HDT Camfire MV60-EU, Camfire MV60S-EU, Camfire MV60T-EU Operation And Maintenance Manual

`

HDT –Tactical Systems Business Unit

30525 Aurora Rd

Solon, Ohio 44139-2795

Tech Support: (800) 684-6111

www.hdtglobal.com

MV60-EU Series Heaters, 220 VAC, 50-60 Hz

SHELTER HEATER

60,000 BTU Multi-fuel Shelter Heater

Operation and Maintenance Manual

MANUAL PART NUMBER: 53858

REVISION 3 – 26APRIL2011

THIS PAGE INTENTIONALLY LEFT BLANK

Operation and Maintenance Manual

Warning Summary

IMPORTANT

Be sure to read and understand this operation and maintenance manual before starting or servicing this

heater.

WARNING!

FIRE, EXPLOSION, CARBON MONOXIDE POISONING

Improper use of this heater can result in serious bodily injury due to hazards of fire and explosion, carbon

monoxide poisoning, burn and electrical shock. Do not adjust the pump pressure higher then the

recommended amount. Failure to do so can result in higher then normal heat exchanger temperatures,

which can cause the heat exchanger to fail allowing dangerous Carbon Monoxide gas to enter the shelter.

Failure to follow these instructions could cause serious injury or death.

WARNING!

FIRE, EXPLOSION

Use only Kerosene, Diesel or Number 1 Fuel Oil, or JP8 can be used for extreme cold conditions. Never

burn gasoline, naphtha, paint thinners, alcohol or other volatile fuels. Fill fuel tank or move heater only

when heater is shut off.

WARNING!

FIRE, EXPLOSION

Use only in areas free of flammable vapor or high dust content. Never use heater where gasoline, paint

thinner or other highly flammable vapors are present.

WARNING!

EXPLOSION

Fully drain and ventilate fuel tank before transporting.

3

Operation and Maintenance Manual

WARNING!

ROTATING MACHINERY

When used with thermostat, heater may start at any time. Do not open access door while heater is

running or plugged in. Remove all power prior to service.

WARNING!

SHOCK HAZARD

Use only with electrical voltage and frequency specified on model plate. Do not perform any service with

heater plugged in.

WARNING!

HIGH VOLTAGE

The ignition transformer develops 10,000 volts. Serious injury or death may occur if personnel come in

contact with high voltage lead.

WARNING!

FIRE, EXPLOSION

Do not operate heater without output duct, P/N CAH-1015, properly installed. Ensure hot air outlet is at

least 1.5 meters from combustible materials. Ensure ducts (outlet and inlet) are free from obstructions and

sharp bends. ALWAYS REMOVE STORAGE PLUG CAH-126-1 BEFORE OPERATING HEATER.

WARNING!

HOT SURFACES

Parts of the heater become very hot when operating and immediately after operating. The exhaust can

reach temperatures in excess of 1000 degrees Fahrenheit. Severe burns may occur if the heater is not

allowed to cool down properly before servicing.

4

Operation and Maintenance Manual

WARNING!

CARBON MONOXIDE POISONING

The heat exchanger must be inspected annually by qualified service personnel for leaks which could

allow dangerous carbon monoxide gas to enter the shelter. Failure to due so, could cause severe

injury or death.

5

Operation and Maintenance Manual

Table of Contents

Operation and Maintenance Manual ............................................................................................................. 1

1. System Overview, Description and Principles of Operation ............................................................... 10

1.1 System Overview .......................................................................................................................... 10

1.2 Description of Major Components ................................................................................................ 11

1.3 Controls and Indicators ................................................................................................................. 14

1.4 WARNING Labels and Data Plates .............................................................................................. 16

1.5 CAMFIRE Heater Specifications .................................................................................................. 19

1.6 Principles of Operation ................................................................................................................. 20

2. Setup and Operation of the CAMFIRE Heater ................................................................................. 25

2.1 Preparing the Heater for Operation .............................................................................................. 25

2.1.1 Unpacking .............................................................................................................................. 25

2.1.2 Installing the Exhaust Stack Extension ................................................................................. 25

2.1.3 Removing the Accessories .................................................................................................... 26

2.2 Siting Considerations .................................................................................................................... 26

2.3 Setup ............................................................................................................................................ 27

2.3.1 Attaching the Flexible Ducts .................................................................................................. 27

2.4 Before Operation Preventative Maintenance Checks and Services (PMCS)............................... 30

2.5 Fueling .......................................................................................................................................... 30

2.5.1 Fueling the Internal Tank (MV60S-EU, MV60T-EU) ............................................................. 30

2.5.2 Connecting and operating the Remote Room Thermostat ................................................... 31

2.5.3 Connecting the Power Cable ................................................................................................. 32

2.6 Final Checks Before Operation .................................................................................................... 33

2.7 Starting and Operating the Heater ................................................................................................ 33

2.7.1 Starting the Heater ................................................................................................................ 33

2.8 Refueling During Operation .......................................................................................................... 34

2.9 Shutting Down the Heater ............................................................................................................ 34

2.10 Preparing for Movement or Storage.......................................................................................... 34

2.10.1 Preparing for Movement ........................................................................................................ 34

2.10.2 Preparing the Heater for Storage .......................................................................................... 35

3. CAMFIRE Troubleshooting .................................................................................................................. 38

3.1 Introduction ................................................................................................................................... 38

3.2 Operator Level Troubleshooting ................................................................................................... 38

3.3 Safety Control Operation and Diagnostics ................................................................................... 38

3.3.1 Operator Level Malfunction Symptom Index ......................................................................... 39

3.3.2 Examining the Heater ............................................................................................................ 39

3.3.3 Test Firing the Heater ............................................................................................................ 40

3.3.4 Operator Level Troubleshooting Procedures ........................................................................ 40

3.4 Maintainer Level Troubleshooting ................................................................................................ 45

3.4.1 Test Firing .............................................................................................................................. 45

3.4.2 Maintainer Level Safety Control Operation and Diagnostics ................................................ 45

3.4.3 Maintainer Level Malfunction Symptom Index ...................................................................... 46

3.4.4 Maintainer Level Troubleshooting Procedures ...................................................................... 47

4. CAMFIRE Maintenance ....................................................................................................................... 54

4.1 Introduction ................................................................................................................................... 54

4.2 Preventive Maintenance Checks and Services ............................................................................ 54

4.2.1 Introduction ............................................................................................................................ 54

4.2.2 Removing Upper Shell .......................................................................................................... 56

4.2.3 Preventive Maintenance Checks and Services ..................................................................... 57

4.3 Special Tools, Equipment and Supplies ....................................................................................... 61

6

Operation and Maintenance Manual

4.4 System Maintenance Procedures ................................................................................................. 61

4.4.1 General .................................................................................................................................. 61

4.4.2 Remote Room Thermostat (Inspect/Test) ............................................................................. 62

4.4.3 Ignition Transformer (Inspect/Test) ....................................................................................... 63

4.4.4 Checking Motor Starting Circuits (Test) ................................................................................ 65

4.4.5 Fan Service ........................................................................................................................... 67

4.4.6 Sediment strainer Service ..................................................................................................... 68

4.4.7 Burner Head Service (Clean) ................................................................................................ 69

4.4.8 Air Pump Repair (Inspect, Test, Repair) ............................................................................... 73

4.4.9 Safety Control Circuit Testing (Test, Clean) .......................................................................... 81

4.4.10 Photocell (Test) ..................................................................................................................... 85

5. Illustrated Parts Listing......................................................................................................................... 88

6. Schematics and Wiring Diagrams ...................................................................................................... 106

7. Alphabetical Index .............................................................................................................................. 108

