Page 1

PRO PLUS® STRETCHER SCALE

MODEL 2000KL

OPERATION MANUAL

AA0339-0

Page 2

PRO PLUS® STRETCHER SCALE

MODEL 2000KL

Thank you

Please read this manual carefully and keep it handy for ready reference.

for your purchase of this product.

TABLE OF CONTENTS

CAUTION AND WARNING.................................................................................................... 2

SPECIFICATIONS.................................................................................................................3

ASSEMBLY INSTRUCTION.................................................................................................. 4

SET UP..................................................................................................................................10

OPERATION INSTRUCTIONS.............................................................................................. 11

MAINTENANCE.....................................................................................................................23

TROUBLESHOOTING........................................................................................................... 24

CALIBRATION PATH ............................................................................................................ 25

EXPLODED VIEW OF SCALE .............................................................................................. 25

PARTS LIST .......................................................................................................................... 27

WARRANTY .......................................................................................................................... 28

1

Page 3

CAUTION AND WARNING

To prevent injury and damage to your scale, please follow these instructions very carefully.

• To ensure proper operation of the ProPlus® Stretcher Scale, this operation manual should be

reviewed carefully before operation. Keep this manual available for future reference, and also

for use in the orientation of new personnel.

• If the scale becomes damaged, it should not be operated until properly serviced. All repairs

should only be performed by authorized Healthometer® Professional service personnel.

• This scale is designed for static weighing of patients only. No scale should be used for

patient transfer. Healthometer® Professional / Pelstar LLC assumes no responsibility

for patient injury or scale damage should this caution be ignored.

• Do not leave patients unattended while on the scale.

• For accurate weighing the scale must be placed on a flat and stable surface with the locking

screw locked properly and the weighing mechanism not touching the floor.

• For accurate weighing, verify proper operation according to the procedure described in this

manual before each use.

• Do not use in the presence of flammable materials.

• Operating at other voltages and frequencies than specified could damage the equipment.

• If the “LOW BAT” indicator activates, for accurate weighing, replace the batteries or connect

the scale to an AC power source as soon as possible.

• Failure to comply with the following will void scale warranty:

o Do not gas sterilize or autoclave the scale.

o Do not place liquids on top of the scale display console.

o Do not exceed recommended weigh limit of 400 lb/181kg for this

scale.

o This scale contains delicate sensors. Do not bang into doors,

elevators, etc., as damage may result.

2

Page 4

SPECIFICATIONS

GENERAL

Health o meter’s ProPlus® Stretcher Scale Model 2000KL uses highly sophisticated

microprocessor technology. This scale is designed to provide accurate, reliable and repeatable

weight measurements and features that make the weighing process simple, fast and convenient.

The scale is set up to use motion-sensing weighing technology, to determine the actual weight

of a moving patient. The scale may be changed to measure live weight; see page 19 for

instructions on changing the scale setting.

The weight can be displayed in pounds (decimals, fractions of a lb or lb/oz) or in kilograms. The

scale features a folding stretcher for easy mobility and a display assembly stand.

The unit can be operated using its AC adapter or by 6-D cell batteries (not included).

SCALE SPECIFICATIONS

Capacity and Resolution

Power Requirements

Environmental

Stretcher Dimensions Closed:

400 Lb x 0.2 Lb / ¼ lb / 4 oz (181 Kg x 0.1 Kg)

Adapter 120VAC - 6VDC - 60Hz or 6 x D size batteries

Operating temperatures: 50°F to 95°F (10°C to 35°C)

Storage temperatures: 30°F to 125°F (0°C to 50°C)

Humidity: 85%

Length: 70 ⅞” (180 cm)

Width: 6” (15 cm)

Weight: 16.5 Lb (7.5 Kg)

Fully extended:

Length: 70 ⅞” (180 cm)

Width: 29½” (75 cm)

