Hayward Pro Logic®, Pro Logic PL-PS-4-CUL, Pro Logic PL-PS-16-CUL, Pro Logic PL-PS-8-CUL, PL-PS-4 Installation Manual

...

Pro Logic

Automation and Chlorination

PL-PS-4 PL-PS-8-V

PL-PS-8 PL-PS-16-V

PL-PS-16

Installation Manual

for models

www.haywardnet.com

IMPORTANT SAFETY INSTRUCTIONS

!

!

!

When using this electrical equipment, basic safety precautions should always be

followed, including the following:

•

•

•

•

• A green colored terminal marked “Grounding” is located inside the wiring

• One bonding lug for US models (two for Canadian models) is provided on the

READ AND FOLLOW ALL INSTRUCTIONS

WARNING: Disconnect all AC power during installation.

WARNING: Water in excess of 100 degrees Fahrenheit may be

hazardous to your health.

WARNING: To reduce the risk of injury, do not permit children to

use this product unless they are closely supervised at all times.

compartment. To reduce the risk of electric shock, this terminal must be

connected to the grounding means provided in the electric supply service

panel with a continuous copper wire equivalent in size to the circuit conductors

supplying the equipment.

external surface. To reduce the risk of electric shock, connect the local

common bonding grid in the area of the swimming pool, spa, or hot tub to

these terminals with an insulated or bare copper conductor not smaller than 8

AWG US / 6 AWG Canada.

• All field installed metal components such as rails, ladders, drains, or other

similar hardware within 3 meters of the pool, spa or hot tub shall be bonded to

the equipment grounding bus with copper conductors not smaller than 8 AWG

US / 6 AWG Canada.

• SAVE THESE INSTRUCTIONS

Table of Contents

Introduction Before You Begin................................................................... 1

Installation Steps.................................................................... 2

1. Preparing General Water Chemistry..................................................... 3

Pool/Spa Water Salt.......................................................................................... 4

2. Mounting Pro Logic Control Center................................................... 5

Equipment PS-16 Expansion Unit.......................................................... 6

Temperature Sensors........................................................... 6

Optional Chlorination Function............................................ 6

Optional AQL-CHEM ORP and pH Sensing Kit................ 6

Optional AQL-COLOR-MODHV Network Module............. 6

Optional Wired Remote Display/Keypad........................... 7

Optional Wireless Remote Display/Keypad....................... 7

Optional Base Station........................................................... 7

Optional Valve Actuators....................................................... 7

3. Plumbing “Standard” Pool/Spa Configuration..................................... 8

“Dual Equipment” Pool/Spa - Separate Heaters............... 9

“Dual Equipment” Pool/Spa - Shared Heaters................... 10

Turbo Cell............................................................................... 11

Flow Switch............................................................................ 11

4. Electrical Main Service.......................................................................... 12

Wiring Grounding and Bonding........................................................ 12

Circuit Breaker Installation and Wiring................................ 12

General Purpose Outlet........................................................ 12

Pro Logic Control Power................................................... 13

High Voltage Pool Equipment.............................................. 13

Low Voltage Wiring............................................................... 15

5. Configuration Group Function...................................................................... 22

Configuration Menus............................................................. 24

Maintenance Menu................................................................ 40

6. System Startup Before Startup........................................................................ 41

and Checkout Heater Checkout.................................................................... 41

Service Mode........................................................................ 42

7. Warranty Pro Logic Limited Warranty................................................. 44

Introduction

Before You Begin

What’s Included

Before attempting to install the Pro Logic system, check that the following components have been included in the

package:

Pro Logic Electronics Unit

(3) Temperature sensors with 15 ft. (5m) cable, hose clamp

Pro Logic Expansion Unit (PS-16 only)

What’s NOT Included

Some of the additional items that you may need to complete an installation include:

Circuit breakers

None are included with control—see page 12 and inside of door for suitable breakers

Wire

4-conductor cable (electronics unit to remote display/keypad)

Wire/conduit for 100A service from main panel to Pro Logic

Wire/conduit for filter pump and other high voltage loads

Wire for bonding

Miscellaneous

Utility electrical outlet and weatherproof cover (for mounting on side of Pro Logic)

Mounting hardware (screws, etc.) for mounting Pro Logic and remote display/keypad

Valves (use standard Hayward, Pentair/Compool, or Jandy valves)

Additional valve actuators

Accessory Products - Order Separately

T-CELL-3 Pick N MixTM Chlorinator Cell (for pools up to 15k gallons)

T-CELL-9 Pick N Mix Chlorinator Cell (for pools up to 25k gallons)

T-CELL-15 Pick N Mix Chlorinator Cell (for pools up to 40k gallons)

P-KIT Chlorination Plumbing Kit containing flow switch and cell unions

AQL-CHEM ORP & pH sense kit

AQL-CHEM2(-240) pH dispense kit

AQL2-Wx-PS-4 Wired Remote Display (see note 1)

AQL2-Wx-PS-8 Wired Remote Display (see note 2)

AQL2-Wx-PS-16 Wired Remote Display (see note 3)

AQL2-POD Handheld Wireless Remote Control (see note 4)

AQL2-Wx-RF-PS-4 Wireless Wallmount Remote Control (see notes 1, 4, 5)

AQL2-Wx-RF-PS-8 Wireless Wallmount Remote Control (see notes 2, 4, 5)

AQL2-Wx-RF-PS-16 Wireless Wallmount Remote Control (see notes 3, 4, 5)

AQL2-Tx-RF-PS-4 (x=W/B) Wireless Table Top Remote Control, specify color - white or black (see notes 1,4,5)

AQL2-Tx-RF-PS-8 (x=W/B) Wireless Table Top Remote Control, specify color - white or black (see notes 2,4,5)

AQL2-Tx-RF-PS-16(x=W/B) Wireless Table Top Remote Control, specify color - white or black (see notes 3,4,5)

AQL-SS-6B-x (x=W/B) Wired Spa Side 6 Function Remote Control, 150ft cable, spec. color (white or black)

AQL-SS-D-x (x=W/B) Wired Spa Side 8 Function Remote Control, 150ft cable, spec. color (white or black)

AQL2-SS-RF Wireless Spa Side Remote Control (see note 4)

AQL2-BASE-RF Base Station

AQL-DIM Light Dimmer Relay

AQL-COLOR-MODHV ColorLogic Network Module for 120V Generation 4 ColorLogic lights

GVA-24 Valve Actuator

V&A-xx Valve & Actuator (xx=1P (1.5” pos. seal), -2P (2” pos. seal))

GLX-PC-12-KIT 10K thermistor sensor w/15’ leads, (necessary if both solar and dual equipment is desired)

Notes: 1. for use with PS-4 model only

2. for use with PS-8 model only

3. for use with PS-16 model only

4. requires base station AQL2-BASE-RF

5. 9V wall plug-in power supply included

1 42

NOTE: Before installing this product as part of a saline water purification system in a pool or spa using natural

stone for coping or for immediately adjacent patios/decking, a qualified stone installation specialist should be

consulted regarding the appropriate type, installation, sealant (if any) and maintenance of stone used around a

saline pool with electronic chlorine generator in your particular location and circumstances.

NOTE: The use of dry acid (sodium bisulfate) to adjust pool pH is discouraged especially in arid regions where

pool water is subject to excessive evaporation and is not commonly diluted with fresh water. Dry acid can cause a

buildup of by-products that can damage your chlorinator cell.

Installation Steps

Details on each installation step are presented on the following pages:

1. Prepare the pool water (page 3)

General Water Chemistry

Salt

2. Mounting the equipment (page 5)

Pro Logic main unit

Temperature sensors

Remote display/keypad (optional)

Valve actuators (if applicable)

3. Plumbing (page 8)

General Pool Equipment

Chlorinator Turbo Cell

Flow Switch

4. Electrical Wiring (page 12)

Main service

Grounding and bonding

Circuit breakers

Pro Logic control power

High Voltage pool equipment

Low voltage wiring (temperature sensors, flow switch, etc.)

5. Pro Logic control configuration (program desired control operation) (page 22)

6. System Startup and checkout (page 41)

241

ºC ºF Ti

Calcuim

Hardness

Ci

To ta l

Alkalinity

Ai

53

60

66

76

84

94

103

12

16

19

24

29

34

39

.3

.4

.5

.6

.7

.8

.9

How to use:

Ai from your measurements. Insert values of pH, Ti, Ci and Ai

may occur.

1

0.2

CORROSIVE SCALING

75 75

100 100

125 125

150 150

200 200

250 250

300 300

400 400

600 600

800 800

1.5 1.9

1.6 2.0

1.7 2.1

1.8 2.2

1.9 2.3

2.0 2.4

2.1 2.5

2.2 2.6

2.4 2.8

2.5 2.9

1. Preparing Pool/Spa Water

VSP Speed

%

Toggle between % and RPM

Move to

variable speed pump

Reset ColorLogic to

Default Press +

Are you sure?

+ to proceed

ColorLogic. reset

Confirmed

Initiate reset of ColorLogic configuration parameters

Reset all configuration parameters

Move to previous/next configuration

Move to previous/next menu (config. not reset)

Move to previous/next configuration menu

Reset Config. to

Default Press +

Are you sure?

