SHELBOURNE

Grain Header Manual

09032101g

HEADSIGHT.COM | 574.546.5022

About Headsight

Headsight Contact Info

Headsight, Inc.

4845 3B Road

Bremen, IN 46506

Phone: 574-546-5022

Fax: 574-546-5760

Email: info@headsight.com

Web: www.headsight.com

Technical Assistance

Phone: 574-220-5511

About this Manual

How to use this manual

The instructions in this manual are in the order that they should be completed for new installations.

Complete all applicable instructions in each section before proceeding. Note that some sections are

labeled to indicate they only apply to certain machines or applications. An index is available in the front

of the manual to help nd technical information for previously installed systems.

This icon designates information of which

you should take note.

This icon designates an important

instruction.

This icon indicates a special tool needed

for a given task.

Disclaimers

Headsight®, Horizon®, Pinpoint®, Insight®, Foresight®, Feathersight® Truesense™ and Truesight® are

trademarks of Headsight, Inc. All other trademarks are property of their respective owners.

Suggestions

If you have any suggestions to improve this manual please call 574-546-5022 or email info@headsight.

com.

Headsight’s products are protected by one or more of the following US Patents 6202395,

6833299, 7310931, 7647753, 9609806 and other patents pending.

Copyright Headsight, Inc. 2018

i

Table of Contents

About Headsight ��������������������������������������������������������������������������������������������� i

About this Manual ������������������������������������������������������������������������������������������� i

Installation �������������������������������������������������������������������������������������������������� 1

Install Terrace Sensors (if equipped) ����������������������������������������������������������������� 2

Terrace Sensor Overview ������������������������������������������������������������������������������ 2

Mounting Sensors to Terrace Tube Brackets ������������������������������������������������������� 3

All models except XCS/XCV �������������������������������������������������������������������������� 4

All XCS/XCV models ������������������������������������������������������������������������������������ 6

Install Standard Mount Sensor (if equipped) �������������������������������������������������������� 8

Mounting Sensors to Undermount Brackets ������������������������������������������������������� 8

All models except XCS/XCV ���������������������������������������������������������������������������� 9

All XCS/XCV models �����������������������������������������������������������������������������������10

Route Wiring ���������������������������������������������������������������������������������������������12

Harness Length Table ���������������������������������������������������������������������������������12

Weatherpack Removal ��������������������������������������������������������������������������������12

Install 6ft Terrace Sensor Harnesses in Terrace Tubes (if equipped) �������������������������13

Route Left Terrace Sensor Harness to Feederhouse ���������������������������������������������15

Install Under Mount Wiring (if equipped) ���������������������������������������������������������16

Install Controller ��������������������������������������������������������������������������������������18

Sensor Adjustment ����������������������������������������������������������������������������������������19

Terrace Sensor �������������������������������������������������������������������������������������������19

Increasing or Decreasing Voltage �������������������������������������������������������������������19

Adjusting Voltage Swing ������������������������������������������������������������������������������19

Adjusting Down Pressure ����������������������������������������������������������������������������19

Parts ���������������������������������������������������������������������������������������������������������20

STATEMENT OF LIMITED WARRANTY �����������������������������������������������������������������21

ii

Installation

Before working under header always:

1. Perform all combine and header manufacturer safety

precautions for servicing header.

2. Insert stop to prevent movement of header.

3. Turn off combine and remove key from ignition.

4. Set combine parking brake.

5. Disconnect all drive shafts from the header.

Installation

1

Installation

Complete the installation portion of this header manual before continuing.

Install Terrace Sensors (if equipped)

Terrace Sensor Overview

1. Correct header setup is essential for proper operation

and protection of Terrace sensors.

• As recommended in Shelbourne’s operator’s manual,

the bottom plane of the end panel must be level or

tipped slightly upward when the header is near the

ground (at the lowest intended operation position).

2. Terrace sensor tube brackets supplied by Headsight

after 2017 have a height adjustment.