3

Page 5

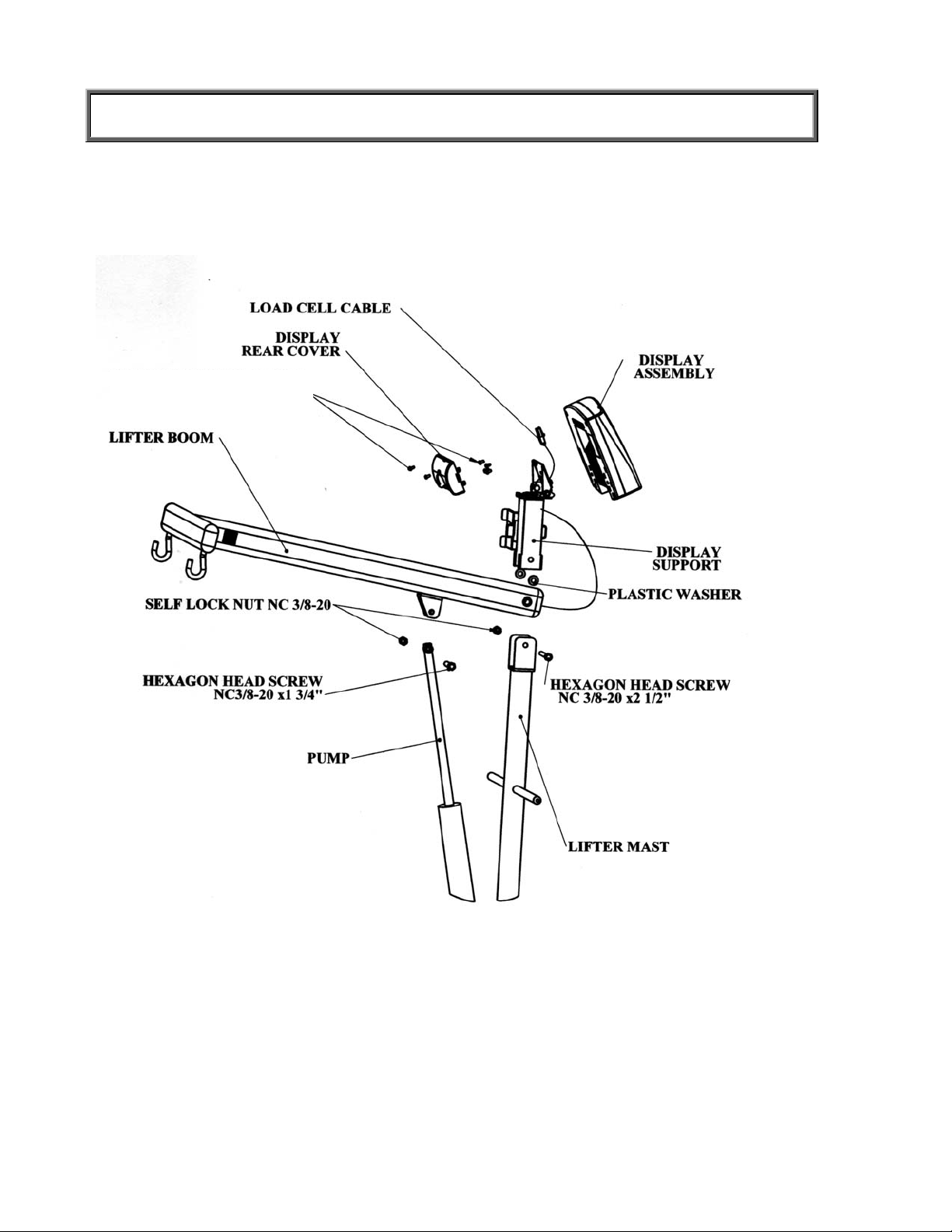

ASSEMBLY INSTRUCTIONS

Before Assembly

The Model 2000KL ProPlus® Stretcher Scale is shipped disassembled in two (2) separate

cartons. Carefully inspect all cartons for shipping damage before unpacking. If damage is found,

contact your shipper or Healthometer Professional immediately. Claims must be filed with the

shipper as soon as possible after receipt of the damaged package.

Remove each assembly from the carton and unwrap packing material carefully to prevent

scratching the unit’s parts. It is recommended that two people perform the assembly.

The scale is shipped in two (2) separate cartons as follows:

A. Large carton containing:

(1) Hydraulic pump assembly

(1) Lifter mast

(1) Base adjustment lever

(1) Lifter base with casters

B. Small carton containing:

(1) Lifter boom (1) Stretcher storage tray (4) Stretcher bars

(1) Display support (1) Adapter holder (2) Stretcher bar joint

(1) Display assembly (1) AC adapter (1) Hexagon screw with

(1) Load cell assembly (1) Display rear cover (2) Plastic washer

(2) Stretcher hoops (6) Screws for display

(1) Stretcher sheet (2) Shoulder screw and washer

Tools required: Phillips head screwdriver, adjustable wrenches, 7/16” Allen wrench.