+ to proceed

Config. reset

Confirmed

Reset all configuration parameters

Move to previous/next configuration

Move to previous/next menu (config. not reset)

Move to previous/next configuration menu

pH Calibration

Wizard, + to enter

Move to previous/next menu item

Clean Probe Wizard

+ to enter

Move to previous/next menu item

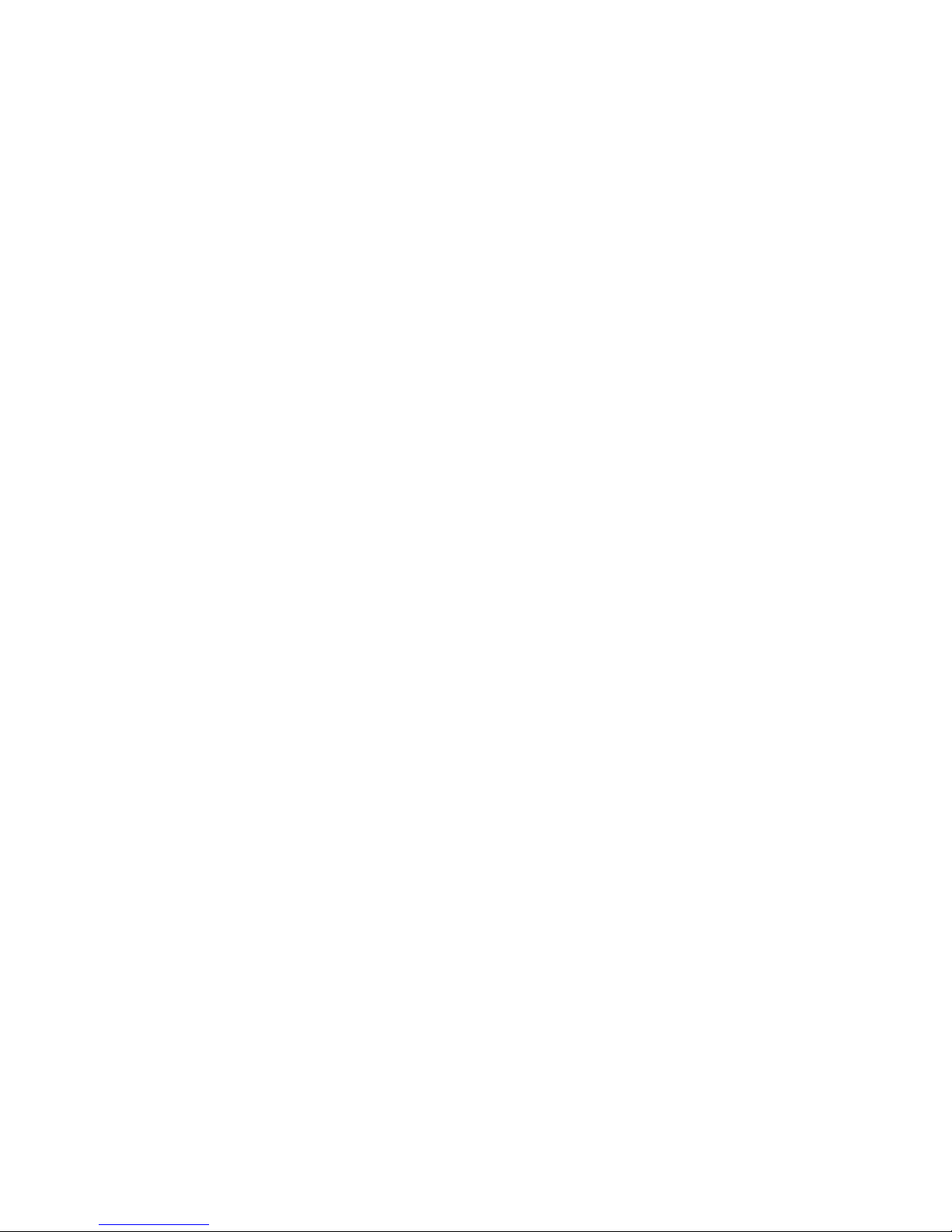

General Water Chemistry

Salt is required only if you are using the chlorinator features on the Pro Logic Control. If you are NOT using the

chlorinator, it is recommended that you follow all of the other chemistry recommendations besides salt. Refer to the

description of the Pro Logic configuration menu for information on enabling/disabling the chlorinator (see page 24).

Water Chemistry

The table below summarizes the levels that are recommended by the Association of Pool and Spa Professionals

(APSP). The only special requirements for the Pro Logic are the salt level and stabilizer.

Saturation index

The saturation index (Si) relates to the calcium and alkalinity in the water and is an indicator of the pool water

“balance”. Your water is properly balanced if the Si is 0 ±0.2. If the Si is below -0.2, the water is corrosive and

plaster pool walls will be dissolved into the water. If the Si is above +0.2, scaling and staining will occur. Use the

chart below to determine the saturation index.

and total alkalinity. Use the chart above to determine Ti, Ci,and

into the above equation. If Si equals .2 or more, scaling and

staining may occur. If Si equals -.2 or less corrosion or irritation

The pool’s chemistry must be balanced BEFORE activating the Pro Logic’s optional chlorinator function. NOTE:

If the pool does not have new water, add metal remover and non-copper based algaecide to the pool, per

manufacturer’s instructions. This ensures a quick, troublefree transfer to the Pro Logic system.

Si = pH + Ti + Ci + Ai - 12.

Measure pool pH, temperature, calcium hardness,

-.2

OK

3

Gall

o

n

s

a

n

d

(

L

i

t

e

r

s

)

o

f

P

o

o

l

/

S

p

a

w

ate

r

12,000 14,000 16,000

1

8

,

0

0

020

,

0

002

2

,

0

0

0

3

2

,

0

0

0

2

4

,

0

0

034

,

0

0

0

2

6

,

0

0

0

3

6

,

0

0

0

2

8

,

0

0

0

3

8

,

0

0

0

3

0

,

0

0

0

4

0

,

0

0

0

Current salt

level

(45000) (52,500) (60,000)

(

6

7

,

5

0

0

)

(

7

5

,

0

0

0

)

(

8

2

,

5

0

0)(

1

2

0

,

0

0

0

)

(

9

0

,

0

0

0)(

1

2

7

,

5

0

0

)

(

9

7

,

5

0

0)(

1

3

5

,

0

0

0)(

1

0

5

,

0

0

0

)

(

1

4

2

,

5

0

0

)

(

1

1

2

,

5

0

0

)

(

1

5

0

,

0

0

0

)

ppm

0

320

(145)

373

(170)

427

(194)

4

8

0

(

2

18)

(242)

587 854

(267) (388)

640 907

(291) (412)

693 960

(315) (436)

747

(339) (4

6

0

)

800

1

0

6

7

(364)

(

4

8

4

)

200

300

(136)

350

(159)

400

(182)

450

(205)

500

(227)

550 800

(250)

(363)

600 850

(273) (385)

650 900

(295) (408)

700 9

5

0

(318) (4

3

0

)

750

1

0

0

0

(341)

(

4

5

3

)

400

280

(127)

327

(148)

373

(170)

420

(191)

467

(212)

513 747

(233) (339)

560 793

(255) (360)

607 840

(276) (382)

653 8

8

7

(297) (4

0

3

)

700

9

3

3

(318)

(

4

2

4

)

600

260

(118)

303

(138)

347

(158)

390

(177)

433

(197)

477 693

(217) (317)

520 737

(236) (337)

563 780

(256) (358)

607 8

2

3

(276) (3

7

8

)

650

8

6

7

(297)

(

3

9

8

)

800

240

(109)

280

(127)

320

(145)

360

(164)

400

(182)

440 640

(200) (291)

480 680

(218)

(310)

520 720

(236) (328)

560 76

0

(255) (3

4

6

)

600

8

0

0

(273)

(

3

6

4

)

1000

220

(100)

257

(117)

293

(133)

330

(150)

367

(167)

403 587

(183) (267)

440 623

(200) (283)

477 660

(217) (300)

513 69

7

(233) (3

1

7

)

550

7

3

3

(250)

(

3

3

3

)

1200

200

(91)

233

(106)

267

(121)

300

(136)

333

(152)

367 533

(167) (243)

400 567

(182) (258)

433 600

(197) (274)

467 63

3

(212) (2

8

9

)

500

6

6

7

(227)

(

3

0

4

)

1400

180

(82)

210

(95)

240

(109)

270

(123)

300

(136)

330 480

(150) (218)

360 510

(164) (232)

390 540

(177) (246)

420 57

0

(191) (2

5

9

)

450

6

0

0

(205)

(

2

6

3

)

1600

160

(73)

187

(85)

213

(97)

240

(109)

267

(121)

293 427

(133)

(195)

320 453

(145) (207)

347 480

(158) (219)

373 50

7

(170) (2

3

1

)

400

5

3

3

(182)

(

2

4

3

)

1800

140

(64)

163

(74)

187

(85)

210

(95)

233

(106)

257 373

(117) (169)

280 397

(127) (180)

303 420

(138) (190)

327 44

3

(148) (20

1

)

350

4

6

7

(159)

(

2

1

1

)

2000

120

100

80

60

20

40

(55)

(45)

(36)

(27)

(9)

(18)

140

117

23

47

(64)

(53)

(11)

(21)

160

133

27

53

(73)

(61)

(12)

(24)

180

150

30

60

(82)

(68)

(14)

(27)

200

167

33

67

(91)

(76)

(15)

(30)

220 320

183 267

37 53

73 107

(100) (145)

(83) (121)

(17) (24)

(33) (48)

240

340

200 283

40

57

80 113

(109) (154)

(91) (129)

(18) (26)

(36) (51)

260 360

217 300

43 60

87 120

(118) (163)

(98) (137)

(20) (27)

(39) (54)

280 38

0

233 31

7

47

6

3

93

1

2

7

(127) (17

2

)

(106) (1

4

4

)

(21) (2

9

)

(42) (5

7

)

300

4

0

0

250

3

3

3

50

6

7

100

1

3

3

(136)

(

1

8

1

)

(114)

(

1

5

2

)

(23)

(

3

0

)

(45)

(60

)

(32)

80

(36)

90

(41)

100

(45)

1

1

0

1

6

0

(

5

0

)

(

7

3

)

1

2

0

1

7

0

(

5

5

)

(

7

7

)

1

3

0

1

8

0

(

5

9

)

(

8

1

)

1

4

0

1

9

0

(

6

4

)

(

8

6

)

1

5

0

2

0

0

(

68)

(

9

0

)

93

(42)

107

(48)

120

(55)

133

(61)

1

4

7

2

1

3

(

67)

(98

)

1

6

0

22

7

(

7

3

)

(

1

0

4

)

1

7

3

2

4

0

(

7

9

)

(

1

1

0

)

1

8

7

2

5

3

(

8

5)(

1

17)

2

0

0

2

6

7

(

9

1

)

(

1

2

3

)

2200

3000

2800

2400

3200

Ideal Ideal Ideal Ideal Ideal

I

d

e

alI

d

e

a

l

I

d

e

alI

d

e

a

l

I

d

e

alI

d

e

a

l

I

d

e

alI

d

e

a

l

I

d

e

a

l

I

d

e

a

l

2600

3400

OK

OK

OK

OK

OK OK OK

O

K

O

KOK

OKO

K

OKO

K

O

K

O

K

O

K

P

OUN

D

S

a

n

d

(

K

g

)