• For most crop conditions, assemble the terrace tube

bracket straight as shown - for maximum cut height

• For very short crop (or when trying to pick up down

crop) it may be necessary to position the terrace tube

bracket in its raised setting - to protect the sensor by

providing adequate clearance between the sensor

and the ground.

2

3. Pre-assemble the tubes for the desired height setting

(straight or raised) before proceeding with the installation.

• Use hardware provided in kit B660

Any time terrace tube position is adjusted, be cautious not to crush the wire routed in the tube.

The Headsight controller and combine will need to be recalibrated. Calibrate header controller

then combine any time terrace tube is adjusted.

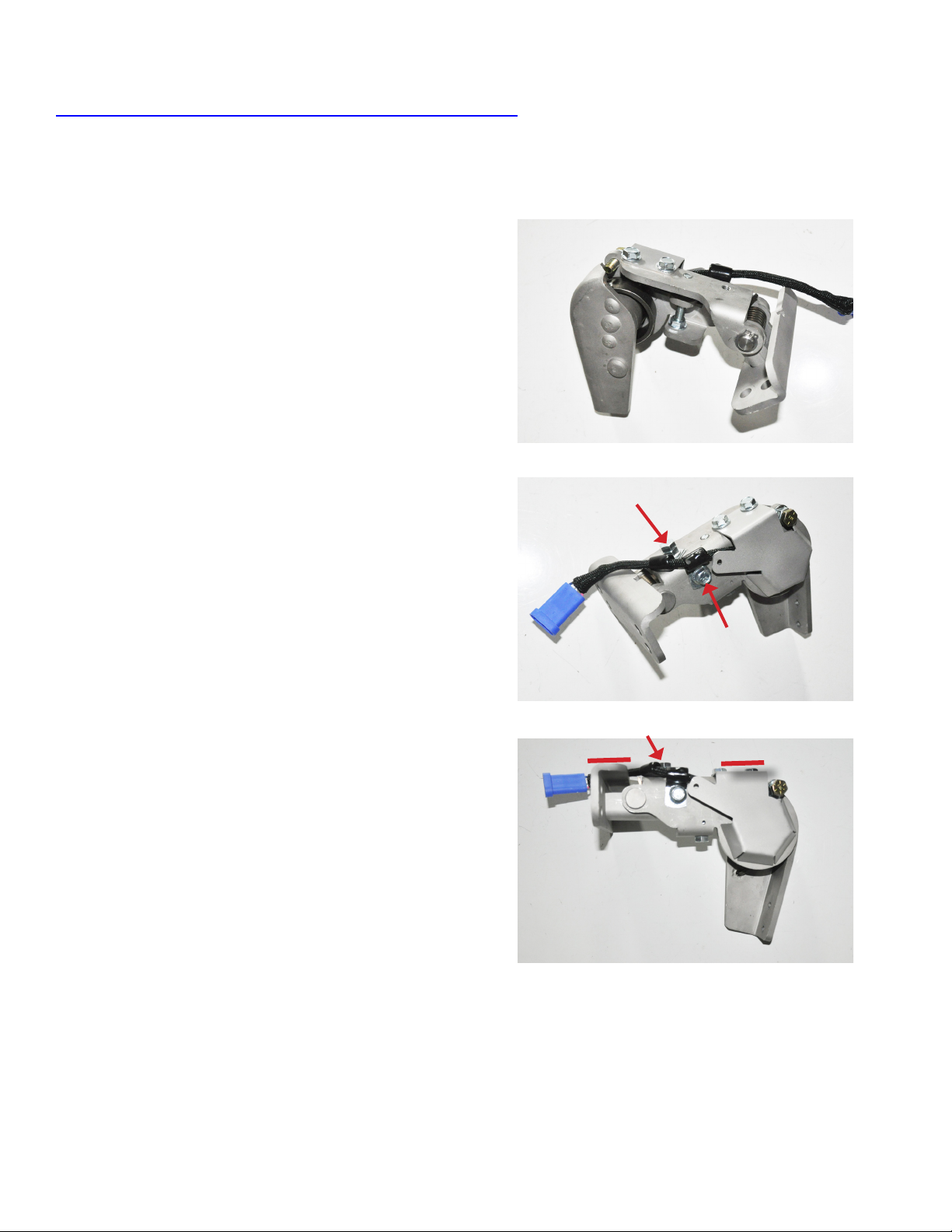

Mounting Sensors to Terrace Tube Brackets

1. Align holes in sensor and mounting bracket with spring.

• Spring must be installed short leg up and long leg

back in mounting tube

• Use hardware provided in kit B7000

Installation

2. Insert pin and secure with retaining ring.

3. Install clamp, leveling bolt (A), and jam nut.

• Place wire clamp over wire tail

• Install jam nut onto bolt

• Insert bolt through wire clamp and thread into sensor

• This bolt will be adjusted to level sensor after the tube

has been mounted on the head

4. Tighten bolt (B) holding clamp on side of sensor.

A

B

3

Installation

All models except XCS/XCV

1. Install parking stands.

2. Remove existing two bolts and discard bolts.

3. Install mounting tube to left end of head with hardware

provided in kit BWT2S.

• Enlarge front bolt hole if necessary

• A washer may be needed between bracket and frame

on front bolt for alignment

• Stand in front of header and make sure tube is

parallel with end panel

4. Repeat steps 2 & 3 for right end of head.

• Tube should align correctly without a washer

4

5. Install crop shields to left end of head with hardware

provided in kit B660.

• Bolt crop shield to tube

• Fasten top of crop shield to blue rod using bolt, nut,

and clamp

6. Mount long poly arms to terrace sensors with hardware

provided in kit BWS2.

7. Adjust the terrace sensor with Bolt (A) so sensor is

parallel to rear section of tube (indicated by red lines).

Cables and clamps shipped in BWS hardware kits are not used on Shelbourne headers.

8. Repeat steps 5-7 for right end of head.