7

Operation and Maintenance Manual

Table of Figures

Figure 1-1. CAMFIRE Control Panel ........................................................................................................... 14

Figure 1-2. Remote Room Thermostat ....................................................................................................... 15

Figure 1-3. System Operational Diagram (simplified for clarity) ................................................................. 21

Figure 4-1. Camfire Maintenance Locations ............................................................................................... 56

Figure 4-2. Wiring Diagram ......................................................................................................................... 66

Figure 4-3. Location of Fan on Shaft .......................................................................................................... 67

Figure 4-4. Checking clearance of air pump rotor....................................................................................... 78

Figure 5-1. MV60-EU Labels and Accessories ........................................................................................... 88

Figure 5-2. MV60-EU FULL ASSEMBLY .................................................................................................... 90

Figure 5-3. COMBUSTION CHAMBER ASSEMBLY .................................................................................. 92

Figure 5-4. BURNER HEAD ASSEMBLY 53649 ........................................................................................ 94

Figure 5-5. MV60 CONTROL BOX-FUEL BRACKET ASSEMBLY ............................................................ 96

Figure 5-6B. CONTROL BOX ASSEMBLY ................................................................................................. 98

Figure 5-7. MOTOR/PUMP/BRACKET ASSEMBLY (53745) ................................................................... 100

Figure 5-8. MOTOR AND PUMP ASSEMBLY(53485) ............................................................................. 102

Figure 6-1. Camfire Heater Wiring Diagram ............................................................................................. 106

Figure 6-2. Camfire (MV60) Fuel Schematic ............................................................................................ 107

Table of Tables

Table 1-1. CAMFIRE Heater Warning Labels and Data Plates ................................................................. 16

Table 1-2. Camfire Heater Specifications ................................................................................................... 19

Table 2-1. Flexible Duct Usage vs. Outside Temperature .......................................................................... 27

Table 2-2. Extension Cord Size Requirements ........................................................................................... 32

Table 3-1. Operator Level Malfunction Symptom Index ............................................................................. 39

Table 3-2. Operator Level Troubleshooting Procedure .............................................................................. 40

Table 3-3. Maintainer Level Malfunction Symptom Index ........................................................................... 46

Table 3-4. Maintainer Level Troubleshooting Procedures .......................................................................... 47

Table 4-1. Camfire Heater Preventive Maintenance Checks and Services ................................................ 57

Table 5-1. MV60 Labels and Accessories .................................................................................................. 89

Table 5-2. Combustion Chamber Assembly ............................................................................................... 93

Table 5-3. Burner Head Assembly 53649 ................................................................................................... 95

Table 5-4. Control Box-Fuel Bracket Assembly .......................................................................................... 97

Table 5-5. Control Box Assembly ............................................................................................................... 99

Table 5-6. Motor/Pump/Bracket Assembly ............................................................................................... 101

Table 5-7. Motor and Pump Assembly P/N 53485.................................................................................... 103

8

Chapter 1

System Overview,

Description and

Operation and Maintenance Manual

Principles of Operation

9

Operation and Maintenance Manual

1. System Overview, Description and

Principles of Operation

1.1 System Overview

The CAMFIRE Heaters are portable, clean-air space heaters that rely on an external input of 220 VAC,

50/60 Hz, single phase power.

The heart of the heater is a heat exchanger that is supplied with air from a fan driven by a 1/4 horsepower

motor. Part of the air from the fan enters the combustion chamber where it mixes with the atomized fuel to

become a combustible mixture. The exhaust gases circulate within the heat exchanger; warming its inner

surfaces, then escape from the heater through a flue pipe adapted to the top of the heater.

The remaining air from the fan passes over and around the combustion chamber and through the heat

exchanger where it is heated, and emerges from the heater as a powerful stream of heated clean air.

The heater is provided with duct connectors at the outlet and inlet ends, allowing use either in a 100%

fresh air mode or 100% recirculation air mode.

The fuel system consists of an air pump mounted on one end of the motor shaft that forces air through

the nozzle. The moving air in the nozzle lifts the fuel from the tank by siphon action and carries it into the

combustion chamber.

Filters protect the fuel system prior to the fuel entering into the spray nozzle. The electrical control system

is protected by a push button type circuit breaker.

A safety control unit, connected to a photoelectric cell, shuts down the heater if a flame is not detected in

the combustion chamber after start up. It also has two diagnostic LEDs to help troubleshoot problems. A

”Duct Over-Heat” switch is installed as a safety measure. In the event that the outlet duct becomes

blocked, the switch will shut the heater down.

A thermostat accessory, which plugs into the electrical system of the heater, may be set to any desired

temperature. When the temperature of the surrounding air reaches the pre-set temperature, the

thermostat contacts open and cause the heater to shut down. When the air cools, the thermostat contacts

close and the heater recycles.

The heater is designed for hard use in rough environments resulting in a minimum of down time for repair

and maintenance. It is protected by roll bars to prevent damage by upset or rollover and shrouded to

protect the working portion of the heater against falling objects.

The heater can be fitted with added accessories such as wheels, skis or toboggan. A spares kit is also

available that includes filters, spark plug, and fuel regulating components.