OF

S

A

L

T

N

E

E

D

E

D

F

OR

3

2

0

0

P

P

M

3600+

Dilute Dilute Dilu

t

e

D

i

l

u

t

e

D

i

l

u

t

e

D

i

l

u

t

e

D

i

l

u

teD

i

l

u

t

e

D

i

l

u

teD

i

l

u

t

e

D

i

l

u

t

e

D

i

l

u

t

e

D

i

l

u

t

e

D

i

l

u

t

e

D

i

l

u

t

e

10,000

8,000

(37,500)

213

267

(97)

(121)

200 250

(91) (114)

187 233

(85)

(106)

173

217

(79)

(98)

160 200

(73)

(91)

147 183

(67) (83)

133 167

(61) (76)

120 150

(55) (68)

107 133

(48) (61)

93 117

(42) (53)

80 100

67 83

53

67

40 50

13 17

27 33

(36) ( 45)

(30) (38)

(24) (30)

(18) (2 3)

(6) (8 )

(12)

(15)

Ideal

Ideal

Dilute

Dilute

(30,000)

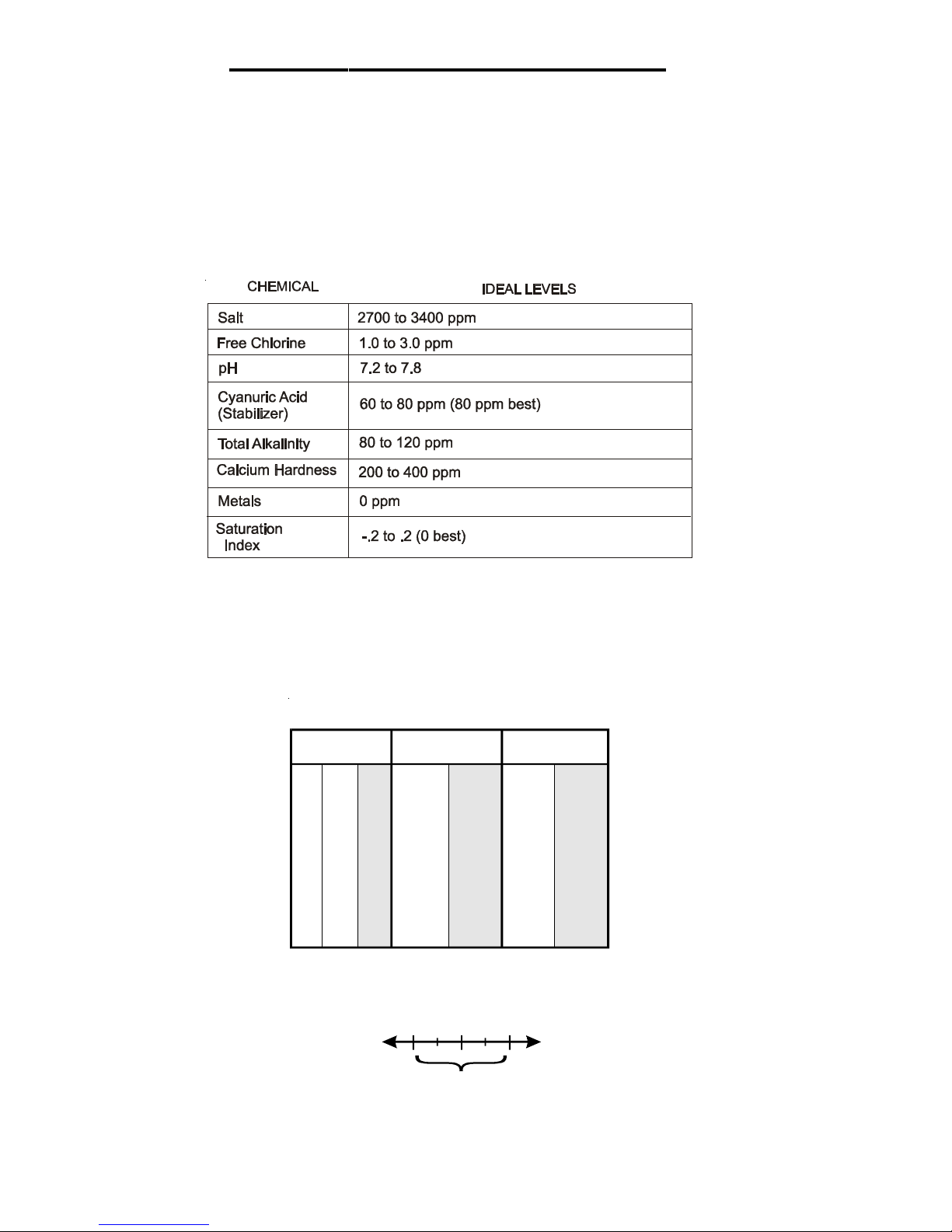

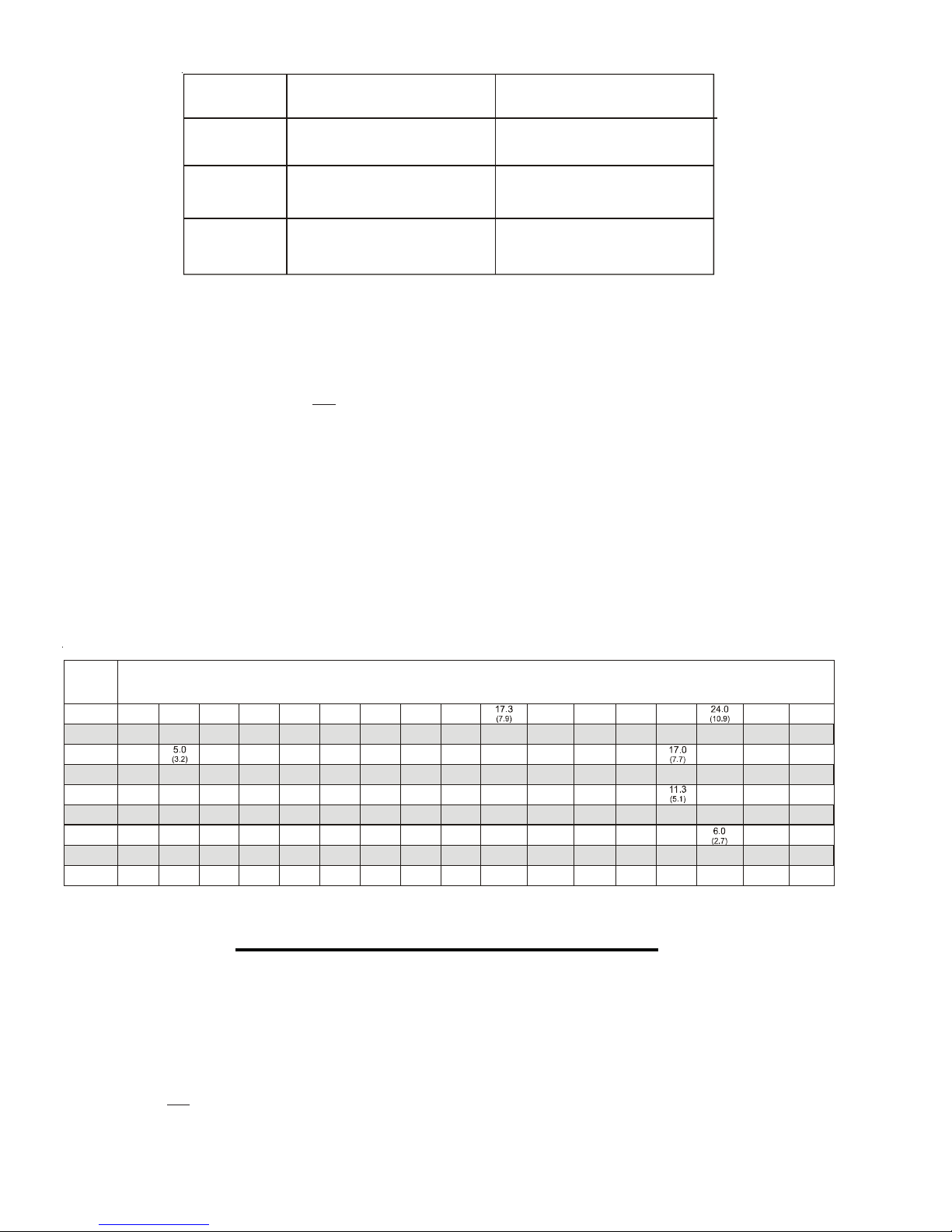

Salt (When using optional chlorinator function)

Salt Level

Use the chart below to determine how much salt in pounds or (Kgs) should be added to reach the recommended

levels. Use the equations on the following page (measurements are in feet/gallons and meters/liters) if pool size is

unknown.

The operating salt level is between 2700-3400 PPM (parts per million) with 3200 PPM being optimal. Before

adding any salt, test the salt level. This is especially important for retrofit installation to older pools where all of the

chlorine added to the pool over time is ending up as salt. If the level is low, determine the number of gallons in the

pool and add salt according to the chart below. A low salt level will reduce the efficiency of the sanitization and

result in low chlorine production. A high salt level can cause the Pro Logic to stop chlorinating. The salt in your

pool/spa is constantly recycled and the loss of salt throughout the swimming season should be minimal. This loss is

due primarily to the addition of water because of splashing, backwashing, or draining (because of rain). Salt is not

lost due to evaporation.

