Page 1

TM

Installation

TM

Instructions

Models:

Cinch Pipe & Termination Cap System

These instructions are replacing VP (for Heatilator) and DV (for Heat-N-Glo) pipe assembly

instructions. See the appliance installation instructions for confi guration of vent assembly

and clearances to pipe.

If you need assistance during installation, contact your local dealer or the Technical Serices Dept., Hearth & Home Technologies

Inc., phone 1-800-927-6841 or 1-888-427-3973.

If DVP-AD adapters are used off the top of the appliance, the termination height will be raised by 2-3/4 in. overall

height.

CAUTION

Sharp Edges

• Wear protective gloves and safety glasses

during installation.

WARNING

Hearth & Home Technologies disclaims any

responsibility for, and the warranty will be

voided by, the following actions:

• Installation and use of any damaged vent

system component.

• Modifi catoin of the vent system.

• Installation other than as instructed by

Hearth & Home Technologies.

• Installation and/or use of any component

part not approved by Hearth & Home

Technologies.

Any such action may cause a fi re hazard.

WARNING

Do not mix pipe, fittings or joining

methods from different manufacturers.

Note: An arrow () found in the text signifi es change in content.

Hearth & Home Technologies Inc. • Cinch Pipe & Term Caps • 4033-900 Rev K • 05/05