10

1.2 Description of Major Components

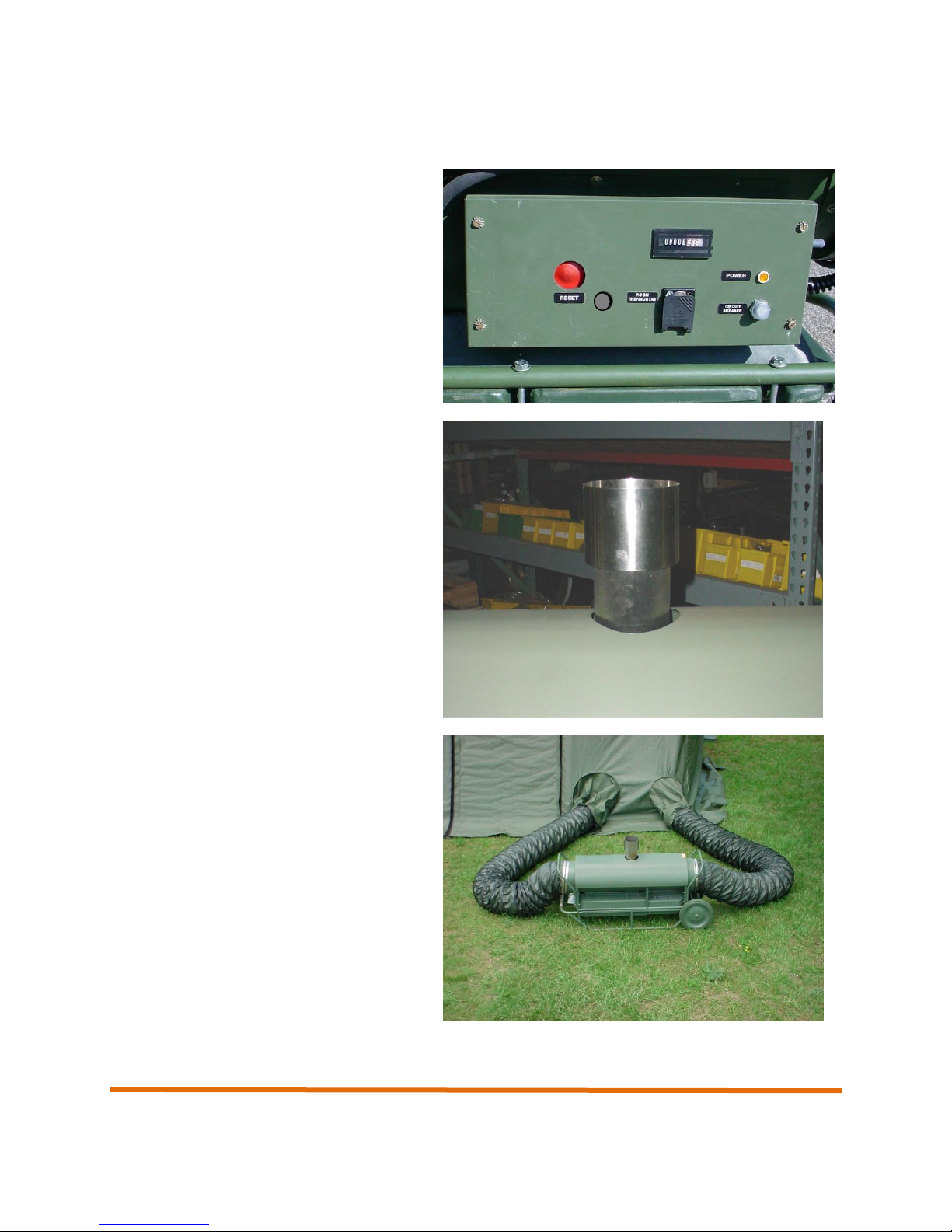

Control Panel – Contains all operation

controls for heater including power input

connector, optional remote room thermostat

connector, and hour meter.

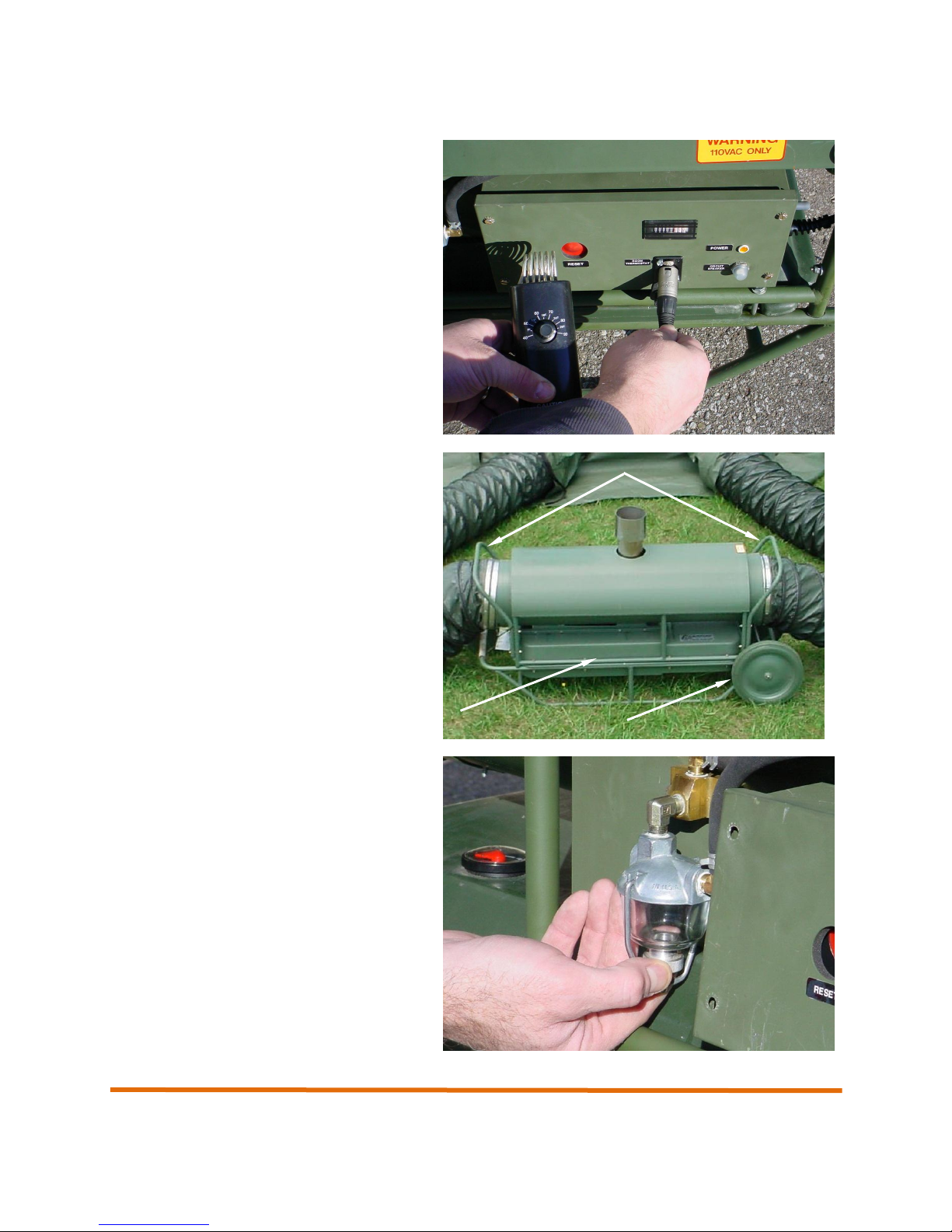

Exhaust Stack Extension– The exhaust

stack extension is installed in the exhaust

outlet on the top of the heater and acts to

direct the combustion gases away from the

heater.

An internal screen in the exhaust stack

extension acts as a spark arrester.