4

Pool Sizing Formula

Gallons

Liters

Rectangular

Round

Oval

Diameter x Diameter x

Average Depth x 5.9

Length x Width x

Average Depth x 6.7

Length x Width x

Average Depth x 7.5

Average Depth x 785

Length x Width x

Average Depth x 893

Length x Width x

Average Depth x 1000

Gallons and (Liters) of Pool/Spa water

Current

Stabilizer

Level (ppm)

0 ppm

20 ppm

60 ppm

30 ppm

40 ppm

50 ppm

70 ppm

80 ppm

10 ppm

12,000

(45000)

8,000

(30000)

14,000

(52500)

10,000

(37500)

16,000

(60000)

18,000

(67500)

20,000

(75000)

22,000

(82500)

32,000

(120000)

24,000

(90000)

34,000

(127500)

26,000

(97500)

36,000

(135000)

28,000

(105000)

38,000

(142500)

30,000

(112500)

40,000

(150000)

8.0

(3.6)

5.3

(3.6)

8.0

(3.6)

9.4

6.7

(4.3)

9.4

10.7

12.0

12.0

13.4

14.7

21.3

16.0

22.7

(10.3)

18.7

25.3

20.0

(9.1)

26.7

7.0

)

(3.2

4.7

(3.2)

8.2

(3.7)

5.8

(3.7)

10.5

(4.8)

11. 7

(5.3)

12.9

(5.9)

18.7

(8.5)

14.0

(6.4)

19.8

(9.0)

15.2

(6.9)

21.0

(9.5)

16.4

(7.4)

22.2

17.2

(8.0)

23.3

6.0

(2.7)

4.0

(2.7)

6.0

(2.7)

6.0

(2.7)

8.5

(3.9)

7.0

(3.2)

9.0

(2.2)

10.0

(4.5)

10.0

(4.5)

14.2

(6.3)

11. 0

(5.0)

16.0

(7.2)

13.0

(5.9)

18.0

14.0

(6.4)

19.0

15.0

(6.8)

20.0

5.0

(2.3)

3.3

(2.3)

5.0

(2.3)

5.9

(2.7)

4.2

(2.7)

6.7

(3.0)

8.4

(3.8)

6.7

(3.0)

7.5

(3.4)

9.2

(4.2)

13.3

(6.0)

10.8

(4.9)

15.0

11. 7

(5.2)

15.8

12.5

(5.6)

16.7

4.0

(1.8)

2.7

(1.8)

4.0

(1.8)

4.0

(1.8)

5.7

(2.6)

4.7

(2.1)

3.3

(2.1)

5.4

(2.4)

7.4

(3.3)

10.7

(4.8)

8.7

(3.9)

12.0

9.3

(4.2)

12.7

10.0

(4.5)

13.3

3.0

(1.4)

2.0

(1.4)

3.0

(1.4)

3.5

(1.6)

2.5

(1.6)

4.5

(2.0)

5.5

(2.5)

8.0

(3.6)

6.5

(2.9)

9.0

7.0

(3.2)

9.5

7.5

(3.4)

10.0

2.0

(.91)

1.3

(.91)

2.0

(.91)

2.8

(1.3)

2.3

(1.1)

1.7

(1.1)

2.7

(1.2)

3.3

(1.5)

3.7

(1.7)

5.3

(2.4)

4.3

(2.0)

6.3

5.0

6.7

1.0

0.7

(.45)

1.2

0.8

1.4

1.5

1.7

1.8

2.7

2.2

3.0

2.3

3.2

2.5

3.3

0.00.0 0.00.0 0.0 0.0 0.0 0.0

0.00.0 0.00.0 0.00.0 0.00.0 0.0

6B Spa Config.

+ to view/change

6B A, Button 1

Pool/Spa

Select 6B Spa

A

Push to access the 6 Button Spa Side Remote options

Valve4, and all available Aux outputs

Rotates between all available remotes

Move to previous/next configuration menu

Move to previous/next menu item or next configuration menu

Move to next menu item

(pool size in feet)

(pool size in meters)

Diameter x Diameter x

Type of Salt to Use

It is important to use only sodium chloride (NaCl) salt that is greater than 99.0% pure. This can be found at most

pool stores in 40-80 lb. bags labeled “for use in swimming pools”. Alternatively, use common food quality or water

softener salt that is at least 99.0% pure. It is also acceptable to use water conditioning salt pellets, however, it will

take longer for them to dissolve. Do not use rock salt, or salt with more than 1% of yellow prussiate of soda, salt

with anti-caking additives, or iodized salt.

How to Add Salt

For new plaster pools, wait 10-14 days before adding salt to allow the plaster to cure. Turn the circulating pump

on and add salt directly into the pool. Brush the salt around to speed up the dissolving process—do not allow salt

to pile up on the bottom of the pool. Run the filter pump for 24 hours with the suction coming from the main drain

(use pool vacuum if there is no main drain) to allow the salt to evenly disperse throughout the pool. The salt display

may take 24 hours to respond to the change in salt concentration.

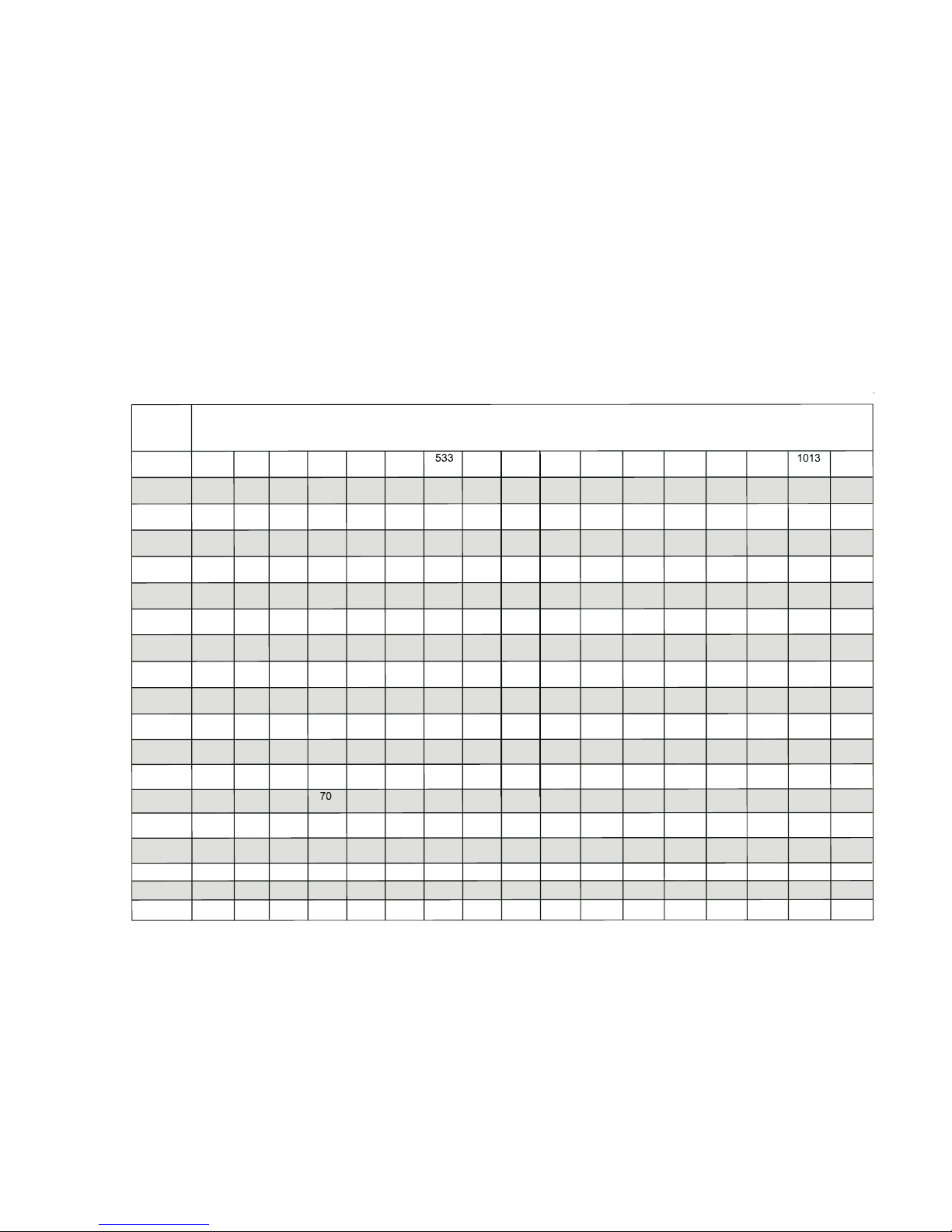

Always check stabilizer (cyanuric acid), when checking salt. These levels will most likely decline together. Use the

chart below to determine how much stabilizer must be added to raise the level to 80 ppm.

POUNDS and (Kg) OF STABILIZER (CYANURIC ACID) NEEDED FOR 80 PPM

(4.3)

(4.9)

(4.3)

8.0

(3.6)

(.45)

(.54)

(.54)

(.64)

2. Mounting the Equipment

Pro Logic Control Center

The Pro Logic is contained in a raintight enclosure that is suitable for outdoor mounting. The control must be

mounted a minimum of 5 ft. (2 meters) horizontal distance from the pool/spa (or more, if local codes require). The

Control Center is designed to mount vertically on a flat surface with the knockouts facing downward. Because the

enclosure also acts as a heat sink (disperses heat from inside the box), it is important not to block the four sides of

the control. Do not mount the Pro Logic inside a panel or tightly enclosed area.

When selecting a location, note that the standard cables supplied with the Turbo Cell, flow switch, temperature

sensors, and valve actuators (if applicable) are all 15 ft. (5m) long.

(5.4)

(6.1)

(6.7)

(7.3)

(5.4)

(.68)

(.77)

(.82)

5 38

(1.0)

(2.3)

(1.2)

(9.7)

(1.2)

(8.5)

4.7

(2.1)

(1.1)

(8.1)

(6.7)

(5.4)

(4.1)

(1.3)

(11.5)

(10.0)

(8.6)

(7.1)

(5.7)

(4.3)

(2.8)

(1.4)

(12.0)

(10.5)

(9.0)

(7.5)

(6.0)

(4.5)

(3.0)

(1.5)

PS-16 Expansion Unit

!

For the PS-16, the relays for Aux1-6 are contained in the Pro Logic Control Center. The relays for Aux7-14 are

contained in the PS-16 Expansion Unit. Valve outputs 7-10, in the PS-16 Expansion Unit follow the outputs of

Aux7-10, respectively.

Temperature Sensors

Three sensors are included with the Pro Logic. A water sensor and an air sensor must be installed at all times for

proper operation. An additional supplied sensor can be used for either solar or dual equipment function. If both

solar and dual equipment functions are desired, an additional sensor will need to be purchased.

Water Sensor

This sensor is used to measure the pool/spa temperature and is installed in the filtration plumbing after the filter but

before either the solar or conventionally fueled heaters—refer to the plumbing overview diagram.

1. Drill a 3/8” (10mm) diameter hole in the PVC piping and remove all chips and burrs.

2. Insert sensor until O-ring collar sits flush on the hole.

3. Position hose clamp over the sensor and gently tighten until O-ring makes an adequate seal. Do not overtighten.

4. For maximum temperature accuracy, cover the sensor and 3” (6cm) of pipe on either side with insulation and

white paint.

Air Sensor

Mount the air sensor outdoors.

IMPORTANT: Mount the air sensor out of direct sunlight.

