warnings have been read and followed.

Note: The fan will not turn on until the appliance has

reached its proper operating temperature. This is

determined by a thermal disc in the fan assembly. Also,

the fan will continue to run until the appliance has cooled

sufficiently after shutdown.

Flex liners and termination cap are properly

installed

Logs and rock wool have been placed correctly.

All fittings are tight and there are no gas leaks.

Glass is in proper position and sealed.

Keep the area near the appliance clear and free from

combustible materials, gasoline and other flammable vapors and liquids.

WARNING!

Prints and smudges are wiped from brass trim.

Check air shutter adjustment.

02-02 13 26678 Rev H

Page 14

GBI25 SERIES B-VENT GAS FIRED FIREPLACE INSERT

G. OPERATING INSTRUCTIONS

FOR YOUR SAFETY READ BEFORE LIGHTING

1. This gas appliance has a manual ignition device that

lights the pilot. When lighting the pilot, follow these

instructions exactly.

2. STOP! BEFORE READING FURTHER, smell around

the appliance area for gas. Be sure to smell next to

the floor because some gas is heavier than air and

will settle to the floor.

3. WHAT TO DO IF YOU SMELL GAS:

Do not try to light the appliance.

Do not touch any electrical switch; do not use any

telephone in your building.

Immediately call your gas supplier from a

neighbors telephone. Follow the instructions of

your utility.

LIGHTING INSTRUCTIONS

If you cannot reach your utility, call the fire

department.

4. If the pilot light and burner went out during use, you

must take the glass off the appliance and wait to clear

out any gas. Follow the lighting instructions below.

5. Use only your hand to push in or turn the gas control

knob to light the pilot. Never use tools. If the knob will

not push in or turn by hand, do not try to repair it; call a

qualified service technician. Using a tool or attempting

repairs may result in a fire or explosion.

6. Do not use this appliance if any part has been under

water. Immediately call a qualified service technician

to inspect the appliance and to replace any part of the

control system and any gas control that has been

under water.

1. STOP! Read the safety information above.

2. Turn off all electric power to the appliance. If your

appliance has a thermostat, set to lowest setting.

3. Open control access panel.

4. Find the pilot. The pilot is inside the combustion

chamber next to the main burner.

5. If the gas control knob is at the OFF position, go to

step 7. If the gas control knob is at the ON position,

go to step 6.

6. If the pilot light went out during normal use with the

gas control knob at the ON position, turn the gas

control knob to the OFF position. REMOVE THE

FIXED GLASS PANEL. Wait ten minutes to clear out

any gas.

7. Smell for gas, including near the floor. If you dont

smell gas, go to the next step. If you smell gas, wait

another five minutes or until the gas odor is no longer

present before continuing. If the odor of gas does not

disappear after fifteen minutes, STOP! Follow B in

the safety information above.

8. Replace glass panel if it has been removed.

9. Turn gas control knob counterclockwise to the PILOT

position.

10. Push the gas control knob in all the way and hold. At

the same time, push in the red ignition button

repeatedly until the pilot lights. Never hold the gas

control knob in for more than ten seconds if the pilot

does not light. Once the pilot lights, continue to hold

the gas control knob in for 15 seconds. Release the

gas control knob and it will pop back up. If pilot does

not remain lit, repeat steps 6 through 9.

If gas control knob does not pop back up when

released, turn the knob to OFF and call your service

technician or gas supplier.

If the pilot will not stay on after two attempts, turn the

gas control knob to OFF and call your service

technician or gas supplier.

11. Turn gas control knob couterclockwise to the ON

position. The knob can be turned to the ON position

only if it is popped out.

12. Close the access panel.

13. Turn on electrical power to the appliance. If equipped

with a thermostat, set to the desired setting.

TO TURN OFF GAS TO APPLIANCE

1. Turn rocker switch to OFF or the wall thermostat to

lowest setting if your appliance is so equipped.

2. Turn off all electric power to the appliance if service is

to be performed.

26678 Rev H 14 02-02

3. Open control access panel.

4. Turn gas control clockwise to OFF.

5. Close control access panel.

Page 15

GBI25 SERIES B-VENT GAS FIRED FIREPLACE INSERT

1. OPERATION PROCEDURE DURING

REGULAR USE

Turn the switch/thermostat to the ON position. This

will ignite the main burner.