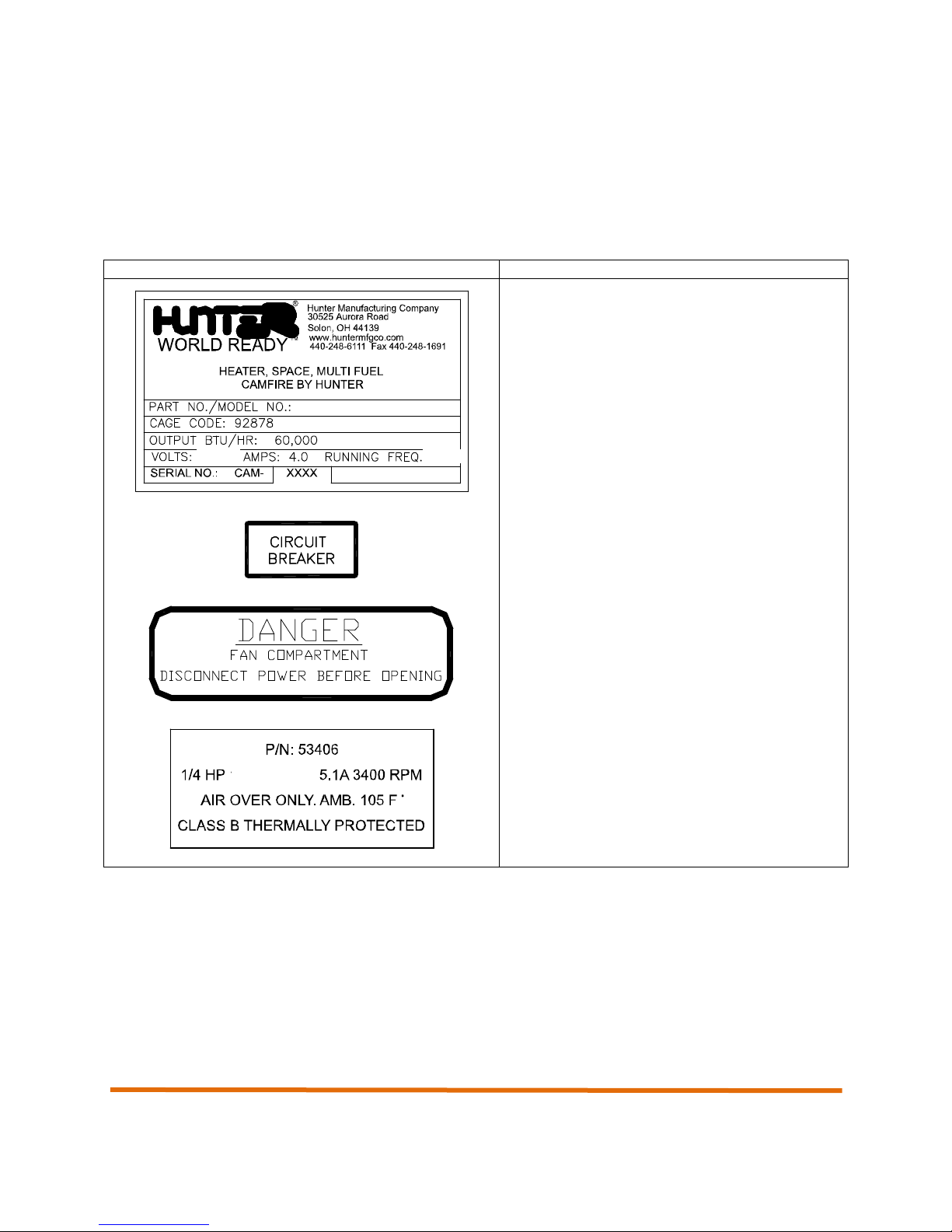

Inlet and outlet ducts – 15 foot flexible

ducts connect to the shelter duct tunnels and

circulate heated and unheated air through the

shelter.

Operation and Maintenance Manual

11

Operation and Maintenance Manual

End plug – Installs into the inlet end of the

heater and is used to house accessory items

such as the remote room thermostat.

Burner assembly – The burner assembly is

where all combustion occurs within the

Camfire heater. Atomized fuel is mixed with

air and ignited by the spark plug to create the

heat circulated through the shelter.

Power cable – A 6-foot long AC power cable

that connects the heater with a 220` VAC

power source. The power cable is wrapped

around the inlet duct adapter.

12

Operation and Maintenance Manual

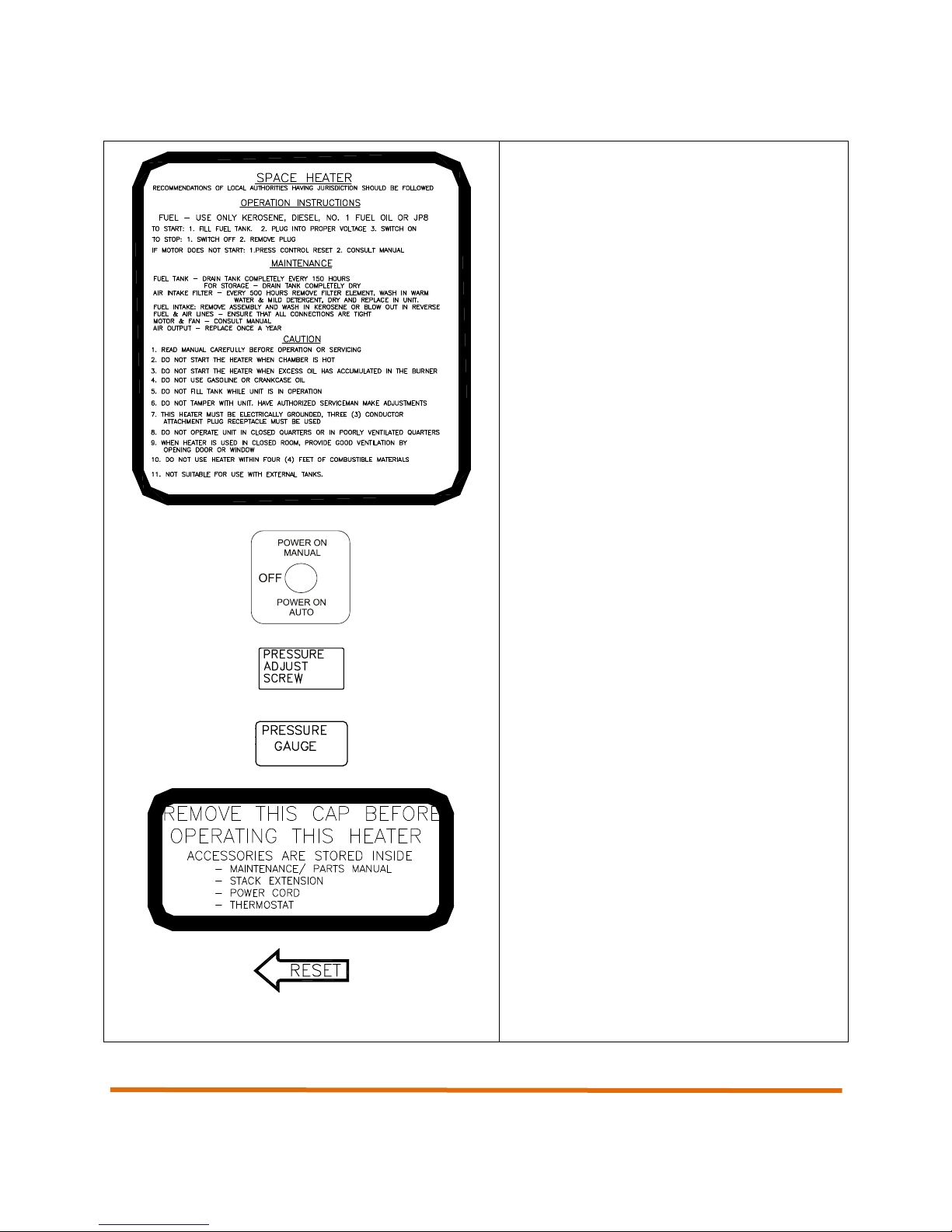

Remote Room Thermostat – Permits

automatic temperature control inside a

shelter. The remote room thermostat hangs

inside the shelter and monitors the shelter

temperature. If the shelter temperature falls

below the set point on the thermostat, the

heater will start and begin supplying heat

until the set point is reached.

Roll bars, handles, and local transport

wheels* – Handles are located at either end

of the heater and permit the heater to easily

be moved into position. Roll bars are located

around the heater and act to protect the

heater from damage. Local transport wheels

(optional accessory) permit the heater to be

rolled into position.

* Local transport wheels are an optional accessory.

Sediment strainer assembly. Allows for

visual inspection of fuel for dirt and water. Is

able to be easily removed and cleaned.

13

No.

Control

Description

1

Reset

Resets the heater in the event a problem shuts the heater down or a fault

condition occurs

2

Power ON AUTO/

ON MANUAL

Turns heater power on and selects AUTO or MANUAL heat mode

3

Pilot Light

Indicates that power is supplied to the heater.

4

Thermostat Jack

Permits the connection of the remote thermostat assembly.

5

Hour meter

Displays the total number of operating hours for the heater.

6

Circuit Breaker

Protects the heater against circuit overload

7

View Port

Allows the user to view the diagnostic LEDs, for troubleshooting and repair

1

2

3

4

5

6

7

1.3 Controls and Indicators

Operation and Maintenance Manual

Figure 1-1. CAMFIRE Control Panel

14

Operation and Maintenance Manual

No.

Control

Description

1

Variable

Temperature

Control

Placed inside the shelter being heated, permits the operator to set the

desired temperature of the shelter.

2

Temperature

Sensing Coil

Located on the top of the remote room thermostat, monitors the temperature

of the shelter.

1

2

Figure 1-2. Remote Room Thermostat

15

Operation and Maintenance Manual

WARNING Label or Data Plate

Location/Description

Located on the side of the heater, the data plate

provides pertinent data including Model Number

and Serial Number

Located on the control panel, identifies the

circuit breaker. See section on controls and

indicators.

Located near the fan compartment, warns user

of electrical shock potential inside fan

compartment.

Located on fan assembly, label identifies part

number and performance specs of fan.