Parts of Stretcher Scale

Lifter mast

Hydraulic pump assembly

Base adjustment lever

L

Lifter base with casters

lock nut

(1) Velcro strap

Figure 1

4

Page 6

ASSEMBLY INSTRUCTIONS

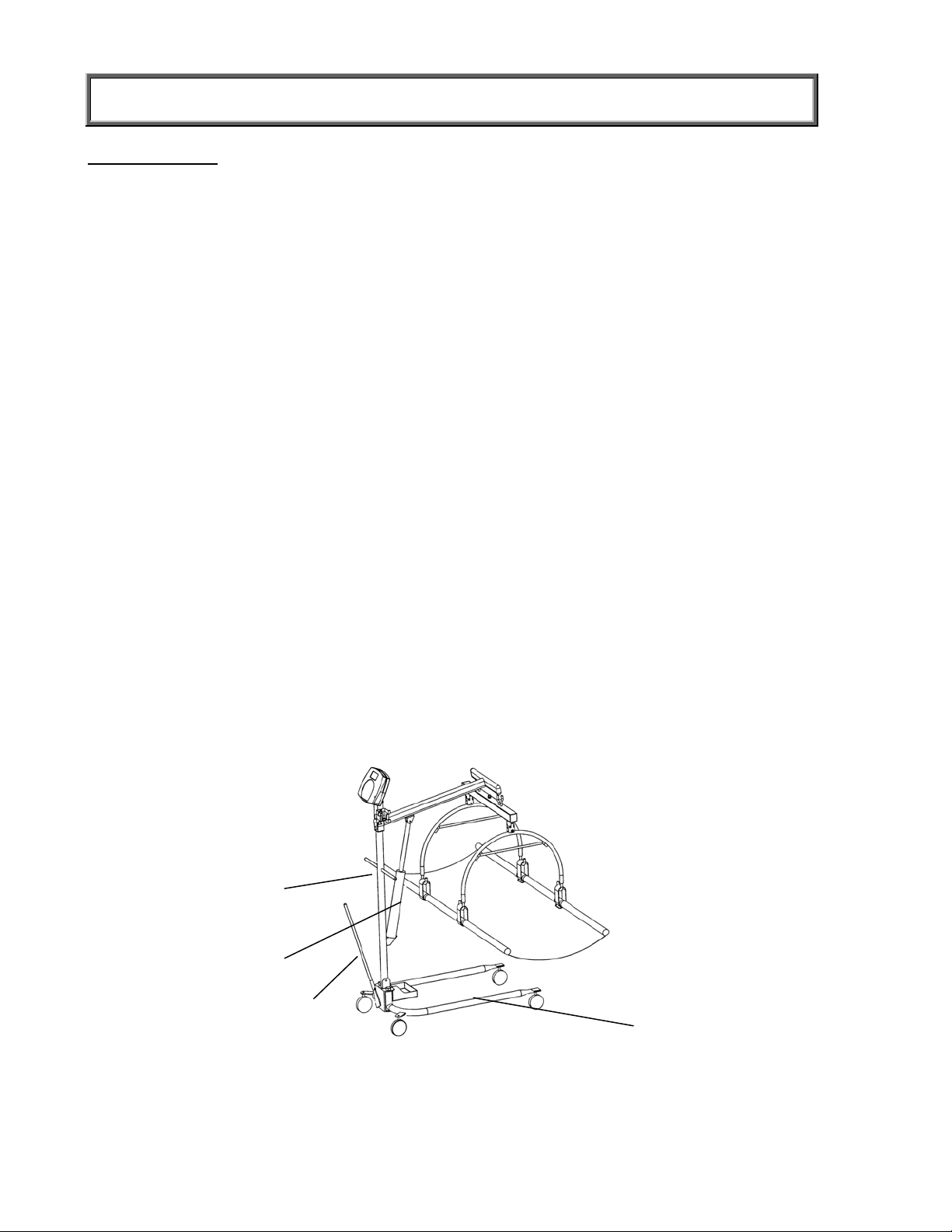

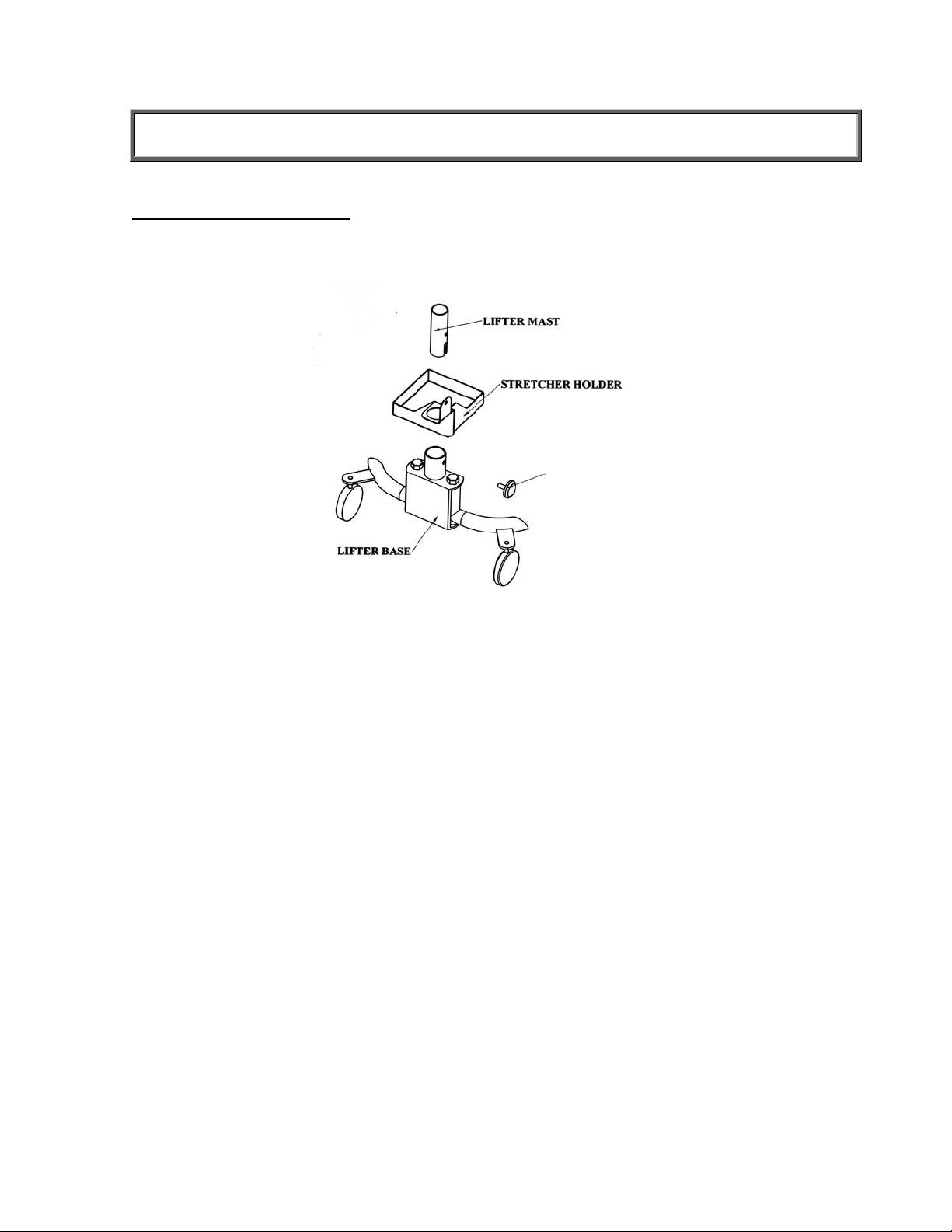

Assembling the Patient Lifter

1. Place the Stretcher Storage Tray on the Lifter Base, as shown below, before attaching the

Lifter Mast.

KNOB

Figure 2

2. Remove black plastic protective caps from Lifter Mast. Insert the bottom of the Lifter

Mast and Hydraulic Pump assembly into the mast sleeve (through the Stretcher Tray

Holder) on the Lifter Base. The notch on the end of the mast fits over the round tube at

the bottom of the Mast Sleeve. The mast must lock into position in the mast sleeve,

making it impossible to rotate. Check that the mast is locked into position and that the

hole in the mast is aligned with the threaded hole in the mast sleeve.

3. Insert the threaded locking device (the plastic knob and stud chained to the base) into

the threaded hole in the mast sleeve. Tighten to lock the mast to the base. Keep mast

and base locked at all times except when removing mast from base for storage.

5

Page 7

ASSEMBLY INSTRUCTIONS

Attaching the Display and Scale to the Patient Lifter

PHILLIPS PAN HEAD

SCREW NC8-32x5/16

Figure 2

Figure 3

6

Page 8

ASSEMBLY INSTRUCTIONS

4. Connect the Lifter Boom and the Display Support to the Lifter Mast using the NC⅜-

20x2 ½” hex screw and tighten the self lock nut on its other side.

Note

: This screw is the axis of the Lifter Boom, so it is imperative that the three parts – Lifter

Boom, Lifter Mast and Display Support – be assembled in the proper order.

Place the Plastic Washers on either side of the Lifter Boom screw hole to prevent friction.

With the Boom hooks facing down, place the Lifter Boom and Washers inside the two

sides of the Lifter Mast and align the holes. Place the Display Support over the Lifter Mast

and Lifter Boom and align holes. Thread the screw through all three parts and tighten the

self lock nut on the other side well.

5. Insert the shaft end of the Pump into the eared bracket on the Lifter Boom and align the

holes. Slip the 1-3/4” nut through the bracket and the Pump shaft hole. Tighten with

locknut.