2. SHUTDOWN DURING REGULAR USE

Simply turn the switch/thermotat to OFF. This will

disengage the burner and the flames will extinguish.

3. SEASONAL SHUTDOWN

When the burning season comes to an end, the entire

system should be shut down to prevent gas running

to the appliance while it is not in use.

4. FAN OPERATION

The fan control is located behind the control access

panel. Lift the panel up and rotate forward. Locate the

fan control knob and turn. See Figure 18. Close the

control access panel.

5. CHECKING FLAME PATTERNS

Check the flame pattern of the burner periodically,

making sure the flames are steady, not lifting or

floating. The flame color should be blue with yellow

tips. The thermopile tip should be covered with flame.

See Figures 26 and 27.

If the vent configuration is installed incorrectly, the vent

may cause the flames inside the appliance to lift or

ghost - a dangerous situation. Inspect the flames

after installation to ensure proper performance. If the

vent configuration is correct, yet the flames are lifting

or ghosting, shut off gas to the appliance and contact

the dealer for information on remedying the problem.

Figure 26 - Standing Pilot

Note: If the air shutter is open all the way and the flames

remain sooty, shut off gas to the appliance and contact

a qualified service technician.

WARNING!

Children and adults should be alerted to the hazards

of high surface temperatures and should stay away

to avoid burns or clothing ignition. Young children

should be carefully supervised when they are in the

same room as the appliance.

Figure 27 - Flame Patterns

02-02 15 26678 Rev H

Page 16

GBI25 SERIES B-VENT GAS FIRED FIREPLACE INSERT

H. MAINTENANCE INSTRUCTIONS

1. CLEANING THE BURNER AND

CONTROL COMPARTMENT

Keep the burner and control compartment clean by

using a clean, dry paint brush and vacuum at least

once a year. Always turn off the gas valve and the

switch before cleaning. (See Step 1 on the bottom of

page 14.)

2. VENTING SYSTEM INSPECTION

The appliance and venting system should be

inspected before use each season, and at least

annually, by a qualified service person to ensure that

the flow of combustion and ventilation air is not

obstructed.

3. CLEANING THE GLASS

a. It is recommended to wear gloves while handling

or removing the glass. DO NOT REMOVE THE

GLASS WHEN HOT.

b. To remove the glass frame for cleaning, follow

Step 3a. on page 7.

c. To clean the glass, use a nonabrasive, mild

cleaning solution. (For example, a glass cleaner

or an oven cleaner for stubborn film.) Apply an

adequate amount to the glass and wipe off with a

damp cloth. Be sure all cleaner is thoroughly

rinsed from the glass.

d. Never operate this appliance without the glass

properly secured in place or if the glass is broken.

e. In the event of glass breakage, follow glass

removal instructions. This will allow the removal

of all glass fragments and sheet metal edge

protection strips. Vacuum all remaining glass

pieces with a shop vac. DO NOT VACUUM IF

PIECES ARE HOT! Replace glass only with the

correct HTI part ordered direct or through your

local distributor. Never use substitute material.

Only ceramic glass may be used on this

appliance.

5. CHECKING THE VENT SYSTEM

a. The venting system should be tested periodically

to ensure proper operation. This can be done

with a match while the appliance is operating.

Locate the draft tube between the glass frame

and top. See Figure 28.

b. Hold the match in front of the tube. If the flame

and smoke are drawn into the tube, the appliance

has good ventilation. If the flames and smoke

are forced away from the draft tube, this may

indicate a ventilation blockage or downdraft

resulting in exhaust spillage into your home. If

this occurs, turn off the appliance and do not burn

it until it has been inspected by a qualified service

person. See Figure 29.

Figure 28

Flame in - Acceptable Ventilation

4. LOG CLEANING

Logs can be easily lifted out of position. Carbon

buildup can be removed with a vacuum cleaner.