Solar Sensor

For solar applications, mount the sensor near the solar collector array so that it is exposed to the same sunlight as

the collectors (see page 9). Use additional cable (20 AWG) if necessary.

Dual Equipment Spa Sensor

For dual equipment applications (separate filter pumps and heaters for both the pool and the spa), mount the dual

equipment spa sensor after the spa filter but before the heater (see page 9). Use additional cable (20 AWG) if

necessary.

Optional Chlorination Function

The PL-PS-4/8/16 models require the use of a chlorinator cell and plumbing kit to provide pool chlorination.

These items are not included with the Pro Logic and can be purchased separately at your local Hayward dealer.

Choose a chlorinator cell model based on the size of your pool. The following models are available:

T-CELL-15 for pools up to 40,000 gallons

T-CELL-9 for pools up to 25,000 gallons

T-CELL-3 for pools up to 15,000 gallons

In addition to the chlorinator cell, a plumbing kit (P-KIT) must be purchased. This kit contains the cell unions and

flow switch. Refer to pages 11 and 21 for plumbing and wiring instructions.

Optional AQL-CHEM ORP and pH Sensing Kit

The AQL-CHEM is an ORP and pH sensing kit for the Pro Logic. When used with the chlorination function, the

Pro Logic senses the pool's ORP and pH levels and generates the correct amount of chlorine to keep your pool

properly sanitized. Wiring and plumbing requirements for the AQL-CHEM should be considered before installing

the Pro Logic. Refer to the AQL-CHEM manual for specific installation information.

Optional AQL-COLOR-MODHV ColorLogic Network Module

Using the optional AQL-COLOR-MODHV network module, the Pro Logic can fully control the color, speed,

motion and brightness of Hayward ColorLogic Generation 4 pool and spa lights as well as provide programmable

light shows. Refer to the AQL-COLOR-MODHV for detailed installation, wiring and operation information.

6

Optional Remote Controls

OUT

(Common)

IN

(Common)

OUT

OUT

IN

Aux7 Relay

Standard

Move to next menu item or previous/next configuration menu

Aux7 Config.

+ to view/change

Aux7 Function

Group

Aux7 Group

Filter: Unaffected

Aux7 Group

Timer: None(Manual)

Push to access Virtual Aux options

Rotates between Super Chlorinate, Group and Manual On/Off

Options available depend on the function that is selected

Rotates between Manual On/Off (default),Countdown Timer and Timeclock

Move to previous/next configuration menu

Move to next menu item

Move to previous/next menu item or next configuration menu

Move to next configuration menu item

Aux7 Name

Cleaner

Rotates between all available names

Move to next menu item

No Virtual

Hayward offers a variety of wired and wireless remote control options for the Pro Logic. Each model gives you

the ability to control your pool’s functions from a remote location, away from the Control Center.

Wired Remote Controls

Up to 3 wired remote controls can be installed. See “Electrical Wiring” (page 19) for instructions on running the

cable from the Pro Logic main unit to the remote control. Also refer to the remote’s installation instructions for more

information.

AQL2-Wx-PS-x (x=4,8, or 16)

The AQL2-Wx-PS-x is a wall mounted display/keypad which must be mounted indoors or in a weather protected

area (rain should never hit the unit). Note that the number of outputs on the remote (“4”, “8” or “16”) must match

the outputs on the Pro Logic main control unit. This remote control is intended to mount on to a standard electrical

utility box (same box as a triple light switch, ideal for new construction) or can be mounted directly onto any wall

surface. When selecting a location, note that the wire to the Pro Logic main unit must be less than 500’ long.

AQL-SS-6B-x, AQL-SS-D-x (x=W or B for White or Black)

The AQL-SS-6B and AQL-SS-D are double insulated, waterproof devices which are intended for installation at

the water's edge. The remote controls come with an attached 150’ cable and are typically installed at the tile-line

of the spa wall, or in the deck, within arm's reach of a pool/spa occupant.

Wireless Remote Controls

A single Base Station must be installed on the Pro Logic in order to use any of the Hayward wireless remote

controls. There is no limit on the number of wireless remotes that can used. The maximum distance between

wireless remotes and the base station on the Pro Logic main control unit is 400 feet (120m) line of sight or 200 feet

(60m) through walls, etc. If in doubt about the distance, test operation before installing the remote. All wireless

models require the user to run the “Teach Wireless” routine in the Settings Menu. This information can be found in

the Pro Logic Operation Manual and the owner’s manual of each remote.

AQL2-Wx-RF-PS-x (x=4,8, or 16)

The AQL2-Wx-RF-PS-x are wall mounted wireless controls designed to be mounted indoors. These remote

controls come with a wall mounted power supply.

AQL2-Tx-RF-PS-x (x=4,8, or 16)

The AQL2-Tx-RF-PS-x are portable battery operated remote controls designed to be used in a weather protected area (rain should never hit the unit). The AQL2-Tx-RF-PS-x comes with a wall mounted power supply for

recharging the built-in batteries.

AQL2-SS-RF, AQL2-POD

The AQL2-SS-RF and AQL2-POD are waterproof portable remote controls that are designed to be used in and

around the pool/spa area. These units float and can be left in the pool/spa water for easy access.

Optional Base Station

Use the AQL2-BASE-RF for all AQL2 wireless remote controls. To install the base station, remove the knockout

on the upper left side of the Pro Logic main control unit, insert the base station, and then tighten the nut from the

inside. Also refer to the Base Station manual and the diagram on page 20.

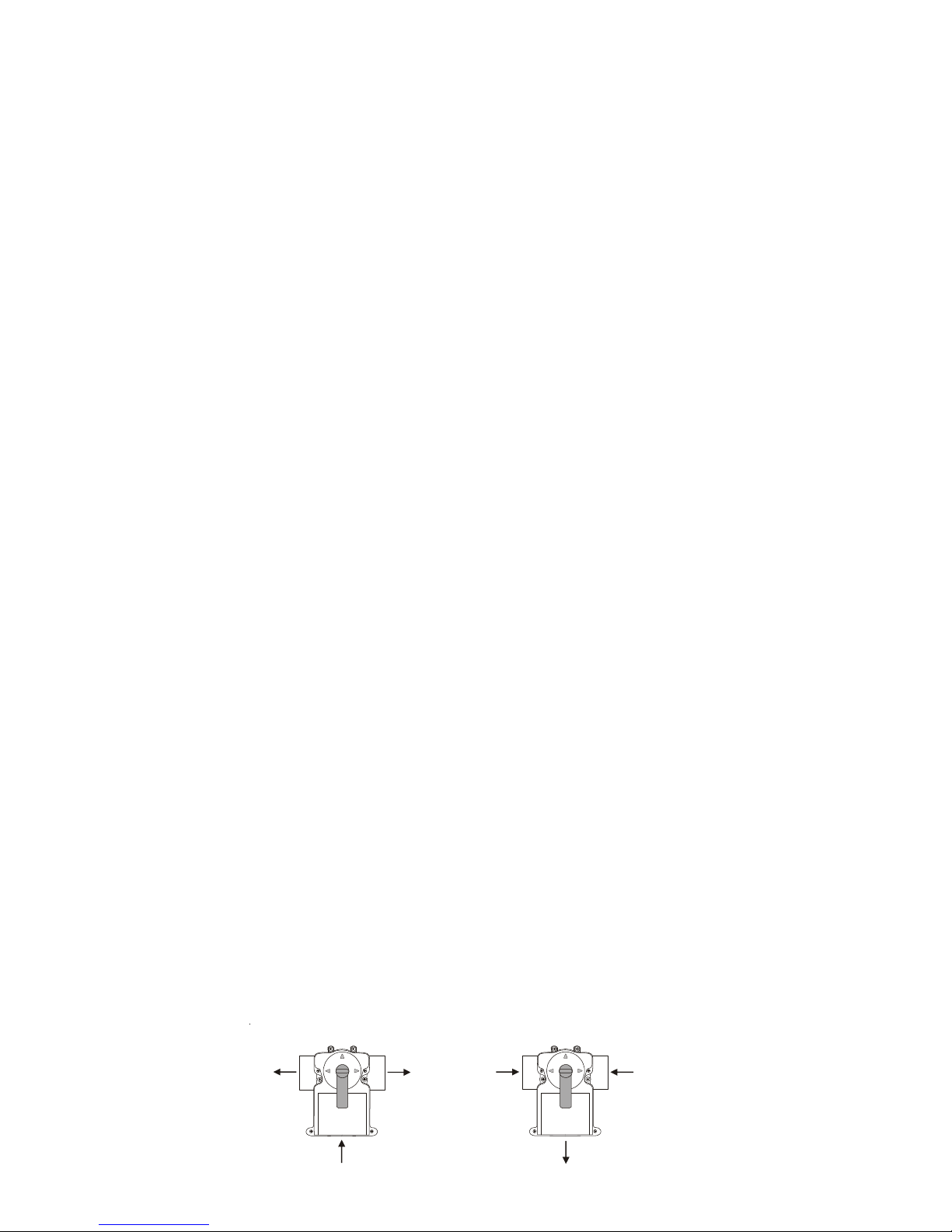

Optional Valve Actuators

For optional actuators supplied with the Pro Logic—note that the internal cams in the actuator may also have to be

adjusted depending on the way the actuator is mounted on the valve and the desired valve action.

