Page 1

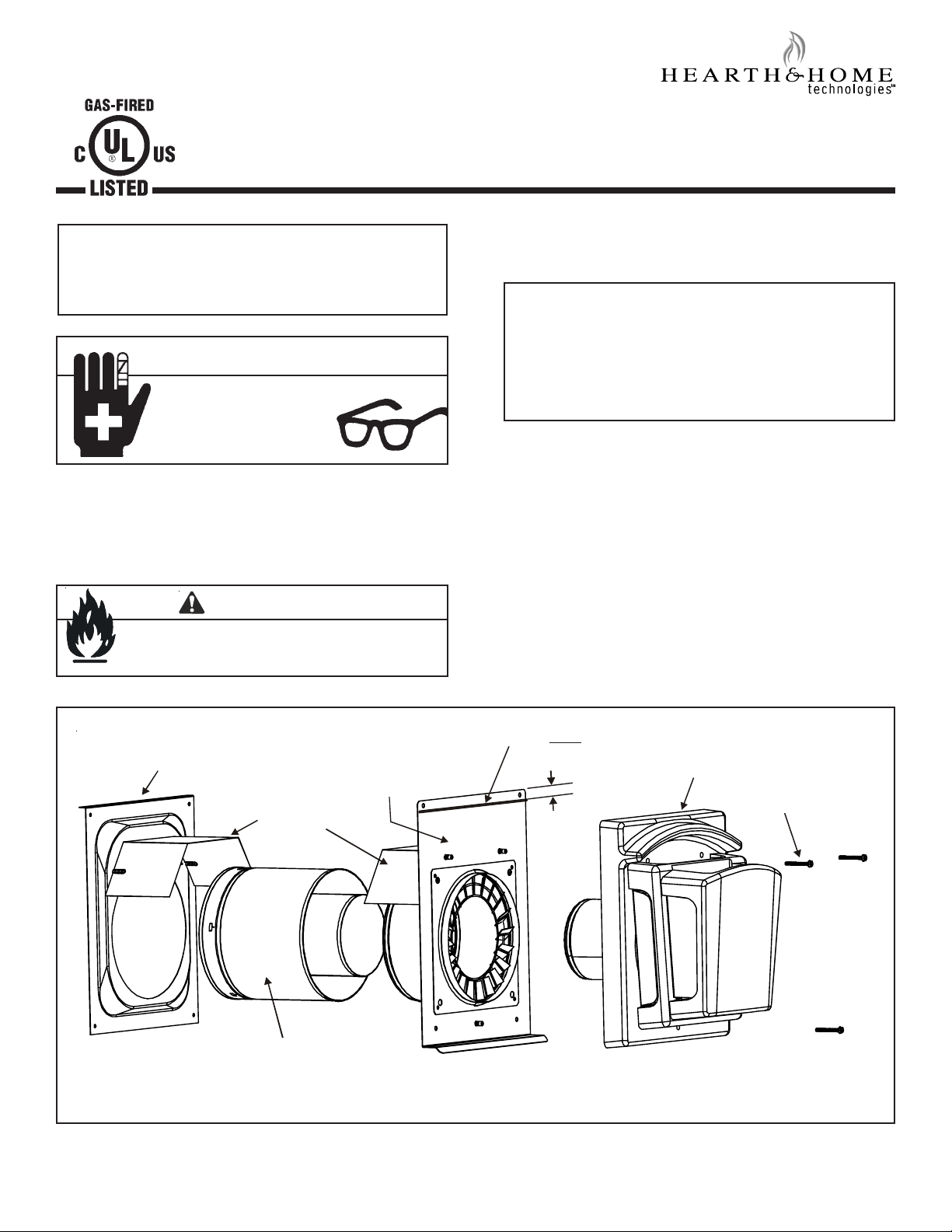

DVP-FBHT

Firebrick Termination Cap

- Installation Instructions -

These instructions should be used along

with the Cinch Pipe and

T ermination Cap System instructions

included with this kit.

CAUTION

Sharp Edges

• Wear protective gloves

and safety glasses

during installation.

The DVP-FBHT is a horizontal firebrick termination cap with

4 inch telescoping flue (see Figure 1).

Included is the DVP-WS wall shield firestop with heat shield

and one fastener pack.

W ARNING

Fire Risk

Do NOT use this termination cap on vinyl siding.