A

Installation

9. If terrace tubes are installed in their raised position,

install crop shields as shown.

10. Adjust the terrace sensor with bolt (A) so the sensor

is parallel to the rear section of the tube (indicated by red

lines).

A

5

Installation

All XCS/XCV models

1. Remove large end shield marked A.

2. Remove bolts marked and discard.

A

3. Install mounting tube to left end of head with hardware

provided in kit BWT2S.

• Install rear bolt (A) into hole using a washer to shim

between tube bracket and header frame - nger

tighten nut

• Stand in front of header and make sure tube is

parallel with end panel

• Drill additional hole in location (B) and secure with

bolt and nut provided – nger tighten nut

• Bracket will need to be removed later to drill holes for

wire routing

4. Install mounting tube to right end of head with hardware

provided in kit BWT2S.

• Remove factory bolt form location A and discard

• Mount bracket/sensor assembly with bolt in position

(A)

• Stand in front of header and make sure tube is

parallel with end panel

• Drill additional holes in locations (B) and secure with

bolts and nuts provided

• Use washers on center bolt to ll gap between tube

bracket and header frame

A

B

A

B

6

5. Install crop shield to right end of head with hardware

provided in kit B660.

• Bolt crop shield to tube

• Fasten top of shield to blue rod using bolt, nut, and

clamp provided

6. Mount long poly arms to Terrace sensors with hardware

provided in kit BWS2.

7. Adjust terrace sensor with bolt (A) so the sensor is

parallel to the tube (indicated by red lines).

Installation

A

8. If terrace tubes are installed in their raised position,

install right crop shield as shown.

9. Adjust the terrace sensor with bolt (A) so the sensor

is parallel to the rear section of the tube (indicated by red

lines).

Cables and clamps shipped in BWS hardware kits are not used on Shelbourne headers.

Terrace tubes lowered position

10. Install crop shield to left end of head with hardware

provided in kit B660.

• Bolt crop shield to tube

• Drill a hole through blue panel in location marked and

fasten with bolt nut, and spacer washers

A

Terrace tube raised position

11. If terrace tubes are installed in their raised position,

install right crop shield as shown and bolt through slot

indicated.