26678 Rev H 16 02-02

Flame out - Unacceptable Ventilation

Figure 29

Page 17

GBI25 SERIES B-VENT GAS FIRED FIREPLACE INSERT

I. TROUBLESHOOTING

melborPesuaCnoitcAevitcerroC

.1tolipthgiltonlliwrotingikrapS

.nottub

.2.tilyatstonlliwtoliP.AtnatsnocnitonemalftoliP

.3FFO/NOdnaevlav,tiltoliphtiW

.thgiltonlliw

.4aretfaffoflestisnrutecnailppA

.5aretfaffoflestisnrutecnailppA

.6.pugofsroodssalG.A.noitsubmocsagfotluserlamroN .smrawecnailppasaraelclliwssalg-yrassecennoitcaoN

.7.semalfeulB.A02tsrifgnirudtluserlamroN

.8.tinomlifsahssalG.AweflaitinignirudtluserlamroN

.A.rotingievitcefeD.rotingiecalpeR

derfognisserpdetaeperretfa

.B.edortceledengilasiM .doohtolipfomottobot"8/1yletamixorppaebdluohskrapS

.C.ecifirodeggulp/tolipotsagoN ,enaporpfI.sevlavffotuhsynadnanoitisopbonkevlavkcehC

.D.tuognidnuorgeriwrotingI.ylbmessatolipecalpeR

.E.gniriwrotingiesooL ondnatcerrocsinoitcennocedortcelefI.krapsrofkcehC

.Bdetaes/denethgittonrosnestoliP

.CrosnestolipevitcefeD

.D.evlavytluaF.evlavecalpeR

.Adenrubsahyticirtcelefostlov011

renrub,noitisop"NO"nihctiws

.B.evitcefedhctiwsllawFFO/NO seriwtcennoC.snoitcennocreporprofhctiwsFFO/NOkcehC

.C.ecifirorenrubdeggulP.egakcolbevomer,ecifirorenrubkcehC

.D.elipomrehtevitcefeD.elipomrehtecalpeR

.E.ecifironotonrenruB.ecifironoecalp;renrubkcehC

.F.gniriwytluafroesooL .)52erugiFeeS(gniriwyfirev;snoitcennocesoolrofkcehC

.G.evlavytluaF.evlavecalpeR

.HtimilhgihytluaF

.AsihctiwsytefastimilhgiH

.tilsyatstoliptub,emitfodoirep

.BFFO/NOnitrohstnettimretnI

.C.elipomrehtevitcefeD.elipomrehtecalpeR

.AtnatsnocnitonemalftoliP

.tilregnolontolip,emitfodoirep

.BrosnestolipevitcefeD

.BgnisuactnemecalpgolreporpmI

.toos

.C.emalfdeppitwolleykraD .oitarsagotriaesaercniotrettuhsrianepO

.ylreporpevlavni

.elpuocomreht

.evlavtuo

.hctiwsorcim/hctiws

.detavitca

.metsysgniriw

.elpuocomreht

.gninrubfosetunim

.noitarepofosruoh

.egakcolb

.rosnestoliphtiwtcatnoc

.rosnestoliphtiwtcatnoc

.yrassecen

.yrassecen

.setunim02

.nottubdergnisserperofebedortcele

morfsdnahevomeR.krapsreporpevigotpagtsujdA

ynaevomer;ecifirotolipkcehC.knatytpmerofkcehc

.rotingiecalper,kraps

fiemalftsujda:emalftolipkcehC.tnemecalpgolkcehC

.evlavnithgitsirotcennocrosnestoliptahtkcehC

.elpuocomrehtrosnestolipecalpeR

.evlavecalperdnaegatlovevomeR

ecalper,nosemocrenrubfI.hctiwsFFO/NOtalanimretssorca

FFO/NOottcennoc,noemoct'nseodrenrubfI.hctiwsFFO/NO

.seriwecalper,nosemocrenrubfI.evlavtasnoitcnujhctiws

.hctiwsorcimrohctiwstimilhgihecalpeR

rofmetsysgnitnevkcehcnaicinhcetecivresdeifilauqaevaH

gnitnevreporperusnE.)egamad,stsendrib.e.i(egakcolb

sayllacitamotuateserlliwhctiwstimilhgiH.noitidnoc

.sloocecnailppa

.metsysgniriwFFO/NOecalper/kcehC

fiemalftsujda,emalftolipkcehc;tnemecalpgolkcehC

.elpuocomrehtrosnestolipecalpeR

tuobaretfawolleyeromnrutlliwsemalf-yrassecennoitcaoN

.hsiloprevlisroossarBhtiwssalgnaelC

.yrassecenfinoitisoper:tnemecalpgolkcehC

02-02 17 26678 Rev H

Page 18

GBI25 SERIES B-VENT GAS FIRED FIREPLACE INSERT

J. REPLACEMENT PARTS

Replacement parts are available from your distributor/dealer, or through Heatilator Technical Services Department,

Hearth Technologies Inc., 1915 W. Saunders Street, Mt. Pleasant, Iowa 52641 (1-800-843-2848)

See Figure A for the burner replacement parts diagram.