Installation

1. Carefully remove cap from the packaging.

Note: Variation in the appearance of the termination

cap color and surface are inherent and unique

characteristics of the manufacturing process and are

to be expected with this product. Such surface

characteristics as chips, small cracks, and pits do

not affect the product performance in any manner .

2. Frame the 12 inch by 10 inch opening in the wall by

following the directions in the Cinch Pipe and T ermination

cap instructions. When housewrap or underlayment is

used, the housewrap manufacturer’s instructions for

flashing a penetration MUST be followed.

3. Install the interior wall shield firestop by following the

instructions in the Cinch Pipe and Termination cap

instructions.

WALL SHIELD

FIRESTOP

HEAT SHIELD

TELESCOPING

FLUE SECTION

Figure 1. DVP-FBHT

Printed in U.S.A. Copyright 2006

Hearth & Home Technologies, 20802 Kensington Boulevard, Lakeville, MN 55044

Exterior finishing materials allowed ONLY above line.

METAL

BACKPLATE

1 IN.

FIREBRICK

BOLT (3)

2084-900B 1/06

1

Page 2

W ARNING

7. Secure the backplate to the wall with four appropriate

length screws from the hardware pack.

Hearth & Home Technologies disclaims

any responsibility for, and the warranty will

be voided by, the following actions:

• Installation and use of any damaged vent system

component.

• Modification of the vent system.

• Installation other than as instructed by Hearth & Home

Technologies.

• Installation and/or use of any component part not

approved by Hearth & Home Technologies.

Any such action may cause a fire hazard.

4. Install the telescoping flue section included with the cap

on the last section of flue pipe.

W ARNING

Fire Hazard

Impaired performance of appliance

• Telescoping flue section of termination cap

MUST be used when connecting pipe

section to termination cap.

• Maintain a 1-1/2 inch minimum overlap on

telescoping flue section of termination cap.

5. Remove the three bolts from the firebrick cap face to

separate the firebrick part of the cap from the metal

backplate (see Figure 1).

8. Seal the backplate to the housewrap or sheathing. Follow

housewrap manufacturer’s instructions for sealing a

penetration when applicable.

