Healy VP1000 Installation, Operation And Maintenance Manual

ARB Approved IOM – Executive Orders VR-201-B and VR-202-B (Wayne Harmony WayneVac Dispen ser) Page 103

WAYNE-DRESSER HARMONY™ SERIES DISPENSER

RETROFIT for HEALY SYSTEMS, INC.

MODEL VP1000

VAPOR RECOVERY ASSIST SYSTEM

(KIT Z080)

OUTLINE

NOTICE: USE THIS PROCEDURE IF CONVERTING A WAYNE-VAC™ VAPOR RECOVERY

ASSIST SYSTEM TO A HEALY VAPOR RECOVERY ASSIST SYSTEM

See Healy Systems Kit Z078 For Dispensers With Balance Systems

1. Purpose

2. Safety

3. Models Covered

4. Parts Lists

5. Tools Required

6. Dispenser Access

7. Survey Scope Of Work

8. Wayne-VAC Removal

9. Installing The Healy VP1000 System

10. Connecting Vapor Lines

11. Installing The Sealed Nipple Assembly

12. Wiring Inside The Electronics Compartment

13. Connecting Healy Systems Dispensing Equipment

14. VP1000 Theory Of Operation

15. Testing The System

16. Trouble Shooting The VP1000

17. VP1000 Vane & Rotor Service & Replacement Guide

Start-up / New Installation / Warranty / Annual Testing Form (Rev. 11/06)

Healy Systems, Inc. Website: http://www.healysystems.com

18 Hampshire Drive Email: sales@healysystems.com

Hudson, New Hampshire 03051 USA Telephone: 603.882.2472

ARB Approved Installation, Operation and Maintenance Manual (November 2006) Fax: 603.882.5189

Healy Systems, Inc. – the innovative leader of Stage II vapor recovery equipment

ARB Approved IOM – Executive Orders VR-201-B and VR-202-B (Wayne Harmony WayneVac Dispen ser) Page 104

1. PURPOSE:

This procedure describes the tools, methods and skill levels required to install a Healy

Systems, Inc. Model VP1000 Vapor Recovery pump in vapor ready Wayne Dresser Harmony™

series gasoline dispensers. Only Healy trained and certified contractors will be able to perform

these retrofits or warranty will be void. The installer shall be a skilled petroleum technician and

thoroughly familiar with the requirements of State, Federal and local codes for installation and

repair of gasoline dispensing equipment. Also, they shall be aware of all the necessary safety

precautions and site safety requirements to assure a safe and trouble free installation. NOTE:

All electrical and hydraulic plumbing fittings referred to in these instructions must be UL

“listed” or “recognized” for the purpose.

2. SAFETY: Before installing the equipment, read, understand and follow:

- The National Electrical Code (NFPA 70)

- The Automotive and Marine Service Code (NFPA 30A)

- Any national, state and local codes that may apply.

The failure to install the equipment in accordance with NFPA 30A and

70 may adversely affect the safe use and operation of the system.

3. MODELS COVERED:

Wayne-Dresser Harmony™ series dispensers, all options except suffix “O”, non vapor

ready and Balance systems. The addition of the Healy Systems VP1000 to the Harmony

Accurate, sound installations reduce service calls: Use experienced,

licensed contractors that practice accurate, safe installation

techniques. Careful installation provides a sound troubleshooting

framework for field repairs and can eliminate potential problems.

1. Read all instructions before beginning.

2. Follow all safety precautions:

Barricade the area.

Do not allow vehicles or unauthorized people in the area.

Do not smoke or allow open flames in the area.

Do not use power tools in the work area.

Wear eye protection during installation.

3. Use circuit breakers for multiple disconnects to turn off power and

prevent feedback from other dispensers.

Healy Systems, Inc. Website: http://www.healysystems.com

18 Hampshire Drive Email: sales@healysystems.com

Hudson, New Hampshire 03051 USA Telephone: 603.882.2472

ARB Approved Installation, Operation and Maintenance Manual (November 2006) Fax: 603.882.5189

Healy Systems, Inc. – the innovative leader of Stage II vapor recovery equipment

ARB Approved IOM – Executive Orders VR-201-B and VR-202-B (Wayne Harmony WayneVac Dispen ser) Page 105

dispenser will increase the current draw of the dispenser by 2 amps. Use the label

supplied to note this change.