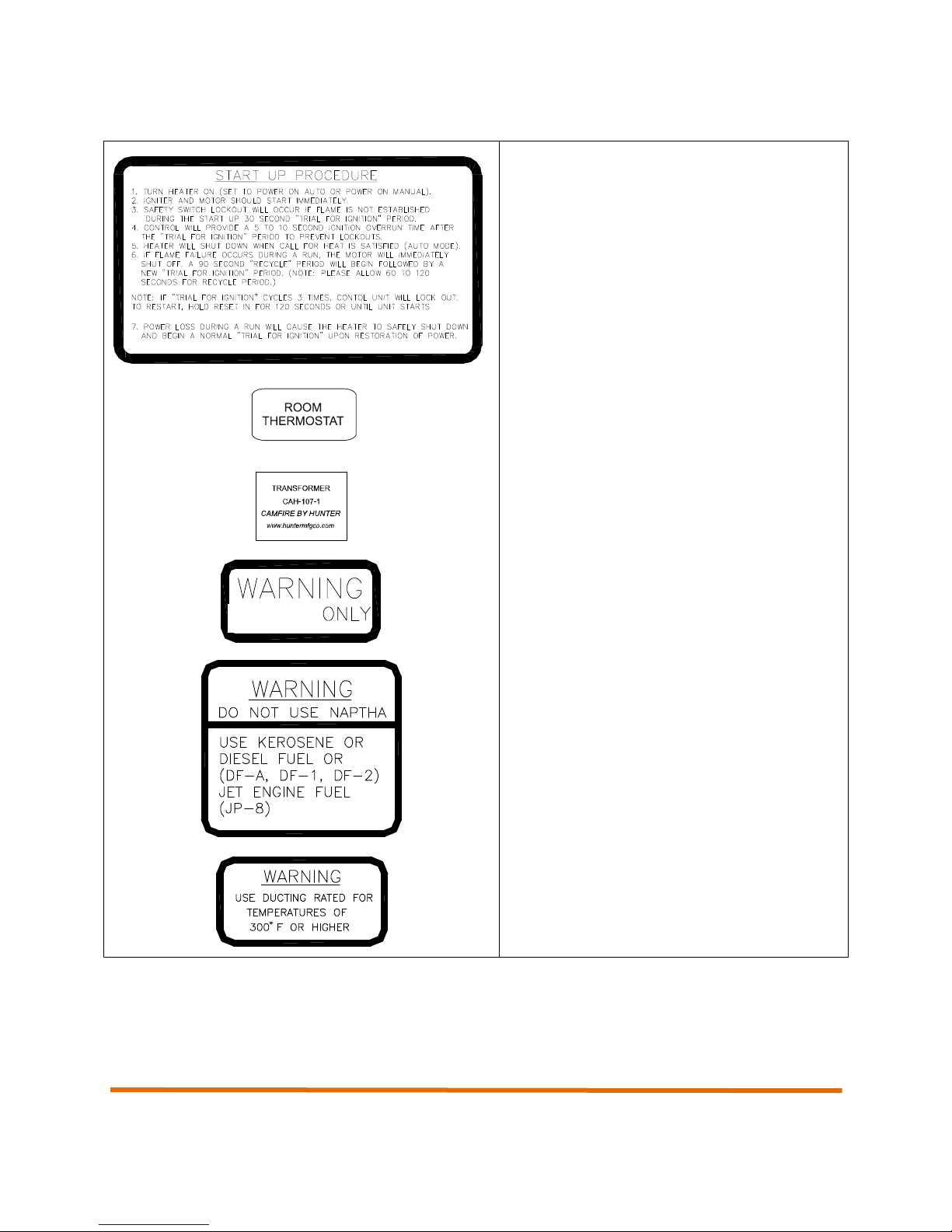

1.4 WARNING Labels and Data Plates

The following section contains a description of all WARNING labels and data plates associated with the

Camfire Heater.

Table 1-1. CAMFIRE Heater Warning Labels and Data Plates

16

Operation and Maintenance Manual

Located on side of heater, label lists the

operating procedures for the heater in

abbreviated form.

Located on the control panel, identifies power

switch.

Located inside heater near air pump, identifies

pressure adjustment screw.

Located inside heater near burner assembly,

identifies pressure gauge.

Located on end plug at end of heater, identifies

the fact that the cap must be removed before

operation. Also informs user of accessories

stored inside end plug.

Located on control panel, identifies Reset

switch.

17

Operation and Maintenance Manual

Located on side of heater, details heater startup procedures.

Located on control panel, identifies remote

ROOM THERMOSTAT.

Parts ID tag located on the ignition transformer.

Located on control panel, alerts user that only

220VAC power should be used.

Located near fuel filler cap on side of heater,

warns user against the use of naptha and

identifies all approved fuels.

Located near duct connections at end of heater.

Warns user that only approved flexible ducts

rated for temperatures of 300 degrees F or

higher can be used.

220 VAC

18

MV60S-EU, MV60T-EU,

Input Heat Rating

BTU/Hour

90,000

Output Ratings

Clean-air Output, BTU/Hour

60,000

Volume, CFM (Approximate)

600

Other Ratings

Current, starting

3.5 AMPS

Current, running

2.2 AMPS

Voltage

220 VAC

Frequency

50/60 Cycles

Fan/Pump Motor

1/4 HP

Air Pump Pressure

5.0 PSI

Fuel Nozzle

Meter Size

0.65 GPH

Spray Angle

80 DEGREES

Fuel

Kerosene, DF1, DF2,

Fuel Oil, JP8 Only

Tank Capacity

8.5 GAL

Flexible Ducts (2)

12 inch diameter

15 ft Length

Dimensions (Without Stack

Extension)

W15” L46” H25”

Weight (Without Fuel)