1

Page 2

1

Parts and Descriptions

1

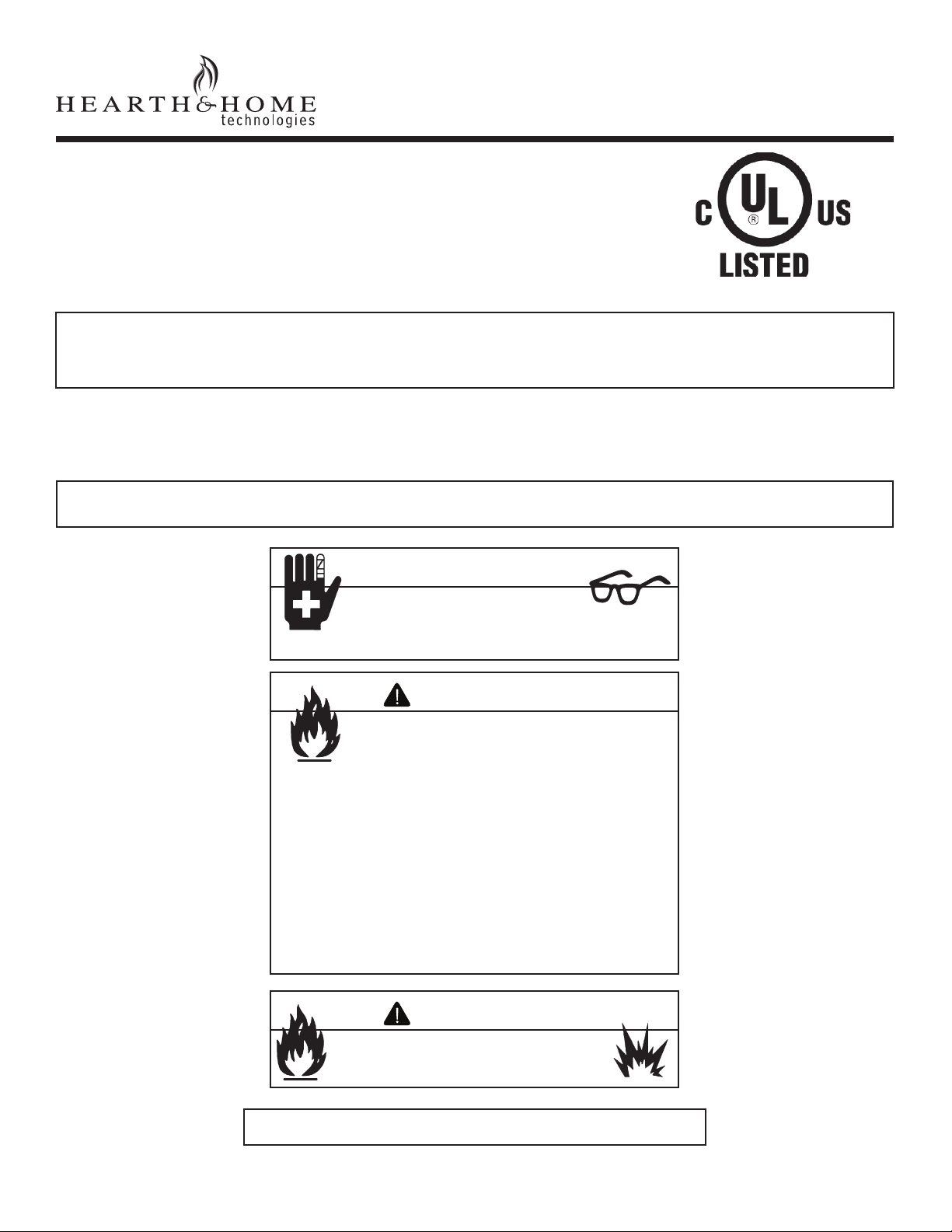

DVP-TV Vertical termination cap. Includes storm collar and

fastener pack.

DVP-TB1 Basement/window well termination cap. Includes fas-

tener pack.

DVP-TRAP1 Horizontal termination cap with 1-3/4 in. telescoping

fl ue. Includes DVP-WS wall shield with heat shield and

one fastener pack.

DVP-TRAP2 Horizontal termination cap with 4 in. telescoping fl ue.

Includes DVP-WS wall shield with heat shield and one

fastener pack.

(not shown)

DVP-TRAPK1 Vent kit containing DVP90ST 90° elbow, DVP-WS wall

shield with heat shield, DVP-TRAP1 termination cap

with telescoping fl ue and one fastener pack.

DVP-TRAPK2 Vent kit containing DVP90ST 90° elbow, DVP-WS wall

shield with heat shield, DVP-TRAP2 termination cap

with telescoping fl ue and one fastener pack.

DVP- TVHW Vertical Termination, high wind cap. Includes storm

collar and fastener pack.

DVP-AS Attic insulation shield

BEK Brick extension kit

2

Hearth & Home Technologies Inc. • Cinch Pipe & Term Caps • 4033-900 Rev K • 05/05

Page 3

DVP-TRAPFL DVP-TRAP1 or DVP-TRAP2 termination

cap rain fl ashing

DVP-TRAP1

DVP-TRAP2

Termination Cap

DVP-TRAPFL

Flashing

COOL ADD Cap shield

DRC-RADIUS Cap shield

Components Description

DRC-RADIUS Cap Shield

COOL-ADDM Cap Shield - pack of six

DVP-TV Vertical Termination Cap

DVP45 45° Elbow

DVP90ST 90° Elbow

RF6M Roof Flashing (vertical termination for 0/12 to 6/12 pitch) - pack of four

RF12M Steep Pitch Roof Flashing (for 7/12 to 12/12 pitch) - pack of six

DVP4 4 in. length Vent Pipe

DVP6 6 in. length Vent Pipe

DVP12 12 in. length Vent Pipe

DVP24 24 in. length Vent Pipe

DVP36 36 in. length Vent Pipe

DVP48 48 in. length Vent Pipe

DVP6A 3 in. - 6 in. Slip Section Vent Pipe (to be used with another piece of pipe)

DVP12A 3 in. - 12 in. Slip Section Vent Pipe (to be used with another piece of pipe)

DVP12MI 12 in. Vent Pipe - non-unitized (can be cut to length)

DVP24MI 24 in. Vent Pipe - non-unitized (can be cut to length)

DVP-HVS Vent Support

DVP-WS Wall Shield to ensure horizontal clearances

DVP-FS Firestop Spacer

DVP-TRAP1 Horizontal Termination Cap with 1-3/4 in. telescoping fl ue and wall shield with heat shield

DVP-TRAP2 Horizontal Termination Cap with 4 in. telescoping fl ue and wall shield with heat shield

DVP-TB1 Basement Horizontal Termination Cap

DVP-TRAPK1 Top Vent Horizontal Kit with DVP-TRAP1 Termination Cap, wall shield with heat shield, and 90° elbow