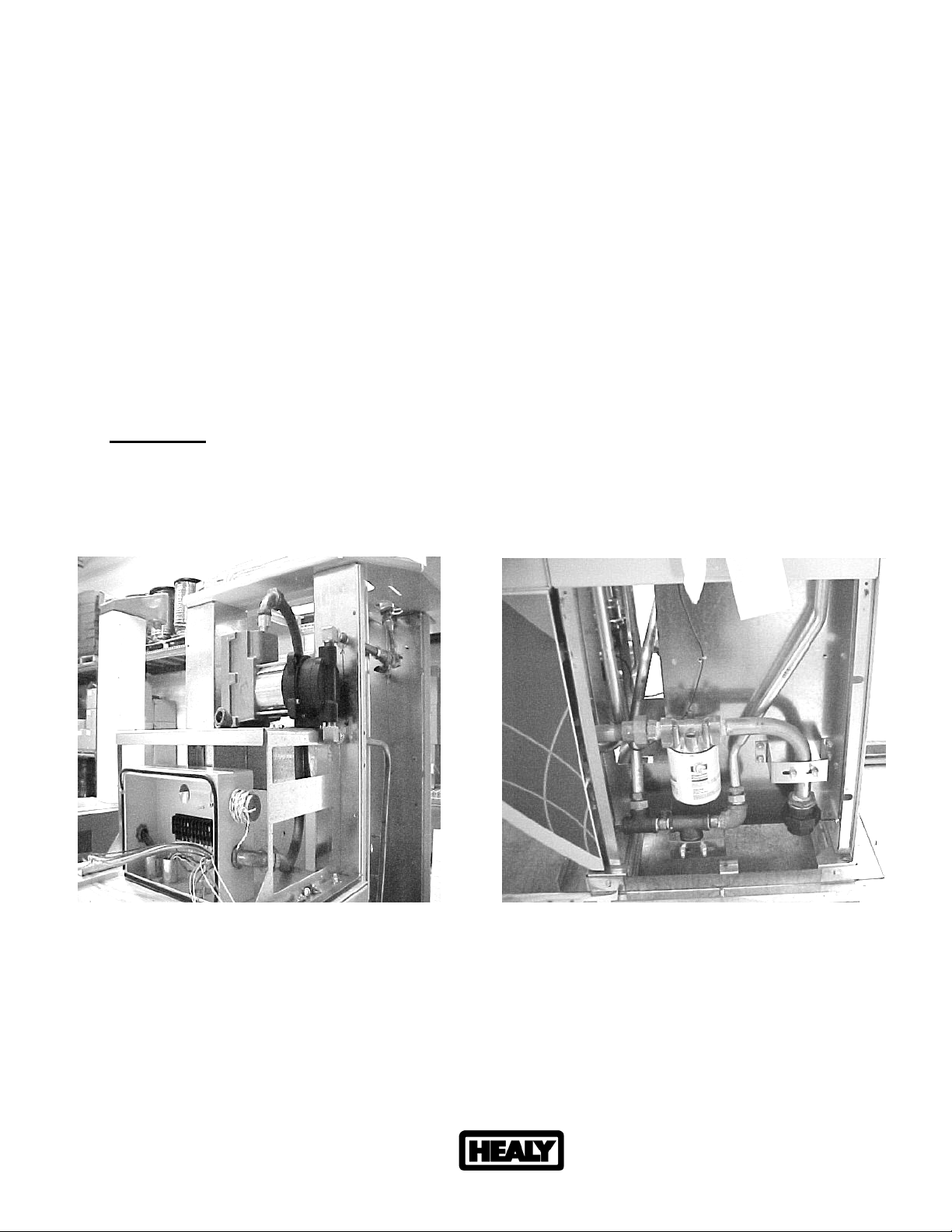

4. PARTS LISTS: (See Photo A)

1 VP1000 Vacuum Pump

1 1365A Wire Harness / MC100 Series Interface Module Assembly

Photo A Photo B

Photo C Photo D

HARDWARE KIT Z080H: (See Photo B)

2 1/4-20 bolts, washers, lock washers and nuts

Healy Systems, Inc. Website: http://www.healysystems.com

18 Hampshire Drive Email: sales@healysystems.com

Hudson, New Hampshire 03051 USA Telephone: 603.882.2472

ARB Approved Installation, Operation and Maintenance Manual (November 2006) Fax: 603.882.5189

Healy Systems, Inc. – the innovative leader of Stage II vapor recovery equipment

ARB Approved IOM – Executive Orders VR-201-B and VR-202-B (Wayne Harmony WayneVac Dispen ser) Page 106

ELECTRICAL KIT Z080E: (See Photo C)

4 4” Tyraps

1 Current change label (p/n 1405)

7 Wire nuts

1 8-32 x 3/4” machine screw, washer & nut

1 1/2” male NPT x 3/4” female NPT electrical reducer fitting

1 #1346 potted conduit nipple

1 #8 Ring tong terminal

1 Notice label (p/n 1406)

1 UL Listed label (p/n 1410)

VAPOR KIT Z080V: (See Photo D)

2 3/8” NPT x 5/8” flare straight fittings

3 1/2” NPT x 5/8” flare elbow fittings

1 1/2” NPT x 5/8” flare straight fitting

3 3/4” NPT x 5/8” flare straight fittings

1 5/8” x 5/8” x 5/8” flare tee

12’ 5/8” OD copper tube, type ‘L’

1 1/4” pipe plug

1 3/8” pipe plug

1 1/2” close nipple

1 1/2” x 1/4” x 1/2” reducing tee

1 1/2” ball valve

1 3/4” elbow

12 5/8” flare nuts

MATERIALS SUPPLIED BY INSTALLER:

Thread Sealing Compound – non-Setting, UL Classified for use on all tapered

thread, Non-electrical, plumbing fittings.