105 LBS

1.5 CAMFIRE Heater Specifications

Table 1-2. Camfire Heater Specifications

Operation and Maintenance Manual

19

Operation and Maintenance Manual

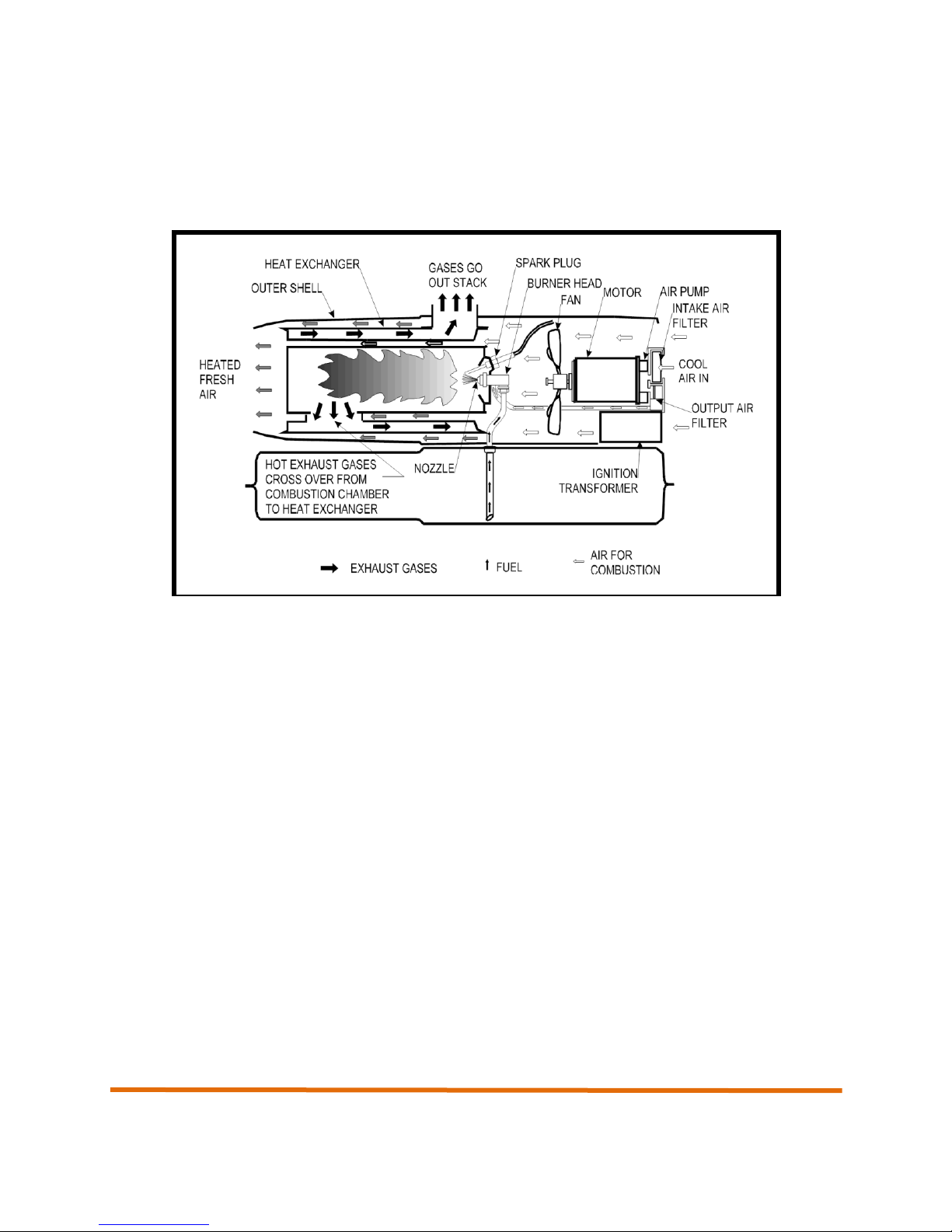

1.6 Principles of Operation

Fuel System

An air pump on one end of the motor shaft forces the air through the nozzle. The moving air lifts fuel from

the tank or from the remote fuel source ( AND version) by a siphon action and carries it into the

combustion chamber in a fine spray.

Air System

The air system is divided into two parts, both are supplied with air from a fan that is attached to the other

end of the motor.

Part of the air from the fan enters the combustion chamber where it mixes with the atomized fuel to

become a combustible mixture, and also mixes with the burning gases to complete the process of

combustion.

The exhaust gases from the combustion chamber circulate within the inner surfaces of the heat

exchanger. They are then ducted out of the heater through the stack adapter on its’ top and out of the

heater space through a flue pipe.

The rest of the air from the fan passes over and around the combustion chamber and through the heat

exchanger where it is heated and emerges from the front of the heater as a powerful stream of heated

fresh air, without being mixed with the products of combustion.

Ignition System

The ignition system consists of a transformer and spark plug. The transformer increases the input voltage

to a very high potential that causes an arc to be drawn between the electrodes of the spark plug. The arc

is used to ignite the fuel and air mixture within the combustion chamber.

Control System

The safety control circuit consists of a duct over heat switch, a light sensitive photocell, and a safety

control. The safety control will trip if the heater fails to ignite or the flame goes out, thereby causing the

heater to shut down. The safety control has two diagnostic LEDs which can be seen through a hole in the

front of the control panel.

The photocell is used to sense the presence of light due to the flame inside the combustion chamber. It

varies its’ electrical resistance in relation to light rays. When under the influence of light, the cell has very

low resistance. The resistance is high when little or no light strikes the light sensitive surface. The flame

sensor’s function is to control the safety control.

A ”duct over-heat” switch is located at the outlet end of the heater. This switch will shut down the heater if

the duct temperature exceeds approximately 275 deg. F.

A thermostat accessory, Part No. CAH-134-1, may be incorporated into the electrical circuit of the heater.

The thermostat can be set to any desired temperature between 35 deg. F and 95 degrees F. When the

20

Operation and Maintenance Manual

temperature of the surrounding air reaches the pre-set temperature, the thermostat contacts open and

cause the heater to shut down. When the air cools, the thermostat contacts close and the heater recycles.

A ”duct over-heat” switch is located at the outlet end of the heater. This switch will shut down the heater if

the duct temperature exceeds approximately 275 degrees F.

Figure 1-3. System Operational Diagram (simplified for clarity)

21

Operation and Maintenance Manual

22

Operation and Maintenance Manual

Chapter 2

Setup and Operation of the

CAMFIRE Heater

23

Operation and Maintenance Manual

24

Operation and Maintenance Manual

2. Setup and Operation of the CAMFIRE Heater

2.1 Preparing the Heater for Operation

2.1.1 Unpacking

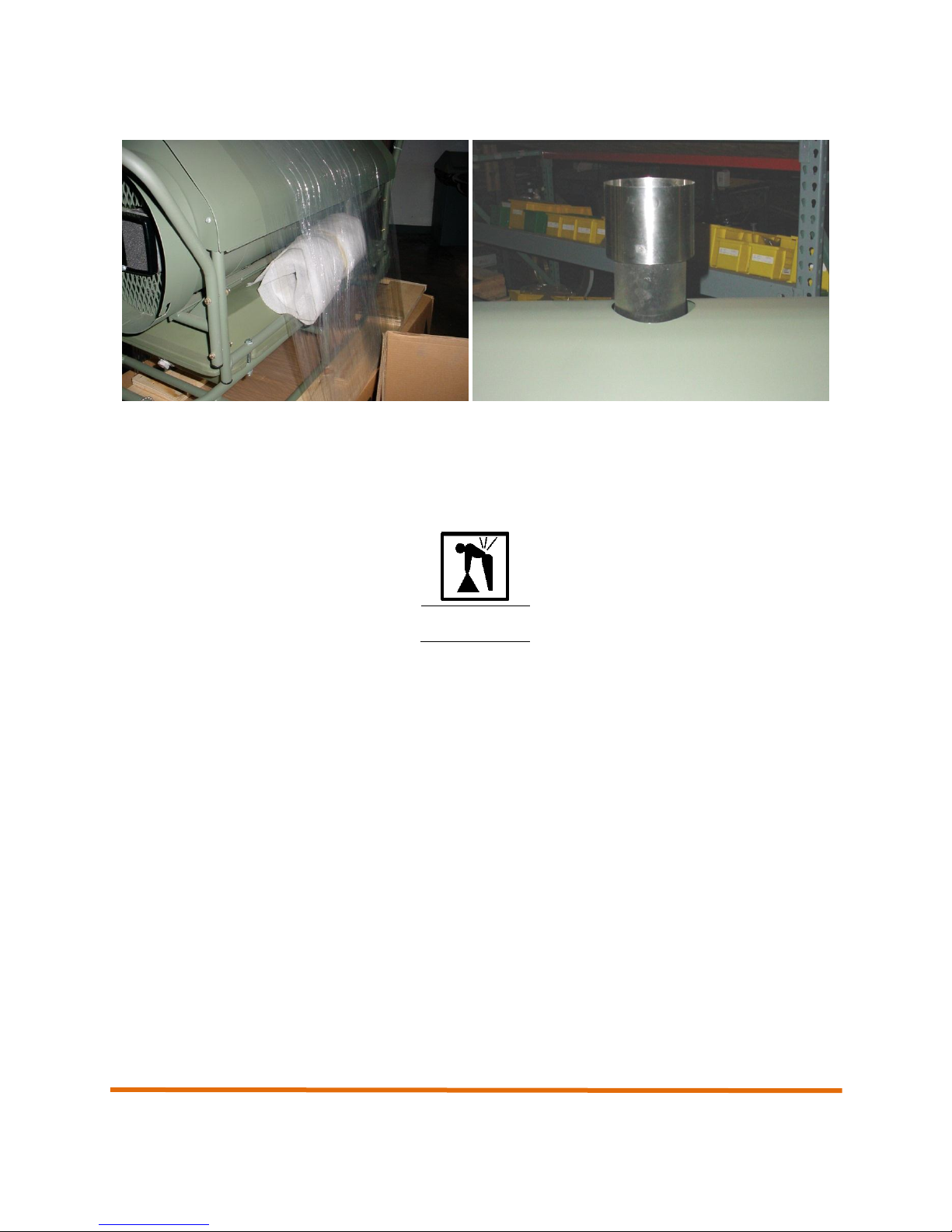

The Camfire heater is shipped mounted to a shipping pallet and wrapped in a plastic wrap material. When

unpacking the heater, remove all protective material covering the heater and remove the unit from the

shipping pallet.