DVP-TRAPK2 Top Vent Horizontal Kit with DVP-TRAP2 Termination Cap, wall shield with heat shield, and 90° elbow

DVP-HSM Extended Heat Shield

BEK Brick Extension Kit

DVP-AS Attic Insulation Shield

Hearth & Home Technologies Inc. • Cinch Pipe & Term Caps • 4033-900 Rev K • 05/05

3

Page 4

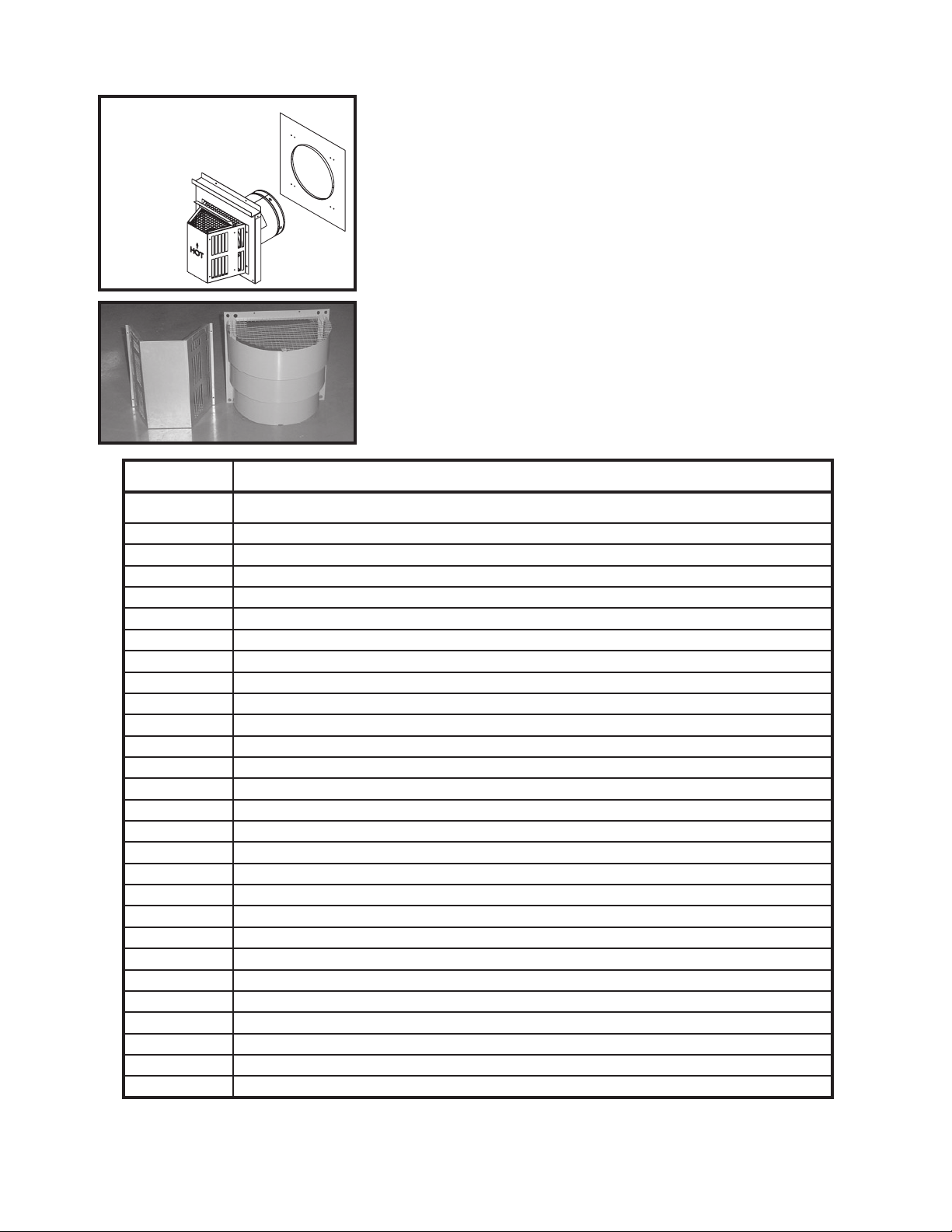

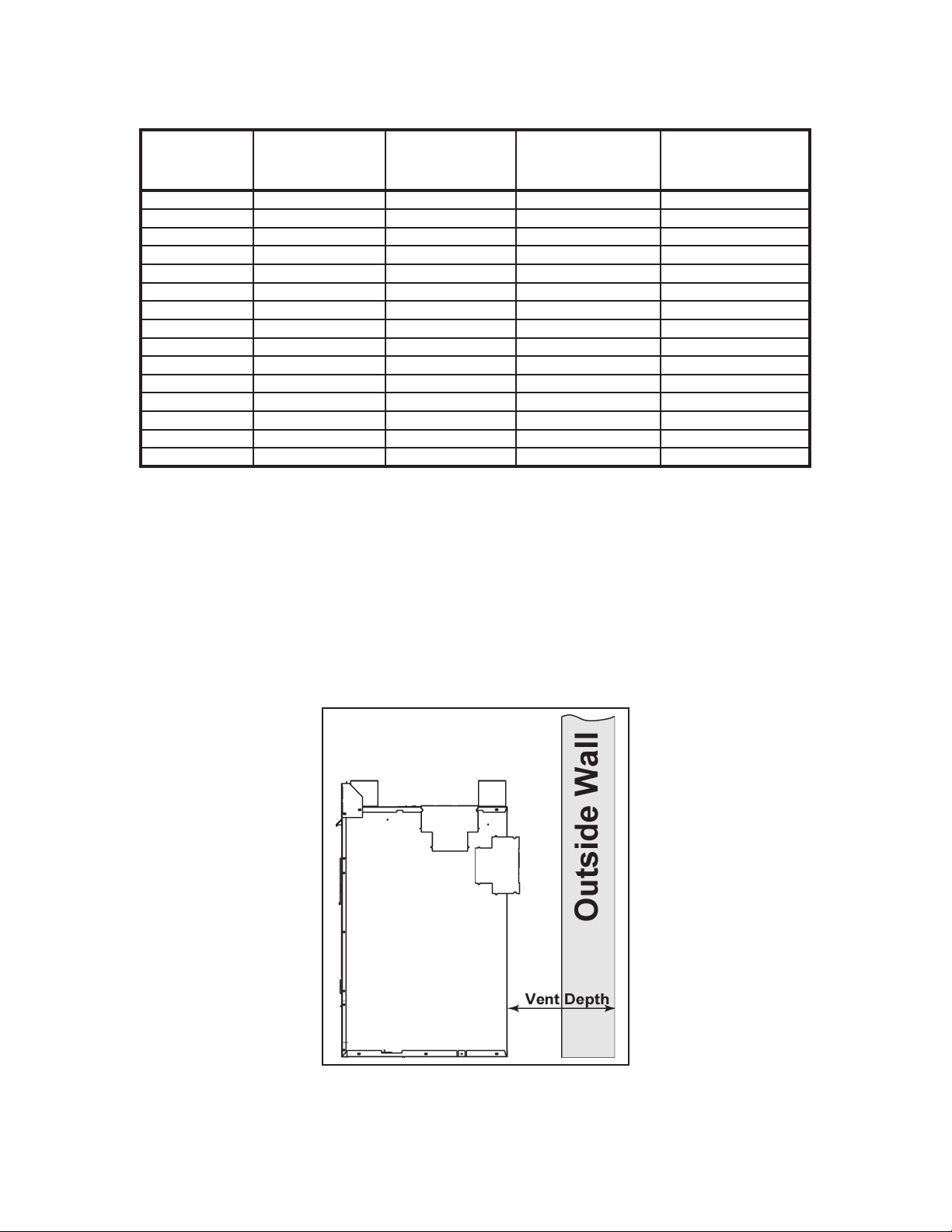

Vent depth is measured from the back of the appliance to the outer edge of the exterior wall. See Table 1 and Figure 1.