RETURN

SUCTION

IN

7

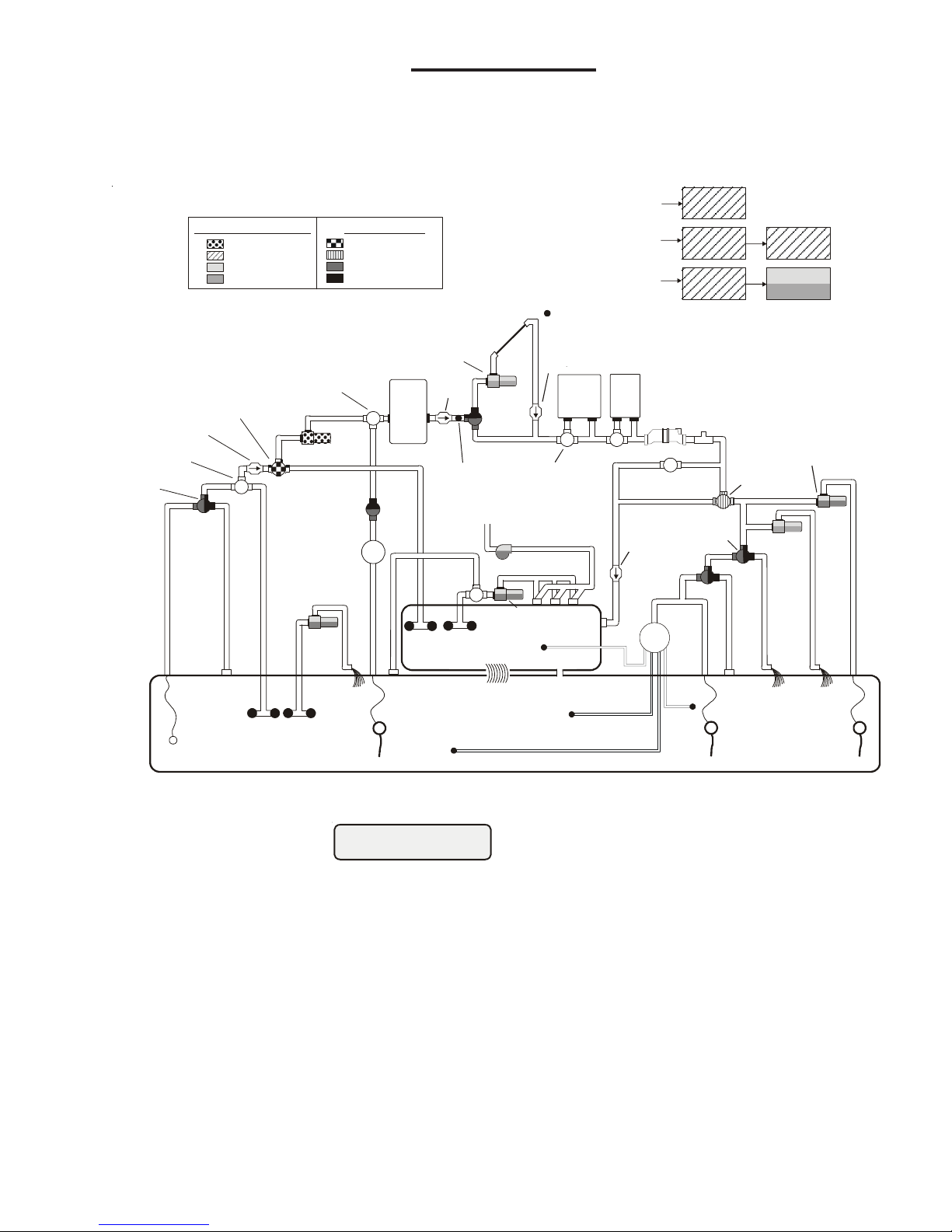

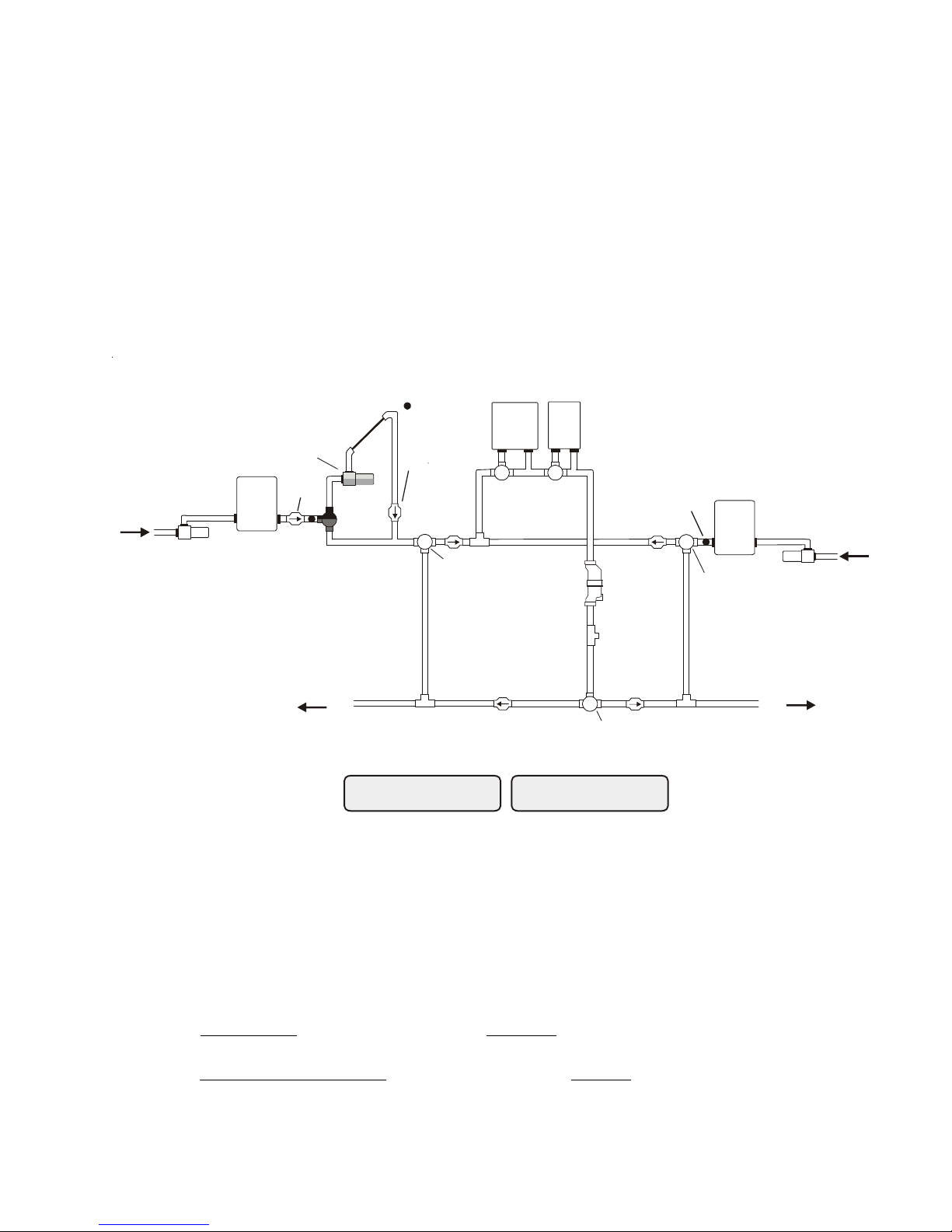

3. Plumbing

Pool/ Spa Setup

Pool and Spa-Std

FILTER

SOLAR BOOST

PUMP

SOLAR

VALV E

HEATER

HEAT

PUMP

HEATER

BYPASS

VALV E

(manual )

CELL

FLOW

SWITCH

CHECK

VALV E

PUMP

RETURN

VALV E

WATER

FEATURE

VALV E

SPA

SPA JET

PUMP

SPA

BLOWER

POOL/SPA SUC TION

VALV E

CHECK VALVE

POOL VACUUM

VALV E

MANUAL

VALV E

MANUAL

VALV E

MANUAL

VALV E

ENERGY

FILTER

TWO-WAY

VALV E

SKIM

POP-UP

SPILLOVER

POP-UP

OVERFLOW

POP-UP

RETURN

JET

IN-FLOOR

CLEANER

VALV E

WATE R

FEATURE

PUMP

WATER

FEATURE

POP-UP

MAIN

DRAIN

ENERGY

SAVER

PRESSURE

CLEANER

NON-BOOST

PRESSURE

CLEANER

PRESSURE

CLEANER

SUCTION

CLEANER

SENSOR

FILTER

PUMP

Valve Outputs

Filter Pump

Lights

Aux 1

Aux 2

Pool/Spa Suction

Pool/Spa Return

Val v e 3

Val v e 4

HIGH VOLTAGE

LIGHTS

LOW VOLTAGE

LIGHTS

FIBER OPTIC

LIGHT SOURCE

COLOR WHEEL

ISOLATED

WATE R

FEATURE

PUMP

TEMPERATURE

SENSOR

CHECK

VALV E

(prevents d raining

of raised sp as)

V

of raised sp as)

“Standard” Pool/Spa system configuration

These systems use a single filter pump and filter. Pool or spa operation is controlled by two 3-way valves (suction

and return). Refer to the diagram below.

High Voltage Relays

POOL/SPA

POOL

SOLAR

TEMPERATURE

CHECK

ALVE

(prevents d raining

TRANSFORMER

POOL/SPA

POOL SWEEP

BOOST PUMP

WATER

FEATURE

Some important notes regarding the Pro Logic control of Standard Pool/Spa systems:

spa.

chlorinated.

temperature, depending on the current operation of the pool. The temperature will only be displayed when

the filter pump is running.

In Pool/Spa Config., select:

1. The Pro Logic can be programmed to accommodate spa spillover, if desired.

2. Up to two conventional heaters (gas or heat pump) plus solar can be used to heat both the pool and the

3. If the chlorinator cell is plumbed prior to the pool/spa return valve, then both the pool and the spa can be

4. The water sensor should be installed prior to any heater or solar and will display either the pool or the spa

5. If any water feature or pressure side cleaner boost pumps are used, be sure to enable the “interlock”

feature (see “Configuration Menu” for details) to ensure that the pumps operate only when the filter pump

is on and the system is in the “pool only” operating mode.

6. The plumbing diagram above is intended to be used as a general guideline and is not a complete plumbing

schematic for the pool.

7. The air sensor must be installed if the freeze protection feature is enabled for the filter, valves or aux

outputs.

835

“Dual Equipment - Separate Heaters” for Pool/Spa configuration

Pool/Spa Setup

Htr1=Spa,Htr2=Pool

Aux1 Pump Spd

Settings Menu

Move to previous/next configuration menu

if filter pump is set to variable speed

and the relay type is set to standard

Aux1 Config.

+ to view/change

Aux1 Function

Manual On/Off

Aux1 Group

Filter: Unaffected

Aux1 Group

Timer: None(Manual)

Aux1 Name

Cleaner

Aux1 Relay

Standard

Push to access Aux options

Options available depend on the function that is selected

Rotates between all available names

Toggle between Standard (default), Dimmer, ColorLogic and VSP

Move to previous/next configuration menu

Move to previous/next menu item or next configuration menu

Move to next configuration menu item

Move to next menu item

Move to next menu item or previous/next configuration menu

Aux1 Interlock

Disable

Aux1 Freeze

Disable

Toggle between Enabled and Disabled Aux1 Freeze(default)

Move to next menu item

Move to previous/next configuration menu

for all functi ons except solar, dimmer relay,super chlorinate

for all functi ons except solar, dimmer relay,super chlorinate

low speed, group and pH dispense

low speed, group and pH dispense

for all functions except dimmer relay, super chlorinate

low speed, group and ph dispense

for group function only

for group function only

for manual on/off, countdown

timer and timeclock functions

Move to next menu item

Rotates between Manual On/Off (default), Countdown Timer, Low Speed- Filter,

Aux1 Ext Input

Disabled

Toggle between Enabled and Disabled (default)

Move to previous/next configuration menu

!