12. Adjust the terrace sensor so the sensor is parallel to the

rear section of the tube bracket.

7

Installation

Install Standard Mount Sensor (if equipped)

Mounting Sensors to Undermount Brackets

1. Align holes in sensor and mounting bracket.

• Spring must be installed short leg up and long leg

back in mounting tube

• Use hardware provided in kit B7000

2. Insert pin and secure with retaining ring.

3. Install leveling bolt (A) and jam nut.

• Place a wire clamp over the wire tail

• Install jam nut onto bolt

• Insert bolt through wire clamp and thread into sensor

4. Tighten bolt (B) holding clamp on side of sensor.

5. Adjust sensor with bolt (A) so it is parallel to ange on

the bracket (indicated by red lines).

A

B

A

8

All models except XCS/XCV

1. Determine sensor mounting locations.

• Mount outer sensors rst, mounting out as far as

possible (if not equipped with terrace option)

• Mount all inner sensors as evenly spaced as possible

across head

• If equipped with terrace sensors, equally space all

standard mount sensors between them

2. Hold bracket with bolts installed and mark holes.

3. Drill the marked holes through bottom and top of beam

with 13/32” drill bit.

4. Mount bracket to frame using hardware provided in kit

B7154.

Installation

5. Install sensor to bracket with two ange nuts provided.

6. Install long wands to outer most sensors (which may be

terrace sensors) and short wands to all inner sensors.

• Use hardware provided in kit BWS1 or BWS2

Cables and clamps shipped in BWS hardware kits

are not used on Shelbourne headers.

9

Installation

All XCS/XCV models

1. Determine sensor mounting locations.

• Mount outer sensors rst, mounting out as far as

possible (if not equipped with terrace option)

• Mount all inner sensors as evenly spaced as possible

across the head

• If equipped with terrace sensors equally space all

standard mount sensors between them

• Sensors mount to curved supports as shown (right or

left side where there is space)

2. Attach previously assembled sensor to mounting

bracket with hardware provided in kit B7154.

• Depending on mounting location, you may need

bracket mounted as a right or a left as shown in

pictures

3. Clamp sensor/bracket assembly to desired gusset. Pull

up on sensor body to fully extent trip back.

• Adjust the placement until you have achieved the

dimensions indicated in the picture.

4. Drill through lower two holes in bracket with a 7/16” drill

bit.

5. Fasten bracket to head with 2 bolts, and nuts provided

in bolt kit B7154

10

1/2” Clearance

6. Install long wands to outer most sensors (which may be

terrace sensors) and short wands to all inner sensors.

• Use hardware provided in kit BWS1 or BWS2

Cables and clamps shipped in BWS hardware kits are not used on Shelbourne headers.

Installation

11

Installation

Route Wiring

1. Select appropriate wiring from chart below and mark blue connector with sensor position.

Properly routing the wiring is the most critical part of the installation process. Please take time

to ensure that you have allowed sufcient slack for motion as well as sufcient clearance from

moving header parts or crop ow.

Terrace sensors use a 6 ft extension harness to route from the sensor back to the end panel

and an addition extension harness to route to the feederhouse. All undermount sensors use

only one extension harness.

Harness Length Table

Header Width Left Left Center Center Right Center Right

0’ up to 33’ 17’

(+6’ for Terrace)

34’ and up 23’

(+6’ for Terrace)

*Use Left, Left Center, Center, Right Center and Right for 5 sensor system

*Use Left, Left Center, Right Center and Right for 4 sensor system

*Use Left, Center and Right for 3 sensor system

*Use Left and Right for 2 sensor system

10’ 17’ 23’ 33’

23’ 17’ 33’ 38’

(+6’ for Terrace)

(+6’ for Terrace)

Weatherpack Removal

1. Removing black Weatherpack connector from extension

harness is sometimes necessary to route through a small

hole.