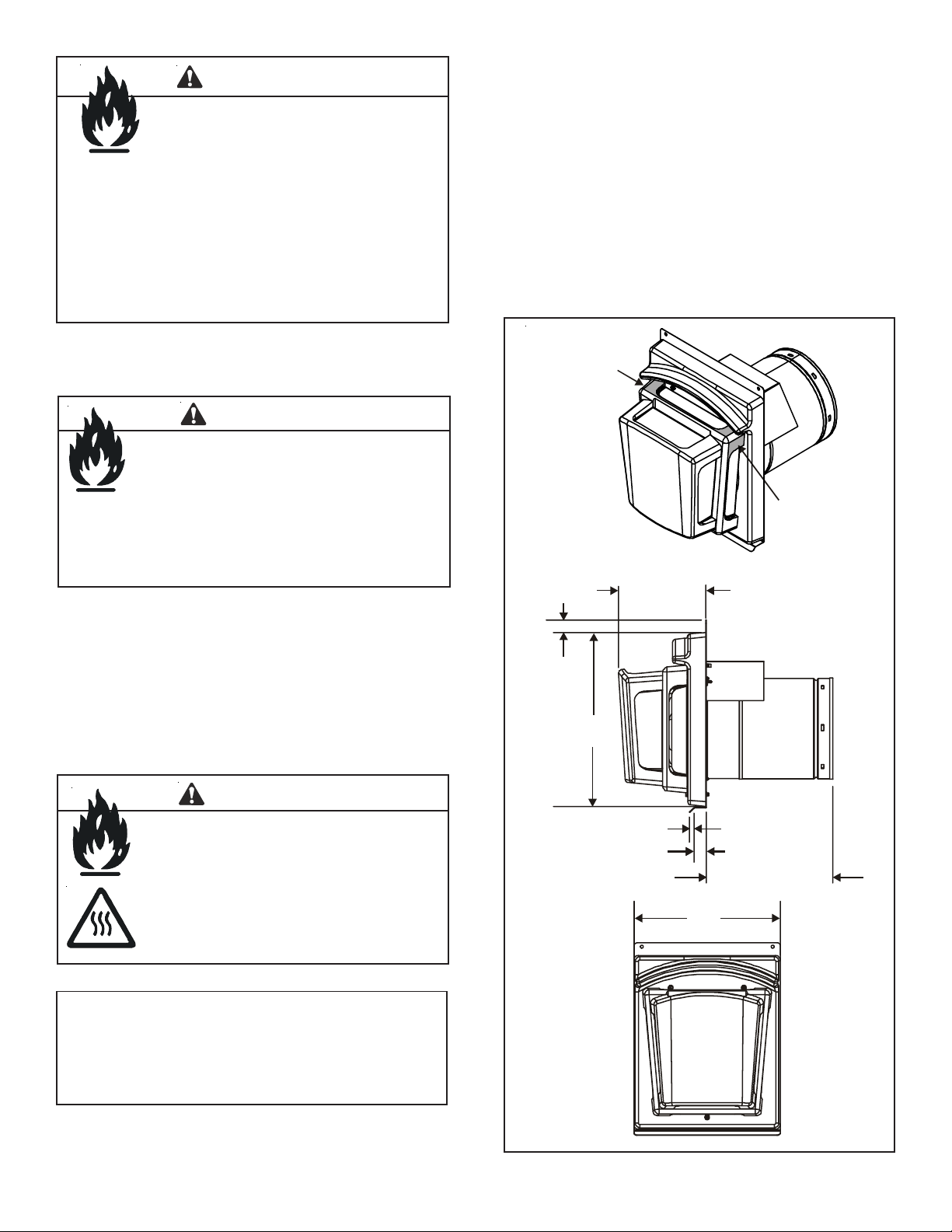

9. Slide the firebrick part of the cap onto the backplate by

aligning the 5 inch collar with the 5 inch flue pipe coming

from the fireplace. Slide the two pieces together until

the firebrick part bottoms out on the backplate.

10.Replace the three bolts removed in step 2. DO NOT

OVERTIGHTEN THE BOL TS.

Measure vertical

clearances from

this surface.

Measure horizontal

clearances from

this surface.

1 in.

(25)

7-3/16 in.

(182)

6. Slide the backplate, with the 8 inch collar on it, onto the

flue pipe from the fireplace. For thinner wall construction,

you may have to trim the heat shield on the metal

backplate and interior wall shield firestop.

W ARNING

Fire Risk

Exhaust Fumes Risk

Impaired Performance of Appliance

• Overlap pipe slip sections at least 1-1/2 inches.

• Use pilot holes for screws.

• Screws must not exceed 1 inch long.

• Pipe may separate if not properly joined.

NOTE: The heat shield on the interior wall shield firestop

and the heat shield on the metal backplate must

overlap 1-1/2 inches. If wall thickness does not allow

the required 1-1/2 inch heat shield overlap, an extended

heat shield must be used.

14 in.

(356)

3/8 in. (9)

1 in. (25)

10-3/8 in. (264) Max.

7-11/16 in. (195) Min.

12 in.

(305)

Figure 2.

2

Page 3

Finishing

The DVP-FBHT cap may be stained or painted. The cap is

subject to high temperatures and stain is preferred over paint.

Laxtex paints may be used, but light colored paints may

discolor slightly. A water-based stain is recommended for

maximum life.

CAUTION

Risk of Water Intrusion or Impaired Performance

• Do NOT use exterior finishing materials thicker than

1-1/2 inch cap base.

• The flashing bend at bottom of metal backplate MUST be

on top of exterior finishing material for proper drainage.

• Maintain 1-1/2 inch minimum overlap on telescoping

flue section and wall shield firestop when adjusting for

wall thickness.

If the firebrick section of the cap is going to be left off until

after the structure’s exterior is finished, do NOT place exterior

finishing materials over the metal backplate. Only the top 1

inch of the metal backplate can be covered with finishing

material (see Figure 1).

CAUTION

Water Damage Risk

The flashing bends on the bottom of the metal backplate

MUST be clearly on top of the exterior for proper drainage.

Caulk the outer sides and top of the cap. Do not caulk the

bottom edge with the flashing bends on it.

CAUTION

Potential Risk of Damage to Finish

• Do NOT expose this cap to acid.

• Remove the firebrick section of the cap if using acid

to clean surrounding masonry.

Service Parts List

DESCRIPTION SERVICE PART NO.

Wall Shield 25259

Fastener Pack 32210

Slip Section 4033-012

3

Loading...

Loading...