TRAP CAP SPECIFICATION CHART

DVP-TRAPK1

Top Vent

Appliance

Novus 4-1/2 in. to 6-1/4 in. 3-1/2 in. to 4-3/4 in. 7 in. to 11 in. 5-1/2 in. to 9-1/2 in.

NXT 4-1/8 in. to 5-7/8 in. 4-5/8 in. to 6-3/8 in. 6-1/2 in. to 10-1/2 in. 7-1/4 in. to 11-1/4 in.

Caliber 4-1/8 in. to 5-7/8 in. 3-5/8 in. to 5-3/8 in. 6-1/2 in. to 10-1/2 in. 6-1/4 in. to 10-1/4 in.

Maxus 4-1/2 in. to 6-1/4 in. 4-1/8 in. to 5-7/8 in. 6-7/8 in. to 10-7/8 in. 6-3/4 in. to 10-3/4 in.

GNTC50 5 in. to 6-3/4 in. 4-7/8 in. to 6-5/8 in. 7-3/8 in. to 11-3/8 in. 7-3/8 in. to 11-3/8 in.

Designer* 4 in. to 5-3/4 in. 5-3/4 in. to 7-1/2 in. 6-3/8 in. to 10-3/8 in. 8-1/8 in. to 12-1/8 in.

Titan 3-1/2 in. to 5-1/4 in. N/A 6 in. to 10 in. N/A

6000 2-3/4 in. to 4-1/2 in. 3-1/8 in. to 4-7/8 in. 5-1/4 in. to 9-1/4 in. 5-5/8 in. to 9-5/8 in.

8000 2-3/4 in. to 4-1/2 in. 3-1/8 in. to 4-7/8 in. 5-1/4 in. to 9-1/4 in. 5-5/8 in. to 9-5/8 in.

Olympian 3-1/2 in. to 5-1/4 in. N/A 6 in. to 10 in. N/A

Multisided 7-1/2 in. to 9-1/4 in. 3-1/8 in. to 4-7/8 in. 10 in. to 14 in. 5-5/8 in. to 9-5/8 in.

Gem 4-1/2 in. to 6-1/4 in. N/A 7 in. to 11 in. N/A

SL units N/A 3-1/8 in. to 4-7/8 in. N/A 5-5/8 in. to 9-5/8 in.

ICON 3-1/2 in. to 5-1/4 in. N/A 6-1/2 in. to 10-1/2 in. N/A

GDST5244I** 4 in. to 5-3/4 in. N/A 6-3/4 in. to 7-3/4 in. N/A

* Top vented appliance - Designer needs a DVP12 after the elbow.

** GDST5244I requires a DVP12 and DVP6 after the elbow.

Depth

DVP-TRAP1

Rear Vent

Depth

Table 1

DVP-TRAPK2

Top Vent

Depth

DVP-TRAP2

Rear Vent

Depth

Figure 1 - Measuring Required Vent Depth

4

Hearth & Home Technologies Inc. • Cinch Pipe & Term Caps • 4033-900 Rev K • 05/05

Page 5

2

Installing Vent Pipe

Note: For termination cap installations only, go directly to Sec-

tion E.

A. Clearances for the Vent Sections

• Top Vented Direct Vent Appliances

For all top vented, direct vent appliances, clearances to

combustible materials from the venting system need to

be maintained as shown in Figure 2.1.

• Rear Vented Direct Vent Appliances

See Figure 2.2.

Note: Refer to the appliance installation instructions for al-

lowed vent lengths and confi gurations.

Note: Heat shields MUST overlap by 1-1/2 in. min. for rear

vented appliances.

B. Penetrating a Wall

Wherever a combustible wall is penetrated, the hole must

be framed with an interior wall shield (DVP-WS) as shown in

Figures 2.3-2.4. This shield maintains minimum clearances

and restricts cold air infi ltration. If the wall being penetrated is

of noncombustible materials (material which will not ignite or

burn, or has a UL fi re rating of zero), a 9 in. diameter hole is

acceptable. Whenever a wall is penetrated the wall shield is only

required on one side and no heat shield is necessary. If your

local inspector requires the wall shield on both sides, then both

wall shields must have a heat shield attached to them.