2. Release wire retaining clip and insert removal tool

(supplied in hardware kit BWS2) over each pin and then pull

the wire out of the connector.

3. After routing the wire, are connector terminals using

removal tool. Reinstall wires into connector body with Black

into A, White, into B, and Green into C.

4. Latch wire retaining clip.

12

Install 6ft Terrace Sensor Harnesses in Terrace Tubes (if equipped)

1. If working on an XCV/XCS header, start with left end of

head. For all other header models skip to step 11.

2. Mark location directly above wire hole in terrace tube

bracket on end divider shield (A).

3. Remove tube bracket and drill a ½ inch hole for wire.

• Deburr edges of hole to protect wire.

4. Drill a 1-1/4 inch hole in the back of the end divider

shield using hole saw provided in kit BSHEL.

5. Remove Weatherpack end from 6ft extension harness.

6. Feed harness through end divider shield.

Installation

A

7. Feed harness through terrace tube up to sensor.

• It may be necessary to remove a bolt in tube bracket

to feed wire through

8. Remount terrace tube and tighten all hardware.

9. Reinstall Weatherpack connector and connect harness

to sensor and zip tie around connector.

10. Work excess wire back into end divider being careful not

to damage the wire insulation.

11. Follow steps 12-14 for right end of XCV/XCS heads and

both ends or all other heads.

12. Insert female end of harness in tube and push through

toward sensor.

• It may be necessary to remove a bolt in tube bracket

to feed wire through

13

Installation

13. Connect harness to sensor, zip tie connector and pull

back into tube.

Route Right Terrace Sensor Harness to Feederhouse

1. Fasten short extension harness with clamps as pictured.

2. Continue routing toward upper tube following existing

wiring and hydraulic hoses.

• Avoiding pinch point, moving parts and all hazards.

3. Connect correct length extension harness and route into

upper tube.

14

4. Drill 1/4” pilot hole in upper tube left of feederhouse

opening. Use 1-1/4 inch hole saw provided in kit BSHEL to

drill out pilot hole.

5. Using a wire sh, pull harness to hole and install

grommet.

Route Left Terrace Sensor Harness to Feederhouse

1. Continue routing short extension harness toward the

lower tube in the back of the end panel.

• Secure with wire clamps away from moving parts

Installation

2. Connect correct length extension harness and route

through lower tube.

3. Drill 1/4” pilot hole in lower tube left of feederhouse

opening. Use 1-1/4 inch hole saw provided in kit BSHEL

to drill out pilot hole. Using a wire sh, pull harness to hole

and install grommet.