FILTER

HEATER

HEATER

BYPASS

VALV E

(manual)

HEATER

BYPASS

VALV E

(manual)

PUMP

VALV E

WATE R

FEATURE

VALV E

SPA

SPA JET

PUMP

SPA

BLOWER

POOL VACUUM

VALV E

MANUAL

VALV E

ENERGY

FILTER

TWO-WAY

VALV E

SKIM

POP-UP

SPILLOVER

POP-UP

OVERFLOW

POP-UP

RETURN

JET

IN-FLOOR

CLEANER

VALV E

WATE R

FEATURE

PUMP

WATE R

FEATURE

POP-UP

MAIN

DRAIN

ENERGY

SAVER

PRESSURE

CLEANER

NON-BOOST

PRESSURE

CLEANER

PRESSURE

CLEANER

SUCTION

CLEANER

High Voltage Relays Valve Ou tp ut s

Heater Outputs

Pool Filter Pump

Lights

Spa Filter Pump (Aux 1)

Aux 2 - Aux 6

Pool/Spa Spillover

Val ve 3

Val ve 4

HIGH VOLTAGE

LIGHTS

LO W VO LTAGE

LIGHTS

FIBER OPTIC

LIGHT SOURCE

COLOR WHEEL

ISOLATED

WATER

FEATURE

PUMP

POOL

TEMPERATURE

SENSOR

SPA

TEMPERATURE

SENSOR

HEATER

CELL

FLOW

MANUAL

VALV E

POOL FILTER

PUMP

SPA FILTER

PUMP

V

of raised spas)

for proper spillove r)

Heater 1 (Spa)

SOLAR BOOST

PUMP

SOLAR

VALV E

CHECK

VALV E

SENSOR

V

FILTER

These systems have 2 complete sets of equipment (filter pump, filter, heater)—1 set for the pool and the other set

for the spa. Refer to the diagram below:

Heater 2 (Pool)

CHECK

ALVE

SOLAR

TEMPERATURE

CHECK

ALVE

(prevents draini ng

TRANSFORMER

SWITCH

(adjust cams as nece ssary

POOL/SPA

SPILLOVER

WATER

FEATURE

POOL SWEEP

BOOST PUMP

Some important notes regarding the Pro Logic control of Dual Equipment Pool/Spa systems with separate heaters:

In the Pool/Spa Config., select:

1. When dual equipment is selected:

a. The “Filter” pump automatically is renamed “Pool Filter” and can not be changed. The pool filter

b. The “Aux1” output is automatically renamed “Spa Filter”, its function is set to “Timeclock” and the

c. The Heater1 output should be connected to the spa heater—the heater will only turn on when the

d. The Heater2 output should be connected to the pool heater—the heater will only operate when

2. The water sensor should be installed on the pool loop prior to the heater and will display the pool temperature

whenever the “Pool Filter” pump is running.

3. The dual equipment spa sensor should be installed on the spa loop prior to the heater and will display the

spa temperature whenever the “Spa Filter” pump is running.

4. The Pro Logic can be programmed to accommodate spillover if desired. Note that spillover operation will

be automatically suspended whenever the spa filter pump is turned on.

can be a one, two or variable pump.

Interlock feature is forced to “Disabled”. None of these can be changed. The spa filter can be a

one, two or variable pump.

spa filter pump is running.

the pool filter is running. If the system does not have a pool heater, disable Heater2 in the configuration

menu and then the relay can be used to operate general purpose Valve4.

Pool and Spa-Dual

POOL

9

Heaters

5. The chlorinator cell must be installed in the pool plumbing. If spillover is enabled, then the Pro Logic can

Pool/Spa Setup

Shared

POOL

FILTER

ELECTROLYTIC

CELL

FLOW

SWITCH

POOL FILTER

PUMP

VALV E 1

VALV E 2

V

In from POOL

Out to SPA

Out to POOL

In from SPA

SENSOR

FILTER

PUMP

HEATER

HEATER

SOLAR BOOST

PUMP

SOLAR

VALV E

CHECK

VALV E

SOLAR

TEMPERATURE

SENSOR

CHECK

VALV E

chlorinate both the pool and spa (during spillover operation). Otherwise, the Pro Logic will only chlorinate

the pool and the spa sanitization will have to be handled manually.

6. If any water feature or pressure side cleaner boost pumps are used, be sure to enable the “interlock”

feature (see “Configuration Menu” for details) to ensure that the pumps operate only when the “Pool

Filter” pump is on and the system is in the “pool only” operating mode.

7. The plumbing diagram on page 9 is intended to be used as a general guideline and is not a complete

plumbing schematic for the pool.

8. When using the wireless spa-side remote control (AQL2-SS-RF), the “POOL” button will position the

valves for Pool mode and the “SPA” button will position the valves for Spillover mode.

“Dual Equipment - Shared Heaters” for Pool/Spa configuration

These systems have 2 complete sets of equipment (filter pump, filter) and shared heaters. Refer to the diagram

below:

SPA

TEMPERATURE

SPA

SPA FILTER

ALVE 3

Some important notes regarding the Pro Logic control of Dual Equipment Pool/Spa systems with shared heaters:

In the Pool/Spa Config., select:

Pool and Spa-Dual

Heaters

1. When dual equipment is selected:

a. The “filter” pump automatically is renamed “Pool Filter” and can not be changed. The pool filter

can be a one, two or variable pump.

b. The “Aux1” output is automatically renamed “Spa Filter”, its function is set to “Timeclock” and the

Interlock feature is forced to “Disabled”. None of these can be changed. The spa filter can be a

2. The water sensor should be installed on the pool loop prior to the heater(s) and will display the pool

one, two or variable pump.

c. The Valve3 configuration menu is disabled.

d. The heater(s) will be dedicated to the spa whenever the spa filter is on and the spa temperature

setting is not off.

temperature whenever the “Pool Filter” pump is running.

3. The dual equipment spa sensor should be installed on the spa loop prior to the heater(s) and will display

the spa temperature whenever the “Spa Filter” pump is running.

1033

4. The Pro Logic can be programmed to accommodate spillover if desired. Note that spillover operation will

!

!

12”

min

Flow switch before cell

Flow switch after cell

Lights Config.

+ to view/change

Lights Function

Manual On/Off

Lights Name

Pool Light

Lights Relay

Standard

Push to access Lights options

Rotates between

Rotates between all available names

Toggle between Standard (default), Dimmer and VSP

Move to previous/next configuration menu

Move to next menu item

Move to next menu item or previous/next configuration menu

Move to next menu item or previous/next configuration menu

Lights Interlock

Disable

Lights Freeze

Disable

Toggle between Enabled and Disabled (default) Lights Freeze

Move to next menu item

Move to previous/next configuration menu

pH dispense, low speed, and group

pH dispense, low speed, and group

f

pH dispense, low speed, and group

or all functions except dimmer relay, super chlorinate

if filter pump is set to variable speed

and the relay type is set to standard

for manual on/off, countdown

timer and timeclock functions

Lights Group

Filter: Unaffected

Lights Group

Timer: None(Manual)

Options available depend on the function that is selected

Rotates between Manual On/Off (default),Countdown Timer and Timeclock

Move to previous/next menu item or next configuration menu

Move to next menu item

for group function only

for group function only

Lights Ext Input

Disabled

Toggle between Enabled and Disabled (default)

Move to previous/next configuration menu

Lights Pump Spd

Settings Menu

Move to previous/next configuration menu

be automatically suspended whenever the spa filter pump is turned on.

5. The chlorinator cell and flow switch must be installed in the heater return path. If spillover is enabled, then

the Pro Logic can chlorinate both the pool and spa (during spillover operation). Otherwise, the Pro Logic

will only chlorinate the pool when the spa does not control the heater(s) and the spa sanitization will have

to be handled manually.

6. If any water feature or pressure side cleaner boost pumps are used, be sure to enable the “interlock”

feature (see “Configuration Menu” for details) to ensure that the pumps operate only when the “Pool

Filter” pump is on and the system is in the “pool only” operating mode.

7. The plumbing diagram on page 10 is intended to be used as a general guideline and is not a complete

plumbing schematic for the pool.

8. When using the wireless spa-side remote control (AQL2-SS-RF), the “POOL” button will position the

valves for Pool mode and the “SPA” button will position the valves for Spillover mode.