6. Insert the Base Adjustment Lever into its socket at the back of the Lifter Base. Check to

see that the bump on the outside of the socket fits securely in the notched adjusting

plate. To adjust the base legs, pull back on the adjusting lever to unlock. Move the lever

to the right to widen the base.

7. A wheel lock is provided on the Lifter Base for parking only. To lock caster, step on cam

lever on side of caster. To unlock, step on higher cam lever. NOTE: Never lock wheel

lock or block wheels when lifting someone. Wheel lock is provided for parking the Lifter

only,

8. Check the operation of the Hydraulic Pump by pumping the handle to elevate the Boom.

Make certain the control valve knob – located on the pump near the handle) is fully

tightened (clockwise).

9. To lower the Boom, slowly turn the control valve knob counterclockwise. The rate of

descent can be controlled by how much the knob is turned. The Boom may not lower

readily with weight. To test, simply apply downward force to the Boom.

Note

: If bolts, mounting pump or Lifter Mast are too tight, the Boom may not lower properly.

7

Page 9

ASSEMBLY INSTRUCTIONS

Figure 4

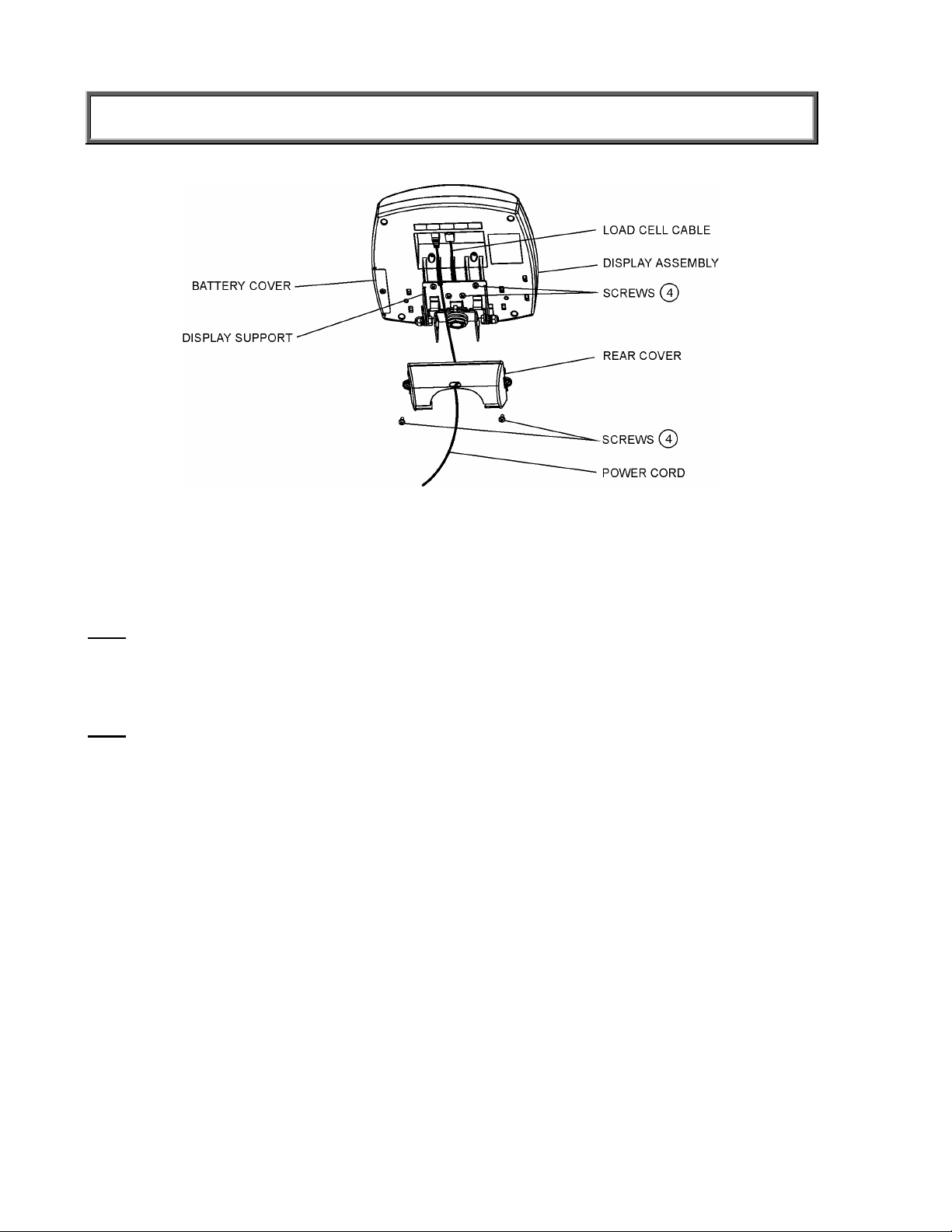

10. Position the Display Assembly close to the Display Support. Connect the load cell cable

connector to the load cell port on the rear of the Display Assembly and insert and secure the

cable into the center channel in the display.

Note

: Do not attach the power cord at this point.

11. Slide the display assembly onto the display support by inserting the two metal supports into

the two slots in the rear display assembly. Tuck the excess load cell cable in the Lifter Boom

tube.

Note

: The load cell cable should now be secured in the channel between the display assembly

and the display support.

12. Insert 4 screws into the display support and tighten.

13. Connect power cord to the power port in the display assembly and insert and secure the

cable into the exposed portion of the 2nd channel from the left in the display.

14. Insert the power cord into the retaining slot on the rear cover. Align the rear cover tabs with

the slots on the rear of the display assembly. Apply pressure to snap the rear cover into

place and secure with 2 screws.

8

Page 10

ASSEMBLY INSTRUCTIONS

Figure 5

15. Hang the Load Cell Assembly on the two hooks at the end of the Lifter Boom, using the

loops on top of the Load Cell Assembly.

16. Connect the end of the Load Cell Cable coming out of the center of the Load Cell Assembly

to its port in the Lifter Boom.

17 Use the two washers and shoulder screws to connect the two Stretcher Hoops to the Load

Cell Assembly and tighten well.

18. Connect the two right stretcher bars by screwing them onto one Stretcher Bar Connector, in

order to make one long Stretcher Bar.