METI#TRAPNOITPIRCSED

175662ylbmessAgoL52iBG

275362goLthgiRpoT

385362goLtfeLpoT

412562goLkcaB

522562goLtnorF

661562giwT

714762piLhsA

860562troppuSgoL

933341looWlareniM

Figure A - Replacement Parts

METI#TRAPNOITPIRCSED

157662renruB

231602rewolBrofhctiwSdeepSelbairaV

317662ylbmessArewolB

489932tatsomrehT

GBi25 Log Assembly

26678 Rev H 18 02-02

Page 19

GBI25 SERIES B-VENT GAS FIRED FIREPLACE INSERT

METI#TRAPNOITPIRCSED

135662ellirG

232562

90562

27662

348662)HL&HR(yrotcarfeRediS

447662yrotcarfeRkcaB

543782

53782

663782

73782

83782

706562dooH

METI#TRAPNOITPIRCSED

801562

ylbmessAemarFssalG

emarF

ylbmessAssalG

sediStfeLdnathgiR04/42DSG

sediStfeLdnathgiR64DSG

poT42DSG

poT04DSG

poT64DSG

956712

0177191

1194562

2186942hctiwStimiLhgiH

3180562ylbmessAdooHtfarD

11562

66712

76712

97191

96852

83362

K. OPTIONAL COMPONENTS

dooHdnuorruS04/42DSG

dooHdnuorruS64DSG

mirTtfeL42DSG

mirTtfeL04DSG

mirTtfeL64DSG

mirTpoT04/42DSG

pirTpoT64DSG

mirTthgiR42DSG

mirTthgiR04DSG

mirTthgiR64DSG

RC-SMART-HTL

Remote Control

RC-BATT-HTL

Battery Operated Remote Control

(Standing Pilot)

SMART-STAT-HTL

Remote Control with Thermostat Control

SMART-BATT-HTL

Battery Operated Remote Control

with Thermostat Control

02-02 19 26678 Rev H

6

3

5

2

4

7

Page 20

GBI25 SERIES B-VENT GAS FIRED FIREPLACE INSERT

HOMEOWNERS NOTES

26678 Rev H 20 02-02

Page 21

GBI25 SERIES B-VENT GAS FIRED FIREPLACE INSERT

HOMEOWNERS NOTES

02-02 21 26678 Rev H

Page 22

GBI25 SERIES B-VENT GAS FIRED FIREPLACE INSERT

HOMEOWNERS NOTES

26678 Rev H 22 02-02

Page 23

GBI25 SERIES B-VENT GAS FIRED FIREPLACE INSERT

Index

A

Air Shutter 15

Appliance Installation 7

B

Baffle Removal 7

Brass Trim 9

Building Supplies 3

C

Certification 3

Cleaning

Burner & Control Compartment

16

Glass 16

Logs 16

Clearances 2

Components 5

Conversion Kits 4

D

Description of the System 3

Dimensions and Clearances 4

Draft Hood

Attachment 7

Removal 7

E

Electrical Grounding Instructions 9

H

High Altitude Installation 5

Hood 9

I

Installation Instructions 6

L

Lighting Instructions 14

Listings and Code Aprovals 3

Local Codes 3

M

Mantel 4

N

Negative Air Locations 3

O

Operating Instructions 14

Optional Components 19

P

Pre-Installation Preparation 5

R

Replacement Parts 18

Rock Wool 10

V

Valve Access 10

Variable Regulator 10

Venting 2

Venting Requirements 6

Venting system inspection 16

W

Wall Thermostat 13

Water 2

Wiring 12

F

Fan 13

Fan Control 10

Fan Operation 15

Fan Removal 11

Flame Patterns 15

Fuel 3

G

Gas Line 6

Gas Pressure 5

Gas Valve 10

Glass Frame 7

02-02 23 26678 Rev H

S

Safety Precautions 2

Sealant Material 3

Seasonal Shutdown 15

Standing Pilot 15

Surround 8

System components 4

T

Troubleshooting 17

Page 24

Gas Appliance (Fireplace)

Limited Lifetime Warranty

HEARTH TECHNOLOGIES INC. (HTI) extends the following warranty for HEATILATORâ gas appliances installed in the United States of

America or Canada (the Appliance). Dealers and employees of HTI have no authority to make any warranty or authorize any remedies in

addition to or inconsistent with the terms of this warranty.