Teflon tape

Healy Systems, Inc. Website: http://www.healysystems.com

18 Hampshire Drive Email: sales@healysystems.com

Hudson, New Hampshire 03051 USA Telephone: 603.882.2472

ARB Approved Installation, Operation and Maintenance Manual (November 2006) Fax: 603.882.5189

Healy Systems, Inc. – the innovative leader of Stage II vapor recovery equipment

ARB Approved IOM – Executive Orders VR-201-B and VR-202-B (Wayne Harmony WayneVac Dispen ser) Page 107

5. TOOLS REQUIRED:

1/2” or 3/8” ratchet set w/ sockets 1/4” through 9/16” + 3” extension

9” lineman’s pliers

Assorted open end wrenches 1/4” through 3/4”

Wire cutters/strippers 18 AWG and 26 AWG

1-1/8” greenlee type sheet metal punch

Mechanical hand drill (egg-beater type)

Assorted drill bits 1/16” through 7/16”

Assorted screwdrivers (flat blade-one must be 1/8” wide and Phillips)

5/8” copper tube bending tool

5/8” copper tube flaring tool

Copper tubing cutter

Electrical multi-meter

Small hand brush (1-1/2” thick, for clearing chips)

12” adjustable wrench

10” pipe wrench

Tape measure

Allen wrenches

#20 torx bit

Whitney type hand sheet metal punch with 3/16” punch and die set

6. DISPENSER ACCESS:

Secure Dispenser Access keys from Station Management.

Lock-out and tag-out all electrical power to dispenser being modified.

Remove the Top Cladding and Upper Shield in order to expose upper vapor tubing

attached to the outlet castings.

Remove both Upper Column Covers above nozzle holsters in order to expose Wayne-

VAC™ vacuum pumps.

Remove the Lower Column Cover below the nozzle holster on the “A” side of the

dispenser. This is the side that the vapor tubes from the out port of the Wayne-VAC™

vacuum pumps are connected to a vapor tee mounted at the base of the dispenser, see

photo F.

Remove the Upper Cladding covering the “J” Box, see photo E.

Healy Systems, Inc. Website: http://www.healysystems.com

18 Hampshire Drive Email: sales@healysystems.com

Hudson, New Hampshire 03051 USA Telephone: 603.882.2472

ARB Approved Installation, Operation and Maintenance Manual (November 2006) Fax: 603.882.5189

Healy Systems, Inc. – the innovative leader of Stage II vapor recovery equipment

ARB Approved IOM – Executive Orders VR-201-B and VR-202-B (Wayne Harmony WayneVac Dispen ser) Page 108

Remove the “J” Box cover.

Remove the Door Cladding assembly and the Access Door assembly in order to expose

the electronics compartment.

7. SURVEY– Scope of Work: Perform this step before beginning steps 8 thru 12.

Read and familiarize yourself with the theory of operations sheet and wiring instructions for the

VP1000 Vapor Pump. The installation of the pump is on the sheet metal shelf over the junction

box, with the pump cover facing the “A” side of the dispenser, see photo E. This is the side

that the vapor tubes from the out port of the Wayne-VAC™ vacuum pumps are connected to a

vapor tee mounted at the base of the dispenser, see photo F. From this survey, you will have

an indication of where the vapor plumbing fittings need to go and where the holes need to be

drilled in the adjoining sheet metal to allow the vapor pipes from the pump to pass through to

the hydraulics compartment. Notice also in the electrical junction box, on the bottom right

side, there is a potted conduit nipple which contains the Wayne-VAC™ wiring harness (for

pump on “A” side) that you will remove to install the Healy potted conduit nipple, See Section

11. CAUTION: ALL POWER TO DISPENSER UNDER MODIFICATION SHOULD BE COMPLETELY

DISCONNECTED AND CAPPED OFF AT JUNCTION BOX TO AVOID UNINTENTIONAL

FEEDBACK FROM OTHER DISPENSERS!!

Photo E Photo F

8. WAYNE-VAC™ REMOVAL:

Disconnect and lockout the power to the dispenser.

Open the dispenser cabinet doors as specified in section 6 above.

Healy Systems, Inc. Website: http://www.healysystems.com

18 Hampshire Drive Email: sales@healysystems.com

Hudson, New Hampshire 03051 USA Telephone: 603.882.2472

ARB Approved Installation, Operation and Maintenance Manual (November 2006) Fax: 603.882.5189

Healy Systems, Inc. – the innovative leader of Stage II vapor recovery equipment

Loading...

Loading...