Figure 2.1 Horizontal Venting Clearances to Combustible Materials - Top Vent

Note: Heat shields

MUST overlap by a

minimum of

1-1/2 in. (38 mm).

Heat

Shield

Wall

Shield

WALL

Figure 2.2 Horizontal Venting Clearances to Combustible Materials - Rear Vent

3 in. (76 mm)

top clearance

Heat

Shield

1 in. (25 mm)

clearance

bottom & sides

Figure 2.3 Exterior Wall Hole

Figure 2.4 Interior Wall Shield

WARNING

Fire Risk

Explosion Risk

Maintain vent clearance to combustibles as

specifi ed.

• Do not pack air space with insulation or

other materials.

Failure to keep insulation or other materials

away from vent pipe may cause fi re.

Hearth & Home Technologies Inc. • Cinch Pipe & Term Caps • 4033-900 Rev K • 05/05

5

Page 6

C. Assemble Vent Sections

WARNING

Fire Risk

Exhaust Fumes Risk

• Overlap pipe slip sections at least

1-1/2 inches.

• Use pilot holes for screws.

• Screws must not exceed one inch long.

• Pipe may separate if not properly

joined.

Attaching Vent to the Firebox Assembly

To attach the fi rst pipe section to the collars, slide the male

end of the inner vent of the pipe section over the inner collar

on the fi rebox assembly. At the same time, slide the outer

fl ue over the outer collar on the appliance. Push the pipe

section into the appliance collar until all the lances (see Figure 2.5) have snapped in place. Tug slightly on the section

to confi rm it has completely locked into place.

Assemble Pipe Sections

Insert the inner fl ue of section A into the fl ared inner fl ue of

section B.

Start the outer fl ue of section A over the outer fl ue of section

B (see Figure 2.6).

Figure 2.5 Lances

A

B

A

B

Note: The end of the pipe sections with the lances/tabs on

it will face towards the appliance.

Once both inner and outer fl ues are started, press section

A onto section B fi rmly until all lances have snapped into

place. Check to make sure they have snapped together (see

Figure 2.7) and the seams are not aligned (see Figure 2.8).

Tug slightly on section A to confi rm it has completely locked

into place.

For 90° and 45° elbows that are changing the vent direction

from horizontal to vertical, one screw minimum should be

put in the outer fl ue at the horizontal elbow joint to prevent

the elbow from rotating.

Figure 2.6 Inner/Outer

Make sure the seams are not aligned to prevent unintentional

disconnection.

CORRECT INCORRECT

Figure 2.8 Seams

Figure 2.7 Snapped

6

Hearth & Home Technologies Inc. • Cinch Pipe & Term Caps • 4033-900 Rev K • 05/05

Page 7

Assemble Minimum Installation (MI) Sections

MI sections are non-unitized so that they can be cut to a

specifi c length. Cut these sections to length from the nonexpanded end (see Figure 2.9).

They can then be attached by fi rst connecting the expanded

end of the MI inner fl ue with the inner pipe from the adjacent

pipe section and securing with three screws. The expanded

portion of the MI inner fl ue must overlap completely with the

unexpanded end of the adjacent pipe section.

The outer fl ue can then be inserted into the adjacent outer

fl ue expanded end and attached to the next pipe section with

three screws. The other end of the MI pipe section can then

be attached by fi tting another pipe section to it and snapping

it together, as normal.

Assemble Slip Sections

The outer fl ue of the slip section should slide over the outer

fl ue of the pipe section and into (inner fl ue) the last pipe section (see Figure 2.10) .

Slide together to the desired length, making sure that a

1-1/2 in. outer fl ue overlap is maintained between the pipe

section and slip section.

The pipe and slip section need to be secured by driving two

screws through the overlapping portions of the outer fl ues

using the pilot holes (see Figure 2.11).

This will secure the slip section to the desired length and

prevent it from separating. The slip section can then be attached to the next pipe section.

If the slip section is too long, the inner and outer fl ues of the

slip section can be cut to the desired length.