19. Repeat step 9 with the left Stretcher Bar.

20. Insert the two bars into the open side of the channel-pockets in the Stretcher Sheet and

through the two hanging loops sewn into both sides of the Stretcher. The Stretcher Bars

should not protrude from the Stretcher Sheet at either end. Make sure one end on both

channel-pockets is sealed with Velcro.

Note

: Make sure the bars are inserted into the two hanging loops sewn on both sides of the

stretcher. This will ensure that the Stretcher Bars hang correctly from the hanging loops.

9

Page 11

SET UP

Preparing the Scale for Use

1. Remove protective plastic film from keypad and display.

2. Place batteries in the battery holder (see “Replacing Batteries”).

3. Plug the scale’s AC adapter into the power source.

4. Press the ON/OFF button to turn the scale on. The display will show “Health o Meter

Pro-Plus” and then ”000

Lb00oz”.

the display will show a negative weight equivalent to the weight of the Stretcher.

5. Hang the stretcher on the Stretcher Hoops to register a 0 weight on the display. Press the

Tare key if necessary.

6. Place a weight [not exceeding 400 Lb (180 Kg)] on the stretcher. The display should read

the correct weight.

7. Press the KG/LB button to select the weight mode (Lb/Kg).

8. Press the Reweigh button; the scale should perform the weighing process again. The

display should read “WEIGHING” until the weight calculation is complete and the weight is

displayed.

9. Remove the weight from the stretcher, the scale will return to zero and the display will read

“ZERO” on the left upper side of the screen along with

10. Disconnect the scale’s AC adapter from the power source, and the scale will switch to

battery power.

(a)

If the Stretcher weight has previously been tared out,

(b)

*

”000Lb00oz”.

Note

: If the set up procedure failed, refer to the troubleshooting instructions. If the problem is

not corrected, refer to qualified service personnel.

(a)

To adjust the display backlight and/or contrast, please refer to page 19.

(b)

To change the display mode in pounds to fractions or decimals, please refer to page 14.

Replacing Batteries

Figure 6. Replacing Batteries

#

(refer to the Parts List on page 25 for details on parts followed by

)

1. Unplug the scale.

2. Remove the battery cover from the display assembly.

3. Disconnect battery holder cable connector from the scale-battery connector.

4. Carefully remove the battery holder by sliding it out of the display assembly.

5. Replace the batteries with new ones.**

6. Carefully slide the battery holder into the display assembly.

7. Plug the battery holder cable connector to the scale-battery connector.

8. Attach the battery cover to the display assembly and install the screw.

* To change the scale default units to kilograms, or to deactivate the LB/KG button,

please contact Technical Support at 1 800 638-3722 or +1 708 598-9100.

** We recommend the use of EVEREADY Energizer

®

e2TM batteries.

10

Page 12

OPERATION INSTRUCTIONS

Preweighing the Stretcher

1. Make sure the scale is free of load (nothing is hanging from it), including the stretcher.

2. Press the ON/OFF button to turn the scale on.

3. Wait until ”000

scale will remember the last amount that was tared, so if the weight of the stretcher

had previously been tared, the scale will display a negative weight when it is turned

on again.

Note

: The ‘ZERO’ sign will show on the upper left side of the display only when the scale is free

of load, including the stretcher.

4. If the weight of the stretcher is known, enter the TARE value according to instructions in

the “Menu”, para 02. If the stretcher’s weight is unknown, place the stretcher only on the

scale; press REWEIGH. Enter the Automatic TARE by pressing the TARE button. Display

will read ”000

Note

: Once the tare is set the “TARE” sign will appear in the upper right side of the display.

Placing Patient in Stretcher

1. After setting the stretcher’s weight as tare, take the stretcher off the lifter. The display will

now show a negative weight, equivalent to the weight of the stretcher.

2. Lay the stretcher on a bed or on any other stable surface you can use to lay the patient

you wish to weigh.

3. Carefully move the patient to a lying position on the stretcher.

Note: lay the patient’s center mass as close as you can to the center of the stretcher.

4. Wheel the lifter scale close to the stretcher and lower the boom with the hoops as far as 5-

10” (12 cm -25 cm) from the patient’s body.

5. Connect the four hanging loops of the stretcher to the four hooks at the end of each

Stretcher Hoop, making sure that the loops are hanging freely from the four hooks.

Note: Make sure both hooks connecting the load cell assembly beam lie on the lifter boom. If

only one of the hooks lies on the beam it can cause inaccurate readings of weight.

6. Tighten the hydraulic control valve knob by turning it clockwise. The control valve knob is

located on the Pump near the Pump handle.

7. Use the Base Adjustment Lever to widen the Lifter Base. The Base must be spread to the

widest possible position to maximize stability.

8. Pump the hydraulic Pump handle to lift the Stretcher and patient until the entire Stretcher

is hanging from the Stretcher Hoops and is not touching the bed or any other object. Do

not lock the Wheel on the Lifter Base. If needed, the Base will move slightly to adjust for

balance.

Caution: Never move patient away from bed or leave patient unattended.

Taking Weight Measurements

1. The scale will calculate the patient’s weight. Depending upon the movement of the

stretcher, the scale may take several seconds to lock into the weight. We recommend

reweighing after the patient is lying still on the stretcher by pressing the REWEIGH button.

2. After weight measurement is obtained and recorded, lower the Stretcher and the patient to

the bed. Open the hydraulic pump control valve knob by turning it counterclockwise very

slowly to control the descent.

3. Guide the patient and Stretcher down onto the bed.

Lb00oz” and “ZERO” on the left side of the display will appear. The

Lb00oz”.

11

Page 13

OPERATION INSTRUCTIONS

4. Release the hanging loops from the lifter.

Note

: The scale is programmed to save the last setting chosen as well as the weight of the

stretcher as tare weight. This enables weighing a number of patients without having to reset the scale.

If a weight was added or reduced from the stretcher scale it is required to reset the tare

weight.

Note

: To zero the scale by using the ZERO key, take the stretcher off the lifter before pressing

ZERO key. Replace the stretcher after zeroing.