2.1.2 Installing the Exhaust Stack Extension

The exhaust stack extension is wrapped in foam and packaged to the side of the heater. Unwrap the

exhaust stack extension and install on the top of the heater by engaging the exhaust stack extension into

the exhaust port at the top of the heater. Push down and seat securely.

25

Operation and Maintenance Manual

WARNING

2.1.3 Removing the Accessories

Remove the end plug by pushing in and rotating counterclockwise to release from the J-slot. Pull the end

plug to disengage it from the heater and remove the remote room thermostat. Set the thermostat aside.

2.2 Siting Considerations

The CAMFIRE heater weighs approximately 105 pounds dry weight (48 kg). A fully fueled

heater weighs 165 pounds (74.8 kg). Two persons must carry the CAMFIRE heater when

lifting or lowering the unit. Be sure to lift with legs, not back, to prevent injury.

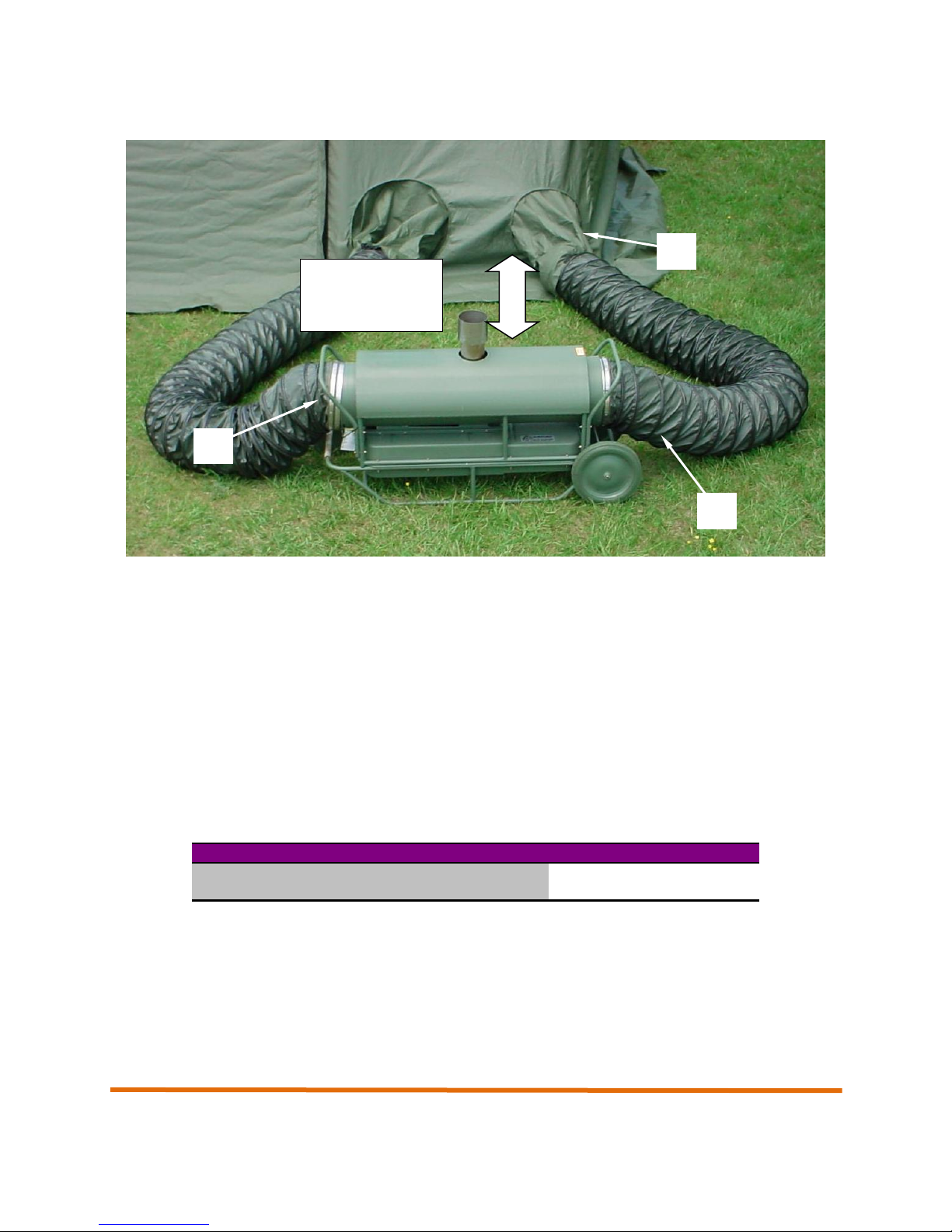

The CAMFIRE heater site location will be dictated by the location of the shelter since the heater inlet (1)

and outlet (2) ducts must be able to reach the shelter duct tunnels (3). (see photo next page)

The heater site must be as level as possible and free of combustible material (e.g. dried twigs, leaves.

etc.). If snow is present, it should be removed from the area immediately beneath and around the heater.

The site should be selected so that the heater will be positioned at least 2 feet (61 cm) from combustibles,

including the shelter wall.

26

Below 320F

Above 320F

Use Heated Air Outlet Duct Only

X

Use Air Inlet Duct and Heated Air Outlet Duct

X

Position heater

at least 2 feet

from shelter wall

1

2

3

Operation and Maintenance Manual

Positioning the Heater Outside Shelter. Place heater on the side of the shelter that has the shelter duct

tunnels. The heater should be a minimum of 2 feet (61 cm) from shelter walls. If possible, position the

heater so that the control panel faces away from the shelter wall. Position the heater so that the two

supplied 15-foot flexible ducts can be connected to the heater and the shelter duct tunnels.