15

Installation

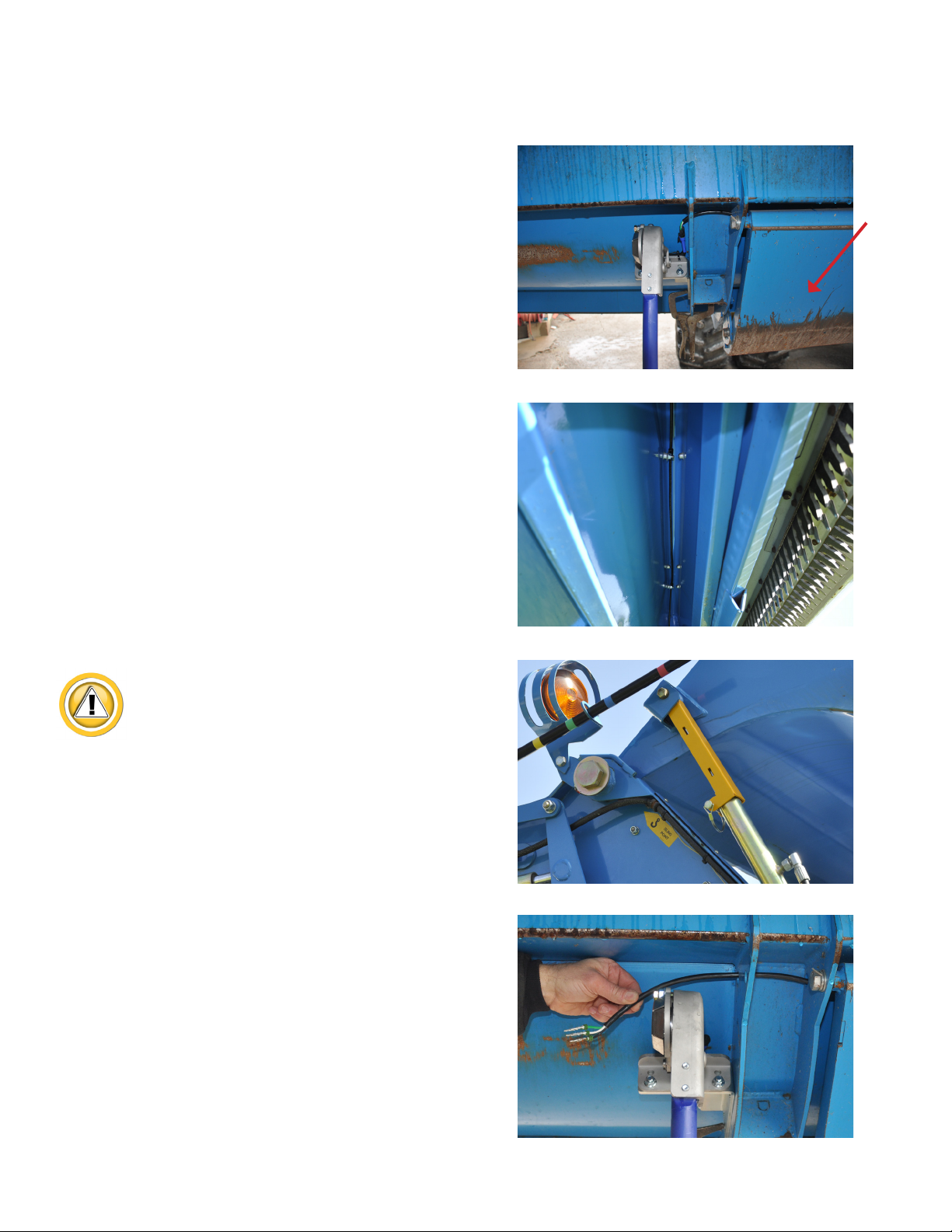

Install Under Mount Wiring (if equipped)

1. Wires must be routed behind the front beam to the

nearest skid (A) before routing back under the header pan

to protect them from crop stubble.

2. Remove the rear bolts from the skid (A) and allow the

back of the skid to hang down to provide access to drill

holes and route wire.

3. It the sensor is not mounted next to a skid, route

harness toward the skid keeping it protected behind the

front beam as shown.

A

If replacing bolts, use jack to raise cover and be

sure to install cylinder stop..

4. Select correct length extension harness.

5. For XCV/XCS heads only, remove Weatherpack

connector and route wire through hole in gusset as shown.

16

6. For older heads route wire above the gusset as shown.

7. Drill 1/4” pilot hole near top of lower tube behind center

of skid. Use 1-1/4 inch hole saw provided in kit BSHEL to

drill out pilot hole. (note: skid shoe has been removed)

8. Route wire into tube and install grommet.

9. For most heads, all harnesses can be routed in lower

tubes to left side of feederhouse.

10. Drill 1/4” pilot hole in lower tube left of feederhouse

opening. Use 1-1/4 inch hole saw provided in kit BSHEL

to drill out pilot hole. Using a wire sh, pull harness to hole

and install grommet.

Installation

11. On XCV/XCS models, the lower tube is not open under

the feederbouse.

12. Drill 1-1/4 inch holes at locations A, B, & C and route

wires across the feederhouse in upper tube as indicated.

13. Use a sh tape to pull wires through tube and install

grommets in holes.

14. Zip tie and clamp harness where needed.

A B

C

17

Installation

Install Controller

1. Mount controller bracket to header with hardware

provided in kit B3113.