5. Press ON/OFF key to turn scale off.

12

Page 14

OPERATION INSTRUCTIONS

Figure 7. Keypad

ITEM DESCRIPTION FUNCTION

POWER Turns scale ON and OFF.

ZERO Zeros the scale prior to weighing.

Holds the value of the weighed object on the display until

HOLD/RELEASE

REWEIGH

KG/LB button

MENU Enters the menu of the scale.

BMI

PRINT Prints patient’s data (if printer is connected to the scale).

ID

TARE

EXIT

the button is pressed again to clear the value. Also used to

scroll down in the menu.

Allows repeated weighing of the patient without stepping

off the scale.

Toggles between kilograms or pounds. Also used to scroll

up in the menu.

Prompts entry of data to calculate the patient’s Body Mass

Index (BMI).

Prompts entry of patient’s identification number (ID). This

ID will be stored with all the weighing made until is cleared

or a different ID is stored.

Prompts entry of TARE value that will be deducted from

the weight on the platform. Also releases tare weight

(returns display to zero).

Reverts back one step when in the menu and data entry

modes.

ENTER Used to enter commands and values into the scale.

13

Page 15

OPERATION INSTRUCTIONS

MENU

In the menu screen the user can set preferences and/or instruct the scale how to handle stored

data. The menu can be navigated using the up and down keys (cd) or by entering the

associated menu position number with the keypad. The menu has a “roll-over” way of working:

when the user scrolls to the bottom of the menu and presses the down button, it will return to the

top of the menu.

Figure 8. Main Menu

01 WEIGHT DISPLAY MODE

(only applies to pound values, NOT the metric values)

The user can set the screen display value in either fraction of pound (¼, ½ or ¾ lb), in pounds

and ounces (resolution of 4 ounces) or in decimals (resolution of 0.2 lb). When kg is selected as

the units of use, these settings have no effect. The mode that is selected is used through all the

screens.

Figure 9. Weight Display Mode

14

Page 16

OPERATION INSTRUCTIONS

02 TARE WEIGHT

NOTE: Due to the scale’s sensitivity, we recommend using the REWEIGH function prior to

setting the TARE weight, in order to eliminate any operator interference with the item to

be tared out.

There are two ways to manually enter a tare weight (such as the weight of a stretcher , shoes,

etc): press MENU (1) and select option 02-Tare Weight or press TARE (9). If there is no weight

on the scale platform (value displayed is zero and there is no tare) and the user presses the

TARE button (9), the Tare Weight window appears and prompts the user to enter the TARE

value and to press ENTER. NOTE: The tare weight must be entered using the following

increments: 4oz, 0.2lb, ¼lb. The value entered will display in minus (-). After the TARE has been

entered, the scale goes back to normal operation. This TARE value is stored in memory until

changed or cleared.

Important: The TARE weight cannot exceed 125 lb.

The number that is to be changed will

flash and will move from the left to the

right after the appropriate number was

entered or by using the c key (left)

and the d key (right).

TARE display

indicates the weight

that has been tared

out

Figure 10. Tare Weight

Automatic Tare

The user can set a tare weight by pressing the TARE button (9) while there is a weight on the

scale platform. The display will come to zero and TARE will be displayed to indicate there is a

tare value in the memory (as displayed in Figure 10 above).

Removing the Tare

Additional pressing of the TARE button will delete the tare value from memory, TARE will

disappear from the display and the scale will resume normal operation.

03 DATA MANAGEMENT

The scale manages patient data including patient ID, weight, height, tare and BMI. The value is

stored in memory or transferred to PC. This function is performed by opening a new data file.

OPENING A NEW DATA FILE:

1. Press the ID button (7).

2. Using the keypad, type in the identification number.

3. Press ENTER.

This scale will also calculate Body Mass Index (BMI).

CALCULATING BMI:

1. Place the patient on the scale platform.

2. Press the BMI button (2).

15

Page 17

OPERATION INSTRUCTIONS

3. The scale will prompt you to enter the patient’s height. Use the keypad to enter the height in

1/4" (1=1/4, 2=1/2, 3=3/4) or 1 cm increments (use inches for weight in lb, cm for kg). Press

ENTER.

4. Display will read the patient’s BMI.

The scale offers you two options to manage your information: to transfer/download the values or

to store them. The first option automatically downloads (transfers) the value to your PC. The

second option stores the value in memory. The maximum capacity of the scale is 270 files of

different data.

01 Auto Download

02 Store in memory

03 Do not store data

Automatic Download is the default option and will transfer the

value to the PC as soon as the patient steps off the scale or

when the user presses the HOLD/RELEASE button if it was

kept in “HOLD”. If no PC is connected, the value is not

transferred and not stored and will be lost after the load is

removed from the scale.

The value is stored in memory

for later download to PC.

If the memory is close to full

the user will be warned and

given the option to transfer all

values to the PC or to clear

the memory of all values.

All the data will be cleared.

16

Page 18

OPERATION INSTRUCTIONS

04 Transfer now

05 Clear memory

04 SCALE SETTINGS

All the values stored in memory are transferred to the PC and

the scale memory is cleared of all values. If the transfer was

unsuccessful, the values are kept in memory until

successfully transferred or cleared.

All the values stored in memory will be cleared.

01 Auto Hold Time

02 Sleep Time

The user can determine how long to display the weight

reading once it is determined, regardless of whether the

patient remains on the platform. The scale defaults to no Auto

Hold Time. The maximum setting is 20 seconds Hold Time.

The user can set the time elapsed before the scale goes into

the sleep mode. The default is 1 minute. When the scale

goes into sleep mode, STANDBY is displayed on the screen.

17

Page 19

OPERATION INSTRUCTIONS

03 Auto Off Time

04 Tone Volume

The user can determine how long the scale will operate

before turning off automatically due to inactivity. Default

time is 10 minutes. If the value is set to zero, the auto off

function is disabled.

There is an option to adjust the beeping tone of the scale.

This tone should sound when the scale has determined

the weight on the platform, when a key is pressed, after

the scale is turned on, at the end of self-test, or in the case

of fault or warning.

Use the c and d keys on the keypad to adjust the

volume.

Whenever the user presses the key to change a volume, a

beep will sound to indicate the set volume level.