2.3 Setup

2.3.1 Attaching the Flexible Ducts

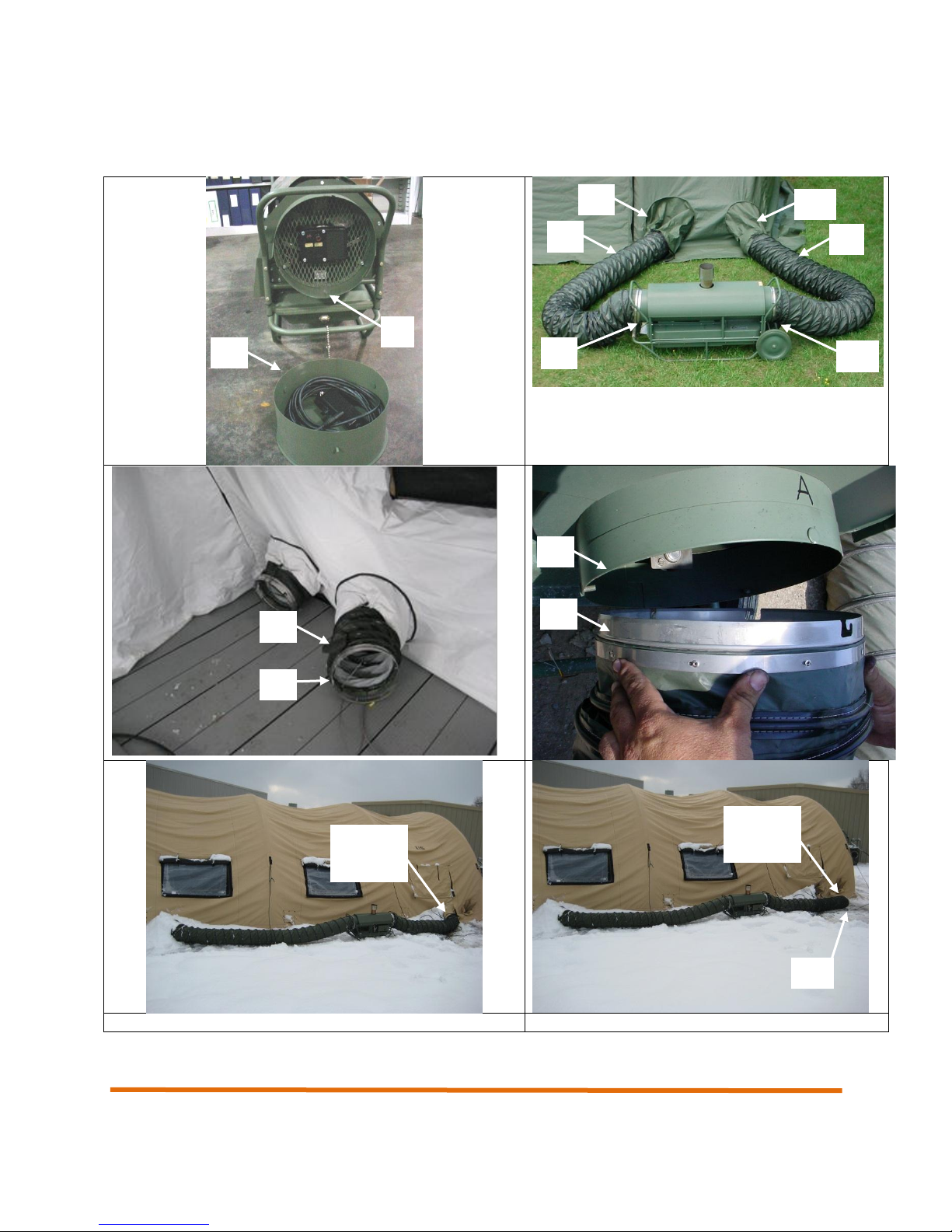

General. Two air ducts, 15 feet in length and 12 inches in diameter, connect to the inlet and outlet ends

of the heater and move air from the interior of the shelter, through the heater, and back to the interior of

the shelter. In conditions where the outside ambient temperature is above freezing, only the heated air

supply duct is used. In this way, the heater draws unheated air from the outside. Operating the heater

without input ducting in warmer temperatures allows the heater to run cooler, thus preventing safety

overheat shutdown.

Table 2-1. Flexible Duct Usage vs. Outside Temperature

27

Operation and Maintenance Manual

WARNING

Installing the Air Supply and Return Ducts (re-circulation mode). To install the heated air return and

air supply ducts (NOTE: air return duct to be installed only if outside temperatures are below freezing),

remove end plug (1) from the heater duct adapter (2) on the air inlet end of the heater by pushing in and

rotating clockwise to disengage the protruding pins on the end plug from the J-slots in the heater duct

adapter. Remove the power cable stowed inside the end plug and set aside.

During heater operation, air leaving the heated air outlet of the heater and passing

through the heated air return duct may exceed 220°F (104°C). Make sure shelter

personnel are aware of burn hazards and equipment hazards presented by the heated air

exiting the heated air duct.

CAUTION

Wear gloves whiles handling ducts. There may be sharp metal edges or burrs that could

cut you.

NOTE: The heater ducts are outfitted with J-slot, twist lock bands on each end. They can only be

attached one way. Make sure to match up the ends before attaching to the shelter. Locate the heated air

supply duct (3). Make sure inside and outside of duct are free of damage, dirt, and obstructions prior to

attachment to the heater assembly. Insert the outlet end (4) of the duct into the shelter duct tunnel (5)

closest to the heated air outlet end (6) of the heater as indicated by the label “Heated Air Outlet” on the

upper housing assembly. Make sure about 12 inches of the outlet end (4) protrude into the shelter (7) so

that the air can be directed away from the inlet properly. Secure the shelter duct tunnel tie straps. Do not

secure the straps so tightly that the air flow within the duct is restricted. Attach the end of the duct with the

J-slot bracket (8) to the duct adapter (9) on the heated air outlet end (6) of the heater. Engage the J-slot

onto the protruding pins on the inside of the duct adapter and push in fully. While pushing the duct in,

rotate the duct counterclockwise until it locks in place.

IMPORTANT

If using the heater on a shelter with a plenum, move the plenum to the side so it does not

obstruct the airflow. DO NOT ATTACH THE HEATER TO THE SHELTER PLENUM. The

heater will do a much better job of heating by blowing the heat on the floor.

Insert the end of the duct without the J-slot mounting bracket into the shelter duct tunnel (14) closest to

the air inlet end (15) of the heater as indicated by the label “Air Inlet” on the upper housing assembly.

Secure the shelter duct tunnel tie straps (16). Do not secure the straps so tightly that the air flow within

the duct is restricted. Attach the end of the duct with the pins onto the J-slots (17) to the duct adapter (18)

on the air inlet end of the heater. Engage the protruding pins onto the J-slots on the duct adapter and

push in fully. While pushing the duct in, rotate the duct counterclockwise until it locks in place.

28

Operation and Maintenance Manual

Re-circulation mode

Outside air mode (see next section)

7

1 2 5

3

4

6

8

9

14 3 15

12

Duct

shelter

Duct

shelter

inside

outside

29

Operation and Maintenance Manual

WARNING

2

3

Installing the Air Supply and Return Ducts (outside air mode) If outside temperatures are above

freezing, the inlet of the air supply duct (12) should be located outside the shelter, drawing outside air, in

accordance with Table 2-1. This helps to keep the heater from shutting down on overheat unexpectedly.

Make sure the duct is still attached to the heater as this keeps rain and snow from being drawn into the

fan compartment. Also, make sure inside and outside of duct and the grill are free of damage, dirt, and

obstructions prior to attachment to the heater assembly.

Never use gasoline in this heater. Never use JP-4. The heater is designed to run only on

DF-1, DF-2, DF.A, JP-5, and JP.8. Failure to use only authorized fuels may result in fire

or explosion.

2.4 Before Operation Preventative Maintenance Checks and Services (PMCS)

Perform the “Before Operation PMCS” on all CAMFIRE heater components as outlined in section 4.2,

prior to preparing the heater for use. All scheduled maintenance must be performed on the heater and its

associated equipment prior to use.

2.5 Fueling

2.5.1 Fueling the Internal Tank (MV60S-EU, MV60T-EU)

Remove the internal fuel tank cap (2) and fill the internal tank with an approved fuel as detailed in section

1.5 of this manual.

Install the internal fuel tank cap (2) and hand tighten securely.

Open the vent on the top of the fuel tank cap

(2).

CAUTION: For fuel tanks with a manual vent.

The fuel tank vent should always be open to

prevent pressure from building up in the fuel

tank. Only close the vent when the heat is

tilted, such as when moving the heater on its

optional wheels.

The fuel level in the tank is displayed on the

fuel gauge to the right of the fuel tank cap (3).

30

Loading...

Loading...