• Mount controller to bracket

2. Fasten main harness to bracket as shown with zip ties.

• For the rest of the installation instructions see the

supplied Horizon manual for system with Horizon

controller and all others see the supplied combine

manual

18

Sensor Adjustment

Terrace Sensor

Increasing or Decreasing Voltage

1. Loosen the screws indicated A.

2. Turn sensor to new location.

3. Tighten screws A.

Adjusting Voltage Swing

1. Loosen jam nut B.

2. Turn Bolt to adjust.

3. Rotating bolt counter clockwise increases voltage swing

4. Rotating bolt clockwise decreases voltage swing

5. Tighten jam nut B.

Adjusting Down Pressure

1. Loosen jam nut A.

2. Turn bolt to adjust tension.

3. Rotating bolt counter clockwise decreases down

pressure.

4. Rotating bolt clockwise increases down pressure.

5. Tighten jam nut A.

A

A

B

Sensor Adjustment

A

19

Parts

12

3

4

5

6

78

12

3

4

5

6

78

A

26* B7000 BOLT KIT, INCLUDES ITEMS WITH AN ASTERISK*

27 HT7000 COMPLETE SENSOR ASSEMBLY STANDARD

28 HT7001 COMPLETE SENSOR ASSEMBLY FOR SHELBOURNE UNDERMOUNTS

(ASSEMBLY EXCLUDES ITEMS 1, 20, 24, 25, & 26*)

(ASSEMBLY EXCLUDES ITEMS 19, 20, 24, 25, & 26*)

24 HT701-BU LONG WAND, BLUE NYLON 1

25 PFBxx HARNESS (xx - LENGTH IN FT)

LENGTHS: 6, 10, 17, 23, 33, & 38

B

17 08100136 O-RING, SIZE-014 1

18 HT7111 SENSOR ARM 1

19 HT631 CROP DIVIDE TIP 1

20 08200187 M8-1.25x30 SERRATED FLANGE BOLT 2

21 08200249 M8-1.25x55 HEX BOLT 1

22 HT7106 SPRING ADJUSTING CLIP 1

23 08200258 M10-1.5 HEX NUT 1

C

11 HT2128 SENSOR 1

12 08100144 O-RING, SIZE-210 1

13 HT7101 SENSOR BODY 1

14 08100141 BUSHING 1

15 HT7109 BEARING BLOCK 1

16 HT7104 SPRING 1

1

D

10 08200248 M5-0.80x20, SHCS 4

7 HT7105 TRIP BACK SPRING 1

8 HT7116 PIN 1

9 08200247 M10-1.5x30, HEX BOLT 1

3 08100102 5/16 CABLE CLAMP, 3/8 HOLE 2

4 08100132 RETAINING RING 2

5 08200119 M8-1.25, SERRATED FLANGE NUT 2

6 08200246 M8-1.25x45 HEX BOLT 1

E

ITEM NUMBER PART NUMBER DESCRIPTION QUANTITY

1 HT7117 SHIELD 1

2 08200245 M8-1.25x12, SERRATED FLANGE BOLT 3

F

25

G

H

1

NOTE: SENSOR CALIBRATION

TARGET HIGH VOLTAGE = 4.30V (ACCEPTABLE RANGE 4.20V - 4.35V)

TARGET LOW VOLTAGE = 0.70V (ACCEPTABLE RANGE 0.65V - 0.95V)

9

10

21

22

5

23

11

12

24

20

13

4

19

THE INFORMATION CONTAINED ON THIS DRAWING IS PROPRIETARY TO

HEADSIGHT, INC. ANY UNAUTHORIZED USE OF SUCH CONTENTS IS

STRICTLY PROHIBITED.

HT7000_PARTS

TERRACE SENSOR PARTS

HEADSIGHT INC.