05 Display Date and Time

This option will turn on or

turn off the date and time

display.

18

Page 20

OPERATION INSTRUCTIONS

06 Display Backlight

07 Display Contrast

08 Live Weight

The user can set the brightness of the backlight.

The user can set the brightness of the LCD.

By selecting “Yes” the user can set the Live Weight mode

to deactivate the motion-sensing mode. In the Live Weight

mode the weight displayed will fluctuate with the patient’s

movement; the scale will not lock on quickly to the weight

as is the case in the motion-sensing mode.

Press the REWEIGH button to operate the motion-sensing

mode and to determine the correct weight on the screen.

To revert back to motion-sensing mode, change the Live

Weight setting to “No”.

05 SYSTEM SETTINGS

01 Set Time & Date

The user can set the time and date using the keypad.

To set the time move between hours, minutes and

seconds using the up and down keys cd and enter the

values on the keypad. To jump to the AM/PM line press

the ENTER button once.

19

Page 21

OPERATION INSTRUCTIONS

Set the date using the up and down keys cd and enter the

values on the keypad.

02 About

06 SYSTEM TEST

This screen displays the software version of the scale.

01 Battery Test

02 USB Connection

The scale will display the estimated amount of battery life

remaining until the batteries will have to be replaced.

NOTE: In order to complete the battery test, the scale must be

powered by batteries only. Unplug the scale from AC power

source prior to battery test.

The scale will test the connection to the PC and will display a

message “Connection is OK” or ”NO Connection”.

If “NO Connection” is displayed, check your USB connections

on the scale and on your PC and retest the connection. Refer

to qualified service personnel if problem persists.

20

Page 22

OPERATION INSTRUCTIONS

03 UI Test

The scale has a diagnostic routine where it tests the User

Interface (UI) hardware functionality (LCD, keypad). In order to

do this the user has to press all the keys according to the

messages displayed on the screen.

07 USER SETTINGS

If the requested command was not received or wrong button

was pressed, the following message will be displayed.

If after 10 seconds the requested command was not received,

the following message will be displayed. If “UI Error Failure” is

displayed, refer to qualified service personnel.

01 Retain Entered Values

This option allows the user to use the same values for ID,

height and TARE between weighing. If this option is disabled,

the user has to re-enter these values for each reading. If the

values are not entered, only the weight is stored.

NOTE: These values cannot be retained by ID number.

21

Page 23

OPERATION INSTRUCTIONS

02 Disp Height & ID

When the user selects to

display the height and ID of the

user, it will be displayed at the

bottom of the screen. We

recommend the use of this

function to ensure that the

patient’s correct ID and height

have been entered.

03 Prompt For Height

04 Prompt For ID

When this option is activated,

the user will be asked to enter

the patient’s height after every

weighing.

When this option is activated,

the user will be asked to enter

the patient’s ID number after

every weighing.

22

Page 24

MAINTENANCE

GENERAL

This section provides instructions for maintenance, cleaning, troubleshooting and operator

replaceable parts for the ProPlus

than those described in this section should be performed by qualified service personnel.

®

Stretcher Scale Model 2000KL. Maintenance operations other

MAINTENANCE

Before first use and after periods of non-use, check the scale for proper operation and function.

If the scale does not operate correctly, refer to qualified service personnel.

1. Check overall appearance of the total scale for any obvious damage, wear and tear.

2. Inspect AC adapter for cord cracking or fraying or for broken or bent prongs.

CLEANING

Proper care and cleaning is essential to ensure a long life of accurate and effective operation.

Disconnect the scale from the AC power source.

1. Clean all external surfaces with a clean damp cloth or tissue. Mild soap and water solution

may be used. Dry with a clean soft cloth.

2. Do not immerse the scale into cleaning or other liquid solution.

3. Do not use Isopropyl Alcohol or other solutions to clean the display surface.

23

Page 25

TROUBLESHOOTING

Refer to the following instructions to check and correct any failure before contacting service

personnel.

SYMPTOM POSSIBLE CAUSE CORRECTIVE ACTION

Scale does not turn on 1. Dead Battery

2. Faulty electrical outlet

3. Bad power supply

Questionable weight or

the scale does not zero

1. External object

interfering with the scale

2. The weight of the

stretcher as tare was not

set correctly

1. Replace batteries

2. Use a different outlet

3. Replace adapter

1. Remove interfering object

from the scale

2. Take the patient and the

stretcher off the scale,

zero the scale, hang the

stretcher on the scale and

enter the tare weight.

After the tare weight is set

start weighing action.

3. The patient’s center

mass is not at the center

of the stretcher and one

of the hanging hooks of

the lifter boom does not

3. Take the patient off the

stretcher and re-position

so that the center mass

will lie between the two

hoops.

lie on the lifter beam.

4. Scale is out of calibration 4. Check weight with known

weight value

Weighing is performed but

the display shows “weigh”

and “reweigh” every few

The patient is not still Ask the patient to be still or

change the scale to use the

live weight setting (p.19).

seconds; the weighing

process takes too long and

no weight is displayed.

The display shows

“Overload” message

The display shows

“LOW BAT” message

The display shows

“Load Cell Error” message

The load on the scale

exceeds the capacity

(400 Lbs)

Remove the excess weight

and use the scale according to

its limits

The batteries are empty Replace batteries according to

instructions

There is a problem with one

or more load cells or the load

cell cable is disconnected.

Check load cell cable

connection at the display and

platform assembly ports. If the

problem is not corrected, refer

to qualified service personnel

to replace the defective load

cell

24

Page 26

CALIBRATION PATH

The calibration is performed in Kg or Lb, according to the units of measure used upon entering

into the calibration path.