Figure 2.9 MI Sections

Figure 2.10 Slip Section Pilot Holes

Figure 2.11 Screws into Slip Section

Hearth & Home Technologies Inc. • Cinch Pipe & Term Caps • 4033-900 Rev K • 05/05

7

Page 8

Secure the Vent Sections

Vertical sections of pipe must be supported every 8 ft after

the 25 ft maximum unsupported rise. The vent support or

plumber’s strap (spaced 120° apart) may be used to do this

(see Figures 2.12 and 2.13).

Horizontal sections of vent must be supported every 5 ft with

a vent support or plumber’s strap.

D. Disassemble Vent Sections

To disassemble any two pieces of pipe, rotate either section

(see Figure 2.14), so that the seams on both pipe sections

are aligned (see Figure 2.15). They can then be carefully

pulled apart.

WARNING

Fire Risk

Explosion Risk

Asphyxiation Risk

Use vent run supports per installation

instructions.

Connect vent sections per installation

instructions

• Maintain all clearances to combustibles.

• Do NOT allow vent to sag below

connection point to appliance.

• Maintain specifi ed slope (if required).

Improper support may allow vent to sag or

separate.

Figure 2.12 Securing Vertical Pipe Sections

Figure 2.13 Securing Horizontal Pipe Sections

Figure 2.14 Rotate Seams for Disassembly

Figure 2.15 Align and Disassembly Vent Sections

8

Hearth & Home Technologies Inc. • Cinch Pipe & Term Caps • 4033-900 Rev K • 05/05

Page 9

E. Install the Heat Shield and Horizontal Termination Cap

on the extended heat shield should rest on the top of the vent

WARNING

A 1-1/2 in. minimum overlap MUST be maintained on

the telescoping fl ue section of the cap.

WARNING

Fire Risk

Exhaust Fumes Risk

Impaired performance of appliance.

• Overlap pipe slip sections at least 2 in.

• Use pilot holes for screws.

• Screws must not exceed 1 in. long.

• Pipe may separate if not properly

joined.

Heat Shield Requirements for Horizontal Termination

For all horizontally vented appliances, a heat shield MUST

be placed 1 in. above the top of the vent between the wall

shield and the base of the termination cap.

There are two sections of the heat shield. One section attaches to the wall shield with two screws. The remaining

section is attached to the cap in the same manner. See

Figure 2.16.

If the wall thickness does not allow the required 1-1/2 in.

heat shield overlap, an extended heat shield must be used.

The extended heat shield will need to be cut to the thickness

of the wall and be attached to the wall shield. The small leg

(pipe section) to properly space it from the pipe section.

Install the Horizontal Termination Cap

Vent termination must not be recessed in the wall. Siding

may be brought to the edge of the cap base.

Caulk the outside edges of the cap.

When installing a horizontal termination cap, follow the cap

location guidelines as prescribed by current ANSI Z223.1

and CAN/CGA-B149 installation codes.

Wall Shield

WARNING

Burn Risk

• Local codes may require installation of a

cap shield to prevent anything or anyone

from touching the hot cap.

Heat Shield or

Extended

Heat Shield

Rear Vent

Heat Shield

1-1/2 in. (38 mm) min.

overlap

Inner Vent

Outer Vent

Figure 2.16 Venting through the Wall

INTERIOR

EXTERIOR

SHEATHING

WARNING

Do NOT connect a pipe section to a termination cap

without using the telescoping fl ue section found on the

termination cap.

Note: W h e re required, an exter i or wall fl ashing is available.

When penetrating a brick wall, a brick extension kit is

available for framing the brick.

Hearth & Home Technologies Inc. • Cinch Pipe & Term Caps • 4033-900 Rev K • 05/05

9

Page 10

F. Vertical Penetration Framing

WARNING

Fire Risk

Keep loose materials or blown insulation

from touching the vent pipe.

• National building codes recommend using

attic shield to keep loose materials/blown

insulation from contacting vent.

• Hearth & Home Technologies requires

the use of an attic shield.

Install the Firestop Spacer

• Frame an opening 10 in. by 10 in. whenever the vent

system penetrates a ceiling/fl oor (see Figure 2.17).

• Frame the area with the same sized lumber as used in

ceiling/fl oor joist.