Limited Lifetime Warranty.

HTI warrants the Appliance for component failure due to a manufacturing defect of any of the following components: combustion chamber,

burner pan, and logs. The Limited Lifetime Warranty specified above is subject to the conditions, exclusions and limitations listed below, is for

the period the Appliance is owned by the original homeowner only, and is nontransferable.

1 Year Limited Warranty.

HTI warrants the Appliance to be free from failure of any of the following components for a period of one year after installation: valve, flexible gas

line connector, glass panel, fan, direct vent chimney components, factory paint, gasket, piezo ignitor, thermopile, thermocouple, junction box, pilot

assembly, shutoff valve, high limit switch, refractory liners, transformer, and control box. If the Heatilator Appliance is found to be defective in

either material or workmanship within one year of the date of original installation, HTI will provide replacement parts at no charge and pay

reasonable labor and freight costs, and is for the period of one year following the date of original installation of the Appliance.

Conditions, Exclusions, & Limitations of Liability.

A. Both the Limited Lifetime and 1 Year Limited Warranties supplied by HTI apply only while the Appliance is in its location of original

installation. HTIs obligation under this warranty does not extend to damages resulting from (1) installation, operation or maintenance of

the Appliance not in accordance with the Installation Instructions, Operating Instructions, and the Listing Agent Identification Label

furnished with the Appliance; (2) installation which does not comply with local building codes; (3) shipping, improper handling, improper

operation, abuse, misuse, accident or unworkmanlike repairs; (4) environmental conditions, inadequate ventilation or drafting caused by

tight sealing construction of the structure, air handling devices such as exhaust fans or forced air furnaces, or other causes; (5) use of fuels

other than those specified in the Operating Instructions; (6) installation or use of components not supplied with the Appliance or any other

components not expressly authorized and approved by HTI; and/or (7) modification of the Appliance not expressly authorized and

approved by HTI in writing. This warranty is limited to only the component parts manufactured or supplied by HTI.

B. HTIs liability under both the Limited Lifetime Warranty and the 1 Year Limited Warranty is limited to the replacement and repair of

defective components or workmanship during the applicable period. HTI may fully discharge all of its obligations under such warranties

by repairing the defective component(s) or at HTIs discretion, providing replacement parts at no charge and paying reasonable labor and

freight costs.

C . EXCEPT TO THE EXTENT PROVIDED BY LAW, HTI MAKES NO EXPRESS WARRANTIES OTHER THAN THE WARRANTY

SPECIFIED HEREIN. THE DURATION OF ANY IMPLIED WARRANTY IS LIMITED TO DURATION OF THE WARRANTY

SPECIFIED ABOVE.

D. Some states do not allow exclusions or limitations of incidental or consequential damages, so those limitations may not apply to you. This

warranty gives you specific rights; you may also have other rights which vary from state to state.

How to Obtain Service.

To obtain service under this warranty you must:

1. Send written notice of the claimed condition to Heatilator Technical Service Department, Hearth Technologies Inc., 1915 W.

Saunders Street, Mt. Pleasant, Iowa 52641-1563. You may also register your claim online at www.heatilator.com/contact.asp.

2. Provide proof of purchase, model number, serial number, and manufacturing date code to HTI.

3. Provide HTI reasonable opportunity to investigate the claim, including reasonable opportunity to inspect the Appliance prior

to any repair or replacement work and before the Appliance or any component of the Appliance has been removed from the

place of original installation.

4. Obtain HTIs consent to any warranty work before the work is done.

ADDITIONAL INFORMATION. If you would like information on current HEATILATOR products or want to locate a dealer in your area, call 1800-843-2848.

ã2001 Heatilatorâ is a Registered Trademark of Hearth Technologies Inc.

26678 Rev H 24 02-02

Loading...

Loading...