Operator Action Display

1. Press ON/OFF button and immediately press

and hold HOLD/RELEASE button for 3-4

seconds

2. Press ENTER Enter load weight

3. Using cd keys and/or the keypad, set the

calibration load to at least 200 lbs (for best

results and greater accuracy, use a 400 lb

weight). Press ENTER

4. Please clear the stretcher and press ENTER Zero calibration

5. Please wait without touching or shaking the

scale until the zero calibration process is

finished

6. Load the stretcher with the required weight and

press ENTER

7. Please wait without touching or shaking the

scale until the calibration process is finished

8. Press ENTER Calibration

9. Please remove weight from the stretcher Rebooting

10. Please wait until the scale resumes normal

operation

Calibration

Process

400.0

Zero calibration

Please clear the scale

Please wait

Weight calibration

Put: XXX.X

Weight calibration

Please wait

Calibration

factor: X.XXXXX

Please clear the scale

Please wait

Health O Meter

Pro Plus

37

EXPLODED VIEW OF SCALE

38

39

40 41

42

43 44

52

25

45 46

51

47

48

50

49

Page 27

EXPLODED VIEW OF SCALE (continue)

26

Page 28

PARTS LIST

Key No. Part No. Description Qty.

1 1109403-0 DISPLAY ASSEMBLY 1

2 2268101-0 TILT MECH. ASSEMBLY 1

3 3848401-0 PLASTIC WASHER 2

4 401369 PLASTIC OVAL BAR COVER 3

5 HEX. HEAD SCREW NC 3/8-16*2 1/2 1

6 HEX. HEAD SCREW NC 3/8-16*1 3/4 1

7 2268001-0 LIFTER BOOM ASSEMBLY 1

8 2034701-0 MAIN BOARD TO CON. DIG CABLE 1

9 3809801-0 BEAM ASSEMBLY 1

10 PHIL.PAN HEAD SCREW NC6-32*1/4” 2

11 2138903-0 CON. DIG BOARD 1

12 SPACER WITH EX.THREAD STUD NC6*1/4” 2

13 SOCKET BUTTON HEAD CAP SCREW NC1/4-20*3/4” 2

14 SAFETY WASHER NC3/8” 2

15 401304 HEX. SOCKET HEAD SCREW NC3/8-16*1 1/2 2

16 3808401-0 STRETCHER HOOP 2

17 401338 STRETCHER 1

18 3835701-0 STRETCHER STORAGE TRAY 1

19 3833801-0 BAR ADAPTER 2

20 3808501-0 STRETCHER BAR 4

21 3816901-0 FORK JOINT 2

22 HEX. SOCKET HEAD SHOULDER SCREW (5/16) 3/8-1” 4

23 3816801-0 LOAD CELL ADAPTER 2

24 3828301-0 LOAD CELL CONNECTING BEAM 1

25 1304202-0 LOAD CELL 2

26 HEX. SOCKET HEAD CAP SCREW NC5/16-18*3/4” 4

27 NUT NC3/8” 2

28 401337 PLASTIC RHS50*50 COVER 2

29 400579 CABLE HOLDER P.G.-7 1

30 400066 SELF LOCK NUT NC3/8” 2

31 PHIL. PAN HEAD SCREW NC8*3/8” 6

32 3822701-0 CABLE COVER 1

33 400412 SELF LOCK NUT NC6 2

34 PHIL. PAN HEAD SCREW NC6-32*3/8” 2

35 3817001-0 ADATPER HOLDER 1

36 420988 ADAPTER 6VDC 120VAC 1

37 411220 KEYPAD 400LB 1

38 INDICATOR COVER 1

39 LCD WINDOW 1

40 LCD BOARD 1

41 WN1412 CROSS HEAD SCREW K22L6 4

42 DISPLAY TO EAGLE P.C.B CABLE 1

43 WN1412 CROSS HEAD SCREW K30L6 4

44 EAGLE BOARD 1

45 INDICATOR BASE 1

46 PHIL. PAN HEAD SCREW NC6-32*3/8” 6

47 MODEL LABEL 1

48 3245801-0 INPUT/OUTPUT PORTS LABEL 1

49 PHIL. PAN HEAD SCREW NC4-40*1/4” 1

50 3822801-0 BATTERY COVER 1

51 400152 RUBBER O RING 1

52 2033801-0 BATTERY HOLDER 1

--- 63855 PATIENT LIFT 1

27

Page 29

WARRANTY

LIMITED WARRANTY

What does the Warranty Cover?

Pelstar LLC scales are warranted from date of purchase against defects of materials or in

workmanship for a period of three (3) years. If product fails to function properly, return the

product, freight prepaid and properly packed to Pelstar. See “To Get Warranty Service” below for

instructions. If manufacturer determines that a defect of material or in workmanship exists,

customers' sole remedy will be repair or replacement of scale at no charge. Replacement will be

made with a new or remanufactured product or component. If the product is no longer available,

replacement may be made with a similar product of equal or greater value. All parts including

repaired and replaced parts are covered only for the original warranty period.

Who is Covered?

The original purchaser of the product must have proof of purchase to receive warranty service.

Pelstar dealers or retail stores selling Pelstar products do not have the right to alter, or modify or

any way change the terms and conditions of this warranty.

What is Excluded?

Your warranty does not cover normal wear of parts or damage resulting from any of the

following: negligent use or misuse of the product, use on improper voltage or current, use

contrary to the operating instruction, abuse including tampering, damage in transit, or

unauthorized repair or alternations. Further, the warranty does not cover Acts of God, such as

fire, flood, hurricanes and tornadoes. This warranty gives you specific legal rights, and you may

also have other rights that vary from country to country, state to state, province to province or

jurisdiction to jurisdiction.

To get Warranty Service

Make sure you keep your sales receipt or document showing proof of purchase.

Call 1 (800) 638-3722 or 1 (708) 598-9100 to receive a return authorization number. Attach

proof of purchase to your defective product along with your name, address, daytime telephone

number and description of the problem. Carefully package the product and send with shipping

and insurance prepaid to:

Pelstar LLC

Attention R/A#_____________

Repair Department

7400 W. 100th Place

Bridgeview, IL 60455

If your scale is not covered by warranty, or has been damaged, an estimate of repair costs or

replacement costs will be provided to you for approval prior to servicing or replacing.

Pelstar LLC

7400 West 100th Place, Bridgeview IL 60455 • 1-800-638-3722 or 1-708-598-9100

www.healthometermedical.com

Health o meter ProPlus® products are manufactured, designed and owned by Pelstar LLC.

Health o meter® is a registered trademark of Sunbeam Products Inc., Boca Raton, FL 33431.

ProPlus® is a trademark of Pelstar LLC

Patents Pending

28

Loading...

Loading...