• When installing a top vent vertical appliance the hole

should be directly above the appliance, unless the fl ue is

offset.

• Do not pack insulation around the vent. Insulation must

be kept away from the pipe.

Note: The fi restop spacer is not required if attic insulation

shield is used.

Attic Above

10 in. (254 mm)

10 in.

(254 mm)

Hole should measure

10 in. x 10 in.

(254 mm x 254 mm)

inside to inside

Install Attic Insulation Shield

• Frame opening for attic insulation shield.

• Attic insulation shield may be installed above or below

ceiling (see Figure 2.18).

• Secure with three fasteners on each side.

• Fold tabs at top of attic shield in toward vent pipe. Tabs

must keep vent pipe centered within shield.

• Field construct additional shield height if insulation is

deeper than height of attic shield.

Bend tabs in

around pipe

3 fasteners

per side

Attic insulation shield

installed below ceiling.

Figure 2.17 Installing Firestop Spacer

Attic insulation shield

installed above ceiling.

10

Figure 2.18 Installing the Attic Insulation Shield

Hearth & Home Technologies Inc. • Cinch Pipe & Term Caps • 4033-900 Rev K • 05/05

Page 11

G. Install Roof Flashing and Vertical Termination Cap

To install roof fl ashing see Figure 2.19.

For installation of vertical termination cap see minimum vent

heights for various pitched roofs (Figure 2.19) .

Horizontal

overhang

24 in. min.

(610 mm)

Termination

Cap

Storm Collar

Roof

Flashing

20 in.

(508 mm)

Lowest

Discharge

Opening

12

H (min.) - Minimum height

from roof to lowest

discharge opening.

Vertical

wall

X

Roof Pitch

is X / 12

To attach the vertical termination cap, slide the inner collar

of the cap into the inner fl ue of the pipe section and place

the outer collar of the cap over the outer fl ue of the pipe

section.

Secure with three screws into the outer fl ue. Secure the cap

by driving the three self-tapping screws (supplied) through

the pilot holes in the outer collar of the cap into the outer fl ue

of the pipe (see Figure 2.20).

Termination Cap

Brackets/

Bolts

Caulk

(1 of three)

Storm

Collar

Screws

Roof Pitch H (Min.) Ft. Roof Pitch H (Min.) Ft.

Flat to 6/12 1.0* Over 11/12 to 12/12 4.0

6/12 to 7/12 1.25* Over 12/12 to 14/12 5.0

Over 7/12 to 8/12 1.5* Over 14/12 to 16/12 6.0

Over 8/12 to 9/12 2.0* Over 16/12 to 18/12 7.0

Over 9/12 to 10/12 2.5 Over 18/12 to 20/12 7.5

Over 10/12 to 11/12 3.25 Over 20/12 to 21/12 8.0

* 3 ft. minimum in snow regions

Figure 2.19 Minimum Height from Roof to Lowest Discharge

Opening

Figure 2.20 Secure with Screws

WARNING

Fire Risk

Explosion Risk

Inspect external vent cap regularly.

• Ensure no debris blocks cap.

• Combustible materials blocking cap may

ignite.

• Restricted air flow affects burner

operation.

Hearth & Home Technologies Inc. • Cinch Pipe & Term Caps • 4033-900 Rev K • 05/05

11

Page 12

H. Assemble and Install Storm Collar

CAUTION

Sharp Edges!

• Wear protective gloves and safety

glasses during installation.

Connect both halves of the storm collar with two screws (see

Figure 2.21).

Wrap the storm collar around the exposed pipe section and

align brackets. Insert a bolt (provided) through the brackets

and tighten nut to complete the storm collar assembly (see

Figure 2.22). Make sure the collar is tight against the pipe

section.

Slide the assembled storm collar down the pipe section until

it rests on the roof fl ashing (see Figure 2.19).

Caulk around the top of the storm collar.

Figure 2.21 Assembling the Storm Collar

12

Figure 2.22 Assembling the Storm Collar Around the

Pipe

Hearth & Home Technologies Inc. • Cinch Pipe & Term Caps • 4033-900 Rev K • 05/05

Loading...

Loading...