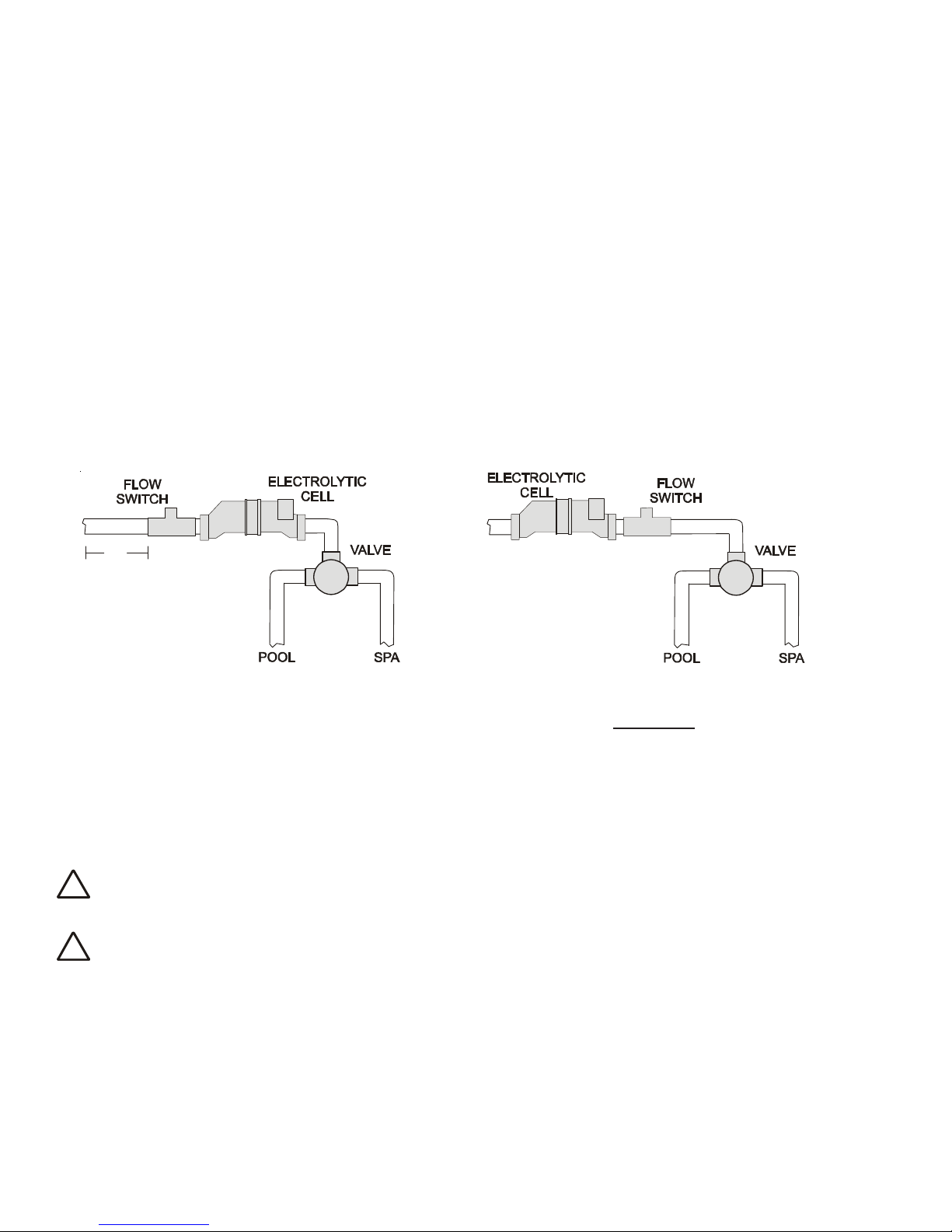

Turbo Cell (choose proper model for your pool)

The Turbo Cell (used for chlorine generation) should be plumbed AFTER the filter and heater. If installed on a

pool/spa combination system, the cell should be plumbed BEFORE the pool/spa return valve in order to allow

proper chlorination of both the pool and the spa. Refer to plumbing diagram below:

The cell may be mounted vertically or horizontally, and water can move in either direction through the cell. Install

using the 2" unions provided in the P-KIT purchased separately. Tighten unions BY HAND for a watertight seal.

For systems with 1½“ plumbing use adaptors (provided by installer).

Flow Switch (supplied with P-KIT)

The flow switch must be plumbed in the same section of plumbing as the Turbo Cell. The flow switch is a safety

device that ensures that water is flowing through the cell before the Pro Logic starts to generate chlorine. Failure

to properly install the flow switch can result in explosive gases accumulating in the pool plumbing system.

IMPORTANT: There must be at least a 12" (30cm) straight pipe run before (upstream) the flow

switch. If the switch is plumbed after the cell, the cell can by counted as the 12" (30cm) of straight pipe.

IMPORTANT: To ensure proper operation, verify that the arrow on the flow switch points in the

direction of water flow

11

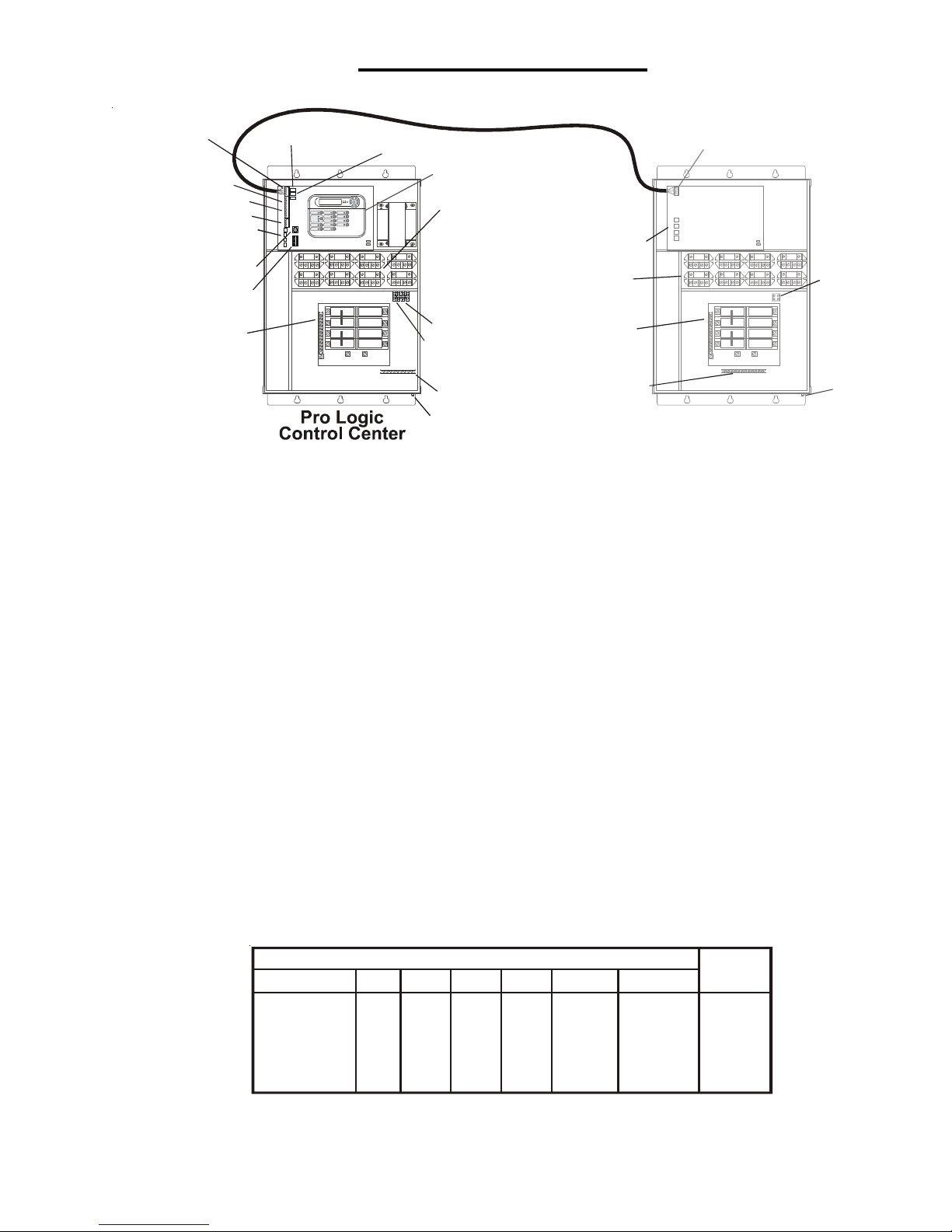

4. Electrical Wiring

8 High Voltage Relays

for PS-8, PS-16

(4 relays for PS-4)

8 High

Voltage Relays

Control Power Input

Control Power

Input

Bonding Lug(s)

Bonding

Lug(s)

“Local” Display

Subpanel

Subpanel

Ground Bus Bar

pH Dispense

Output

Ground Bus Bar

L2 L2

N N

L1 L1

4 Valve Connectors

4 Valve Connectors

2 Heater Outputs

External Input Interlock

4 Temp

Sensor Inputs

To PS-16 Display/Keypad

Connector

Flow Switch

Connector

Cell Connector

Wireless Base

Receiver Connector

10

4 wire connection between PS-16 and -EXP

For use with

PS-16 only

Remote Display/Keypad

Connector

(AQL-PS-16 only)

AQL-CHEM

Connector

Torqu e

Cutler-Hammer

Murray

Siemens

Square D

Thomas & Betts

G.E.

Manufacturer

Single

Double

Quad

Twi n

GFCB

Filler Plates

BR

MP-T

QP

HOM

TB

THQL

BR

MP-T

QP

HOM

TB

THQL

BRD

MH-T

QT

HOMT

TBBD

BRD

MH-T

QT

HOMT

TBBQ

GFCB

MP-GT

QPF

HOM-GFI

GFB

THQL-GF

BRFP

LX100FP

QF3

HOMFP

FP-1C-TB

TFH

25lb-in

25lb-in

25lb-in

25lb-in

25lb-in

25lb-in

SUITABLE LISTED BREAKERS

9

8

7

Expansion Unit

The Pro Logic Control Center and PS-16 Expansion Unit require both high and low voltage connections. Low

voltage connections will be made to actuators, sensors, remote keypad, etc. High voltage connections will be

made to pumps, lights, etc., as well as providing direct input power to the Control Center. Always:

-Ensure that Power is disconnected prior to doing any wiring

-Follow all local and NEC (CEC if applicable) codes

-Use copper conductors only

Main Service (Power to the Circuit Breaker Subpanel)

The Pro Logic circuit breaker subpanel is rated for 100A service. Run properly rated conductors (L1, L2, N, and

ground) from the primary house electrical panel to the main power connections on the Pro Logic circuit breaker

base. The connection at the main house panel should be to a 240VAC circuit breaker rated at 100A maximum.

Grounding and Bonding

Connect a ground wire from the primary electrical panel to the Pro Logic ground bus bar. Also ground each piece

of high voltage (120 or 240VAC) equipment that is connected to the Pro Logic control relays or circuit breakers.

The Pro Logic should also be connected to the pool bonding system by an 8AWG (6AWG for Canada) wire. A

lug for bonding (2 for Canada) is provided on the outside/bottom of the Pro Logic enclosure.

Circuit Breaker Installation and Wiring

Circuit breakers are to be supplied by the installer. See the chart below for a list of suitable circuit breakers that

can be used. Follow the code and the circuit breaker manufacturer’s rating requirements regarding the size and

temperature rating for wiring. Note that some pool equipment may be required to be connected to ground fault

circuit breakers—check local and NEC (CEC) codes.

General Purpose Outlet

If desired, a duplex receptacle with weatherproof cover (supplied by installer) may be installed in the knockouts on

the lower right side of the Pro Logic enclosure. Per code, the receptacle should be a GFCI type. Alternatively,

connect a standard receptacle to a GFCB.

12

Tightening

Loading...

Loading...