Parts

CHG LEVEL

02

C

A

MATERIAL N/A

UNLESS OTHERWISE SPECIFIED

DIMENSIONS ARE IN INCHES

DIMENSIONS W/O TOL ARE BASIC

THIRD ANGLE

PROJECTION

SHEET OF

DATE

AUG 8, 17

1

1

B

C

D

E

14

15

17

F

2

3

4*

3*

6*

5*

7*

8*

16

HT7000_PARTS

18

G

H

20

STATEMENT OF LIMITED WARRANTY

For Headsight® Products

Headsight Inc. (Headsight) warrants its new products to be free from defects in material and workmanship for a period of twelve

(12) consecutive months following the date of purchase by the retail purchaser.

Headsight Inc. (Headsight) warrants its new corn sensors assemblies for a period of thirty-six (36) months.

Headsight warrants genuine Headsight replacement parts and components to be free from defects in material and workmanship

for a period of six (6) consecutive months following the date of purchase or the remainder of the original equipment warranty

period, whichever is longer.

Headsight’s obligation under these warranties shall be limited to repairing or replacing, free of charge to the original purchaser,

any part that, in Headsight’s judgment, shows evidence of such defect.

Limitations to Warranty

This warranty does not cover:

• Warranty claims directly resulting from improper installation of the product.

• Any product damaged by accident, abuse, misuse, or negligence after shipment from Headsight.

• Any unauthorized product alteration or modication.

• Any unauthorized repairs made with parts other than genuine Headsight parts.

• Any repairs performed by anyone other than Headsight or an authorized Headsight dealer unless specically authorized

by Headsight.

Warranty Procedure

• Troubleshooting should be done between farmer/dealer and Headsight through our technical assistance @

574.220.5511.

• Labor reimbursement will occur only pre-arranged through Headsight technical assistance and be scheduled to a at rate

basis or reasonable time allowance in Headsight’s judgment.

• There is no mileage reimbursement.

• Diagnostic time will not be reimbursed except in pre-arranged circumstances.

• Warranty claims should be on typical dealer service work order with a number and name to be attached for any future

correspondence.

• All warranty work must be performed, and claims submitted, within thirty (30) days of the occurrence of the claim and

within the warranty period.

• All parts removed during warranty repair must be returned to Headsight with Headsight’s Return Form within thirty (30)

days of the occurrence of the claim and within the warranty period.

• Headsight, Inc. reserves the right to either inspect the product at the original retail purchaser’s location or require it to be

returned to Headsight, Inc. for inspection.

Limitation of Liability

Headsight makes no express warranties other than those, which are specically described herein. Any description of the goods

sold hereunder, including any reference to buyer’s specications and any descriptions in circulars and other written material

published by Headsight is for the sole purpose of identifying such goods and shall not create an express warranty that the goods

shall conform to such description.

THIS WARRANTY IS EXPRESSLY IN LIEU OF ALL OTHER WARRANTIES EXPRESSED OR IMPLIED. There are no implied

warranties of merchantability or tness of a particular purpose. This warranty states Headsight’s entire and exclusive liability and

buyer’s exclusive remedy or any claim for damages in connection with the sale of furnishing of Headsight products, their design,

suitability for use, installation or operation, or for any claimed defects herein. HEADSIGHT WILL IN NO EVENT BE LIABLE

FOR ANY INCIDENTAL OR CONSEQUENTIAL DAMAGES WHATSOEVER, NOR FOR ANY SUM IN EXCESS OF THE PRICE

RECEIVED FOR THE GOODS FOR WHICH LIABILITY IS CLAIMED.

No representative of Headsight nor any dealer associated with Headsight has the authority to change the items of this warranty

in any manner whatsoever, and no assistance to purchaser by Headsight in the repair of operation of any Headsight product

shall constitute a waiver of the conditions of this warranty, nor shall such assistance extend or revive it.

Headsight reserves the right to make improvements in design or changes in specications at any time, without incurring any

obligation to owners of units previously sold. Warranty: 1/2017

21

P 574.546.5022 • F 574.546.5760

4845 3B Rd • Bremen, IN 46506

info@headsight.com

www.headsight.com

Loading...

Loading...